Page 1

Intel® Server System SR1690WB Service Guide

A Guide for Technicall y Qualified Assemblers of Intel® Identified Subassemblies/

Products

Intel Order Number E78186-004

Page 2

Disclaimer

®

Information in this document is provided in connection with Intel

products. No license, express or implied, by

estoppel or otherwise, to any intellectual property rights is granted by this document. Except as provided in Intel's

Terms and Conditions of Sale for such products, Intel assumes no liability whatsoever, and Intel disclaims any

express or implied warranty, relating to sale and/or use of Intel products including liability or warranties relating to

fitness for a particular purpose, merchantability , or infringement of any patent, copyright or other intellectual property

right. Intel products are not designed, intended or authorized for use in any medical, life saving, or life sustaining

applications or for any other application in which the failure of the Intel product could create a situation where

personal injury or death may occur. Intel may make changes to specifications and product descriptions at any time,

without notice.

Intel server boards contain a number of high-density VLSI and power delivery components that need adequate

airflow for cooling. Intel's own chassis are designed and tested to meet the intended thermal requirements of these

components when the fully integrated system is used together. It is the responsibility of the system integrator that

chooses not to use Intel developed server building blocks to consult v endor datasheets and operating parameters to

determine the amount of airflow required for their specific application and environmental conditions. Intel Corporation

can not be held responsible if components fail or the server board does not operate correctly when used outside any

of their published operating or non-operating limits.

Intel, Intel Pentium, and Intel Xeon are trademarks or registered trademarks of Intel Corporation or its subsidiaries in

the United States and other countries.

* Other names and brands may be claimed as the property of others.

Copyright © 2010, Intel Corporation. All Rights Reserved

ii Intel® Server System SR1690WB Service Guide

Page 3

Preface

About this Manual

Thank you for purchasing and using the Intel® Server System SR1690WB.

This manual is written for system technicians responsible for troubleshooting, upgrading,

and repairing this server board. This document provides a brief overview of the features of

the board/chassis, a list of accessories or other components you may need, troubleshooting

information, and instructions on how to add and replace components on the Intel

System SR1690WB. For the latest version of this manual, see http://support.intel.com/

support/motherboards/server/S5500WB.

Manual Organization

®

Server

Chapter 1 provides a list of reference resources. In this chapter, you will find a list of

technical documents that give additional details on the Intel

and the location where they can be found.

®

Chapter 2 provides a brief overview of the Intel

chapter, you will find a list of the server board features, photos and illustrations of the

product, and product diagrams to help you identify components and their locations.

Chapter 3 provides instructions on using the utilities that are shipped with the board or

that may be required to update the system. This includes how to navigate through the

BIOS Setup screens, how to perform a BIOS update, and how to reset the password or

CMOS. Information about the specific BIOS settings and screens available in the Intel

Server System SR1690WB Technical Product Specification. See the “Server System

References” chapter for more information.

Chapter 4 provides instructions on adding and replacing components. Use this chapter for

step-by-step instructions and diagrams for installing or replacing components such as the

memory, processor, front panel board, and the battery, among other components.

The rest of this manual provides technical specifications, regulatory information, “Getting

Help” information, and the warranty.

Server System SR1690WB. In this

®

Server System SR1690WB,

®

iii

Page 4

Product Contents

The Intel® Server System SR1690WB ships with the Intel® Server Board S5500WB. For

further information, see the following documents:

• Intel

• Intel

The contents of the server system are listed below.

Intel® Server System SR1690WB - Product Contents

Your Int el® Server System SR1690WB ships with the following items:

• Intel

• Chassis master assembly with single 650W high-efficiency power supply unit

• One PCI Express* riser card assembly, installed in the server system

• Four system fan blowers, installed in the server system

• Standard control panel module and cables (I/O and USB), installed in the server

• Four hot-swap HDD carriers, installed in the server system

®

Server Board S5500WB Technical Product Specification

®

Server System SR1690WB Technical Product Specification

®

Server Board S5500WB, installed in the server system

system

• System air duct, installed in the server system

• Attention document, in the server system product box

• Quick Start User's Guide, in the server system product box

• Intel

®

Server Deployment Toolkit 3.0 CD

• Hardware accessary bag, described as below:

— Optical drive latch assembly

— Optical drive SATA/Power cable

— Rack handles

— One SES cable

— Various types of screws

— Two STS-100P processor heatsinks for 1U rack chassis

Note: You may need or want to purchase one or more of the following items for your server:

• One or two Intel

®

Xeon 5500 series and Intel® Xeon 5600 series processors

• DDR3 RDIMM/UDIMM Memory

• Hard drive

• Slimline CD-ROM or DVD-ROM drive

• RAID controller add-in card

iv Intel® Server System SR1690WB Service Guide

Page 5

• Operating system

• For information about which accessories, memory, processors, and third-party

hardware were tested and can be used with your board, and for ordering information

for Intel products, see: http://support.intel.com/support/motherboards/server/

S5500WB/compat.htm

Intel® Server System SR1690WB Service Guide v

Page 6

vi Intel® Server System SR1690WB Service Guide

Page 7

Safety Information

Important Safety Instructions

Read all caution and safety statements in this document before performing any of the

instructions. See also Intel Server Boards and Server Chassis Safety Information on the

®

Server Deployment Toolkit CD and/or at http://support.intel.com/support/

Intel

motherboards/server/sb/cs-010770.htm.

Wichtige Sicherheitshinweise

Lesen Sie zunächst sämtliche Warnund Sicherheitshinweise in diesem Dokument, bevor

Sie eine der Anweisungen ausführen. Beachten Sie hierzu auch die Sicherheitshinweise zu

Intel-Serverplatinen und Servergehäusen auf der Intel

oder unter http://support.intel.com/support/motherboards/server/sb/cs-010770.htm.

®

Server Deployment Toolkit CD

Consignes de sécurité

Lisez attention toutes les consignes de sécurité et les mises en garde indiquées dans ce

document avant de suivre toute instruction. Consultez Intel Server Boards and Server

Chassis Safety Information sur le Intel

vous sur le site http://support.intel.com/support/motherboards/server/sb/cs-010770.htm.

®

Server Deployment Toolkit CD ou bien rendez-

Instrucciones de seguridad importantes

Lea todas las declaraciones de seguridad y precaución de este documento antes de realizar

cualquiera de las instrucciones. Vea Intel Server Boards and Server Chassis Safety

Information en el Intel

support/motherboards/server/sb/cs-010770.htm.

重要安全指导

在执行任何指令之前,请阅读本文件中的所有注意事项及安全声明。并参阅 http://

support.intel.com/support/motherboards/server/sb/CS-010770.htm 上的

Boards and Server Chassis Safety Information

机箱安全信息》)。

®

Server Deployment Toolkit CD y/o en http://support.intel.com/

(《Intel 服务器主板与服务器

Intel Server

vii

Page 8

Warnings

Heed safety instructions: Before working with your server product, whether you are

using this guide or any other resource as a reference, pay close attention to the safety

instructions. You must adhere to the assembly instructions in this guide to ensure and

maintain compliance with existing product certifications and approvals. Use only the

described, regulated components specified in this guide. Use of other products /

components will void the UL listing and other regulatory approvals of the product and

will most likely result in noncompliance with product regulations in the region(s) in which

the product is sold.

System power on/off: The power button DOES NOT turn off the system AC power. To

remove power from system, you must unplug the AC power cord from the wall outlet.

Make sure the AC power cord is unplugged before you open the chassis, add, or remove

any components.

Hazardous conditions, devices and cables: Hazardous electrical conditions may be

present on power, telephone, and communication cables. Turn off the server and

disconnect the power cord, telecommunications systems, networks, and modems attached

to the server before opening it. Otherwise, personal injury or equipment damage can

result.

Electrostatic discharge (ESD) and ESD protection: ESD can damage disk drives,

boards, and other parts. We recommend that you perform all procedures in this chapter

only at an ESD workstation. If one is not available, provide some ESD protection by

wearing an antistatic wrist strap attached to chassis ground—any unpainted metal

surface—on your server when handling parts.

ESD and handling boards: Always handle boards carefully. They can be extremely

sensitive to ESD. Hold boards only by their edges. After removing a board from its

protective wrapper or from the server, place the board component side up on a grounded,

static free surface. Use a conductive foam pad if available but not the board wrapper. Do

not slide board over any surface.

Installing or removing jumpers: A jumper is a small plastic encased conductor that slips

over two jumper pins. Some jumpers have a small tab on top that you can grip with your

fingertips or with a pair of fine needle nosed pliers. If your jumpers do not have such a tab,

take care when using needle nosed pliers to remove or install a jumper; grip the narrow

sides of the jumper with the pliers, never the wide sides. Gripping the wide sides can

damage the contacts inside the jumper, causing intermittent problems with the function

controlled by that jumper. Take care to grip with, but not squeeze, the pliers or other tool

you use to remove a jumper, or you may bend or break the pins on the board.

viii Intel® Server System SR1690WB Service Guide

Page 9

Contents

Preface ........................................................................................................................iii

About this Manual ................................................................................................................. iii

Manual Organization ............................................................................................................. iii

Product Contents ..................................................................................................................iv

Safety Information ....................................................................................................vii

Important Safety Instructions ............................................................................................... vii

Wichtige Sicherheitshinweise .............................................................................................. vii

Consignes de sécurité ......................................................................................................... vii

Instrucciones de seguridad importantes .............................................................................. vii

Warnings ..............................................................................................................................viii

Chapter 1: Server System References .....................................................................1

Chapter 2: Server System Features ..........................................................................3

Cable Routing ........................................................................................................................6

Chassis Component Identification .........................................................................................8

Server Board Connector and Component Locations ............................................................9

Configuration Jumpers .........................................................................................................11

Intel

Back Panel Connectors .......................................................................................................15

RAID Support .......................................................................................................................16

Front Panel of Server System ..............................................................................................17

Rear of Server System ........................................................................................................19

Rack-Mounted Systems .......................................................................................................20

Hardware Requirements ...................................................................................................... 21

Memory Sparing and Mirroring ............................................................................................22

Power Supply .......................................................................................................................23

Optional Hardware ...............................................................................................................23

®

Intel

Server System SR1690WB - Product Contents .................................................iv

Internal Components .....................................................................................................8

®

Light Guided Diagnostics ...........................................................................................13

Standard Control Panel ...............................................................................................17

Peripheral Devices ......................................................................................................19

Hard Disk Drives ..........................................................................................................20

Slimline Optical Drive latch ..........................................................................................20

Processor ....................................................................................................................21

Memory ........................................................................................................................21

®

Intel

RAID Activation Key ..........................................................................................23

®

Intel

Remote Management Module 3 ........................................................................23

®

I/O Expansion Module .......................................................................................24

Intel

Intel® Server System SR1690WB Service Guide ix

Page 10

Chapter 3: Hardware Installations and Upgrades ..................................................25

Before You Begin ................................................................................................................25

Tools and Supplies Needed ........................................................................................25

System References .....................................................................................................25

Removing and Installing the System Cover ........................................................................25

Removing the System Cover ......................................................................................25

Installing the System Cover ........................................................................................26

Removing and Installing the Processor Air Duct .................................................................27

Removing the Processor Air Duct ............................................................................... 27

Installing the Processor Air Duct ................................................................................. 28

Installing and Removing Memory ........................................................................................29

Installing DIMMs ..........................................................................................................29

Removing DIMMs ........................................................................................................30

Installing or Replacing the Processor ..........................................................................31

Installing the Processor ...............................................................................................31

Installing the Heat Sink(s) ...........................................................................................34

Replacing a Processor ................................................................................................ 34

Installing and Removing a Hot-swap Hard Drive .................................................................35

Installing a SAS or SATA Hot-swap Hard Disk Drive ..................................................35

Removing a SAS or SATA Hot-swap Hard Disk Drive ................................................38

Installing or Removing a Slimline Optical Drive ...................................................................38

Installing a Slimline Optical Drive ........................................................................................38

Removing a Slimline Optical Drive ..............................................................................41

Installing and Removing the PCI Riser Assembly ............................................................... 41

Removing the PCI Riser Assembly ............................................................................. 41

Installing the PCI Riser Assembly ............................................................................... 41

Installing and Removing a PCI Add-In Card ........................................................................42

Installing a PCI Add-In Card ........................................................................................42

Removing a PCI Add-In Card ......................................................................................43

Removing and Installing the System Fans .......................................................................... 44

Replacing the System Fans ........................................................................................44

Installing and Removing the I/O Expansion Module(s) .......................................................47

Installing the I/O Expansion Module(s) .......................................................................47

Removing the I/O Expansion Module(s) .....................................................................49

Installing and Removing the Intel

50

Installing the Intel® RMM3 and Intel® RMM3 NIC ...................................................... 50

Removing the Intel

®

RMM3 and Intel® RMM3 NIC .....................................................51

Replacing the Backplane Board ..........................................................................................51

Removing the Backplane Board ..................................................................................52

Installing the Backplane Board ....................................................................................52

Replacing the Server Board ................................................................................................53

Removing the Server Board ........................................................................................53

Installing the Server Board ..........................................................................................54

®

Remote Management Module 3 and the Intel® RMM 3 NIC

x Intel® Server System SR1690WB Service Guide

Page 11

Replacing the Backup Battery .............................................................................................56

Replacing the Power Supply ................................................................................................57

Removing the Power Supply .......................................................................................57

Installing the Power Supply .........................................................................................58

Installing and Removing the Rack Handles .........................................................................59

Installing the Rack Handles .........................................................................................59

Removing the Rack Handles ...............................................................................................60

Chapter 4: Server Utilities ........................................................................................61

Using the BIOS Setup Utility ................................................................................................61

Starting Setup ..............................................................................................................61

If You Cannot Access Setup ........................................................................................61

Setup Menus ...............................................................................................................61

Upgrading the BIOS .............................................................................................................63

Preparing for the Upgrade ...........................................................................................63

Upgrading the BIOS ....................................................................................................64

Clearing the CMOS ..............................................................................................................64

Resetting the Password .......................................................................................................65

Appendix A: Technical Reference ..........................................................................67

650-W Single Power Supply Input Voltages ........................................................................67

650-W Single Power Supply Output Voltages .....................................................................67

System Environmental Specifications ..................................................................................68

Appendix B: Intel® Server Issue Report Form .......................................................69

Appendix C: LED Decoder .......................................................................................73

Appendix D: Getting Help ........................................................................................83

Warranty Information ...........................................................................................................83

Appendix E: Regulatory and Compliance Information .........................................85

Product Regulatory Compliance ..........................................................................................85

Product Safety Compliance .................................................................................................85

Product EMC Compliance - Class A Compliance ........................................................86

Certifications / Registrations / Declarations .................................................................86

Product Regulatory Compliance References ..............................................................87

Electromagnetic Compatibility Notices ................................................................................90

FCC Verification Statement (USA) ..............................................................................90

Industry Canada (ICES-003) .......................................................................................91

Europe (CE Declaration of Conformity) .......................................................................91

VCCI (Japan) ...............................................................................................................91

BSMI (Taiwan) .............................................................................................................92

KCC (Korea) ................................................................................................................92

Rack Mount Installation Guidelines .............................................................................93

Power Cord Usage Guidelines ....................................................................................94

Product Ecology Compliance ......................................................................................95

Intel® Server System SR1690WB Service Guide xi

Page 12

Other Markings ............................................................................................................98

Regulated Specified Components ...............................................................................99

End-of-Life / Product Recycling .................................................................................100

Appendix F: Warranty .............................................................................................101

Limited Warranty for Intel® Chassis Subassembly Products .............................................101

Extent of Limited Warranty ........................................................................................ 101

Limitations of Liability ................................................................................................ 102

How to Obtain Warranty Service ...............................................................................102

Appendix G: Installation/Assembly Safety Instructions .....................................105

Important Safety Instructions .............................................................................................105

English ...............................................................................................................................105

Wichtige Sicherheitshinweise ............................................................................................106

Consignes de sécurité ...............................................................................................107

Italiano ...............................................................................................................................109

Appendix H: Safety Information ............................................................................111

English ...............................................................................................................................111

Server Safety Information .........................................................................................111

Safety Warnings and Cautions ..................................................................................111

Intended Application Uses ........................................................................................ 112

Site Selection ............................................................................................................112

Equipment Handling Practices ..................................................................................112

Deutsch .............................................................................................................................113

Sicherheitshinweise für den Server ...........................................................................113

Sicherheitshinweise und Vorsichtsmaßnahmen .......................................................113

Zielbenutzer der Anwendung ....................................................................................114

Standortauswahl .......................................................................................................114

Handhabung von Geräten .........................................................................................114

Warnungen zu Netzspannung und Elektrizität ..........................................................115

Warnhinweise für den Systemzugang .......................................................................116

Warnhinweise für Racks ...................................................................................... .....116

Elektrostatische Entladungen (ESD) ......................................................................... 117

Andere Gefahren .......................................................................................................117

Français .............................................................................................................................118

Consignes de securite sur le serveur ........................................................................118

Séurité: avertissements et mises en garde ............................................................... 118

Domaines d’utilisation prévus ...................................................................................119

Sélection d’un emplacement ..................................................................................... 119

Pratiques de manipulation de l’équipement ..............................................................120

Alimentation et avertissements en matiére d’électricité ............................................ 120

Avertissements sur le cordon d’alimentation .............................................................121

Avertissements sur l’accés au systéme ....................................................................121

Avertissements sur le montage en rack .................................................................... 122

xii Intel® Server System SR1690WB Service Guide

Page 13

Décharges électrostatiques (ESD) ............................................................................123

Autres risques ............................................................................................................123

Périphériques laser ....................................................................................................124

Español ..............................................................................................................................124

Información de seguridad del servidor ......................................................................124

Advertencias y precauciones sobre seguridad ..........................................................124

Aplicaciones y usos previstos ....................................................................................125

Seleccién de la ubicación ..........................................................................................125

Manipulacién del equipo ............................................................................................126

Advertencias de alimentacién y eléctricas .................................................................126

Advertencias sobre el cable de alimentación ............................................................126

Advertencias el acceso al sistema ............................................................................127

Advertencias sobre el montaje en bastidor ...............................................................128

Descarga electrostática (ESD) ..................................................................................129

Otros riesgos .............................................................................................................129

Intel® Server System SR1690WB Service Guide xiii

Page 14

xiv Intel® Server System SR1690WB Service Guide

Page 15

List of Figures

Figure 1. Intel® Server System SR1690WB.............................................................................. 3

Figure 2. Cable Routing ............................................................................................................ 8

Figure 3. System Components.................................................................................................. 8

Figure 4. Server Board Connector and Component Locations............................................... 10

Figure 5. Configuration Jumper Location................................................................................ 12

Figure 6. Light Guided Diagnostic LEDs................................................................................. 14

Figure 7. Back Panel Connectors............................................................................................ 15

Figure 8. Front Control Panel - Intel

Figure 9. Server System I/O Connector Locations.................................................................. 19

Figure 10. Optional Peripherals............................................................................................... 20

Figure 11. DIMM Configuration Diagram................................................................................. 21

Figure 12. Channel Slots Configuration.................................................................................. 22

Figure 13. Removing the Server System Cover...................................................................... 26

Figure 14. Installing the Server System Cover........................................................................ 27

Figure 15. Removing the Processor Air Duct.......................................................................... 28

Figure 16. Installing the Processor Air Duct............................................................................ 29

Figure 17. Installing the Memory............................................................................................. 30

Figure 18. Lifting the Load Lever............................................................................................. 31

Figure 19. Open the Load Plate.............................................................................................. 32

Figure 20. Removing the socket.............................................................................................. 32

Figure 21. Aligning the Processor........................................................................................... 33

Figure 22. Close the Load Plate and Socket Lever................................................................. 33

Figure 23. IU Reference Heat sink Assembly ......................................................................... 34

Figure 24. Pulling out the back lever....................................................................................... 36

Figure 25. 2.5 HDD Installation............................................................................................... 36

Figure 26. 3.5 HDD Installation............................................................................................... 37

Figure 27. Locking the drive assembly.................................................................................... 37

Figure 28. Removing the Knockout in Bezel for Optical Opening........................................... 39

Figure 29. Attaching the Brackets to the Optical Drive............................................................ 39

Figure 30. Installing the Optical Drive into the Server System................................................ 40

Figure 31. Removing the PCI Riser Assembly from the Server System................................. 41

Figure 32. Installing the PCI Riser Assembly.......................................................................... 42

Figure 33. Installing a PCI Card in a Riser Card..................................................................... 43

Figure 34. Removing a PCI Card in a Riser Card................................................................... 43

Figure 35. Replacing the system fans..................................................................................... 45

Figure 36. Remove the screws from the fans.......................................................................... 46

Figure 37. Inserting the fan into the fan module...................................................................... 47

Figure 38. Installing the I/O Expansion Module(s).................................................................. 48

Figure 39. Attaching the I/O Expansion Module(s).................................................................. 49

Figure 40. Installing the Intel

Figure 41. Attach the Intel

Figure 42. Removing the backplane board............................................................................. 52

®

®

RMM3 module to rear chassis.................................................... 51

®

Server System SR1690WB.......................................... 17

RMM3 and Intel® RMM3 NIC.................................................. 50

Intel® Server System SR1690WB Service Guide xv

Page 16

Figure 43. Installing the backplane board............................................................................... 53

Figure 44. Removing the Server Board .................................................................................. 54

Figure 45. Installing the Server Board .................................................................................... 55

Figure 46. Replacing the Backup Battery ............................................................................... 57

Figure 47. Removing the Power Supply from the Server System........................................... 58

Figure 48. Installing the Power Supply into the Server System.............................................. 59

Figure 49. Installing the Rack Handle..................................................................................... 60

Figure 50. Removing the Rack Handle................................................................................... 60

Figure 51. CMOS Recovery Jumper....................................................................................... 65

Figure 52. Password Recovery Jumper.................................................................................. 66

Figure 53. Diagnostic LED Placement Diagram ..................................................................... 73

xvi Intel® Server System SR1690WB Service Guide

Page 17

List of Tables

Table 1. Server System References .........................................................................................1

Table 2. Intel

Table 3. NIC LED Descriptions ...............................................................................................15

Table 4. Control Panel LED Functions ....................................................................................17

Table 5. List of Supported I/O Modules on SR1690WB ..........................................................24

Table 6. Setup Menu Key Use ................................................................................................62

Table 7. 650-W Single Power Supply Output Voltages ...........................................................67

Table 8. System Environmental Specifications .......................................................................68

Table 9. POST Progress Code LED Example .........................................................................73

Table 10. Diagnostic LED POST Code Decoder .....................................................................74

Table 11. Product Regulatory Compliance References ..........................................................87

Table 12. Product Ecology Compliance ..................................................................................95

Table 13. Other Markings ........................................................................................................98

®

Server System SR1690WB Feature Summary .................................................3

Intel® Server System SR1690WB Service Guide xvii

Page 18

xviii Intel® Server System SR1690WB Service Guide

Page 19

1 Server System References

If you need more information about this product or information about the accessories that

can be used with this server system, use the following resources.

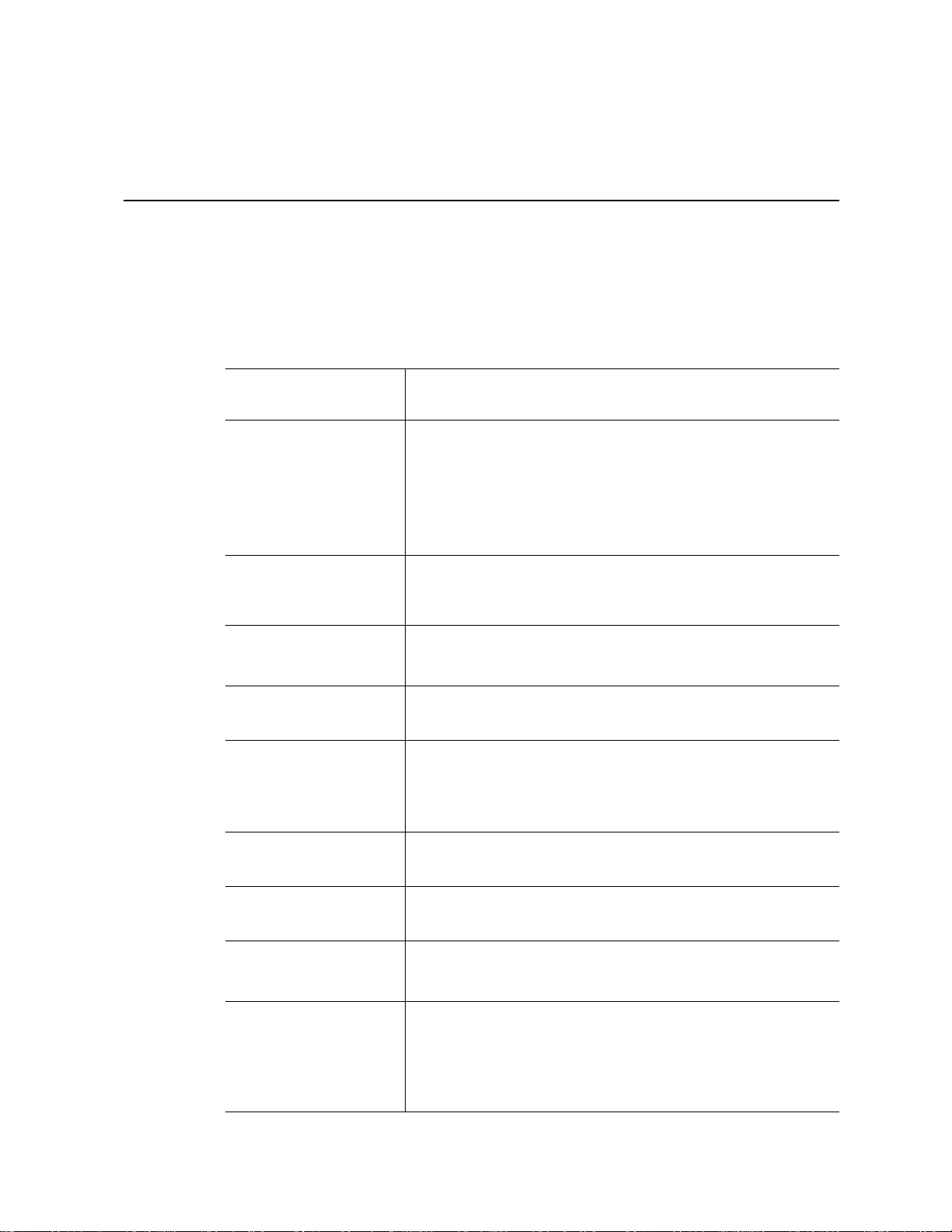

Table 1. Server System References

For this information or

software

For in-depth technical

information about the

server system, including

sub-system overviews

and mechanical drawings

For basic BIOS settings

and chipset information

If you just received this

product and need to

install it

Accessories or other Intel

server products

Hardware (peripheral

boards, adapter cards)

and operating systems

that were tested with this

product

Use this Document or Software

®

Intel

Server System SR1690WB Technical Product Specification

can be found at:

http://support.intel.com/support/motherboards/server/S5500WB/

®

Server System SR1690WB Technical Product Specification

Intel

can be found at:

http://support.intel.com/support/motherboards/server/S5500WB/

Intel® Server System SR1690WB Technical Product Specification

Found at:

http://support.intel.com/support/motherboards/server/S5500WB/

Intel® Server System SR1690WB Quick Start User's Guide in the

product box

Spares and Configuration Guide can be found at:

http://support.intel.com/support/motherboards/server/S5500WB/

Tested Hardware and Operating System List can be found at:

http://support.intel.com/support/motherboards/server/S5500WB/

Processors there were

tested with this product

DIMMs that were tested

with this product

T o make sure y our system

falls within the allowed

power budget

For software to manage

your Intel

®

server

Supported Processors can be found at:

http://support.intel.com/support/motherboards/server/S5500WB/

Supported Memory can be found at:

http://support.intel.com/support/motherboards/server/S5500WB/

Power Budget Tool can be found at:

http://support.intel.com/support/motherboards/server/S5500WB/

®

Server Management Software can be found at:

Intel

http://support.intel.com/support/motherboards/server/sysmgmt/

index.htm

®

and on the Intel

your system.

Server Management Software CD that ships with

1

Page 20

Table 1. Server System References

For this information or

For drivers Driver (for an extensive list of drivers available)

For firmware and BIOS

updates

For diagnostics test

software

software

Operating System Driver (for operating system driv er s)

http://support.intel.com/support/motherboards/server/S5500WB/

Firmware Update can be found at:

http://support.intel.com/support/motherboards/server/S5500WB/

Diagnostics: Platform Confidence Test (PCT)

Found at:

http://support.intel.com/support/motherboards/server/S5500WB/

and available on the Intel

ships with your system.

Use this Document or Software

®

Server Deployment Toolkit 3.0 CD that

2 Intel® Server System SR1690WB Service Guide

Page 21

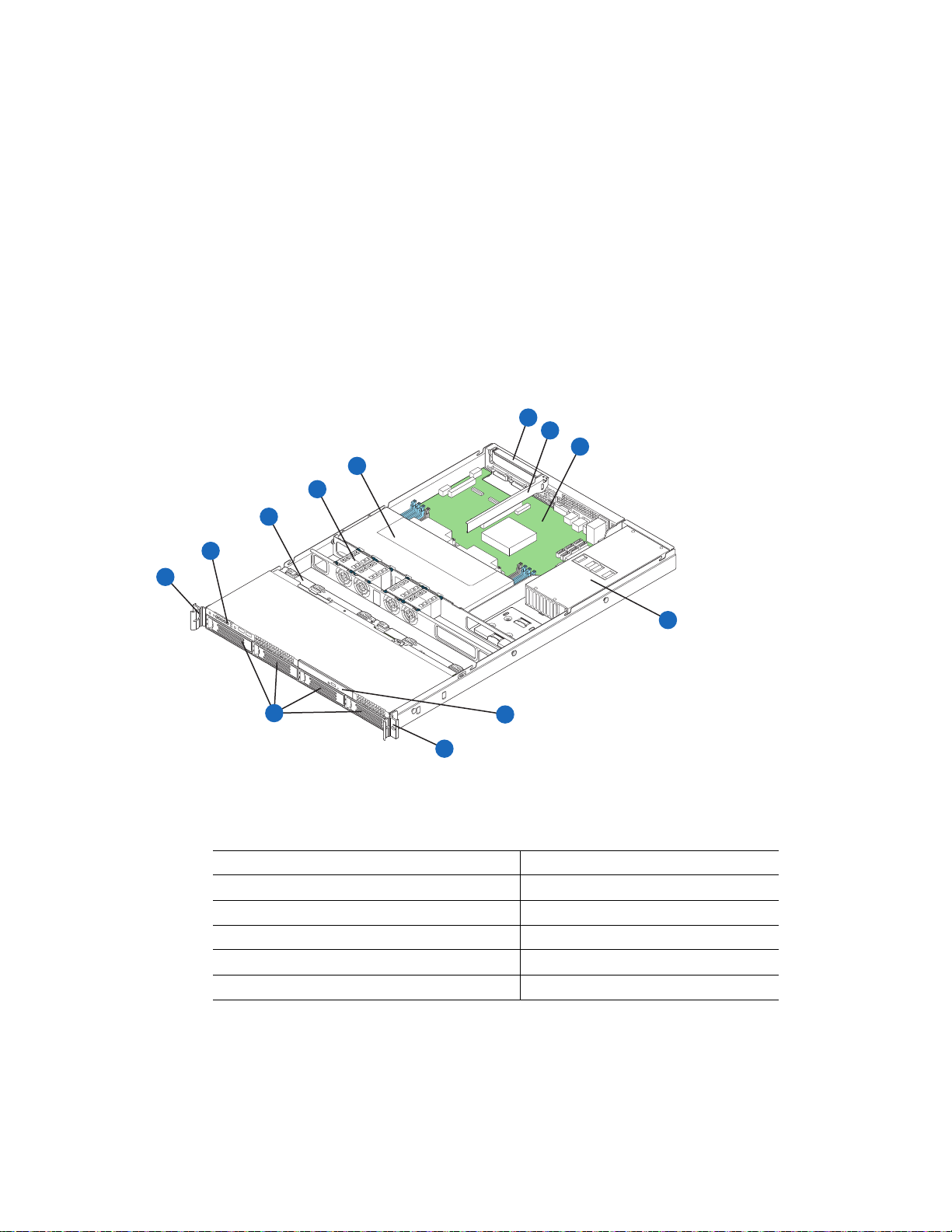

2 Server System Features

Optical

Device

AF003210

This chapter briefly describes the main features of the Intel® Server System SR1690WB.

This chapter provides illustrations of the product, a list of the server system features, and

diagrams showing the location of important components and connections on the server

system.

®

Figure 1. Intel

Server System SR1690WB

Table 2 summarizes the features of the server system.

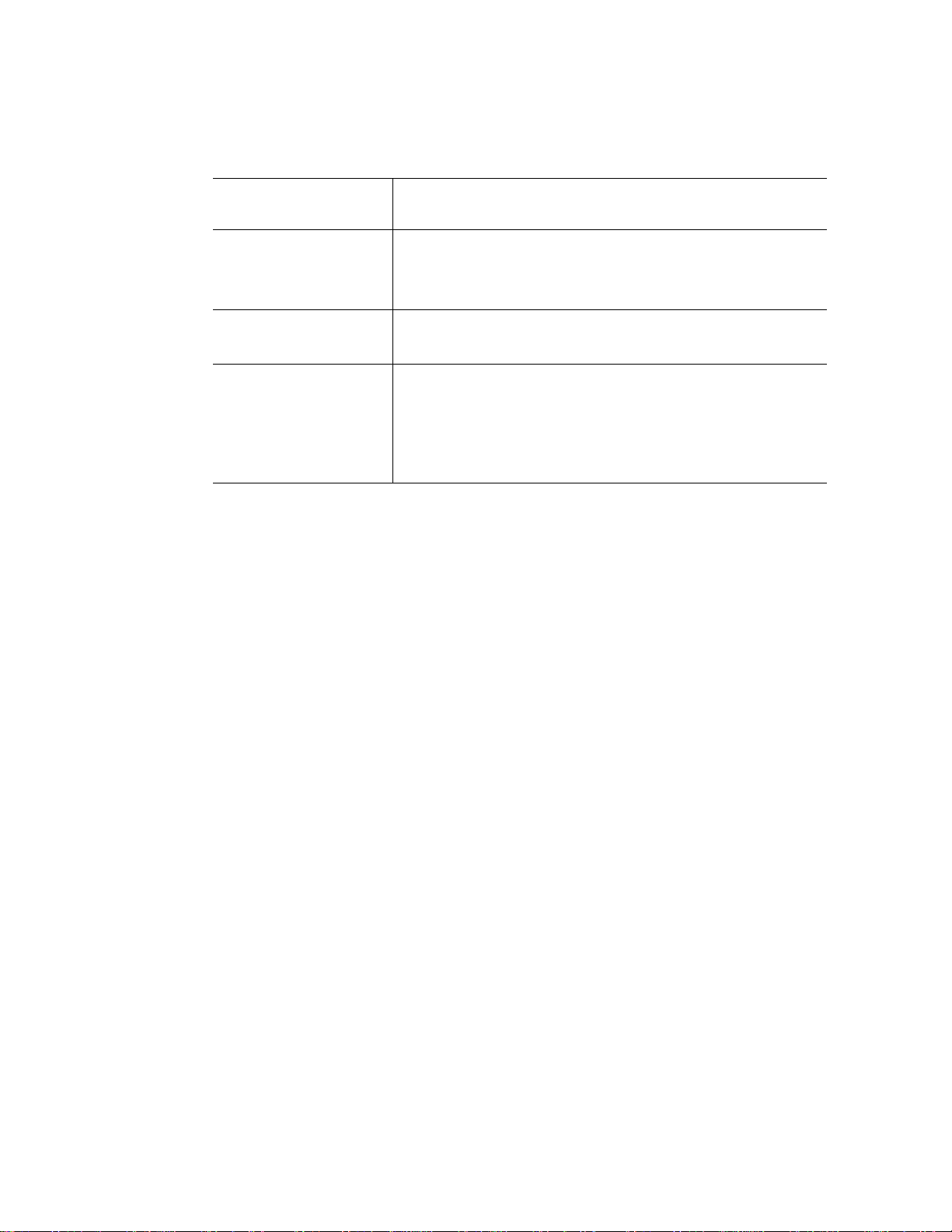

Table 2. Intel® Server System SR1690WB Feature Summary

Feature Description

Dimensions

• 1.69 inches (43mm) high

• 17.76 inches (451.17mm) wide

• 26.42 inches (671.08mm) deep

• 24.58 lbs (11.15kg) weight

Raw Storage Capacity System raw storage capacity is based on the HDD capacity and

number of HDDs used in the system. Raw storage capacity is the sum

of single HDD capacity used in system.

External Drive Bays Four hot-pluggable external drive bays

Hard Disk Drive

Supported

• 3.5-inch SATA, SAS HDD.

• 2.5-inch SATA, SAS HDD.

3

Page 22

Table 2. Intel® Server System SR1690WB Feature Summary

Feature Description

Processor

• Support for one or two Intel

®

Intel

Xeon® Processor 5600 series processors in FC-LGA 1366

Socket B package with up to 95 W Thermal Design Power (TDP).

• Supports future processor compatibility guidelines

4.8 GT/s, 5.86 GT/s, and 6.4 GT/s Intel

®

QPI).

(Intel

Meets EVRD11.1

Memory Capacity Expandable to 64 GB maximum.

Memory T ype

• 240-pin keyed support for 800/166/1333 MT/s ECC Registered

(RDIMM) or Unbuffered (UDIMM) DDR3 memory.

• 8 DIMMs total across six memory channels (three channels per

processor in a 2:1:1 configuration).

No support for Quad-Rank x4 DIMMs

DIMM Slots Eight

®

Chipset Intel

System Connectors/

Headers

Chipset which includes the following components:

Intel® 5500 chipset IOH (IOH24D)

Intel® 82801Jx I/O Controller Hub (ICH10R)

• External I/O connectors:

– DB-15 Video connectors

– RJ-45 serial Port A connector

– RJ-45 connector for 10/100/1000 LAN

– One 2x USB 2.0 connectors

– One RJ-45 over USB for 10/100/1000 LAN

• Internal connectors/headers:

– Two USB 2x5 pin header, supporting up to four USB 2.0 ports

– One low-profile USB 2x5 pin

– One DH-10 Serial Port B header

– One 2x8 pin VGA header with presence detection to switch

from rear I/O video connector

– Six SATA II connectors

– Dual Connectors for Intel

– One RMM3 connector to support optional Intel

Management Module 3

– SATA SW RAID 5 Activation Key Connector

– One SSI-EEB compliant front panel header

®

Xeon® Processor 5500 series and

®

Quick Path Interconnect

®

I/O Expansion Module

®

Remote

System Fan Support

• Two sets of CPU fans

• Two sets of DIMM fans

Add-in Adapter

Support

4 Intel® Server System SR1690WB Service Guide

®

Intel

Server Board S5500WB SSI-compliant

One riser slot supporting full-height or low-profile 1U and 1U MD2 PCI

Express* x16 riser cards.

®

Two connectors supporting double- and single-wide Intel

Expansion Modules.

I/O

Page 23

Table 2. Intel® Server System SR1690WB Feature Summary

Feature Description

On-board Video On-board Server Engines* LLC Pilot II Controller

Matrox* G200 2D Video Graphics controller

Uses 8 MB of the BMC 32 MB DDR2 Memory

LAN Support Two 10/100/1000 ports provided by Intel

Acceleration Technology (I/OAT)

System Power Single 650-W power supply, 80 plus silver with PFC

System Management On-board Server Engines* LLC Pilot II Controller.

Integrated Baseboard Management Controller (Integrated BMC), IPMI

2.0 compliant

®

82576 with Intel® I/O

• Basic

– BMC Controller: ARC 926E-S microcontroller

– Super IO: Serial Port logic, legacy interfaces, LPC interface,

Port80

– Hardware Monitoring: Fan speed control and voltage

monitoring

• Advanced

– Video and USB compression and redirection

– NC-SI port, a high-speed sideband management interface

– Integrated Super I/O on LPC interface

Intel® Server System SR1690WB Service Guide 5

Page 24

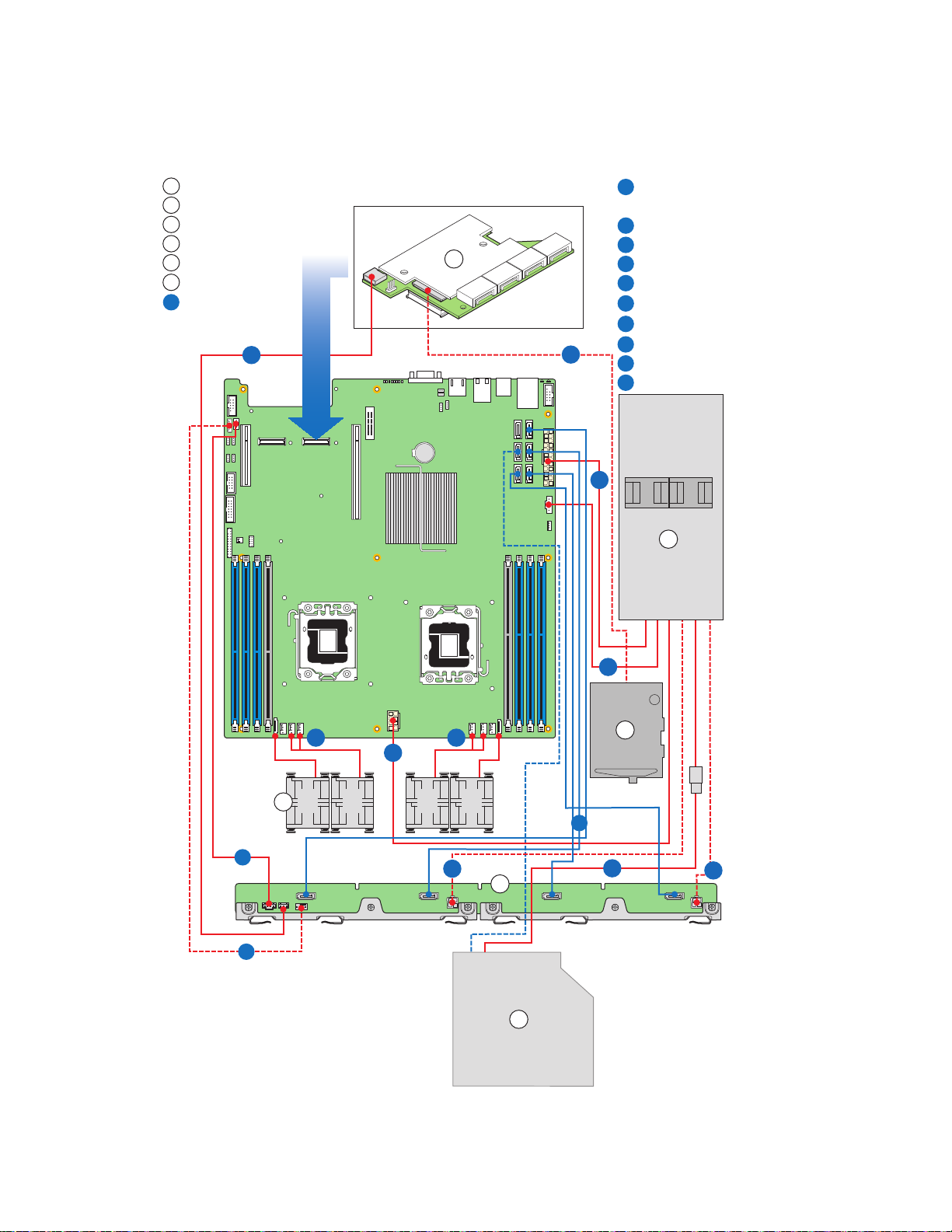

Cable Routing

When you add or remove components from your server system, make sure your cables are

routed correctly before reinstalling the server system cover. Use caution to make sure no

cables or wires are pinched and that the airflow from the fans is not blocked. Use the

following figures to determine the correct cable routing for the SR1690WB system.

6 Intel® Server System SR1690WB Service Guide

Page 25

AF003307

H

SES cable from RAID

Module to Backplane

I

Main Power

J

Aux. Signal Power

K

CPU Power

L

Power to Fans

M

Power to Optical Drive

N

Power to Backplane(2)

A

RAID Module

B

Battery Backup Unit

C

Power Supply

D

Backplane

E

Optical Drive

F

Fan Modules

Server Board

0

1

2

5

4

3

21 43

F

N

N

J

I

LL

M

K

G

D

B

A

E

RAID Card

H

G

Power from BBU

to RAID Module

O

IPMB Cable from Backplane

P

SGPIO Cable from Backplane

Q

SATA Data Cables

O

P

HDD 0

HDD 1 HDD 2 HDD 3

C

Q

Intel® Server System SR1690WB Service Guide 7

Page 26

Figure 2. Cable Routing

Optical

Device

AF003211

K

D

E

A

B

C

G

F

I

A

J

H

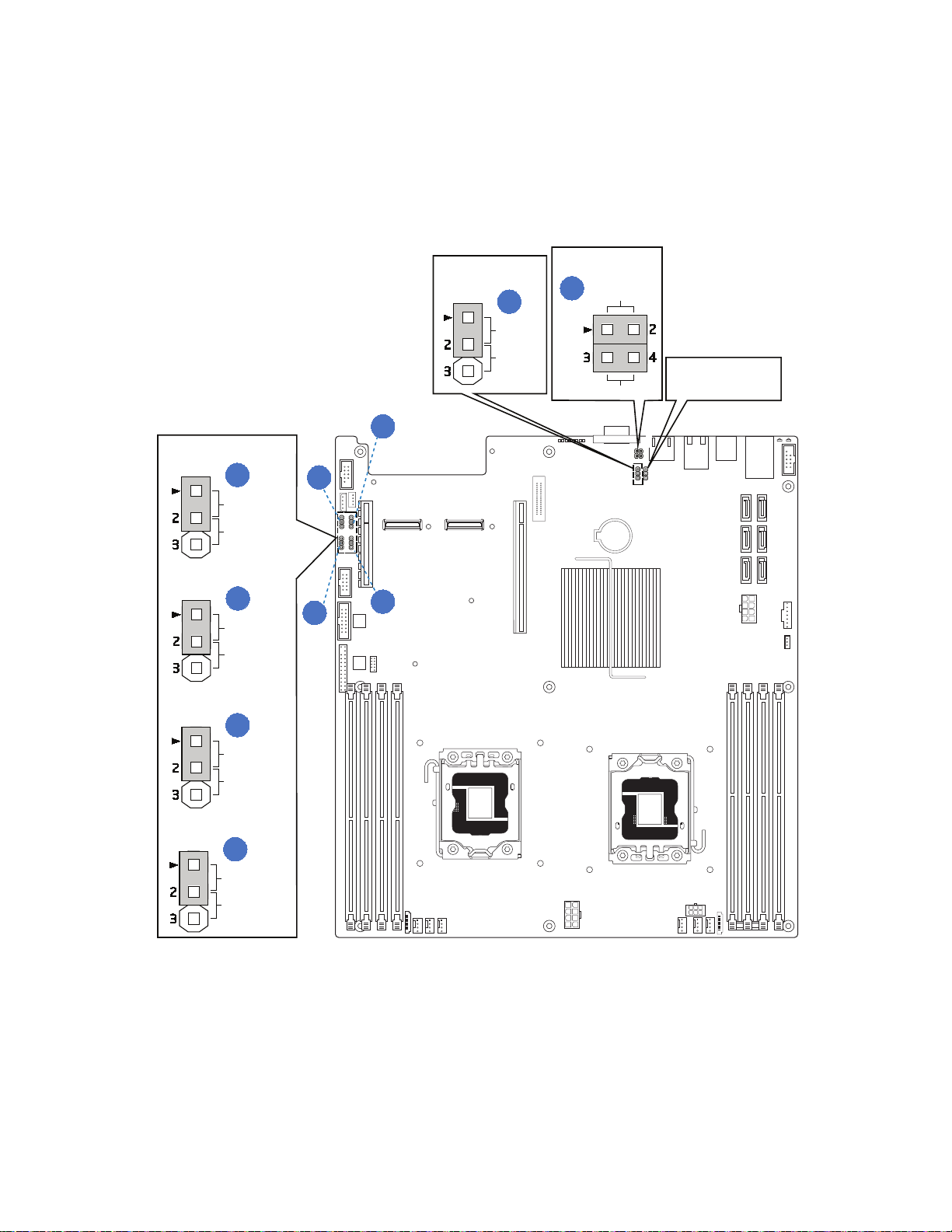

Chassis Component Identification

This section helps you identify the components of your server system. If you are near the

system, you can also use the Quick Reference Label provided on the inside of the chassis

cover to assist in identifying components.

Internal Components

A. Rack handles (two) G. PCI Express* x16 riser

B. Front Control Panel H. Mother board

C. Hot swap backplane I. 650W power supply unit

D. System Fans (CPU fans and Memory fans) J. Optional slimline optical drive

8 Intel® Server System SR1690WB Service Guide

E. Air Duct K. Hot swap HDD carrier

F. PCI Express* add-in card bracket

Figure 3. System Components

Page 27

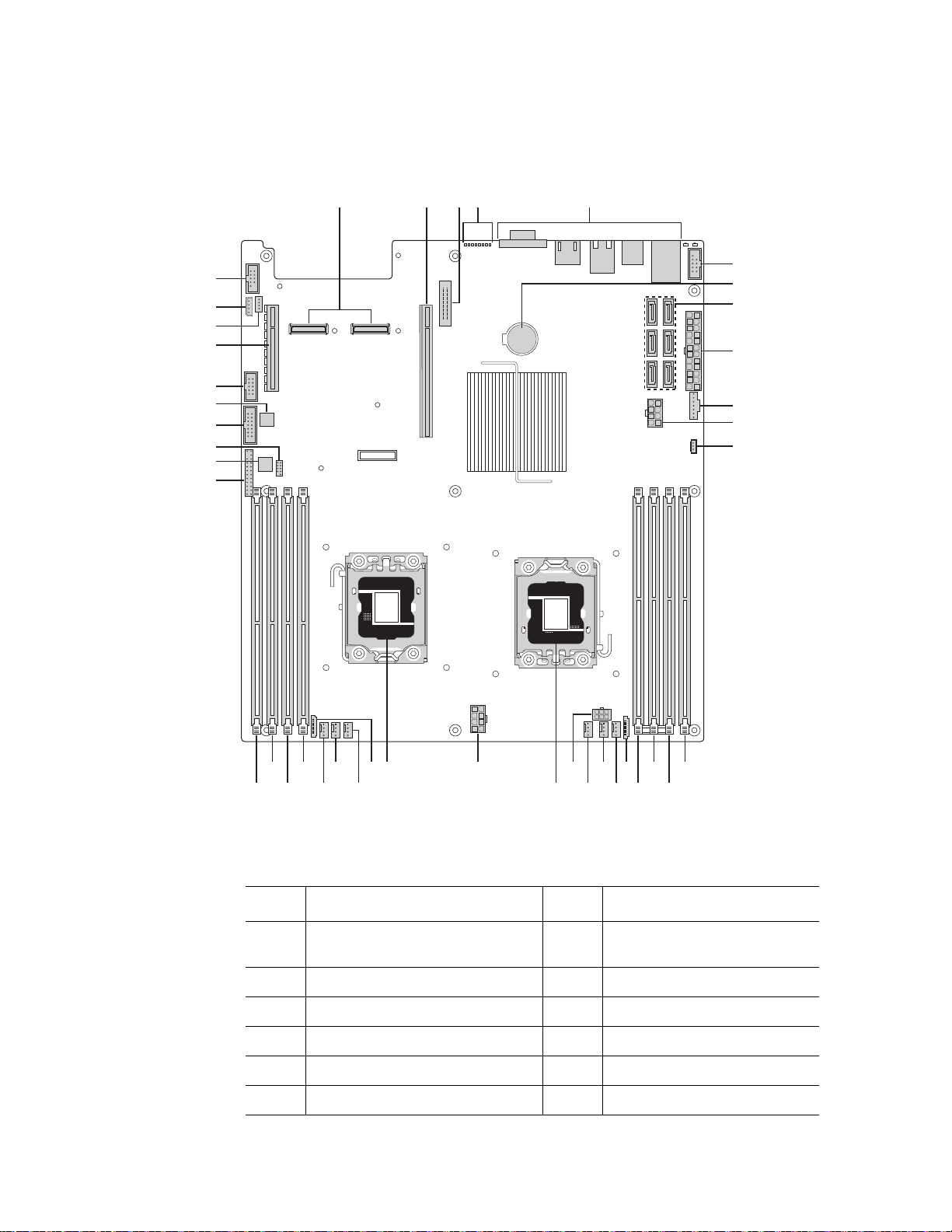

Server Board Connector and Component Locations

AF003212

EA B C

JJ

GG

LL

MM

PP

OO

NN

L

K

F

H

I

J

P

R

Q

S

T

ONM

D

U

FFEEDDCCBBAAZ

WXY

V

II

KK

HH

G

Description Description

A. Dual Intel

Connectors

B. PCI Express* x16 Gen2 X. Processor Socket 2

C. Remote Management Module 3 Y. 4-pin Fan Connector (CPU2)

D. POST Code LEDs Z. 4-pin Fan Connector (CPU2A)

®

I/O Expansion Module

W. 8-pin CPU Connector

E. External I/O AA. 4-pin Fan Connector (MEM2)

F. USB Connector BB. 8-pin Fan Connector (MEM2R)

Intel® Server System SR1690WB Service Guide 9

Page 28

Description Description

G. Battery CC. DIMM Slot D2

H. SATA Connectors 0~5 DD. DIMM Slot D1

I. 24-pin Power Connector EE. DIMM Slot E1

J. N/A FF. DIMM Slot F1

K. Aux Power (5-pin or 7-pin) GG. Front Panel Connector

L. RAID Key HH. HDD LED Header

M. DIMM Slot C1 II. Low-Profile USB Connector

N. DIMM Slot B1 JJ. Internal VGA Connector

O. DIMM Slot A1 KK. N/A

P. DIMM Slot A2 LL. USB Connector

Q. 8-pin Fan Connector (MEM1R) MM. Slot 1 PCI Express* x8 Gen2

R. 4-pin Fan Connector (MEM1) NN. SGPIO Connector

S. 4-pin Fan Connector (CPU1A) OO. IMPB Connector

T. 4-pin Fan Connector (CPU1) PP. Serial Port B

U. N/A

V. Processor Socket 1

Figure 4. Server Board Connector and Component Locations

10 Intel® Server System SR1690WB Service Guide

Page 29

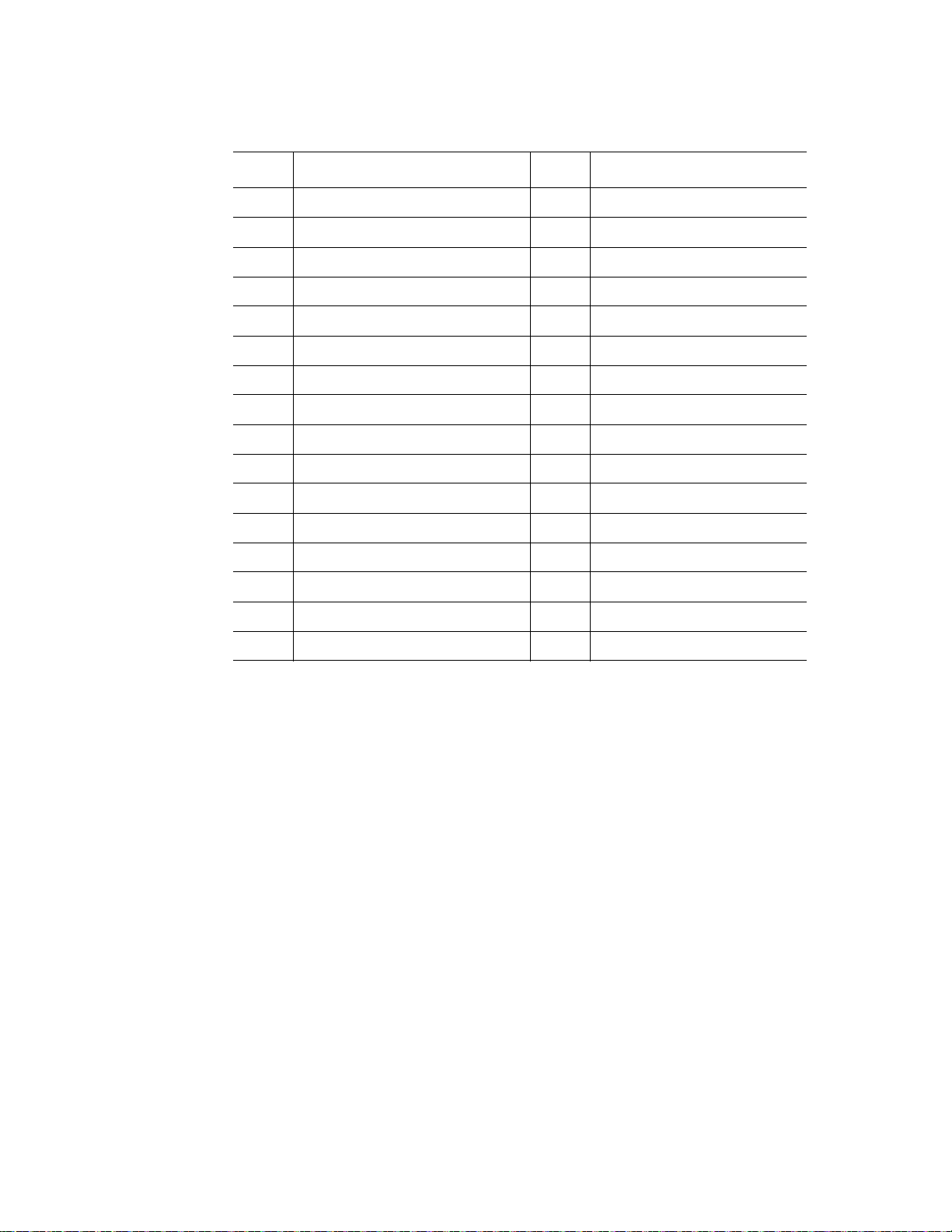

Configuration Jumpers

AF003049

F

A

B

C

D

ME BMC Update

Update

Normal

Clear

Password

Normal

Recovery

Normal

Reset BIOS

Normal

BMC Force Update

Password Clear

BIOS Recovery Mode

J1B5

J1B4

J1C3

J1C2

A

D

B

C

J6A2

DCD to DTR

DSR to DTR

E

Internal

External

J6A3

J7A2

Intel® Server System SR1690WB Service Guide 11

Page 30

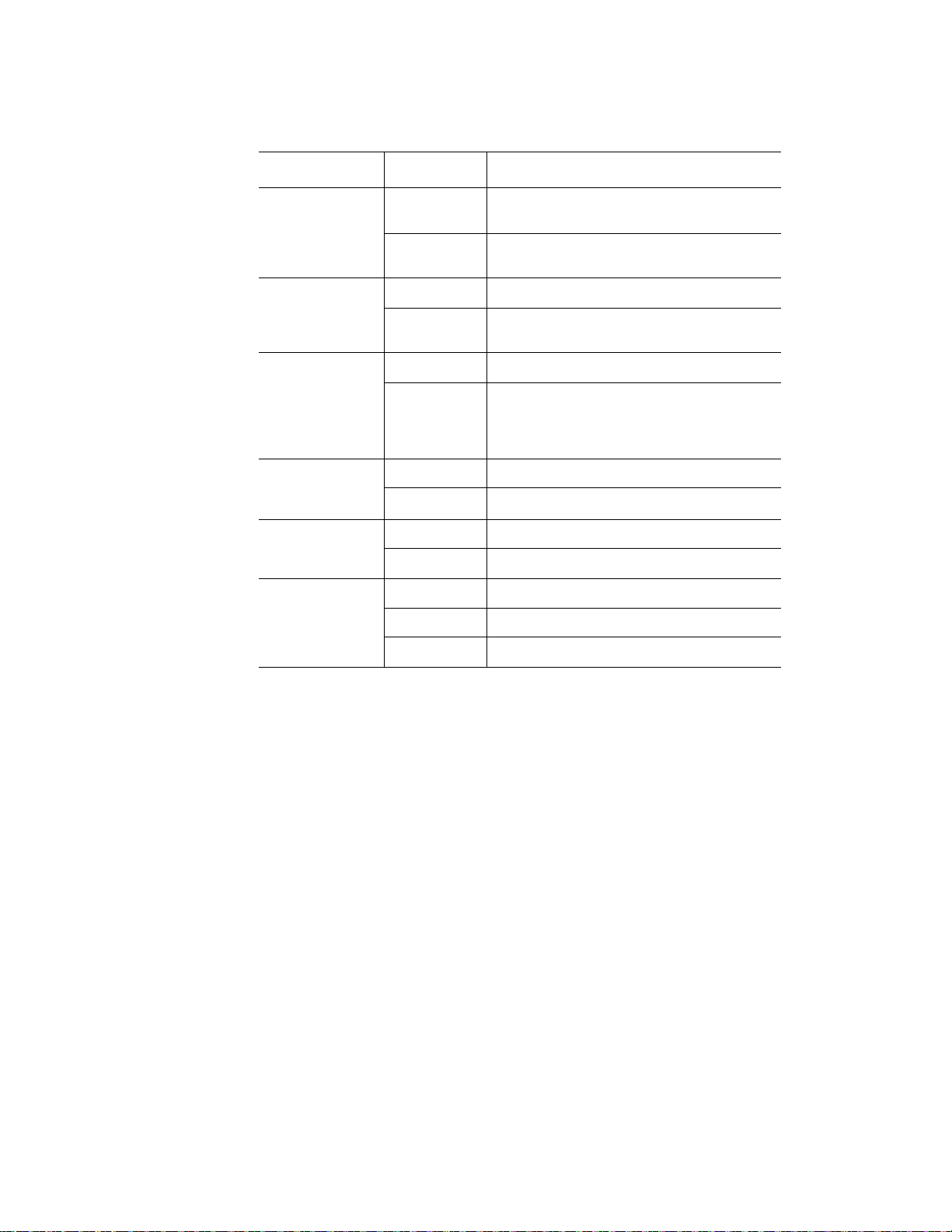

Jumper Name Pins What happens at system reset...

J8C1: BMC

Force Update

Password

Clear(J1C2)

BIOS

Recovery(J1C3)

Reset BIOS

Configuration(J1

B4)

Video

Master(J6A3)e

Serial

Interface(J6A2)

1-2 BMC Firmware Force Update Mode -

Disabled (Default)

2-3 BMC Firmware Force Update Mode -

Enabled

1-2 Normal System Operation (Default)

2-3 Administrator and user passwords are

cleared on the next reset

1-2 Normal System Operation (Default)

2-3 The main system BIOS will not boot with

these pins jumpered. Note: the system boots

from EFI-bootable recovery media with a

recovery BIOS image.

1-2 Normal System Operation (Default)

2-3 Clear CMOS settings

1-2 Internal connector overrides

2-3 External connector overrides

1-2 DTR (Data Terminal Ready) mode

2-3 DCD (Data Carrier Detect) mode

None DSR (Data Set Ready) mode

Figure 5. Configuration Jumper Location

12 Intel® Server System SR1690WB Service Guide

Page 31

Intel® Light Guided Diagnostics

The server system contains numerous LEDs providing the following functions:

• The System Status LED on the front and back panels (see Figure 6) shows the

overall health of the system (green, blinking green, blinking amber, and off).

• The System Identification LED on the back panel (see Figure 6) helps identify the

server from among several servers. By default, the ID LED is off, and blue when

activated by button or software.

• DIMM Fault LEDs on the server board (see Figure 6) help identify failed and failing

DIMM slots. The DIMM fault LEDs turn on (amber) if there is a DIMM fault.

• POST Code Diagnostic LEDs on the server board (see Figure 6) change color or

state (off, green, red, amber) according to the POST sequence.

• The 5-V STBY LED on the server board (see Figure 6) is illuminated (green) when

AC power is applied.

• The Fan Fault LEDs on the server board (see Figure 6) help identify failed and

failing fans. The fan fault LEDs turn on (amber) if there is a fan fault.

Intel® Server System SR1690WB Service Guide 13

Page 32

AF003216

FLT_F

FLT_E FLT_D2

FLT_D1

FLT_A2

FLT_A1

FLT_C

FLT_B

A

B

C

D

E

G

F

A. Diagnostic LED G. CPU2 DIMM fault

LEDs

B. System Status LED

C. System ID LED

D. 5V Standby LED

E. CPU1 DIMM fault LEDs

F. Fan Fault LEDs

Figure 6. Light Guided Diagnostic LEDs

14 Intel® Server System SR1690WB Service Guide

Page 33

Back Panel Connectors

AF003217

A

B C D E

A. NIC1 connector with USB

ports 2, 5

C. NIC2 connector D. RJ-45 Serial B port

E. Internal Video Connector

B. USB ports 8, 9

Figure 7. Back Panel Connectors

The NIC LEDs at the right and left of each NIC provide the following information.

Table 3. NIC LED Descriptions

LED

NIC1/

NIC2

LED

State

Left

LED

Right

LED

LED State Description

Off No network connection

Solid Amber Network connection in place

Blinking Amber Transmit/receive activity

Off 10 Mbps connection (if left

LED is on or blinking)

Solid Amber 100 Mbps connection

Solid Green 1000 Mbps connection

Intel® Server System SR1690WB Service Guide 15

Page 34

RAID Support

The Intel® Server Board S5500WB provides an integrated SATA II host controller that

supports independent DMA operation on the six Ports and supports data transfer rates of

up to 3.0 Gb/Sec.

The ICH10R provides support for Intel

AHCI and integrated RAID functionality. The industry-leading RAID capability provides

high-performance RAID 0, 1, 5 and 10 functionality on up to six SATA ports.

The BIOS Setup utility provides multiple drive configuration options on the Advanced |

Mass Storage Controller Configuration setup page, some of which affect the ability to

configure RAID. The “Onboard SATA Controller” option is enabled by default. When this

option is enabled, the “SATA Mode” option can be set to ENHANCED mode,

COMPATIBILITY mode, AHCI mode or SW RAID mode. The modes affect the

configuration as follows:

• ENHANCED mode supports up to six SATA ports with IDE Native Mode.

• COMPATIBILITY mode supports up to four SATA ports[0/1/2/3] with IDE Legacy

mode and 2 SATA ports[4/5] with IDE Native Mode.

• AHCI mode supports all SATA ports using the Advanced Host Controller Interface

when the option is enabled.

®

Matrix Storage Technology, providing both

Note: For AHCI capability in EFI, the AHCI legacy Option ROM should be set to “disabled”.

• SW RAID mode supports configuration of SATA ports for RAID via RAID

configuration software.

For RAID 0, 1, and 10, enclosure management is provided through the SATA_SGPIO

connector on the server board when a cable is attached between this connector on the

server board and to the backplane or I2C interface.

®

If RAID 5 is desired, the optional Intel

installed. To enable RAID 5, this activation key is placed on the SATA Key connector that

is located at the right side of the server board. For information on how to install the Intel

RAID Activation Key AXXRAKSW5 accessory to enable RAID 5, see the

documentation that is included with the accessory kit.

RAID Activation Key AXXRAKSW5 can be

®

16 Intel® Server System SR1690WB Service Guide

Page 35

Front Panel of Server System

AF003218

A

I

HG

F

E

D

C

B

Standard Control Panel

The following diagram shows the features of the standard control panel.

Item Feature

A. Power/Sleep Button

B. System Reset Button

C. Power/Sleep LED

D. System NIC 1 Activity LED

E. System NIC 2 Activity LED

F. System Identification LED

G. System Status LED

H. System Identification Button

I. USB 2.0 connectors – Port 0 & 1

Figure 8. Front Control Panel - Intel

®

Server System SR1690WB

.

Table 4. Control Panel LED Functions

LED Color State Description

Power/

Sleep

LAN 1 and

LAN 2

Intel® Server System SR1690WB Service Guide 17

Green On Power On/ACPI S0 state

Green Blink Sleep /ACPI S1 state

- Off Power Off /ACPI S5 state

Green On LAN Link no Access

Green Blink LAN Activity

- Off No Link

Page 36

Table 4. Control Panel LED Functions

LED Color State Description

System ID Blue On Identify Active via command or button

Off No Identification

System

Status

Green On System Ready / No Alarm

Green Blink System ready, but degraded: redundancy lost such as

Amber On Critical Alarm: Critical power modules failure, critical

Amber Blink Non-Critical Alarm: Redundant fan failure, redundant

- Off AC power off: System unplugged AC power on:

Note: Blink rate is ~1 Hz at 50% duty cycle.

It is also off when the system is powered off (S5) or in a sleep state (S1).

The power LED sleep indication is maintained on standby by the chipset. If the system is

powered down without going through the BIOS, the LED state in effect at the time of

power off is restored when the system is powered on until the BIOS clear it.

If the system is not powered down normally, it is possible the Power LED will blink at the

same time the system status LED is off due to a failure or configuration change that

prevents the BIOS from running.

the power supply or fan failure; non-critical temp/

voltage threshold; battery failure; or predictive power

supply failure.

fans failure, voltage (power supply), critical

temperature and voltage

power module failure, non-critical temperature and

voltage

System powered off and in standby, no prior

degraded\non-critical\critical state

18 Intel® Server System SR1690WB Service Guide

Page 37

Rear of Server System

EFGHI

J

K

L

M

N

AF003220

A B C D

AF003221

CDE

A B

A. AC Power Receptacle I. RJ-45 Serial B port

B. NIC 1 connector J. NIC2 Connector

C. Top Cover Release Screw K. USB port 9

D. PCI Express* Add-in Card L. USB port 8

E. IO module external connector 2 (optional) M. USB port 5

F. IO module external connector 1 (optional) N. USB port 2

G. Management Network Interface (optional)

H. Internal Video Connector

Figure 9. Server System I/O Connector Locations

Peripheral Devices

The server system provides locations and hardware for installing hard drives and a

slimline optical drive. You must purchase the drives separately. The following figure

shows the available options.

Intel® Server System SR1690WB Service Guide 19

Page 38

A. Front Control Panel

B. Slimline Optical Drive

C. Hard Drive Bays HDD0~3

D. HDD Status LED

E. HDD Power LED

Hard Disk Drives

The server system ships with four hot-swap drive carriers for installing four SATA/SAS

Hard disk drives, both 3.5-inch or 2.5-inch HDDs.

For instructions on installing hard drives, see “Installing and Removing a Hot-swap Hard

Drive” on page -35.

Slimline Optical Drive latch

You can use a slimline optical drive latch with an optional optical drive. One slimline

optical drive latch is included with your server system; you must purchase the optical

drive separately.

Figure 10. Optional Peripherals

You can only insert or remove the slimline optical drive when the system power is turned

off. Drive in the optical drive bay is NOT hot-swappable. For installation instructions on

installing an optical drive, see “Installing or Removing a Slimline Optical Drive” on

page -38.

To use one of the drives provided by Intel, use the following order codes:

• SATA Slimline DVD Drive: AXXSATADVDROM

• SATA Slimline DVD Rewriteable Drive: AXXSATADVDRWROM

Rack-Mounted Systems

Your Int el® Server System SR1690WB can be mounted into a rack. Intel provides three

options to mount this server into a rack. When installing the chassis into a rack, Intel

recommends you install systems from the bottom of the rack to the top. In other words,

install the first system in the rack into the bottom position of the rack, the second system

in the second position from the bottom, and so on. Instructions for installing your chassis

into a rack are included in the rail kit.

20 Intel® Server System SR1690WB Service Guide

Page 39

Hardware Requirements

AF003226

DIMM A2

DIMM A1

DIMM B1

DIMM C1

DIMM D2

DIMM D1

DIMM E1

DIMM F1

Channel F

Channel E

Channel D

Channel C

Channel B

Channel A

To avoid integration difficulties and possible board damage, your system must meet the

requirements outlined below. For a list of qualified components, see the links under

“Server System References”.

Processor

Memory

The Intel® Server System SR1690WB supports one or two Intel® Xeon® Processor 5500

series and Intel

®

Xeon® Processor 5600 series with 95W Thermal Design Power (TDP) or

less and with a max data transfer rate of 6.4 GT/s. For a complete list of supported

processors, see the links under “Server System References”.

The Intel® Server System SR1690WB supports a DDR3-based memory subsystem. The

®

Server System SR1690WB supports two DIMMs per channel. The silkscreen on

Intel

the board for the DIMMs displays DIMM_A1, DIMM_A2, DIMM_B1, DIMM_B2,

DIMM_D1, DIMM_D2, DIMM_E1, DIMM_E2. See Figure 11. The minimal memory

population possible is DIMM_A1.

Figure 11. DIMM Configuration Diagram

For two slots per channel configurations, the server board requires DDR3 DIMMs within

a channel to be populated starting with the DIMM farthest from the processor. See the

following figure (Figure 12).

For a complete list of supported memory DIMMs, see the links under “Server System

References”.

Intel® Server System SR1690WB Service Guide 21

Page 40

Figure 12. Channel Slots Configuration

The Independent Channel Mode is the default Maximum Performance Mode preferred for

®

Xeon® Processor 5500 series and Intel® Xeon® Processor 5600 series based

Intel

platforms. All three channels may be populated in any order and have no matching

requirements. All channels must run at the same interface frequency, but individual

channels may run at different DIMM timings (RAS latency, CAS latency, and so forth).

Memory Sparing and Mirroring

The spare mode is not supported by Intel® Server System SR1690WB.

With memory mirroring, the system maintains two copies of all data in the memory

subsystem. If a DIMM fails, the data is not lost because the second copy of the data is

available from the mirrored DIMM in the opposite channel. The system will not fail due

to memory error unless both the primary and the mirrored copy of the data become corrupt

at the same time.

In a mirrored system, the maximum usable memory is one-half of the installed memory,

with a minimum of two DIMMs installed. Since the data is duplicated across DIMMs, it

means that up to one-half of the installed DIMMs are actively in use at any one time. The

remaining DIMMs are used for mirroring.

22 Intel® Server System SR1690WB Service Guide

Page 41

See the Intel® Server System S5500WB Technical Product Specification for additional

information regarding the memory sub-system.

Power Supply

TThe Power supply in SR1690WB system provides 650W at maximum. The power

supply must provide a minimum of 2.6 A of 5V standby current or the board will not boot.

Optional Hardware

Intel® RAID Activation Key

If RAID 5 is needed, you can install the optional Intel® RAID Activation Key

AXXRAKSW5. To enable RAID 5, this activation key is placed on the SATA Key

connector located at the left side of the server board. For information on how to install the

®

RAID Activation Key AXXRAKSW5 accessory to enable RAID 5, see the

Intel

documentation that is included with the accessory kit.

Intel® Remote Management Module 3

The RMM3 advanced management board serves two purposes. The first is to give the

customer the option to add a dedicated management 100-Mbit LAN interface to the

product. The second is to give additional flash space, enabling the Advanced Management

functions to support WS-MAN and CIMOM. The RMM3 comes with a third 10/100GbE

NIC that connects to the board. RMM3 management traffic can use the third NIC or NIC

1.

To install the RMM3 module, following the instruction in the RMM3 kit package, which

is purchased separately.

Intel® Server System SR1690WB Service Guide 23

Page 42

Intel® I/O Expansion Module

The Intel® Server System SR1690WB supports a variety of I/O Module options using 2x4

PCI Express* Gen2 Intel

®

I/O Expansion Module connectors on the rear of the server

board. It accommodates both the double-wide I/O expansion modules and the PCI

Express* Gen 1 I/O modules. Below is the list of supported I/O modules on SR1690WB:

Ta ble 5. List of Supported I/O Modules on SR1690WB

Product Code Description

AXX4SASMOD Intel

AXXGBIOMOD Dual Gigabit Ethernet I/O Expansion

AXXROMBSASMR Intel

AXXSASIOMOD External 4-port SAS I/O Expansion

AXX10GBIOMOD Dual-port 10 Gigabit Ethernet I/O

®

SAS Entry RAID I/O Expansion

Module: Provides 4-port pass through

SAS, entry-level RAID 0/1/1E, and

optional host RAID (4 internal por ts).

Module

®

Integrated RAID I/O Expansion

Module: Provides four internal ports,

full-featured SAS / SATA RAID 0,1,5,6

and striping capability for spans 10, 50,

60. You must order the optional backup

battery AXXRSBBU3 separately.

Module.

Expansion Module with CX4

connectors.

AXX4GBIOMOD2 Quad port Gigabit Ethernet I/O

Expansion Module based on the Intel

82576EB Gigabit Ethernet Controller.

AXXIBQDRMOD InfiniBand* I/O Expansion Module

Single Port QDR.

®

24 Intel® Server System SR1690WB Service Guide

Page 43

3 Hardware Installations and Upgrades

Before You Begin

Before working with your server product, pay close attention to the “Safety Information”

at the beginning of this manual.

Note: Whenever you service the system, you must first power down the server and unplug all

peripheral devices and the AC power cord.

Tools and Supplies Needed

• Phillips* (cross head) screwdrivers (#1 bit and #2 bit)

• Needle nosed pliers

• Pen or pencil

• Antistatic wrist strap and conductive foam pad (recommended)

System References

All references to the left, right, front, top, and bottom assume the reader is facing the front

of the server system as it would be positioned for normal operation.

Removing and Installing the System Cover

Removing the System Cover

You must operate the server system with the system cover in place to ensure proper

cooling. You must remove the top cover to add or replace components inside of the server.

None of the internal components are hot-swappable. Before you remove the server system

cover, power down the server and unplug all peripheral devices and the AC power cable.

Note: You may need a non-skid surface or a stop behind the server system to prevent the server

system from sliding on your work surface.

1. Remove the top cover screw (see letter “A”).

2. Loosen the screw at the rear of the chassis (see letter “B”).

3. Push rearward on the blue grip point at the front of the server.

25

Page 44

4. Slide the cover back until it stops and then lift the cover upward to remove it. See

Optical

Device

C

A

B

AF003222

letter “C”.

Figure 13. Removing the Server System Cover

Installing the System Cover

1. Observe the safety and ESD precautions at the beginning of this book. See “Safety

Information”.

2. Place the cover over the server system so that the side edges of the cover sit just

inside the server system sidewalls. Slide the cover forward (see letter “A” in

Figure 14).

3. Tighten the screw at the rear of the server (see letter “B”) and install the two screws

at the front of the server (see letter “C”).

26 Intel® Server System SR1690WB Service Guide

Page 45

Figure 14. Installing the Server System Cover

Optical

Device

C

A

B

AF003223

Removing and Installing the Processor Air Duct

The system requires the use of an air duct to direct airflow and sustain appropriate air

pressure. Always operate your server system with the air duct in place. The air duct is

required for proper airflow within the server system.

Removing the Processor Air Duct

1. Observe the safety and ESD precautions at the beginning of this book. See “Safety

Information”.

2. Power down the server and unplug all peripheral devices and the AC power cable.

3. Remove the server system cover. For instructions, see “Removing the System

Cover”.

4. Lift the processor air duct from its location behind the two system blower fans.

Intel® Server System SR1690WB Service Guide 27

Page 46

Figure 15. Removing the Processor Air Duct

Optical

Device

AF003224

Installing the Processor Air Duct

1. Observe the safety and ESD precautions at the beginning of this book. See “Safety

Information”.

2. Power down the server and unplug all peripheral devices and the AC power cable.

3. Remove the server system cover. For instructions, see “Removing the System

Cover”.

4. Lower the air duct into place; align the air duct side walls to the corresponding slots

on the bracket behind the four system blower fans and insert into position. Use

caution not to pinch or disengage cables that may be near or under the air duct.

28 Intel® Server System SR1690WB Service Guide

Page 47

Figure 16. Installing the Processor Air Duct

Optical

Device

AF003225

Installing and Removing Memory

The silkscreen on the board for the DIMMs displays DIMM_A1, DIMM_A2, DIMM_B1,

and DIMM_B2, DIMM_D1, DIMM_D2, DIMM_E1, and DIMM_E2 starting from the

inside of the board. For two slots per channel configurations, the server board requires

DDR3 DIMMs within a channel to be populated starting with the DIMM farthest from the

processor. The DIMM farthest from the processor per channel is in blue on boards.

Installing DIMMs

To install DIMMs, follow these steps:

1. Observe the safety and ESD precautions at the beginning of this book.

2. Turn off all peripheral devices connected to the server.

3. Turn off the server.

4. Disconnect the AC power cord from the server.

Intel® Server System SR1690WB Service Guide 29

Page 48

5. Remove the cover from the server and locate the DIMM sockets (see Figure 17).

D

C

B

A

E

AF003227

Figure 17. Installing the Memory

6. Make sure the clips at either end of the DIMM socket(s) are pushed outward to the

open position (see letter “A” in Figure 17).

7. Holding the DIMM by the edges, remove it from its anti-static package.

8. Position the DIMM above the socket. Align the two small notches in the bottom

edge of the DIMM with the keys in the socket (see letter “B” in Figure 17).

9. Insert the bottom edge of the DIMM into the socket (see letter “C” in Figure 17).

10. When the DIMM is inserted, push down on the top edge of the DIMM until the

retaining clips snap into place (see letter “D” in Figure 17). Make sure the clips are

firmly in place (see letter “E” in Figure 17).

11. Replace the server’s cover and reconnect the AC power cord.

Removing DIMMs

To remove a DIMM, follow these steps:

1. Observe the safety and ESD precautions at the beginning of this book.

2. Turn off all peripheral devices connected to the server. Turn off the server.

3. Remove the AC power cord from the server.

4. Remove the server's cover.

5. Gently spread the retaining clips at each end of the socket. The DIMM lifts from

6. Holding the DIMM by the edges, lift it from the socket, and store it in an anti-static

the socket.

package.

30 Intel® Server System SR1690WB Service Guide

Page 49

7. Reinstall and reconnect any parts you removed or disconnected to reach the DIMM

AF003228

B

A

sockets.

8. Replace the server's cover and reconnect the AC power cord.

Installing or Replacing the Processor