Page 1

Intel® Server Chassis SC1400UP /

®

Intel

Technical Product Specification

Server Platform SR1425BK1-E

Intel order number C94051-001

Revision 1.0

October 2004

Enterprise Platforms and Services Marketing

Page 2

Revision History

Date Revision

Number

February 2004 0.5 Updated to reflect Alpha – first external release

July 2004 0.8 Added CPU air duct, updated SATA and SCSI backplane info, added LCP

info, added riser card info,

October 2004 0.9 Updated P/S specification

October 2004 1.0 Final Release

Modifications

Revision 1.0 ii

Page 3

Disclaimers

Information in this document is provided in connection with Intel® products. No license, express

or implied, by estoppel or otherwise, to any intellectual property rights is granted by this

document. Except as provided in Intel's Terms and Conditions of Sale for such products, Intel

assumes no liability whatsoever, and Intel disclaims any express or implied warranty, relating to

sale and/or use of Intel products including liability or warranties relating to fitness for a particular

purpose, merchantability, or infringement of any patent, copyright or other intellectual property

right. Intel products are not intended for use in medical, life saving, or life sustaining

applications. Intel may make changes to specifications and product descriptions at any time,

without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked

"reserved" or "undefined." Intel reserves these for future definition and shall have no

responsibility whatsoever for conflicts or incompatibilities arising from future changes to them.

This document contains information on products in the design phase of development. Do not

finalize a design with this information. Revised information will be published when the product

is available. Verify with your local sales office that you have the latest datasheet before

finalizing a design.

The Intel® Server Chassis SC1400UP and Intel® Server Platform SR1425BK1-E may contain

design defects or errors known as errata which may cause the product to deviate from

published specifications. Current characterized errata are available on request.

This document and the software described in it is furnished under license and may only be used

or copied in accordance with the terms of the license. The information in this manual is

furnished for informational use only, is subject to change without notice, and should not be

construed as a commitment by Intel Corporation. Intel Corporation assumes no responsibility or

liability for any errors or inaccuracies that may appear in this document or any software that may

be provided in association with this document.

Except as permitted by such license, no part of this document may be reproduced, stored in a

retrieval system, or transmitted in any form or by any means without the express written consent

of Intel Corporation.

Intel, Pentium and Xeon are trademarks or registered trademarks of Intel Corporation.

*Other brands and names may be claimed as the property of others.

Copyright © Intel Corporation 2004.

Revision 1.0 iii

Page 4

Table of Contents

1. Intel® Server Chassis SC1400UP Feature Summary ..................................................- 13 -

1.1 Chassis Views ...................................................................................................- 13 -

1.2 Chassis Dimensions ..........................................................................................- 13 -

1.3 Intel® Server Chassis SC1400UP System Components...................................- 14 -

1.4 Rear Panel Components ...................................................................................- 15 -

1.5 Hard Drive and Peripheral Bays ........................................................................- 15 -

1.6 Control Panel .....................................................................................................- 16 -

1.7 Power Sub-system.............................................................................................- 17 -

1.8 System Cooling..................................................................................................- 18 -

1.9 Chassis Security ................................................................................................- 18 -

1.10 Rack and Cabinet Mounting Options .................................................................- 18 -

1.11 Front Bezels.......................................................................................................- 18 -

2. Cooling Sub-System ......................................................................................................- 20 -

2.1 System Fans......................................................................................................- 21 -

2.2 Power Supply Fans............................................................................................- 22 -

2.3 CPU/Memory Air Duct and Side Air Baffle.........................................................- 22 -

2.4 Hard Drive Bays.................................................................................................- 23 -

3. Peripheral and Hard Drive Support...............................................................................- 24 -

3.1 Slimline Drive Bay..............................................................................................- 24 -

3.1.1 Floppy Drive Support with or without Backplane present ..................................- 24 -

3.2 Hard Disk Drive Bays.........................................................................................- 27 -

3.2.1 Hot Swap Hard Disk Drive Trays .......................................................................- 28 -

3.2.2 Fixed Drive Trays...............................................................................................- 28 -

3.2.3 Drive Blanks.......................................................................................................- 28 -

3.3 Hot-Swap SCSI Backplane................................................................................- 29 -

3.3.1 Hot-Swap SCSI Backplane Board Layout .........................................................- 29 -

3.3.2 SCSI Backplane Functional Architecture...........................................................- 30 -

3.3.3 SCSI Backplane Connector Definitions .............................................................- 33 -

3.4 Hot-Swap SATA Backplane...............................................................................- 36 -

3.4.1 SATA Backplane Layout....................................................................................- 37 -

3.4.2 SATA Backplane Functional Architecture..........................................................- 37 -

3.4.3 SATA Backplane Connector Definitions ............................................................- 40 -

4. Standard Control Panel .................................................................................................- 42 -

4.1 Control Panel Buttons.......................................................................................- 42 -

Revision 1.0 iv

Page 5

4.2 Control Panel LED Indicators ............................................................................- 43 -

4.2.1 Power / Sleep LED ............................................................................................- 44 -

4.2.2 System Status LED............................................................................................- 44 -

4.2.3 Drive Activity LED ..............................................................................................- 45 -

4.2.4 System Identification LED..................................................................................- 45 -

4.3 Control Panel Connectors..................................................................................- 46 -

4.4 Internal Control Panel Assembly Headers.........................................................- 46 -

5. PCI Riser Cards and Assembly.....................................................................................- 48 -

5.1 Riser Card Options ............................................................................................- 48 -

6. Power Sub-system .........................................................................................................- 50 -

6.1 Mechanical Specifications .................................................................................- 50 -

6.2 Airflow Requirements.........................................................................................- 51 -

6.3 Acoustics ...........................................................................................................- 51 -

6.4 Temperature ......................................................................................................- 52 -

6.5 Output Connectors.............................................................................................- 52 -

6.5.1 P1 Main power connector ..................................................................................- 52 -

6.5.2 P2 Processor Power Connector ........................................................................- 53 -

6.5.3 P3-P5 Peripheral Connectors ............................................................................- 53 -

6.6 AC Inlet Connector ............................................................................................- 54 -

6.7 Marking and Identification..................................................................................- 54 -

6.8 AC Input Voltage................................................................................................- 54 -

6.9 AC Line Transient Specification.........................................................................- 54 -

6.10 Susceptibility......................................................................................................- 55 -

6.10.1 Electrostatic Discharge Susceptibility ................................................................- 55 -

6.10.2 Fast Transient/Burst ..........................................................................................- 55 -

6.10.3 Radiated Immunity.............................................................................................- 55 -

6.10.4 Surge Immunity..................................................................................................- 55 -

6.11 AC Line Fast Transient (EFT) Specification ......................................................- 56 -

6.12 AC Line Dropout / Holdup..................................................................................- 56 -

6.12.1 AC Line 5VSB Holdup .......................................................................................- 56 -

6.13 Power Recovery ................................................................................................- 56 -

6.13.1 Voltage Brown Out.............................................................................................- 56 -

6.13.2 Voltage Interruptions..........................................................................................- 56 -

6.14 AC Line Inrush ...................................................................................................- 57 -

6.15 AC Line Isolation Requirements ........................................................................- 57 -

6.16 AC Line Leakage Current ..................................................................................- 57 -

6.17 AC Line Fuse .....................................................................................................- 57 -

Revision 1.0 v

Page 6

6.18 Power Factor Correction....................................................................................- 57 -

6.19 Efficiency ...........................................................................................................- 57 -

6.20 Grounding ..........................................................................................................- 58 -

6.21 Remote Sense ...................................................................................................- 58 -

6.22 Output Power / Currents ....................................................................................- 58 -

6.22.1 Standby Outputs ................................................................................................- 59 -

6.22.2 Fan-less Operation ............................................................................................- 59 -

6.23 Voltage Regulation ............................................................................................- 59 -

6.23.1 Dynamic Loading ...............................................................................................- 59 -

6.24 Capacitive Loading ............................................................................................- 60 -

6.25 Closed loop stability...........................................................................................- 60 -

6.26 Common Mode Noise ........................................................................................- 60 -

6.27 Ripple / Noise ....................................................................................................- 61 -

6.28 Soft Starting .......................................................................................................- 61 -

6.29 Zero Load Stability Requirements .....................................................................- 61 -

6.30 Timing Requirements.........................................................................................- 61 -

6.31 Residual Voltage Immunity in Standby mode ....................................................- 63 -

6.32 Protection Circuits..............................................................................................- 63 -

6.33 Current Limit (OCP) .........................................................................................- 63 -

6.34 Over Voltage Protection (OVP).........................................................................- 64 -

6.35 Over Temperature Protection (OTP).................................................................- 64 -

6.36 Control and Indicator Functions.........................................................................- 64 -

6.37 PSON

#

Input Signal ..........................................................................................- 65 -

6.38 PWOK (Power OK) Output Signal .....................................................................- 65 -

6.39 Environmental Requirements ............................................................................- 66 -

6.40 Temperature ......................................................................................................- 66 -

6.41 Humidity.............................................................................................................- 66 -

6.42 Altitude...............................................................................................................- 66 -

6.43 Mechanical Shock..............................................................................................- 66 -

6.44 Random Vibration ..............................................................................................- 67 -

6.45 Thermal Shock (Shipping) .................................................................................- 67 -

6.46 Ecological Requirements ...................................................................................- 67 -

6.47 Catastrophic Failure...........................................................................................- 67 -

7. Electromagnetic Compatibility......................................................................................- 68 -

7.1 EMI ....................................................................................................................- 68 -

7.2 Input Line Current Harmonic Content (PFC) ....................................................- 68 -

7.3 Magnetic Leakage Fields...................................................................................- 68 -

Revision 1.0 vi

Page 7

7.4 Voltage Fluctuations and Flicker........................................................................- 69 -

7.5 Reliability / Warranty / Service...........................................................................- 69 -

7.6 Component De-rating ........................................................................................- 69 -

7.7 Component Life requirement .............................................................................- 69 -

7.8 Mean Time Between Failures (MTBF)...............................................................- 69 -

7.9 Warranty Period.................................................................................................- 69 -

7.10 Serviceability......................................................................................................- 69 -

7.11 Power Supply Returned for Repair ....................................................................- 69 -

7.12 Modifications / Change Control..........................................................................- 70 -

7.13 Power Supply Compliance Overview.................................................................- 70 -

7.14 Power Supplies Compliance Information...........................................................- 70 -

7.15 EMC Compliance Information............................................................................- 71 -

7.16 Immunity Compliance Information .....................................................................- 71 -

7.17 Harmonics & Voltage Flicker Compliance Information ......................................- 71 -

7.18 Environmental / Ecology Compliance Information .............................................- 71 -

7.19 Other Safety Requirement Notations.................................................................- 72 -

7.19.1 Certification Conditions......................................................................................- 72 -

7.19.2 Isolation Between Primary - Secondary.............................................................- 72 -

7.19.3 Creepage & Clearance Requirements...............................................................- 72 -

7.19.4 Leakage Current Maximums..............................................................................- 72 -

7.19.5 Max Surface Temperatures ...............................................................................- 72 -

7.19.6 Date Coded Serial Numbers..............................................................................- 73 -

7.19.7 Power Input Electrical Ratings...........................................................................- 73 -

7.19.8 Maximum Allowable Temperatures on Inlet Receptacles..................................- 73 -

7.19.9 Maximum Allowable Temperatures on Power Cords.........................................- 73 -

8. Supported Intel® Server Boards...................................................................................- 74 -

8.1 Intel® Server Board SE7221BK1-E Feature Set ...............................................- 74 -

9. Regulatory, Environmentals, and Specifications........................................................- 76 -

9.1 Product Regulatory Compliance ........................................................................- 76 -

9.1.1 Product Safety Compliance ...............................................................................- 76 -

9.1.2 Product EMC Compliance .................................................................................- 76 -

9.1.3 Product Regulatory Compliance Markings ........................................................- 76 -

9.2 Electromagnetic Compatibility Notices ..............................................................- 77 -

9.2.1 USA ...................................................................................................................- 77 -

9.2.2 FCC Verification Statement ...............................................................................- 77 -

9.2.3 ICES-003 (Canada) ...........................................................................................- 78 -

9.2.4 Europe (CE Declaration of Conformity) .............................................................- 78 -

Revision 1.0 vii

Page 8

9.2.5 Japan EMC Compatibility ..................................................................................- 78 -

9.2.6 BSMI (Taiwan) ...................................................................................................- 78 -

9.3 Replacing the Back up Battery ..........................................................................- 78 -

9.4 System Level Environmental Limits...................................................................- 79 -

9.5 Serviceability......................................................................................................- 80 -

Appendix A: Intel® Server Chassis SC1400UP Integration and Usage Tips.......................... I

Glossary....................................................................................................................................... II

Revision 1.0 viii

Page 9

List of Figures

Figure 1. Front and Rear Chassis Views ................................................................................- 13 -

Figure 2. Major Chassis Components.....................................................................................- 14 -

Figure 3. Back Panel Feature Overview .................................................................................- 15 -

Figure 4. Front Panel Feature Overview.................................................................................- 16 -

Figure 5. Control Panel Module ..............................................................................................- 16 -

Figure 6. Standard Control Panel Overview ...........................................................................- 17 -

Figure 7. Optional Front Bezel ................................................................................................- 18 -

Figure 8. Front Bezel Options .................................................................................................- 19 -

Figure 9. Intel® Server Chassis SC1400UP Cooling Subsystem ...........................................- 20 -

Figure 10. Intel® Server Chassis SC1400UP System Fans 4, 5, 6, 7, 8 ................................- 21 -

Figure 11. Intel® Server Platform SE7221BK1-E System Fan headers 4, 5, 6, 7, 8 ..............- 21 -

Figure 12. Air Baffle ................................................................................................................- 22 -

Figure 13. CPU/Memory Air Duct ...........................................................................................- 23 -

Figure 14. Intel® Server Chassis SC1400UP Peripheral Bay Configuration Options.............- 24 -

Figure 15. View of Slim-Line Drive Bay ..................................................................................- 24 -

Figure 16. Optional Floppy Drive Configuration......................................................................- 25 -

Figure 17. Hard Drive Tray Assembly.....................................................................................- 28 -

Figure 18. Drive Tray with Drive Blank ...................................................................................- 29 -

Figure 19. Hot-Swap SCSI Backplane Layout ........................................................................- 30 -

Figure 20. Hot-Swap SCSI Backplane Functional Diagram....................................................- 30 -

Figure 21. Intel® Server Chassis SC1400UP 1U SCSI HSBP I2C Bus Connection Diagram- 32 -

Figure 22. 68-Pin SCSI Cable Connector ...............................................................................- 33 -

Figure 23. 80-pin SCA2 SCSI Interface ..................................................................................- 34 -

Figure 24. SATA Backplane Layout........................................................................................- 37 -

Figure 25. SATA Backplane Layout........................................................................................- 37 -

Figure 26. SATA Backplane Functional Block Diagram..........................................................- 38 -

Figure 27. Intel® Server Chassis SC1400UP 1U SATA HSBP I2C Bus Connection Diagram- 39 -

Figure 28. Standard Control Panel Assembly Module ............................................................- 42 -

Figure 29. Control Panel Buttons............................................................................................- 42 -

Figure 31. PCI Riser bracket and optional PCI-X and PCI-Express risers .............................- 48 -

Figure 32. 1U Full Height PCI-X Riser Card Mechanical Drawing..........................................- 49 -

Figure 33. 1U Full Height PCI-Express Riser Card Mechanical Drawing ...............................- 49 -

Figure 34. Power Supply Enclosure Drawing .........................................................................- 50 -

Figure 35. Airflow Characteristics ...........................................................................................- 51 -

Revision 1.0 ix

Page 10

Figure 36. Output Voltage Timing ...........................................................................................- 62 -

Figure 37. Turn On/Off Timing (Power Supply Signals)..........................................................- 63 -

Figure 38. PSON# Required Signal Characteristic. ................................................................- 65 -

Figure 39. SE7221BK1-E Board Layout .................................................................................- 75 -

Revision 1.0 x

Page 11

List of Tables

Table 1. Chassis Dimensions .................................................................................................- 13 -

Table 2. Individual Fan Assy Pinout (J6J1, J6J2, J6J3, J6J4)................................................- 22 -

Table 3. 4-pin floppy power connector Pinout (J3) .................................................................- 25 -

Table 4. 34-pin floppy connector Pinout (J2) ..........................................................................- 25 -

Table 5. 50-pin CD-ROM connector Pinout (J6) .....................................................................- 26 -

Table 6. 4-pin CD-ROM power connector Pinout (J5) ............................................................- 26 -

Table 7. 40-pin CD-ROM connector Pinout (J1) .....................................................................- 27 -

Table 8. SCSI Backplane Power Connector Pinout (J1).........................................................- 33 -

Table 9. UltraWide (SE) and Ultra2 (LVD) Ultra320 SCSI Connector Pinout (J8) ..................- 33 -

Table 10. 80-pin SCA2 SCSI Interface Pinout (J9, J2, J10) ...................................................- 35 -

Table 11. LED Function ..........................................................................................................- 40 -

Table 12. SATA Backplane Power Connector Pinout.............................................................- 40 -

Table 13. 7-Pin SATA Connector Pinout (J2, J3, J4, J5, J6) ..................................................- 41 -

Table 14. 22-Pin SATA Connector Pinout ..............................................................................- 41 -

Table 15. Contol Button and Intrusion Switch Functions ........................................................- 43 -

Table 16. Control Panel LED Functions..................................................................................- 43 -

Table 17. SSI Power LED Operation ......................................................................................- 44 -

Table 18. External USB Connectors (J1B1) ...........................................................................- 46 -

Table 19. 50-pin Control Panel Connector (J6B1) ..................................................................- 47 -

Table 20. Internal USB Header (J2B1) ...................................................................................- 47 -

Table 21. Acoustic Requirements ...........................................................................................- 51 -

Table 22. Environmental Requirements.................................................................................- 52 -

Table 23. Cable Lengths.........................................................................................................- 52 -

Table 24. P1 Main Power Connector .....................................................................................- 52 -

Table 25. P2 Processor Power Connector.............................................................................- 53 -

Table 26. Peripheral Power Connectors ................................................................................- 53 -

Table 27. AC Input Rating.......................................................................................................- 54 -

Table 28. AC Line Sag Transient Performance ....................................................................- 54 -

Table 29. AC Line Surge Transient Performance .................................................................- 55 -

Table 30. Performance Criteria...............................................................................................- 55 -

Table 31. Load Ratings..........................................................................................................- 58 -

Table 32. Load Range 2 .........................................................................................................- 58 -

Table 33. Voltage Regulation Limits .......................................................................................- 59 -

Table 34. Transient Load Requirements.................................................................................- 60 -

Revision 1.0 xi

Page 12

Table 35. Capacitve Loading Conditions ................................................................................- 60 -

Table 36. Ripple and Noise.....................................................................................................- 61 -

Table 37. Output Voltage Timing ............................................................................................- 61 -

Table 38. Turn On/Off Timing .................................................................................................- 62 -

Table 39. Over Current Protection (OCP)...............................................................................- 64 -

Table 40. Over Voltage Protection (OVP) Limits ....................................................................- 64 -

Table 41. PSON

#

Signal Characteristic...................................................................................- 65 -

Table 42. PWOK Signal Characteristics .................................................................................- 66 -

Table 43. Harmonic Limits, Class A equipment ......................................................................- 68 -

Table 44: Baseboard Layout Reference .................................................................................- 75 -

Table 45. System Office Environment Summary ....................................................................- 79 -

Table 46. Mean Time To Repair Estimate ..............................................................................- 80 -

Revision 1.0 xii

Page 13

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

1. Intel® Server Chassis SC1400UP Feature

Summary

The Intel® Server Chassis SC1400UP is a 1U server chassis specifically designed to support

the Intel® Server Board SE7221BK1-E. The integration of the SC1400UP chassis and

SE7221BK1-E server board comprise the Intel® Server Platform SR1425BK1-E. The

SC1400UP is not offered as a standalone chassis solution from Intel and is only available as an

integrated system as the SR1425BK1-E. Both the board and chassis have a feature set that is

designed to support the high-density server market. This document provides details on the

chassis feature set and technical specifications. For technical details related to the Intel® Server

Board SE7221BK1-E, please refer to the baseboard Technical Product Specification document.

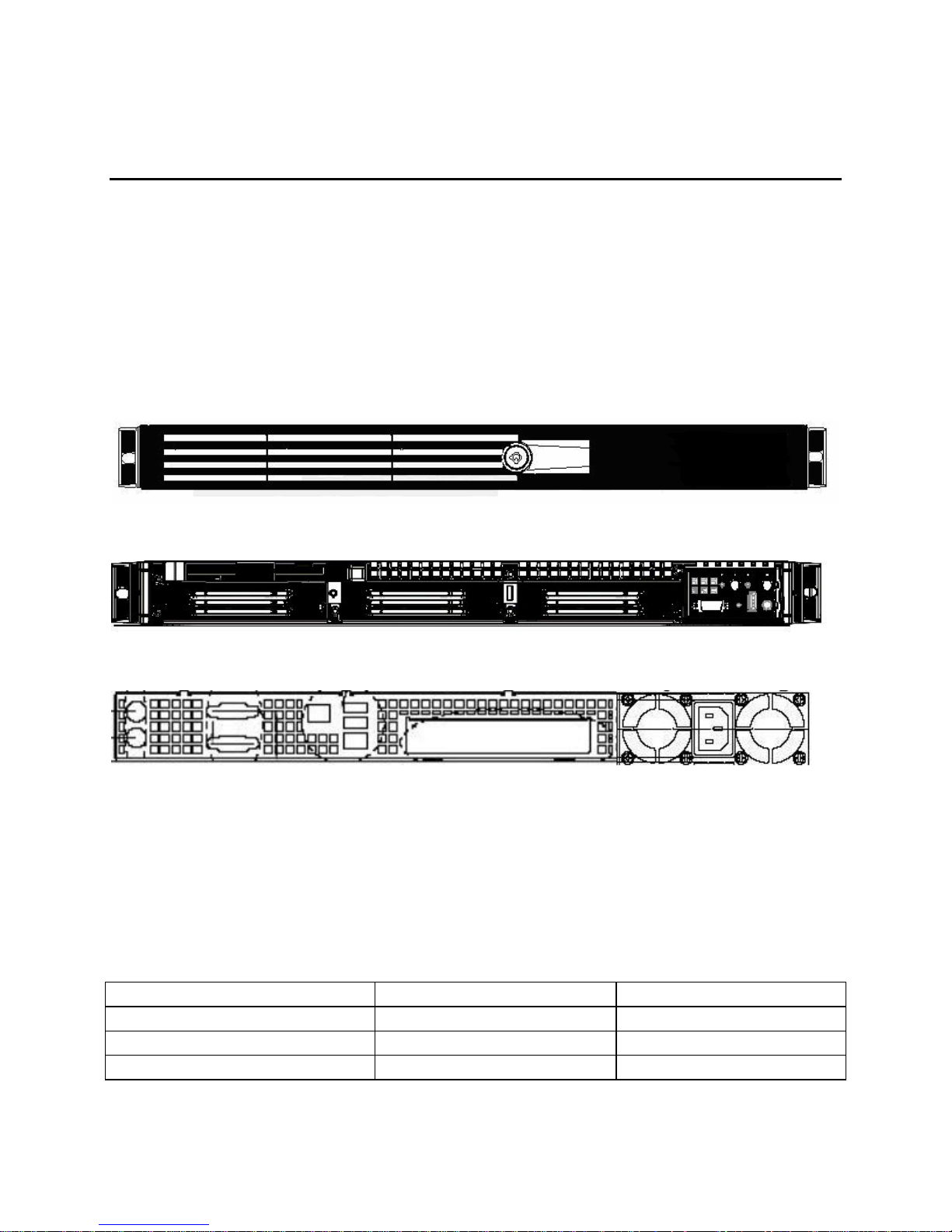

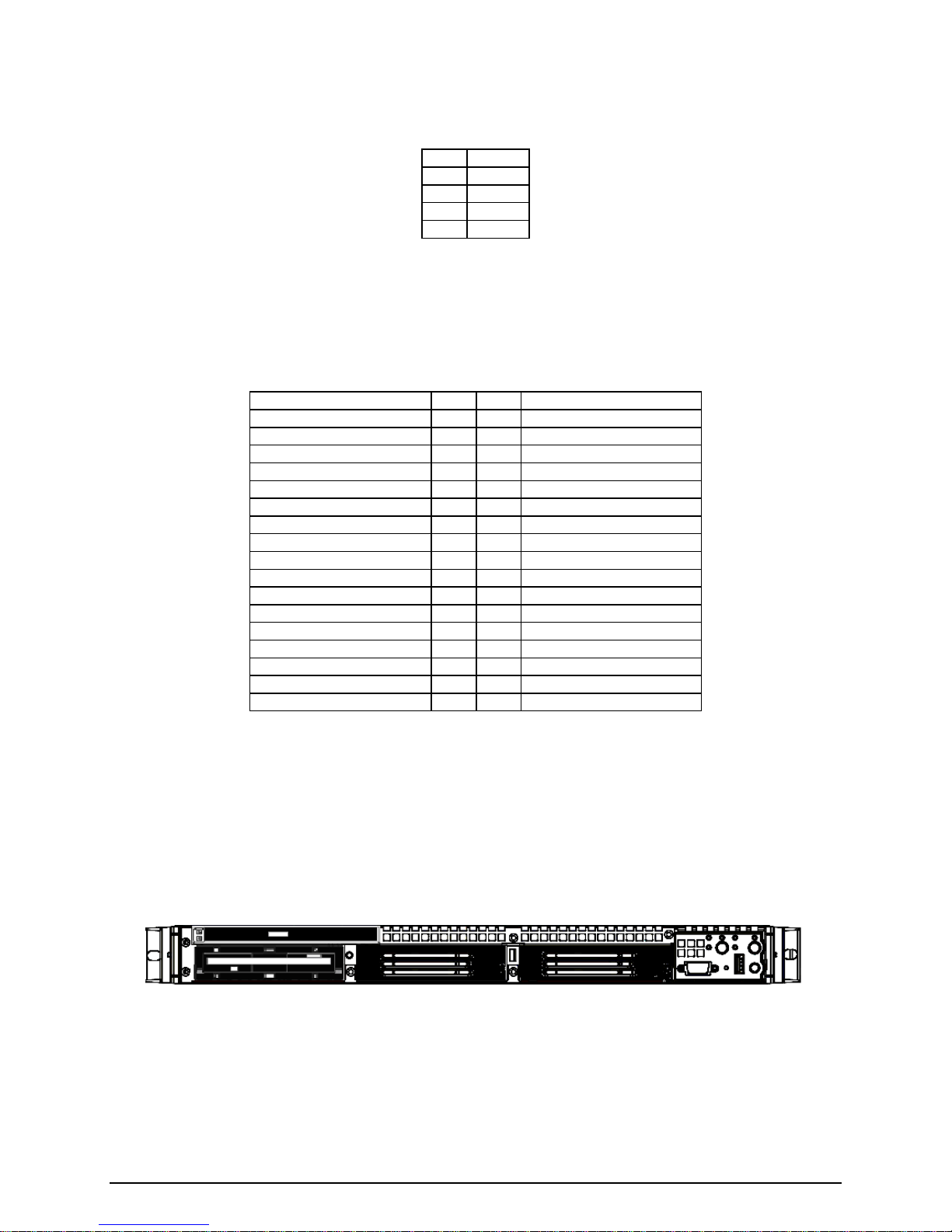

1.1 Chassis Views

Front view without bezel

Figure 1. Front and Rear Chassis Views

1.2 Chassis Dimensions

Front view with Bezel

Rear view

Height 43.25 mm 1.703”

Width 430 mm 16.930”

Depth 672 mm 26.457”

Max. Weight 14.1 kg 31 LBS

Table 1. Chassis Dimensions

- 13 -

Page 14

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

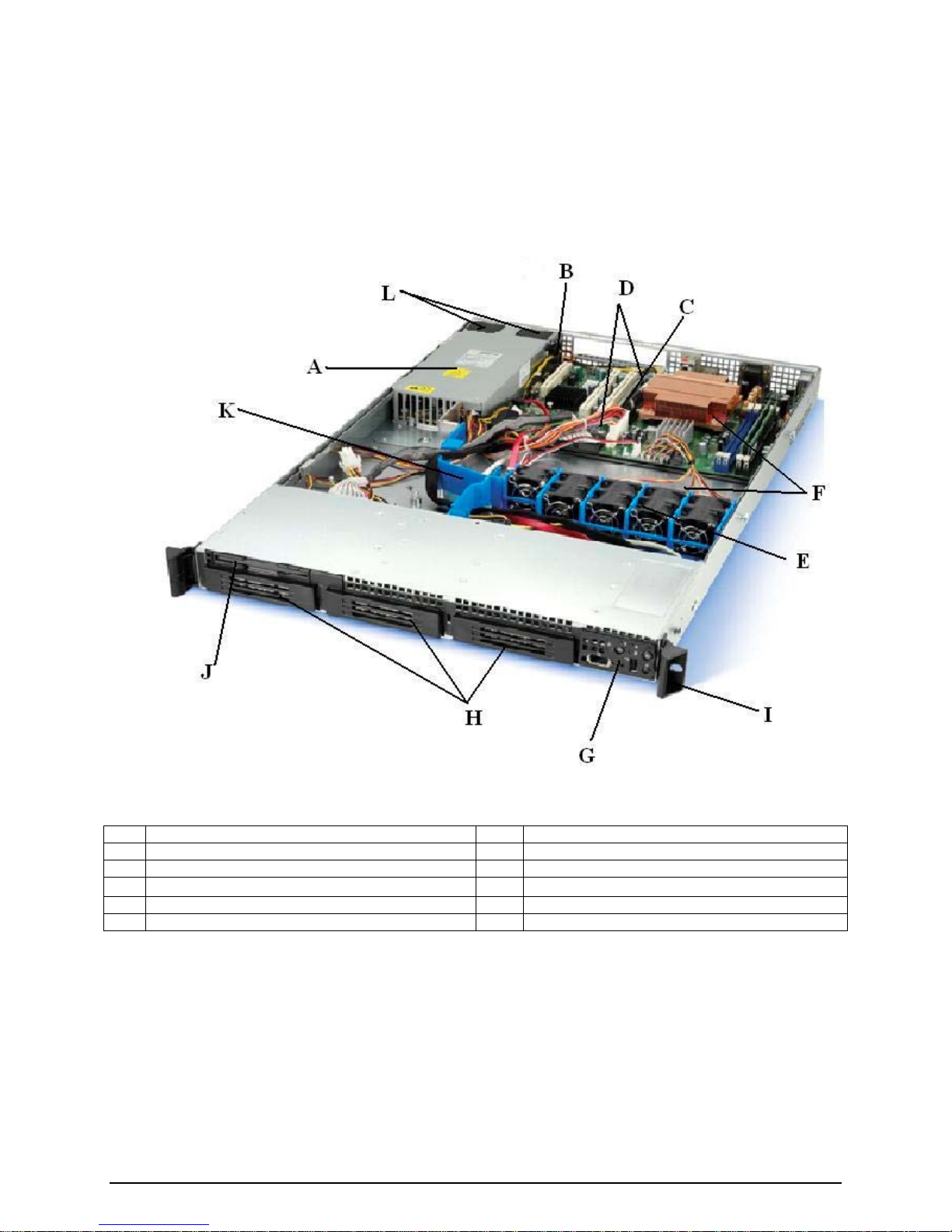

1.3 Intel® Server Chassis SC1400UP System Components

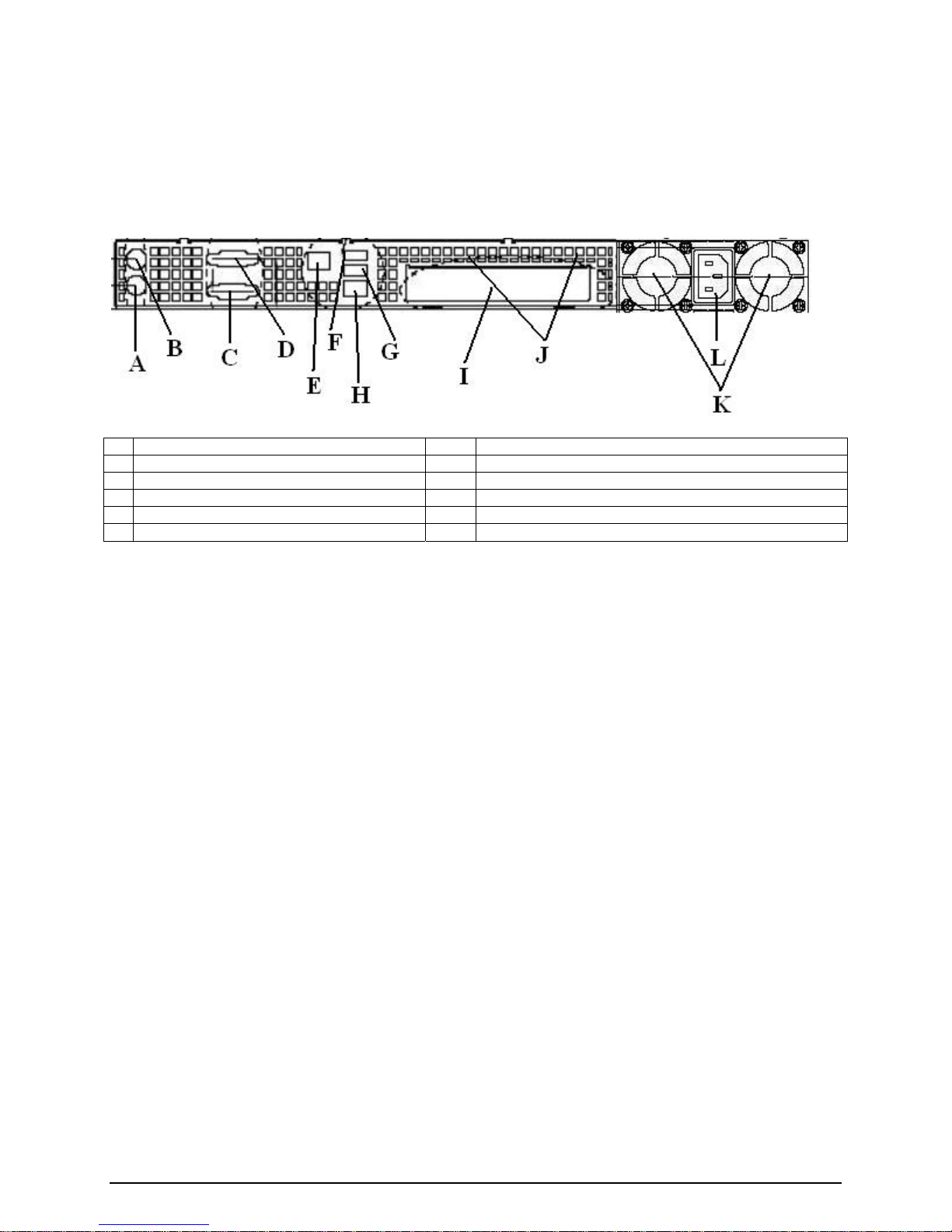

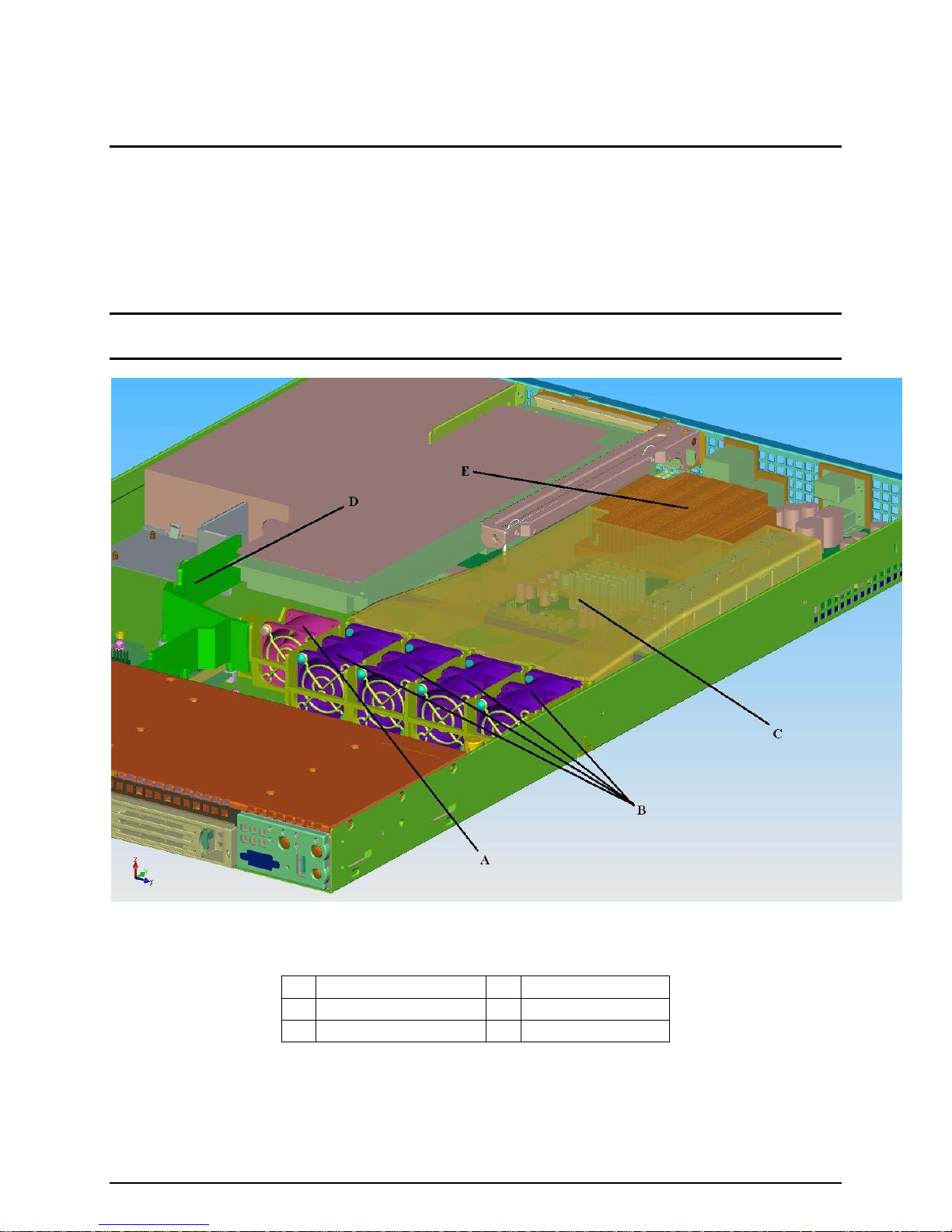

A Power supply G Control Panel

B Chassis Intrusion Switch H Hard Drive Bays

C Full length PCI Add in card slot I Chassis Handle

D PCI Riser Card Assembly Placement J Slim Line Drive Bay

E System Fan Module K PS / Electronics Bay Isolation Air Baffle

F CPU Air Duct Placement L Power Supply Fans

Revision 1.0 - 14 -

Figure 2. Major Chassis Components

Page 15

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

1.4 Rear Panel Components

On the back of the chassis are cutouts for all external I/O connectors found on the server board.

The I/O connector locations are pre-cut, so the use of an I/O shield is not required.

A PS2 keyboard connector G USB 2 connector

B PS2 mouse connector H NIC 1 connector (RJ45)

C Serial port A connector (DB9) I PCI card bracket (full-height)

D Video connector J Rear chassis venting holes

E NIC 2 connector (RJ45) K Power Supply fans

F USB 1 connector L AC Power Receptacle

Figure 3. Back Panel Feature Overview

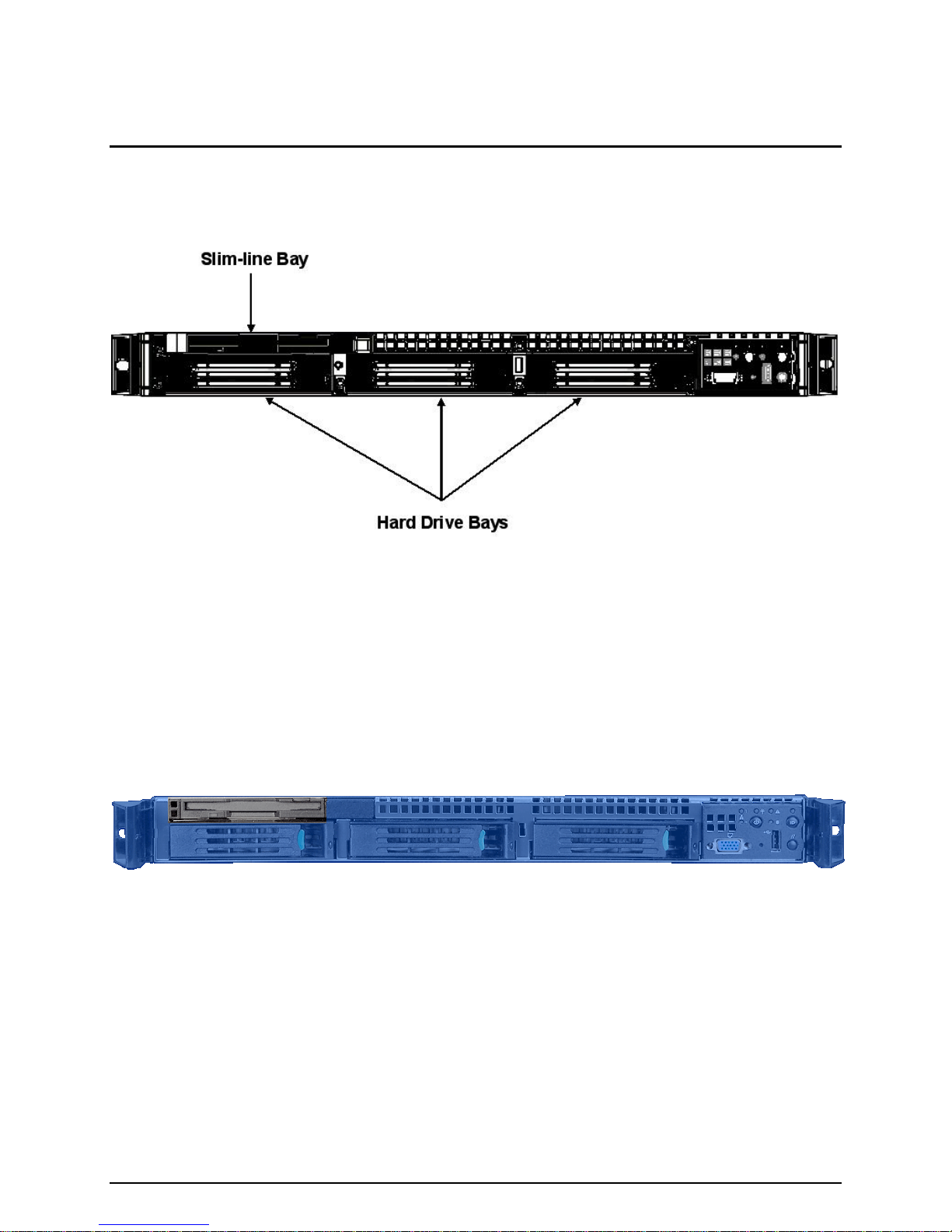

1.5 Hard Drive and Peripheral Bays

The Server Chassis SC1400UP is designed to support several different hard drive and

peripheral configurations. The hard drive bay is designed to support up to three cabled SATA

or SCSI drives or hot-swappable SATA or SCSI drives. SATA and SCSI hot-swap

configurations require an orderable accessory kit which includes the necessary cables, drive

trays and applicable backplane. Reference Intel Server Chassis SR1400 for detailed accessory

information.

The slim-line peripheral bay is capable of supporting any of the following slim-line devices:

CDROM drive, DVD Drive, DVD/CDR Drive, or Floppy drive. If both a CDROM or DVD/CDR and

Floppy drive are required, on optional kit is available to convert the first 1” hard drive bay to a

floppy drive bay. The kit includes the necessary cables and slim-line floppy drive mounting tray.

Revision 1.0 - 15 -

Page 16

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

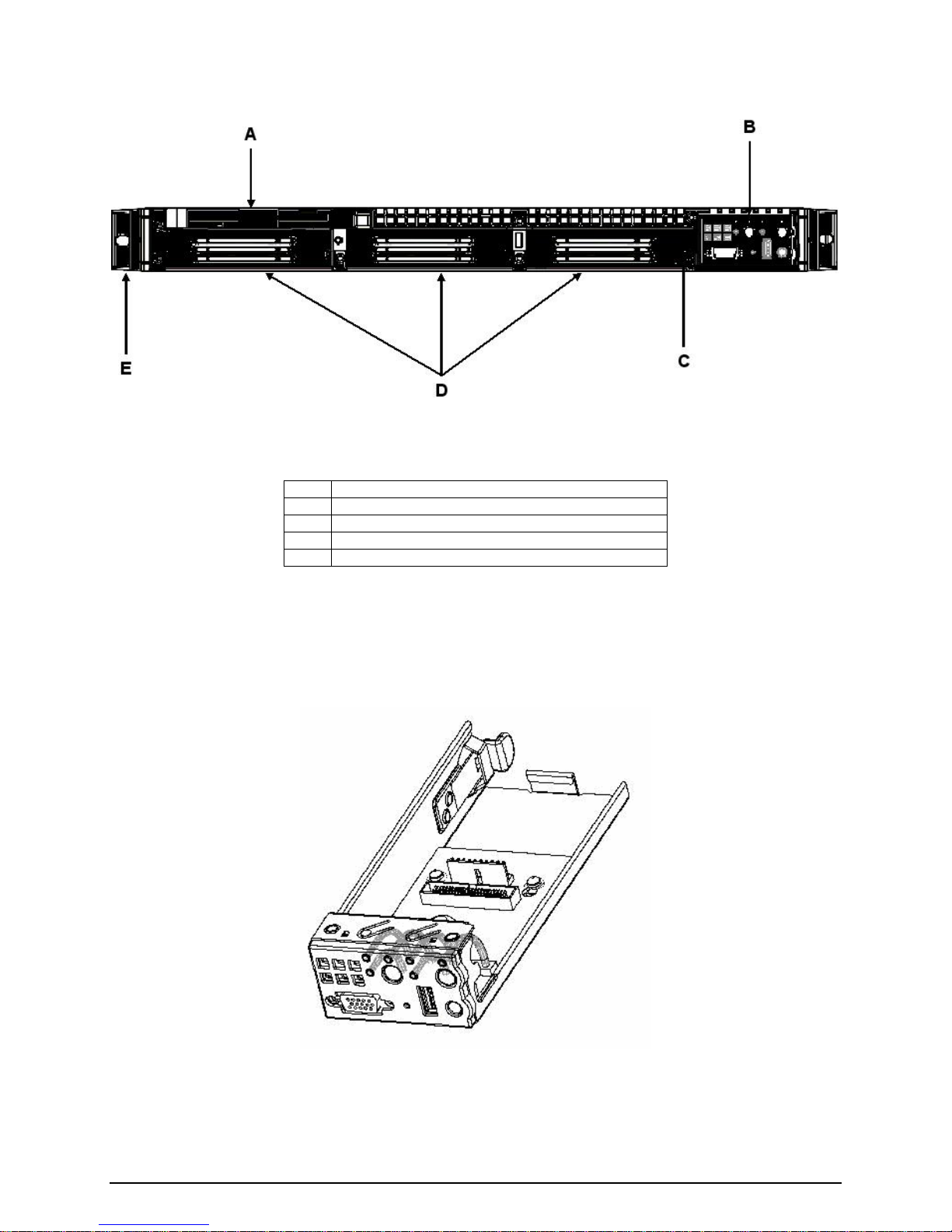

Figure 4. Front Panel Feature Overview

A Slim-line drive bay (CDROM or DVD/CDR or Floppy)

B Control Panel

C Hard Drive Fault/Activity LED

D 1” Hard Drive Bays

E Chassis Handle

1.6 Control Panel

The Server Chassis SC1400UP control panel assembly is pre-assembled and modular in

design. The entire module assembly slides into a predefined slot in the front of the chassis.

Revision 1.0 - 16 -

Figure 5. Control Panel Module

Page 17

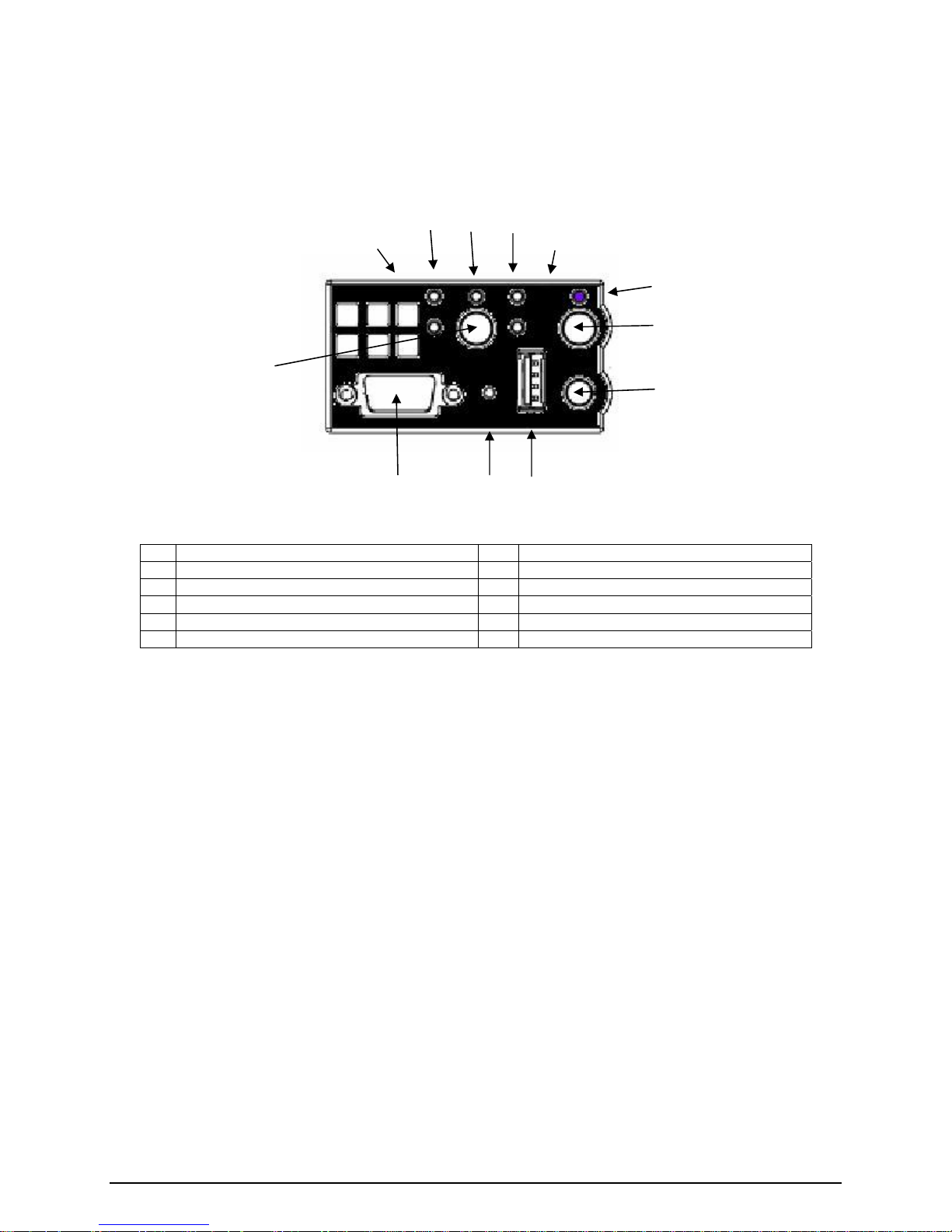

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

The control panel supports several push buttons and status LEDs, along with USB and video

ports to centralize system control, monitoring, and accessibility to within a common compact

design. The following diagram overviews the layout and functions of the control panel.

C D E

B

F

G

H

A

I

L

Figure 6. Standard Control Panel Overview

A Power / Sleep Button G System Identification LED

B NIC #2 Activity LED H System Identification Button

C NIC #1 Activity LED I System Reset Button

D Power / Sleep LED J USB 2.0 Connector

E System Status LED K Recessed NMI Button (Tool Required)

F Hard Drive Activity LED L Video connector (not supported on SC1400UP)

K

J

1.7 Power Sub-system

The power sub-system of the SC1400UP consists of a single non-redundant 300 watt power

supply and provides several integrated management features including:

• Status LED

• Over temperature protection circuitry

• Over voltage protection circuitry

With the addition of Server Management Software, the power subsystem is capable of

supporting several system management features including:

• Remote Power On/Off

• Status Alerting

• FRU Information Reporting

The power supply operates within the following voltage ranges and ratings 100-127VAC (V) ∼ at

50/60 Hertz (Hz); 8.2 Ampere (A) maximum (max) 200-240VAC∼ at 50/60 Hz; 4.1 A maximum

Revision 1.0 - 17 -

Page 18

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

1.8 System Cooling

The chassis provides a non-redundant system fans and dual non-redundant power supply fans

to provide sufficient air flow for cabled and hot-swap drive configurations, processors, memory

and add-in cards, when external ambient temperatures remain within specified limits.

1.9 Chassis Security

The SC1400UP provides support for several platform security features including a lockable front

bezel, chassis intrusion switch, and a Kensington style lock attach point.

1.10 Rack and Cabinet Mounting Options

The SC1400UP chassis was designed to support 19” wide by up to 24”-30” deep server

cabinets. The chassis can be configured to support either a relay rack / cabinet mount kit that

can be configured to support both 2-post racks and 4-post cabinets, or with a tool-less sliding

rail kit that is used to mount the chassis into a standard (19” by up to 30” deep) EIA-310D

compatible server cabinet.

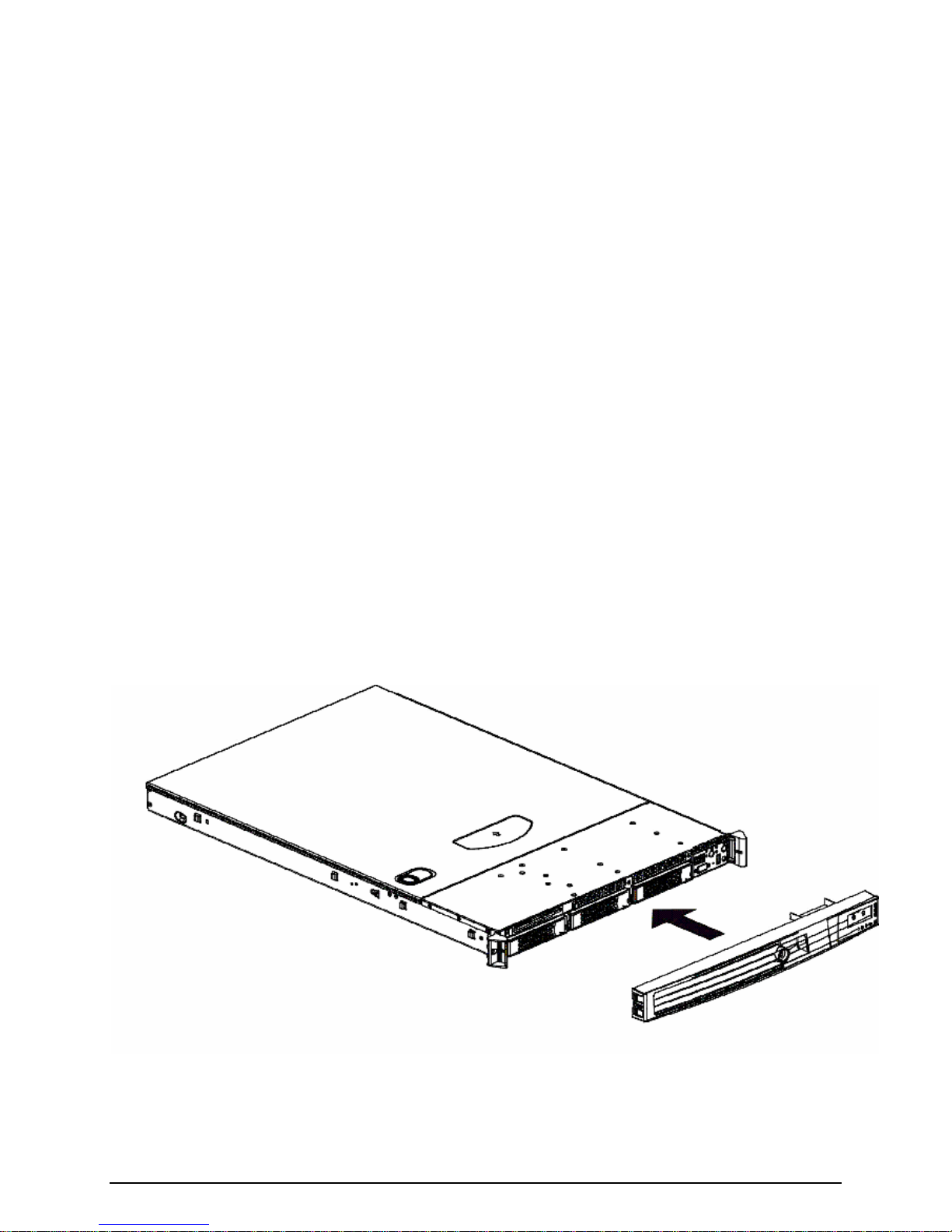

1.11 Front Bezels

The optional front bezel is made of molded plastic and uses a snap-on design. When installed,

its design allows for maximum airflow. Separate front bezels are available to support systems

that use either a Standard Control Panel or Intel Local Control Panel.

Revision 1.0 - 18 -

Figure 7. Optional Front Bezel

Page 19

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

Light pipes in the front bezel supporting the Standard Control Panel allow the system status

LEDs to be monitored with the bezel installed

Figure 8. Front Bezel Options

Revision 1.0 - 19 -

Page 20

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

2. Cooling Sub-System

The cooling sub-system on the SC1400UP is compromised of four 40x40x56mm dual rotor fans,

one 40x40x28mm single rotor fan, two 40x40x28mm power supply fans, CPU/Memory air duct,

and PS/Electronics Bay Isolation Air Baffle, to provide the necessary cooling and airflow to the

system. A fan on the processor heat sink is not necessary in this chassis. In order to maintain

the necessary airflow within the system, the air baffle, CPU/Memory air duct, and the top cover

need to be properly installed.

Note: The Server Chassis SC1400UP does not support redundant cooling. Should a fan fail, the

system should be brought down as soon as possible to replace the failed fan.

Figure 9. Intel® Server Chassis SC1400UP Cooling Subsystem

A System Fan #4 D Air Baffle

B Fans 5, 6, 7, 8 E CPU Heat Sink

C CPU / Memory Air Duct

Revision 1.0 - 20 -

Page 21

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

2.1 System Fans

The Intel® Server Chassis SC1400UP system fans consist of four 40x40x56mm dual rotor and

one 40x40x28mm single rotor multi-speed fans, which provide the primary airflow for the

system. The four dual rotor fans provide the primary cooling for the CPU, GMCH, and memory

components on the Intel Server Board SE7221BK1-E. The single rotor fan provides the primary

cooling for PCI add-in cards, the ICH6R and PXH chipset components.

Removal and insertion of individual fans is a tool-less operation, and provides for ease of

installation and serviceability of the server chassis cooling subsystem. The individual fans are

not hot swappable. The server must be turned off and power removed from the system before

any of the fans can safely be replaced.

Each dual rotor fan has an 8-pin wire harness which connects to the system fan headers 5,6,7

and 8 on the Intel Server Board SE7221BK1-E. These are shown, from left to right, in the

following figure. Each fan harness provides power and tachometer lines allowing the fans to be

monitored independently by server management software. The fan distribution board has a 20pin connector which provides the power and communication signal path from the baseboard.

Figure 10. Intel® Server Chassis SC1400UP System Fans 4, 5, 6, 7, 8

Figure 11. Intel® Server Platform SE7221BK1-E System Fan headers 4, 5, 6, 7, 8

Revision 1.0 - 21 -

Page 22

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

The following table provides the pin-outs for each dual rotor fan header.

Table 2. Individual Fan Assy Pinout (J6J1, J6J2, J6J3, J6J4)

Pin Signal Name Description

1 FAN_SPEED_CNTL2 Control the fan speed

2 FAN_FAIL FAN_TACH signal

3 GND Power Supply Ground

4 Reserved Reserved

5 GND Power Supply Ground

6 GND Power Supply Ground

7 FAN_FAIL FAN_TACH signal

8 Fan speed control Variable Speed Fan Power

The single rotor fan is a standard 3 pin SSI fan header that connects directly to the baseboard

system fan header #4 (JP5J2).

Each fan within the module is capable of supporting multiple speeds. If the internal ambient

temperature of the system exceeds the value programmed into the thermal sensor data record

(SDR), the Baseboard Management Controller (BMC) firmware will increase the rotational

speed for all the fans within fan module.

Note: There is no fan redundancy. Should a fan fail, the system should be shut down as soon

as possible to have the fan replaced. The system fans are not hot-swapable.

2.2 Power Supply Fans

The power supply supports two non-redundant 40mm fans. They are responsible for the cooling

of the power supply and drive bay 1 (the far left hard drive as viewed from the front of the

chassis).

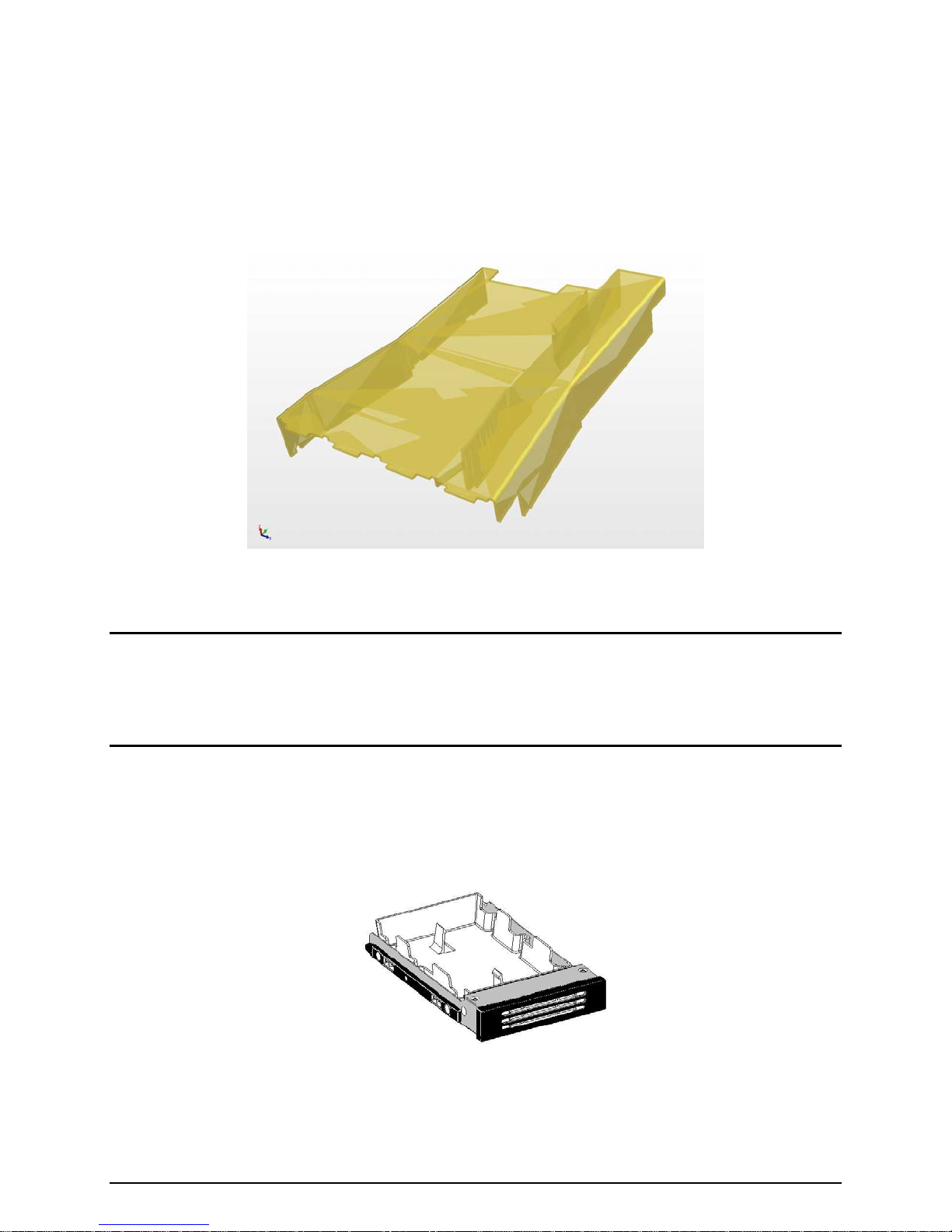

2.3 CPU/Memory Air Duct and Side Air Baffle

The chassis requires the use of a CPU/Memory air duct and power supply / electronics bay

isolation air baffle to direct airflow and sustain appropriate air pressure.

An air baffle is used to isolate airflow of the two power supply fans from that of the system fan

module. The baffle is mounted into three stand-offs with one end fitting under the back edge of

the hard drive bay

The CPU/Memory air duct must be properly installed to direct airflow through the processor

heatsink(s) to the low profile PCI and memory area of the system. The CPU air duct is

Revision 1.0 - 22 -

Figure 12. Air Baffle

Page 23

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

designed to support either a single or dual processor configuration. For single processor

configurations the pre-installed air damn must be left in place in order to maintain necessary air

pressure and air flow through the processor heat sink. For dual processor configurations, the

air damn must be snapped off of the CPU air duct. The CPU air duct cannot be installed if the

air damn is in place and two processors are installed.

Figure 13. CPU/Memory Air Duct

Note: If the CPU/Memory air duct is removed, the system will not meet the thermal cooling

requirements of the processor, which will most likely result in degraded performance as a result

of throttling or thermal shutdown of the system.

Note: Once the air damn is removed from the CPU air duct, it cannot be reinstalled.

2.4 Hard Drive Bays

Hard drive bays must be populated in order to maintain system thermals. Hard drive trays, both

hot-swap and cabled drive, must ether have a hard drive or drive blank installed in them.

Revision 1.0 - 23 -

Page 24

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

3. Peripheral and Hard Drive Support

The server chassis SC1400UP provides three hard drive bays and one slim-line peripheral drive

bay at the front of the chassis. The drive bays are designed to support both SCSI and SATA

hot-swap backplanes or can support cabled SATA drive configurations.

Figure 14. Intel® Server Chassis SC1400UP Peripheral Bay Configuration Options

3.1 Slimline Drive Bay

The chassis provides a slim-line drive bay that can be configured for either CDROM,

DVD/CDRW, or Floppy drives with or without the presence of a backplane. Regardless of

whether a SATA or SCSI backplane is present, all slimline devices attach directly to the

SE7221BK1-E baseboard The 100pin connector on the SATA and SCSI backplane DOES

NOT APPLY to the Intel Server Chassis SC1400UP and Intel Server Board SE7221BK1-E.

Drives are mounted on a tool-less tray which allows for easy installation into and removal from

the chassis. The slim-line devices are not hot-swappable.

Figure 15. View of Slim-Line Drive Bay

3.1.1 Floppy Drive Support with or without Backplane present

Whether a SATA or SCSI backplane is used in the Intel Server Chassis SC1400UP or not, the

floppy drive is mated with an interposer card which provides the power and IO interconnects

between the drive, power supply and SE7221BK1-E baseboard. The 100pin connector on the

backplane is not used with the Intel Server Board SE7221BK1-E. The interposer card has

three connectors; the first has 28 pins which is cabled directly to the drive. The second

connector has 4 pins and is cabled to the 2x3 pin power lead from the power supply. This

connector has the following pinout.

Revision 1.0 - 24 -

Page 25

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

Table 3. 4-pin floppy power connector Pinout (J3)

Pin Name

1 P12V

2 GND

3 GND

4 P5V

The power cable for the floppy drive is provided via a slimline Y cable which comes with the

SC1400UP chassis. The third connector has 34 pins and is cabled to the legacy floppy

connector on the baseboard. This connector has the following pinout.

Table 4. 34-pin floppy connector Pinout (J2)

Name Pin Pin Name

GND 1 2 FD_DENSEL0

GND 3 4 2M_MEDIA

GND 5 6 FD_DRATE0_L

GND 7 8 FD_INDEX_L

GND 9 10 FD_MTR0_L

GND 11 12 FD_DS1_L

GND 13 14 FD_DS0_L

GND 15 16 FD_MTR1_L

Unused 17 18 FD_DIR_L

GND 19 20 FD_STEP_L

GND 21 22 FD_WDATA_L

GND 23 24 FD_WGATE_L

GND 25 26 FD_TRK0_L

Unused 27 28 FD_WP_L

GND_FDD 29 30 FD_RDATA_L

GND 31 32 FD_HDSEL_L

MSEN0 33 34 FD_DSKCHG_L

3.1.1.1 Optional Floppy Drive Configuration

For system configurations that require a CDROM or DVD-CDR and Floppy drive, where using a

USB Floppy or USB CDROM is not desired, an accessory kit which consists of a slim-line floppy

drive tray and face plate can be used to install a floppy drive into the hard drive bay directly

beneath the slim-line drive bay a shown in the following diagram.

Figure 16. Optional Floppy Drive Configuration

Revision 1.0 - 25 -

Page 26

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

3.1.1.2 CDROM or DVD-CDR Drive Use with or without Backplane present

Regardless of whether a backplane is present or not, the slim-line CDROM or DVD-CDR drive

is mated with an interposer card which provides the power and IO interconnects between the

drive, power supply and baseboard. The interposer card has three connectors; the first has 50

pins and is plugged directly into the drive connector. The connector has the following pinout.

Table 5. 50-pin CD-ROM connector Pinout (J6)

Name Pin Pin Name

RSV_LCM 1 2 RSV_RCM

RSV_GND 3 4 GND

RST_IDE_S_L 5 6 IDE_SDD<8>

IDE_SDD<7> 7 8 IDE_SDD<9>

IDE_SDD<6> 9 10 IDE_SDD<10>

IDE_SDD<5> 11 12 IDE_SDD<11>

IDE_SDD<4> 13 14 IDE_SDD<12>

IDE_SDD<3> 15 16 IDE_SDD<13>

IDE_SDD<2> 17 18 IDE_SDD<14>

IDE_SDD<1> 19 20 IDE_SDD<15>

IDE_SDD<0> 21 22 IDE_SDDREQ

GND 23 24 IDE_SDIOR_L

IDE_SDIOW_L 25 26 GND

IDE_SIORDY 27 28 IDE_SDDACK_L

IRQ_IDE_S 29 30 NC_IDEIO16_L

IDE_SDA<1> 31 32 NC_CBL_DET_S

IDE_SDA<0> 33 34 IDE_SDA<2>

IDE_SDCS0_L 35 36 IDE_SDCS1_L

IDE_SEC_HD_ACT_L 37 38 P5V

P5V 39 40 P5V

P5V 41 42 P5V

GND 43 44 GND

GND 45 46 GND

IDEP_ALE_H 47 48 GND

49 50

52 Unused (50 pin or 52 pin)

The second connector has 4 pins and is cabled to the 2x3 pin power lead from the power

supply. The power cable for the drive is included in the SC1400UP in the form of a Y power

cable. Both ends of the Y cable are necessary when a slimline CD/DVD is used in conjunction

with a floppy installed in the hard drive bay. Both ends of this are identical and have the

following pinout.

Table 6. 4-pin CD-ROM power connector Pinout (J5)

Revision 1.0 - 26 -

Pin Name

1 P12V

2 GND

3 GND

4 P5V

Page 27

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

The third connector has 40 pins and is cabled to the legacy IDE connector on the baseboard.

This connector has the following pinout.

Table 7. 40-pin CD-ROM connector Pinout (J1)

Name Pin Pin Name

RST_IDE_S_L 1 2 GND

IDE_SDD<7> 3 4 IDE_SDD<8>

IDE_SDD<6> 5 6 IDE_SDD<9>

IDE_SDD<5> 7 8 IDE_SDD<10>

IDE_SDD<4> 9 10 IDE_SDD<11>

IDE_SDD<3> 11 12 IDE_SDD<12>

IDE_SDD<2> 13 14 IDE_SDD<13>

IDE_SDD<1> 15 16 IDE_SDD<14>

IDE_SDD<0> 17 18 IDE_SDD<15>

GND 19 20 Unused

IDE_SDDREQ 21 22 GND

IDE_SDIOW_L 23 24 GND

IDE_SDIOR_L 25 26 GND

IDE_SIORDY 27 28 IDEP_ALE_H

IDE_SDDACK_L 29 30 GND

IDE_IDE_S 31 32 NC_IDEIO16_L

IDE_SDA<1> 33 34 IDE_CBL_DET_S

IDE_SDA<0> 35 36 IDE_SDA<2>

IDE_SDCS0_L 37 38 IDE_SDCS1_L

IDE_SEC_HD_ACT_L 39 40 GND

3.2 Hard Disk Drive Bays

The server chassis SC1400UP can be configured to support either hot swap SCSI or SATA

hard disk drives or fixed SATA drive configurations. For hot swap drive configurations, 3.5” x 1”

hard disk drives are mounted to hot swap drive trays for easy insertion to or extraction from the

drive bay. For cabled drive configurations, the SATA drives are mounted to a drive tray which is

only removable from inside the chassis.

Note: All hard drive bays must be populated to maintain system thermals. Drive trays should

either have a hard drive or drive blank inserted.

Revision 1.0 - 27 -

Page 28

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

3.2.1 Hot Swap Hard Disk Drive Trays

In a hot swap configuration, each hard drive must be mounted to a hot swap drive tray, making

insertion and extraction of the drive from the chassis very simple. Each drive tray has its own

dual purpose latching mechanism which is used to both insert/extract drives from the chassis

and lock the tray in place. Each drive tray supports a light pipe providing a drive status indicator,

located on the backplane, to be viewable from the front of the chassis.

Note: Depending on the controller used, SATA hard disk drives may not report errors using the

drive’s status indicator.

E

A

B

C

D

Figure 17. Hard Drive Tray Assembly

OM11684

A. Hard Drive

B. Drive Carrier

C. Side Rail

D. Mounting Screw

E. Hard Drive Connector

3.2.2 Fixed Drive Trays

In a fixed drive configuration, each SATA/SCSI hard drive must be mounted to a non-hot swap

drive tray. The tray is designed to slide into the drive bay and lock into place. To remove the

drive, the chassis must be opened to disengage the drive tray latch from the bay.

3.2.3 Drive Blanks

Drive blanks must be used when no drive is used in a hard drive bay. Drive blanks simulate the

spatial volume of a hard disk which is required to maintain proper air pressure limits necessary

to cool the system.

Revision 1.0 - 28 -

Page 29

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

Figure 18. Drive Tray with Drive Blank

3.3 Hot-Swap SCSI Backplane

The SC1400UP SCSI hot-swap backplane (HSBP) supports the following feature set:

QLogic

®

GEM359 enclosure management controller

o External non-volatile Flash ROM

2

o Two I

C interfaces

o Low Voltage Differential (LVD) SCSI Interface

o SCSI-3 compatible

o Compliance with SCSI Accessed Fault Tolerant Enclosures (SAF-TE) specification,

version 1.00 and addendum

o Compliance with Intelligent Platform Management Interface (IPMI)

Support for up to three U320 LVD SCSI Drives

o Onboard LVD SCSI Termination – SPI-4 compatible

Temperature Sensor

Hard Drive Status LEDs

FRU EEPROM

One 2x3-pin Power Connector

IDE Connector provided for Slim-line CDROM or DVD support

Floppy Connector provided for Slim-line floppy support

Control Panel Connector

3.3.1 Hot-Swap SCSI Backplane Board Layout

The following diagram shows the layout of major components and connectors of the board.

Revision 1.0 - 29 -

Page 30

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

Floppy Drive

Connector

not used in

SR1425BK1

IDE Connector

not used in

SR1425BK1

Power

Connector

SCSI Connector

to SCSI add-in

card

Figure 19. Hot-Swap SCSI Backplane Layout

100pin connector

not used in

SR1425BK1

SCA2 SCSI

Hard Drive

Connectors

Thumb

Screw

Drive Status

LEDs

Control Panel

Connector not

used in

SR1425BK1

3.3.2 SCSI Backplane Functional Architecture

This section provides a high-level description of the functionality distributed between the

architectural blocks of the SC1400UP 1U SCSI HSBP. The following figure shows the functional

blocks of the hot-swap SCSI backplane.

Figure 20. Hot-Swap SCSI Backplane Functional Diagram

Revision 1.0 - 30 -

Page 31

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

3.3.2.1 Enclosure Management Controller

The SCSI backplane utilizes the features of the QLogic

®

GEM359 for enclosure management

which monitors various aspects of a storage enclosure. The chip provides in-band SAF-TE and

SES management through the SCSI interface. Also supported is the IPMI specification by

providing management data to the baseboard management controller via the I2C connection to

the baseboard.

The GEM359 comes in a 144-pin Low profile Quad Flat Pack package and operates from 3.3V

and input clock frequency of 10MHz. It has general input and output pins that allow

customization, some of which are used for drive detection and power controller enable/disable

functionality.

3.3.2.1.1 SCSI Interface

The GEM359 supports LVD SCSI operation through 8-bit asynchronous SCSI data transfers.

The following SCSI Command Set is supported:

Inquiry

Read Buffer

Write Buffer

Test Unit Ready

Request Sense

Send Diagnostic

Receive Diagnostic

The GEM359 supports the following SAF-TE Command Set:

Read Enclosure Configuration

Read Enclosure Status

Red Device Slot Status

Read Global Flags

Write Device Slot Status

Perform Slot Operation

3.3.2.1.2 I2C Serial Bus Interface

The GEM359 supports two independent I2C interface ports with bus speeds of up to 400Kbits.

The I2C core incorporates 8-bit FIFOs for data transfer buffering. The I

National

value readings to be returned to the host. The Intelligent Platform Management Bus (IPMB) is

supported through I

The figure below provides a block diagram of I

®

LM75 or equivalent I2C -based temperature sensor. This enables actual temperature

2

C port 1.

2

C bus connection implemented on the

2

C bus supports the

SC1400UP 1U SCSI HSBP

Revision 1.0 - 31 -

Page 32

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

Figure 21. Intel® Server Chassis SC1400UP 1U SCSI HSBP I2C Bus Connection Diagram

3.3.2.1.3 Temperature Sensor

SC1400UP 1U SCSI HSBP provides a National Semiconductor

®

LM75 or equivalent

temperature sensor with over-temperature detector. The host can query the LM75 at any time

to read the temperature. The host can program both the temperature alarm threshold and the

temperature at which the alarm condition goes away.

3.3.2.1.4 Serial EEPPROM

SC1400UP 1U SCSI HSBP provides an Atmel

®

24C02 or equivalent serial EEPROM for storing

the FRU information. The 24C02 provides 2048 bits of serial electrically erasable and

programmable read-only

3.3.2.1.5 External Memory Device

SC1400UP 1U SCSI HSBP contains a non-volatile 16K Top Boot Block, 4Mbit Flash memory

device that stores the configuration data and operating firmware executed by the GEM359’s

internal CPU.

The Flash memory operates off the 3.3V rail and housed in a 48-pin TSOP Type 1 package.

3.3.2.1.6 LED Support

SC1400UP 1U SCSI HSBP contains a green ACTIVITY LED and a yellow FAULT LED for each

of the six drive connectors. The SCSI HD itself drives the ACTIVITY LED whenever the drive

gets accessed. The GEM359 controller drives the FAULT LED whenever an error condition

gets detected.

Revision 1.0 - 32 -

Page 33

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

3.3.3 SCSI Backplane Connector Definitions

As a multi-functional board, several different connectors can be found on the SCSI backplane.

This section defines the purpose and pin-out associated with each connector.

3.3.3.1 Power Connector (Backplane to Power Supply Harness)

The SCSI backplane provides power to the three drive bays supporting up to three hard disk

drives and the slim-line drive bay supporting one floppy drive or CD-ROM drive. A 6-pin power

cable is routed from the power distribution board and plugs into a 2 x 3 shrouded plastic PC

power connector on the SCSI backplane. The following table shows the power connector

pinout.

Table 8. SCSI Backplane Power Connector Pinout (J1)

Pin Name Pin Name

1 GND 4 P12V

2 GND 5 P12V

3 P5V 6 P5V_STBY

3.3.3.2 SCSI Connector (Backplane to SCSI add-in card)

A 68-pin SCSI cable is used to interface the SCSI backplane with an add-in PCI SCSI controller

installed on the PCI riser card.

Figure 22. 68-Pin SCSI Cable Connector

Table 9. UltraWide (SE) and Ultra2 (LVD) Ultra320 SCSI Connector Pinout (J8)

Name Pin Pin Name

BP_SCSI_D12P A1 B1 BP_SCSI_D12N

BP_SCSI_D13P A2 B2 BP_SCSI_D13N

BP_SCSI_D14P A3 B3 BP_SCSI_D14N

BP_SCSI_D15P A4 B4 BP_SCSI_D15N

BP_SCSI_DP1P A5 B5 BP_SCSI_DP1N

BP_SCSI_D0P A6 B6 BP_SCSI_D0N

BP_SCSI_D1P A7 B7 BP_SCSI_D1N

BP_SCSI_D2P A8 B8 BP_SCSI_D2N

BP_SCSI_D3P A9 B9 BP_SCSI_D3N

BP_SCSI_D4P A10 B10 BP_SCSI_D4N

BP_SCSI_D5P A11 B11 BP_SCSI_D5N

BP_SCSI_D6P A12 B12 BP_SCSI_D6N

BP_SCSI_D7P A13 B13 BP_SCSI_D7N

Revision 1.0 - 33 -

Page 34

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

Name Pin Pin Name

BP_SCSI_DP0P A14 B14 BP_SCSI_DP0N

GND A15 B15 GND

BP_SCSI_DIFSNS A16 B16 GND

TERMI_PWR A17 B17 TERMI_PWR

TERMI_PWR A18 B18 TERMI_PWR

Unused A19 B19 Unused

GND A20 B20 GND

BP_SCSI_ATNP A21 B21 BP_SCSI_ATNN

GND A22 B22 GND

BP_SCSI_BSYP A23 B23 BP_SCSI_BSYN

BP_SCSI_ACKP A24 B24 BP_SCSI_ACKN

BP_SCSI_RSTP A25 B25 BP_SCSI_RSTN

BP_SCSI_MSGP A26 B26 BP_SCSI_MSGN

BP_SCSI_SELP A27 B27 BP_SCSI_SELN

BP_SCSI_CDP A28 B28 BP_SCSI_CDN

BP_SCSI_REQP A29 B29 BP_SCSI_REQN

BP_SCSI_IOP A30 B30 BP_SCSI_ION

BP_SCSI_D8P A31 B31 BP_SCSI_D8N

BP_SCSI_D9P A32 B32 BP_SCSI_D9N

BP_SCSI_D10P A33 B33 BP_SCSI_D10N

BP_SCSI_D11P A34 B34 BP_SCSI_D11N

3.3.3.3 SCA2 Hot-Swap SCSI Drive Connectors

The SCSI backplane provides three hot-swap SCA2 connectors, which provide power and SCSI

signals using a single connector. Each SCA drive attaches to the backplane using one of these

connectors.

Figure 23. 80-pin SCA2 SCSI Interface

Revision 1.0 - 34 -

Page 35

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

Table 10. 80-pin SCA2 SCSI Interface Pinout (J9, J2, J10)

Signal Name Pin Pin Signal Name

GND 41 1 P12V

GND 42 2 P12V

GND 43 3 P12V

SCSI_MATED 44 4 P12V

NC_3V_CHG 45 5 NC_3V_1

BP_SCSI_DIFSNS 46 6 NC_3V_2

BP_SCSI_D11P 47 7 BP_SCSI_D11N

BP_SCSI_D10P 48 8 BP_SCSI_D10N

BP_SCSI_D9P 49 9 BP_SCSI_D9N

BP_SCSI_D8P 50 10 BP_SCSI_D8N

BP_SCSI_IOP 51 11 BP_SCSI_ION

BP_SCSI_REQP 52 12 BP_SCSI_REQN

BP_SCSI_CDP 53 13 BP_SCSI_CDN

BP_SCSI_SELP 54 14 BP_SCSI_SELN

BP_SCSI_MSGP 55 15 BP_SCSI_MSGN

BP_SCSI_RSTP 56 16 BP_SCSI_RSTN

BP_SCSI_ACKP 57 17 BP_SCSI_ACKN

BP_SCSI_BSYP 58 18 BP_SCSI_BSYN

BP_SCSI_ATNP 59 19 BP_SCSI_ATNN

BP_SCSI_DP0P 60 20 BP_SCSI_DP0N

BP_SCSI_D7P 61 21 BP_SCSI_D7N

BP_SCSI_D6P 62 22 BP_SCSI_D6N

BP_SCSI_D5P 63 23 BP_SCSI_D5N

BP_SCSI_D4P 64 24 BP_SCSI_D4N

BP_SCSI_D3P 65 25 BP_SCSI_D3N

BP_SCSI_D2P 66 26 BP_SCSI_D2N

BP_SCSI_D1P 67 27 BP_SCSI_D1N

BP_SCSI_D0P 68 28 BP_SCSI_D0N

BP_SCSI_DP1P 69 29 BP_SCSI_DP1N

BP_SCSI_D15P 70 30 BP_SCSI_D15N

BP_SCSI_D14P 71 31 BP_SCSI_D14N

BP_SCSI_D13P 72 32 BP_SCSI_D13N

BP_SCSI_D12P 73 33 BP_SCSI_D12N

SCSI_MATED 74 34 P5V

GND 75 35 P5V

GND 76 36 P5V

HD_ACT_LED_L 77 37 Unused

Unused 78 38 GND

Unused 79 39 Unused

Unused 80 40 Unused

GND B2 B1 GND

Revision 1.0 - 35 -

Page 36

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

3.4 Hot-Swap SATA Backplane

The SC1400UP 1U SATA Hot-Swap Back Plane (HSBP) supports the following feature set:

QLogic

®

GEM424 enclosure management controller

o External non-volatile SEEPROMs

2

o Three I

C interfaces

o SATA and SATA-II extension compatible

o Compliance with SATA Accessed Fault Tolerant Enclosures (SAF-TE) specification,

version 1.00 and addendum

o Compliance with Intelligent Platform Management Interface 1.5 (IPMI)

Support for up to three SATA Drives

Hot Swap Drive support

Temperature Sensor

FRU EEPROM

One 2 x 3-pin Power Connector

IDE Connector provided for slim-line CDROM or DVD support

Floppy Connector provided for slim-line floppy support

Control Panel Connector

Drive Status LEDs

Revision 1.0 - 36 -

Page 37

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

3.4.1 SATA Backplane Layout

The SATA backplane is located on the backside of the hot-swap drive bays on the inside of the

chassis. Stand-offs on the chassis and a single thumb screw make for easy tool-less

installation. The following diagram shows the layout of major components and connectors of the

board.

Floppy Drive

Connector not used

in SR1425BK1

SATA Drive

Connectors

Power Connector

Figure 24. SATA Backplane Layout

Drive Status LEDs

Figure 25. SATA Backplane Layout

IDE Connector not

used in SR1425BK1

100-pin connector not

used in SR1425BK1

SATA Connectors

Control Panel

Connector not used in

SR1425BK1

3.4.2 SATA Backplane Functional Architecture

This section provides a high-level description of the functionality distributed between the

architectural blocks of the SC1400UP 1U SATA HSBP. The figure below shows the functional

blocks of the SATA backplane.

Revision 1.0 - 37 -

Page 38

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

Figure 26. SATA Backplane Functional Block Diagram

3.4.2.1 Enclosure Management Controller

The SC1400UP SATA backplane utilizes the features and functionality of the QLogic

enclosure management controller, which is capable of monitoring various aspects of a storage

enclosure. The chip provides in-band SAF-TE management through the SATA Host I

®

GEM424

2

C

interface.

The GEM424 comes in a 80-pin Thin Quad Flat Pack (TQFP) package and operates from 3.3V

and input clock frequency of 20MHz. It has general input and output pins that are used for

hardware drive detection and driving FAULT and ACTIVITY LEDs.

3.4.2.1.1 SATA Interface

The GEM424 implements SAF-TE over the HBA I

2

C interface. The GEM424 supports the

following SAF-TE Command Set:

Read Enclosure Configuration

Read Enclosure Status

Read Device Slot Status

Read Global Flags

Write Device Slot Status

Perform Slot Operation

Revision 1.0 - 38 -

Page 39

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

3.4.2.1.2 I2C Serial Bus Interface

The GEM424 supports two independent I2C interface ports with bus speeds of up to 400Kbits.

2

The I

C core incorporates 8-bit FIFOs for data transfer buffering. The I2C bus supports National

Semiconductor

temperature value readings to be returned to the host. The Intelligent Platform Management Bus

(IPMB) is supported through I

®

LM75 or equivalent I2C -based temperature sensors. This enables actual

2

C port 0.

The figure below provides a block diagram of I

2

C bus connection implemented on the

SC1400UP 1U SATA HSBP.

Figure 27. Intel® Server Chassis SC1400UP 1U SATA HSBP I2C Bus Connection Diagram

3.4.2.1.3 Temp Sensor

SC1400UP 1U SATA HSBP provides National

®

LM75 or equivalent temperature sensor with

over-temperature detector. The host can query the LM75 at any time to read the temperature.

The temperature sensor has the I

2

C address of 0x90h on GEM424’s Port 0.

3.4.2.1.4 Serial EEPROM

The SC1400UP 1U SATA HSBP provides an Atmel

®

24C02 or equivalent serial EEPROM for

storing the FRU information. The 24C02 provides 2048 bits of serial electrically erasable and

programmable read-only

The serial EEPROM has the I

2

C addres of 0xA6h on GEM424’s Port 1.

3.4.2.1.5 External Memory Device

SC1400UP 1U SATA HSBP contains non-volatile 32K and 64K Serial EEPROM devices for

Boot and Run-Time/Configuration code storage respectively. These devices reside on the

GEM424’s private I

2

C bus.

Revision 1.0 - 39 -

Page 40

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

The SEEPROMs operate off the 5.0V rail and are housed in 8-pin SOIC packages.

3.4.2.1.6 LED Support

SC1400UP 1U SATA HSBP contains a green ACTIVITY LED and an amber FAULT LED for

each of the three drive connectors. The ACTIVITY LED is driven by the GEM424 or, for drives

that support the feature, by the SATA HD itself whenever the drive gets accessed. The FAULT

LED is driven by the GEM424 controller whenever an error condition is detected, as defined by

the firmware.

Activity and Fault LED functions are only available when a SATA host controller that supports

the SAF-TE protocol over I

2

Host I

C connector, J2A3.

2

C is connected to the SC1400UP 1U SATA HSBP via the SATA

Table 11. LED Function

Status LED Definition

GREEN ON HDD Activity

AMBER ON HDD Fail

AMBER Blinking Rebuild in progress

3.4.3 SATA Backplane Connector Definitions

3.4.3.1 Power Connector

The SATA backplane provides power for up to three ATA drives, and one floppy drive or CDROM drive. A 6-pin power cable from the power supply harness is routed to the backplane and

plugs into a 2x3 shrouded plastic PC power connector. The following table provides the

connector pinout.

Table 12. SATA Backplane Power Connector Pinout

3.4.3.2 SATA Connectors (Backplane to Baseboard)

The SATA backplane has three 7-pin SATA connectors (Drive0, Drive1 and Drive2). These

connectors correspond to the SATA connectors on the Intel Server Board SE7221BK1-E

(SATA1, SATA2 and SATA3). The backplane connectors relay SATA signals from the

baseboard to the ATA drives. Each connector is used for a separate SATA channel and is

configured as a bus master. The following table provides the connector pinout.

Revision 1.0 - 40 -

Pin Name Pin Name

1 GND 4 P12V

2 GND 5 P12V

3 P5V 6 P5V_STBY

Page 41

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

Table 13. 7-Pin SATA Connector Pinout (J2, J3, J4, J5, J6)

Pin Name

1 GND

2 DRV_RX_P

3 DRV_RX_N

4 GND

5 DRV_TX_P

6 DRV_TX_N

7 GND

8 GND

9 GND

3.4.3.3 Hot-Swap SATA Drive Connectors

The SATA drive interface combines both SATA and power signals into a single connector. The

pin-out of the drive interface connector is the same as a standard ATA and power connector.

The following table provides the pinout.

Table 14. 22-Pin SATA Connector Pinout

Name Pin Pin Name

GND 1 13 GND

DRV_RX_P 2 14 SCSI+5V

DRV_RX_N 3 15 SCSI+5V

GND 4 16 SCSI+5V

DRV_TX_P 5 17 GND

DRV_TX_N 6 18 Unused

GND 7 19 GND

P3V3 8 20 SCSI+12V

P3V3 9 21 SCSI+12V

P3V3 10 22 SCSI+12V

GND 11 23 GND

GND 12 24 GND

3.4.3.4 Slim-line Floppy Drive Connector

With a slim-line floppy drive installed into either the slim-line drive bay or the optionally installed

floppy drive kit located in one of the hard drive bays, the floppy cable from the drive is routed to

the legacy floppy connector on the baseboard floppy connector on the Intel Server Board

SE7221BK1-E.

3.4.3.5 Slim-line CDROM / DVD Interface Assembly

When a CDROM or DVD drive is installed into the slim-line peripheral bay, the drive cable is

routed from a connector on the drive interposer card, to the baseboard legacy IDE connector on

the Intel Server Board SE7221BK1-E.

Revision 1.0 - 41 -

Page 42

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

4. Standard Control Panel

The standard control panel supports several push buttons and status LEDs, along with USB and

video ports to centralize system control, monitoring, and accessibility to within a common

compact design.

The control panel assembly comes pre-assembled and is modular in design. The control panel

assembly module slides into a predefined slot on the front of the chassis. Once installed,

communication to the baseboard can be achieved by either attaching a 50-pin cable to a hotswap backplane, or if cabled drives are used, can be connected directly to the baseboard. In

addition, a USB cable is routed to a USB port on the baseboard.

Figure 28. Standard Control Panel Assembly Module

4.1 Control Panel Buttons

The standard control panel assembly houses several system control buttons. Each of their

functions is listed in the table below.

Revision 1.0 - 42 -

Figure 29. Control Panel Buttons

Page 43

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

y

y

Table 15. Contol Button and Intrusion Switch Functions

Reference Feature Function

A

B

C

D

Power / Sleep

Button

ID Button Toggles the front panel ID LED and the baseboard ID LED on/off. The baseboard

Reset Button Reboots and initializes the system.

NMI Button Pressing the recessed button with a paper clip or pin puts the server in a halt state

Toggles the system power on/off. This button also functions as a Sleep Button if

enabled by an ACPI-compliant operating system.

ID LED is visible through the rear of the chassis and allows you to locate the server

you’re working on from behind a rack of servers.

for diagnostic purposes and allows you to issue a non-maskable interrupt. After

issuing the interrupt, a memory download can be performed to determine the cause

of the problem.

4.2 Control Panel LED Indicators

The control panel houses six LEDs, which are viewable with or without the front bezel to display

the system’s operating state.

NIC1 and NIC2

LEDs

Activit

Power and

Sleep LED

System Status

LED

Hard Drive

LED

Activit

System

Identify LED

Figure 30. Control Panel LEDs

The following table identifies each LED and describes their functionality.

Table 16. Control Panel LED Functions

LED Color State Description

Green On NIC Link NIC1 / NIC2

Activity

Power / Sleep

(on standby power)

System Status

(on standby power)

Green Blink NIC Activity

On Legacy power on / ACPI S0 state Green

1,4

Blink

Off Off Power Off / ACPI S4 or S5 state

On Running / normal operation Green

Blink

On Critical or non-recoverable condition. Amber

Blink

Off Off POST / system stop.

Sleep / ACPI S1 state

1,2

Degraded

1,2

Non-critical condition.

Revision 1.0 - 43 -

Page 44

Intel® Server Chassis SC1400UP / Intel® Server Platform SR1425BK1-E

LED Color State Description

Disk Activity

System Identification

Green Random

blink

Off Off

Blue Blink Identify active via command or button.

Off Off No Identification.

3

Provides an indicator for disk activity.

No hard disk activity

Notes:

1. Blink rate is ~1 Hz with at 50% duty cycle.

2. The amber status takes precedence over the green status. When the amber LED is on or blinking, the green

LED is off.

3. Also off when the system is powered off (S4/S5) or in a sleep state (S1).

4. The power LED sleep indication is maintained on standby by the chipset. If the system is powered down

without going through BIOS, the LED state in effect at the time of power off will be restored when the system

is powered on until the BIOS clears it. If the system is not powered down normally, it is possible that the

Power LED will be blinking at the same time that the system status LED is off due to a failure or

configuration change that prevents the BIOS from running.

The current limiting resistors for the power LED, the system fault LED, and the NIC LEDs are

located on the server board SE7221BK1-E.

4.2.1 Power / Sleep LED

Table 17. SSI Power LED Operation

State Power Mode LED Description

Power Off Non-ACPI Off System power is off, and the BIOS has not initialized the chipset.

Power On Non-ACPI On System power is on, but the BIOS has not yet initialized the chipset.

S5 ACPI Off Mechanical is off, and the operating system has not saved any context to the

hard disk.

S4 ACPI Off Mechanical is off. The operating system has saved context to the hard disk.

S3-S1 ACPI Slow blink 1 DC power is still on. The operating system has saved context and gone into a

level of low-power state.

S0 ACPI Steady on System and the operating system are up and running.

Notes:

1

. Blink rate is ~ 1Hz with at 50% duty cycle.

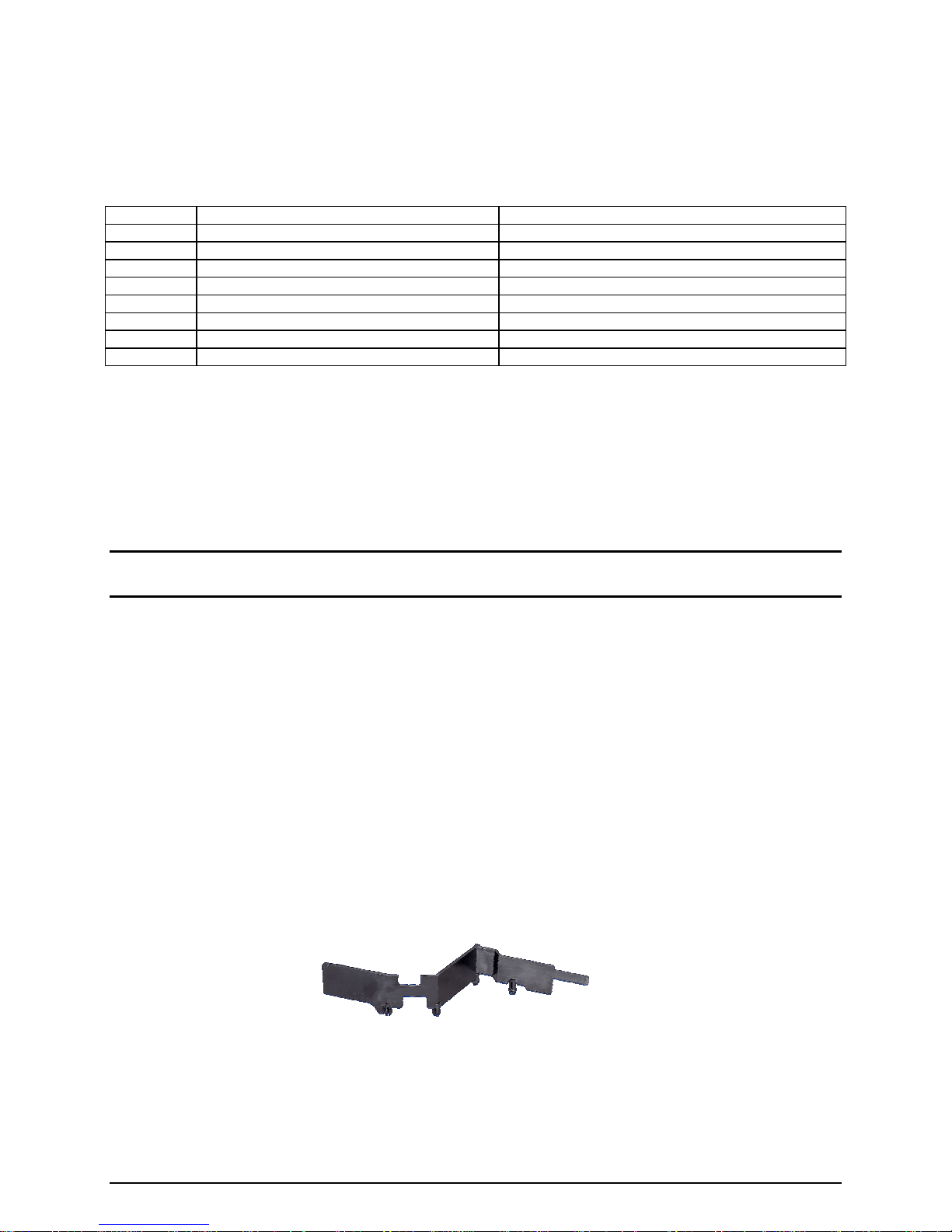

4.2.2 System Status LED