Page 1

Intel® NetStructure™ ZT 7102

Chassis Management Module

Technical Product Specification

August 2004

Order Number: 273770-017

Page 2

Intel® NetStructure™ ZT 7102 Chassis Management Module

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED, BY

ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED IN

INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUM ES NO LIABILIT Y WHA T SOEVER, AND INTE L DISCLAIMS

ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING LIABILITY OR WARRANTIES

RELATING T O FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER

INTELLECTUAL PROPERTY RIGHT . Intel products are not intended for use in medical, life saving, life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked "reserved" or "undefined." Intel reserves these for

future definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from future changes to the m.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an order number and are referenced in this document, or other Intel literature, may be obtained by calling 1-800-

548-4725, or by visiting Intel's website at http://www.intel.com.

AlertVIEW, AnyPoint, AppChoice, BoardWatch, BunnyPeople, CablePort, Celeron, Chips, CT Connect, CT Media, Dialogic, DM3, EtherExpress,

ETOX, FlashFile, i386, i486, i960, iCOMP, InstantIP, Intel, Intel logo, Intel386, Intel486, Intel740, IntelDX2, IntelDX4, IntelSX2, Intel Create & Share,

Intel GigaBlade, Intel InBusiness, Intel Inside, Intel Inside logo, Intel NetBurst, Intel NetMerge, Intel NetStructure, Intel Play, Intel Play logo, Intel

SingleDriver, Intel SpeedStep, Intel StrataFlash, Intel TeamStation, Intel Xeon, Intel XScale, IPLink, Itanium, LANDesk, LanRover, MCS, MMX, MMX

logo, Optimizer logo, OverDrive, Paragon, PC Dads, PC Parents, PDCharm, Pentium, Pentium II Xeon, Pentium III Xeon, Performance at Your

Command, RemoteExpress, Shiva, SmartDie, Solutions960, Sound Mark, StorageExpress, The Computer Inside., The Journey Inside,

TokenExpress, Trillium, VoiceBrick, Vtune, and Xircom are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United

States and other countries.

*Other names and brands may be claimed as the property of others.

Copyright © Intel Corporation 2004.

2 Technical Product Specification

Page 3

Intel® NetStructure™ ZT 7102 Chass is Manage ment Module

Contents

Contents

1.0 Introduction......................................................................................................................................13

1.1 Overview.............................................................................................................................13

1.2 ZT 7102 Features ...............................................................................................................13

1.3 Terms Used in This Document ...........................................................................................15

2.0 Hardware Specifications....................................................................................................................17

2.1 Overview.............................................................................................................................17

2.2 System Ar chit ect ure.............. ...................................... ....... ...... ....... ...... ....... ...... ....... ...... . ...18

2.3 Backplane Connections......................................................................................................18

2.3.1 Slot Connections....................................................................................................18

2.3.2 Chassis Sensor Connections.................................................................................19

2.3.3 Chassis FRU Device Connections.........................................................................19

2.3.4 Redundancy...........................................................................................................19

2.4 Power Modules...................................................................................................................19

2.5 Fan Modules.......................................................................................................................19

2.6 Face Plate...........................................................................................................................20

2.6.1 Faceplate Features................................................................................................21

2.7 Mechanical..........................................................................................................................22

2.7.1 Board Dimensions and Weight ..............................................................................22

2.7.2 PCB Dimensions....................................................................................................22

2.8 Connectors .........................................................................................................................22

2.8.1 J1 Backplane Connector........................................................................................24

2.8.2 J2 Backplane Connector........................................................................................24

2.8.3 J3 Backplane Connector........................................................................................25

2.8.4 Backplane Pin Descriptions...................................................................................26

2.8.5 JA1 Ethernet Port ..................................................................................................27

2.8.6 J6 Serial Port .........................................................................................................28

2.8.7 J7 Telco Alarm Connector .....................................................................................28

2.9 Electrical and Environmental ..............................................................................................29

2.9.1 CMM Power...........................................................................................................29

2.9.2 Power Ramp Circuitry............................................................................................30

2.9.3 Operating Temperature .........................................................................................30

2.9.4 Reliability ...............................................................................................................30

2.9.5 Absolute Maximum Ratings...................................................................................30

2.9.6 DC Operating Characteristics................................................................................31

2.10 Onboard Switches ..............................................................................................................31

2.10.1 Switch Descriptions ...............................................................................................32

2.10.1.1 S1 (Alarm Cutoff and Board Reset).......................................................32

2.10.1.2 SW1-1 (Password Reset) ......................................................................32

2.11 Processor and Chipset .......................................................................................................32

2.12 Memory...............................................................................................................................33

2.12.1 Removing the SODIMM.........................................................................................33

2.12.2 Installing Memory........................ ....... ...... ...... ....... ...... ....... ...... ..............................33

2.13 Flash...................................................................................................................................33

2.14 Dual Ethernet Controllers ...................................................................................................33

2.15 Serial I/O.............................................................................................................................33

Technical Product Specification 3

Page 4

Intel® NetStructure™ ZT 7102 Chassis Management Module

Contents

2.16 Telco Alarm Signal..............................................................................................................34

2.16.1 Alarm Relays .........................................................................................................34

2.16.2 Opto Inputs ............................................................................................................34

2.17 Real Time Clock ............... ....... ...... ....... ...... ....... ...................................... ....... ...... ....... .......34

2.18 Network Time Synchronization...........................................................................................34

2.19 Watchdog Timer .................................................................................................................35

2.20 Battery Backup ...................................................................................................................35

2.20.1 Replacing the Battery ................................. ...... ....... ...... ....... .................................35

2.21 Running Your System Without A CMM...............................................................................36

3.0 Software Specifi ca tio ns.....................................................................................................................37

3.1 Operating System...............................................................................................................37

3.2 Command Line Interface (CLI) ...........................................................................................37

3.3 SNMP/UDP.........................................................................................................................37

3.4 Remote Procedure Call (RPC) Interface ............................................................................37

3.5 Ethernet Interfaces .............................................................................................................37

3.6 Sensor Event Logs (SEL) ...................................................................................................38

3.6.1 CMM SEL Architecture ..........................................................................................38

3.6.2 Satellite Management Controller (SMC) Boards....................................................38

3.6.3 Baseboard Management Controller (BMC) Boards...............................................38

3.6.4 Retrieving a SEL....................................................................................................38

4.0 CMM Redundancy, Synchronization and Failover................................................................................39

4.1 Overview.............................................................................................................................39

4.2 Hardware Redundancy Specification..................................................................................39

4.3 Synchronization..................................................................................................................39

4.3.1 Synchronization Requirements..............................................................................40

4.4 CMM Failover .....................................................................................................................41

4.4.1 Scenarios That Force a Failover............................................................................41

4.4.2 Scenarios That Prevent Failover ............................. ...... ....... .................................41

4.4.3 Scenarios That Failover to a Healthier Standby CMM...........................................41

4.4.4 Scenarios That Failover to an Equally Healthy CMM............................................42

4.4.5 Failover Timing ......................................................................................................42

4.4.6 Manual Failover .....................................................................................................42

5.0 CMM Instal lation and Removal ..........................................................................................................43

5.1 Unpacking...........................................................................................................................43

5.2 Connectivity........................................................................................................................43

5.3 Installing the CMM..............................................................................................................43

5.4 Removing the CMM............................................................................................................44

6.0 Built-In Self Test...............................................................................................................................47

6.1 BIST Test Flow...................................................................................................................47

6.2 Boot-BIST...........................................................................................................................48

6.3 Early-BIST ..........................................................................................................................48

6.4 Mid-BIST.............................................................................................................................48

6.5 Late-BIST............................................................................................................................49

6.6 Event Log Area and Event Management............................................................................49

6.7 OS Flash Corruption Detection and Recovery Design .......................................................50

6.7.1 Monitoring the Static Images.................................................................................50

6.7.2 Monitoring the Dynamic Images............................................................................50

4 Technical Product Specification

Page 5

Intel® NetStructure™ ZT 7102 Chass is Manage ment Module

Contents

6.7.3 CMM Failover ........................................................................................................50

6.8 BIST Test Descriptions.......................................................................................................51

6.8.1 Flash Checksum Test........... ...... ....... ...... ...... ....... ...... ....................................... ....51

6.8.2 Base Memory Test.................................................................................................51

6.8.3 Extended Memory Tests........................................................................................51

6.8.3.1 Walking Ones Test.................................................................................51

6.8.3.2 32-Bit Address Test ...............................................................................51

6.8.3.3 32-Bit Inverse Address Test...................................................................51

6.8.4 FPGA Version Check.............................................................................................52

6.8.5 DS1307 RTC Test .................................................................................................52

6.8.6 NIC Presence/Local PCI Bus Test........................ ...... ....... ....................................52

6.8.7 OS Image Checksum Test.....................................................................................52

6.8.8 CRC32 Checksum.................................................................................................52

6.8.9 IPMB Bus Busy/Not Ready Test............................................................................52

7.0 CMM Connection and Setup..............................................................................................................53

7.1 CLI Overview .... ....... ...... ....... ............................................................................. ....... ..........53

7.2 Connecting to the CLI.........................................................................................................53

7.2.1 Connecting through a Console ..............................................................................53

7.2.2 Telnet into the CMM ..............................................................................................53

7.2.3 FTP Into the CMM .................................................................................................54

7.3 Initial Setup - Logging in for the First Time.........................................................................54

7.3.1 Setting IP Address Properties................................................................................54

7.3.1.1 Setting IP Information (IP Address, Netmask, and Gateway)................55

7.3.1.2 Setting Eth0 to DHCP ............................................................................55

7.3.2 Setting a Hostname ...............................................................................................56

7.3.3 Setting Auto-Logout Time Limit .............................................................................56

7.3.4 Rebooting the CMM................................. ...... ....... ...... ....... ...... ....... ...... ....... ...... ....56

8.0 Command Line Interface (CLI) Syntax and Arguments..........................................................................57

8.1 cmmget and cmmset syntax...............................................................................................57

8.2 Help Parameter: -h .............................................................................................................57

8.3 Location Parameter: -l ........................................................................................................57

8.4 Target Parameter: -t ...........................................................................................................58

8.5 Dataitem Parameter: -d ......................................................................................................58

8.6 Value Parameter: -v............................................................................................................61

8.7 Sample CLI Operations ......................................................................................................61

8.8 Generating a System Status Report...................................................................................62

9.0 Resetting the Password ....................................................................................................................63

9.1 Resetting the Password in a Single CMM System .............................................................63

9.2 Resetting the Password in a Dual CMM System................................................................63

10.0 Sensor Types...................................................................................................................................65

10.1 Threshold-Based Sensors..................................................................................................65

10.1.1 Threshold-Based Sensor Events...........................................................................65

10.2 Discrete Sensors ................................................................................................................65

10.2.1 Discrete Sensor Events .........................................................................................65

11.0 Health Event Strings.........................................................................................................................67

11.1 Syntax of Health Event Strings...........................................................................................67

Technical Product Specification 5

Page 6

Intel® NetStructure™ ZT 7102 Chassis Management Module

Contents

11.1.1 “healthevents” Query Event Syntax.......................................................................67

11.1.2 SEL Event Syntax..................................................................................................67

11.1.3 SNMP Trap Event Syntax......................................................................................68

11.2 Sensor Targets...................................................................................................................68

11.3 Healthevents Queries .........................................................................................................69

11.3.1 HealthEvents Queries for Individual Sensors........................................................69

11.3.2 HealthEvents Queries for All Sensors on a Location.............................................69

11.3.3 No Active Events ...................................................................................................69

11.3.4 Not Present or Non-IPMI Locations.......................................................................70

11.4 List of Possible Health Event Strings..................................................................................70

11.4.1 All Locations ..........................................................................................................71

11.4.2 PowerSupplyN Location (IPMI-Compliant Supplies Only).....................................71

11.4.3 CMM Location........................................................................................................72

11.4.4 Chassis Location ...................................................................................................73

12.0 Slot Power Control............................................................................................................................77

12.1 Difference between a Board’s HEALTHY# Signal and a Board’s Health ...........................77

12.2 Slot Power-Up Sequence ...................................................................................................77

12.2.1 Assertion of BD_SEL#...........................................................................................77

12.2.1.1 System Master Boards...........................................................................77

12.2.1.2 Peripheral Boards.......... ....... ...................................... ....... ...... ....... ...... .77

12.2.1.3 Fabric and PCI-Less Slots .....................................................................78

12.2.1.4 Drone Mode Boards...............................................................................78

12.2.2 Assertion of HEALTHY# During Power-Up............................................................78

12.3 Obtaining the Power State of a Board ................................................................................78

12.4 Controlling the Power State of a Slot..................................................................................79

12.4.1 Powering Off a Board ............................................................................................79

12.4.2 Powering On a Board ............................................................................................79

12.4.3 Resetting a Board..................................................................................................79

12.5 Power Sequencing Commands and Policies......................................................................79

12.5.1 Retrieving the Healthy# Ramp-Up Time................................................................80

12.5.2 Setting the Healthy# Ramp-Up Time................ ....... ...... ....... ...... ....... ...... ....... ...... .80

12.5.3 Retrieving the Maximum Power-Up Attempts........................................................80

12.5.4 Setting the Maximum Power-Up Attempts.............................................................80

12.5.5 Power Sequencing SEL Events.............................................................................81

13.0 Power Supplies................................................................................................................................83

13.1 Power Supply Detection .....................................................................................................83

13.2 Inhibit, Degrade, and Fail Signals.......................................................................................83

13.3 Inhibiting Power Supplies ........................... ....... ...... ...... ....... ...... ....... ...... ....... ....................83

13.4 Precautions For Inhibiting Power Supplies.........................................................................83

13.5 Inhibiting Power Supplies ........................... ....... ...... ...... ....... ...... ....... ...... ....... ....................84

13.6 Enabling Power Supplies....................................................................................................84

14.0 Drone Mode SBC Support.................................................................................................................85

14.0.1 Adding a Drone Mode Capable SBC.....................................................................85

14.0.2 Removing a Drone Mode Capable SBC................................................................85

15.0 Active vs. Offline Slots ......................................................................................................................87

15.1 Determining the State of a Slot...........................................................................................87

15.2 Setting a Slot to Offline Mode.............................................................................................87

6 Technical Product Specification

Page 7

Intel® NetStructure™ ZT 7102 Chass is Manage ment Module

Contents

15.3 Setting a Slot to Active Mode..............................................................................................87

15.4 Limitations of the Offline Mode ................ ....... ...... ...... ....... ...... ....................................... ....87

16.0 Obtaining FRU Information................................................................................................................89

16.1 FRU Information .................................................................................................................89

16.2 FRU Query Syntax..............................................................................................................89

16.3 Chassis FRU Validity Check...............................................................................................90

17.0 Fan Control and Monitoring ...............................................................................................................91

17.1 Setting Fan Speed..............................................................................................................91

17.1.1 Considerations for Turning Off the Fans................................................................91

17.2 Automatic Fan Control........................................................................................................91

17.3 Querying Fan Tray Sensors................................................................................................92

18.0 CMM Scripting.................................................................................................................................93

18.1 CLI Scripting ............................... ....... ...................................... ....... ...... ....... ...... ....... ..........93

18.1.1 Script Synchronization...........................................................................................93

18.2 Associating Scripts to Event Severity .................................................................................93

18.2.1 Listing Scripts Associated With Events..................................................................94

18.2.2 Removing Scripts From an Associated Event........................................................94

18.3 Setting Scripts for Specific Individual Events......................................................................94

18.3.1 Event Codes ..........................................................................................................94

18.4 Setting Event Scripts ..........................................................................................................95

18.5 Slot Events..........................................................................................................................95

19.0 SNMP.............................................................................................................................................97

19.1 CMM MIB............................................................................................................................98

19.2 MIB Design .........................................................................................................................98

19.2.1 CMM MIB Objects..................................................................................................98

19.2.2 Querying Non-IPMI Compliant Blades and Power Supplies..................................98

19.3 SNMP Agent......................................................... ...... ....... ...... ....... ...... ....... ...... ....... ..........98

19.3.1 Configuring the SNMP Agent Port.........................................................................99

19.3.2 Configuring the Agent to Respond to SNMP v3 Requests ....................................99

19.3.3 Configuring the Agent Back to SNMP v1...............................................................99

19.3.4 Setting up an SNMP v3 MIB Browser....................................................................99

19.4 SNMP Trap Utility .............................. ...... ....... ...... ...... ....... ...... ....... ...... ....... .....................100

19.4.1 Configuring the SNMP Trap Port.........................................................................100

19.4.2 Configuring the CMM to Send SNMP v3 Traps ...................................................100

19.4.3 Configuring the CMM to Send SNMP v1 Traps ...................................................100

19.5 Configuring and Enabling SNMP Trap Addresses............................................................100

19.5.1 Configuring an SNMP Trap Address....................................................................100

19.5.2 Enabling and Disabling SNMP Traps...................................................................100

19.5.3 Alerts Using SNMPv3 ..........................................................................................101

19.5.4 Alert Using UDP Alert ..........................................................................................101

19.6 Security Model..................................................................................................................101

19.6.1 SNMPv3 Security: Authentication Protocol and Privacy Protocol........................101

19.7 snmpd.conf .......................................................................................................................101

20.0 RPC..............................................................................................................................................103

20.1 Setting Up the RPC Interface ...........................................................................................103

20.2 Using the RPC Interface ...................................................................................................103

Technical Product Specification 7

Page 8

Intel® NetStructure™ ZT 7102 Chassis Management Module

Contents

20.2.1 GetAuthCapability() .............................................................................................104

20.2.2 ChassisManagementApi() ...................................................................................104

20.2.3 ChassisManagementApi() Threshold Response Format.....................................109

20.2.4 ChassisManagementApi() String Response Format ...........................................110

20.2.5 ChassisManagementApi() Integer Response Format..........................................113

20.2.6 FRU String Response Format .............................................................................114

20.3 RPC Sample Code ...........................................................................................................115

20.4 RPC Usage Examples......................................................................................................115

21.0 Command Log gin g.........................................................................................................................119

22.0 Telco Al arm Sensors ......................................................................................................................121

22.1 Configuring the Telco Alarm Connector Pins....................................................................121

22.2 Obtaining the Configuration of the Telco Alarm Sensor Connector Pins..........................121

22.3 Telco Alarm Connector Sensor Naming ...........................................................................121

22.3.1 Sensor Names using SNMP................................................................................122

22.4 Telco Alarm Sensors and Redundancy ............................................................................122

23.0 Application Hosting.........................................................................................................................123

23.1 System Details..................................................................................................................123

23.2 Startup and Shutdown Scripts..........................................................................................123

23.3 System Resources Available to User Applications...........................................................123

23.3.1 File System Storage Constraints.........................................................................123

23.3.1.1 Flash Storage Locations............. ...... ....................................... ....... .....123

23.3.1.2 RAM-Disk Storage Locations...............................................................124

23.3.2 RAM Constraints..................................................................................................124

23.3.3 Interrupt Constraints ............................................................................................124

23.4 Ram Disk Directory Structure...........................................................................................124

24.0 Busless Backplane Support.............................................................................................................125

25.0 Updating Software..........................................................................................................................127

25.1 Key Features of the Firmware Update Process................................................................127

25.2 Update Process Architecture............................................................................................127

25.3 Critical Software Update Files and Directories .................................................................128

25.4 Update Package ...............................................................................................................128

25.4.1 Update Package File Validation...........................................................................129

25.4.2 Update Firmware Package Version.....................................................................129

25.4.3 Component Versioning ........................................................................................130

25.5 saveList and Data Preservation........................................................................................130

25.6 Update Mode ....................................................................................................................131

25.7 Update_Metadata File ......................................................................................................131

25.8 Synchronization ................................................................................................................132

25.8.1 Updating to a Newer Synchronization Version ....................................................132

25.8.2 Updating to an Older Synchronization Version....................................................132

25.8.3 Updating to the Same Synchronization Version..................................................133

25.9 Single CMM System .........................................................................................................133

25.10 Redundant CMM Systems................................................................................................133

25.11 CLI Support.......................................................................................................................133

25.12 Hooks for User Scripts......................................................................................................134

25.12.1 Update Mode User Scripts...................................................................................134

8 Technical Product Specification

Page 9

Intel® NetStructure™ ZT 7102 Chass is Manage ment Module

Contents

25.12.2 Data Restore User Scripts.......... ....... ...... ...... ....... ...... ....... ...... ....... ...... ...............134

25.12.3 Example Task - Replace /home/scripts/myScript with a newer version if updating forward or an older version if updating backward135

25.13 Update Process ................................................................................................................136

25.14 Update Process Status and Logging ................................................................................137

25.15 DEBUG_UPDATE Variable ..............................................................................................137

25.16 Update Process Sensor and SEL Events.........................................................................137

25.17 RedBoot Update Process .................................................................................................138

25.17.1 Required Setup....................................................................................................138

25.17.2 Update Procedure................................................................................................138

D Example CLI Commands.................................................................................................................139

E Datasheet Reference......................................................................................................................141

E.1 Intel® CompactPCI* Product Information .........................................................................141

E.2 CompactPCI ..................................................................................................................... 141

E.3 IPMI ..................................................................................................................................141

E.4 Intel

F Warranty Information ......................................................................................................................143

F.1 Intel

®

IOP310 Processor Chipset .....................................................................................141

®

NetStructure™ Compute Boards & Platform Products

Limited Warranty143

F.1.1 Returning a Defective Product (RMA)..................................................................143

F.1.2 For the Americas .................................................................................................143

F.1.3 For EMEA............................................................................................................144

F.1.4 For APAC.............................................................................................................144

G Customer Support ..........................................................................................................................147

G.2 Technical Support and Return for Service Assistance .....................................................147

G.3 Sales Assistance ..............................................................................................................147

H Agency Approvals...........................................................................................................................149

H.1 CE Cer tif icati on..................... ...... ....... ...... ....... ...... ....................................... ...... ....... ... .....149

H.2 Safety................................................................................................................................149

H.3 Emissions Test Regulations .............................................................................................149

H.3.5 EN 50081-1 Emissions ........................................................................................149

H.3.6 EN 55024 Immunity .............................................................................................149

H.4 Regulatory Information .....................................................................................................150

H.4.7 FCC (USA)...........................................................................................................150

H.4.8 Industry Canada (Canada) ..................................................................................150

H.5 Product Safety Information ...............................................................................................150

Figures

1 Functional Block Diagram...........................................................................................................14

2 System Management Architecture..............................................................................................18

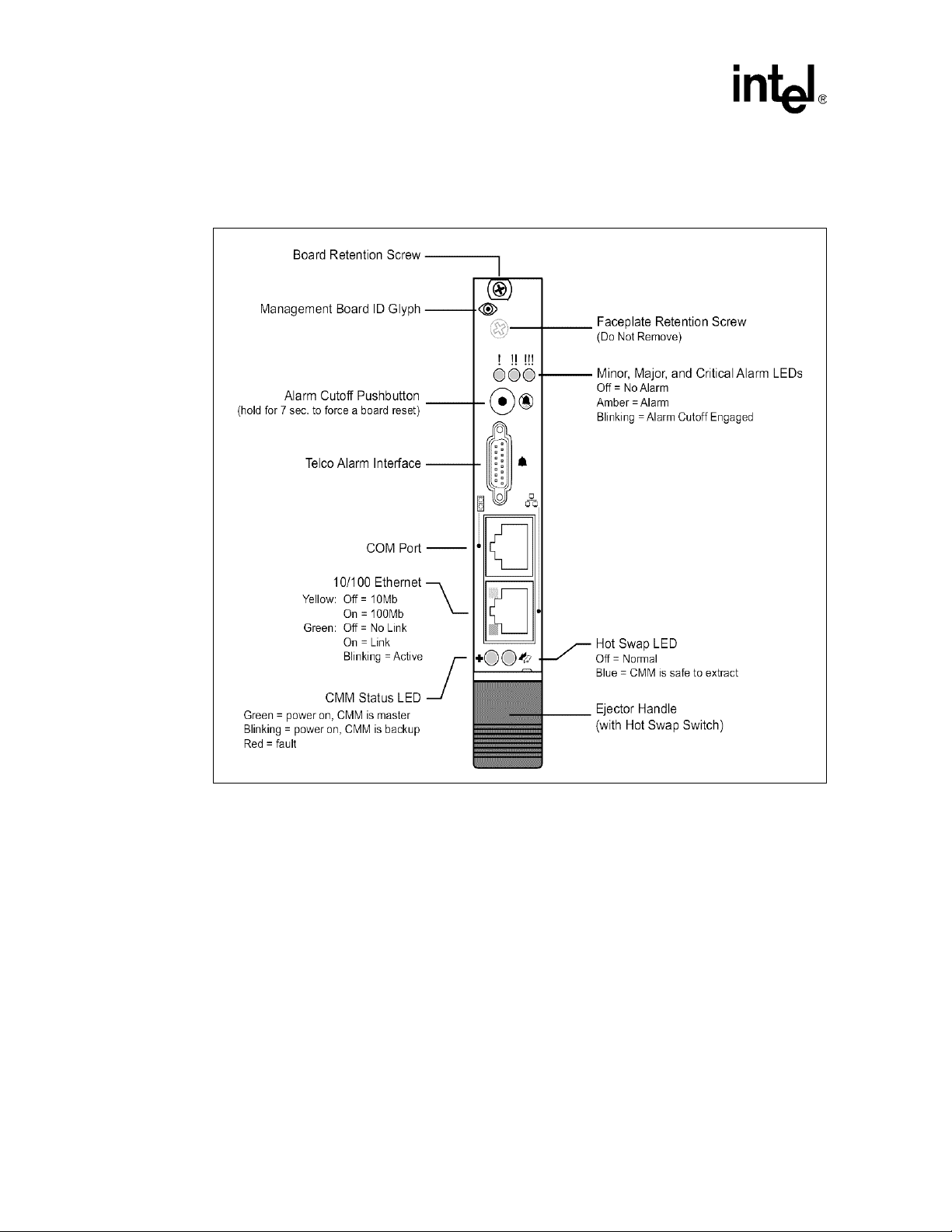

3 Face Plate...................................................................................................................................20

4 PCB Dimensions.........................................................................................................................22

5 Connector Locations...................................................................................................................23

6 Backplane Connectors - Pin Locations.......................................................................................23

7 Default Switch Configuration ......................................................................................................31

8 Ejector Handle Operation ...........................................................................................................44

Technical Product Specification 9

Page 10

Intel® NetStructure™ ZT 7102 Chassis Management Module

Contents

9 BIST Flow Chart .........................................................................................................................47

10 Timing of BIST Stages................................................................................................................49

11 High Level SNMP/MIB Layout....................................................................................................97

Tables

1 Glossary .....................................................................................................................................15

2 Faceplate Features.....................................................................................................................21

3 Board Dimensions and Weight ...................................................................................................22

4 Connector Assignments .............................................................................................................22

5 J1 Connector Pinout...................................................................................................................24

6 J2 Connector Pinout...................................................................................................................25

7 J3 Connector Pinout...................................................................................................................25

8 Pin Type Definitions....................................................................................................................26

9 Pin Descriptions..........................................................................................................................26

10 JA1 Ethernet Port Pinout ............................................................................................................28

11 J6 Serial Port Pinout...................................................................................................................28

12 J7 Telco Alarm Connector Pinout...............................................................................................29

13 CMM Power Availability..............................................................................................................29

14 Absolute Maximum Ratings........................................................................................................30

15 DC Operating Characteristics.....................................................................................................31

16 Switch Cross Reference Table...................................................................................................31

17 SW1-1 Functions........................................................................................................................32

18 Battery Characteristics ...............................................................................................................35

19 CMM Synchronization ................................................................................................................40

20 BIST Implementation..................................................................................................................48

21 Location (-l) Keywords................................................................................................................57

22 Target (-t) Keywords........... ...... ....... ...... ....... ...... ....................................... ...... ....... ...... ..............58

23 dataitem (-d) Keywords for All Locations....................................................................................58

24 dataitem (-d) Keywords for System location...............................................................................59

25 dataitem (-d) Keywords for BladeN Locations............................................................................59

26 dataitem (-d) Keywords for Chassis Location.............................................................................60

27 dataitem (-d) Keywords for CMM Location.................................................................................60

28 CMM Sensor Targets .................................................................................................................68

29 Threshold-Based Sensor Event Strings (Voltage, Temp, Current, Fan) ....................................71

30 Power Supply Event Strings (PowerSupplyN)............................................................................71

31 BIST Event Strings (BIST)..........................................................................................................72

32 Telco Alarm Sensor Event Strings (TASensor[1,2]) ...................................................................73

33 LAN Sensor Event Strings (Eth[0,1,1:1] Interface) .....................................................................73

34 Fan Tray Presence Event Strings (Fan Tray [1-3] Presence) ....................................................73

35 Chassis Power Supply Event Strings (Pwr Supply N) ................................................................73

36 Slot Event Strings (Slot N Event)................................................................................................74

37 CMM Redundancy Event Strings (CMM [1-2] Redundancy)......................................................74

38 CMM Failover Event Strings (CMM Failover).............................................................................74

39 CMM File Sync Event Strings (CMM File Sync) .........................................................................75

40 Chassis Sensor Event Strings....................................................................................................75

41 Dataitems Used With FRU Target (-t) to Obtain FRU Information .............................................89

42 MIB II Objects - System Group...................................................................................................98

43 MIB II - Interface Group ..............................................................................................................98

44 SNMPv3 Security Fields..................................... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... .....101

45 Error and Return Codes for the RPC Interface.........................................................................106

10 Technical Product Specification

Page 11

Intel® NetStructure™ ZT 7102 Chass is Manage ment Module

Contents

46 Threshold Response Formats ..................................................................................................110

47 String Response Formats.........................................................................................................110

48 Integer Response Formats .......................................................................................................113

49 FRU Data Items String Response Format................................................................................114

50 RPC Usage Examples..............................................................................................................116

51 List of Critical Software Update Files and Directories...............................................................128

52 Contents of the Update Package..............................................................................................128

53 saveList Items and Their Priorities............................................................................................130

54 Synchronization Behavior for Differing Synch Versions ...........................................................132

55 Example CLI Commands.............. ...................................... ....... ...... ....... ...... ....... ...... ....... ...... . .139

Technical Product Specification 11

Page 12

®

Intel

NetStructure™ ZT 7102 Chassis Management Module

Contents

Revision History

Date Revision Description

August 2004 017

April 2004 016

March 2004 015 Changes related to V4.11b frimware verison

March 2004 014

October 2003 010

April 2003 005 V3 .00a Release

Changes related to V4.11h firmware

Added new BIST events for RTC and FRU checking.

Added new Chassis Slot event for IPMI capable

Added information on /etc/version checking

Added infomation on chassis FRU validity checking.

Changes related to V4.11c firmware

Added rdate feature information

Changes related to V4.11a firmware version

Changes to Software Update section

Slotcontrol description

Changes to Heatlh Event Strings

Changes related to V4.0x firmware version

New Password Reset Implementation

PSInhibit

Power Sequencing Policies

Updated Warranty and Customer Support information.

12 Technical Product Specification

Page 13

1.0 Introduction

1.1 Overview

The Intel® NetStructureTM ZT 7102 is a 3U, single-slot Chassis Management Module (CMM)

intended for use with PICMG* 2.1 , 2.16, and 2. 9-compl iant sy stems (the Compact PCI* Hot Swap,

Packet Switching Backplane, and System Management specifications, respectively). This

document details the features and specifications of the ZT 7102.

The ZT 7102 plugs into a dedicated slot in compatible systems. It provides centralized

management and alarming for up to 21 node and/or fabric slots as well as for system power

supplies and fans. The ZT 7102 may be paired with a backup for use in high-availability

applications.

The ZT 7102 is a special purpose single board computer with its own CPU, memory, PCI bus,

operating system, and peripherals. The ZT 7102 monitors and configures Intelligent Platform

Management Interface (IPMI)-based components in the chassis. When thresholds such as

temperature and voltage are crossed or a failure occurs, the CMM captures these events, stores

them in an event log, sends SNMP traps, and drives the Telco alarm relays and alarm LEDs. The

CMM can query FRU information (such as serial number, model number, manufacture date, etc.),

detect presence of components (such as fan tray, CPU board, etc.), and perform health monitoring

of each component. In addition, the CMM controls the power-up sequencing of each node board

and the power to each slot via the BD_SEL# signal.

Intel® NetStructureTMZT 7102 Chassis Manage ment Module

Introduction

The ZT 7102 can also be used at a limited degree to manage non-IPMI based chassis components.

1.2 ZT 7102 Features

• High-density 3U X 1-slot form factor

• Compatible with PICMG* 2.1, 2.16, and 2.9-compliant chassis and components

• Monitors via the Intelligent Platform Management Bus (IPMB) protocol

• Provides isolated IPMB signals for each slot for maximum security and reliability

• Manage through the command line interface, SNMP v1/v3, or Remote Procedure Call (RPC)

• Hot-add/hot-swap support for IPMI-based, field-replaceable components

• µDB15 Telco Alarm Interface at the front panel

• Critical, Major, and Minor alarm LEDs at the front panel

• CMM status and hot swap LEDs at the front panel

• Monitors backplane voltages and status for up to eight power supplies

• Monitors system temperature sensors

• Monitors system fan tray presence

• Monitors tachometers for up to 16 system fans

• Monitors sensors on PICMG 2.9 compliant single board computers

• Power state control for single board compute blades

Technical Product Specification 13

Page 14

Intel® NetStructureTMZT 7102 Chassis Management Module

Introduction

Figure 1. Functional Block Diagram

!

(73

8 9, 3

9: ,,3

*!*!+

(&! 01

!* "/+

"!

% 2

(&! 3

.%3 4)3+

. *)

$

%

&'

(" !)!

!*

!+

. .

,- ,!!

#

#

66

!

'"/

( !*

/ !+

2%

&

%

5%

/"%%

; / ! !* -!* - * ,, 6 :

14 Technical Product Specification

Page 15

Intel® NetStructureTMZT 7102 Chassis Manage ment Module

1.3 Terms Used in This Document

Table 1. Glossary

Acronym Description

CMM Chassis Management Module

CLI Command Line Interface

FRU Field Replaceable Unit

IPMI Intelligent Platform Management Interface

IPMB Intelligent Platform Management Bus

MIB Management Information Base

MIB II RFC1213 - A standard Management Information Base for Network Management

SEL System Event Log

SBC Single Board Computer

SNMP Simple Network Management Protocol

SNMP v.1 SNMP version 1

SNMP v.3 SNMP version 3

SDR Sensor Data Record

Introduction

Technical Product Specification 15

Page 16

Intel® NetStructureTMZT 7102 Chassis Management Module

Introduction

16 Technical Product Specification

Page 17

Intel® NetStructureTMZT 7102 Chassis Manage ment Module

Hardware Specifications

2.0 Hardware Specifications

2.1 Overview

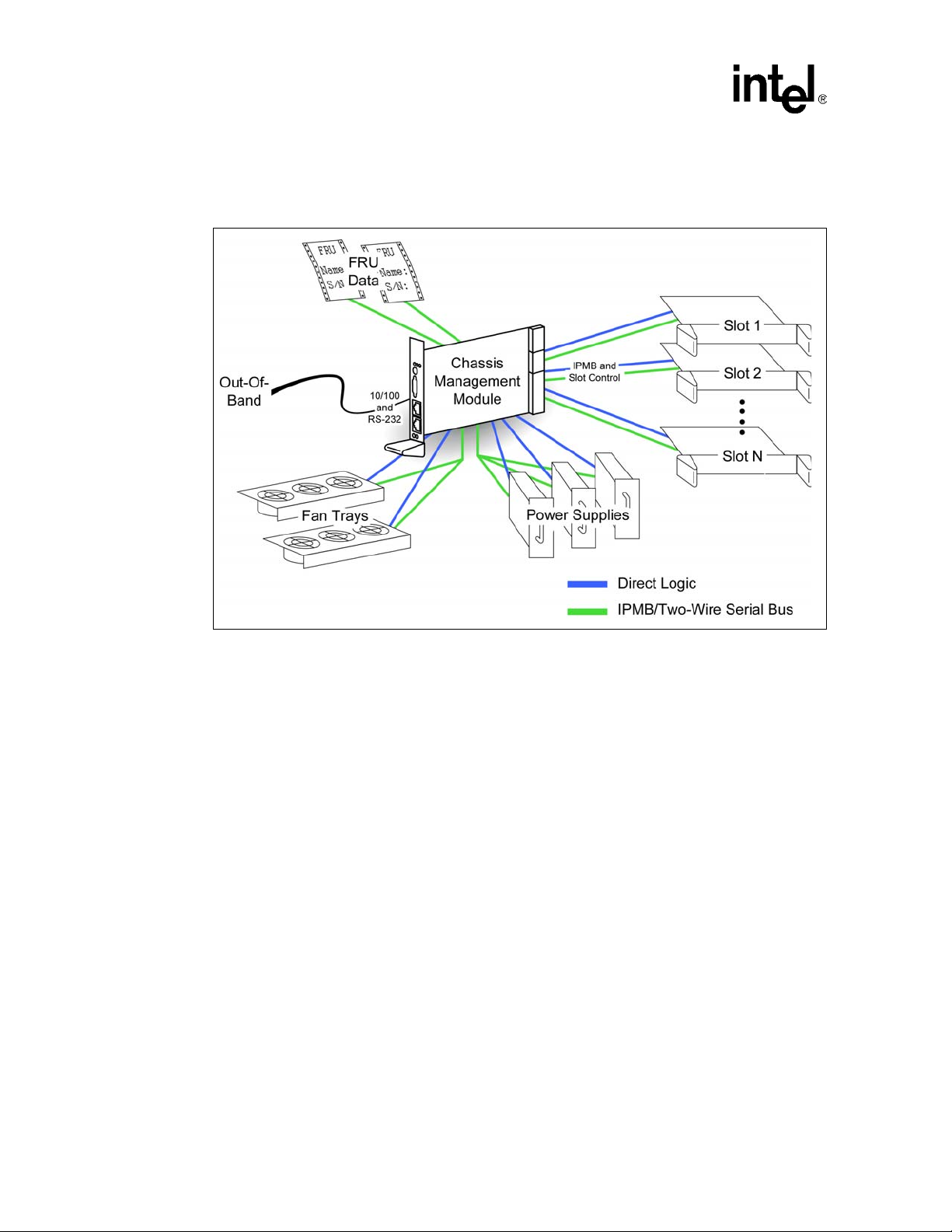

The chassis management module (CMM) is intended to operate as a chassis management building

block in a CompactPCI chassis. The CMM uses a unique backplane interface pinout and requires a

dedicated slot within the chassis.

Caution: The ZT 7102 plugs into a dedicated chass is management slot. Syst em components w ill be damaged

if a standard 3U board is plugged into the chassis management slot.

Intelligent Platform Management Buses (IPMBs) are the primary management connection between

components. A unique star topology radiating from the CMMs is used to provide reliability,

flexibility and security. In some cases, direct logic is used to support non-intelligent devices and to

eliminate active components on the backplane and chassis.

The CMM provides 30 master/slave two-wire serial bus (2WSB) interfaces. The 2WSBs are

electrically equivalent to I2C*. As such, all outputs are open drain, so they are driven low and

passively pulled high. The 2WSB interfaces support multi-master operation on the bus, however

they do not support being the target of a read transaction from another master device. The 2WSB

interfaces are used by the CMM as IPMBs or non-intelligent management busses. Refer to the

individual sections for specific usage information. The 2WSB interfaces are used for:

• Up to 21 general-purpose slots (21 independent 2WSBs, 2WSB_S0 - 2SB_S20)

• Power supplies (two buses, 2WSB_PS0 and 2WSB_PS1 )

• Fan trays (one bus, 2WSB_FT)

• Chassis sensors (one bus, 2WS B_ CS )

• Chassis FRU mo dules (two indep endent buses, 2WSB_CF0 and 2WSB_CF1)

• Redundant CMM link (one bus for bi-directional communication, 2WSB_RCMM)

Technical Product Specification 17

Page 18

Intel® NetStructureTMZT 7102 Chassis Management Module

Hardware Specifications

2.2 System Architecture

Figure 2. System Management Architecture

2.3 Backplane Connections

2.3.1 Slot Connections

The slots are connected to the CMM via an IPMB defined in the PICMG* 2.9 specification. The

CMM also has connections for BD_SEL# and HEAL THY# signals to each slot. Each slot has an

independent IPMB, BD_SEL#, and HEALTHY#. The CMM supports up to 21 general-purpose

node slots.

The IPMB is used for IP MI management communication between the CMM and the board in the

slot. Each board that is to be managed by the CMM is required to support the IPMB as a

management channel.

BD_SEL# is used in CompactPCI slots to control board power and to detect board presence. The

CMM provides a bi-directional open drain driver for each BD_SEL#. The board installed in the

slot provides a pull-up resistor (1.2 KΩ ± 5% per PICMG* 2.0). The CMM provides a weak

pulldown resistor (and a diode clamp ). When not asserted , BD_SEL# can be read to determine if a

board is present in the slot. If BD_SEL# is high, a board is present. If BD_SEL# is not asserted a

board is not present. Asserting BD_SEL# allows the board to power up.

HEALTHY# is an input to the CMM. The CMM provides a pull-up resistor. The board in the slot

asserts HEALTHY# based on board power being good and optionally other board-specific

requirements. BD_SEL# must be asserted for HEALTHY# to be asserted. When BD_SEL# is

asserted, and a board is removed, HEALTHY# will be deasserted.

18 Technical Product Specification

Page 19

Intel® NetStructureTMZT 7102 Chassis Manage ment Module

2.3.2 Chassis Sensor Connections

Chassis sensors are connected to the CMM via one two-wire serial bus.

2.3.3 Chassis FRU Device Connections

Chassis sensors are connected to the CMM via one two-wire serial bus. The CMM provides two

2WSB interfaces for chassis FRU modules. Each chassis FRU module is on a dedicated 2WSB in

order to provide redundant access to vital chassis information (e.g., the physical location of the

chassis). The backplane FRU storage device used MUST be an Atmel* AT24C16 or other

24C16-compatible device.

2.3.4 Redundancy

The CMM supports redundant operation with automatic failover under hardware or software

control. The following hardware interfaces exist for the support of redundancy and automatic

failover:

• Cross-connected CMM present inputs (PRES_I#) and outputs (PRES_O#)

• Cross-connected CMM healthy inputs (HLY_I#) and outputs (HLY_O#)

• Cross-connected negotiation inputs (NEG_I) and outputs (NEG_O)

Hardware Specifications

The active CMM monitors its PRES_I# and HL Y_I# inputs to determine if it has a healthy, standby

CMM. The active CMM deasserts its HLY_O# output to trigger a failover to the standby CMM.

The cross-connected negotiation signals are used to assure that only one CMM is active at a time.

At anytime, the standby CMM can trigger a failover by driving its NEG_O output low.

2.4 Power Modules

Power supply sleds are connected to the CMM via two IPMBs. Each power supply sled connects to

one IPMB. Multiple power supplies can share a single IPMB. The CMM also provides independent

DEG#, FAIL#, and INH# signals as defined in PICMG* 2.11 for up to eight power supplies. The

CMM will communicate with intelligent supplies via the IPMBs. Non-intelligent supplies are

supported via the DEG# (degrade), FAIL# (fail), and INH# (inhibit) signals.

The CMM uses INH# rather than EN# t o control the power supplies. The EN# pin is grounded on

the backplane to signal to a power supply when it is fully seated in its connector.

2.5 Fan Modules

Fan trays are connected to the CMM via one two-wire serial bus (2WSB). Intelligent fan trays

communicate with the CMM via the IPMB. To support non-intelligent fan trays, the CMM also

provides independent fan tachometer input s for up to 16 fans, fan t ray pr esen t inputs for up to four

fan trays, and four fan speed outputs (four buffered copies of a single PWM). Non-intelligent fan

trays are monitored and controlled via the fan tachometer inputs and the fan speed output.

Technical Product Specification 19

Page 20

Intel® NetStructureTMZT 7102 Chassis Management Module

Hardware Specifications

2.6 Face Plate

Figure 3. Face Plate

20 Technical Product Specification

Page 21

2.6.1 Faceplate Features

The following features are found on the faceplate of the ZT 7102:

T able 2. Faceplate Features

Feature Purpose

Minor, Major, and Critical Alarm

LEDs

Alarm Cutoff (ACO) push button

Telco Alarm I nterface (µDB15

connector)

COM Port (RJ-45 connector)

Ethernet Port (RJ-45 with LEDs)

CMM Status LED

Hot Swap LED

Ejector with hot swap switch

Intel® NetStructureTMZT 7102 Chassis Manage ment Module

Hardware Specifications

These LEDs indicate the presence of various event-triggered alarms.

The LEDs function as follows:

Off = no alarm triggered.

Amber = alarm triggered.

Blinking = alarm cutoff (ACO) is activated.

This push button toggles the ACO state. When ACO is activated, the

active alarm LEDs blink and all of the alarm relays are deactivated. This

button does not clear alarms.

The ZT 7102 can be reset by pressing and holding the ACO button for

about five seconds.

This interface relays alarm signals to off-board equipment. Contact Intel

for a compatible cable (µDB15 to standard DB15). See Appendix G,

“Customer Support.” for details.

This serial port may be used to access the CMM's Command Line

Interface (CLI).

This port provides an out-of-band 10/100 Ethernet connection. The

port's integrated LEDs function as follows:

Yellow: Off = 10 Mbit

On = 100 Mbit

Green: Off = No Link

On = Link

Blinking = Ac tivity

This LED indicates CMM status as follows:

Green = power is on and the board is acting as the master (active)

CMM.

Blinking green = power is on and the board is acting as the backup

(standby) CMM.

Red = the CMM needs attention (a critical problem exists).

This LED indicates when it is safe to remove the CMM from a live

(powered-on) chassis. The LED functions as follows:

Off = the CMM is not ready to be removed from a live chassis.

Blue = the CMM is ready to be removed from a live chassis.

The ejector functions as a handle and a lever for installing or removing

the CMM. The ejector incorporates a switch that tells the CMM when the

board is about to be removed from a system.

Technical Product Specification 21

Page 22

Intel® NetStructureTMZT 7102 Chassis Management Module

Hardware Specifications

2.7 Mechanical

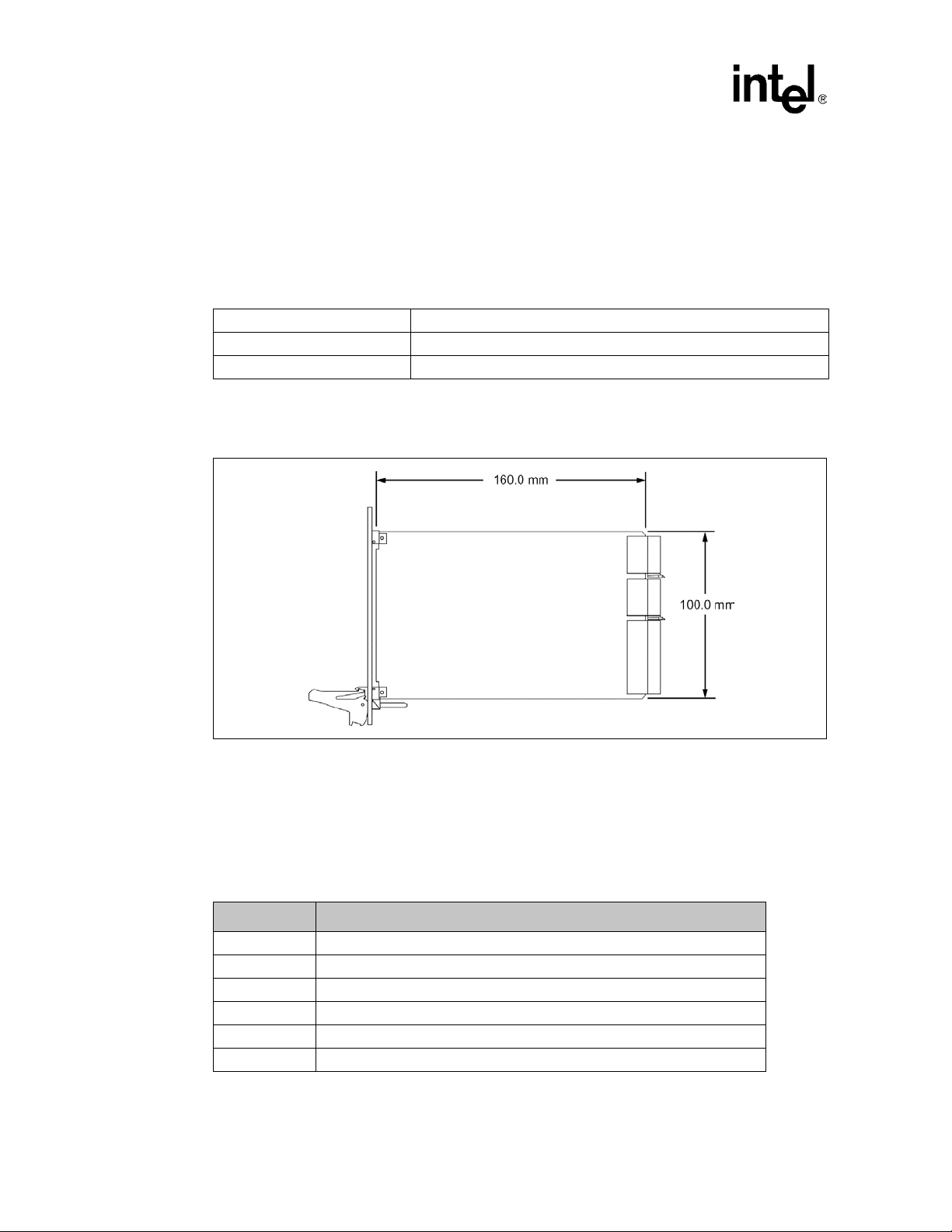

2.7.1 Board Dimensions and Weight

In a compatible enclosure, the ZT 7102 occupies a single 3U CMM slot. Mechanical dimensions

are shown in Figure 4 and outlined in Table 3.

Table 3. Board Dimensions and Weight

PCB Dimensions: 100 mm x 160 mm x 1.6 mm

Board Dimensions: 3U x 4HP (one slot)

Weight: 7.7 ounces w/ 128 Mbyte SODIMM

2.7.2 PCB Dimensions

Figure 4. PCB Dimensions

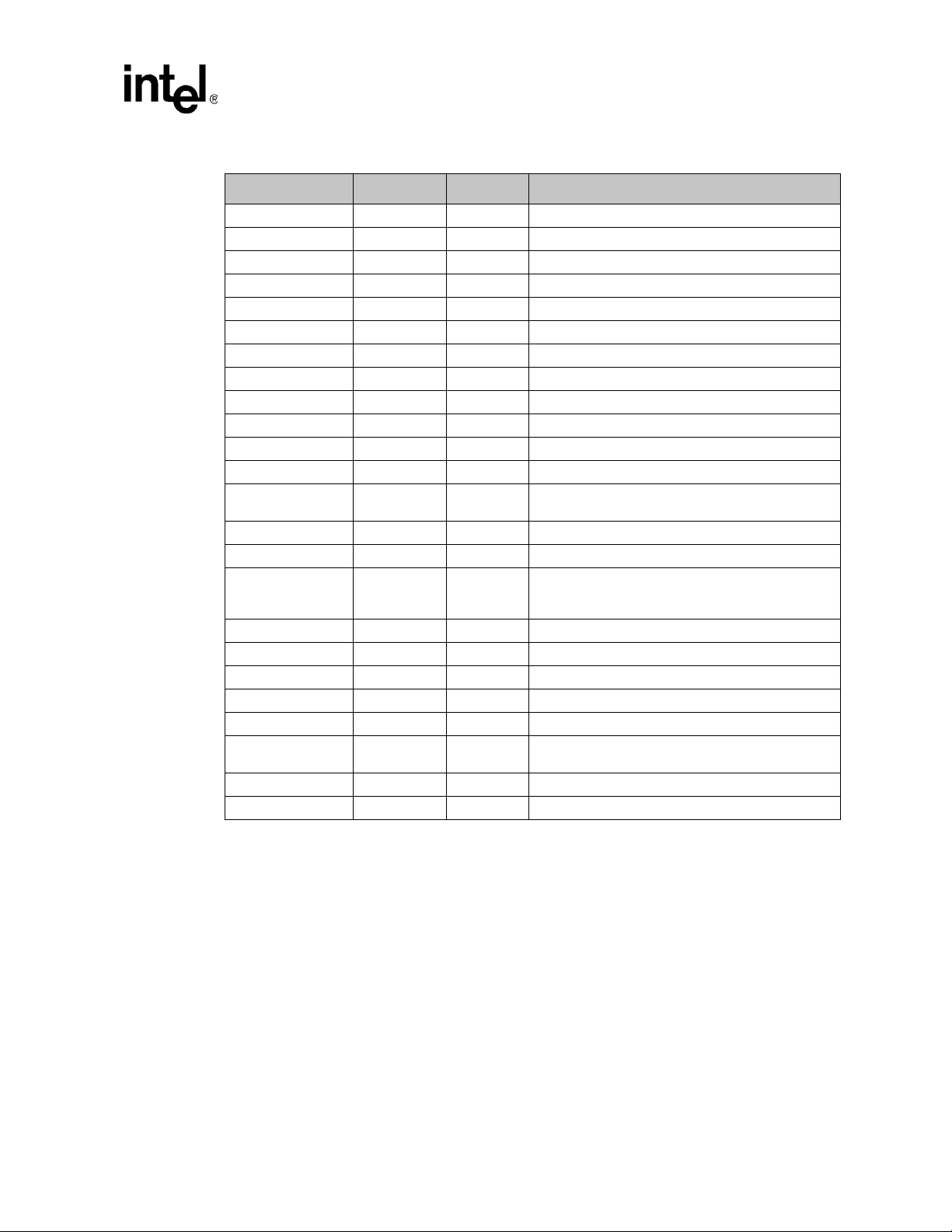

2.8 Connectors

As shown in Figure 5, the ZT 7102 includes several connectors to interface to application-specific

devices. A brief description of each connector is given in Table 4 below. A detailed descr iption and

pinout for the backplane connectors is given in the following sections.

Table 4. Connector Assignments

Connector Function

J1, Table 5 Backplane Connector (110-pin, 2mm x 2 mm, female)

J2, Table 6 Backplane Connector (55-pin, 2 mm x 2 mm, female)

J3, Table 7 Backplane Connector (55-pin, 2 mm x 2 mm, female)

J4 Connector reserved for test.

JA1, Table 10 Ethernet Connector (RJ-45, 8-pin)

J6, Table 11 Serial Port (RJ-45, 8-pin)

22 Technical Product Specification

Page 23

Table 4. Connector Assignments

Connector Function

J7, Table 12 Telco Alarm Connector (uDB-15, 15-pin)

J8, SODIMM Socket (144-pin)

J9 Connector reserved for test.

Figure 5. Connector Locations

Intel® NetStructureTMZT 7102 Chassis Manage ment Module

Hardware Specifications

Figure 6. Backplane Connectors - Pin Locations

Technical Product Specification 23

Page 24

Intel® NetStructureTMZT 7102 Chassis Management Module

Hardware Specifications

2.8.1 J1 Backplane Connector

J1 is a 110-contact, 2 mm x 2 mm female CompactPCI form-factor connector (AMP 352152-1).

See Table 5 for pin definitions and Figure 6, “Backplane Connectors - Pin Locations” on page 23

for relative pin placement.

Table 5. J1 Connector Pinout

Pin# A B C D E F

22 PDEG0# PDEG2# GND PDEG4# PDEG6#

21 PDEG1# PDEG3# IPMB_PWR PDEG5# PDEG7#

20 PFAIL0# PFAIL2# GN D PFAIL4# PFAIL6#

19 PFAIL1# P FAIL3# IPMB_PWR PFAIL5# PFAIL7#

18 PINH0# PINH2# GND PINH4# PINH6#

17 PINH1# PINH3# IPMB_PWR PINH5# PINH7#

16 PS_SCL0 PS_SDA0 GND PRES_I# GA0

15 PS_SCL1 PS_SDA1 RES FANP0# FANP2#

14 FT_SCL FT_SDA GND FANP1# FANP3#

13 CS_SCL CS_SDA RES FANPWM0 FANPWM2

12 CF_SCL0 CF_SDA0 GND FANPWM1 FANPWM3

11 CF_SCL1 CF_SDA1 RES FANTK0 FANTK8

10 RES RES GND FANTK1 FANTK9

9 RES RES RES FANTK2 FANTK10

8 STx SRx SRI FANTK3 FANTK11

7 SCTS SRTS SCD FANTK4 FANTK12

6 SDSR SDTR RES FANTK5 FANTK13

5 RPMAC # RPMIC# RES FANTK6 FANTK14

4 RPCR# RPMAR# RPMIR# FANTK7 FANTK15

3 BP_5V BP_N12V BP_12V BP_3.3V VIO

2 SwTx+ SwTx- GND RpTx+ RpTx1 SwRx+ SwRx- GND RpRx+ RpRx-

NOTE: # Designates a low true signal. All signals interface to medium length pins on the backplane.

GROUND

SHIELD

2.8.2 J2 Backplane Connector

J2 is a 55- contact, 2 mm x 2 mm female CompactPCI* form-factor connector (AMP* 352115-1).

See Table 6 for pin definitions and Figure 6 for relative pin placement.

24 Technical Product Specification

Page 25

Table 6. J2 Connector Pinout

Pin# A B C D E F

11 N_SCL1 N_SDA1 N_SCL10 N_SDA10 N_SCL18

10 N_SCL2 N_SDA2 N_SCL11 N_SDA11 N_SDA18

9 N_SCL3 N_SDA3 N_SCL12 N_SDA12 N_SCL19

8 N_SCL4 N_SDA4 N_SCL13 N_SDA13 N_SDA19

7 N_SCL5 N_SDA5 N_SCL14 N_SDA14 N_SCL20

6 N_SCL6 N_SDA6 N_SCL15 N_SDA15 N_SDA20

5 N_SCL7 N_SDA7 N_SCL16 N_SDA16 N_SCL21

4 N_SCL8 N_SDA8 N_SCL17 N_SDA17 N_SDA21

3 N_SCL9 N_SDA9

2 R_SCL IPMB_PWR RES

1

NOTE: # Designates a low true signal.

GND R_SDA CMM_SEL# NEG_I GND

All signals interface to medium length pins on the backplane except as noted.

= Interfaces to long connector pins on the backplane.

= Interfaces to short connector pins on the backplane.

Intel® NetStructureTMZT 7102 Chassis Manage ment Module

Hardware Specifications

GROUND

SHIELD

GND NEG_O HLY_O#

IPMB_PWR HLY_I#

2.8.3 J3 Backplane Connector

J3 is a 55-contact 2 mm x 2 mm female CompactPCI form-factor connecto r (AMP 352115-1). See

Table 7 for pin definitions and Figure 6 for relative pin placement.

Table 7. J3 Connector Pinout

Pin# A B C D E F

11 N_HLY1# N_BDS1# N_HLY10# N_BDS 10# N_HLY18#

10 N_HLY2# N_BDS2# N_HLY11# N_BDS11# N_BDS18#

9 N_HLY3# N_BDS3# N_HLY12# N_BDS12# N_HLY19#

8 N_HLY4# N_BDS4# N_HLY13# N_BDS13# N_BDS19#

7 N_HLY5# N_BDS5# N_HLY14# N_BDS14# N_HLY20#

6 N_HLY6# N_BDS6# N_HLY15# N_BDS15# N_BDS20#

5 N_HLY7# N_BDS7# N_HLY16# N_BDS16# N_HLY21#

4 N_HLY8# N_BDS8# N_HLY17# N_BDS17# N_BDS21#

3 N_HLY9# N_BDS9#

2 RES GND RES

1

IPMB_PWR RES PRES_O# PIMP1# IPMB_PWR

NOTE: # Designates a low true signal.

All signals interface to medium length pins on the backplane except as noted.

= Interfaces to long connector pins on the backplane.

= Interfaces to short connector pins on the backplane.

GROUND

SHIELD

IPMB_PWR PIMP0# RES

GND RES

Technical Product Specification 25

Page 26

Intel® NetStructureTMZT 7102 Chassis Management Module

Hardware Specifications

2.8.4 Backplane Pin Descriptions

Table 8. Pin Type Definitions

Pin Type Definition

OD O pen Drain

I Input

I/O Input/Output

O Output

Table 9. Pin Descriptions (Sheet 1 of 2)

Name Count Type Description

N_SCL[1..21] 21 OD Node IPMI clock

N_SDA[1..21] 21 OD Node IMPI data

PS_SCL[0..1] 2 OD Power Supply Chassis IMPI clock

PS_SDA[0..1] 2 OD Power Supply Chassis IMPI data

FT_SCL 1 OD Fan Tray Chassis IMPI clock

FT_SDA 1 OD Fan Tray Chassis IMPI data

CS_SCL 1 OD Chassis Sensor IMPI clock

CS_SDA 1 OD Chassis Sensor IMPI data

CF_SCL[0..1] 2 OD Chassis FRU IMPI clock

CF_SDA[0..1] 2 OD Chassis FRU IMPI data

R_SCL 1 OD Redundant CMM serial clock

R_SDA 1 OD Redundant CMM serial data

N_HLY#[1..21] 21 I Node Healthy (0 = Node is healthy)

N_BDS#[1..21] 21

SwTx(+/-) 2 I/O 10/100 Ethernet To Switch

SwRx(+/-) 2 I/O 10/100 Ethernet From Switch

FANTK[0..15] 16 I Fan Tach Inputs

FANPWM[0..3] 4 O Fan Speed Control (3.3 V = ON)

FANP#[0..3] 4 I Fan tray present (3.3 V = fan tray is missing)

PDEG#[0..7] 8 I Power supply degrade

PFAIL#[0..7] 8 I Power supply fail

PINH#[0..7] 8 O Power supply inhibit

STx 1 O Ser ial transmit

SRx 1 I Serial receive

SCTS 1 I Serial clear to send

SRTS 1 O Serial request to send

SDSR 1 I Serial data set ready

OD

I/O

Node Board Select (5 V = Node is present, drive to 0

to turn node on)

26 Technical Product Specification

Page 27

Table 9. Pin Descriptions (Sheet 2 of 2)

Name Count Type Description

SDTR 1 O Serial data terminal ready

SRI 1 I Serial ring indicator

SCD 1 I Serial carrier detect

RpTx(+-) 2 I/O 10/100 Ethernet To rear panel

RpRx(+-) 2 I/O 10/100 Ethernet From rear panel

NEG_O 1 O Negotiate output to other CMM

NEG_I 1 I Negotiate input from other CMM

HLY_O# 1 O Healthy output to other CMM

HLY_I# 1 I Healthy input from other CMM

PRES_I# 1 I Other CMM is present (0V)

PRES_O# 1 O Grounded on CMM.

GA0 1 I Location Address

CMM_SEL# 1 I

GND 14 I CMM GND

IPMB_PWR 8 I CM M Power

BP_12V, BP_N12V,

BP_5V, and

BP_3.3V

RPMAC# 1 I Rear panel major alarm clear

RPMIC# 1 I Rear panel minor alarm clear

RPCR# 1 O Rear panel critical alarm relay

RPMAR# 1 O Rear panel major alarm relay

RPMIR# 1 O Rear panel minor alarm relay

VIO 1 I

RES 18 NC No Connect on Backplane

TOTAL 220

4 I Monitor backplane power 12,-12,5,3.3

Intel® NetStructureTMZT 7102 Chassis Manage ment Module

Hardware Specifications

Tells CMM it has been seated. (Backplane grounds

this pin)

Backplane IO voltage (may not be present in non-PCI

system)

2.8.5 JA1 Ethernet Port

JA1 is an RJ -45 Etherne t port providing 10 Mbit (10BASE -T) and 100 Mbit (100BASE-TX)

protocols. JA1 connects to the CMM's LAN 0 Ethernet channel. A second Ethern et channel, LAN1,

is only available at the backplane.

Two LEDs are located in the RJ-45 Ethernet connector:

• Yellow indicates speed

• Green indicates a link/activity

See Table 10 for JA1 Ethernet port pin definitions.

Technical Product Specification 27

Page 28

Intel® NetStructureTMZT 7102 Chassis Management Module

Hardware Specifications

Table 10. JA1 Ethernet Port Pinout

Pin # Description

1TX+

2TX3RX+

4,5 Unused pair; terminated on ZT 7102

6RX7 Unused pair; terminated on ZT 7102

2.8.6 J6 Serial Port

J6 is an RJ-45 connector providing a front-panel RS-232 serial port interface. Serial port signals are

also directed out connector J1 to the backplane. See Table 11 f or J6 serial port pin definitions.

Table 11. J6 Serial Port Pinout

Pin# Function Description

1 SRTS Serial Request To Send

2 SDTR Serial Data Terminal Ready

3 STx Serial Transmit

4 GND Ground

5 GND Ground

6 SRx Serial Receive

7 SDSR Serial Data Set Ready

8 SCTS Serial Clear to Send

- SRI Serial Ring Indicator (not utilized)

- SCD Serial Carrier Detect (not utilized)

2.8.7 J7 Telco Alarm Connector

J7 is a µ DB-15 connector providing a front-panel telco alarm interface. See Table 12 for J7 Telco

alarm connector pin definitions. Contact Intel for information about obtaining a compatible

µDB-15 to DB-15 cable. Contact information is located in Appendix G, “Customer Support”.

For additional information on the Telco Alarm Connector, refer to the Wiring Telco Alarm

Connectors Application Note posted at the following location:

http://www.intel.com/design/network/applnots/273926.htm

28 Technical Product Specification

Page 29

Intel® NetStructureTMZT 7102 Chassis Manage ment Module

Table 12. J7 Telco Alarm Connector Pinout

Pin # Function Description

1 AMIR+ MinorReset +

2 AMIR- MinorReset 3 AMAR+ MajorReset +

4 AMAR- MajorReset 5 ACNO CriticalAlarm - NO

6 ACNC CriticalAlarm - NC

7 ACCOM CriticalA larm - COM

8 AMINO MinorAlarm - NO

9 AMINC MinorAlarm - NC

10 AMINCOM MinorAlarm - COM

11 AMANO MajorAlarm - NO

12 AMANC MajorAlarm - NC

13 AMACOM MajorAlarm - COM

14 APRCO PwrAlarm - NO

15 APRCOM PwrAlarm - COM

- GND Not Utilized

COM=Common

NO=Normally Open

NC=Normally Closed

Hardware Specifications

2.9 Electrical and Environment al