Page 1

2800T SERIES

Installation Instructions

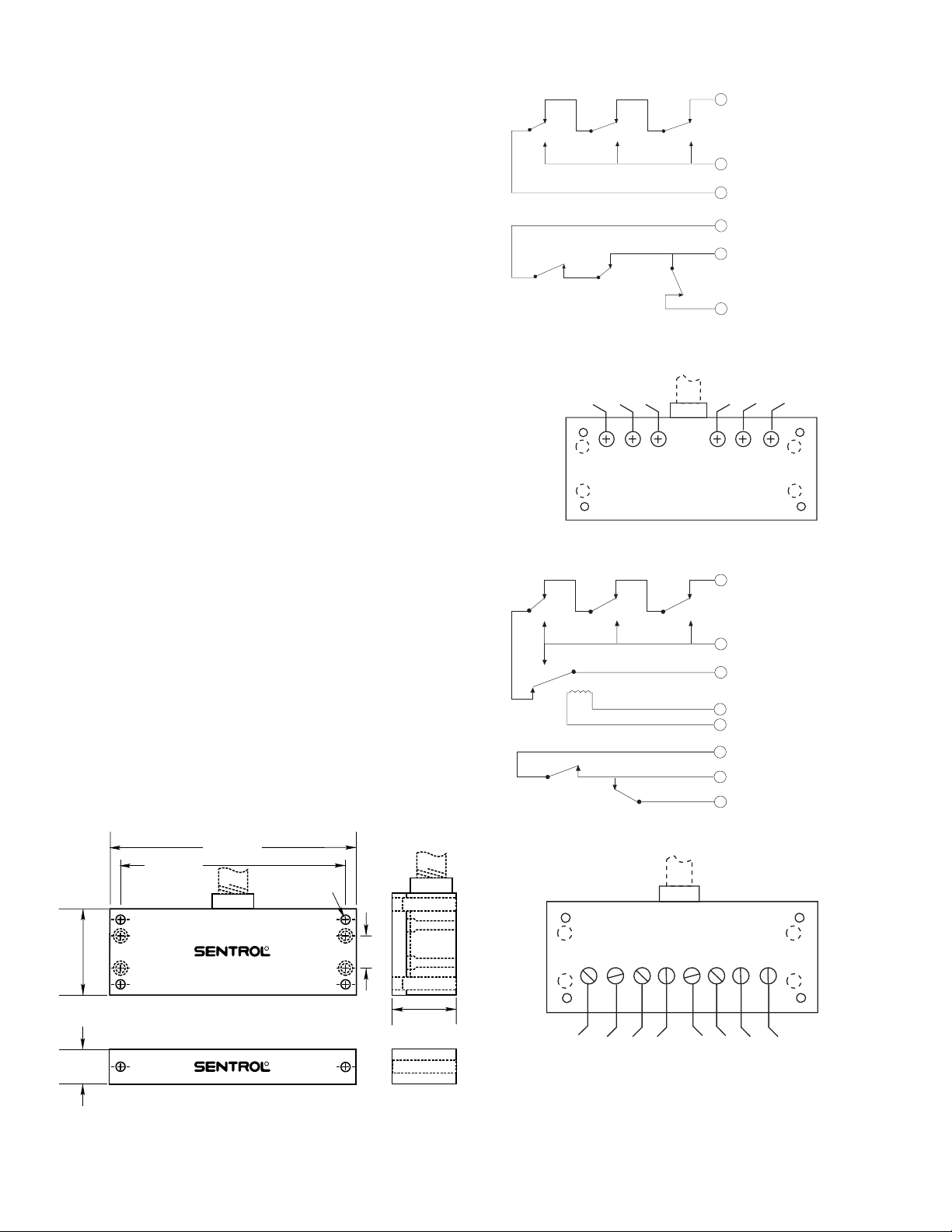

2807T, 2804T SERIES

Closed Loop

Models: 2804T, 2807T, 2808T

ARCHITECTS' AND ENGINEERS' SPECIFICATIONS

Switch and magnet housings shall be die cast aluminum, coated

with brown textured paint. Switch housing dimensions shall be

nominally 1.5" (3.81 cm) W x 5.75" (14.61 cm) L x 2.0" (5.08 cm)

H. Mounting holes for #10 screws shall be on 5.25" (13.34 cm) x

.75" (1.91 cm) centers. Switch housing lid shall be attached on

5.25" (13.34 cm) x 1.5" (3.81 cm) spacing with #10-24 screws.

Fitting with .50" threads shall be provided for direct connection to

conduit. Magnet housing dimensions shall be nominally 5.75"

(14.61 cm) L x .813" (2.06 cm) H x 1.5" (3.81 cm) D. Mounting

holes for #10 screws shall be on 5.25" (13.34 cm) centers.

Switch shall comprise three biased reed contacts, wired in SPDT

configuration, and include a plunger-type tamper actuated on

removal of cover. Connection to switch shall be made by screw

terminals.

2807T, 2808T

Switch shall include a magnetic tamper switch and an optional pry

tamper switch. It shall be fastened to the mounting surface with a

pry tamper plate mounted with #6 x .75" flathead screws on 2"

centers. Model 2808T shall include a remote test function.

Magnetic Tamper

Closed loop N/O

Open loop N/C

2808T SERIES

Open Loop

Common No Label

Supervised Common

Magnetic Tamper Only

Lid-Tamper

Common

Pry Tamper

W/pry tamper

Pry/Tamper/Magnetic

Tamper

W/o pry tamper

123 456

Closed Loop

Common

2804T

Switch shall include a magnetic tamper switch and optional circuit

breaker-type switch protection at 80% of maximum current. Switch

shall also include a tamper resistant, two-piece magnet.

2800 SERIES

Conduit

(.50 threads)

1.50"

3.81cm

2.00"

5.08cm

.813"

2.06cm

5.75"

5.25"

13.34cm

14.61cm

Switch

Mounting holes not accessible

when cover is in place.

Magnet

Mounting holes not accessible

when cover is in place.

#10-24 thread

R

.75"

1.92cm

R

Remote Test/Magnetic Tamper

Secure Position

1 2 3

Common

Open Loop

Closed Loop

Supervised Common

Pry Tamper

4

Open Loop

Common

Remote Test (12V; 1K ohm coil)

Remote Test

Supervised Common

Lid Tamper Only

Pry Tamper/Lid Tamper

5 6

7 8

Remote Test

Lid Tamper Only

Pry Tamper/Lid Tamper

Remote Test

Page 2

INSTALLATION INSTRUCTIONS

x

2807T, 2808T

Mount switch in desired location. The gap distance is approximately

.4". However, environmental conditions, such as the thickness of the

metal to which the switch and magnet are attached, may cause slight

variations in gap distance. Therefore, recommended installation

method is as follows:

Bring magnet toward switch until ohmmeter reads "0" ohms. Mark this

point, then continue bringing magnet toward switch until meter reads

INFINITY. Mark this point, and position the magnet between these

two marks. Once this position is established, use the magnet template

and mark the mounting holes. With magnet positioned properly, the

switch will trip if an external magnet (67 gauss or greater) is used in an

attempt to defeat the switch.

2807T, 2804T

When pry tamper is used, mount pry tamper plate beneath the switch

with #6 x .75" flathead screws. Connect terminals 4 and 6 to 24-hour

loop. When pry tamper is not used, discard plate and connect terminals

5 and 6 to 24-hour loop. The pry tamper plate is required for the

Certified Safe and Vault applications.

2808T

When pry tamper is used, mount pry tamper plate beneath the switch

with #6 x .75" flathead screws. Connect terminals 4 and 5 for pry

tamper. Use terminals 4 and 6 for use without pry tamper. The pry

tamper plate is required for the Certified Safe and Vault applications.

2804T

To install Model 2804T on a safe or vault:

1. Using template included for switch housing, place the bottom of

template approximately

Mark the mounting holes.

2. Drill the four mounting holes

holes for a #10-24 machine screw thread. Mount the contact with

the #10-24 x 1

1

/4" flathead machine screws provided.

3. Before running the conduit attach an ohmmeter to the common and

the closed loop terminals. Meter should read INFINITY with

magnet away from switch (wiring diagram provided).

1

/4" from the edge of the door on the frame.

5

/8" deep using a 5/32" drill. Tap the

4. The magnet for the unit is contained in two pieces. The master

magnet is brown, and the sub-magnet is silver. Place the sub-magnet

housing into the master magnet housing, making sure that the yellow

dot on the sub housing is towards the switch.

5. Position magnet and switch so that the labels read in the same

direction, and the Sentrol "S" on the magnet is directly aligned with

the "S" on the switch. The set-up gap distance is .4". Switches will

operate at approximately .2" to .6" on closing, and go into alarm at

approximately .4" to .8" on opening. Minimum gap is .1". However,

environmental conditions, such as the thickness of the metal to

which the switch and magnet are attached, may cause slight

variations in gap distance. Therefore, recommended installation

method is as follows:

Bring magnet toward switch until ohmmeter reads "0" ohms. Mark

this point, then continue bringing magnet towards switch until meter

reads INFINITY. Mark this point, and position the magnet between

these two marks. Once this position is established, use the magnet

template and mark the mounting holes.

5

6. First drill the two inside mounting holes

Tap the holes for a #8-32 machine screw thread. Then drill the two

outside mounting holes

5

/8" deep using a 5/32" drill. Tap the holes for

/8" deep using a 9/64" drill.

a #10-24 machine screw thread.

7. Remove the sub-magnet housing from the master magnet housing.

Mount the sub-magnet housing first utilizing the two center holes.

Use the #8-32 x 1

1

/2" machine screws provided. ENSURE THAT

THE YELLOW DOT FACES THE SWITCH.

8. Mount the master magnet housing directly over the sub-magnet

housing. Use the #10-24 x 1

3

/4" machine screws provided. ENSURE

THAT THE LABELS ON SWITCH AND MAGNET READ IN

SAME DIRECTION.

9. Recheck switch with an ohmmeter to ensure proper continuity.

10. Install conduit.

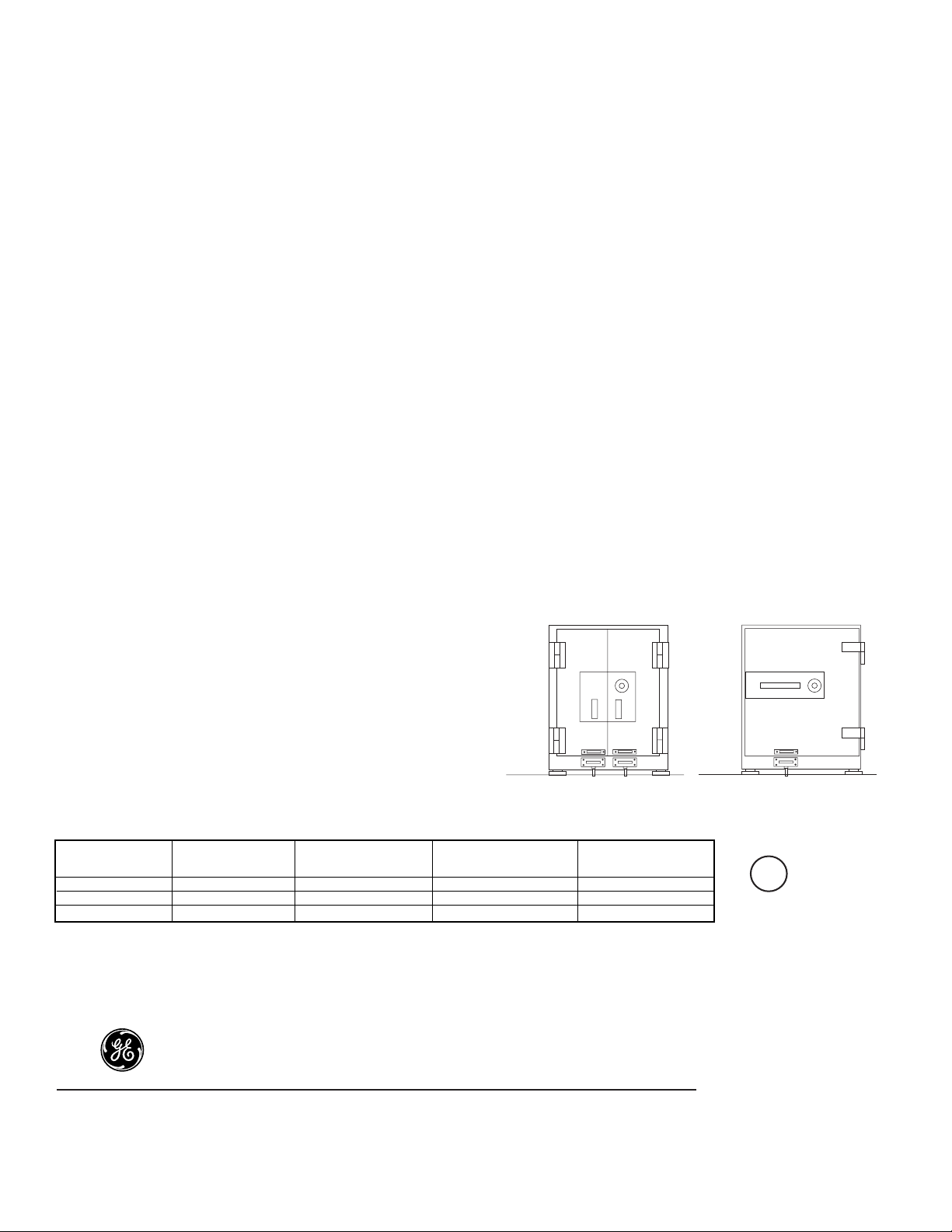

ORDERING INFORMATION

PART NUMBER LOOP TYPE ELECTRICAL GAP DISTANCE LEAD TYPE

2804T Open or Closed SPDT 3/16" min., 5/8 "max. #6 screw terminal

2807T Open or Closed SPDT 3/16" min., 5/8" max. #6 screw terminal

2808T Open or Closed SPDT 3/16" min., 5/8" max. #6 screw terminal

Form C (2804T, 2807T, 2808T)

Voltage: 30 V AC

Current: .25 A Max.

Power: 3.0 W Max.

www.GE-Interlogix.com

© 2003 GE Interlogix

CONFIRGURATION (MAKE)*

Cover Tamper:

At 24 V AC/DC Max.

125 mA Max.

At 6 to 12 V DC

250 mA Max.

12345 SW Leveton Drive

Tualatin, OR 97062

Phone: 503-692-4052

USA & Canada: 800-547-2556

Technical Service: 800-648-7424

FaxBack: 800-483-2495

*Gap distances are nominal make distance ±20%.

LISTED

GE Interlogi

U

L

11256 Rev D 08/03

Loading...

Loading...