Page 1

2700 Series Installation Instructions

With magnet positioned correctly, the switches will trip if an

Installation

These are the installation instructions for models 2706AP,

2706AS, 2707A, and 2707AD.

2707A/2707AD: Position magnet and switch so that the labels

read in the same direction and the Sentrol S on the magnet

aligns directly with the S on the switch. The set-up gap

distance is .4" (3/8") (1.02 cm). Switches will operate at

approximately .2" (.5 cm) to .6" (1.52 cm) on closing and go

into alarm at approximately .4" (1.02 cm) to .8" (2.03 cm) on

opening. Minimum gap is .2" (.5 cm). However, environmental

conditions, such as thickness of the metal to which the switch

and magnet attach, may alter gap distance. Therefore, we

recommend the following installation method:

external magnet (67 gauss or greater) is used in an attempt to

defeat the switch.

Ordering information

Part # Loop type Electrical

configuration

2706AS Open or closed SPDT 0.2" to 0.6"

2706AP Open or closed SPDT 0.2" to 0.6"

2707A Open or closed SPDT 0.2" to 0.6"

2707AD Open or closed DPDT 0.2" to 0.6"

Lead Type for all models: 3' Stainless steel armored cable

*Gap distances are nominal make distance ±20%.

Gap distance

(Make)*

1. Bring the magnet toward the switch until an ohmmeter

connected to the closed loop wires reads 0 ohms. Mark

this point.

2. Now bring the magnet closer to the switch until the meter

reads infinity. Mark this point.

3. Position the magnet midpoint between the two marks.

4. Use the magnet template to mark the mounting holes.

5. Pre-drill the mounting holes.

6. If a Pry Tamper plate is required, install it under the switch

with two #6 x 3/4" flathead screws. Connect the gold and

blue painted leads to the 24-hour circuit. The pry temper

plate is required for the Certified Safe and Vault

applications.

7. If the pry tamper is not used, discard the tamper plate and

mount the switch directly to the surface. Be sure to

connect the gold and green painted leads to the 24-hour

circuit.

2706AP/2706AS: Follow steps 1 through 7 as outlined for

models 2707A/2707AD. The 2706AP/2706AS has a built-in

remote test feature which you may order either on the

protective or supervised loop. To perform remote test

operation, apply 12 V DC, 5 mA max. current, to the green

(remote test) wires. 24 V DC remote test is available on

request.

Form C (2747A)

Voltage: 30 V AC

Current: .25 A Max.

Power: 3.0 W Max.

P/N 11247 • REV E • 21SEP11 1

Page 2

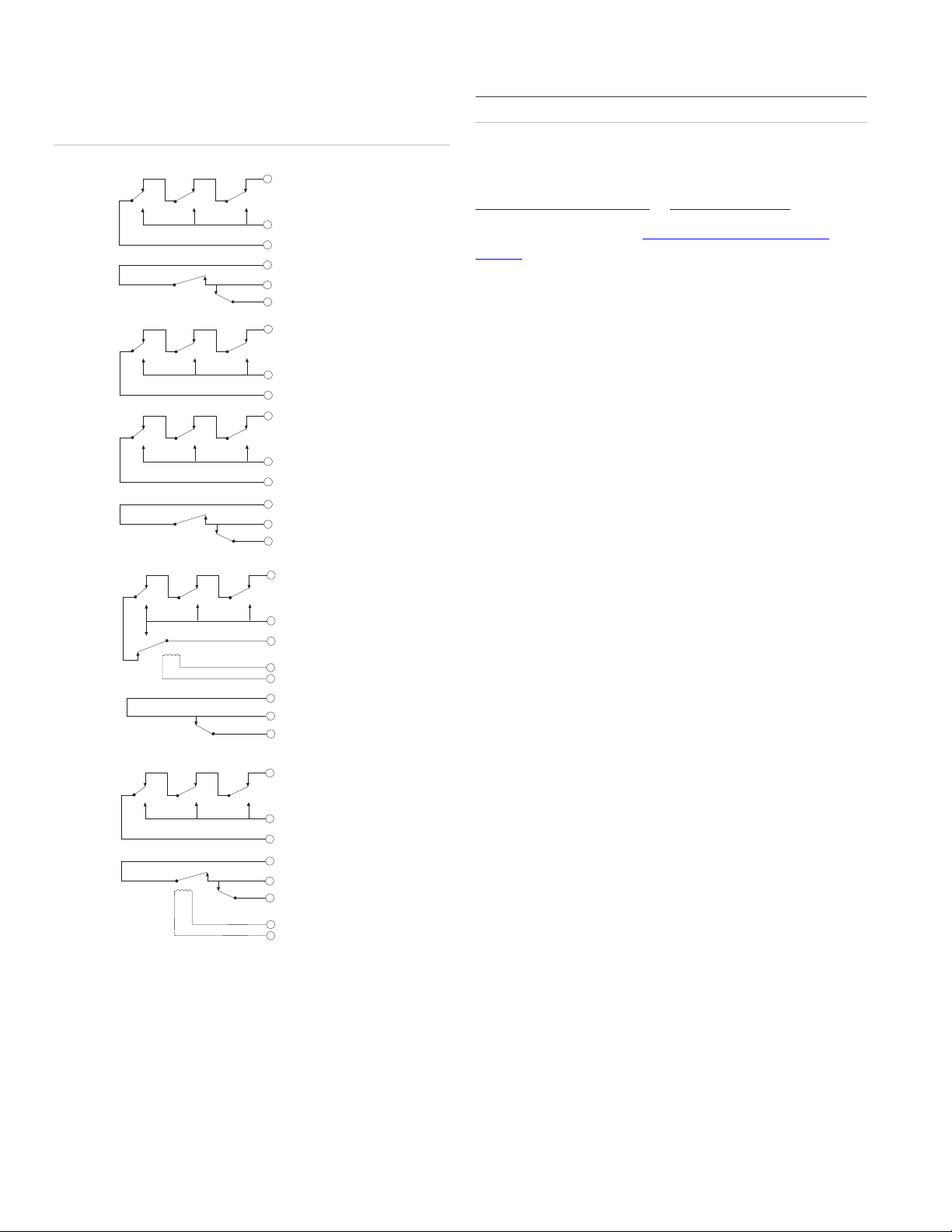

Wiring

Figure 1: Wiring for the 2700 Series

Regulatory information

Listings UL

2707A

Magnetic tamper

Pry tamper

2707AD

Magnetic tamper

Pry tamper

2706AP Remote Test on Protective Loop

Closed loop

(white)

Open loop

(red/white)

Common

(silver/white)

Supervised common

(gold/white)

Magnetic tamper only

(green/white)

Pry tamper/Magnetic tamper

(blue/white)

Closed loop

(white)

Open loop

(red/white)

Common

(silver/white)

Closed loop

(white/black)

Open loop

(red/black)

Common

(black)

Supervised common

(gold/white)

Magnetic tamper only

(green/white)

Pry tamper/Magnetic tamper

(blue/white)

Closed loop

(white)

Contact information

www.utcfireandsecurity.com or www.interlogix.com

For customer support, see www.interlogix.com/customer-

support

Copyright © 2011 UTC Fire & Security. All rights reserved.

Open loop

(red/white)

Common

Remote test/Magnetic tamper

Pry tamper

2706AS Remote Test on Supervised Loop

Remote test

NOTE: Circuits shown with magnet in secure postion.

Tam p er

Pry tamper

(silver/white)

Remote test

(green)

Remote test

(green)

Supervised common

(gold/white)

Supervised loop

(green/white)

Pry tamper

(blue/white)

Closed loop

(white)

Open loop

(red/white)

Common

(silver/white)

Supervised

(gold/white)

Magnetic tamper only

(green/white)

Pry tamper/Magnetic tamper

(blue/white)

Remote test

(green)

Remote test

(green)

2 2700 Series Installation Instructions

Loading...

Loading...