Page 1

Intel® SPSH4 Server Platform Product Guide

Order Number: A76346-003

A Guide for Technically Qualified Assemblers of Intel® Identified Subassemblies and Products

Page 2

Disclaimer

Intel Corporation (Intel) makes no warranty of any kind with regard to this material, incl udi ng, but not limit ed to, the implied

warranties of merchantability and fitness for a particular purpose. Intel assumes no responsibility for any errors that may

appear in this document. Intel makes no commitment to update nor to keep current the information contained in this

document. No part of this document may be copied or reproduced in any form or by any means without prior written consent

of Intel.

®

An Intel

installation, it accurately stores, displ ays, processes, provides, and/or receives date data from, into, and between the

twentieth and twenty-first centuries, including leap year calculat i ons, prov i ded that all other t echnology used i n combinat i on

with said product properly exchanges date data with it.

Intel and Intel Xeon are trademarks or registered trademarks of Intel Corporation or its subsidiaries i n the United States and

other countries.

†

Copyright © 2002 Intel Corporation

product, when used in accordance with its associated documentation, is "Year 2000 Capable" when, upon

Third party brands and names are the property of their respective owners.

Page 3

Contents

1 Important Safety Information

Important Safety Information...............................................................................................11

Intended Application Uses.............................................................................................11

Safety Instructions and Information................................................................................11

Checking the Power Cords............................................................................................12

Multiple Power Cords.....................................................................................................12

Earth Grounded Socket-Outlets.....................................................................................12

Before You Remove the Access Cover..........................................................................13

Power Supply Modules..................................................................................................13

Fans..............................................................................................................................13

Electrostatic Discharge (ESD) .......................................................................................13

Cooling and Airflow........................................................................................................14

Lifting and Moving .........................................................................................................14

Equipment Rack Precautions.........................................................................................14

Important Set-Up Safety Information...................................................................................15

WARNING: English (US) ..............................................................................................16

AVERTISSEMENT: Français........................................................................................18

WARNUNG: Deutsch ...................................................................................................20

AVVERTENZA: Italiano................................................................................................22

ADVERTENCIAS: Español...........................................................................................24

2 Unpacking and Inspecting

Checking for Damage to the Packagi n g..............................................................................27

Checking the Package Contents .........................................................................................27

3 Getting Started

Selecting a Site...................................................................................................................29

Space and Power Requirements...................................................................................29

General Site Criteria......................................................................................................30

Installing Processors, Memory, Hard Disk Drives, and Options...........................................31

Connecting the Monitor, Keyboard, and Mouse...................................................................32

Turning On the Server and Running the Power-On Self Test (POST) .................................32

Hot Keys for POST........................................................................................................33

Configuring the System with the FRU/SDR Load Utility.......................................................33

Installing the Service Partition (Recommended)..................................................................34

Installing the Op e rating System...........................................................................................34

The System Resource CD-ROM .........................................................................................34

System Security..................................................................................................................35

Mechanical Locks..........................................................................................................35

Software Security ..........................................................................................................36

Installing the Server in a Rack.............................................................................................37

4 Configuration Software and Utilities

BIOS Setup.........................................................................................................................39

Recording BIOS Setup Settings.....................................................................................39

iii

Page 4

Clearing CMOS Memory................................................................................................40

Using BIOS Setup .........................................................................................................40

SCSISelect..........................................................................................................................41

When to Run SCSISelect ..............................................................................................41

Running SCSISelect......................................................................................................41

Software Updates................................................................................................................42

Creating Bootable Diskettes ..........................................................................................42

Software Update Packages...........................................................................................43

Individual Updates.........................................................................................................43

5 System Management

Integrated Hardware System Management.........................................................................47

Baseboard Management Controller...............................................................................47

Field Replaceable Units and Sensor Data Records.......................................................48

System Event Log .........................................................................................................48

Platform Event Management .........................................................................................48

Emergency Management Port.......................................................................................49

Intel Server Management....................................................................................................49

Using the System Setup Utility ............................................................................................50

Creating SSU Diskettes.................................................................................................50

Running the SSU ...........................................................................................................51

Setting Boot Device Priority...........................................................................................52

Setting Passwords and Security Options.......................................................................52

Viewing the System Event Log......................................................................................54

Viewing FRU Information...............................................................................................54

Viewing Sensor Data Records.......................................................................................55

Updating System Firmware and BIOS...........................................................................55

Saving and Restoring the System Configuration............................................................56

Alerting for Platform Events...........................................................................................57

Managing the Server Remotely.....................................................................................60

FRU/SDR Load Utility ..........................................................................................................62

When to Run the FRU/SDR Load Utility.........................................................................62

Running the FRU/SDR Load Utility................................................................................62

6 Installing and Removing Components

Tools and Supplies Needed.................................................................................................65

Access Covers....................................................................................................................65

Removing the Rear Access Cover.................................................................................66

Installing the Rear Access Cover...................................................................................66

Removing the Front Access Cover................................................................................67

Installing the Front Access Cover ..................................................................................67

Accessing the System Boards.............................................................................................68

Removing the Access Cover to the System Boards.......................................................68

Installing the Access Cover to the System Boards.........................................................68

Removing the Memory Board........................................................................................69

Installing the Memory Board..........................................................................................70

Removing the Processor Board Air Baffle......................................................................71

Installing the Processor Board Air Baffle........................................................................72

iv Intel SPSH4 Server Platform Product Guide

Page 5

Removing the Processor Board.....................................................................................73

Installing the Processor Board.......................................................................................74

Removing the Baseboard..............................................................................................75

Installing the Baseboard................................................................................................77

Processors..........................................................................................................................78

Installing Processors......................................................................................................78

Removing Processors....................................................................................................81

Memory...............................................................................................................................82

Installing DIMMs............................................................................................................82

Removing DIMMs..........................................................................................................84

Hot-Swap SCSI Drives........................................................................................................85

Checking a Hot-Swap SCSI Drive Status Indicator........................................................85

Installing a Hot-Swap Drive in a Carrier.........................................................................86

Removing a Hot-swap Drive from a Carrier...................................................................87

Removing and Installing Hot-Swap Disk Drives.............................................................88

DC Power Supplies.............................................................................................................90

Checking the Power Status LEDs..................................................................................90

Removing a Power Supply Module................................................................................91

Installing a Power Supply Module..................................................................................92

PCI Add-In Boards ..............................................................................................................93

Operating System Support for Hot-Plug Add-In Boards.................................................93

Checking the Status Indicators for a Hot-Plug Add-In Board..........................................94

Installing a Hot-Plug PCI Add-In Board..........................................................................95

Removing a Hot-Plug PCI Add-In Board........................................................................96

Installing a PCI Add-In Board in a Non-Hot-Plug Slot.....................................................97

Removing a PCI Add-In Board from a Non-Hot-Plug Slot..............................................98

Cooling System Fans..........................................................................................................99

Checking a Fan Status Indicator....................................................................................99

Removing a Fan Module..............................................................................................100

Installing a Fan Module................................................................................................100

Backup Battery..................................................................................................................101

Front Subchassis and Rear Electronics Bay...................................................................... 103

Opening the Front Subchassis and Rear Electronics Bay............................................103

Removing the Front Subchassis and Rear Electronics Bay.........................................104

Installing the Front Subchassis and Rear Electronics Bay...........................................104

Closing the Front Subchassis and Rear Electronics Bay.............................................105

System Cables..................................................................................................................106

Front Panel Board.............................................................................................................109

Diskette Drive....................................................................................................................110

5.25-Inch Peripheral Drives...............................................................................................112

Preliminary Considerations..........................................................................................112

Removing a 5.25-inch Peripheral Drive........................................................................113

Installing a 5.25-inch Peripheral Drive .........................................................................114

Hot Swap Drive Bays.........................................................................................................115

Removing a Hot Swap Drive Bay.................................................................................115

Installing a Hot-Swap Drive Bay ..................................................................................116

Power Distribution Board...................................................................................................117

Fan Distribution Board.......................................................................................................118

Contents v

Page 6

Foam Fan Baffle................................................................................................................119

Removing the Foam Fan Baffle...................................................................................119

Installing the Fan Baffle...............................................................................................119

Hot-Plug Indicator Board...................................................................................................120

7 Solving Problems

Resetting the System........................................................................................................121

Initial System Startup.........................................................................................................121

Running New Application Software....................................................................................122

Application Software Checklist.....................................................................................122

After the System Has Been Running Correctly..................................................................122

Monitoring POST......................................................................................................... 122

Verifying Proper Operation of Key System Lights........................................................123

Confirming Loading of an Operating System ...............................................................123

Specific Problems and Corrective Actions.........................................................................123

Power Light Does Not Light.........................................................................................123

No Beep Codes...........................................................................................................124

No Characters Appear on Screen................................................................................124

Characters Are Distorted or Incorrect..........................................................................124

System Cooling Fans Do Not Rotate Properly.............................................................125

Diskette Drive Activity Light Does Not Light.................................................................125

Hard Drive Activity Light Does Not Light......................................................................125

CD-ROM Drive Activity Light Does Not Light...............................................................126

Network Problems.......................................................................................................126

PCI Installation Tips.....................................................................................................127

Problems with Application Software.............................................................................127

Bootable CD-ROM Is Not Detected.............................................................................127

A Server Description

Feature Summary..............................................................................................................129

Chassis Access.................................................................................................................130

Main Chassis Components................................................................................................131

Electronics Bay Components.............................................................................................132

Front Control Panel...........................................................................................................133

Rear Panel........................................................................................................................134

Peripheral Device Bay.......................................................................................................135

Hot-Swap Hard Drive Bays................................................................................................135

Power Supplies .................................................................................................................136

System Cooling.................................................................................................................136

Server Board Set Features................................................................................................137

Baseboard Connector and Component Loca tions........................................................138

Baseboard Jumpers.....................................................................................................139

Processors..................................................................................................................141

DIMM Memory.............................................................................................................141

Onboard Video............................................................................................................141

SCSI Controller............................................................................................................141

Network Interface Controll e rs......................................................................................142

Network Teaming Features..........................................................................................143

ACPI ............................................................................................................................145

vi Intel SPSH4 Server Platform Product Guide

Page 7

B Regulatory Information

Product Regulation Compliance Information......................................................................147

Product Safety.............................................................................................................147

Electromagnetic Compatibility (EMC) - Emissions.......................................................147

Electromagnetic Compatibility - Immunity....................................................................147

Power Line Harmonics / Voltage Flicker......................................................................147

Regional EMC Compliance Information.......................................................................149

Product Ecology Documentation.......................................................................................151

Energy Saving Features..............................................................................................151

Disposal Considerations..............................................................................................151

Disassembly Instructions.............................................................................................151

C Error Messages and Error Codes.........................................................................153

D Equipment Log and Configuration Worksheets

Equipment Log..................................................................................................................161

Calculating Power Consumption........................................................................................163

Index.....................................................................................................................................165

Figures

1. PSH4 Server (Rack-Mount and Pedestal)...................................................................29

2. Integrated System Management.................................................................................47

3. Removing the Rear Access Cover..............................................................................66

4. Removing the Front Access Cover.............................................................................67

5. Removing the Access Cover to the System Boards....................................................68

6. Removing the Memory Board.....................................................................................69

7. Installing the Memory Board.......................................................................................70

8. Removing the Processor Board Air Baffle...................................................................71

9. Installing the Processor Board Air Baffle.....................................................................72

10. Removing the Processor Board..................................................................................73

11. Installing the Processor Board....................................................................................74

12. Removing the Front Retention Mechanism.................................................................75

13. Baseboard Mounting...................................................................................................76

14. Correct Order for Populating Processor Sockets........................................................78

15. Raising the Locking Bar..............................................................................................79

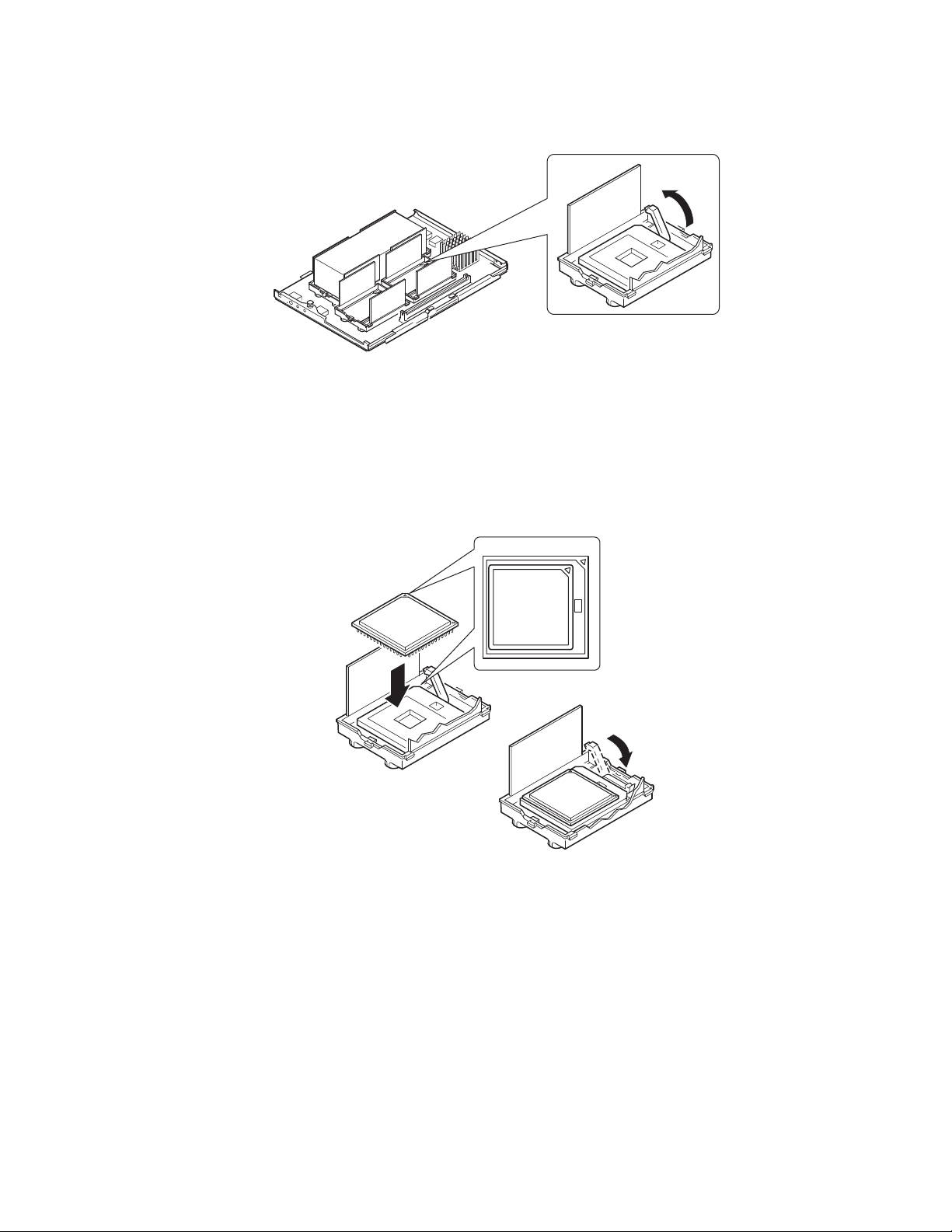

16. Installing Processors...................................................................................................79

17. Installing the Heat Sink...............................................................................................80

18. Removing a Processor...............................................................................................81

19. Installing Memory.......................................................................................................83

20. Removing DIMMs.......................................................................................................84

21. Hot-Swap SCSI Drive Bay and Status Indicators........................................................85

22. Removing a Plastic Air Baffle from a Carrier ...............................................................86

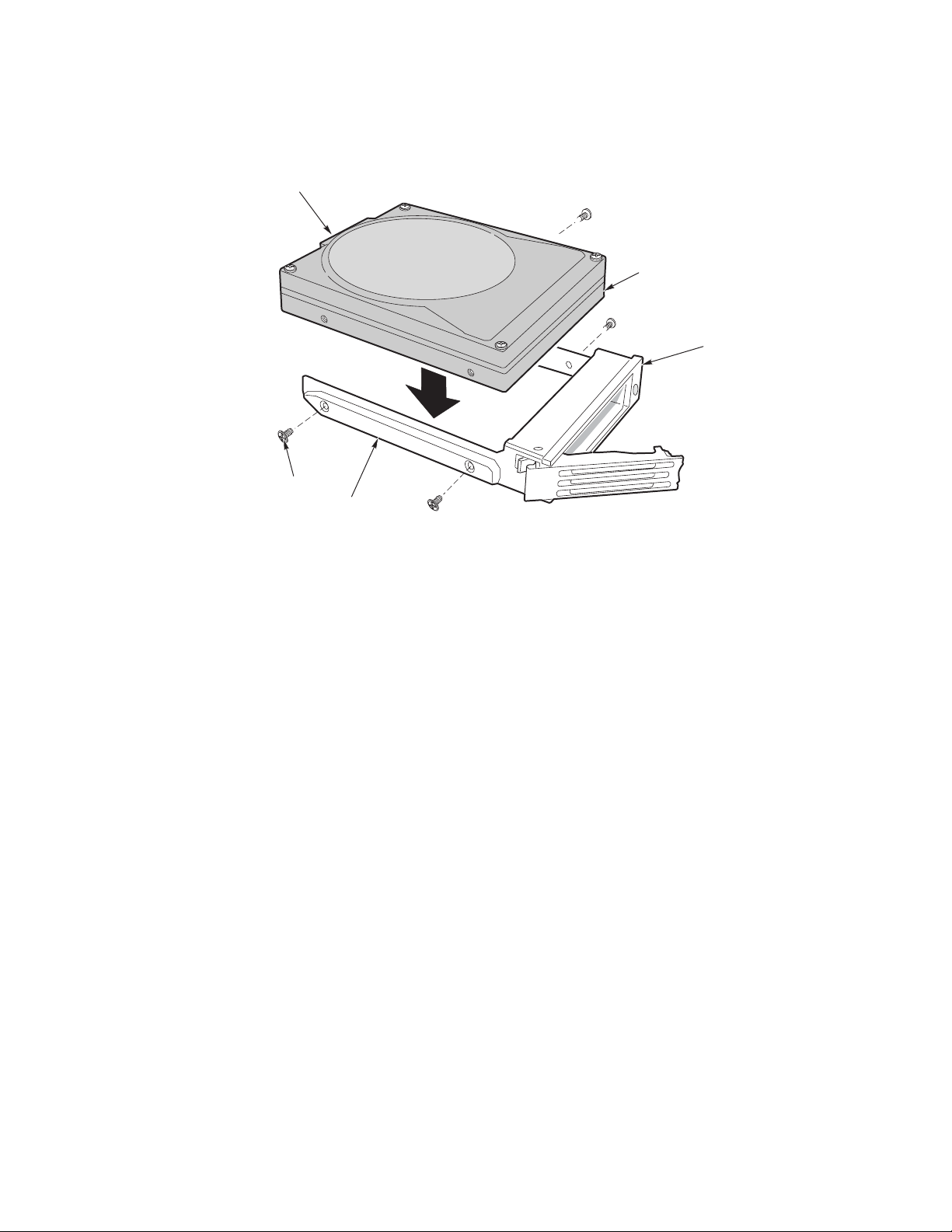

23. Installing a SCSI Hard Disk Drive in a Carrier.............................................................87

24. Removing a Drive Carrier ...........................................................................................88

25. Installing a Drive Carrier.............................................................................................89

26. Power and Standby LEDs...........................................................................................90

27. Removing a Power Supply Module.............................................................................91

28. PCI Add-In Board Locations .......................................................................................93

Contents vii

Page 8

29. Status Indicators for Hot-Plug PCI Add-In Boards.......................................................94

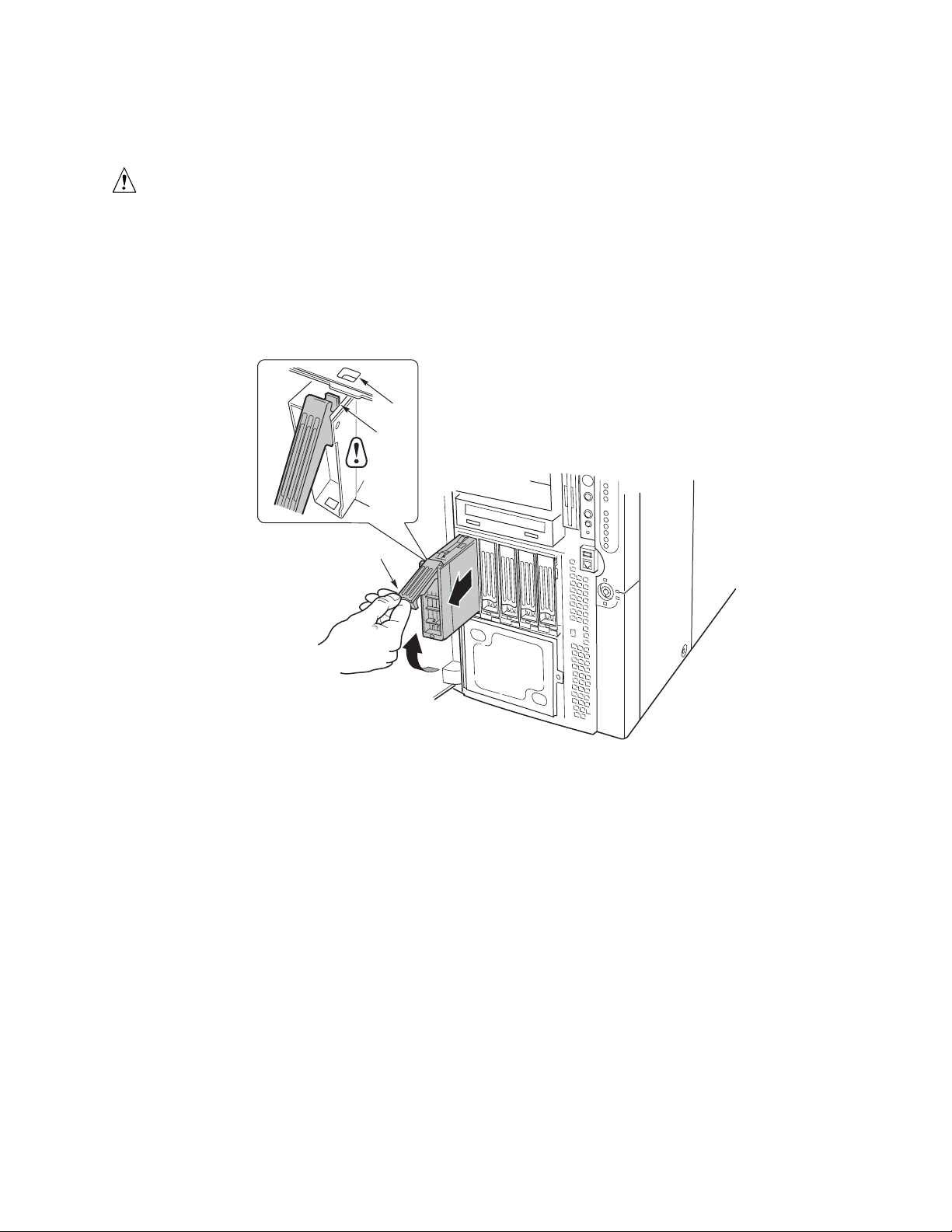

30. Installing a Hot-Plug PCI Add-In Board.......................................................................95

31. Removing a Hot-Plug PCI Add-In Board.....................................................................96

32. Installing and Removing a Non-Hot-Plug PCI Add-In Board........................................97

33. Fan Status LEDs ........................................................................................................99

34. Removing and Installing a Fan Module.....................................................................100

35. Replacing the Backup Battery...................................................................................102

36. Opening the Front Subchassis and Rear Electronics Bay.........................................103

37. Installing the Front Subchassis and Rear Electronics Bay........................................104

38. Closing the Front Subchassis and Rear Electronics Bay .......................................... 105

39. Cables to the Subchassis .........................................................................................106

40. Front Cables in the Cable Clamp..............................................................................107

41. Rear Cables in the Cable Clamp...............................................................................108

42. Replacing the Front Panel Board..............................................................................109

43. Replacing the Diskette Drive.....................................................................................110

44. Inserting the Diskette Drive into the Bracket.............................................................111

45. Removing a 5.25-inch Peripheral Drive.....................................................................113

46. Installing a 5.25-inch Peripheral Drive......................................................................114

47. Removing a Hot Swap Drive Bay..............................................................................115

48. Removing a Power Distribution Board......................................................................117

49. Removing a Fan Distribution Board..........................................................................118

50. Removing the Fan Baffle..........................................................................................119

51. Removing a Hot-plug Indicator Board.......................................................................120

52. SPSH4 Server Hot-Swap Access.............................................................................130

53. Chassis with Access Covers Removed.....................................................................131

54. Electronics Bay Internal Components.......................................................................132

55. SPSH4 Front Control Panel......................................................................................133

56. SPSH4 Rear Panel View..........................................................................................134

57. Hard Drive Bay.........................................................................................................135

58. Baseboard Connector and Component Locations.....................................................138

59. Baseboard Jumpers..................................................................................................139

Tables

1. Safety Symbols...........................................................................................................11

2. SPSH4 Server Physical Specifications .......................................................................30

3. Hot Keys.....................................................................................................................33

4. Software Security Features.........................................................................................36

5. BIOS Setup Menu Navigation.....................................................................................40

6. Command Line Format...............................................................................................63

7. LED States for Hot-Swap SCSI Drive Status..............................................................85

8. LED Power Supply Status Indicators..........................................................................90

9. LED Hot-Plug PCI Status Indicators...........................................................................94

10. Feature Summary.....................................................................................................129

11. Front Control Panel Features....................................................................................133

12. Server Board Set Features.......................................................................................137

13. Boot Block Jumper Descriptions...............................................................................139

14. Main Jumper Descriptions........................................................................................140

15. Serial Port B Jumper Descriptions............................................................................140

16. Product Regulatory Compliance Markings................................................................148

viii Intel SPSH4 Server Platform Product Guide

Page 9

17. Regional EMC Compliance Information......................................................................149

18. Standard BIOS POST Codes......................................................................................153

19. Recovery BIOS POST Codes.....................................................................................156

20. BMC Beep Codes.......................................................................................................157

21. Error Messages and Codes........................................................................................157

22. Power Usage Worksheet 1.........................................................................................163

23. Power Usage Worksheet 2.........................................................................................164

Contents ix

Page 10

x Intel SPSH4 Server Platform Product Guide

Page 11

1 Important Safety Information

Important Safety Information

Only a technically qualified person shall access, integrate, configure, and service this product.

Intended Application Uses

This product was evaluated as Information Technology Equipment (ITE), which may be installed in

offices, schools, computer rooms, and similar commercial type locations. The suitability of this

product for other Product Categories and Environments (such as medical, industrial, alarm systems,

and test equipment), other than an ITE application, may require further evaluation.

Safety Instructions and Information

To avoid personal injury or property damage, before you begin installing the product, read, observe,

and adhere to all of the following safety instructions and information. The following safety

symbols may be used throughout this product guide, and may be marked on the product and or its

packaging.

Table 1. Safety Symbols

CAUTION

WARNING

Indicates the presence of a hazard that may cause minor personal injury or property

damage if the CAUTION is ignored.

Indicates the presence of a hazard that may result in serious injury or death if the

WARNING is ignored.

Indicates potential hazard if hazard symbol is ignored.

Indicates shock hazards that result in serious injury or death if safety instructions are not

followed.

Indicates hot components or surfaces.

Indicates do not touch fan blades, may result in injury.

Indicates product has multiple power cords, and all power cords must be unplugged to

disconnect AC power or mains.

Indicates ESD sensitive components. Use of an antistatic wrist strap connected to ground is

recommended.

11

Page 12

Checking the Power Cords

WARNING

To avoid electrical shock, do not attempt to modify or use the supplied AC

power cord(s), if they are not the exact type required. If a power cord(s)

supplied is not compatible with the AC wall outlet in your region, get one

that meets the following criteria:

• The power cord must be properly rated for the AC voltage in your region.

• The power cord plug cap must have an electrical current rating that is at least

125% of the electrical current rating of the product.

• The power cord plug cap that plugs into the wall socket-outlet must have a

grounding-type male plug designed for use in your region.

• The power cord must have safety certifications for your region, and shall be

marked with the certificatio n marki ngs.

• The power cord plug cap that plugs into the AC receptacle on the power

supply must be an IEC 320, sheet C13, type female connector.

• In Europe, the power cord must be less than 4.5 meters (14.76 feet) long, and

it must be flexible <HAR> (harmonized) or VDE certified cordage to comply

with the chassis’ safety certifications.

The power supply cord(s) is the main disconnect device to AC power. The

socket outlet(s) shall be near the equipment and shall be readily accessible

for disconnection.

Multiple Power Cords

WARNING

To avoid electrical shock, disconnect all AC power cords before accessing

inside the system.

Earth Grounded Socket-Outlets

WARNING

To avoid electrical shock, the system power cord(s) must be plugged into

socket-outlet(s) that is provided with a suitable earth ground. The system will

be provided with the following marking:

Connect only to properly earthed socket outlet.

Apparaten skall anslutas till jordat uttag när den ansluts till ett nätverk.

12 Intel SPSH4 Server Platform Product Guide

Page 13

Before You Remove t he Access Cover

WARNING

To avoid personal injury or property damage, the following safety

instructions apply whenever accessing inside the prod u ct:

• Turn off all peripheral devices connected to this product.

• Turn off the system by pressing the power button on the front of the product.

• Disconnect the AC power by unplugging all AC power cords from the

system or wall outlet.

• Disconnect all cables and telecommunication lines that are connected to the

system.

• Retain all screws or other fasteners when removing access cover(s). Upon

completion of accessing inside the produ ct, ref as ten access cove r with

original screws or fasteners.

• Do not access inside power supply. There are no serviceable parts in the

power supply. Return to manufacturer fo r servicing.

Power Supply Modules

CAUTION

Power supply modules have double-pole/neutral fusing.

Fans

WARNING

To avoid injury do not contact moving fan blades.

Electrostatic Discharge (ESD)

CAUTION

Perform the procedures in this chapter only at an electrostatic discharge

(ESD) workstation, because the server components can be extremely

sensitive to ESD. If no such station is available, you can reduce the risk of

electrostatic discharge ESD damage by doing the following:

• Wear an antistatic wrist strap and attach it to a metal part of the server.

• Touch the metal on the server chassis before touching the server components.

• Keep part of your body in contact with the metal server chassis to dissipate

the static charge while handling the components.

• Avoid moving around unnecessarily.

• Hold the server components (especially boards) only by the edges.

• Place the server components on a grounded, static-free surface. Use a

conductive foam pad if available but not the component wrapper.

• Do not slide the components over any surface.

Important Safety Information 13

Page 14

Cooling and Airflow

CAUTION

For proper cooling and airflow, always install all access covers before

turning on the system. Operating the system for longer than five minutes

without the covers in place can cause overheating and damage to system

components.

Lifting and Moving

CAUTION

Do not attempt to lift or move the server by the handles on the power

supplies.

Equipment Rack Precautions

Follow the rack manufacturer’s safety and installation instructions for proper rack installation.

The following additional rack safety installation measures shall be considered:

ANCHOR THE EQUIPMENT RACK

The equipment rack must be anchored to an unmovable suitable support to

prevent the rack from falling over when one or more systems are fully

extended out of the rack assembly. You must also consider the weight of any

other devices installed in the rack assembly. The equipment rack must be

installed according to the manufa ctu rer's instructions.

MAIN AC POWER DISCONNECT

You are responsible for installing an AC power disconnect for the entire rack

unit. This main disconnect must be readily accessible, and it must be labeled

as controlling power to the entire unit, not just to the sy ste m(s).

GROUNDING THE RACK INSTALLATION

To avoid the potential for an electrical shock hazard, the rack assembly itself

must be suitably earth grounded, according to your local regional electrical

codes. This typically will require the rack to have its own separate earth

ground. We recommend you consult your local approv ed electrici an.

14 Intel SPSH4 Server Platform Product Guide

Page 15

OVER CURRENT PROTECTION

The system is designed to operate on a 20A AC voltage source that is

provided with 20A over current protection. If the AC source for the rack

exceeds 20A over current protection, each system must be provided with

20A or less over current supplemental protection. The supplementary over

current protection must have the appropriate regional safety certifications for

the over current application.

TEMPERATURE LIMITS

The operating temperature of the system, when installed in the rack, must not

go below 10 °C (50 °F) or rise above 35 °C (95 °F). Extreme fluctuations in

temperature may cause a variety of problems in system, and safety limits

may be broken.

VENTILATION CONSIDERATIONS

The equipment rack must provide sufficient airflow to the front of the system

to maintain proper cooling. The rack selected and the ventilation provided

must be suitable to the environment in which the system will be used.

Important Set-Up Safety Information

WARNING: ENGLISH (US)

AVERTISSEMENT: FRANÇAIS

WARNUNG: DEUTSCH

AVVERTENZA: ITALIANO

ADVERTENCIAS: ESPAÑOL

Important Safety Information 15

Page 16

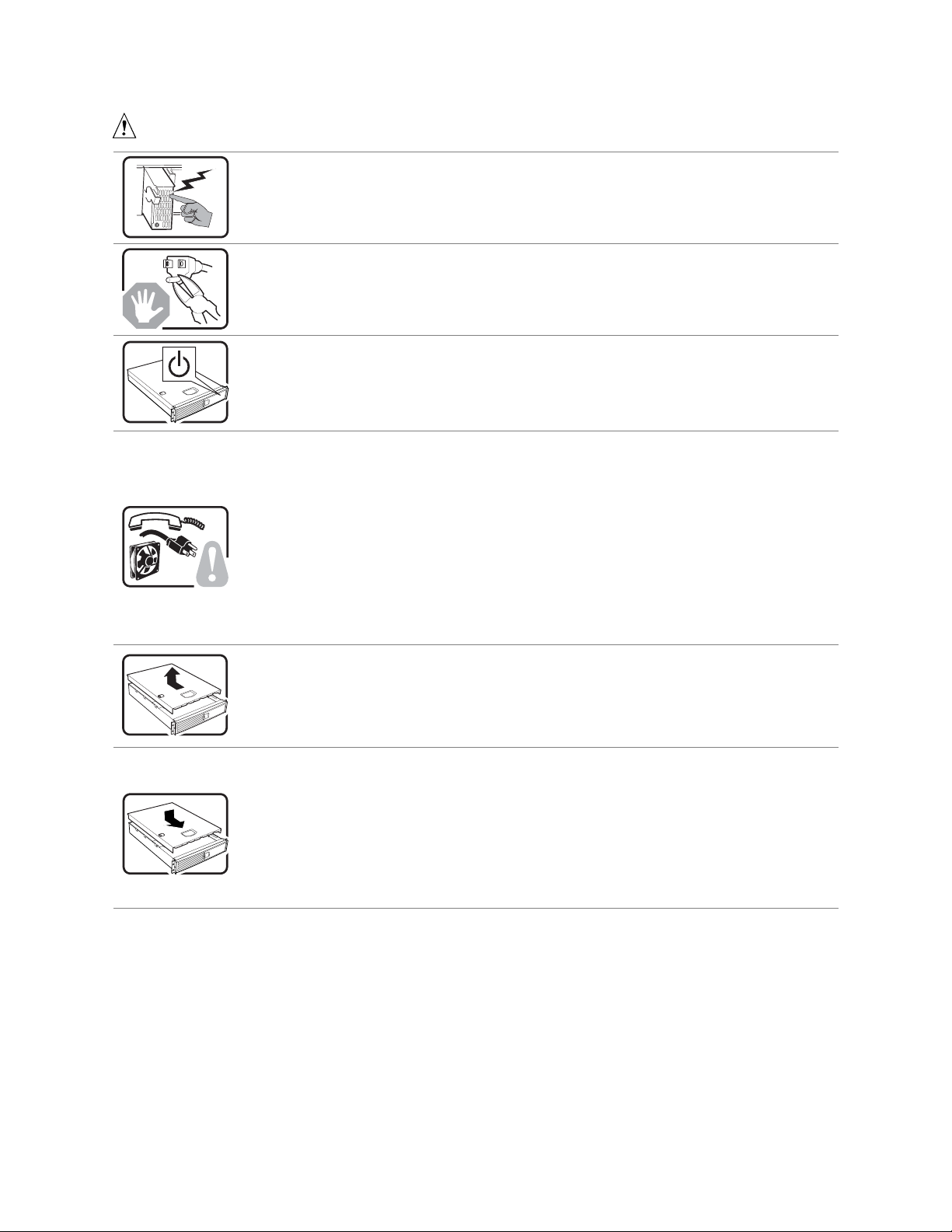

WARNING: English (US)

The power supply in this product contains no user-serviceable parts. There may be more than

one supply in this product. Refer servicing only to qualified personnel.

Do not attempt to modify or use the supplied AC power cord if it is not the exact type required.

A product with more than one power supply will have a separate AC power cord for each

supply.

The power but ton on the system does not turn off system AC power. To remove AC power

from the syste m, you must unplug each AC power cord from the wall outlet or power supply.

The power cord(s) is considered the disconnect device to the mains (AC) power. The socket

outlet that the system p lugs into shall be installed near the equipment and shall be easily

accessible.

SAFETY STEPS: Whenever you remove the chassis covers to access the inside of the

system, follow these steps:

1. Turn off all peripheral devices connected to the system.

2. Turn o ff the system by pressing the power button.

3. Unplug all AC power cords from the system or from wall outlets.

4. Label and disconnect all cables connected to I/O connectors or ports on the back of the

system.

5. Provide some electrostatic discharge (ESD) protection by wearing an antistatic wrist strap

attached to chassis ground of the system—any unpainted metal surface—when handling

components.

6. Do not operate the system with the chassis covers removed.

After you have completed the six SAFETY steps above, you can remove the system covers.

To do this:

1. Unlock and remove the padlock from the back of the system if a padlock has been installed.

2. Remove and save all screws from the covers.

3. Remove the covers.

For proper cooling and airflow, always reinstall the chassis covers before turning on the

system. Operating the system without the covers in place can damage syste m parts. To

install the covers:

1. Check first to make sure you have not left loose tools or parts insi de the system.

2. Check that cables, add-in boards, and other components are properly installed.

3. Attach the covers to the chassis with the screws removed earlier, and tighten them firmly.

4. Insert and lock the pa dlock to the system to prevent unauthorized access inside the system.

5. Connect all external cables and the AC power cord(s) to the system.

continued

16 Intel SPSH4 Server Platform Product Guide

Page 17

WARNING: English (US) (Continued)

A microprocessor and heat sink may be hot if the system has been running. Also, there may

be sharp pins and edges on some board and chassis parts. Contact should be made with

care. Consider wearing protective gloves.

Danger of explosion if the battery is incorrectly replaced. Replace only with the same or

equivalent type recommended by the equipment manufacturer. Dispose of used batteries

according to manufacturer’s instructions.

The system is designed to operate in a typical office environment. Choose a site that is:

• Clean and free of airborne particles (other than normal room dust).

• Well ventilated and away from sources of heat including direct sunlight.

• Away from sources of vibration or physical shock.

• Isolated from strong electromagnetic fields produced by electrical devices.

• In regions that are susceptible to electrical storms, we recommend you plug your system

into a surge suppresser and disconnect telecommunication lines to your modem during an

electrical storm.

• Provided with a properly grounded wall outlet.

• Provided with sufficient space to access the power supply cord(s), because they serve as

the product’s main power disconnect.

Important Safety Information 17

Page 18

AVERTISSEMENT: Français

Le bloc d'alimentation de ce produit ne contient aucune pièce pouvant être réparée par

l'utilisateur. Ce produit peut contenir plus d'un bloc d'alimentation. Veuillez contacter un

technicien qualifié en cas de problème.

Ne pas essayer d'utiliser ni modifier le câble d'alimentation CA fourni, s'il ne correspond pas

exactement au type requis. Le nombre de câbles d'alimentation CA fournis correspond au

nombre de blocs d'alimentation du produit.

Notez que le commutateur CC de mise sous tension /hors tension du panneau avant n'éteint

pas l'alimentation CA du système. Pour mettre le système hors tensio n, vous devez

débrancher chaque câble d'alimentation de sa prise.

CONSIGNES DE SÉCURITÉ -Lorsque vous ouvrez le boîtier pour accéder à l’intérieur du

système, suivez les consignes suivantes:

1. Mettez hors tension tous les périphériques connectés au système.

2. Mettez le système hors tension en mettant l’interrupteur général en position OFF (boutonpoussoir).

3. Débranchez tous les cordons d’alimentation c.a. du système et des prises murales.

4. Identifiez et débranchez tous les câbles reliés aux connecteurs d’E-S ou aux accès derrière

le système.

5. Pour prévenir les décharges électrostatiques lorsque vous touchez aux composants, portez

une bande antistatique pour poignet et reliez-la à la masse du système (toute surface

métallique non peinte du boîtier).

6. Ne faites pas fonctionner le système tandis que le boîtier est ouvert.

Une fois TOUTES les étapes précédentes accomplies, vous pouvez retirer les panneaux du

système. Procédez comme suit:

1. Si un cadenas a été installé sur à l’arrière du système, déverrouillez-le et retirez-le.

2. Retirez toutes les vis des panneaux et mettez-les dans un endroit sûr.

3. Retirez les panneaux.

Afin de permettre le re froidissement et l’aérat ion du système, réinstallez toujours les panneaux

du boîtier avant de mettre le système sous tension. Le foncti onnement du système en

l’absence des panneaux risque d’endommager ses pièces. Pour installer les panneaux,

procédez comme suit:

1. Assurez-vous de ne pas avoir oublié d’outils ou de pièces démontées dans le système.

2. Assurez-vous que les câbles, les cartes d’extension et les autres composants sont bien

installés.

3. Revissez solidement les panneaux du boîtier avec les vis retirées plus tôt.

4. Remettez le cadenas en place et verrouillez-le afin de prévenir tout accès non autorisé à

l’intérieur du système.

5. Rebranchez tous les cordons d’alimentation c. a. et câbles externes au système.

Suite

18 Intel SPSH4 Server Platform Product Guide

Page 19

AVERTISSEMENT: Français (Suite)

Le microprocesseur et le dissipateur de chaleur peuvent être chauds si le système a été sous

tension. Faites également attention aux broches aiguës des cartes et aux bords tranchants du

capot. Nous vous recommandons l'usage de gants de protection.

Danger d'explosion si la batterie n'est pas remontée correctement. Remplacer uniquement

avec une batterie du même type ou d'un type équivalent recommandé par le fabricant.

Disposez des piles usées selon les instructions du fabricant.

Le système a été conçu pour fonctionner dans u n cadre de travail normal. L'emplacement

choisi doit être:

• Propre et dépourvu de poussière en suspension (sauf la poussière normale).

• Bien aéré et loin des sources de chaleur, y compris du soleil direct.

• A l'abri des chocs et des sources de vibrations.

• Isolé de forts champs électromagnétiques géenérés par des appareils électriques.

• Dans les régions sujettes aux orages magnétiques il est recomandé de brancher votre

système à un supresseur de surtension, et de débrancher toutes les lignes de

télécommunications de votre modem durant un orage.

• Muni d'une prise murale correctement mise à la terre.

• Suffisamment spacieux pour vous permettre d'accéder aux câbles d'alimentation (ceux-ci

étant le seul moyen de mettre le système hors tension).

Important Safety Information 19

Page 20

WARNUNG: Deutsch

Benutzer können am Netzgerät dieses Produkts keine Reparaturen vornehmen. Das

Produkt enthält möglicherweise mehrere Netzgeräte. Wartungsarbeiten müssen von

qualifizierten Technikern ausgeführt werden.

Versuchen Sie nicht, das mitgelieferte Netzkabel zu ändern oder zu verwenden, wenn es

sich nicht genau um den erforderlichen Typ handelt. Ein Produkt mit mehreren Netzgeräten

hat für jedes Netzgerät ein eigenes Netzkabel.

Der Wechselstrom des Systems wird durch den Ein-/Aus-Schalter für Gleichstrom nicht

ausgeschaltet. Ziehen Sie jedes Wechselstrom-Netzkabel aus der Steckdose bzw. dem

Netzgerät, um den Stromanschluß des Systems zu unterbrechen.

SICHERHEISMASSNAHMEN: Immer wenn Sie die Gehäuseabdeckung abnehmen um an

das Systeminnere zu gelangen, sollten Sie folgende Schritte beachten:

1. Schalten Sie alle an Ihr System angeschlossenen Peripheriegeräte aus.

2. Schalten Sie das System mit dem Hauptschalter aus.

3. Ziehen Sie den Stromanschlußstecker Ihres Systems aus der Steckdose.

4. Auf der Rückseite des Systems beschriften und ziehe n Sie alle Anschlußkabel von den

I/O Anschlüssen oder Ports ab.

5. Tragen Sie ein geerdetes Antistatik Gelenkband, um elektrostatische Ladungen (ESD)

über blanke Metallstellen bei der Handhabung der Komponenten zu vermeiden.

6. Schalten Sie das System niemals ohne ordnungsgemäß montiertes Gehäuse ein.

Nachdem Sie die oben erwähnten ersten sechs SICHERHEITSSCHRITTE durchgeführt

haben, können Sie die Abdeckung abnehmen, indem Sie:

1. Öffnen und entfernen Sie die Verschlußeinrichtung (Padlock) auf der Rückseite des

Systems, falls eine Verschlußeinrichtung installiert ist.

2. Entfernen Sie alle Schrauben der Gehäuseabdeckung.

3. Nehmen Sie die Abdeckung ab.

Zur ordnungsgemäßen Kühlung und Lüftung muß die Gehäuseabdeckung immer wieder vor

dem Einschalten installiert werden. Ein Betrieb des Systems ohne angebrachte Abdeckung

kann Ihrem System oder Teile darin beschädigen. Um die Abdeckung wieder anzubringen:

1. Vergewissern Sie sich, daß Sie keine Werkzeuge oder Teile im Innern des Systems

zurückgelassen haben.

2. Überprüfen Sie alle Kabel, Zusatzkarten und andere Komponenten auf ordnungsgemäßen

Sitz und Installation.

3. Bringen Sie die Abdeckungen wieder am Gehäuse an, indem Sie die zuvor gelösten

Schrauben wieder anbringen. Ziehen Sie diese gut an.

4. Bringen Sie die Verschlußeinrichtung (Padlock) wieder an und schließen Sie diese, um

ein unerlaubtes Öffnen des Systems zu verhindern.

5. Schließen Sie alle externen Kabel und den AC Stromanschlußstecker Ihres Systems

wieder an.

Fortsetzung

20 Intel SPSH4 Server Platform Product Guide

Page 21

WARNUNG: Deutsch (Fortsetzung)

Der Mikroprozessor und der Kühler sind möglicherweise erhitzt, wenn das System in Betrieb

ist. Außerdem können einige Platinen und Gehäuseteile scharfe Spitzen und Kanten

aufweisen. Arbeiten an Platinen und Gehäuse sollten vorsichtig ausgeführt werden. Sie

sollten Schutzhandschuhe tragen.

Bei falschem Einsetzen einer neuen Batterie besteht Explosionsgefahr. Die Batterie darf nur

durch denselben oder einen entsprechenden, vom Hersteller empfohlenen Batterietyp

ersetzt werden. Entsorgen Sie verbrauchte Batterien den Anweisungen des Herstellers

entsprechend.

Das System wurde für den Betrieb in einer normalen Büroumgebung entwickelt. Der

Standort sollte:

• sauber und staubfrei sein (Hausstaub ausgenommen);

• gut gelüftet und keinen Heizquellen ausgesetzt sein (einschließlich direkter

Sonneneinstrahlung);

• keinen Erschütterungen ausgesetzt sein;

• keine starken, von elektrischen Geräten erzeugten elektromagnetischen Felder

aufweisen;

• in Regionen, in denen elektrische Stürme auftreten, mit einem Überspannungsschutzgerät

verbunden sein; während eines elektrischen Sturms sollte keine Verbindung der

Telekommunikationsleitungen mit dem Modem bestehen;

• mit einer geerdeten Wechselstromsteckdose ausgerüstet sein;

• über ausreichend Platz verfügen, um Zugang zu den Netzkabeln zu gewährleisten, da der

Stromanschluß des Produkts hauptsächlich über die Kabel unterbrochen wird.

Important Safety Information 21

Page 22

AVVERTENZA: Italiano

Rivolgersi ad un tecnico specializzato per la riparazione dei componenti dell’alimentazione di

questo prodotto. È possibile che il prodotto disponga di più fonti di alimentazione.

Non modificare o utilizzare il cavo di alimentazione in c.a. fornito dal produttore, se non

corrisponde esattamente al tipo richiesto. Ad ogni fonte di alimentazione corrisponde un

cavo di alimentazione in c.a. separato.

L’interruttore attivato/disattivato nel pannello anteriore non interrompe l’alimentazione in c.a.

del sistema. Per interromperla, è necessario scollegare tutti i cavi di alimentazione in c.a.

dalle prese a muro o dall’alimentazione di corrente.

PASSI DI SICUREZZA: Qualora si rimuovano le coperture del telaio per accedere all’interno

del sistema, seguire i seguenti passi:

1. Spegnere tutti i dispositivi periferici collegati al sistema.

2. Spegnere il sistema, usando il pulsante spento/acceso dell’interruttore del sistema.

3. Togliere tutte le spine dei cavi del sistema dalle prese elettriche.

4. Identificare e sconnettere tutti i cavi attaccati ai collegamenti I/O od alle prese installate

sul retro del sistema.

5. Qualora si tocchino i componenti, proteggersi dallo scarico elettrostatico (SES), portando

un cinghia anti-statica da polso che è attaccata alla presa a terra del telaio del sistema –

qualsiasi superficie non dipinta – .

6. Non far operare il sistema quando il telaio è senza le coperture.

Dopo aver seguito i sei passi di SICUREZZA sopracitati, togliere le coperture del telaio del

sistema come seque:

1. Aprire e rimuovere il lucchetto dal retro del sistema qualora ve ne fosse uno installato.

2. Togliere e mettere in un posto sicuro tutte le viti delle coperture.

3. Togliere le coperture.

Per il giusto flusso dell’aria e raffreddamento del sistema, rimettere sempre le coperture del

telaio prima di riaccendere il sistema. Operare il sistema senza le coperture al loro proprio

posto potrebbe danneggiare i componenti del sistema. Per rimettere le coperture del telaio:

1. Controllare prima che non si siano lasciati degli attrezzi o dei componenti dentro il

sistema.

2. Controllare che i cavi, dei supporti aggiuntivi ed altri componenti siano stati installati

appropriatamente.

3. Attaccare le coperture al telaio con le viti tolte in precedenza e avvitarle strettamente.

4. Inserire e chiudere a chiave il lucchetto sul retro del sistema per impedire l’accesso non

autorizzato al sistema.

5. Ricollegare tutti i cavi esterni e le prolunghe AC del sistema.

continua

22 Intel SPSH4 Server Platform Product Guide

Page 23

AVVERTENZA: Italiano (Continua)

Se il sistema è stato a lungo in funzione, il microprocessore e il dissipatore di calore

potrebbero essere surriscaldati. Fare attenzione alla presenza di piedini appuntiti e parti

taglienti sulle schede e sul telaio. È consigliabile l'uso di guanti di protezione.

Esiste il pericolo di un esplosione se la pila non viene sostituita in modo corretto. Utilizzare

solo pile uguali o di tipo equivalente a quelle consigliate dal produttore. Per disfarsi delle pile

usate, seguire le istruzioni del produttore.

Il sistema è progettato per funzionare in un ambiente di lavoro tipo. Scegliere una

postazione che sia:

• Pulita e libera da particelle in sospensione (a parte la normale polvere presente

nell'ambiente).

• Ben ventilata e lontana da fonti di calore, compresa la luce solare diretta.

• Al riparo da urti e lontana da fonti di vibrazione.

• Isolata dai forti campi magnetici prodotti da dispositivi elettrici.

• In aree soggette a temporali, è consigliabile collegare il sistema ad un limitatore di

corrente. In caso di temporali, scollegare le linee di comunicazione dal modem.

• Dotata di una presa a muro correttamente installata.

• Dotata di spazio sufficiente ad accedere ai cavi di alimentazione, i quali rappresentano il

mezzo principale di scollegamento del sistema.

Important Safety Information 23

Page 24

ADVERTENCIAS: Español

El usuario debe abstenerse de manipular los componentes de la fuente de alimentación de

este producto, cuya reparación debe dejarse exclusivamente en manos de personal técnico

especializado. Puede que este producto disponga de más de una fuente de alimentación.

No intente modificar ni usar el cable de alimentación de corriente alterna, si no corresponde

exactamente con el tipo requerido.

El número de cables suministrados se corresponden con el número de fuentes de

alimentación de corriente alterna que tenga el producto.

Nótese que el interruptor activado/desactivado en el panel frontal no desconecta la corriente

alterna del sistema. Para desconectarla, deberá desenchufar todos los cables de corriente

alterna de la pared o desconectar la fuente de alimentación.

INSTRUCCIONES DE SEGURIDAD: Cuando extraiga la tapa del chasis para acceder al

interior del sistema, siga las siguientes instrucciones:

1. Apague todos los dispositivos periféricos conectados al sistema.

2. Apague el sistema presionando el interruptor encendido/apagado.

3. Desconecte todos los cables de alimentación CA del sistema o de las tomas de corriente

alterna.

4. Identifique y desconecte todos los cables enchufados a los conectores E/S o a los

puertos situados en la parte posterior del sistema.

5. Cuando manipule los componentes, es importante protegerse contra la descarga

electrostática (ESD). Puede hacerlo si utiliza una muñequera antiestática sujetada a la

toma de tierra del chasis — o a cualquier tipo de superficie de metal sin pintar.

6. No ponga en marcha el sistema si se han extraído las tapas del chasis.

Después de completar las seis instrucciones de SEGURIDAD mencionadas, ya puede

extraer las tapas del sistema. Para ello:

1. Desbloquee y extraiga el bloqueo de seguridad de la parte posterior del sistema, si se ha

instalado uno.

2. Extraiga y guarde todos los tornillos de las tapas.

3. Extraiga las tapas.

Para obtener un enfriamiento y un flujo de aire adecuados, reinstale siempre las tapas del

chasis antes de poner en marcha el sistema. Si pone en funcionamiento el sistema sin las

tapas bien colocadas puede dañar los componentes del sistema. Para instalar las tapas:

1. Asegúrese primero de no haber dejado herramientas o componentes sueltos dentro del

sistema.

2. Compruebe que los cables, las placas adicionales y otros componentes se hayan

instalado correctamente.

3. Incorpore las tapas al chasis mediante los tornillos extraídos anteriormente, tensándolos

firmemente.

4. Inserte el bloqueo de seguridad en el sistema y bloquéelo para impedir que pueda

accederse al mismo sin autorización.

5. Conecte todos los cables externos y los cables de alimentación CA al sistema.

continuación

24 Intel SPSH4 Server Platform Product Guide

Page 25

ADVERTENCIAS: Español (Continuación)

Si el sistema ha estado en funcionamiento, el microprocesador y el disipador de calor

pueden estar aún calientes. También conviene tener en cuenta que en el chasis o en el

tablero puede haber piezas cortantes o punzantes. Por ello, se recomienda precaución y el

uso de guantes protectores.

Existe peligro de explosión si la pila no se cambia de forma adecuada. Utilice solamente

pilas iguales o del mismo tipo que las recomendadas por el fabricante del equipo. Para

deshacerse de las pilas usadas, siga igualmente las instrucciones del fabricante.

El sistema está diseñado para funcionar en un entorno de trabajo normal. Escoja un lugar:

• Limpio y libre de partículas en suspensión (salvo el polvo normal).

• Bien ventilado y alejado de fuentes de calor, incluida la luz solar directa.

• Alejado de fuentes de vibración.

• Aislado de campos electromagnéticos fuertes producidos por dispositivos eléctricos.

• En regiones con frecuentes tormentas eléctricas, se recomienda conectar su sistema a un

eliminador de sobrevoltage y desconectar el módem de las líneas de telecomunicación

durante las tormentas.

• Provisto de una toma de tierra correctamente instalada.

• Provisto de espacio suficiente como para acceder a los cables de alimentación, ya que

éstos hacen de medio principal de desconexión del sistema.

Important Safety Information 25

Page 26

26 Intel SPSH4 Server Platform Product Guide

Page 27

2 Unpacking and Inspecting

Checking for Damage to the Packaging

Inspect the packaging container for evidence of mishandling during transit. If the packaging

container is damaged, photograph it for reference. Save the packaging container and packing

materials in the event you need to package the server for reshipment.

Checking the Package Contents

Remove the server from the packaging container and, using the list below, check that all parts and

accessories are included. Inspect the server and accessories for damage. If any of the contents

appear damaged, file a damage claim with the carrier immediately.

• Intel

• Quick Start Guide (fold-out poster)

• System Accessory Kit

®

SPSH4 Server Platform with the following parts installed:

SSH4 baseboard

SSH4 processor board

SSH4 memory board

Fan distribution board

Front panel board

Hot plug indicator board

Power distribution board

Two 600-W power supplies

Four fan modules

3.5-inch floppy drive

5.25-inch CD-ROM drive

1-inch hard disk drive bay

Bezel and either handles fo r rack moun ting or fee t for pedesta l mounting

Additional parts or components depending on specific system configuration. See system

specific documentation for a list of additio nal par ts.

Two North American power cords

SPSH4 Server Platform System Resource CD (contains product documentation, device

drivers, and software utilities)

Three sets (six rails) 5.25- in ch periph eral rai ls and scr ews

27

Page 28

28 Intel SPSH4 Server Platform Product Guide 29

Page 29

3 Getting Started

This section discusses the main steps you need to perform to get your server up and runn ing :

1. Select an appropriate site.

2. Install processors, memory, hard disk drives, and other options.

3. Connect the monitor, keyboard, and mouse.

4. Turn on the server and boot to the System Resource CD-ROM.

5. Configure the system with the FRU/SDR load utility.

6. Install the service partition (optional).

7. Install an operating system.

8. Set up system security.

9. Install the server into a rack unit (rack-mount version only).

Selecting a Site

This section describes the space and power requirements and general site criteria for installing the

server.

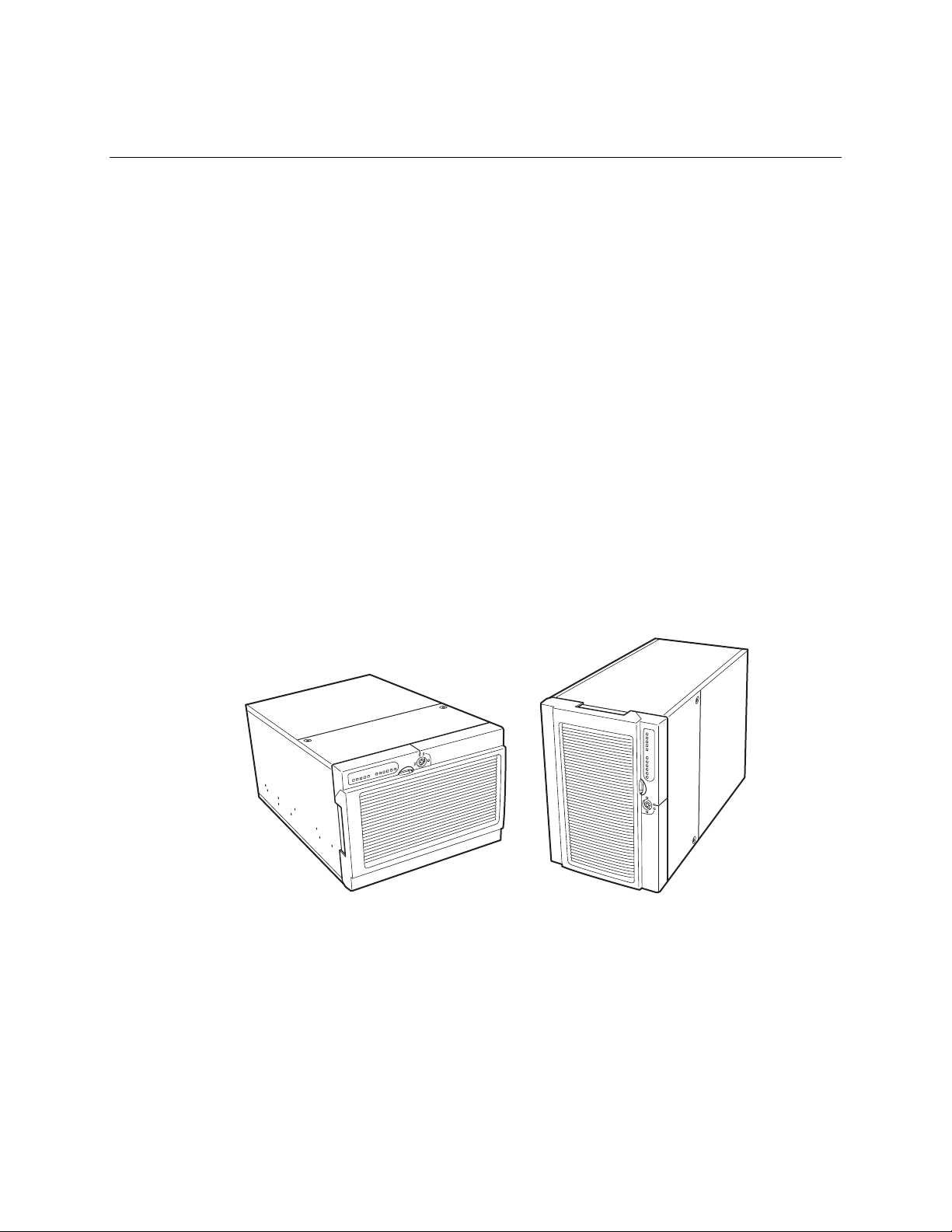

Space and Power Requirements

The server is available in both rack-mount and pedestal versions.

Figure 1. SPSH4 Server (Rack-Mount and Pedestal)

OM13380

Page 30

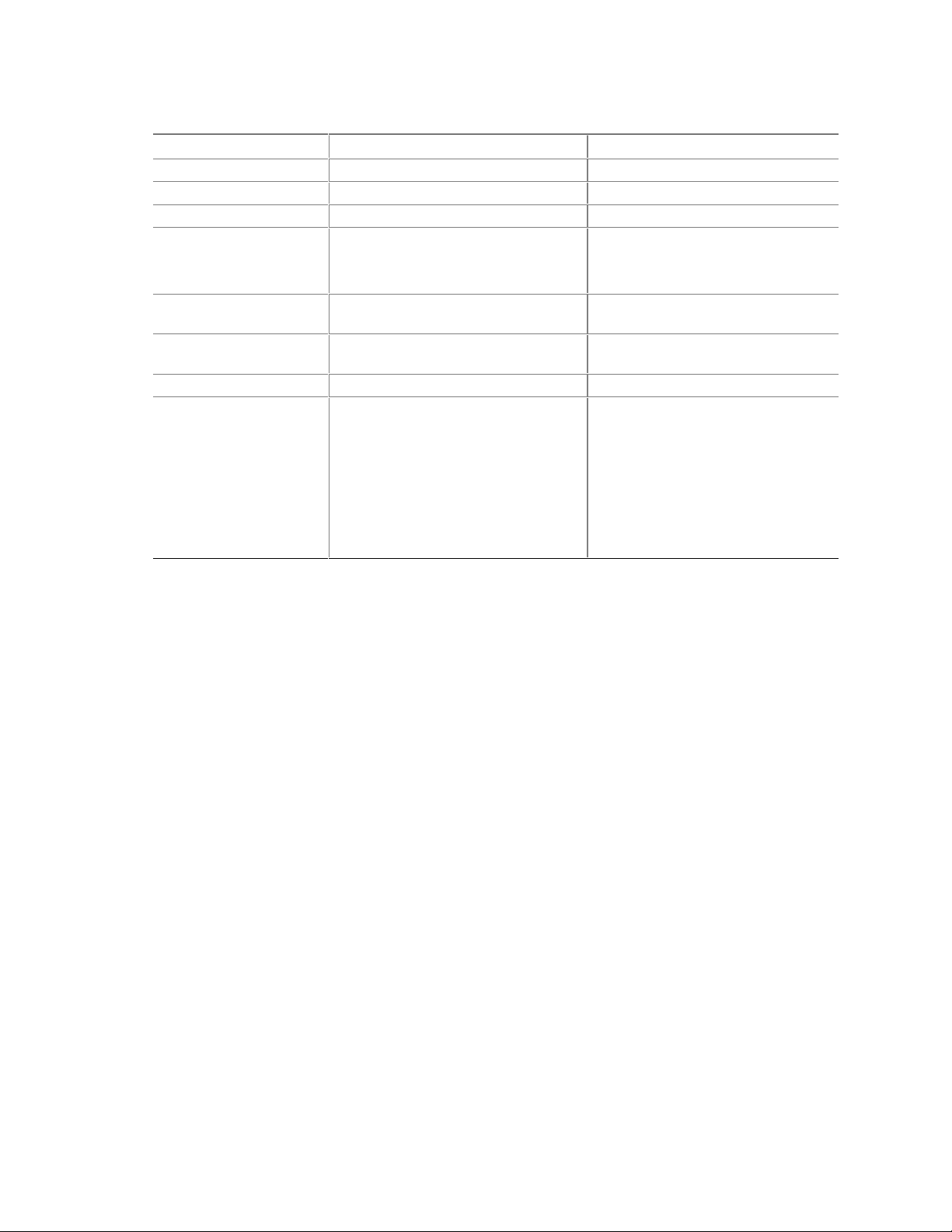

Table 2. SPSH4 Server Physical Specifications

Specification Rack Mount Pedestal

Height 12.25 inches (311 mm) (7U) 18.09 inches (459 mm)

Width Fits 19-inch rack 12.24 inches (311 mm)

Depth 25.25 inches (641 mm) 25.25 inches (641 mm)

Weight

Minimum configuration

Maximum configuration

Required front clearance 3 inches (76 mm), inlet airflow <35 °C

Required rear clearance 4.5 inches (114 mm), no airflow

Required side clearance 0 inch (0 mm) 0 inch (0 mm)

Power requirements

Voltage (110)

Voltage (220)

Frequency

90 pounds (41 kg)

119 pounds (57 kg)

(95 °F)

restriction

90 V

180 V

47 Hz min, 63 Hz max

* Amperage is total system power, with

two or three power suppl y modules

installed.

min, 132 V

rms

min, 264 V

rms

rms

rms

max, 9 A

rms

max, 4.5 A

96 pounds (44 kg)

125 pounds (57 kg)

12 inches (305 mm)

9 inches (229 mm)

*

90 V

*

180 V

rms

A

47 Hz min, 63 Hz max

* Amperage is total system power, with

two or three power suppl y modules

installed.

rms

min, 132 V

rms

min, 264 V

rms

*

rms

rms

max, 9 A

max, 4.5

rms

*

For detailed information on calculating power consumption for specific server configurations, see

page 163.

General Site Criteria

The server operates reliably within normal office environmental limits. Select a site that meets

these criteria:

• Near a properly grounded, three-pronged power outlet.

In the United States and Canada: a NEMA 6-15R outlet for 100-120 V and for 200-240 V.

In other geographic areas: a properly grounded outlet in accordance with the local

electrical authorities and electrical code of the region.

• Clean and relatively free of excess dust.

• Well ventilated and away from sources of heat, with the ventilating openings on the server kept

free of obstructions.

• Maximum ambient air temperature should not exceed 35 °C (95 °F).

• Away from sources of vibration or physical shock.

• Isolated from strong electromagnetic fields and noise caused by electrical devices such as

elevators, copy machines, air conditi one rs, larg e fans, large ele ct ri c moto rs, rad io and TV

transmitters, and high-frequency security devices.

• Access space provided so the server power cords can be unplugged from the power supply or

the wall outlet; this is the only way to remove AC power from the server.

• Clearance provided for cooling and airflow.

30 Intel SPSH4 Server Platform Product Guide

Page 31

NOTES

✏

Surge suppressor recommended: I n geograp h ic re gions tha t are

susceptible to electrical storms, Intel strongly recommends that you plug the

server into a surge suppressor.

EMI information: For information about complying with electromagnetic

interference regulations, see “Regional EMC Compliance Information” on

page 149.

Installing Processors, Memory, Hard Disk Drives, and Options

The server is shipped without processors, memory, or hard drives. To install the memory,

processors, hard drives, and other options, follow the steps shown on the Quick Start User Guide

that is included with the server. For more information on any of the steps listed on the guide, see

the references below:

1. Removing the covers:

a. Removing the rear access cover—see page 66.

b. Removing the access cover to the system boards—see page 68.

2. Removing the memory and processor boards:

a. Removing the memory board—see page 69.

b. Removing the air baffle—see page 71.

c. Removing the processor board—see page 73.

3. Installing memory and processors:

a. Installing the DIMMs in the memory board—see page 82.

b. Installing the processors on the processor board—see page 78.

4. Installing an ICMB board—follow the instructions that came with the ICMB board kit.

5. Installing the processor and memory boards:

a. Installing the processor board on the baseboard—see page 74.

b. Installing the air baffle—see page 72.

c. Installing the memory board—see page 70.

6. Installing PCI add-in cards—see page 93. For a description of the PCI slots, see Figure 28 on

page 93.

7. Installing hard disk drives—see page 85.

8. Installing an additional power supply or additional peripherals—see page 92, page 112, and any

additional documentation that came with the peripherals.

9. Installing covers:

a. Installing the access cover to the system boards—see page 68.

b. Installing the rear access cover—see page 66.

10. Configuring your system—complete the remainder of this “Getting Started” section.

Getting Started 31

Page 32

Connecting the Monitor, Keyboard, and Mouse

Connect the monitor, keyboard, and mouse to the appropriate connectors on the rear panel of the

server. See Figure 56 on page 134.

You have completed the hardware setup. The remainder of this section discusses software setup

and configuration.

Turning On the Server and Running the Power-On Self Test (POST)

Each time you start the server, the Power-On Self Test (POST) runs automatically. POST is stored

in flash memory.

To start the server, do the following:

NOTE

✏

To access certain features, such as BIOS Setup, you must press specific keys

at specific times during POST. To familiarize yourself with this procedure,

read the following instructions through completely before actually

performing them. For a summary of hot keys active during POST, see

Table 3 on page 33.

1. Make sure all external devices, such as a monitor, keyboard, and mouse, are connected.

2. If a drive protection card or diskette is present in the diskette drive, remove it.

3. Plug the video monitor power cord into the power source or wall outlet. Turn on the video

monitor.

4. Plug the AC power cords into the power connectors on the back of the chassis and into the

power source or wall outlet.

5. If the server does not turn on when you plug it into the AC outlet, press the on/off power button

on the front panel.

6. Verify that the main power LED on the front panel is lit (see Figure 55 on page 133).

7. Insert the SPSH4 Server Platform System Resource CD into the CD-ROM drive.

After a few seconds, POST begins and a splash screen is displayed (if the splash screen is

disabled in BIOS Setup, a diagnostics screen is displayed). POST discovers, configures, and

tests the processors, memory, keyboard, and most installed peripheral devices. The length of

time needed to complete POST depends on the amount of memory installed and the number of

option boards installed.

8. Shortly after the splash screen is displayed, POST displays the message “Press <F2> to enter

Setup…” at the bottom of the screen. At this point, you can press any of the keys identified

with an asterisk (*) in Table 3 on page 33, or you can do nothing and wait until the server boots

from the CD-ROM. If you enter BIOS Setup, the Service Partition, or the Adaptec

SCSISelect

9. After POST completes, the system beeps once and then searches all boot devices in the order

defined by the boot priority settings in the BIOS. The system finds, loads, and runs the limited

operating system on the System Resource CD.

†

Utility, when you exit those features, the server might reboot.

†

32 Intel SPSH4 Server Platform Product Guide

Page 33

NOTE

✏

If there is no device with a bootable operating system, the boot process

continues, the system beeps once, and the following message is displayed:

Operating System not found

If you have a device with a bootable operating system but see this message

anyway, reboot and use BIOS Setup (page 39) to make sure your boot device

settings are correct.

Hot Keys for POST

Table 3 lists the hot keys you can use during POST to access setup utilities and alter the normal

POST execution.

Table 3. Hot Keys

To Do This: Press These Keys:

Abort memory test during POST.

Resume after a POST error is displayed. (The

system pauses after displaying an error.)

Enter BIOS Setup during POST. <F2>*

Boot to the service partition. <F4>*

Boot from a network using Preboot Execution

Environment (PXE).

Remove the splash screen to view the diagnostic

messages during POST and display a menu for

selecting the boot device.

Enter the Adaptec SCSISelect Utility during POST. <Ctrl+A>*

* Press any of these keys when the prompt “Press <F2> to enter Setup…” is displayed.

<Space>

Press while BIOS is updating memory size on screen.

<F1>

<F12>*

<ESC>*

Note: Using BIOS Setup, you can enable the BootTime Diagnostic Screen, in which case POST does

not display the splash screen.

Note: If you use the displayed menu to change the

boot device, the change affects the current boot only.

Configuring the System with the FRU/SDR Load Utility

After POST completes and the system has finished booting from the System Resource CD, run the

FRU/SDR Load Utility to configure the sensor data record (SDR) and field replaceable unit (FRU)

inventory for the server. For instructions, see page 62.

NOTE

✏

When you first set up your server and any time you change the number of

processors, fans, or power supplies, you must run the FRU/SDR load utility.

Running FRU/SDR loads the sensor configuration (SDR) that is used to monitor

temperature, voltage, and other parameters. If the FRU/SDR configuration does

not match the physical configuration of the server, false errors might be

generated by sensors that don’t actually exist, and sens ors tha t do exist migh t not

be monitored.

Getting Started 33

Page 34

Installing the Service Partition (Recommended)

When you are setting up your server system, you can install a service partition on your hard drive.

®

The service partition, in conjunction with Intel