Page 1

Intel® RealSense™ Depth Module

D400 Series Custom Calibration

Revision 1.1.0

January 2018

Page 2

2

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL

OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED IN INTEL'S TERMS AND

CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY, RELATING TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A

PARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

A "Mission Critical Application" is any application in which failure of the Intel Product could result, directly or indirectly, in personal injury or death.

SHOULD YOU PURCHASE OR USE INTEL'S PRODUCTS FOR ANY SUCH MISSION CRITICAL APPLICATION, YOU SHALL INDEMNIFY AND HOLD

INTEL AND ITS SUBSIDIARIES, SUBCONTRACTORS AND AFFILIATES, AND THE DIRECTORS, OFFICERS, AND EMPLOYEES OF EACH, HARMLESS

AGAINST ALL CLAIMS COSTS, DAMAGES, AND EXPENSES AND REASONABLE ATTORNEYS' FEES ARISING OUT OF, DIRECTLY OR INDIRECTLY,

ANY CLAIM OF PRODUCT LIABILITY, PERSONAL INJURY, OR DEATH ARISING IN ANY WAY OUT OF SUCH MISSION CRITICAL APPLICATION,

WHETHER OR NOT INTEL OR ITS SUBCONTRACTOR WAS NEGLIGENT IN THE DESIGN, MANUFACTURE, OR WARNING OF THE INTEL PRODUCT

OR ANY OF ITS PARTS.

Intel may make changes to specifications and product descriptions at any time, without notice. Designers must not rely on the absence or

characteristics of any features or instructions marked "reserved" or "undefined". Intel reserves these for future definition and shall have no

responsibility whatsoever for conflicts or incompatibilities arising from future changes to them. The information here is subject to change without

notice. Do not finalize a design with this information.

The products described in this document may contain design defects or errors known as errata which may cause the product to deviate from

published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an order number and are referenced in this document, or other Intel literature, may be obtained by calling 1800-548-4725, or go to: http://www.intel.com/design/literature.htm.

Code names featured are used internally within Intel to identify products that are in development and not yet publicly announced for release.

Customers, licensees and other third parties are not authorized by Intel to use code names in advertising, promotion or marketing of any product

or services and any such use of Intel's internal code names is at the sole risk of the user.

Intel and the Intel logo are trademarks of Intel Corporation in the U.S. and other countries.

*Other names and brands may be claimed as the property of others.

Copyright © 2018, Intel Corporation. All rights reserved.

Page 3

3

Contents

1 Introduction ....................................................................................................... 8

1.1 Purpose and Scope of This Document ........................................................ 8

1.2 Organization .......................................................................................... 8

2 Overview .......................................................................................................... 9

2.1 Calibration API and Calibration Data Read/Write/Restore ............................. 9

2.2 Calibration Parameters .......................................................................... 10

2.3 Frame Formats Used in Custom Calibration .............................................. 11

2.4 Frame Sync .......................................................................................... 11

2.5 Accuracy .............................................................................................. 11

3 Setup ............................................................................................................. 13

3.1 Hardware ............................................................................................. 13

3.1.1 Device .................................................................................... 14

3.1.2 Target .................................................................................... 14

3.1.3 Tripod .................................................................................... 15

3.1.4 USB ....................................................................................... 17

3.1.5 PC ......................................................................................... 17

3.2 Software .............................................................................................. 17

3.2.1 Custom Calibration Sample Application ....................................... 17

3.2.2 Intel® RealSense™ Calibration Tool and API ............................... 18

3.2.3 Intel® RealSense™ SDK ........................................................... 19

3.2.4 OpenCV 3.3.0 ......................................................................... 19

3.2.5 Glut Library ............................................................................ 20

4 Calibrating Device with Custom Calibration Sample Application.............................. 21

4.1 Process Overview .................................................................................. 21

4.2 Connect Device to Computer .................................................................. 21

4.3 Running Custom Calibration Sample Application ....................................... 21

4.3.1 Starting Application ................................................................. 21

4.3.2 Capturing Images from 6 Viewpoints .......................................... 22

4.4 Calibration Result .................................................................................. 35

4.5 Updating Results to Device ..................................................................... 37

4.5.1 Depth Quality Check before Updating Calibration ......................... 38

4.5.2 Writing Optimized Calibration to Device ...................................... 38

4.5.3 Depth Quality Check after Updating Calibration ........................... 40

5 Developing Custom Calibration Application .......................................................... 42

5.1 Sample Application Source Code and Compile ........................................... 42

5.2 Calibration Mode Camera Configuration ................................................... 44

5.2.1 Emitter ................................................................................... 44

5.2.2 Auto Exposure ......................................................................... 44

5.2.3 Streaming Resolution and Format .............................................. 45

5.2.4 Image Captures ....................................................................... 45

5.2.5 Demosaic Left/Right Images for ASR / PSR SKUs ......................... 45

5.3 Detecting the Chessboard in an Image with OpenCV ................................. 45

Page 4

4

5.4 Calculating Depth Camera Calibration with OpenCV ................................... 46

5.5 Calculating RGB Camera Calibration with OpenCV ..................................... 47

5.6 Calculating RGB Camera Calibration Extrinsics with OpenCV ....................... 47

5.7 Writing Calibration Parameters ............................................................... 48

Page 5

5

Tables

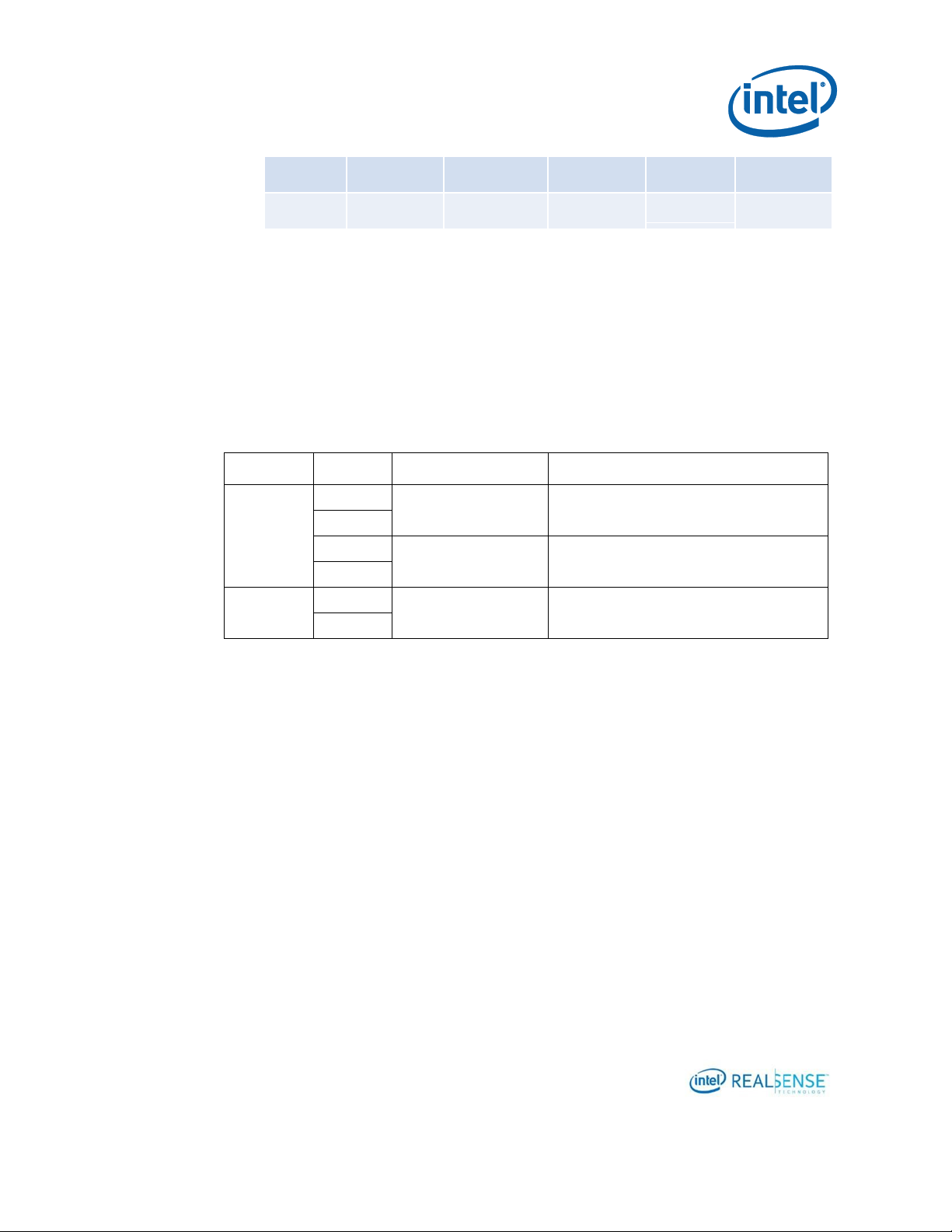

Table 2-1. Frame Formats Used in Custom Calibration .......................................... 11

Table 3-1. Intel® RealSense™ Calibration API Resources ..................................... 18

Table 3-2. Intel® RealSense™ SDK Resources .................................................... 19

Table 3-3. OpenCV 3.3.0 Resources ................................................................... 20

Table 3-4. OpenCV 3.3.0 Libraries Required for the Example ................................. 20

Page 6

6

List of Figures

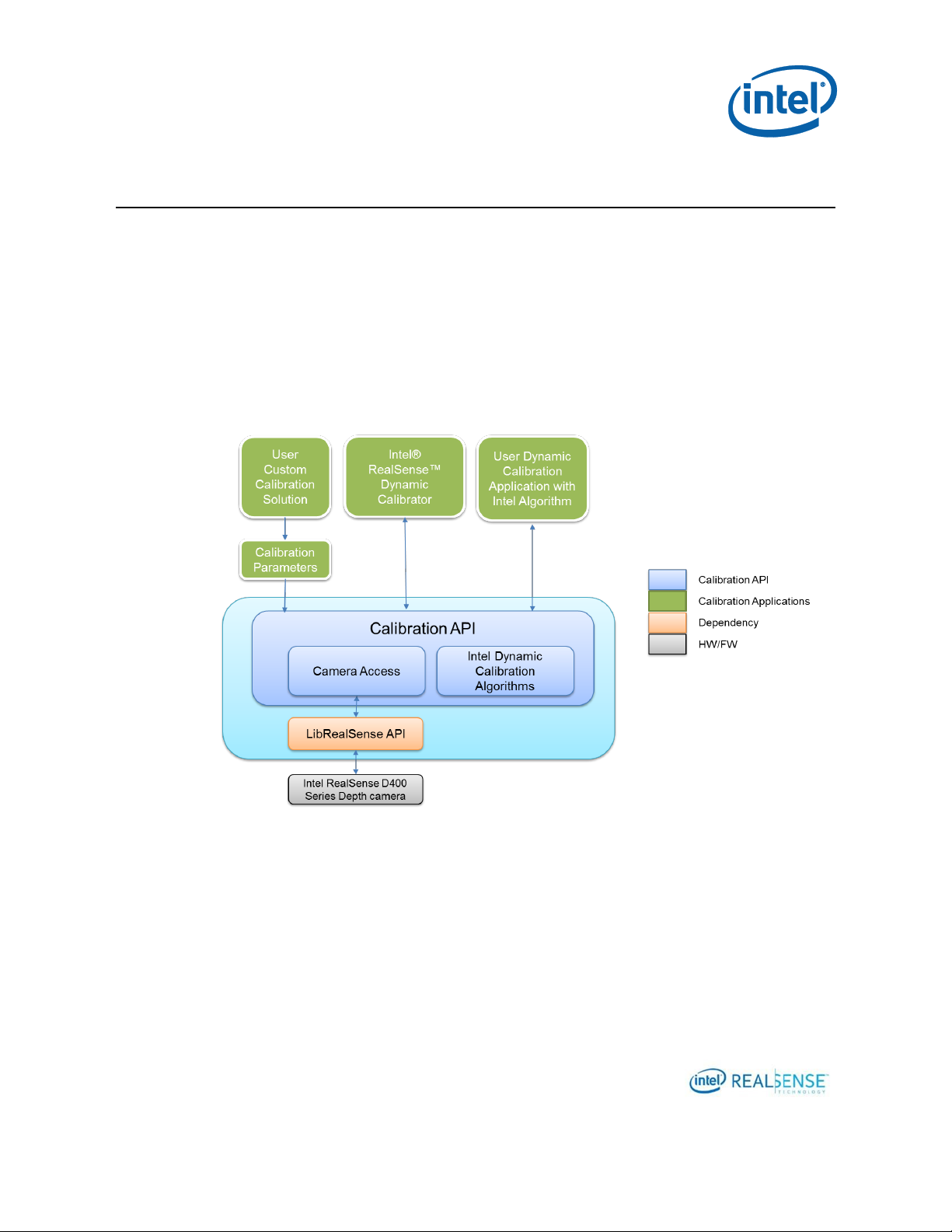

Figure 2-1 Software Stack with Dynamic Calibration API and Calibration Apps ........... 9

Figure 3-1 Hardware Setup ............................................................................... 13

Figure 3-2 D415 Device .................................................................................... 14

Figure 3-3 8x7 60x60 mm Checker Calibration Target .......................................... 15

Figure 3-4 Tripod ............................................................................................. 16

Figure 4-1 Center Right Position ........................................................................ 25

Figure 4-2 Viewpoint #1 ................................................................................... 26

Figure 4-3 Center Right .................................................................................... 27

Figure 4-4 Viewpoint #2 ................................................................................... 28

Figure 4-5 Left ................................................................................................ 29

Figure 4-6 Viewpoint #3 ................................................................................... 29

Figure 4-7 Right .............................................................................................. 30

Figure 4-8 Viewpoint #4 ................................................................................... 31

Figure 4-9 Top Looking Down ............................................................................ 32

Figure 4-10 Viewpoint #5 ................................................................................. 33

Figure 4-11 Bottom Looking Up ......................................................................... 34

Figure 4-12 Viewpoint #6 ................................................................................. 34

Figure 4-13 Depth Quality before Updating Calibration ......................................... 38

Figure 4-14 Updating Calibration Parameters to Device ........................................ 39

Figure 4-15 Calibration Parameter Change .......................................................... 40

Figure 5-1 General Process for custom Calibration ............................................... 42

Page 7

7

Document

Number

Revision

Number

Description

Revision Date

XXXXXX

1.0

Initial Release

01/2018

1.1

Update with Calibration API 2.5.2.0 release

01/2018

Revision History

Page 8

8

Introduction

1 Introduction

1.1 Purpose and Scope of This Document

In order to operate Intel® RealSense™ D400 device efficiently and accurately, users need

to make sure the device is well calibrated. The Intel supplied calibration tools including

Intel® RealSense™ Dynamic Calibrator and OEM Calibration Tool for Intel® RealSense™

Technology are designed to calibrate the devices using Intel proprietary algorithms.

Some customers or developers may choose to use their own calibration algorithms and

update the device with their custom calibration data.

This document contains technical information to assist those developing custom

calibration solutions for Intel® RealSense™ D400 series modules. The primary goal is to

guide the user how to create a calibration application, using the D400 corresponding

APIs. This includes a description how to configure the device under calibration, define

the calibration parameters, and how to read/write these parameters from/into the

device. In addition, a simple sample application based on OpenCV algorithm is

provided as an example.

It is not in the scope of this document to discuss details of calibration algorithm or

accuracy. Developing custom calibration requires knowledge in computer vision as well

as good understanding of the RealSense device operating details. It is a complex topic

and intended only for those with expert level knowledge.

1.2 Organization

This document is organized into four main parts: overview, setup, calibrating a device

with custom calibration sample app, and developing custom solution:

Overview – brief overview of the Calibration API and parameters.

Setup – hardware and software setup for running the Custom Calibration

Sample App to calibrate a device and developing custom calibration solutions.

Calibrating Device with Custom Calibration Sample App – describes the

necessary hardware and software setup required running the Custom

Calibration Sample App and details steps to calibrate device.

Developing Custom Calibration Solution – uses the sample application as an

example to describe details of steps implementing a custom calibration

solution for Intel® RealSense™ D400 series modules.

Page 9

9

Overview

2 Overview

2.1 Calibration API and Calibration Data

Read/Write/Restore

Intel provides a software interface in Calibration API to enable user uploading those

calibration parameters to Intel® RealSense™ D400 devices and read the parameter

back from device:

WriteCustomCalibrationParameters – write parameters to device

ReadCalibrationParameters – read parameters from device

Figure 2-1 Software Stack with Dynamic Calibration API and Calibration Apps

An example tool CustomRW is also included in Calibration API to read calibration

parameters from XML file and write them to the device.

A user custom calibration app can choose one of the two approaches to update the

results to the device:

To link to the WriteCustomCalibrationParameters and

ReadCalibrationParameters and write directly to the device through the APIs.

Page 10

10

Factory

Calibration

OEM

Calibration

Technician

Calibration

User Custom

Calibration

Dynamic

Calibration

Overview

To write the results into a parameter XML file and then use CustomRW to

read/write the parameters to the device.

In case user needs to restore the calibration data on the device,

ResetDeviceCalibration in Calibration API can be called to programmatically restore

the device calibration to gold settings.

ResetDeviceCalibration – restore device calibration to gold settings

The CustomRW example tool also supports restore through command line option.

2.2 Calibration Parameters

Calibration parameters includes INTRINSICS and EXTRINSICS. Assume left camera is

the reference camera and is located at world origin. RGB parameters only apply to

modules with RGB, e.g., D415 and D435.

Intrinsic includes

Focal length - specified as [fx; fy] in pixels for left, right, and RGB cameras

Principal point - specified as [px; py] in pixels for left, right, and RGB cameras

Distortion - specified as Brown's distortion model [k1; k2; p1; p2; k3] for left,

right, and RGB cameras

Extrinsic includes

RotationLeftRight - rotation from right camera coordinate system to left camera

coordinate system, specified as a 3x3 rotation matrix

TranslationLeftRight - translation from right camera coordinate system to left

camera coordinate system, specified as a 3x1 vector in millimeters

RotationLeftRGB - rotation from RGB camera coordinate system to left camera

coordinate system, specified as a 3x3 rotation matrix

TranslationLeftRGB - translation from RGB camera coordinate system to left

camera coordinate system, specified as a 3x1 vector in millimeters

The calibration data read/write API allows user to upload both INTRINSICS and

EXTRINSICS. The user custom algorithm is free to optimize all these parameters. The

sample in this document optimizes both intrinsic and extrinsic parameters.

The following table shows how the various calibration tools would impact calibration

parameters for Intel® RealSense™ D400 series depth cameras.

Page 11

11

Intrinsic

x x x

x

Extrinsic

x x x x x

Format

SKU

Used

Comment

Y16

(16-bit)

D400

Left and Right Sensors:

1920x1080 @ 15 FPS

Intel® RealSense™ Camera D400, D410, D415

D410

D420

Left and Right Sensors:

1280x800 @ 15 FPS

Intel® RealSense™ Camera D430 D420, D435

D430

YUY2

D415

RGB Sensor:

1920x1080 @ 15 FPS

Intel® RealSense™ Camera D415, D435

D435

Overview

2.3 Frame Formats Used in Custom Calibration

The following unrectified calibration frame formats are available. The Custom

Calibration Sample App uses these formats.

Table 2-1. Frame Formats Used in Custom Calibration

2.4 Frame Sync

The calibration frames are not synced. To avoid possible motion blur, calibrate the

device with images captured at static positions. In this sample, a tripod is used to keep

the camera device at fixed positions while capturing the images for calibration. This is

same if you want to develop your own custom calibration app.

2.5 Accuracy

The calibration will not be accurate if the checkerboard doesn’t sufficiently cover the

field of view or the poses are not diverse enough between captures. The calibration will

Page 12

12

Overview

also not be accurate if the camera or board is handheld (or not completely still) as there

is no framesync in calibration mode.

Page 13

13

Setup

3 Setup

This section describes the required hardware and software setup for running the

Custom Calibration Sample Application to calibrate a device and developing a Custom

Calibration Application.

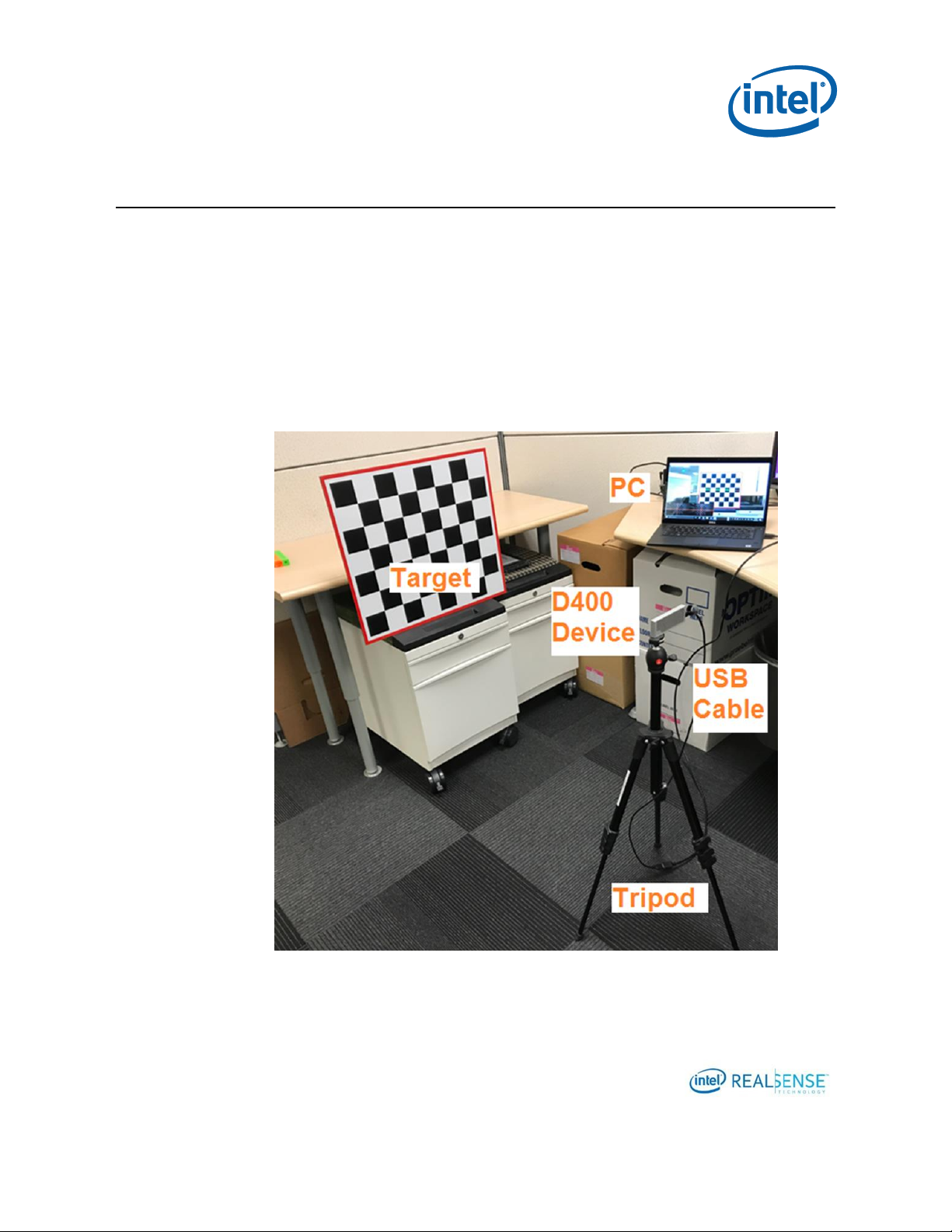

3.1 Hardware

The hardware required including a calibration target, D400 series device to be

calibrated, USB cable, and a Windows 10 computer. To ensure the images are synced,

pictures are captured at static device positions, a tripod is used to support the device

during calibration.

Figure 3-1 Hardware Setup

Page 14

14

Setup

3.1.1 Device

Intel® RealSense™ D415 device as shown below is used to show case the custom

calibration process. All D400 series devices can use the same process.

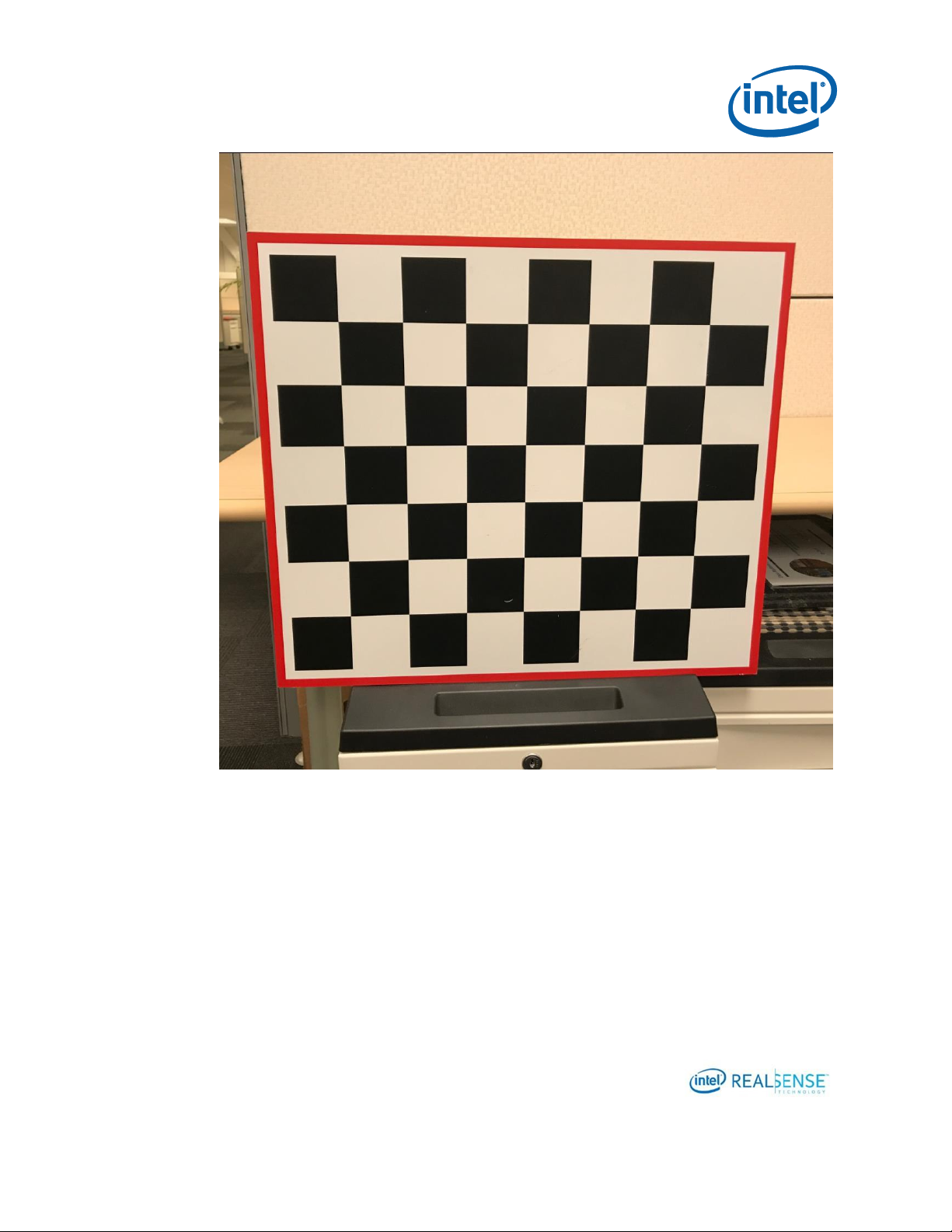

3.1.2 Target

The target used in this custom calibration example is an 8x7 checkerboard with a

60x60mm checker size. The target image pdf 540x480_60mm.pdf is included in the

software package described in 3.2.1 Custom Calibration Sample Application. The

target pdf is located under the target directory. Users must ensure that when printing

the target, the target is not scaled.

Figure 3-2 D415 Device

A developer may choose to use a different target, but will need to modify the sample

application accordingly and recompile.

Page 15

15

Setup

Figure 3-3 8x7 60x60 mm Checker Calibration Target

3.1.3 Tripod

Any medium sized tripod should be sufficient. In this example setup, we used a

Manfrotto Compact Light Aluminum Tripod with ball head. The ball head makes

adjustment to device orientation easier.

Page 16

16

Setup

Figure 3-4 Tripod

Page 17

17

Setup

3.1.4 USB

A long USB type C cable to connect the device to the host computer where the custom

calibration sample application will run.

3.1.5 PC

A Windows 10 computer.

3.2 Software

Install the following to the windows computer.

3.2.1 Custom Calibration Sample Application

A CustomCalibrationSample.zip package is provided for the Custom Calibration

Sample Application. It includes the binary executable and a calibration target file. The

source code is included in Intel® RealSense™ Calibration API package.

Unzip the package:

CustomCalibrationSample

|

|---------Bin

| |-------- CustomCalibrationSampleApp.exe

|

|--------- Target

| |-------- 540x480_60mm.pdf

|

|--------- CustomResult

Bin folder contains the executable. CustomCalibrationSampleApp.exe is the

executable for the Custom Calibration Sample Application.

Target contains the target image pdf 540x480_60mm.pdf. User will need to print it

without scaling.

CustomResult contains all device calibration results.

Page 18

18

Resource

URL

Intel®

RealSense™

Depth Module

D400 Series

Dynamic

Calibration

Software

Download

https://downloadcenter.intel.com/download/27415/?v=t

Intel®

RealSense™

Depth Module

D400 Series

Dynamic

Calibration User

Guide

https://cdrd.intel.com/v1/dl/getContent/574999.htm

Intel®

RealSense™

Depth Module

D400 Series

Dynamic

Calibration

Programmer

Guide

https://www.intel.com/content/www/us/en/support/articles/000026724.html

Setup

3.2.2 Intel® RealSense™ Calibration Tool and API

The calibration example uses support functions provided by the Intel® RealSense™

Calibration API to store updated calibration parameters into the non-volatile storage

on the Intel® RealSense™ D400 series modules. Required functions were first

introduced in version 2.5.2.0 of the Dynamic Calibration API, so install the latest

version and ensure that it is version 2.5.2.0 or later. Table 3-1 lists where to

download the Intel® RealSense™ Calibration API software and associated

documentation.

Table 3-1. Intel® RealSense™ Calibration API Resources

Find Calibration Tool and Calibration API installers and follow instruction to install.

The latest version 2.5.2.0. After installation, the directory structure should look like

below:

CalibrationToolAPI

|

|-------- 2.5.2.0

| |-------- bin

| | |-------- Intel.Realsense.CustomRW.exe

|

| |-------- Include

| |-------- attributions.txt

Page 19

19

Resource

URL

Intel® RealSense™

SDK

Home Page

https://software.intel.com/en-us/realsense/sdk

LibRealSense GitHub*

https://github.com/IntelRealSense/librealsense

SDK Documentation

https://github.com/IntelRealSense/librealsense/tree/master/doc

Setup

| |-------- release_notes.txt

| |-------- license.txt

| |-------- gimbal

| |-------- target

| |-------- examples

| | |-------- CustomCalibration

Intel.Realsense.CustomRW.exe under bin directory is the calibration data read/write

tool. We will be using it to update the calibration parameters to the device after

running the Custom Calibration Sample App and obtained optimized parameters for

the device.

CustomCalibration under examples directory is the Custom Calibration Sample App

source code and project solution files to compile it. We will go over it later in this

document.

3.2.3 Intel® RealSense™ SDK

Install the latest release of the Intel® RealSense™ SDK so your custom calibration

application can use LibRealSense to conveniently open and access Intel® RealSense™

D400 series modules. Table 3-2 contains pointers to the SDK homepage, GitHub*

repository where you can download the latest release, and the SDK documentation.

Table 3-2. Intel® RealSense™ SDK Resources

3.2.4 OpenCV 3.3.0

The calibration example presented in this document uses several OpenCV 3.3.0

libraries for computations, so OpenCV 3.3.0 must be installed. Table 3-3 lists URLs

for downloading OpenCV 3.3.0, and Table 3-4 lists the specific OpenCV libraries that

are required by the example code.

Page 20

20

Resource

URL

OpenCV GitHub* Repository

https://github.com/opencv/opencv

OpenCV 3.3.0 Download

https://github.com/opencv/opencv/releases/tag/3.3.0

OpenCV 3.3.0 Library

ittnotify.lib

opencv_calib3d330.lib

opencv_core330.lib

opencv_features2d330.lib

opencv_flann330.lib

opencv_imgproc330.lib

zlib.lib

Setup

Table 3-3. OpenCV 3.3.0 Resources

Table 3-4. OpenCV 3.3.0 Libraries Required for the Example

3.2.5 Glut Library

The FreeGLUT package is a convenient open source alternative to the OpenGL Utility

Toolkit for displaying graphical output to the operator of the custom calibration

application. You can download and install the FreeGLUT package at

http://freeglut.sourceforge.net/.

Page 21

21

Calibrating Device with Custom Calibration Sample Application

4 Calibrating Device with Custom

Calibration Sample Application

4.1 Process Overview

The general process to calibrate a device with the Custom Calibration Sample App

involves running the app capturing images of the target from various viewpoints, the

app optimizes the calibration parameters based on the captured images and writes the

results to a XML file. The user then run CustomRW calibration data R/W tool to read the

parameters from the XML file and write them to the device.

4.2 Connect Device to Computer

Connect the device through the USC cable to the PC where Custom Calibration Sample

App locates.

4.3 Running Custom Calibration Sample Application

4.3.1 Starting Application

Use Windows explorer to browse to CustomCalibration\bin directory and find the

CustomCalibrationTest.exe and double click it to start running.

Page 22

22

Calibrating Device with Custom Calibration Sample Application

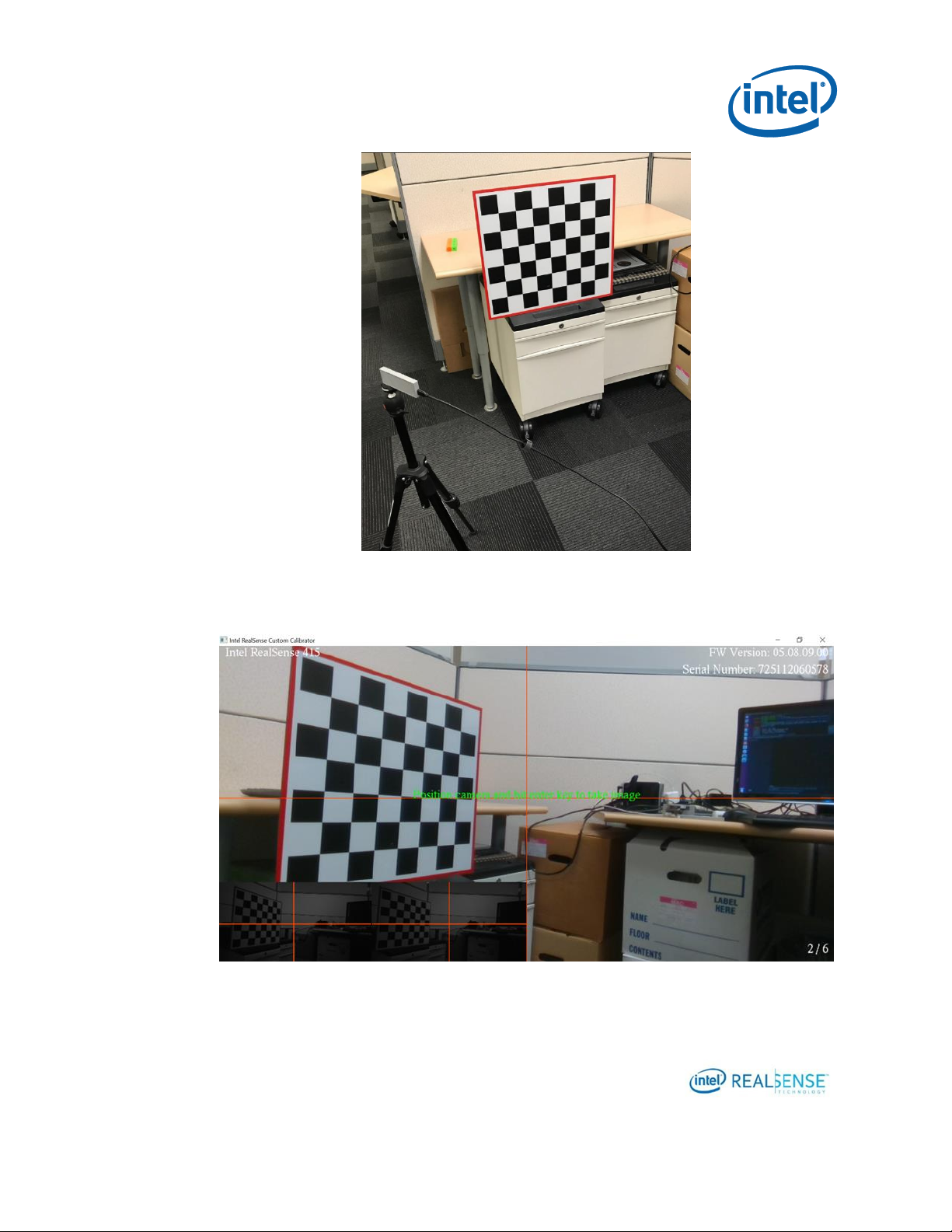

The app runs with a simple UI. The main window displays the image from RGB imager,

the lower left corner displays the left and right images. In case the device does not

have RGB, only the left and right images display on the lower left corner.

A few text messages are overlay on top of the images:

On the top left corner, it display the device model name, for example, Intel

RealSense 415.

On the top right corner, it displays the FW version and serial number of the

device.

On the bottom right corner, it displays a progress counter in the form of x/6

where x is the number of images captured and accepted out of the total 6

images required.

In the middle of the Window is a green help message to instruct the user to

position the camera and press the enter key to capture image.

In the top middle portion of the Window is an area where error message will

display in red when the image is not accepted or other error conditions.

4.3.2 Capturing Images from 6 Viewpoints

The calibration algorithm in the Custom Calibration Sample Application requires 6

images of the target from different viewpoints. This is the minimum number of images

for simplicity. The application UI will guide the user to go through the image capturing

process.

Page 23

23

Calibrating Device with Custom Calibration Sample Application

Viewpoints - the choice of the viewpoint is critical to the accuracy of the

calibration results. A general rule is that the target in these 6 images combined

should cover as much as possible of the entire field of view and from different

angles and distances from the target.

Cover whole target - images from any of the viewpoints should cover the entire

target in all imagers (Left, Right and RGB).

Good example – cover the entire target in all three imagers:

Page 24

24

Calibrating Device with Custom Calibration Sample Application

Bad example - cover only portion of the target in any of the three imagers:

Now, let’s capture the images.

4.3.2.1 Viewpoint #1 – Center Right

Adjust the tripod and position the device on the center right facing directly to the

target.

Page 25

25

Calibrating Device with Custom Calibration Sample Application

Figure 4-1 Center Right Position

The viewpoint should looks like below with the target cover much of the right side the

FOV.

Page 26

26

Calibrating Device with Custom Calibration Sample Application

Figure 4-2 Viewpoint #1

Press enter to capture the image. If successful, the frame counter on the lower right

corner will increase to 1/6 meaning 1 out of 6 images are captured. If it failed, a red

error message will appear and user is directed to retake a viewpoint.

4.3.2.2 Viewpoint #2 - Center Left

Move the device to the center left directly facing the target so the target covers much

of the left portion of the FOV.

Page 27

27

Calibrating Device with Custom Calibration Sample Application

Figure 4-3 Center Right

Page 28

28

Calibrating Device with Custom Calibration Sample Application

Figure 4-4 Viewpoint #2

Press enter to capture the image. If successful, the frame counter on the lower right

corner will increase to 2/6 meaning 2 out of 6 images are captured. If it failed, a red

error message will appear and user is directed to retake a viewpoint.

4.3.2.3 Viewpoint #3 - Left

Move the device to the left of the camera facing the device at an angle. Use the

viewpoint below for reference.

Page 29

29

Calibrating Device with Custom Calibration Sample Application

Figure 4-5 Left

Figure 4-6 Viewpoint #3

Page 30

30

Calibrating Device with Custom Calibration Sample Application

Press enter to capture the image. If successful, the frame counter on the lower right

corner will increase to 3/6 meaning 3 out of 6 images are captured. If it failed, a red

error message will appear and user is directed to retake a viewpoint.

4.3.2.4 Viewpoint #4 – Right

Move the device to the right facing the target at an angle. Use the viewpoint below for

reference.

Figure 4-7 Right

Page 31

31

Calibrating Device with Custom Calibration Sample Application

Figure 4-8 Viewpoint #4

Press enter to capture the image. If successful, the frame counter on the lower right

corner will increase to 4/6 meaning 4 out of 6 images are captured. If it failed, a red

error message will appear and user is directed to retake a viewpoint.

4.3.2.5 Viewpoint #5 – Top Looking Down

Adjust the tripod so the device high enough to look down the target at an angle. Use

the viewpoint below for reference.

Page 32

32

Calibrating Device with Custom Calibration Sample Application

Figure 4-9 Top Looking Down

Page 33

33

Calibrating Device with Custom Calibration Sample Application

Figure 4-10 Viewpoint #5

Press enter to capture the image. If successful, the frame counter on the lower right

corner will increase to 5/6 meaning 5 out of 6 images are captured. If it failed, a red

error message will appear and user is directed to retake a viewpoint.

4.3.2.6 Viewpoint #6 – Bottom Looking Up

Folding the tripod so that the device will be in a very low position looking up to the

target. Use the viewpoint below for reference.

Page 34

34

Calibrating Device with Custom Calibration Sample Application

Figure 4-11 Bottom Looking Up

Figure 4-12 Viewpoint #6

Page 35

35

Calibrating Device with Custom Calibration Sample Application

Press enter to capture the image. If successful, the frame counter on the lower right

corner will increase to 6/6 meaning 6 out of 6 images are captured. If it failed, a red

error message will appear and user is directed to retake a viewpoint.

4.4 Calibration Result

Once all 6 images captured, calibration will run and should finish very quickly. The

results usually located under the CustomCalibrationSample\CustomResult folder with

device serial number as the folder name. For example, CustomCalibrationSample

\CustomResult\725112060578\DC1

6 RGB images:

colorImage001.png

colorImage002.png

colorImage003.png

colorImage004.png

colorImage005.png

colorImage006.png

6 left images:

leftImage001.png

leftImage002.png

leftImage003.png

leftImage004.png

leftImage005.png

leftImage006.png

Right RGB Images

rightImage001.png

rightImage002.png

rightImage003.png

rightImage004.png

rightImage005.png

rightImage006.png

Optimized calibration parameters in XML:

CalibrationParameters.xml

For example:

<?xml version="1.0"?>

<Config>

<param name = "ResolutionLeftRight">

<value>1920</value>

<value>1080</value>

</param>

<param name = "FocalLengthLeft">

<value>1378.69</value>

<value>1379.13</value>

</param>

Page 36

36

Calibrating Device with Custom Calibration Sample Application

<param name = "PrincipalPointLeft">

<value>965.562</value>

<value>542.603</value>

</param>

<param name = "DistortionLeft">

<value>0.09689</value>

<value>-0.0235634</value>

<value>-5.05513e-05</value>

<value>0.000105855</value>

<value>-0.640377</value>

</param>

<param name = "FocalLengthRight">

<value>1389.55</value>

<value>1390.1</value>

</param>

<param name = "PrincipalPointRight">

<value>957.402</value>

<value>553.108</value>

</param>

<param name = "DistortionRight">

<value>0.123289</value>

<value>-0.290911</value>

<value>0.000149083</value>

<value>0.000723527</value>

<value>0.0992178</value>

</param>

<param name = "RotationLeftRight">

<value>0.999983</value>

<value>0.00150008</value>

<value>-0.00558928</value>

<value>-0.00150249</value>

<value>0.999999</value>

<value>-0.000428313</value>

<value>0.00558863</value>

<value>0.000436704</value>

<value>0.999984</value>

</param>

<param name = "TranslationLeftRight">

<value>-55.3888</value>

<value>0.0448052</value>

<value>1.52189</value>

</param>

<param name = "HasRGB">

<value>1</value>

</param>

<param name = "ResolutionRGB">

<value>1920</value>

<value>1080</value>

</param>

<param name = "FocalLengthRGB">

<value>1376.09</value>

<value>1376.4</value>

Page 37

37

Calibrating Device with Custom Calibration Sample Application

</param>

<param name = "PrincipalPointRGB">

<value>947.958</value>

<value>531.068</value>

</param>

<param name = "DistortionRGB">

<value>0.109862</value>

<value>-0.122685</value>

<value>-0.000453445</value>

<value>-8.61456e-05</value>

<value>-0.396171</value>

</param>

<param name = "RotationLeftRGB">

<value>0.999994</value>

<value>0.00346622</value>

<value>0.000876088</value>

<value>-0.00346642</value>

<value>0.999994</value>

<value>0.000222113</value>

<value>-0.000875313</value>

<value>-0.000225148</value>

<value>1</value>

</param>

<param name = "TranslationLeftRGB">

<value>14.6987</value>

<value>-0.0644999</value>

<value>0.448085</value>

</param>

</Config>

4.5 Updating Results to Device

We will use Intel.Realsense.CustomRW to read the CalibrationParameters.xml and

write the parameters to the device. Checking the depth quality before and after

updating the calibration data on the device.

Page 38

38

Calibrating Device with Custom Calibration Sample Application

4.5.1 Depth Quality Check before Updating Calibration

Figure 4-13 Depth Quality before Updating Calibration

4.5.2 Writing Optimized Calibration to Device

Change directory to Calibration Tool API bin:

Cd C:\CalibrationToolAPI\2.5.2.0\bin

Dump the current parameters on the device into before.txt:

Intel.Realsense.CustomRW.exe –r > before.txt

Writing the parameters in the XML result file into device:

Intel.Realsense.CustomRW.exe –w CalibrationParameters.xml

Page 39

39

Calibrating Device with Custom Calibration Sample Application

Figure 4-14 Updating Calibration Parameters to Device

Dump the parameters from device into after.txt:

Intel.Realsense.CustomRW –r > after.txt

Compare the parameters changed:

Page 40

40

Calibrating Device with Custom Calibration Sample Application

Figure 4-15 Calibration Parameter Change

4.5.3 Depth Quality Check after Updating Calibration

Page 41

41

Calibrating Device with Custom Calibration Sample Application

Page 42

42

Developing Custom Calibration Application

5 Developing Custom Calibration

Application

This section demonstrates how to develop custom calibration application through key

aspects of the sample app we used in Calibrating Device with Custom Calibration

Sample Application. The sample app uses OpenCV algo as example.

The general process is to configure the Intel® RealSense™ device for calibration, capture

images from the camera module, perform the desired calibration computations with

OpenCV, and to write the new calibration parameters back to the cameras using

routines from the Intel® RealSense™ calibration library.

Figure 5-1 General Process for custom Calibration

5.1 Sample Application Source Code and Compile

The source code for Custom Calibration Sample Application is included in the

Calibration API package as example. The packages are described in section 3.2.2 “Intel®

RealSense™ Calibration Tool and API”.

The following directory structure is related to the sample app:

CalibrationToolAPI

|

|-------- 2.5.2.0

| |----------- bin

Page 43

43

Developing Custom Calibration Application

| | |------- DSDynamicCalibrationAPI.dll

| | |------- freeglut.dll

| | |------- realsense2.dll

| |

| |-------- Include

| | |------- DSDynamicCalibration.h

| | |------- DSOSUtils.h

| | |------- DSShared.h

| |

| |------------- lib

| | |------- DSDynamicCalibrationAPI.lib

| |

| |-------- librealsense

| | |------- include

| | |------- lib

| |

| |-------- examples

| | |------- CustomCalibration

| | | |-------- CalibrationManager.cpp

| | | |-------- CalibrationManager.h

| | | |-------- CustomCalibration.cpp

| | | |-------- CustomCalibration.h

| | | |-------- CustomCalibrationWrapper.cpp

| | | |-------- CustomCalibrationWrapper.h

| | | |-------- Rs400Dev.cpp

| | | |-------- Rs400Dev.h

| | | |-------- FileOp.h

| | | |-------- Main.cpp

| | | |-------- CustomCalibrationTest.vcxproj

| | | |-------- CustomCalibrationTest.sln

| |

| | |------- Common

| | | |-------- CalibParamXmlWrite.h

| |

| | |------- ThirdParty

| | | |-------- glut

The sample app depends on a few third party libraries, including GLUT, LibRealSense, and

OpenCV 3.3. GLUT is included under examples\ThirdParty\glut. LibRealSense is included under

librealsense.

bin contains the runtime libraries for Calibration API, GLUT, and LibRealSense.

Include contains header files for Calibration API.

lib contains Calibration API library.

librealsense contains the header files and libraries for LibRealSense

Page 44

44

Developing Custom Calibration Application

examples contains all Calibration API examples and related files. The

CustomCalibration sample app source is under CustomCalibration folder.

OpenCV 3.3 is not included. To compile the CustomCalibration sample app, user will need to set

it up so that the OpenCV header files and libraries is under CalibrationToolAPI\2.5.2.0.

OpenCV setup is discussed in section 3.2.4 “OpenCV 3.3.0” earlier in this document.

CalibrationToolAPI

|

|-------- 2.5.2.0

| |-------- OpenCV

| | |-------- OpenCV330

| | | |-------- include

| | | | |--------opencv

| | | | |--------opencv2

| | | |

| | | |-------- x64

| | | | |-------- vc14

To build the project, open the CustomCalibrationTest.sln under

examples\CustomCalibration with Visual Studio 2015 and build “Release” “x64”.

5.2 Calibration Mode Camera Configuration

For calibration, the camera device needs to be configured to capture calibration

images for both depth and RGB camera using LibRealSense. Basic device operations

are defined in Rs400Dev.h and Rs400Dev.cpp. The Configurations for the device is

defined in CalibrationManager.h and CalibrationManager.cpp.

5.2.1 Emitter

The emitter should be turned off during calibration to avoid interference.

Sample code in Rs400Device:

m_rsDevice->EnableEmitter(0.0f);

5.2.2 Auto Exposure

Auto exposure should be turn on and the AE setpoint be adjusted according to lighting

condition. In indoor room lighting, a setpoint value around 500 – 800 should be

sufficient. In outdoor, 1200 or higher.

m_rsDevice->EnableAutoExposure(1.0f);

if (m_cameraInfo.isWide)

Page 45

45

Developing Custom Calibration Application

m_rsDevice->SetAeControl(800);

else

m_rsDevice->SetAeControl(500);

5.2.3 Streaming Resolution and Format

Calibration frame resolutions and formats are described in Table 2-1 Frame Formats

Used in Custom Calibration, for example, in this sample, or D415 device, the

resolution is 1920x1080 with frame rate of 15 fps. The L/R format is Y16 and the RGB

format is YUY2.

m_rsDevice->SetMediaMode(m_width, m_height, m_fps, m_rgbWidth,

m_rgbHeight, m_cameraInfo.isRGB);

m_rsDevice->StartCapture([&](const void *leftImage, const void *rightImage,

const void *colorImage, const uint64_t timeStamp)

5.2.4 Image Captures

The sample app captures 6 images. More images from different positions may improve

accurate. The number of images is defined in CalibrationManager.h:

const int NUM_SHOTS = 6;

5.2.5 Demosaic Left/Right Images for ASR / PSR SKUs

For ASR/PSR SKUs, left and right images need to be demosaiced.

5.3 Detecting the Chessboard in an Image with

OpenCV

For each of the captured images, find the chessboard corners with OpenCV

findChessboardCorners.

#include <opencv2/opencv.hpp>

#include <opencv2/core/core.hpp>

#include <opencv2/calib3d.hpp>

#include <vector>

using namespace std;

using namespace cv;

bool DetectChessboard(const Mat& image, const Size& chessboardSize, vector<Point2f>&

corners)

Page 46

46

Developing Custom Calibration Application

{

// Find chessboard corners

if (!findChessboardCorners(image, chessboardSize, corners,

CALIB_CB_ADAPTIVE_THRESH | CALIB_CB_NORMALIZE_IMAGE | CALIB_CB_FILTER_QUADS))

return false;

// Refine them

cornerSubPix(image, corners, Size(11, 11), Size(-1, -1),

TermCriteria(CV_TERMCRIT_EPS | CV_TERMCRIT_ITER, 30, 0.1));

return true;

}

5.4 Calculating Depth Camera Calibration with

OpenCV

#include <opencv2/opencv.hpp>

#include <opencv2/core/core.hpp>

#include <opencv2/calib3d.hpp>

#include <vector>

using namespace std;

using namespace cv;

static void CreateCorners3D(const Size& chessboardSize, float checkerSize, size_t

numImages, vector<vector<Point3f> >& corners3D)

{

corners3D.resize(numImages);

corners3D[0].resize(chessboardSize.width * chessboardSize.height);

for (int i = 0; i < chessboardSize.height; i++)

for (int j = 0; j < chessboardSize.width; j++)

corners3D[0][i * chessboardSize.width + j] = Point3f(j *

checkerSize, i * checkerSize, 0.0f);

for (size_t i = 1; i < numImages; i++)

corners3D[i] = corners3D[0];

}

double CalibrateDepthCamera(const vector<vector<Point2f> >& cornersLeft, const

vector<vector<Point2f> >& cornersRight, const Size& chessboardSize, float checkerSize,

const Size& imageSizeLR, Mat& Kl, Mat& Dl, Mat& Kr, Mat& Dr, Mat& Rlr, Mat& Tlr)

{

CV_Assert(cornersLeft.size() != 0 && cornersLeft.size() == cornersRight.size());

CV_Assert(checkerSize > 0.0f);

// Create 3D prototype of the corners

vector<vector<Point3f> > corners3D;

CreateCorners3D(chessboardSize, checkerSize, cornersLeft.size(), corners3D);

// Calibrate each camera individualy

calibrateCamera(corners3D, cornersLeft, imageSizeLR, Kl, Dl, noArray(),

noArray(), CV_CALIB_FIX_ASPECT_RATIO, TermCriteria(TermCriteria::COUNT +

TermCriteria::EPS, 60, DBL_EPSILON));

calibrateCamera(corners3D, cornersRight, imageSizeLR, Kr, Dr, noArray(),

noArray(), CV_CALIB_FIX_ASPECT_RATIO, TermCriteria(TermCriteria::COUNT +

TermCriteria::EPS, 60, DBL_EPSILON));

Page 47

47

Developing Custom Calibration Application

// Calibrate the extrinsics between them

return stereoCalibrate(corners3D, cornersLeft, cornersRight, Kl, Dl, Kr, Dr,

Size(-1, -1), Rlr, Tlr, noArray(), noArray(), CV_CALIB_FIX_INTRINSIC |

CV_CALIB_USE_INTRINSIC_GUESS, TermCriteria(TermCriteria::COUNT + TermCriteria::EPS, 300,

DBL_EPSILON));

}

5.5 Calculating RGB Camera Calibration with OpenCV

Note: Assumes good depth camera calibration

double CalibrateRGBCamera(const vector<vector<Point2f> >& cornersLeft, const

vector<vector<Point2f> >& cornersRGB, const Size& chessboardSize, float checkerSize,

const Size& imageSizeRGB, const Mat& Kl, const Mat& Dl, Mat& Kc, Mat& Dc, Mat& Rlc, Mat&

Tlc)

{

CV_Assert(cornersLeft.size() != 0 && cornersLeft.size() == cornersRGB.size());

CV_Assert(checkerSize > 0.0f);

// Create 3D prototype of the corners

vector<vector<Point3f> > corners3D;

CreateCorners3D(chessboardSize, checkerSize, cornersLeft.size(), corners3D);

// Calibrate RGB camera

calibrateCamera(corners3D, cornersRGB, imageSizeRGB, Kc, Dc, noArray(),

noArray(), CV_CALIB_FIX_ASPECT_RATIO, TermCriteria(TermCriteria::COUNT +

TermCriteria::EPS, 60, DBL_EPSILON));

// Calibrate the extrinsics between them

return stereoCalibrate(corners3D, cornersLeft, cornersRGB, Kl, Dl, Kc, Dc, Size(1, -1), Rlc, Tlc, noArray(), noArray(), CV_CALIB_FIX_INTRINSIC |

CV_CALIB_USE_INTRINSIC_GUESS, TermCriteria(TermCriteria::COUNT + TermCriteria::EPS, 300,

DBL_EPSILON));

}

5.6 Calculating RGB Camera Calibration Extrinsics

with OpenCV

Note: Assumes good depth camera calibration and intrinsics for the RGB

camera.

The CustomCalibration.h header file in the sample code contained the following

unimplemented prototype:

double RecalibrateRGBCamera(const std::vector<std::vector<cv::Point2f> >& cornersLeft,

const std::vector<std::vector<cv::Point2f> >& cornersRGB, const cv::Size& chessboardSize,

float checkerSize, const cv::Mat& Kl, const cv::Mat& Dl, const cv::Mat& Kc, const

cv::Mat& Dc, cv::Mat& Rlc, cv::Mat& Tlc);

Page 48

48

Developing Custom Calibration Application

5.7 Writing Calibration Parameters

A user custom calibration app can choose one of the two approaches to update the

results to the device:

To link to the WriteCustomCalibrationParameters and

ReadCalibrationParameters and write directly to the device through the APIs.

To write the results into a parameter XML file and then use CustomRW to

read/write the parameters to the device.

Custom Calibration Sample Application write the results into a parameter XML file and

use CustomRW to update the calibration parameters to the device.

Page 49

49

Developing Custom Calibration Application

Loading...

Loading...