Page 1

TDZ-300, TDZ-400 Desktop

Setup and Maintenance Guide

March 1996

Page 2

Warranties and Liabilities

The information and the software discussed in this document are subject to change without

notice and should not be considered commitments by Intergraph Corporation. Intergraph

Corporation assumes no responsibility for any errors in this document.

The software discussed in this document is furnished under a license and may be used or

copied only in accordance with the terms of the license. No responsibility is assumed by

Intergraph for the use or reliability of software on equipment that is not supplied by Intergraph

or its affiliated companies.

All warranties given by Intergraph Corporation about equipment or software are set forth in

your purchase contract, and nothing stated in, or implied by, this document or its contents

shall be considered or deemed a modification or amendment of such warranties.

Copyright

1996, Intergraph Corporation including this documentation, and any software and its file

formats and audio-visual displays described herein; all rights reserved; may only be used

pursuant to the applicable software license agreement; contains confidential and proprietary

information of Intergraph and/or other third parties which is protected by copyright, trade

secret and trademark law and may not be provided or otherwise made available without prior

written authorization.

Restricted Rights Legend

Use, duplication, or disclosure by the United States Government is subject to restrictions as

set forth in subdivision (c)(1)(ii) of the rights in technical data and computer software clause

at DFARS 252.227-7013.

Intergraph Corporation

Huntsville AL 35894-0001

Trademarks

Intergraph

Microsoft

and the Intergraph logo are registered trademarks of Intergraph Corporation.

, Windows, and the Microsoft logo are registered trademarks of Microsoft

Corporation. Windows NT is a trademark of Microsoft Corporation.

Other brands and product names are trademarks of their respective owners.

Page 3

Power Input Rating

The product ID information is located on the back of the base unit. The unit rating is listed in

Appendix B, “Hardware Information.”

Power Cord Specifications

For units operating at 115 V: Use a UL listed cord set consisting of a minimum 18 AWG,

type SJT three conductor cord, a maximum of 15-feet in length with a parallel blade, and a

grounding type attachment plug rated 15 A, 125 V.

For units operating at 230 V (domestic use): Use a UL listed cord set consisting of a

minimum 18 AWG, type SJT three conductor cord, a maximum of 15-feet in length with a

tandem blade, and a grounding type attachment plug rated 15 A, 250 V.

For units operating at 230 V (outside of U.S.): Use a cord set consisting of a minimum 18

AWG cord and grounding type attachment plug rated 15 A, 250 V. The cord set should have

the appropriate safety approvals for the country in which the equipment will be installed and

marked HAR.

FCC Statement

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy. If the

equipment is not installed and used in accordance with the instruction manual, it may cause

harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

CDC Statement

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian Department of

Communications.

Page 4

Cautions

Changes or modifications made to the system that are not approved by the party responsible

for compliance could void the user’s authority to operate the equipment.

THIS PRODUCT CONFORMS TO THE APPLICABLE REQUIREMENTS OF 21 CFR

SUBCHAPTER J AT DATE OF MANUFACTURE.

Read all safety and operating instructions before using the equipment. Keep these instructions

for future reference. Follow all warnings on the equipment or in the operating instructions.

Warnings

To reduce the risk of electrical shock, do not attempt to open the equipment unless instructed.

Do not use a tool for purposes other than instructed.

There are no user serviceable parts in the power supply. Refer all servicing of the power

supply to qualified service personnel.

Page 5

Contents

Preface........................................................................................................... ix

About This Document....................................................................................ix

Document Conventions................................................................................... x

Finding Operating System Information .......................................................... x

Getting Documentation and Training ............................................................ xi

Getting Telephone Support............................................................................ xi

Using the Intergraph Bulletin Board Service................................................xii

Using the Intergraph FAXLink....................................................................xiii

Finding Intergraph on the Internet...............................................................xiii

Learning About System Ergonomics........................................................... xiv

Chapter 1 Getting Started.......................................................................... 1

Unpacking....................................................................................................... 1

Setting Up ....................................................................................................... 2

Connecting the Video Cables.......................................................................... 5

Starting the System ......................................................................................... 8

Observing System Precautions...................................................................... 10

Using the Online Reference.......................................................................... 11

Obtaining Windows NT Updates.................................................................. 12

Ensuring PC Card Support............................................................................ 13

v

Chapter 2 Configuring the System.......................................................... 15

Before You Begin ......................................................................................... 15

About the System’s Video Display............................................................... 16

Configuring the Video Display..................................................................... 17

Starting and Stopping Video Configuration.......................................... 17

Changing GL Video Display Configuration......................................... 19

Changing the Default Video Display Driver......................................... 21

Correcting Video Display Problems ..................................................... 22

Configuring TCP/IP Networking.................................................................. 23

Chapter 3 Opening and Closing the Base Unit ...................................... 25

Removing the Top Cover.............................................................................. 25

Avoiding Electrostatic Discharge ................................................................. 26

Attaching an Antistatic Wrist Strap.............................................................. 27

Replacing the Top Cover .............................................................................. 28

Page 6

vi Preface

Chapter 4 Maintaining the System..........................................................31

Cleaning the System......................................................................................31

Replacing System Parts.................................................................................32

Reprogramming the Flash EPROM...............................................................51

Changing the System Boot Sequence............................................................53

Chapter 5 Upgrading the System.............................................................55

Adding Main Memory...................................................................................55

Internal SCSI Devices ...................................................................................58

External SCSI Devices..................................................................................60

Adding Option Boards...................................................................................61

Using the System Configuration Utility........................................................65

Exterior Surfaces ...................................................................................31

Mouse ....................................................................................................31

Keyboard................................................................................................31

Combo Drive..........................................................................................33

CD-ROM Drive.....................................................................................35

System Hard Disk Drive........................................................................36

Auxiliary Hard Disk Drive ....................................................................39

SCSI Termination Card .........................................................................42

Riser Card..............................................................................................43

System Board.........................................................................................45

Power Supply.........................................................................................49

PCI Option Boards.................................................................................62

ISA and PnP Option Boards..................................................................63

ISA Boards with a Configuration File...................................................66

ISA Boards without a Configuration File..............................................67

Chapter 6 GLZ Graphics..........................................................................71

Replacing Graphics Boards...........................................................................71

GLZ1 and GLZ3....................................................................................72

GLZ1T and GLZ5..................................................................................73

GLZ2......................................................................................................74

Geometry Accelerator............................................................................75

Dual-Screen Upgrade ....................................................................................76

Chapter 7 Using AMIBIOS Setup............................................................79

Starting AMIBIOS Setup...............................................................................80

Setup Menu....................................................................................................81

Standard Setup.......................................................................................81

Advanced Setup.....................................................................................82

Chipset Setup.........................................................................................83

Peripheral Setup.....................................................................................84

Page 7

Preface vii

Security Menu............................................................................................... 86

Password ............................................................................................... 86

Anti-Virus ............................................................................................. 87

Default Menu ................................................................................................ 87

Original ................................................................................................. 87

Optimal.................................................................................................. 88

Fail-safe................................................................................................. 88

Chapter 8 Troubleshooting...................................................................... 89

System Power Errors..................................................................................... 89

System Boot Errors....................................................................................... 90

Sound Errors ................................................................................................. 93

Video Errors.................................................................................................. 94

Other Hardware Errors.................................................................................. 94

Network Errors.............................................................................................. 95

Appendix A Installing System Software................................................. 97

Appendix B Hardware Infomration...................................................... 103

External Ports.............................................................................................. 103

MIDI/Game......................................................................................... 103

Ethernet AUI....................................................................................... 104

SCSI .................................................................................................... 105

Serial (COM)....................................................................................... 106

Ethernet 10Base-T............................................................................... 106

Parallel ................................................................................................ 107

Video................................................................................................... 108

Mouse and Keyboard .......................................................................... 108

System Board Connector Pinouts ............................................................... 109

Floppy ................................................................................................. 110

ISA Bus J3........................................................................................... 110

ISA Bus J6........................................................................................... 111

Audio................................................................................................... 111

System Board Jumper Connectors.............................................................. 112

G95 VGA Mode Disable/Enable ........................................................ 112

Vibra 16S Sound Disable/Enable........................................................ 112

CPU Frequency................................................................................... 113

Power Supply Information.......................................................................... 114

DC Output Specifications ................................................................... 114

Cable Connectors................................................................................ 116

P1-P9 Connector Pinouts .................................................................... 116

Page 8

viii Preface

Returned Goods Authorization (RGA) Form

Warranty Procedure

Repair Depot Address Labels

Page 9

Preface

The TDZ-300, TDZ-400 Desktop Setup and Maintenance Guide contains

information for setting up, configuring, and servicing your desktop

workstation.

About This Document

The TDZ-300, TDZ-400 Desktop Setup and Maintenance Guide is organized

as follows:

♦ Chapter 1, “Getting Started,” describes how to set up the system

hardware and start the system.

♦ Chapter 2, “Configuring the System,” describes how to configure the

video display and the TCP/IP networking software.

♦ Chapter 3, “Opening and Closing the Base Unit,” describes how to open

and close the system for maintenance and upgrades.

♦ Chapter 4, “Maintaining the System,” describes how to maintain the

system and replace its major components, and how to reprogram the

system’s flash EPROM.

♦ Chapter 5, “Upgrading the System,” describes how to upgrade the

system with new components.

♦ Chapter 6, “GLZ Graphics,” describes how to replace graphics boards

and install a dual-screen graphics upgrade.

♦ Chapter 7, “Using AMBIOS Setup,” describes how to configure the

system’s Basic Input/Output System (BIOS).

♦ Chapter 8, “Troubleshooting,” describes how to resolve common system

problems.

Preface ix

Page 10

x Preface

♦ Appendix A, “Installing System Software,” describes how to install the

operating system and associated system software.

♦ Appendix B, “Hardware Information,” provides information for external

ports, system board connectors, system board jumper connectors, and the

power supply.

Document Conventions

Bold Commands, words, or characters that you key in literally.

Italic Variable values that you supply, or cross-references.

Monospace Output displayed on the screen.

UPPERCASE Names of files and directories. You can type filenames

and directory names in the dialog boxes or the command

line in lowercase unless directed otherwise.

SMALL CAPS Key names on the keyboard, such as D, ALT or F3.

CTRL+D Press a key while simultaneously pressing another key;

for example, press

CTRL and D simultaneously.

Finding Operating System Information

For more information on using the Windows NT operating system, refer to

the printed and online Windows NT documentation from Microsoft:

♦ For detailed information on installing and configuring Windows NT

Server, refer to the Windows NT Workstation Installation Guide.

♦ For detailed information on using the Windows NT Server operating

system, refer to the online Windows NT Workstation System Guide,

delivered on CD-ROM with the operating system, and to Windows NT

Help. You can purchase a printed copy of the System Guide from

Intergraph.

Page 11

Getting Documentation and Training

You can purchase additional system or software product documentation from

Intergraph.

♦ In the United States, contact your sales account representative, call the

Intergraph Order Desk at 1-800-543-1054, or send a fax to

1-800-548-3318 to place an order. If you call or fax the Order Desk,

have the document numbers ready for the items you wish to purchase.

♦ At international locations, contact the Intergraph subsidiary or

distributor from which you purchased your Intergraph system or

software to place an order.

To find information on training for Intergraph systems and products, or to

enroll in an available class, contact Intergraph Education Services at

1-800-240-3000.

Preface xi

Getting Telephone Support

If you experience problems with your Intergraph system or software, or have

questions about the information in this document, you can contact Intergraph

for help.

♦ In the United States, call the Customer Response Center at

1-800-633-7248 between the hours of 7:00 a.m. and 7:00 p.m. Central

Time, Monday through Friday (except holidays).

♦ At international locations, contact the Intergraph subsidiary or

distributor from which you purchased your Intergraph system or

software.

Have the following information readily available when you call:

♦ Workstation model number:

♦ Workstation serial number:

♦ Your name and telephone number.

♦ A brief description of the problem.

Page 12

xii Preface

Locate the model and serial numbers on a label on the base unit carton, or on

a label on the back of the base unit. Write these numbers in the spaces

provided above.

Using the Intergraph Bulletin Board Service

Available 24 hours a day, 7 days a week, the Intergraph Bulletin Board

Service (IBBS) is an electronic forum for Intergraph customers to exchange

information with Intergraph’s technical and marketing staff, and with other

Intergraph customers. You can use the IBBS to get technical support

information, documentation and training information, programs, and

software updates and fixes. The IBBS is also available for you to give

suggestions, make inquiries, and report problems.

To connect to the IBBS:

➤

1. Set your communications protocol for eight (8) data bits, no parity,

one (1) stop bit, and any baud rate up to 14,400.

2. Using a modem, dial the IBBS number, 1-205-730-8786. You can dial

1-205-730-6504 if you are using a 2,400 baud connection.

3. Mirror sites are maintained for international locations. Information on

these sites is available on Intergraph Online, Intergraph’s World Wide

Web server. Refer to “Finding Intergraph on the Internet” for more

information.

4. When connected, respond to the login request by keying in your user

ID. If you have not connected before, key in new to create a user ID.

Follow the menus to find what you need. If you are new to computer

bulletin boards, the IBBS provides clear choices and plenty of online help.

A text file that explains IBBS commands and organization is available for

you to download.

If you have trouble connecting to or using the IBBS, call the System

Operator (Sysop) at 1-205-730-1413, or send a fax to 1-205-730-1110.

Page 13

Using the Intergraph FAXLink

You can use the Intergraph FAXLink to get technical support information by

fax 24 hours a day, 7 days a week. To use FAXLink from a touch-tone

phone or fax machine phone:

♦ Call 1-800-240-4300 to get new user instructions, an index listing of

available documents, and an overview of the categories of available

information.

♦ Call 1-205-730-9000 to order the documents (up to 5 per call).

Follow the prompts provided to locate and deliver the information you need.

Finding Intergraph on the Internet

You can find Intergraph on the Internet in the following ways:

Preface xiii

♦ If you have a World Wide Web browser, connect to Intergraph Online,

Intergraph’s Web server, at http://www.intergraph.com.

♦ If you have an application that allows you to transfer files to and from a

system using File Transfer Protocol (FTP), connect to Intergraph’s

anonymous FTP site at ftp.intergraph.com.

♦ If you have an application that allows you to search and retrieve files

using Gopher, connect to Intergraph’s Gopher site at

gopher.intergraph.com.

♦ You can get information from Intergraph’s email server at

info@intergraph.com. Put HELP in the body of the message (the

subject line is ignored) to get information on such subjects as

Intergraph’s online services and where to get World Wide Web

browsers.

Page 14

xiv Preface

Learning About System Ergonomics

Please read the Ergonomics Guide included with your Intergraph system.

This document provides valuable information on ways to minimize repetitive

stress injuries for persons working with a computer.

Page 15

Chapter 1

Getting Started

The TDZ-300 and TDZ-400 desktop workstations are easy to set up and use.

Follow the instructions in this chapter to set up and start your system.

Unpacking

If you have not removed everything from the shipping carton, do so now and

verify you have the following equipment. The workstation carton contains

the following items:

♦ Workstation base unit

♦ Keyboard

♦ Mouse

♦ Footstands

♦ Base unit power cord

♦ Operating system and system software carton

1

The carton for the operating system and system software contains the

folllowing items:

♦ Windows NT software (CD-ROM and setup diskettes)

♦ Intergraph GL video display driver diskette

♦ Intergraph Quick-Fix Engineering (QFE) diskette

♦ Intergraph System Utilities (SYSUTIL) diskette

♦ Intergraph TDZ-300, TDZ-400 Desktop Online Reference diskette

Note: The workstation is delivered with the operating system and

associated system software installed on the system’s hard disk drive.

Page 16

2 Chapter 1 - Getting Started

If you ordered a monitor from Intergraph, its carton contains the following

items:

♦ Monitor

♦ Monitor power cord

♦ Video cable

♦ Documentation

Note: If any of the base unit or monitor parts were not delivered, call the

Customer Response Center immediately at 1-800-633-7248

Retain all packaging materials. If you return equipment for repair, you must

return it in the original packaging to obtain warranty service (if provided

under your contract agreement).

Setting Up

Before you begin setting up your workstation, determine where you want to

place the system. Keep these guidelines in mind:

♦ Place the base unit in an area where air can circulate freely around it.

The back panel of the base unit should have at least a 3-inch clearance,

and the sides should have at least a 1-inch clearance unless the base unit

is set in the vertical position.

♦ Do not expose the system to high levels of dust, smoke, or moisture.

♦ Place the system in an area where the temperature range stays between

10 °C and 26 °C (50 °F to 80 °F). The optimum operating temperature is

21 °C (70 °F).

♦ Place the system in an area where the humidity stays between 20% and

80% (non-condensing). The optimum operating humidity is 50% (noncondensing)

To set up the workstation:

➤

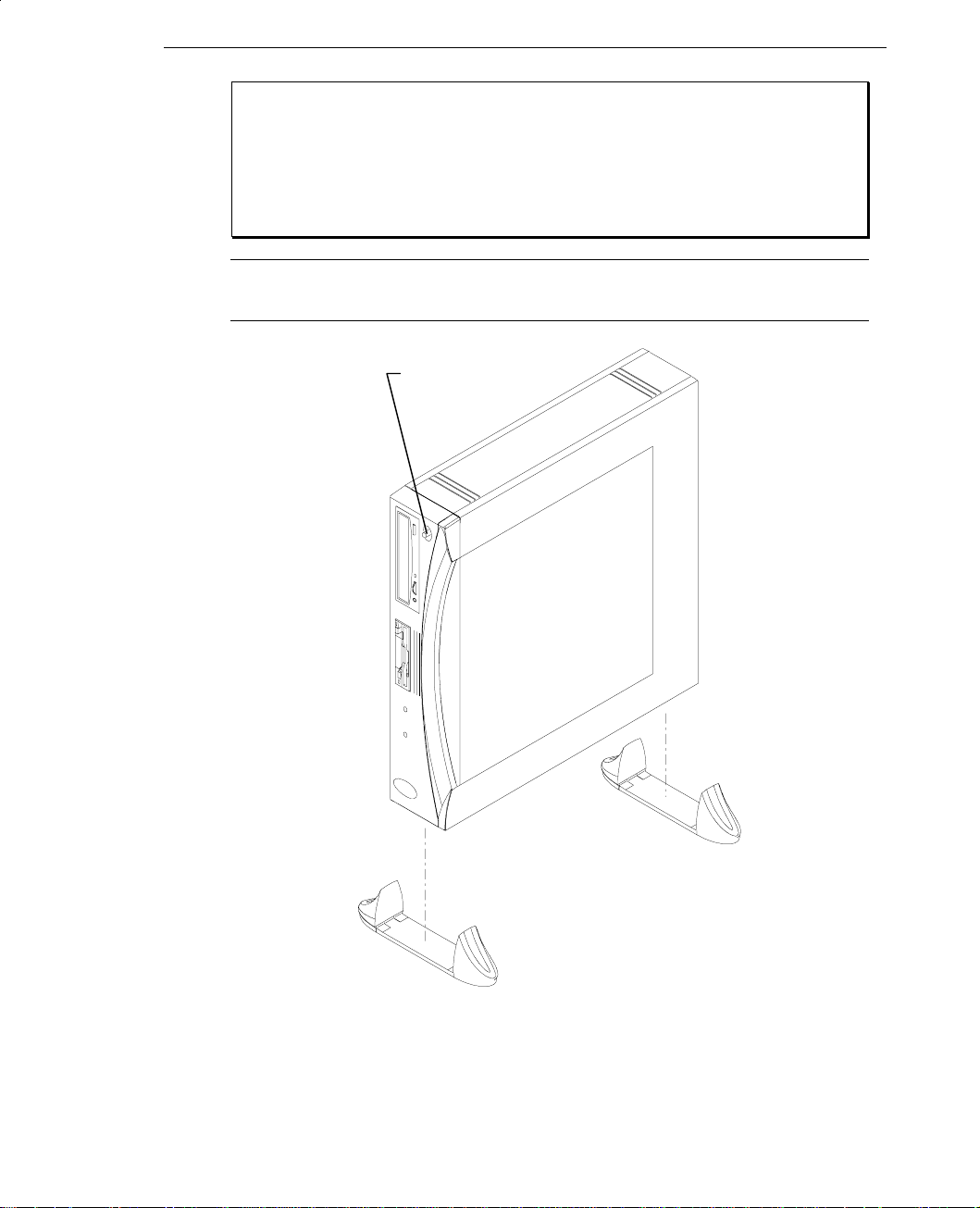

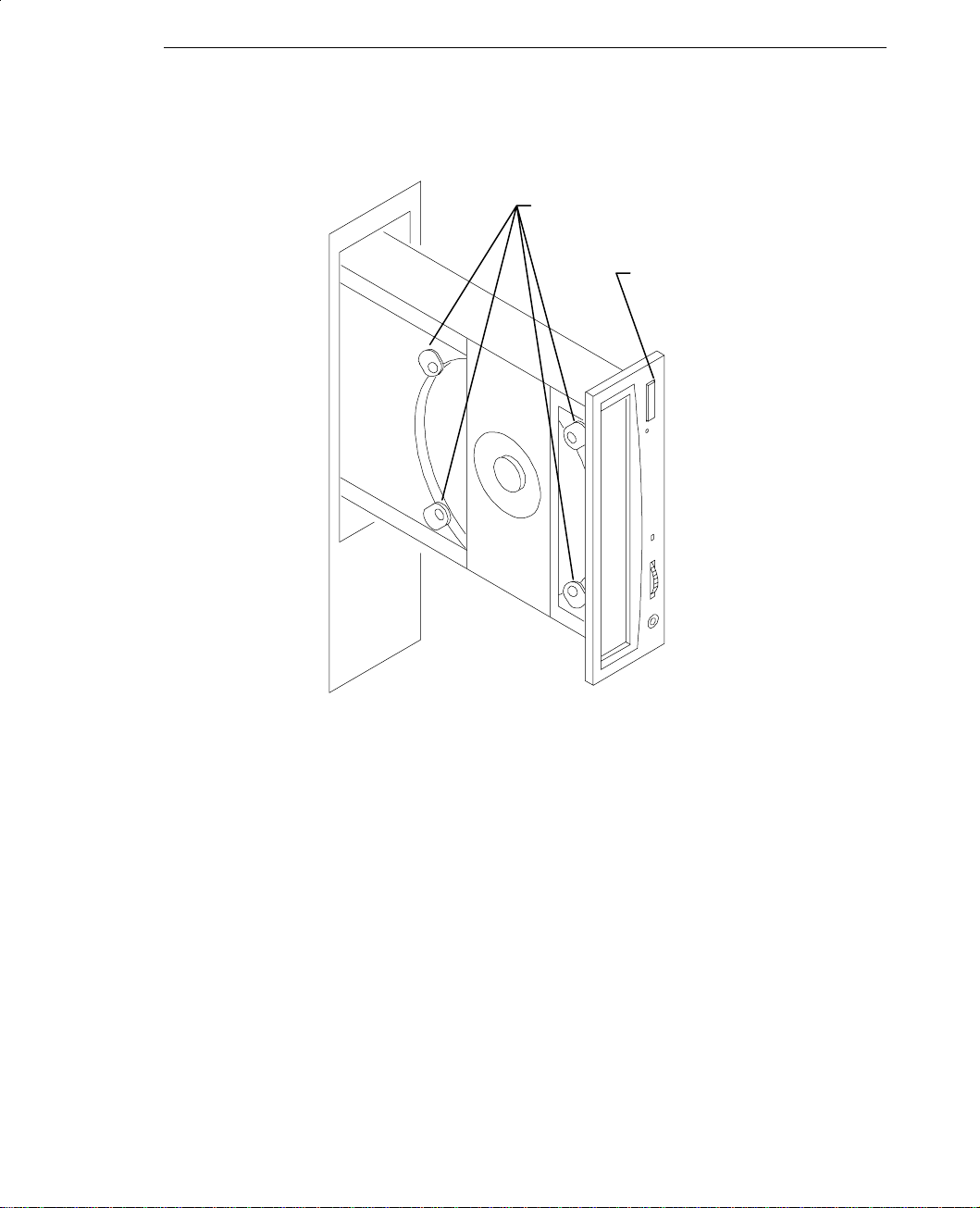

1. If putting the base unit in a vertical position, set the footstands on the

bottom of the base unit as shown in the following figure. Place the

back footstand between the ribs on the back and side of the base unit.

Page 17

Chapter 1 - Getting Started 3

WARNING

To avoid personal injury or equipment damage, and to allow proper

airflow, you must use the footstands when setting the base unit in the

vertical position.

Note: Ensure the power switch is at the top when setting the base unit in

the vertical position.

Power Switch

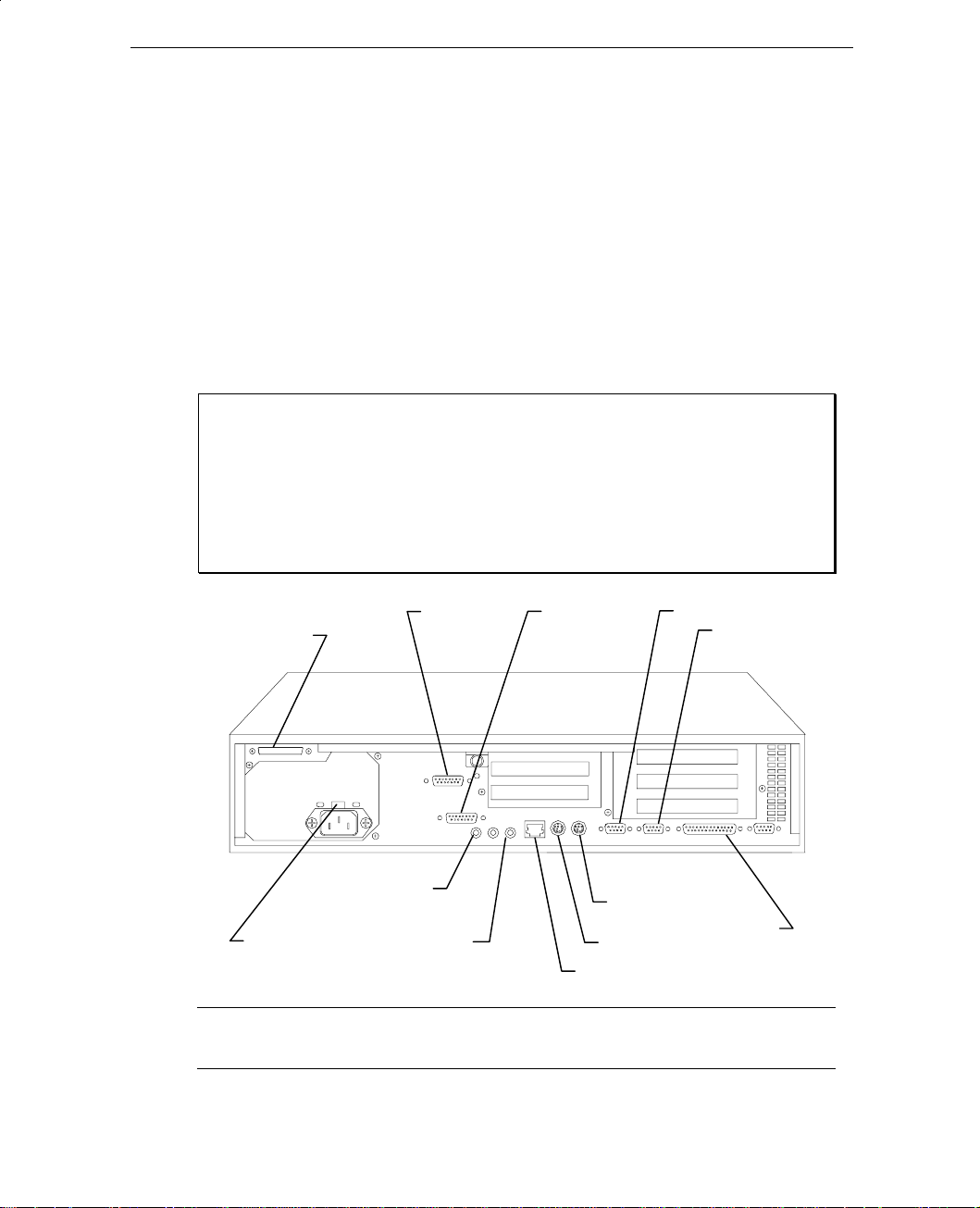

2. Connect the keyboard cable to the Keyboard port on the back of the

base unit. Refer to the following figure.

Page 18

4 Chapter 1 - Getting Started

Keyboard

3. Connect the audio cables (bundled with the keyboard cable) to the

audio jacks. The cable labeled Mic connects to the Microphone jack,

and the cable labeled Audio connects to the Line Out jack. Refer to

the following figure.

4. Connect the mouse cable to the Mouse port on the back of the base

unit. Refer to the following figure.

5. Connect the remaining cables, such as Ethernet (AUI or 10Base-T

ports), printer (parallel port), and modem cables (COM1 and COM2

ports) to their ports on the back of the base unit. Refer to the

following figure.

If you are using cables not supplied by Intergraph, you must use

shielded cables to prevent excessive electromagnetic interference

(EMI). Intergraph cables are designed to reduce the amount of EMI

produced by the system.

WARNING

Fast

SCSI-2

AC Voltage

Switch

Microphone

Line Out

Ethernet

AUI

MIDI

Mouse

Ethernet 10Base-T

COM1

COM2

Parallel

Note: The ports on the back on the base unit are labeled using PC 95

compliant icons.

Page 19

Chapter 1 - Getting Started 5

WARNING

Do not connect a MIDI or game cable to the Ethernet AUI port. This

will short out the local area network on which the system resides.

6. Set the power supply range switch to the proper setting for your

country. If you do not know the voltage for your location, contact

your local utilities.

7. Ensure the power switch on the front of the base unit is in the out

position. If the power switch is in, power will be applied when the

base unit power cord is plugged into the AC outlet.

8. Connect the power cords for the monitor and base unit to an

Uninterruptible Power Supply (UPS) or a grounded three-prong wall

outlet. Then connect the power cords to the base unit and the monitor.

9. Connect the video cables as described in “Connecting the Video

Cables.”

10. Start the system as described in “Starting the System.”

Connecting the Video Cables

This section describes the video cable hookups for systems using GLZ1,

GLZ1T, GLZ2, GLZ3, or GLZ5 graphics.

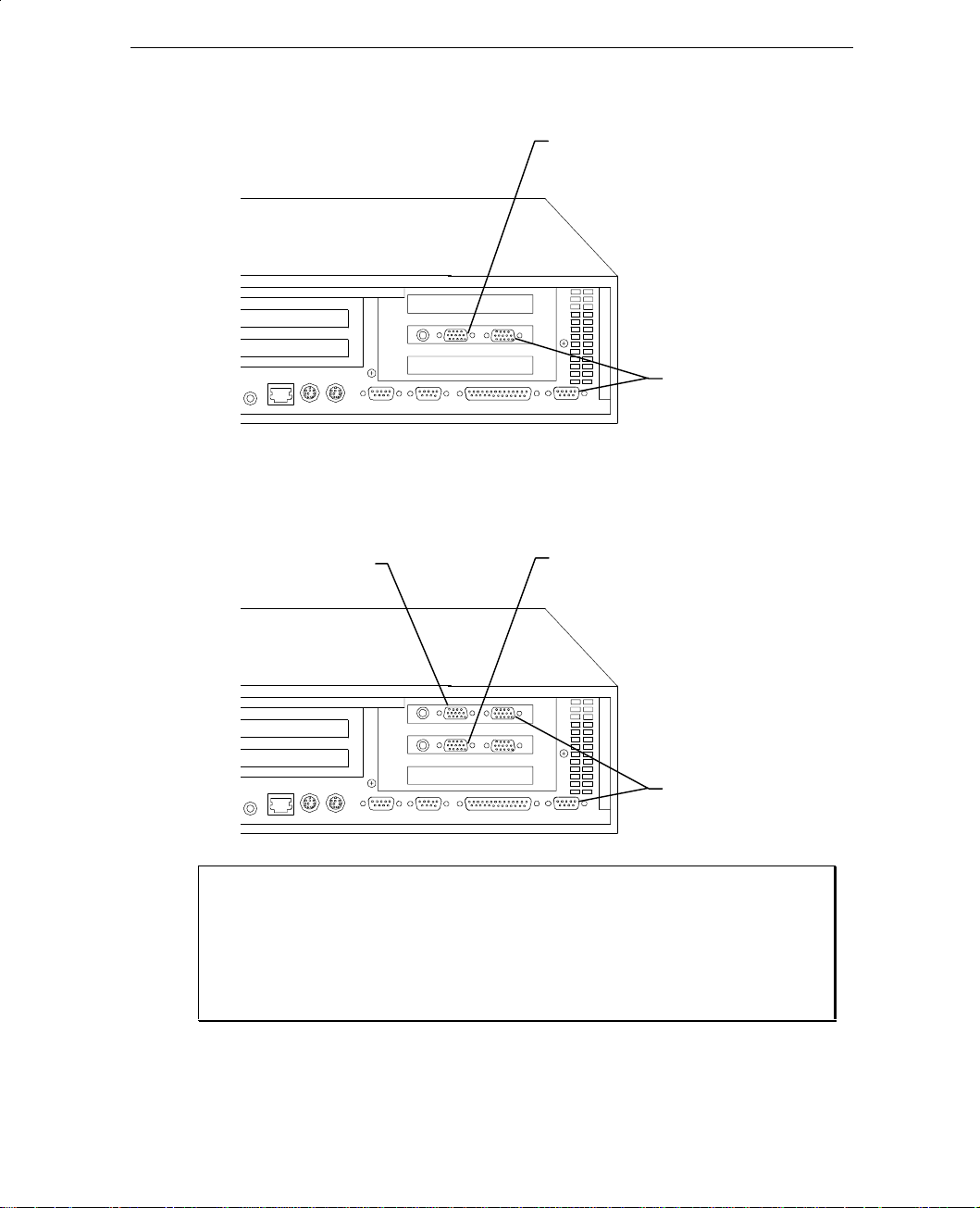

For GLZ1 (single- or dual-screen) or GLZ3 (single-screen):

➤

1. Connect the video cable for each monitor to a Video port on the back

of the base unit and to the monitor. Refer to the following figures.

2. Connect the VGA loopback cable to the VGA Loopback ports on the

back of the base unit. Refer the following figures.

Page 20

6 Chapter 1 - Getting Started

For single-screen GLZ1 or GLZ3:

For dual-screen GLZ1:

Video Port

VGA Loopback

Ports

Video Port

(Primary

Monitor)

Video Port

(Secondary

Monitor)

VGA Loopback

Ports

CAUTION

Do not connect the video cables for the monitors to either VGA

Loopback port. If you do, the system will boot up to the blue screen

and stop, or video will not display at all.

Page 21

Chapter 1 - Getting Started 7

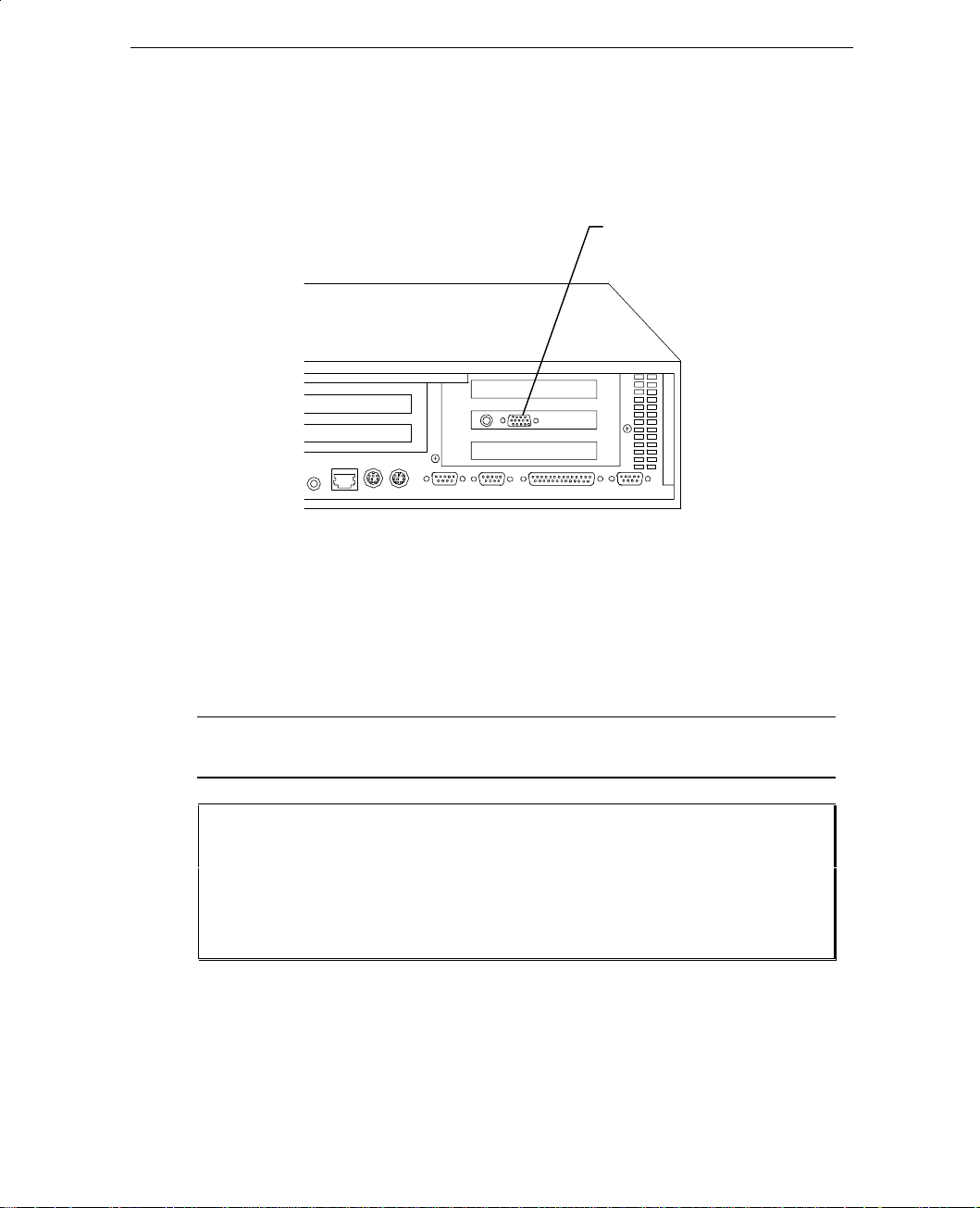

For GLZ1T (single-screen) or GLZ5 (single-screen):

➤

1. Connect the video cable for the monitor to the Video port on the back

of the base unit and to the monitor. Refer to the following figure.

2. Connect the VGA loopback cable to the VGA Loopback ports on the

back of the base unit. Refer the following figure.

Video Port

VGA Loopback

Ports

CAUTION

Do not connect the video cable for the monitor to either VGA Loopback

port. If you do, the system will boot up to the blue screen and stop, or

video will not display at all.

Page 22

8 Chapter 1 - Getting Started

For GLZ2 (single-screen):

➤

Connect the video cable for the monitor to the Video port on the back of the

base unit and to the monitor. Refer to the following figure.

Video Out Port

Starting the System

The workstation is delivered with the operating system installed on the

system’s hard disk drive. After setting up the system, you can start it and

begin using it.

Note: If you need to re-install the operating system, refer to Appendix A,

“Installing System Software.”

If the AC voltage switch on the back of the base unit is not set correctly

for your location, the workstation will be seriously damaged when the

power switch is turned on.

WARNING

Page 23

Chapter 1 - Getting Started 9

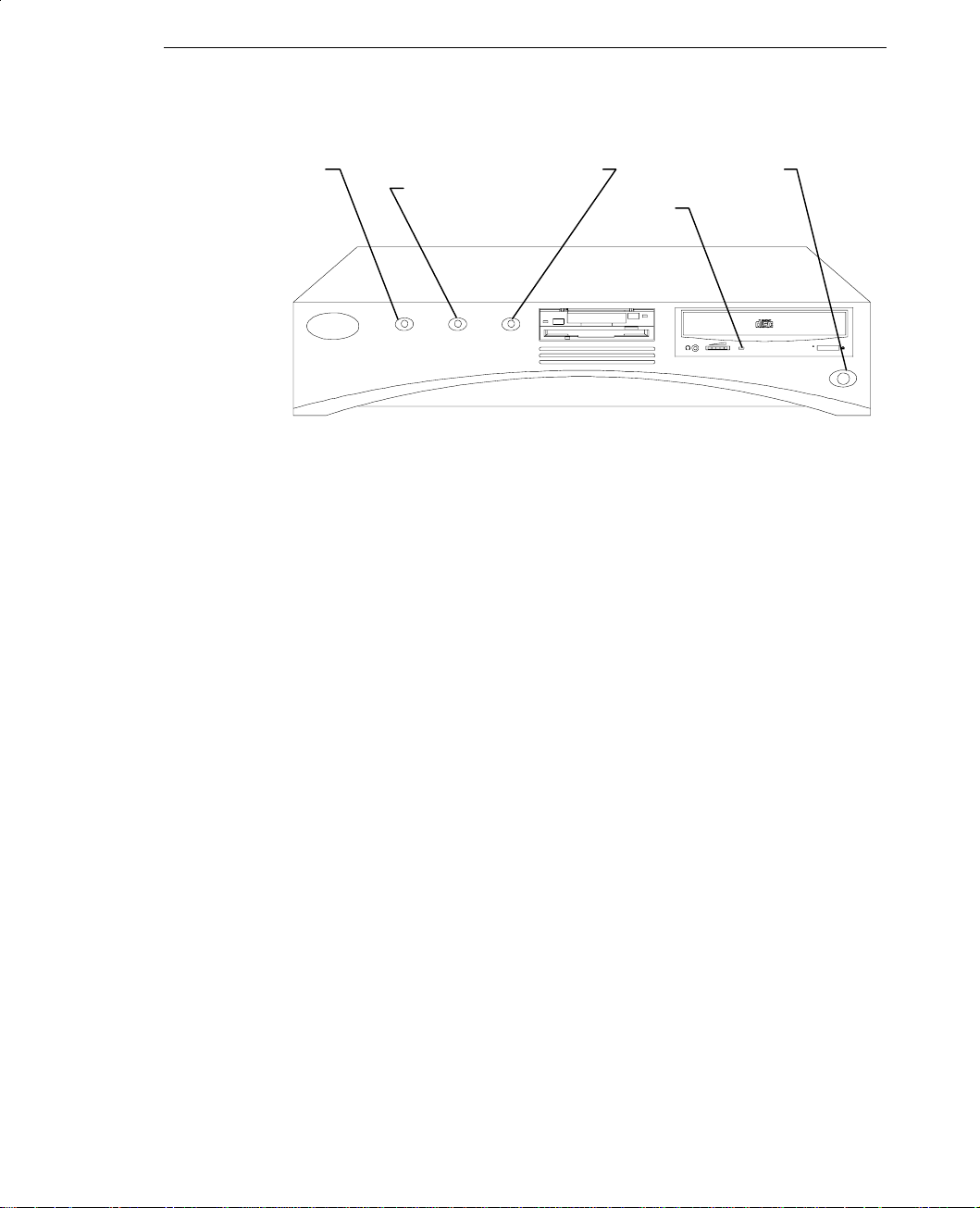

The following figure shows the front of the base unit.

Reset Disk Power Power

Switch Activity On LED Switch

LED CD-ROM

LED

To start the system:

➤

1. Press the power switch on the base unit and the power switch on the

monitor to turn on power to the system. The following events occur:

♦ The power on LED lights green.

♦ The CD-ROM drive LED blinks green and amber.

♦ The BIOS boot screen displays the American Megatrends logo.

♦ The boot screen displays.

2. At the initial Windows NT boot screen, select the following option:

Windows NT Workstation 3.51 [VGA Mode]

After additional messages display, Windows NT Workstation starts in

VGA mode, allowing you to log on and configure your system’s date,

time, and video display.

3. Press

CTRL+ALT+DELETE to display the Windows NT Workstation

logon dialog. The first time the logon dialog displays,

Administrator displays in the Username box. The From and

Password boxes are blank.

4. Select OK or press

ENTER to log on to Windows NT Workstation. For

instructions to create a user account and join a workgroup or domain,

refer to the online Windows NT Workstation System Guide.

Page 24

10 Chapter 1 - Getting Started

5. Use the Date/Time application in the Windows NT Control Panel to

set the system date and time. Refer to the online Windows NT

Workstation System Guide for instructions on using the applications in

the Control Panel.

6. Configure the video display and TCP/IP networking software as

described in Chapter 2, “Configuring the System.”

7. Create an Emergency Repair Disk for your system using the Windows

NT Repair Disk utility (RDISK.EXE). The files on the Emergency

Repair Disk can restore the original contents of a damaged Windows

NT Registry (that is, at the time Windows NT was installed), along

with the standard Windows NT drivers. Refer to Windows NT Help

for information on creating an Emergency Repair Disk, and to the

Windows NT Workstation Installation Guide for information on using

it.

Note: If your system came pre-configured from Intergraph, you can run the

Repair Disk utility from an icon in the Startup group of Program

Manager.

Observing System Precautions

Observe the following precautions when using the system.

♦ When restarting the system, use the operating system controls instead of

pressing the reset button or turning the power switch off and on. Use the

reset button and power switch only when instructed, or as the last

alternative for restarting the system.

♦ Never turn the base unit off when the disk access LED is on.

♦ After powering off the base unit, wait at least 30 seconds before

powering on again to allow the system to power cycle.

♦ Periodically run virus scan software to ensure your system files are not

corrupted.

Page 25

Chapter 1 - Getting Started 11

♦ If you placed the system in a vertical position, press the eject/load button

to open the CD-ROM drive tray. Rotate or slide at least three of the

media tabs so that when you insert a compact disc, it will not fall out.

Media Tabs

Eject/Load

Button

Using the Online Reference

Detailed technical information about your workstation is delivered in an

Online Reference document. This Windows Help-based document is

delivered on diskette in the form of a self-extracting archive file named

TDZDTOR.EXE.

To install and display your system’s Online Reference:

➤

1. Insert the diskette containing the Online Reference into the floppy

diskette slot of the combo drive.

2. Copy the TDZDTOR.EXE and README.TXT files from the diskette

to a directory on your system’s hard disk drive; then remove the

diskette from the combo drive.

Page 26

12 Chapter 1 - Getting Started

3. Open TDZDTOR.EXE. The following files are extracted:

GLZX.CNT

GLZX.HLP

SUPPORT.CNT

SUPPORT.HLP

TDZDTOR.CNT

TDZDTOR.HLP

4. Ensure the extracted files remain in the same directory for the Online

Reference to work properly. After the files have been extracted, you

can delete TDZDTOR.EXE from the system’s hard disk drive.

5. Open TDZDTOR.HLP to display the Online Reference.

You can obtain the latest version of your system’s Online Reference from the

Intergraph Bulletin Board Service (IBBS) or Intergraph’s FTP site.

To receive Online Reference updates:

➤

1. From the IBBS login, go to Intergraph Product Centers → Systems

and Networking → File Libraries → Technical Notes. From the FTP

login, go to /bbs/ssd/note.

2. Look for self-executing (.EXE) archive files whose names start with

TD and end in OR (such as TDZDTOR.EXE or TDZDSOR.EXE).

The file descriptions in the IBBS or the FTP index should note the

title and part number of each Online Reference.

3. Download the file to your system.

4. Open the .EXE file and review the README.TXT file. Follow the

instructions in the README.TXT file to properly install the new

Online Reference.

Obtaining Windows NT Updates

Microsoft Service Packs contain the latest improvements and system fixes

that have been requested for the Windows NT operating system. Service

Packs are created by Microsoft approximately every three months. You may

obtain Service Packs from the following sources:

Page 27

Chapter 1 - Getting Started 13

♦ Intergraph Bulletin Board Service (IBBS)

♦ Microsoft Inside Sales

♦ CompuServe

♦ Microsoft FTP locations

The service packs are for post-release support only. The product media for

Windows NT will not include improvements or fixes in a given Service Pack

until the next major Windows NT release.

CAUTION

If Intergraph provides a Service Pack through the IBBS, it has been

certified against Intergraph hardware as described with the

announcement of its availability. If you obtain a Service Pack from any

other source, be aware that it may not have been certified with your

Intergraph hardware.

Ensuring PC Card Support

Your system may have a PC Card slot for use with devices based on

standards developed by the Personal Computer Memory Card International

Association (PCMCIA). Windows NT Workstation 3.51 provides support

for PC Card devices.

Note: Windows NT 3.51 provides basic support for PC Card devices, and

not all PC Card devices are supported. You must shut down a

system running Windows NT 3.51 before inserting or removing a PC

Card device.

Page 28

14 Chapter 1 - Getting Started

Page 29

Chapter 2

Configuring the System

After setting up the system hardware and starting the system for the first

time, you can configure it for your use. Follow the instructions in this

chapter to configure the system’s video display and TCP/IP networking

software.

Before You Begin

Before you begin configuring the system, get and record the following

TCP/IP networking information from your network administrator:

♦ Internet Protocol (IP) address for

your system:

15

♦ IP subnet mask for your system:

♦ IP domain name for your network:

♦ IP address for your network’s

default gateway:

♦ IP addresses for your network’s

Domain Name System (DNS)

servers, if any:

The Windows NT delivery media contain software and drivers for both

Reduced Instruction Set Computing (RISC)- and Intel-based systems. When

installing Windows NT distribution files, make sure to install them from the

\I386 directory (the Intel software directory) on the delivery media. For

example, if you are installing a device driver from the Windows NT

CD-ROM, key in the following when asked for the path to the file, where

drive is the drive letter for the CD-ROM drive:

drive:\i386

Page 30

16 Chapter 2 - Configuring the System

About the System’s Video Display

When you start your system for the first time, it uses the Windows NT

Workstation VGA display driver to run the video display. To enable your

system to use its installed GLZ video display adapter, you must configure the

video display to use the Intergraph GL video display driver. This driver is

installed on the system’s hard disk, and is also delivered on a backup

diskette.

The Intergraph GLZ video display adapter is a 3D graphics accelerator.

GLZ provides a number of advanced graphics features, including hardware

acceleration of OpenGL and Windows NT graphics operations. GLZ is

available in several configurations, as follows:

♦ GLZ1 -- 12 MB of frame buffer memory, resolutions up to 1 megapixel

(1152 x 864).

♦ GLZ1T -- same features as GLZ1, with support for texture mapping.

♦ GLZ2 -- 24 MB of frame buffer memory, resolutions up to 1600 x 1280.

♦ GLZ3 -- same features as GLZ1, with support for geometry acceleration.

♦ GLZ4 -- same features as GLZ2, with support for geometry acceleration.

♦ GLZ5 -- same features as GLZ3, with support for texture mapping.

♦ GLZ6 -- 34 MB of frame buffer memory, hardware-accelerated support

for texture mapping and geometry acceleration, resolutions up to 1600 x

1280.

If your system is set up for dual-screen display, the video display driver

treats the combined display area of the dual screens as a single canvas that

covers both screens. In this Full Canvas style, windows centered on the

canvas are split between the two screens. This includes most system dialog

boxes.

When the system is running Windows NT Workstation 3.5 (or later), the

video display driver can treat the left or top monitor as the primary screen,

while the full desktop extends across both screens. This Primary Left/Top

style results in different windowing behaviors than those displayed by

default, including the following:

Page 31

Chapter 2 - Configuring the System 17

♦ Dialogs display fully and applications maximize on the primary screen.

♦ Most centered windows center on the primary screen.

♦ Testing a dual-screen mode from the Display Properties application

actually tests only the corresponding single-screen mode.

♦ Toolbars may not use the whole desktop.

♦ Screen savers may work only on the primary screen.

To select a dual-screen style, refer to the configuration instructions for the

GL video display driver later in this chapter.

Configuring the Video Display

Use Intergraph’s Video Configuration application in the Windows NT

Control Panel to change the configuration of the GL video display driver.

The Video Configuration application controls basic and advanced display

attributes of the GL video display driver.

Note: Windows NT provides a Display application in the Control Panel for

changing the video display. Use the Video Configuration

application instead of the Windows NT Display application to

configure the GL display driver on your system.

Starting and Stopping Video Configuration

To start Video Configuration:

➤

Open Video Config in the Windows NT Control Panel. The Video

Configuration dialog displays.

Page 32

18 Chapter 2 - Configuring the System

To stop Video Configuration:

➤

Select OK to close Video Configuration using the new settings, or select

Cancel to close Video Configuration without changing the settings. If you

changed settings other than contrast or gamma correction, restart the system.

Note: If you have not changed the default video display driver, ensure that

you select the Windows NT Workstation option (not the

VGA option) on the boot menu. Refer to “Changing the Default

Video Display Driver” later for more information.

Note the following about the operation of Video Configuration:

♦ Supported options display in black; unsupported options display in gray.

♦ If a video display driver is not running, the main dialog of Video

Configuration tells you that certain options may not be supported.

♦ Any changes you make using Video Configuration are updated in the

Windows NT Display application after you restart the system.

The options provided by Video Configuration vary, depending on the

specific GLZ display adapter in use. For more information, see the online

Help available in Video Configuration, as well as your system’s Online

Reference.

Page 33

Chapter 2 - Configuring the System 19

Changing GL Video Display Configuration

To change GL video display configuration:

➤

1. Start Video Configuration.

2. Move the Desktop Area scroll bar to set the display resolution. Some

options may not be supported.

3. Select the number of colors from the Color Palette list.

4. Select the refresh rate from the Refresh Frequency list.

5. Select the monitor type from the Monitor Type list (GLZ1, GLZ3, and

GLZ5 only support multi-sync monitors, and this option is unavailable

for selection).

Note: By default, the GL video display driver should determine the type of

monitor connected to the system by querying the monitor if an

InterVue monitor is connected to the system.

6. Select Dual, if applicable. This enables Orientation and Style.

7. Select the screen display orientation, if applicable.

8. Select the screen display style, if applicable.

9. Select Stereo, if applicable.

10. Select the Preferences button, if applicable. The Preferences dialog

displays, letting you configure switching buffers during OpenGL

double-buffering operations.

Page 34

20 Chapter 2 - Configuring the System

Check the Synchronize Buffer Swap to Vertical Sync check box (the

default) to make the GL display driver wait for a vertical retrace of the

monitor to occur before switching the displayed buffer. Clear the

check box to make the GL display driver switch the displayed buffer

without waiting. Select OK to return to the Video Configuration

dialog.

11. Select Color Calibration to display the Color Calibration dialog and

set the contrast and gamma correction value(s).

12. Select the screen to modify, if applicable.

13. Move the Contrast scroll bar to set the contrast value. The default

contrast value is 100%.

14. Select a Gamma Correction option, and choose the value or specify a

gamma correction file.

15. If you selected Gamma File, select Test to verify the effect of the

specified gamma correction file. The system displays a color

reference graphic for 5 seconds.

Page 35

Chapter 2 - Configuring the System 21

16. Select OK to return to the Video Configuration dialog with the

modified gamma correction/contrast values in effect, or select Cancel

to return to the Video Configuration dialog without updating the

gamma correction/contrast.

17. Stop Video Configuration.

If you use 3D applications with the GL driver, the video display may update

slowly when you drag objects across it. To avoid this inconvenience, turn

off full drag before using 3D applications with the GL driver.

To turn off full drag:

➤

1. Open Desktop in the Windows NT Control Panel. The Desktop

Settings dialog displays.

2. Under Applications, clear the Full Drag check box.

3. Select OK.

Windows NT lets you use software cursors, such as decorated or animated

cursors, in place of the standard cursor. If you use a software cursor while

running an OpenGL application, the performance of that application will

drop sharply whenever you position the software cursor in that application’s

window. For optimum performance of OpenGL applications, Intergraph

recommends that you use only the standard cursor.

Changing the Default Video Display Driver

After configuring the video display and restarting the system, you can

configure the system to use the Intergraph GL video display driver by

default.

To change the default video display driver:

➤

1. Open System in the Windows NT Control Panel. The System dialog

displays.

2. Under Operating System, select

from the Startup list.

3. Select OK.

Windows NT Workstation 3.51

Page 36

22 Chapter 2 - Configuring the System

Correcting Video Display Problems

If the system’s video display is black, not synchronized, or distorted after

you restart the system, you may have a video configuration problem. Do not

press

CTRL+ALT+DEL to log on to the Windows NT operating system.

Instead, try to correct the problem by using the Last Known Good option to

return the system to the last know good configuration recorded by Windows

NT:

To use the Last Known Good option:

➤

1. Press the Reset button on the front panel of the base unit to restart the

system.

2. Press the space bar at the following prompt:

Press space bar NOW to invoke the Last Known Good Menu

If using the Last Known Good option fails to correct the video display

problems, you can obtain a functional video resolution by restarting the

system in VGA mode.

To restart the system in VGA mode:

➤

1. Press the Reset button on the front panel of the base unit to restart the

system.

2. At the boot screen, select the following option:

Windows NT Workstation 3.51 [VGA mode]

After logging on to Windows NT in VGA mode, check for the following

common configuration problems and solutions:

♦ A multi-sync monitor type is selected in Video Configuration, but an

InterVue monitor is connected to the system. Select the InterVue

monitor type.

♦ A multi-sync monitor is connected to the system, but a multi-sync

monitor type is not selected in Video Configuration, and the display

driver cannot determine this by querying the monitor. Select an

appropriate multi-sync monitor type.

Page 37

Chapter 2 - Configuring the System 23

♦ A selected resolution, depth, or refresh rate is not supported by the

multi-sync monitor. Try different settings in Video Configuration.

♦ The Dual Screen option is selected in Video Configuration, but only one

video board is detected. Clear the Dual Screen option.

Restart the system and select

reconfigured video display driver. If problems persist, contact the Intergraph

Customer Response Center for help.

Windows NT Workstation 3.51 to use the

Configuring TCP/IP Networking

Configure the TCP/IP networking software using the networking information

you recorded at the beginning of this chapter.

To configure the TCP/IP networking software:

➤

1. Open Network in the Windows NT Control Panel. The Network

Settings dialog displays.

2. Select Change next to the Computer Name field. The Computer Name

dialog displays.

3. Type a name for the computer and select OK.

4. If appropriate, select Change next to the Workgroup field. The

Domain/Workgroup Settings dialog displays.

5. Type a new workgroup name and select OK.

6. Select TCP/IP Protocol from the Installed Network Software list, and

then select Configure. The TCP/IP Configuration dialog displays.

7. Type your system’s Internet Protocol (IP) address and IP subnet mask,

and the IP address of your network’s default gateway.

8. If your network uses the Domain Name System (DNS), select DNS.

The DNS Configuration dialog displays.

9. Type your network’s IP domain name and the addresses of your

network’s DNS servers, and then select OK.

Page 38

24 Chapter 2 - Configuring the System

10. In the TCP/IP Configuration dialog, select OK.

11. Restart the system.

Page 39

Chapter 3

Opening and Closing the Base Unit

This chapter describes opening and closing the system’s base unit, taking

precautions to avoid electrostatic discharge, and attaching an antistatic wrist

strap.

Removing the Top Cover

WARNING

Before opening the base unit, turn the system power off. Use caution

when removing the top cover to avoid injury.

25

To remove the top cover:

➤

1. Pull the plunger out and rotate it to lock it in the open position.

ISA I/O Panel

Plunger

Page 40

26 Chapter 3 - Opening and Closing the Base Unit

2. Lift up the top cover above the ISA I/O panel and pull up and back.

3. Set the top cover aside. The following figure shows inside the base

unit.

Peripheral

Brace

System

Board

Riser Card

Auxiliary Di sk

Drive Brac k et

Memo ry So ckets

SCSI Terminator

Card

Power Supply

CD-ROM

Drive

Combo

Drive

4. Take precautions to avoid electrostatic discharge, as described in the

next section, whenever the base unit is open.

Avoiding Electrostatic Discharge

Some of the sensitive components inside the base unit can be damaged by

static electricity. To minimize this possibility, take the following

precautions when working with the internal components of the system to

avoid electrostatic discharge.

♦ Touch the bare metal of the base unit to discharge any accumulated

electrostatic charge.

Page 41

Chapter 3- Opening and Closing the Base Unit 27

♦ Do not service the system on surfaces known to have high electrostatic

buildup, such as rugs and carpets. Work on a static-safe surface instead.

♦ Handle all printed circuit boards as little as possible and by the edges

only. Leave new parts in their protective packaging until you install

them.

♦ To maintain ground, do not unplug the power cord from the base unit,

AC outlet, or UPS.

♦ After opening the base unit, attach an antistatic wrist strap as described

in the next section.

Attaching an Antistatic Wrist Strap

Use a disposable or reusable antistatic wrist strap when servicing or

upgrading the workstation.

Note: There is no increased risk of electrical shock when using an

antistatic wrist strap. If the wrist strap does not snugly contact bare

skin, static protection will not be effective.

To attach a disposable antistatic wrist strap:

➤

1. Remove the wrist strap from the envelope.

2. Unfold the wrist strap and wrap the exposed adhesive side firmly

around your bare wrist.

3. Peel the liner from the wrist strap copper foil. Attach the adhesive

side of the copper foil to a bare flat metal surface (electrical ground)

inside the base unit.

Note: After using a disposable wrist strap once, you cannot used it again.

Page 42

28 Chapter 3 - Opening and Closing the Base Unit

To attach a reusable antistatic wrist strap:

➤

1. Attach the wrist strap to the ground loop shown in the following

figure.

Ground Loop

2. Slip the elastic end of the wrist strap snugly around your bare wrist.

Note: The metal conductor bead in the elastic must contact bare skin.

Replacing the Top Cover

Replacing the top cover is almost as easy as removing it. Follow these quick

steps:

To replace the top cover:

➤

1. When closing the system, disconnect the wrist strap from the metal

inside the base unit.

Page 43

Chapter 3- Opening and Closing the Base Unit 29

2. Replace the top cover by aligning the tabs on the front of the top cover

with the notches behind the faceplate.

3. Lower the back of the top cover and slide it into place.

4. Turn the plunger to lock the top cover to the base unit.

Page 44

30 Chapter 3 - Opening and Closing the Base Unit

Page 45

Chapter 4

Maintaining the System

This chapter describes cleaning the system’s exterior surfaces, replacing

system parts, and reprogramming the flash EPROM with a new Basic

Input/Output System (BIOS).

Cleaning the System

Follow these guidelines for cleaning the system.

CAUTION

Power off the system before cleaning the exterior surfaces, mouse, and

keyboard. Do not clean the CD-ROM drive.

31

Exterior Surfaces

Use mild cleaning detergent and a clean cloth to clean the monitor screen

and the exterior surfaces of the base unit.

Mouse

On the bottom of the mouse, a retaining ring holds the tracking ball in place.

To clean the mouse, remove the retaining ring and turn the mouse over; the

tracking ball will fall out. Blow gently into the opening. Clean the tracking

ball and rollers with a cotton swab and alcohol. Replace the tracking ball

and the retaining ring.

Keyboard

Dust the keyboard with a dry cloth. Aerosol cleaners are commercially

available to remove the dust between the keys of the keyboard. Never allow

moisture on the keyboard or the surface beneath the keys.

Page 46

32 Chapter 4 - Maintaining the System

Replacing System Parts

This section describes replacing the following parts of the system:

♦ Combo drive

♦ CD-ROM drive

♦ System hard disk drives

♦ Auxiliary hard disk drives

♦ SCSI termination card

♦ Riser card

♦ System board

♦ Power supply

You will need the following tools to service the system:

♦ Quarter-inch nutdriver

♦ No. 1 Phillips screwdriver

♦ No. 2 Phillips screwdriver

♦ Three-sixteenth-inch nutdriver

♦ Five-sixteenth-inch or 8 mm nutdriver

♦ Small single-slot screwdriver

Open the base unit, take precautions against electrostatic discharge, and

attach an antistatic wrist strap as described in Chapter 3, “Opening and

Closing the Base Unit,” before replacing any parts. After replacing system

parts, close the base unit as described in Chapter 3.

CAUTION

The parts inside the base unit are designed with very tight tolerances.

Some force is required to remove or insert parts. However, if the part is

not removing or installing properly, ensure that there are no

obstructions hindering the part.

Page 47

Chapter 4 - Maintaining the System 33

Combo Drive

To remove the combo drive:

➤

1. Lift the combo drive out of the base unit and disconnect the ISA bus

cables, power cable, and floppy cable. Note the position of pin 1

(identified by the red stripe) on the floppy cable as shown.

Combo Drive

Floppy

Cable

Red

Stripe

Power

Cable

ISA Bus

Cables

Page 48

34 Chapter 4 - Maintaining the System

2. Using a No. 1 Phillips screwdriver, remove the four screws holding

the combo drive to the support bracket.

Screws

Support

Bracket

To install the new combo drive:

➤

1. Mount the replacement combo drive to the support bracket using the

four screws removed previously.

2. Connect the ISA bus cables, power cable, and floppy cable to the

combo drive.

3. Slide the combo drive through the faceplate. Ensure the bracket fits

into the peripheral brace.

4. Close the base unit.

Page 49

Chapter 4 - Maintaining the System 35

CD-ROM Drive

To remove the CD-ROM drive:

➤

1. Remove the combo drive as described in “Replacing the Combo

Drive,” leaving the cables attached.

2. Disconnect the power cable, SCSI cable and audio cable from the

CD-ROM drive, as shown in the following figure.

SCSI

Cable

CD-ROM

Drive

Audio Cable Power Cable

3. Disconnect the audio cable from the system board connector.

4. Using a No. 1 Phillips screwdriver, remove the four Phillips screws

holding the CD-ROM drive to the support bracket.

5. Remove the CD-ROM drive from the base unit by pushing it through

the face plate.

Page 50

36 Chapter 4 - Maintaining the System

To install the new CD-ROM drive:

➤

1. Disable SCSI termination and set the SCSI ID to 4. Refer to the

documentation delivered with the CD-ROM drive for instructions.

2. Insert the new CD-ROM drive through the front panel.

3. Secure the CD-ROM drive to the support bracket using the four

screws removed previously.

4. Connect the SCSI cable and power cable to the CD-ROM drive. The

SCSI cable is keyed to ensure proper insertion, so that the red stripe

(pin 1) is adjacent to the power connector.

5. If installing an Intergraph CD-ROM drive, the audio cable is already

connected to the drive. Connect the loose end of the audio cable to its

system board connector.

Note: If installing a non-Intergraph CD-ROM drive, use the audio cable

delivered with the new CD-ROM drive.

6. Replace the combo drive.

7. Close the base unit.

System Hard Disk Drive

The system hard disk drive is located under the CD-ROM drive.

To remove the system hard disk drive:

➤

1. Remove the CD-ROM drive as described in “CD-ROM Drive.”

2. Disconnect the internal SCSI cable and the power cable from the hard

disk drive.

Page 51

Chapter 4 - Maintaining the System 37

3. Using a No. 2 Phillips screw driver, remove the power switch cable

from the chassis.

Screw

Ground

Wire

Power

Switch Cable

Page 52

38 Chapter 4 - Maintaining the System

4. Using a No. 2 Phillips screwdriver, remove only the two screws on the

side of the hard disk drive as shown in the following figure. Do not

remove the grommets.

Mounting

Bracket

System Hard

Disk Drive

5. Slide the hard disk drive toward the power supply and then out of the

base unit.

6. Using a No. 2 Phillips screwdriver, remove the other two screws and

grommets from the side of the hard disk drive.

To install the new hard disk drive:

➤

1. Disable SCSI termination and set the SCSI ID to the same SCSI ID as

the previous hard disk drive. Refer to the documentation delivered

with the hard disk drive for details.

2. Install the screws and grommets to the left side of the hard disk drive.

3. Lower the hard disk drive into the mounting bracket; then, slide the

drive toward the front panel.

Page 53

Chapter 4 - Maintaining the System 39

4. Mount the drive to the bracket by installing the screws to the right

side.

5. Replace the power switch cable and ground wire to the chassis.

6. Attach the power cable and SCSI cable to the hard disk drive. The

SCSI cable is keyed to ensure proper insertion, so that the red stripe

(pin 1) is adjacent to the power connector.

7. Replace the CD-ROM drive.

8. Close the base unit.

9. Restart the workstation.

10. Partition and format the hard disk drive as described in the operating

system documentation.

11. Install the operating system onto the new hard disk drive as described

in Appendix A, “Installing the Operating System.”

Auxiliary Hard Disk Drive

The auxiliary hard disk drive is located between the power supply and the

riser card.

To remove the auxiliary hard disk drive:

➤

1. Disconnect the internal SCSI cable and power cable from the auxiliary

hard disk drive.

2. Remove the hard disk drive and its support bracket. Set the hard disk

drive on a flat antistatic surface.

Page 54

40 Chapter 4 - Maintaining the System

3. Using a No. 2 Phillips screwdriver, remove and retain the screws

attaching the hard disk drive to the bracket. Leave the grommets in

the bracket.

Grommets

Tabs

To install the new hard disk drive:

➤

1. Disable SCSI termination and set the SCSI ID to the same SCSI ID as

the previous hard disk drive. Refer to the documentation delivered

with the hard disk drive for instructions.

2. Secure the new disk drive to the auxiliary hard disk drive bracket

using the screws removed previously.

3. Attach the power cable and SCSI cable to the new disk drive. The

SCSI cable is keyed to ensure proper insertion, so that the red stripe

(pin 1) is adjacent to the power connector.

Page 55

Chapter 4 - Maintaining the System 41

4. Install the hard disk drive and bracket into the base unit, inserting the

tabs into the peripheral brace. Refer to the following figure.

5. Route the SCSI cable as shown in the following figure.

Peripheral

Brace

SCSI Cable

6. Close the base unit.

7. Partition and format the auxiliary hard disk drive as described in the

operating system documentation.

Page 56

42 Chapter 4 - Maintaining the System

SCSI Termination Card

To replace the SCSI termination card:

➤

1. Disconnect the external SCSI cable, if installed.

2. Using a No. 1 Phillips screwdriver, remove the two screws from the

Fast SCSI-2 port.

3. Note how the SCSI termination card is attached. Slide the card out of

the chassis and disconnect the SCSI cable.

SCSI Cable

SCSI Termination

Card

Fast SCSI-2

Port

5. Remove the new card from the antistatic bag.

6. Connect the internal SCSI cable to the card.

7. Insert the card into the chassis and mount it using the two screws

removed previously.

8. Close the base unit.

Page 57

Chapter 4 - Maintaining the System 43

9. Connect the external SCSI cable.

Riser Card

To remove the riser card:

➤

1. Remove the combo drive as described in “Replacing the Combo

Drive,” leaving the cables attached.

2. Remove the auxiliary hard disk drive as described in “Replacing the

Auxiliary Hard Disk Drive,” leaving the cables attached. If an

auxiliary disk drive is not installed, remove the auxiliary drive

bracket.

3. Remove all boards connected to the riser card. Note the position of

the boards installed in the ISA slots. To remove the ISA boards in the

ISA I/O panel, lift up the I/O lock bracket (note orientation) as shown

in the following figure.

I/O Lock

Bracket

4. Lift up and remove the peripheral brace as shown in the following

figure.

5. Disengage the riser card from the system board, and remove the card

from the base unit as shown in the following figure.

Page 58

44 Chapter 4 - Maintaining the System

Grounding

Riser

Card

To install the new riser card:

➤

Tabs

Peripheral

Brace

1. Remove the new riser card from the antistatic bag.

2. Insert the riser card into its system board slot, pushing firmly over the

center of the PCI connectors to ensure it seats completely. Do not

rock the riser card back and forth, but press firmly so the card

connector slides evenly into the slot.

3. Replace the peripheral brace. Ensure the grounding tabs slide to the

ISA slot side of the riser card.

4. Replace the boards connected to the riser card. Connect any external

cables attached to the boards. ISA boards must be installed in the

same slots from which they were removed.

5. Replace the I/O lock bracket into the two-panel I/O slot.

Page 59

Chapter 4 - Maintaining the System 45

6. Replace the auxiliary hard disk drive (or bracket) and the combo

drive.

7. Close the base unit.

System Board

CAUTION

The system board is extremely sensitive to static electricity. To prevent

serious damage to the system board, wear the antistatic wrist strap while

performing the following steps. Do not open the antistatic bag

containing the system board until instructed.

To remove the system board:

➤

1. Remove the auxiliary hard disk drive (or its bracket if not installed) as

described in “Replacing the Auxiliary Hard Disk Drive.”

2. Remove the combo drive as described in “Replacing the Combo

Drive.”

3. Remove the riser card as described in “Replacing the Riser Card.”

4. Remove the PCI option board support bracket that sets above the

memory sockets.

Page 60

46 Chapter 4 - Maintaining the System

5. Disconnect the reset, disk activity LED, and power on LED cables

from the system board. Note the orientation of the LED cables.

Reset - Green

Black

Disk Activity Black

LED - Orange

Power On LED - Black

White

6. Disconnect all other cables from the system board. The following

figure shows the cable connector locations.

SCSI Cable

Connector

Power Cable

Connectors

Audio Cable

Connector

MIDI/Game

Cable

Connector

AUI Cable

Connector

ISA Bus Cable

Connectors

Floppy Cable

Connector

Page 61

Chapter 4 - Maintaining the System 47

7. Disconnect the cables from the external ports.

8. Using a three-sixteenth-inch nutdriver, remove the jackscrews from

the video, parallel, and serial ports.

9. Using an 8 mm or five-sixteenth-inch nutdriver, remove the hex nuts

from the audio jacks.

10. Using a quarter-inch nutdriver, remove the eight grounding screws

from the system board.

11. Slide the system board to the front of the base unit.

12. Lift the board and remove it from the base unit. Set the board on a flat

antistatic surface.

13. Remove the new system board from the antistatic bag and place it on a

flat antistatic surface.

14. Remove the SIMMs from the old system board and install them onto

the new one in the same configuration.

To install the new system board:

➤

The new system board should have the SIMMs installed before placing it

into the base unit.

1. Lower the new system board into the base unit. Ensure the standoff

lines up with the hole in the chassis. Slide the system board to the

back of the base unit so the external ports fit into the back panel.

2. Install the jackscrews onto the video, parallel, and serial ports.

3. Install the hex nuts onto the audio jacks.

4. Install the eight grounding screws.

5. Connect the MIDI (or game), audio, and Ethernet AUI cables to the

system board.

Page 62

48 Chapter 4 - Maintaining the System

Do not connect the MIDI or game cable to the Ethernet AUI port. This

will short out the local area network on which the system resides.

6. Connect the system power cables to the P1 through P5 connectors.

The power cable connectors are labeled with the corresponding

system board connector.

7. Connect the reset, disk activity LED, and power on LED cables to the

system board.

Note: The orange wire for the disk activity LED cable must connect to pin

1. The white wire for the power on LED cable must connect to pin

1. The orientation of the reset cable wires is not critical.

8. Install the riser card and the peripheral brace.

CAUTION

9. Replace the PCI option board support bracket, option boards, and their

external cables.

Note: If installing ISA boards they must be placed in the same slots from

which they were removed. Also replace the I/O lock bracket for the

ISA boards on side two of the riser card.

10. Install the combo drive; then, connect the floppy cable and ISA bus

cables to the system board.

11. Install the auxiliary hard disk drive (or its bracket) and connect the

SCSI cable to the system board.

12. Connect the external system cables (video, parallel, serial, etc.) to the

external ports.

13. Close the base unit.

Page 63

Chapter 4 - Maintaining the System 49

Power Supply

CAUTION

Purchase replacement power supplies from Intergraph to ensure proper

specifications are met and to guarantee safety.

WARNING

Set the AC voltage switch on the back of the power supply to the

correct voltage for your location, or the power supply will be

irreparably damaged when power is applied. If you do not know the

voltage range, call your local utilities company for assistance.

To remove the power supply:

➤

1. Remove the AC power cord from the back of the base unit.

2. Remove the SCSI termination card as described in “Replacing the

SCSI Termination Card.” It is not necessary to disconnect the card

from the SCSI cable.

3. Remove the auxiliary disk drive (or its bracket if not installed) as

described in “Replacing the Auxiliary Hard Disk Drive.”

4. Disconnect the power cable from the combo drive, CD-ROM drive,

and system hard disk drive.

5. Disconnect the system power cables from the system board P1

through P5 connectors.

6. Open the clip that secures the bundle of power cables. Remove the

audio cable (connecting the CD-ROM drive to the system board) from

the power cable bundle.

7. Using a quarter-inch nutdriver, remove the screws securing the power

supply to the back of the base unit.

8. Slide the power supply to the front and remove it from the base unit.

Page 64

50 Chapter 4 - Maintaining the System

9. Using a No. 2 Phillips screwdriver (preferably with a long shank),

remove the screw that secures the power switch cable to the chassis as

shown in the following figure.

Screw

Power Switch

Cable

To install the new power supply:

➤

1. Remove the new power supply from its packaging and set the AC

voltage switch on the back of the new power supply to the correct

voltage for your location.

2. Mount the power switch cable and grounding wire to the chassis.

3. Place the new power supply in the base unit and slide it to the back of

the chassis. Mount the power supply using the four screws removed

previously.

4. Connect the system power cables to the P1 through P5 connectors on

the system board.

5. Connect the power cables to the CD-ROM drive, system hard disk

drive, and combo drive.

6. Secure the clip around the power cable bundle.

Page 65

Chapter 4 - Maintaining the System 51

7. Mount the SCSI termination card to the chassis.

8. Replace the auxiliary hard disk drive (or its bracket if not installed)

and connect the power cable.

9. Connect the AC power cord to the back of the base unit.

10. Close the base unit.

Reprogramming the Flash EPROM

You can use the Flash Programming Utility (FPU) to reprogram the system

board flash EPROM with a new BIOS. When run, the FPU first looks on the

diskette in the floppy disk drive for a valid BIOS. Therefore it is best to save

the BIOS file and the FPU (available on the IBBS) to the System Utilities

(SYSUTIL) diskette.

Note: The desktop workstations use the 741XX.ROM BIOS, where XX is

the version number.

The FPU is an MS-DOS utility that will not run in the Windows NT

environment. Use the SYSUTIL diskette delivered with your system to boot

the system into MS-DOS. The system must be set to boot from the floppy

disk drive (normally drive A) to use these utilities. If necessary, refer to

“Changing the System Boot Sequence.”

To reprogram the flash EPROM:

➤

1. Connect to the Intergraph Bulletin Board Service (IBBS) via modem.

Refer to the “Preface” for instructions.

2. From the TOP menu, go to Intergraph Product Centers, Systems and

Networking, File Libraries, and Delivered Drivers; then, select the

appropriate operating system and hardware platform.

3. Choose Find File to search for the FLASHPROG product; then,

download FLASHPROG to your system.

4. Several files are bundled in the FLASHPROG product, and must be

extracted using an unzip utility. The following files are extracted:

Page 66

52 Chapter 4 - Maintaining the System

741XX.ROM

AUTOEXEC.BAT

FLASH.EXE

FLASH.TXT

MANIFEST.TXT

README.TXT

5. Insert the SYSUTIL diskette into the floppy diskette slot of the combo

drive; then, copy FLASH.EXE and 741XX.ROM to the diskette.

6 Confirm that you want to replace the existing FLASH.EXE with the

new FLASH.EXE.

7. Shut down and power off the system.

8. Restart the system. When the MS-DOS Startup menu displays, select