Page 1

Salient Fibre Channel Storage System

Tower Assembly Instructions

August 1998

DHA024800

Page 2

Copyright

1998 Intergraph Computer Systems. All rights reserved. This document contains information protected by copyright, trade secret, and

trademark law. This document may not, in whole or in part, be reproduced in any form or by any means, or be used to make any

derivative work, without written consent from Intergraph Computer Systems.

Use, duplication, or disclosure by the United States Government is subject to restrictions as set forth in subdivision (c)(1)(ii) of the rights in

technical data and computer software clause at DFARS 252.227-7013. Unpublished rights are reserved under the copyright laws of the

United States.

Intergraph Computer Systems, Huntsville AL 35894-0001

Notice

Information in this document is subject to change without notice and should not be considered a commitment by Intergraph Computer

Systems. Intergraph Computer Systems shall not be liable for technical or editorial errors in, or omissions from, this document. Intergraph

Computer Systems shall not be liable for incidental or consequential damages resulting from the furnishing or use of this document.

All warranties given by Intergraph Computer Systems about equipment or software are set forth in your purchase contract. Nothing stated

in, or implied by, this document or its contents shall be considered or deemed a modification or amendment of such warranties.

Trademarks

Intergraph Computer Systems and the Intergraph Computer Systems logo are registered trademarks of Intergraph Computer Systems.

StudioZ is a trademark of Intergraph Computer Systems.

Other brands and product names are trademarks of their respective owners.

Page 3

Salient Fibre Channel Storage System

Assembly as a Tower Unit

The Salient Fibre Channel storage system chassis arrives unassembled. To set up the Fibre

Channel as a tower unit rather than as a rack-mount unit, you will need to install the foot

and the chassis cover. You will then install the two power supplies, the I/O module, the

operator panel, the hard drive assemblies, and the blanking plates. This document contains

instructions for unpacking the various parts of the Fibre Channel storage system, placing the

tower cover and foot onto the chassis, and installing the storage system components.

Unpacking and Orienting the Fibre Channel Chassis

Unpack the Fibre Channel chassis and make sure you have all the components, and then

determine which end of the chassis will be the top of the tower unit.

To unpack and orient the chassis:

1. Open the box containing the Fibre Channel chassis. When you remove the chassis from

the box, it is in the rack-mount position.

1

2. Turn the chassis upright to determine its proper vertical orientation. To determine

which end is the top, you can do the following:

−

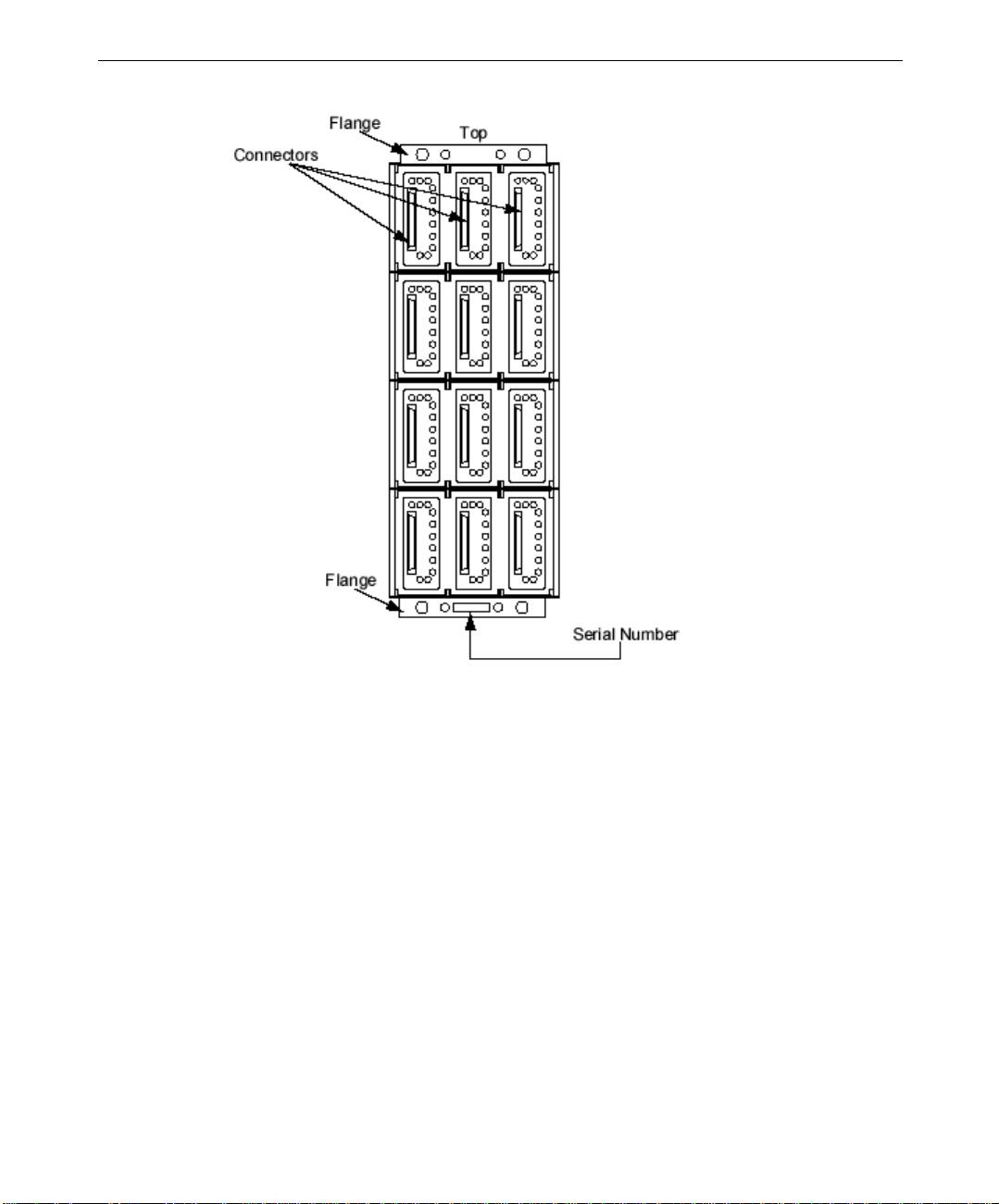

Look inside the drive bays and note the docking connector for each drive. When the

chassis is right side up, these docking connectors are on the left side of each drive

bay, as shown in the following figure.

−

When the chassis is in the correct tower position, you can read the labels inside the

back of the chassis (where the power supplies, I/O module, and so on go).

−

The serial number on the front of the chassis (where the drives are inserted) is right

side up.

Page 4

2

Unpacking the Tower Kit Components

After you have determined which end is the top of the chassis, carefully unpack the tower kit

components.

To unpack the Fibre Channel tower kit components:

1. Open the box containing the Fibre Channel tower kit components.

2. Carefully slide out the tower cover, which is protected by a layer of protective wrap.

CAUTION All of the tower kit components are contained within the tower kit cover. To ensure that you

do not scratch the surface of the tower cover, leave the protective wrap on until you are ready

to install the cover.

3. The tower foot is held inside the cover with two pieces of Styrofoam. Hold the foot

securely, and remove one of the Styrofoam pieces. Then remove the other piece of

Styrofoam and take the plastic wrap off of the foot.

Page 5

CAUTION It is best to remove one piece of Styrofoam at a time, while holding the foot securely. This

portion of the tower kit is quite heavy, and could warp the tower cover if both pieces of foam

are removed at the same time and the foot slips.

4. Remove the front and rear brackets and set them aside. These are both black; the front

bracket is L-shaped and has a handle; the rear bracket is flat.

5. Remove the package containing the mounting screws and washers. This package also

contains a document titled “SS-1200 Tower Cover Kit Assembly Instructions,” which

has pictures you may find helpful while you are assembling the tower.

Assembling the Fibre Channel Tower Components

In a previous section, “Unpacking and Orienting the Fibre Channel Chassis,” you

determined which end of the chassis was the top side. If you have moved the chassis around,

make sure you still know which end is the top. The first component you will install is the

tower foot.

To assemble the Fibre Channel tower components:

1. Invert the chassis so that it is upside down.

2. Place the foot on the chassis, making sure that the flange on the front of the chassis fits

into the slot on the foot.

3

3. Use two M6 pan head screws and washers to attach the front of the foot to the bottom

front of the chassis (the pan head screws and their washers are the larger of the two

types of screws and washers provided in the tower kit).

NOTE The heads of the screws will face the back of the chassis.

4. Use two M5 countersunk screws and compression (crinkle) washers to attach the rear of

the foot to the rear of the chassis.

NOTE Because you will be inserting components into the chassis bays, you must insert the

countersunk screws and washers from inside the chassis. Also, you must ensure that the

screws are completely countersunk so that the components you install later will fit.

NOTE You may need a short screwdriver to install the screws from inside the chassis.

5. Turn the chassis upright on its foot. If you are working on a table or counter, make sure

you secure the chassis so that it doesn’t roll off of your work surface.

6. Using two M6 pan head screws and washers, attach the front bracket (the one that has a

handle) to the flange on the front of the chassis, aligning the holes in the bracket with

the inside holes on the flange. Again, the tops of the screws should face the rear of the

chassis.

7. Using two M5 countersunk screws and compression washers, attach the rear bracket (the

one that is L-shaped) to the top rear of the chassis.

Page 6

4

NOTE Proper placement of the cover depends on the brackets, so do not tighten the back bracket

fully in case you need to adjust it to make the cover fit.

8. Place the cover over the chassis. There are two slots, or notches, at the bottom of each

side of the tower cover front; these fit around the flange on the bottom front of the

chassis. Also, there is a cutout on the inside of the cover at the front and the back.

Make sure that the front and rear brackets fit inside these cutouts.

NOTE At this point, you may need to adjust the rear bracket to ensure that the cover fits properly.

9. Finish tightening the rear bracket screws you inserted in step 7 so that they are fully

countersunk.

10. Turn the unit upside down again, and use six M5 countersunk screws to secure the cover

to the unit.

11. Turn the unit right side up again.

Installing the Fibre Channel Storage System Components

Now that you have installed the tower foot and cover, you can install all of the components

in the Fibre Channel chassis. The SS-1200-FCAL Rack Installation and User Guide

describes each of the components of the storage system in detail. Installation of these

components is described for a rack-mount system; for example, the slots are referred to in

terms of left to right instead of top to bottom as in a tower configuration. The following

illustration shows the unit in the tower position with the slots labeled accordingly.

Page 7

5

Installing the Power Supplies, Operator Panel, and Input/Output Module

The following instructions show you how to install the components that go in the rear of the

Fibre Channel chassis.

WARNING Make sure that you wear the anti-static wrist strap included with the Tower Kit

components to avoid damaging the power supplies, operator panel, or I/O module.

See the

SS-1200-FCAL Rack Installation and User Guide

for more information.

To install the storage system components:

1. Remove the protective covering from each of the storage system components.

2. Check the power supplies and verify that the voltage switch is set to the correct voltage

(either 115V or 220V) for your country.

3. Turn the storage system around so that you are looking at the back of the unit (see the

previous illustration).

4. Remove the alignment screws and washers located above each side of slots 4 and 1 (see

the previous illustration). These ensure the correct orientation and secure placement of

the power supplies you will install; set these screws and washers aside for now because

you cannot install the power supplies while these screws are in place.

Page 8

6

NOTE Alignment screws are located in the upper left corner of each power supply bay, and in the

upper left corner of the slot 2. You only need to remove the alignment screws above each

power supply bay at this time.

CAUTION Be very careful with the power supplies, as they are heavy and the connecting pins can be

easily bent.

5. Install the first power supply (CPWS17900) in slot four; hold down the black tab to

make sure the component clicks into place.

CAUTION Make sure the label on the power supply faces the left of the chassis rear, or the power

supply will break when you install it. This is the same label that would be on the top of the

power supply in a rack-mount unit.

6. Using the same method described in the previous step, install the second power supply

(CPWS179) into slot 1.

7. Reinsert the two alignment screws and washers that you removed in step 2.

8. Remove the key that is taped to the operator panel (CINFE48), and install the panel in

the column 1 of slot 3, making sure that the “This Side Up” label on the operator panel

faces the left of the chassis rear; this label would be on the top in a rack-mount unit. Set

the key aside for now.

9. Insert the I/O module (CINFE49) in the middle column of slot 3. Again, make sure that

the “This Side Up” label faces the left of the chassis rear.

10. Place the smaller blanking plate (CGEN575) over the last column (3) in slot 3.

11. Remove the alignment screws and washers above slot 2, and place the final blanking

plate (CGEN574) over slot 2.

Populating the Fibre Channel Storage System Drive Bays

The following instructions show you how to install all of the drives in the proper order.

There are eight drives (CDSK238) and four dummy carriers (CGEN576) in a typical setup.

To open the drive front, you will push the indentation on the plastic cover. This indentation

should be on the top of each drive.

To install the Fibre Channel storage system drives:

1. Turn the storage system around so that you are looking at the front of the unit (refer to

the illustration in “Unpacking and Orienting the Fibre Channel Chassis” if necessary).

2. Press the indentation on a drive to open its door, and install this first drive in the bottom

right column of slot 4. Push the drive all the way in until the face of the drive is flush

with the trim on the tower cover, then press the indentation until it clicks shut. Again,

the indentation on the drive should be on the top.

3. Continue to install the remaining drives in the same fashion, working your way to the

top of the right column, then starting over at the bottom (slot 4) of the middle column.

Page 9

4. If you are only installing eight drives, place the dummy carriers (CGEN576) into the

remaining drive bays in the left column. These install the same way as the regular

drives and will look the same once installed, with the exception of the serial number

label (the dummy carriers do not have serial number labels). Otherwise, continue

installing the drives as described in steps 2 and 3.

NOTE Use a torx driver (CTOL805) to lock a drive. Insert the torx driver into the red, star-shaped

hole on the drive face. Turn the driver counterclockwise until you see a red tab appear in the

drive face; this indicates that the drive is locked and cannot be opened accidentally. See the

SS-1200-FCAL Rack Installation and User Guide

locks.

for more information on these anti-tamper

Setting Up the Fibre Channel Storage System

Once you have installed all of the storage system components, you are ready to hook it up to

a system and a power outlet and start creating. There are some things the system must have;

if you purchased the StudioZ GT1 workstation, it will have all of the requirements necessary

for the Fibre Channel storage system.

7

NOTE See the

StudioZ GT for SOFTIMAGE|DS System Guide

for information on this workstation.

Workstation Requirements

StudioZ GT1 base unit

Q-Logic adapter card (CINFE50)

Q-Logic driver software

Microsoft Windows NT 4.0

To connect the Fibre Channel storage system to your workstation:

1. Make sure that your workstation is properly shut down and powered off.

2. Connect the HSSDC end of the Fibre Channel cable (MCBL337) to the Fibre Channel

port on the Q-Logic adapter card in the StudioZ GT1 base and tighten the thumb screws.

3. Connect the DB9 end of the Fibre Channel cable to the FC-AL Tx/Rx port on the Fibre

Channel I/O module (column 2 of slot 3) and tighten the thumb screws.

4. Insert the key into the operator panel and turn it to the Service position (this is the key

that was taped to the operator panel module before you installed the module).

5. Connect the two female ends of the bifurcated power cord to both power supplies, then

plug the male end of the bifurcated power cord into the female end of the power cord.

Plug this into your power source (preferably the same power source that your StudioZ

GT1 workstation uses).

NOTE The part number for the power cord depends on the country where the workstation will be

used. Make sure you obtain the proper power cord for your region.

Page 10

8

WARNING The bifurcated power cord provides a single-source power connection. For safety

precautions, this power cord should always be used. The bifurcated power cord is the

same for all countries.

6. Power up your StudioZ GT1 workstation, and turn the key in the Fibre Channel I/O

module from Service to Run to power up the Fibre Channel storage system. See SS-

1200-FCAL Rack Installation and User Guide for more information on the I/O module.

NOTE The spinup light on each drive is a steady green when the Fibre Channel has powered up

properly. If you see an amber spinup light on any drive, make sure that the Fibre Channel

cable (MCBL337) is securely connected.

NOTE The initialization light on the Fibre Channel storage system is amber until Windows NT

initializes the storage system, whereupon this light turns green.

Installing Additional Fibre Channel Storage Systems

You can add up to two additional Fibre Channel Storage systems to the system discussed

above. Each of these systems is delivered with eight drives, and you can purchase four

additional drives for each storage system.

To add an additional Fibre Channel storage system:

1. Connect the HSSDC end of the Fibre Channel cable (MCBL337) to the Fibre Channel

port on the Q-Logic adapter card in the system and tighten the thumbscrews.

2. Connect the other end of the Fibre Channel cable to the female DB9 end of the Y cable

(MCBL384) and tighten the thumbscrews.

NOTE The side of the Y cable with two legs has one short leg and one long leg—both are male DB9

connectors.

3. Attach the short leg of the Y cable to the Tx/Rx port on the I/O module of the first Fibre

Channel chassis.

4. Attach the long leg of the Y cable to the Tx port on the I/O module in the second Fibre

Channel chassis.

5. Connect one end of a one-meter DB9-to-DB9 Fibre Channel cable (MCBL336) to the Tx

port on the first chassis; then connect the other end of the cable to the Tx/Rx port on the

second chassis.

To add a third Fibre Channel storage system:

1. Obtain an additional one-meter DB9-to-DB9 Fibre Channel cable (MCBL336A0).

2. Repeat steps 1 through 3 of the previous set of instructions.

3. Connect the long leg of the Y cable to the Tx port of the I/O module on the third Fibre

Channel chassis.

Page 11

4. Using the DB9-to-DB9 cable (MCBL336), connect the Tx port on the first chassis to the

Tx/Rx port on the second chassis.

5. Using the additional DB9-to-DB9 cable (MCBL336), connect the Tx port on the second

chassis to the Tx/Rx port on the third chassis.

NOTE Make sure that you tighten all of the cable thumbscrews.

6. Power up your StudioZ GT1 workstation, and turn the keys in each Fibre Channel I/O

module from Service to Run to power up the Fibre Channel storage systems. See SS-

1200-FCAL Rack Installation and User Guide for more information on the I/O module.

NOTE A steady green light appears on each drive when the Fibre Channel storage systems have

powered up properly. If you see an amber light on any drive, make sure that the Fibre

Channel cables (MCBL337) are securely connected.

9

Loading...

Loading...