Intercontinental Technologies F24 140, F24 115, F24 123, F24 119, F24 125 User Manual

...

Telecrane Radio Remote Control

F21 Series & F24 Series

Manual

Rev. 4a

April 18, 2012

Intercontinental Technologies Ltd. 558 Plate Drive Bldg. #2, East Dundee, IL 60118

Ph: 847-426-9597, Fax: 847-426-9724, TELECRANE.COM

Telecrane F21 Series & F24 Series Manual

|

Chapter Index |

|

|

|

Page |

General Specifications |

3 |

|

1.0 |

Installation Instructions |

5 |

2.0 |

Operation Instructions |

6 |

3.0 |

Safety |

8 |

4.0 |

Troubleshooting on Installation |

10 |

5.0 |

Programming |

11 |

6.0 |

Internal Horn Option |

13 |

7.0 |

Product Selection Guide |

14 |

8.0 |

Product Options |

16 |

9.0 |

F21 Receiver and Wiring Diagrams |

17 |

10.0 |

F24 Receiver and Wiring Diagrams |

18 |

Program and Button Labeling |

19 |

|

This manual Copyright 2006, 2009, 2011 Intercontinental Technologies, Ltd.

1

This Page Intentionally Left Blank

2

Technical Specifications for: F21-2S, 2D, 4S, 4D, 6S and F24-6S, 6D, 8S, 8D, 10S, 10D, 12S, 12D

Receiver input voltage: 110 volts AC.

Other Input voltages available 220 VAC, 12V AC/DC, 24 VAC/DC Temperature: -35 deg C to 75 deg C (-31 deg F to 167 deg F)

Receiver relay ratings: the receiver relays are rated at 10 amps at 250 volts AC. All COM wires are fused at 10A in both the F21 and F24 series. The total current drawn through the receiver relays (through the COM wire) must not exceed 10A.

Transmitter weights: 5 ounces for F21-2S, 2D; 9 ounces for F21-4S, 4D, 6S; 11 ounces for F24-6S, 6D, 8S, 8D, 10S, 10D

Transmitter dimensions: F21-2S, 2D are 5.2” x 1.75” x .9”; F21-4S, 4D, 6S are 6.2” x 2.4”x2”; F24-6S, 6D, 8S, 8D, 10S, 10D, 12S, 12D are 7.25” x 2.4” x 2”

Frequency generation: Crystal (plug-in)

Transmitter and Receiver housing material: 30% glass fiber-reinforced nylon-6

Transmitter button life: Tested to 2,000,000 operations

Control range: 150 feet for F21-2 button models, 250 feet for F21-4 & F21-6 button models and 500+ feet for all F24 models.

Transmitter batteries: 2 AA alkaline batteries.

Channel |

Frequency |

Channel |

Frequency |

Channel |

Frequency |

Channel |

Frequency |

1 |

310.0325 |

11 |

312.7075 |

21 |

315.3825 |

31 |

318.0575 |

2 |

310.3000 |

12 |

312.9750 |

22 |

315.6500 |

32 |

318.3250 |

3 |

310.5675 |

13 |

313.2425 |

23 |

315.9175 |

33 |

318.5925 |

4 |

310.8350 |

14 |

313.5100 |

24 |

316.1850 |

34 |

318.8600 |

5 |

311.1025 |

15 |

313.7775 |

25 |

316.4525 |

35 |

319.1275 |

6 |

311.3700 |

16 |

314.0450 |

26 |

316.7200 |

36 |

319.3950 |

7 |

311.6375 |

17 |

314.3125 |

27 |

316.9875 |

37 |

319.6625 |

8 |

311.9050 |

18 |

314.5800 |

28 |

317.2550 |

38 |

319.9300 |

9 |

312.1725 |

19 |

314.8475 |

29 |

317.5225 |

|

|

10 |

312.4400 |

20 |

315.1150 |

30 |

317.7900 |

|

|

Channel |

Frequency |

Channel |

Frequency |

Channel |

Frequency |

Channel |

Frequency |

112 |

428.5350 |

123 |

431.4775 |

134 |

434.4200 |

145 |

437.3625 |

113 |

428.8025 |

124 |

431.7450 |

135 |

434.6875 |

146 |

437.6300 |

114 |

429.0700 |

125 |

432.0125 |

136 |

434.9550 |

147 |

437.8975 |

115 |

429.3375 |

126 |

432.2800 |

137 |

435.2225 |

148 |

438.1650 |

116 |

429.6050 |

127 |

432.5475 |

138 |

435.4900 |

149 |

438.4325 |

117 |

429.8725 |

128 |

432.8150 |

139 |

435.7575 |

|

|

118 |

430.1400 |

129 |

433.0825 |

140 |

436.0250 |

|

|

119 |

430.4075 |

130 |

433.3500 |

141 |

436.2925 |

|

|

120 |

430.6750 |

131 |

433.6175 |

142 |

436.5600 |

|

|

121 |

430.9425 |

132 |

433.8850 |

143 |

436.8275 |

|

|

122 |

431.2100 |

133 |

434.1525 |

144 |

437.0950 |

|

|

3

Warranty:

Intercontinental Technologies, Ltd. (ITL) guarantees that this product meets its published specifications at the time of shipment. This equipment is warranted against defects in material and manufacturing for a period of one year from the date of shipment. During the warranty period, ITL will repair or replace defective components at no charge, if the failure of the product was due to defective material or manufacturing. For warranty service, the product must ultimately be returned to ITL. The buyer must pay shipping charges to the ITL service facility, and ITL will pay return ground shipping charges. Warranty service on F21 and F24 units shall be provided by ITL only and ITL will not be responsible for service or repair costs charged by third parties. ITL will not be liable for any damage to the warranted product, and no other warranty is expressed or implied, except as explicitly described. ITL does not warranty any consumable parts, including batteries, fuses, buttons, relays, or housings. This warranty does not include damage caused by improper installation (including ignoring environmental specifications), improper or insufficient maintenance, any modifications, improper operation, or improper software interfacing. The remedies provided herein are the buyer’s sole and exclusive remedies. ITL shall not be liable for any direct, indirect, special, incidental, or consequential damages.

FCC and Industry Canada Approval Information

The following information applies to transmitters:

This device complies with part 15 of the FCC Rules and RSS-210 of Industry Canada. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

Changes or modifications not expressly approved by Intercontinental Technologies, Ltd. could void the user’s authority to operate equipment.

Ce dispositif est conforme aux normes CNR-210 d’Industrie Canada et la partie 15 des règles de la FCC.

L’utilisation de ce dispositif est autorisée seulement aux conditions suivantes: 1) il ne doit pas produire de brouillage et 2) l’utilisateur du dispositif doit être prêt à accepter tout brouillage radioelectrique reçu, même si ce brouillage est susceptible de compromettre le fonctionnement du dispositif .

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

The following information applies to receivers: |

|

Models F21-2S and F21-2D, |

Models F21-4S and F21-4D, |

Model F21-6S, |

Models F24-6S and F24-6D, |

Models F24-8S and F24-8D, |

Models F24-10S and F24-10D, |

Model F24-12S and F24-12D |

|

4

1.0Installation Instructions:

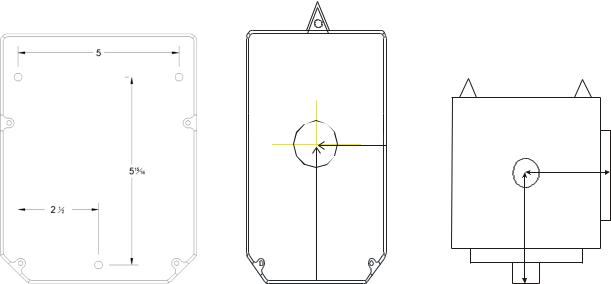

1.The F21 and F24 receivers should be mounted in a location that is convenient to the control box and is securely attached to the equipment. The F21 receiver measures 7.37” L x 3.37” W x 7.10” D and is mounted by drilling one 5/16” (8mm) hole and the F24 receiver measures 10” L x 6.5” W x 4.5” D and is mounted by drilling three ¼” (6mm) holes (see diagrams below).

Mount the receiver using the supplied hardware. It is best to keep the receiver as far away (approximately 6 feet) from variable frequency drives and the motors and cables attached to them to avoid interference.

1.5”

3.4”

1.9”

2.2”

F24 Receiver Mounting Diagram |

F21 Receiver Mounting Diagram F21-2S Mini Receiver Mounting Diagram |

2.The F21 receiver wires are color coded, and the F24 receiver wires are numbered. The wires are identified on the label on the top of the receiver and on the wiring diagrams on page 15 of this manual.

3.All the contacts in the receiver are “dry” relay contacts. This means that is there is no internal source of power to the contacts. You will need to connect the “common” lead for each output or set of outputs that you plan to use to the same power supply that it would be connected to in a corded pendant. For most cranes this wire is X1 (the 120 volt AC control transformer “hot” side). Some cranes have separate hoist/trolley and bridge transformers. In these cases, connect each transformer’s X1 to the function(s) it powers. There is no requirement that the common leads be connected to a 120 volt AC supplythese are “dry” relay contacts; whatever you put into the common wire, comes out each function’s wire when that relay closes. The only restrictions are, do not exceed 10 amps or 250 volts AC. For DC applications call the factory at 1-800-382-3558.

4.Put 2 AA alkaline batteries into each transmitter. For F21-2 button models, remove the 4 screws on the back of the transmitter. Insert the batteries as indicated inside the unit. Replace

5

the screws. For the F21-4, F21-6, F24-6, F24-8, F24-10, and F24-12 button units, remove the battery compartment cover on the bottom of the unit by unscrewing the thumb-screw. Insert the batteries as indicated on the label inside the battery compartment. Replace the cover and tighten the thumb-screw until the cover is fully seated against the transmitter body.

5.Test the system thoroughly before releasing it for use.

2.0Operation Instructions:

2.1 Battery Indicator:

The LED on the front of the transmitter indicates the condition of the batteries. It will flash green during operation if the battery power is sufficient, and will flash red if the battery power is low. If the LED is flashing red, or if the operation becomes erratic, or will only work from a short distance, replace both batteries with new AA alkaline batteries using the procedure given in section 1.0.

2.2 Fuses

There are three fuses in the F21 series receivers and six fuses in the F24 series receivers. On all models there is one fuse in the AC power line that operates the receiver (0.5A, 250V), and one is in the internal 12 volt DC supply (1.5A, 250V). In the F21 receivers there is one fuse in the COM wire. On the F24 series radios there are four fuses in the COM wires (10A, 250V). These fuses are for relay contact protection in the event of a short circuit in the equipment being controlled by the radio. To replace a fuse, push down the fuse cover and turn counter-clockwise ¼ turn with thumb and forefinger or a flat-blade screwdriver. Remove the fuse from the cover and insert a new one of the same rating. Insert the fuse and cover into the fuse holder, press down, and turn clockwise ¼ turn. For protection from fire hazard, damage, or injury, always replace a blown fuse with one of the same rating.

2.3Start Procedure for the F21-2S and F21-2D:

1.Put the green magnetic safety key into its slot in the front of the transmitter.

2.Use the UP and DOWN pushbuttons to control the equipment. The first time that either button is pressed, the mainline contactor will engage. If there is no mainline contactor provided on the equipment being controlled by the radio, the Main (red) wire does not need to be connected to any of the equipment controls. The model F21-2D has two-step buttons; pressing them to the first detent will activate the equipment at the slow speed, and pressing them fully will activate the equipment at the fast speed.

3.Press the STOP button to stop movement immediately and drop out the mainline contactor, if one is used.

4.Remove the green magnetic safety key whenever the transmitter is not in use to prevent unintentional operation.

6

2.4Start Procedures for the F21-4S, F21-4D, F21-6S:

1.If the red STOP knob is pushed in, turn it clockwise about 45 degrees to reset it and allow it to pop up. This knob must be in the up position in order to operate the transmitter.

2.Put the green key into its slot in the front of the transmitter, next to the red STOP knob.

3.Turn the green key clockwise. The green key must go past the ON position detent, to the START position. Then release it and it will spring back to the ON position.

4.Use the pushbuttons to control the equipment. The model F21-4D uses two-step pushbuttons; pressing them to the first detent will activate the equipment at the slow speed, and pressing them fully will activate the equipment at the fast speed.

5.Press the red STOP knob or turn the green key to OFF to stop movement immediately and drop out the mainline contactor.

6.Turn the green key to OFF and remove it whenever the transmitter is not in use to prevent unintentional operation.

7.The F21-4 and F21-6 models have an extra relay in the receiver, labeled R0. Turning the green key to START after the equipment has already been started will close this relay. This relay will not engage the first time the key is turned to START when starting up the equipment. See section 5.3 for detailed information on this option.

2.5Start Procedures for all F24 Models (except the F24-12S and 12D models)

1.If the red STOP knob is pushed in, turn it clockwise about 45 degrees to reset it and allow it to pop up. This knob must be in the up position in order to operate the transmitter.

2.Put the green key into its slot in the front of the transmitter, next to the red STOP knob.

3.Turn the green key clockwise to the ON position, then press the green (START) pushbutton. This will engage the mainline contactor, if one is used.

4.Use the pushbuttons to control the equipment. Models F24-6D, F24-8D, and F24-10D use two-step pushbuttons; pressing them to the first detent will activate the equipment at the slow speed, and pressing them fully will activate the equipment at the fast speed.

5.Press the red STOP knob or turn the green key to OFF to stop movement immediately and drop out the mainline contactor.

6.Turn the green key to OFF and remove it whenever the transmitter is not in use to prevent unintentional operation.

7.The F24-6, F24-8, and F24-10 models have an extra relay in the receiver, labeled R0. Pushing the green start button after the equipment has already been started will close this relay. This relay will not engage the first time the Start pushbutton is pressed when starting up the equipment. See section 5.3 for detailed information on this option.

7

2.6Start Procedures for the F24-12S, F24-12D:

1.If the red STOP knob is pushed in, turn it clockwise about 45 degrees to reset it and allow it to pop up. This knob must be in the up position in order to operate the transmitter.

2.Put the green key into its slot in the front of the transmitter, next to the red STOP knob.

3.Turn the green key clockwise. The green key must go past the ON position detent, to the START position. Then release it and it will spring back to the ON position.

4.Use the pushbuttons to control the equipment. The model F24-12D uses two-step pushbuttons; pressing them to the first detent will activate the equipment at the slow speed, and pressing them fully will activate the equipment at the fast speed.

5.Press the red STOP knob or turn the green key to OFF to stop movement immediately and drop out the mainline contactor.

6.Turn the green key to OFF and remove it whenever the transmitter is not in use to prevent unintentional operation.

7.The F24-12S and F24-12D models have an extra relay in the receiver, labeled R0. Turning the green key to START after the equipment has already been started will close this relay. This relay will not engage the first time the key is turned to START when starting up the equipment. See section 5.3 for detailed information on this option.

3.0Safety:

EMERGENCY PROCEDURE: In case of emergency, perform these steps IN ORDER.

1.Press the red STOP button.

2.Remove the green magnetic safety key on F21-2 button models only or turn the green key to OFF on the F21-4, F21-6, F24-6, F24-8, F24-10, and F24-12 button models.

3.Switch off the main power to the equipment.

4.Contact qualified service personnel.

This manual is intended for the user as a general reference only. Please consult your distributor for specific installation or assistance with technical issues. In an industrial environment, safety must always be a top priority. Persons responsible for installation, operation, and maintenance must make certain that both their actions, and the equipment on which they work, are safe.

Following are a list of safety rules that must be followed when working with TELECRANE products, as well as cranes and industrial equipment in general. This list is not intended to be allinclusive. General industrial safety rules must always be followed. If there is any doubt about how to proceed, always take the safest course of action.

8

-Only qualified personnel who are familiar with the product and who have read these safety instructions should install TELECRANE products.

-Before installing or operating this product, read this manual thoroughly. If you have any questions, please contact ITL.

-All sources of power to the crane or controlled equipment must be de-energized and locked out before installing the unit.

-Before installing the receiver, energize it in a controlled environment (such as an office) where it can be tested and set up properly before it is mounted in the field. If it does not work exactly as intended, fix the problem and test it again.

-Before installation, be certain to understand the electrical functioning of the crane or equipment, including the sequence and relationship of motions and contactors.

-Fall prevention devices should be used when anyone is working at an elevated height.

-The receiver must be securely attached and located where it will not be hit by any moving part of the building, crane, or load.

-The crane or hoist must be equipped with limit switches for each motion and a main power contactor that cuts off all power to the motors of the crane when it is de-energized.

-Special care must be taken for magnets and other load-carrying devices to ensure that if the crane is de-energized the load remains supported.

-The receiver must be located so that it receives sufficient signal strength from the transmitter.

-Operating any piece of equipment in an industrial facility can be dangerous; therefore, adequate training will need to be provided to operators of cranes or other equipment that uses a TELECRANE product.

-At least once each shift, check the amount of power remaining in the transmitter batteries. If it is low, change both batteries before beginning operation. Operating the unit with excessively discharged batteries can be unsafe.

-The safety key should be removed from the transmitter whenever it is not in use and should only be issued to authorized personnel.

-All TELECRANE Radio Remote Controls are tested before they leave the factory. However, they should not be used in dangerous situations or in a manner such that damage might result.

-Although the transmitter is very durable and weather-resistant, precautions should always be taken to limit its exposure to weather, physical impact, and corrosives.

-After use, or if the unit will not be used for a long interval, turn off power to the crane or equipment and remove the safety key from the transmitter.

9

-Remove the batteries from the transmitter if the transmitter will not be used for two weeks or longer.

-Transmitters that are not in use, including spare transmitters, should be stored, with batteries removed, and secured to prevent accidental operation.

-Before each shift, check that the limit switches function correctly and that movement corresponds to the button being pressed on the transmitter.

-Do not use the equipment during lightning storms or high electrical interference conditions.

-In general only authorized service facilities should perform maintenance on this product.

-Ensure that anyone performing maintenance on the crane or equipment is thoroughly familiar with its operation.

-Power should be shut off to the crane or equipment before any maintenance begins, unless absolutely required for troubleshooting the unit. When the power is on, use extreme caution. High voltage or unexpected movement could cause death or severe injury.

-Only certified maintenance personnel should attempt a repair more involved than the swapping of printed circuit boards. Improper repair can compromise the builtin safety features and cause unexpected operation and damage.

-This product uses two AA alkaline batteries. When replacing batteries, both must be replaced at the same time.

-ITL does not recommend use of nickel-cadmium or nickel-metal-hydride batteries due to voltage characteristics that cause a sudden loss of power when discharged. They also have less capacity than alkaline batteries and therefore will not last as long.

4.0Trouble Shooting Common Mistakes In Installation:

Receiver dead: Is 120 volt AC applied between X1 and X2 wires? On the F21 models these are the BLACK and BROWN wires; and on the F24 models they are wires 1 and 2. You must provide both the hot and the neutral sides of the control transformer secondary to power the unit.

Does the equipment have a mainline contactor: Not all equipment has a mainline contactor. The best way to determine if your equipment has a mainline contactor is to check whether there is a START and STOP on the corded pendant. If the equipment does not have a mainline contactor then these wires do not have to be connected. On the F21 models this wire is the MAIN wire and on the F24 models this is MAIN-IN (3) and MAIN-OUT (4). The MAIN wire on the F21

10

models will be hot when mainline is on; this wire has to be terminated with a wire nut or isolated.

Relays close but there is no movement from the crane: Are the COMMON wires hooked up properly? The receivers have “dry” contacts. Even though X1 and X2 have been applied to power the receiver, you still need to apply power to the common side of the relay contacts in order to get power to your contactors. On the F21 models the COM wire on the diagram is separate from the power wires and on the F24 models each COM wire is completely isolated from the others as well as the power wires. In most cranes, the COM wires will be connected to the X1 supply.

If you have any problems or questions not covered above, please call ITL at 1-800-382-3558.

5.0Programming options:

5.1All units:

-Auto-shut-down time. An auto-shut-down feature is available on all models. If the radio has not been used for a period of time the receiver automatically drops out the main line contactor. The default setting is 1 hour for the F24 Series and “Never” for the F21

Series. Auto-shut-down times can be set between 0 and 4 hours. Typical selections are available on the programming data sheets in the back of this manual.

-Pushbutton options. Each pushbutton is set by default to momentary (relay closes when a button is pressed and opens when released), and interlocked in opposed motion pairs (UP-DOWN, EAST-WEST, SOUTH-NORTH). When set as momentary, they can be set as un-interlocked. They can also be set as toggle (press once to close relay, press again to open) or as On-Off pairs (press On to close relay, press Off to open relay). When programmed as toggle or On-Off, they will be set as controlled by Stop (opening automatically when the STOP button is pressed). They can be specially rewired by the factory for uncontrolled by Stop (unaffected by STOP button); please call for more information.

5.2Models F21-2D, F21-4D, F24-6D, F24-8D, F24-10D, and F24-12D:

-Acceleration delay. Delay between actuation of relays for the first and the second detents of the two-step button can be programmed on the two speed models. This delay time can be set between 0 and 4 seconds; default is 0 seconds. Typical selections are available on the programming data sheet.

11

5.3Models F21-4S, F21-4D, F21-6S, F24-6S, F24-6D, F24-8S, F24-8D, F24-10S, F24-10D, F24-12S, and F24-12D:

-R0 function. On the F21 models the R0 relay operates when the green key is turned to START after the unit is already started. On the F24 models the R0 relay operates when the START button is pushed after the unit is already started. It is by default set to momentary (closed when START key is turned on the F21 models or START button is pressed on the F24 models, open when released). It can also be set to toggle (turn the START key once to close, turn it again to open on F21 models or push the START button once to close, then push the button again to open on the F24 models), or inching (does not activate the R0 relay, but instead only allows pushbuttons pressed after turning the key to remain on for a preset length of time, no matter how long the button is held). For inching, the inch time may be set from 0.05 to 0.8 seconds in 0.1-second increments. Typical selections are available on the programming data sheet.

5.4Other Programming options for the F24 UP/DOWN 2 Step Buttons:

Dual Motor. When the first detent of the button is reached the first step relay turns ON, when the button is fully depressed the second step relay turns ON and the first step relay turns OFF. When the button is released back to the first detent, the first step relay will turn ON until the button is released.

Dual Motor (1). Works the same as Dual Motor, with the difference being the first step relay will not activate when returning from fully depressed to the first detent. The button must be completely released and repressed in order to activate the first step relay again.

Combination. When 2 buttons are depressed simultaneously, it will result in a third relay output that is set to toggle. The relays of the two buttons depressed will not engage, instead a third relay will engage. This feature is designed to suit some special applications such as lighting systems. Combination setting is prohibited for magnetic devices. Combination setting is always set to controlled by stop. Uncontrolled by stop is not available.

3 Speeds. The START button can be used to control a third speed. Once the motion button (either up or down) is fully depressed, a third speed can be obtained by pushing the START button.

Call Factory for more information 1-800-382-3558.

12

6.0 Internal Horn option:

This section describes the Internal Horn Option on the following model numbers:

F24-6S-HN |

F24-8S-HN |

F24-10S-HN |

F24-6D-HN |

F24-8D-HN |

F24-10D-HN |

F24-12S-HN |

F24-12D-HN |

|

Instructions for use:

The Internal Horn Option operates automatically with usage of the TELECRANE F24 Series

Radio Remote Control in which it is installed. F24 models ending in ”-HN” contain this option.

It will sound the horn on two conditions:

-The horn will sound for approximately two (2) seconds upon initially pressing START in order to provide a warning that the crane or other equipment is being started;

-The horn may be sounded by pressing START at any time after startup, regardless of whether a motion button is being pressed. The horn will sound as long as the START button is pressed. (This may be eliminated: see Adjustments, below)

Adjustments:

There are two (2) small DIP-style rocker switches near the lower edge of the Horn printed circuit board. This board is mounted inside the front cover of the receiver. These switches constitute the only adjustments available on the Internal Horn Option. As shipped, both switches are set to

“ON”.

SOUNDING HORN AFTER STARTUP: The switch closer to the edge, numbered “1”, controls whether pressing the START button after startup sounds the horn. If it is desired to use the R0 relay without the horn sounding, press the rocker switch toward the “OFF” or “OPEN” position. To resume sounding the horn on R0 activation, press the switch toward the “ON” position.

13

Loading...

Loading...