Page 1

SuperBus 2000 2-Amp Power Supply 600-1019

Installation Instructions

Description

The power supply provides an additional 12 VDC, 2 amps

(current limited) for Concord 4 system devices and is

supervised via the SuperBus

® 2000 digital data bus. The

power supply uses a 24 VAC, 50 VA power transformer. In

case of an AC power failure, a 12 VDC, 4.5 or 7 Ah backup

battery (not included) provides power to connected devices.

The battery is tested by the power supply on power up, every

two minutes afterward, and whenever the panel tests its own

backup battery.

The power supply also includes a hardwire zone input that

accepts normally open (NO) or normally closed (NC) intrusion

detection devices. The power supply can be located inside the

Concord 4/Concord Express V4 cabinet or it can be mounted

in a separate Concord Residential Enclosure (444-1700 and

444-1711 ordered as a separate kit) or Concord Commercial

Expansion Enclosure (444-1391 ordered as 60-816).

Figure 1

Figure 1. Power supply main components

describes the power supply main components.

Backup

Battery

Connections

Ter mi nal S tr ip

Red LED-bus

communication

status

Green LEDpower status

Installation

Use the following guidelines for installing the power supply.

Guidelines

• The power supply AC transformer must be plugged into an

AC outlet that is not a ground fault interrupt circuit (GFIC)

or controlled by a switch.

• When mounting the power supply inside the panel cabinet,

the backup battery can also be stored inside the panel

cabinet.

• When mounting the power supply in a separate enclosure,

the maximum wire length from the power supply bus and

power connections to the panel is 4,000 feet.

• When mounting the power supply in a separate enclosure,

the power supply mounting location should be determined

by the wire runs needed to provide power to devices with

minimal loss on the +12V OUT wire. Table

1 shows the

maximum wire runs between the power supply +12V OUT

terminal and the devices it will power.

Table 1. Maximum +12V OUT wire length

Gauge Maximum wire length from power supply +12V

OUT terminal

22 100 feet

18 200 feet

16 350 feet

14 550 feet

• For large installations with long wire runs, power supply

location is important. The total system wiring length (all

partitions) for all bus devices connected to a Concord 4/

Concord Express V4 panel must not exceed 4,000 feet.

This not only includes the power supply bus and power

connections to the panel, but also any bus devices you

may connect to the power supply. For example, touchpads

and other bus devices in a remote partition should be

connected to the power supply rather than running the

wires all the way to the panel (Figure 2

).

• Up to 16 SuperBus 2000 devices can be connected to

Concord 4/Concord Express V4 panels (touchpads,

receivers, transceivers, HIMs, HOMs, ESMs, etc.).

P/N 466-2185 • REV B • January 2011 1

Page 2

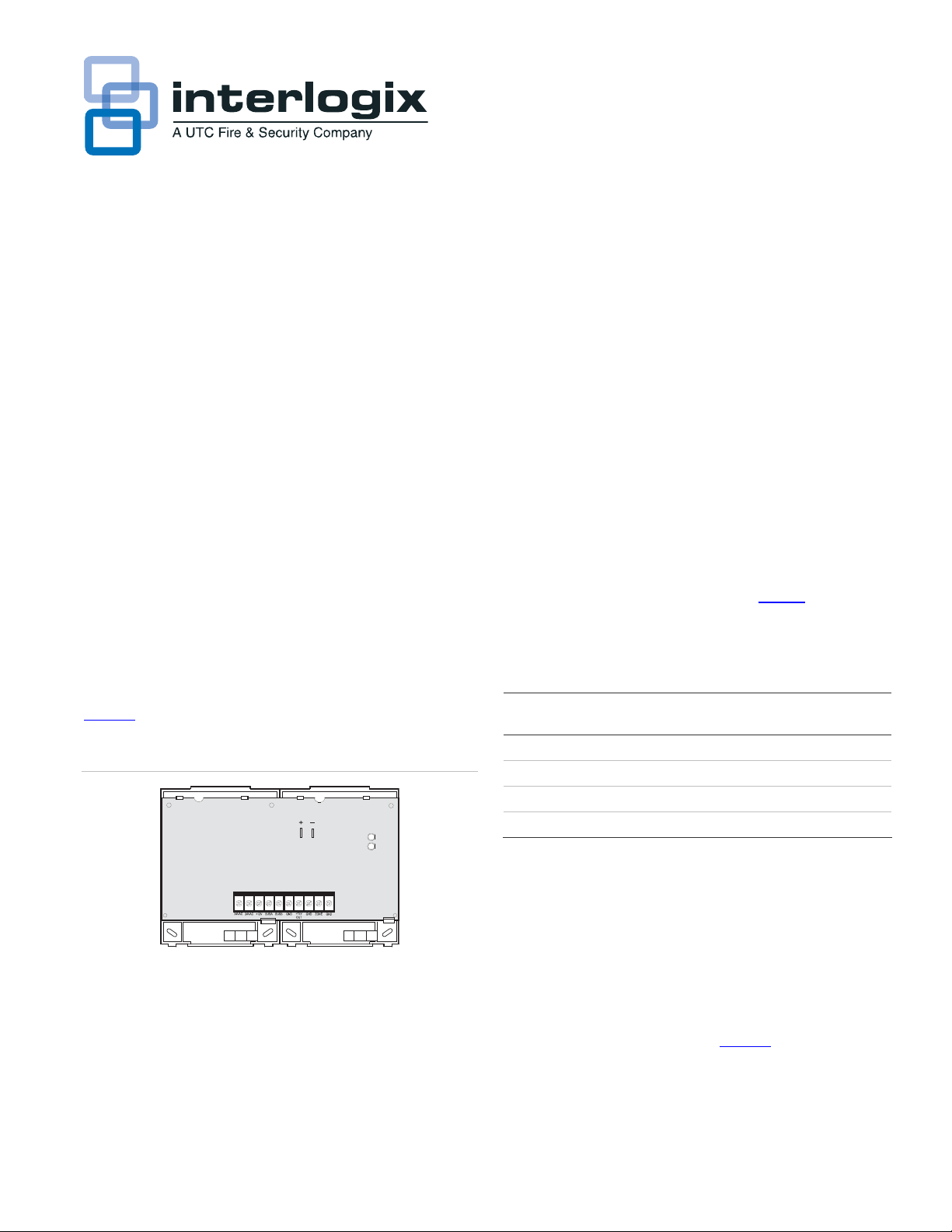

2. Bus device wiring example for remote partitions

Figure

Panel

Bus devices

connected to

panel

Power

supply

Bus devices

connected to

power supply

then snap the backplates on to the support standoffs

(Detail in Figure 4

Figure 4. Mounting power supply inside panel cabinet

).

Mounting

Clips

Tools and supplies

• 12 V backup battery (4.5 Ah part no. 60-681 or 7 Ah part

no. 60-680)

• Screwdrivers

• Separate enclosure—if not mounting power supply inside

panel cabinet

• Mounting screws

• Support Standoffs (included with panel)

• 4-conductor, 22- or 18-gauge stranded wire

• 2-conductor, 18-gauge wire (for AC transformer)

Mounting

Caution: To prevent damaging the panel or power supply,

remove the panel AC power transformer and disconnect the

backup battery before installation.

You must be free of static electricity before handling circuit

boards. Wear a grounding strap or touch a bare metal surface

to discharge static electricity.

Power Supply

on Backplates

Detail

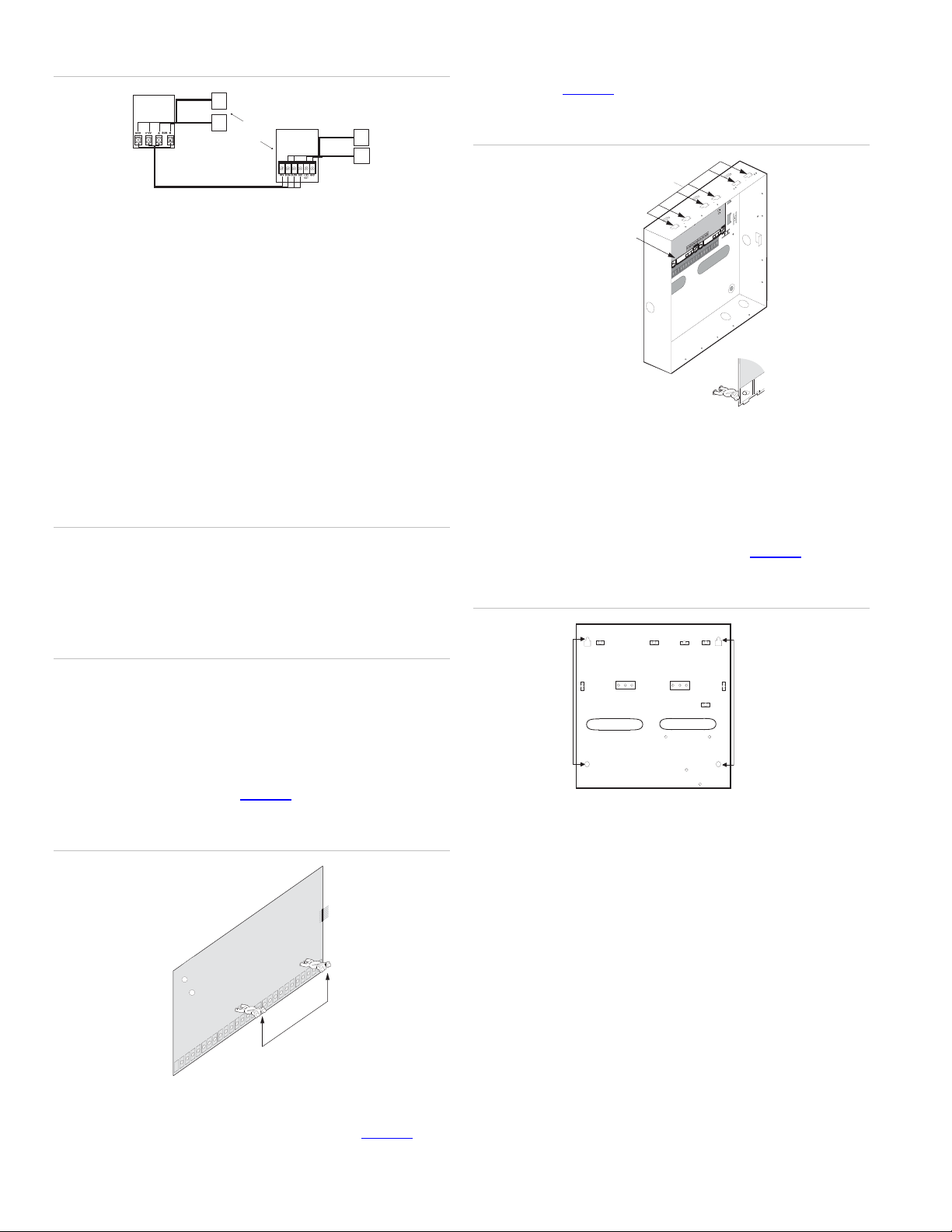

Mounting inside Concord residential enclosure

1. Unplug the panel AC power transformer and disconnect

the backup battery.

2. Place the cabinet at the desired location and mark the

cabinet mounting holes and knockouts (Figure 5

Figure 5. Residential enclosure mounting holes and knockouts

).

Mounting inside panel cabinet

1. Unplug the panel AC power transformer and disconnect

the backup battery.

2. Install the support standoffs (included with panel) at the

panel locations shown in Figure 3

Figure 3. Installing panel support standoffs

.

4. Slide the top of the backplates onto the left and center

module mounting clips on the panel cabinet (Figure 4

),

Cabinet

Mounting

Knockout

Knockout

Holes (4)

3. Drill holes and insert the appropriate anchors where studs

are not present.

4. Run wires from all devices to be powered, to the power

supply.

5. Run a 4-conductor, 22-gauge or larger stranded wire from

the power supply to the panel.

6. Run a 2-conductor, 18-gauge stranded wire from the

power supply to the AC transformer location.

7. Feed all wires through the knockouts and secure the

cabinet to the wall with the included screws.

8. Remove the power supply circuit board from the plastic

mounting plates.

2 SuperBus 2000 2-Amp Power Supply 600-1019 Installation Instructions

Page 3

9. Position the plastic mounting plates in the cabinet on the

top-left or top-right side and secure them with the six selftapping screws included with the power supply (Figure 6

Figure 6. Power supply mounting positions in residential

enclosure (arrows indicate screw locations)

9. Secure the power supply to the cabinet using either the

right side or left side power supply mounting holes, with

).

the six self-tapping screws included with the power supply

(Figure 8

Figure 8. Power supply mounted in commercial enclosure

).

10. Re-install the power supply circuit board on the plastic

mounting plates.

Mounting inside Concord Commercial enclosure

1. Unplug the panel AC power transformer and disconnect

the backup battery.

2. Remove the necessary knockouts for wire access (Figure

7).

3. Place the cabinet at the desired location and mark the

Cabinet

Mounting

Holes (4)

).

cabinet mounting holes and knockouts (Figure 7

Figure 7. Commercial enclosure power supply mounting holes

and knockouts

Knockouts (4)

Power Supply

Mounting

Holes

Right Side Mounting

Left Side Mounting

Wiring

Connect the power supply to the panel terminals and devices

as shown in Figure 9

Figure 9. Power supply wiring connections to panel and devices

.

To bus

devices

To power

inputs on

devices

N/C circuit with 2k Ohm

Resistor (49-454)

N/O circuit with2k Ohm

Resistor (49-454)

Power Up

Use the following procedure for powering up the power supply

and panel to verify bus communication.

1. Verify that all wiring at the panel and devices are correct.

2. Connect the power supply backup battery to the battery

4. Drill holes and insert the appropriate anchors where studs

terminals on the power supply board (Figure 10

Figure 10. Power supply AC and DC power connections

).

are not present.

5. Run wires from all devices to be powered, to the power

supply.

6. Run a 4-conductor, 22-gauge or larger stranded wire from

the power supply to the panel.

7. Run a 2-conductor, 18-gauge stranded wire from the

RED BLACK

power supply to the AC transformer location.

8. Feed all wires through the knockouts and secure the

cabinet to the wall with the included screws.

SuperBus 2000 2-Amp Power Supply 600-1019 Installation Instructions 3

Page 4

3. Wire the power supply AC transformer to the power supply

board, then plug in the transformer (Figure 10

). The green

LED should turn on to indicate power is present. The red

LED should be off for the moment.

Note: If the green LED is not on, unplug the power supply

AC power transformer, disconnect the backup battery, and

proceed to Table

2 in “Troubleshooting”.

4. Connect the panel backup battery and plug in the panel

AC power transformer. The panel should automatically

scan for new bus devices and the red LED on the power

supply board should flicker to indicate bus communication

with the panel.

5. If using the optional zone input, learn the zone into panel

memory (see panel installation instructions).

Specifications

Panel compatibility Concord 4 series control panels

Power output required 24 VAC, 50 VA class II power transformer

Power output 12 VDC, 2.0 amps maximum, current limited

Battery type 12V, 4.5Ah or 7Ah lead acid

Standby load 95 mA (4.5Ah battery), 190 mA (7 Ah battery)

Operating temperature 32° to 120° F (0° to 49° C)

Storage temperature -30° to 140° F (-34° to 60° C)

Max. relative humidity 85%, non-condensing

Dimensions (LxWxD) 5.125 in. x 7.85 in. x 1.0 in. (13 cm x 20 cm x

2.5 cm)

Regulatory information

Troubleshooting

Table 2. Troubleshooting

Problem Action

Green LED is off 1. Check that power supply transformer is

plugged into outlet.

2. Check that transformer is not plugged into

an outlet controlled by a switch.

3. Check outlet circuit breaker/fuse. Reset/

replace as needed.

Red LED is off. Check/correct bus (A & B) wiring connections

at module and panel.

System touchpads

display AUX POWER

FAIL.

System touchpads

display AUX POWER

BATT trouble.

System touchpads

display AUX AC

POWER trouble.

1. Check for shorts on wire connected to

power supply +12V OUT terminal.

2. Verify that devices connected to power

supply +12V OUT terminal are not drawing

more than 2 amps.

1. Check that power supply battery is

connected.

2. Power supply battery needs charging.

Battery may need at least 4 hours to fully

charge.

1. Check that power supply transformer is

plugged into outlet.

2. Check that power supply transformer is not

plugged into an outlet controlled by a switch.

3. Check outlet circuit breaker/fuse. Reset/

replace as needed.

Manufacturer UTC Fire & Security Americas Corporation, Inc.

1275 Red Fox Rd., Arden Hills, MN 55112-6943,

USA

UL/cUL listings 985, 1023, and 1610

FCC compliance This device complies with FCC Rules Part 15.

Operation is subject to the following two

conditions. This device may not cause harmful

interference. This device must accept any

interference that may be received, including

interference that may cause undesired operation.

Changes or modifications not expressly approved

by Interlogix can void the user’s authority to

operate the equipment.

Contact information

For contact information, see www.utcfireandsecurity.com or

www.interlogix.com.

For technical support, toll-free: 888.437.3287 in the US

including Alaska, Hawaii, Puerto Rico, and Canada. Outside

the tool-free area, contact your dealer.

Copyright © 2011 Interlogix, a UTC Fire & Security Company.

All rights reserved.

4 SuperBus 2000 2-Amp Power Supply 600-1019 Installation Instructions

Loading...

Loading...