Page 1

Intel® Server System R2000WF

Product Family

System Integration and Service Guide

A guide providing instructions for the insertion and extraction of system components

and available Intel accessories and spares

Revision 1.0

July 2017

Intel® Server Products and Solutions

Page 2

Intel® Server System R2000WF Product Family System Integration and Service Guide

<This page is intentionally left blank.>

2

Page 3

Intel® Server System R2000WF Product Family System Integration and Service Guide

Document Revision History

Date

July 2017

Revision

Number

1.0 Production Release

Modifications

3

Page 4

Intel® Server System R2000WF Product Family System Integration and Service Guide

Disclaimers

No license (express or implied, by estoppel or otherwise) to any intellectual property rights is granted by this

document.

Intel disclaims all express and implied warranties, including without limitation, the implied warranties of

merchantability, fitness for a particular purpose, and non-infringement, as well as any warranty arising from

course of performance, course of dealing, or usage in trade.

The products and services described may contain defects or errors known as errata which may cause

deviations from published specifications. Current characterized errata are available on request.

You may not use or facilitate the use of this document in connection with any infringement or other legal

analysis concerning Intel products described herein. You agree to grant Intel a non-exclusive, royalty-free

license to any patent claim thereafter drafted which includes subject matter disclosed herein.

Intel, the Intel logo, are trademarks of Intel Corporation in the U.S. and/or other countries.

*Other names and brands may be claimed as the property of others.

© Intel Corporation.

4

Page 5

Intel® Server System R2000WF Product Family System Integration and Service Guide

Safety Information

Important Safety Instructions

Read all caution and safety statements in this document before performing any of the instructions. See also

Intel Server Boards and Server Chassis Safety Information at

http://www.intel.com/support/motherboards/server/sb/cs-010770.htm.

Wichtige Sicherheitshinweise

Lesen Sie zunächst sämtliche Warnund Sicherheitshinweise in diesem Dokument, bevor Sie eine der

Anweisungen ausführen. Beachten Sie hierzu auch die Sicherheitshinweise zu Intel-Serverplatinen und

Servergehäusen auf der

http://www.intel.com/support/motherboards/server/sb/cs-010770.htm.

Consignes de sécurité

Lisez attention toutes les consignes de sécurité et les mises en garde indiquées dans ce document avant de

suivre toute instruction. Consultez Intel Server Boards and Server Chassis Safety Information sur le site

http://www.intel.com/support/motherboards/server/sb/cs-010770.htm.

Instrucciones de seguridad importantes

Lea todas las declaraciones de seguridad y precaución de este documento antes de realizar cualquiera de las

instrucciones. Vea Intel Server Boards and Server Chassis Safety Information en

http://www.intel.com/support/motherboards/server/sb/cs-010770.htm.

重要安全指导

在执行任何指令之前,请阅读本文档中的所有注意事项及安全声明。和/或

®

http://www.intel.com/support/motherboards/server/sb/cs-010770.htm 上的 Intel

Chassis Safety Information(《Intel 服务器主板与服务器机箱安全信息》)。

Server Boards and Server

5

Page 6

Intel® Server System R2000WF Product Family System Integration and Service Guide

Warnings

Heed safety instructions: Before working with your server product, whether you are using this guide or any

other resource as a reference, pay close attention to the safety instructions. You must adhere to the

assembly instructions in this guide to ensure and maintain compliance with existing product certifications

and approvals. Use only the described, regulated components specified in this guide. Use of other

products/components will void the UL listing and other regulatory approvals of the product and will most

likely result in noncompliance with product regulations in the region(s) in which the product is sold.

System power on/off: The power button DOES NOT turn off the system AC power. To remove power from

the system, you must unplug the AC power cord from the wall outlet. Make sure the AC power cord is

unplugged before you open the chassis, add, or remove any components.

Hazardous conditions, devices and cables: Hazardous electrical conditions may be present on power,

telephone, and communication cables. Turn off the server and disconnect the power cord,

telecommunications systems, networks, and modems attached to the server before opening it. Otherwise,

personal injury or equipment damage can result.

Installing or removing jumpers: A jumper is a small plastic encased conductor that slips over two jumper

pins. Some jumpers have a small tab on top that you can grip with your fingertips or with a pair of fine needle

nosed pliers. If your jumpers do not have such a tab, take care when using needle nosed pliers to remove or

install a jumper; grip the narrow sides of the jumper with the pliers, never the wide sides. Gripping the wide

sides can damage the contacts inside the jumper, causing intermittent problems with the function controlled

by that jumper. Take care to grip with, but not squeeze, the pliers or other tool you use to remove a jumper,

or you may bend or break the pins on the board.

Slide / Rail mounted equipment is not to be used as a shelf or a work space

Electrostatic Discharge (ESD)

Electrostatic discharge can cause damage to your computer or the components within it. ESD can occur

without the user feeling a shock while working inside the system chassis or while improperly handling

electronic devices like processors, memory or other storage devices, and add-in cards.

Intel recommends the following steps be taken when performing any procedures described within this

document or while performing service to any computer system.

• Where available, all system integration and/or service should be performed at a properly equipped ESD

workstation

• Wear ESD protective gear like a grounded antistatic wrist strap, sole grounders, and/or conductive shoes

• Wear an anti-static smock or gown to cover any clothing that may generate an electrostatic charge

• Remove all jewelry

• Disconnect all power cables and cords attached to the server before performing any integration or

service

• Touch any unpainted metal surface of the chassis before performing any integration or service

• Hold all circuit boards and other electronic components by their edges only

• After removing electronic devices from the system or from their protective packaging, place them

component side up on to a grounded anti-static surface or conductive foam pad. Do not place electronic

devices on to the outside of any protective packaging.

6

Page 7

Intel® Server System R2000WF Product Family System Integration and Service Guide

Preface

About this document

This document is written for system integrators and service technicians who are responsible for system

assembly, server upgrades, server repair, and component replacement.

This document is divided into two major sections. The first half of the document provides detailed

instructions on how to assemble a system from the bare chassis to a functional server. It will guide you

through the installation of system components and available accessories. The second half of the document

is focused on system service. It provides many reference diagrams used to identify all key physical features

of the system. It also provides detailed instructions for the replacement of field replaceable components.

For the latest revision of this document, go to http://www.intel.com/support

Document Organization

System Integration

Chapter 1 –– Server Building Block System Integration – provides grounds up assembly instructions for the

integration of individual server building blocks, starting with a bare chassis option and installing all the

system boards and major server components, including power supply and system fans. This chapter can be

skipped if the server board and other major components are pre-installed in the system.

Chapter 2 – Essential System Component Integration and Service – provides instructions for adding

essential system components required to complete the integration of the server system. This includes

installation of Processors, Memory, Add-in Cards, and storage devices

Chapter 3 – Options and Accessory Kit Integration and Service – provides instructions for adding and

removing various system options and available accessory option kits that maybe installed in the system.

Chapter 4 – System Software Updates and Configuration - provides instructions for completing the

integration of the server system by updating the system software and accessing the BIOS Setup utility to

configure various system settings.

Chapter 5 – System Packaging Assembly – Provides package assembly instructions when re-using the Intel

packaging the system was originally shipped in.

System Service

Chapter 6 - System Features Overview – provides a high level overview of the Intel® Server System

R2000WF product family. In this chapter, you will find a list of the server system features and illustrations

identifying the major system components.

Chapter 7 – FRU Replacement – provides guidance for the replacement of system components considered

as field replaceable units (FRUs).

Appendix A – Getting Help

Appendix B – System Status LED Operating States and Definition

Appendix C – POST Code Diagnostic LED Decoder Table

Appendix D – POST Code Error

7

Page 8

Intel® Server System R2000WF Product Family System Integration and Service Guide

–

–

–

Additional Information and Software

For additional information about this family of products or any of their supported accessories, refer to the

following resources available at: http://www.intel.com/support

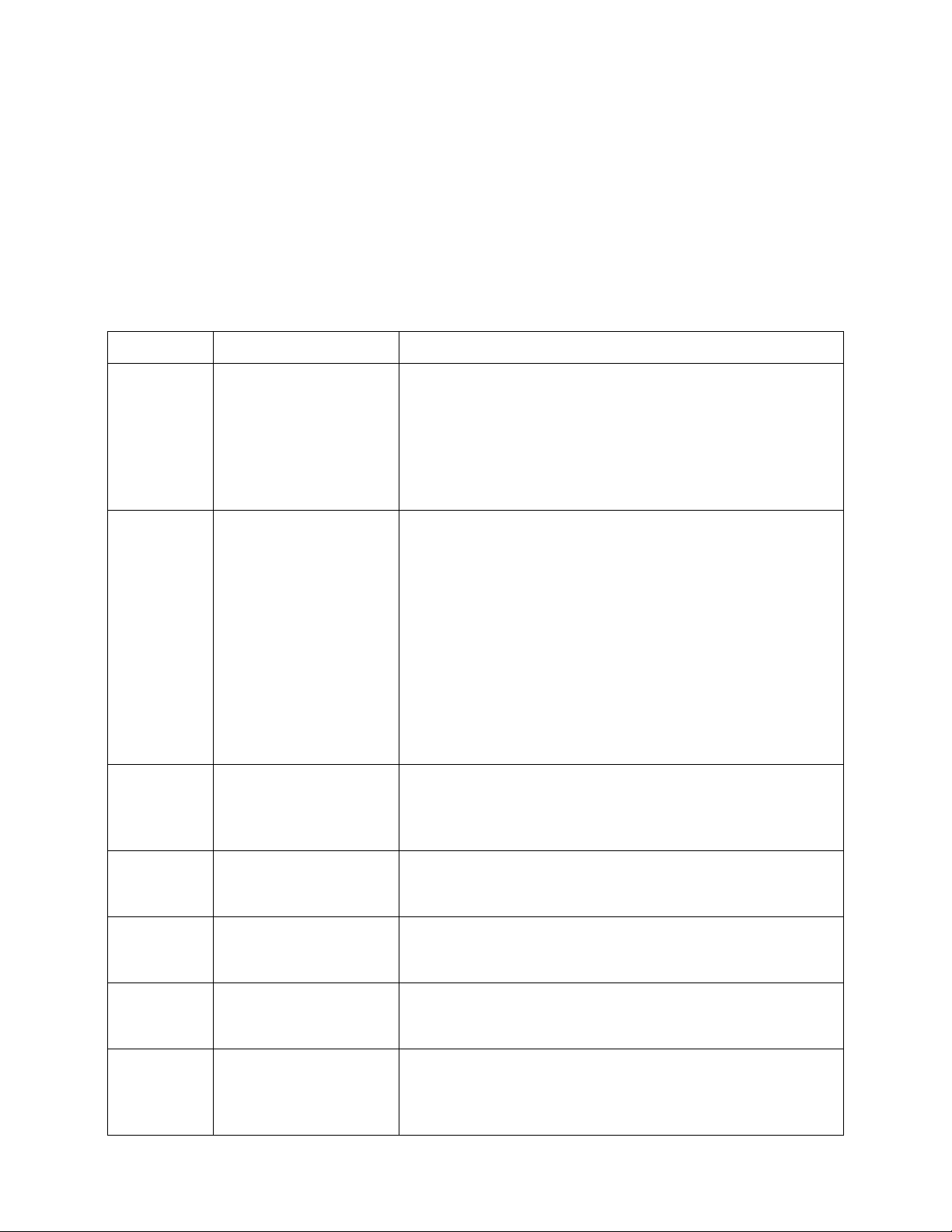

Table 1. Server System References

For this information or software Use this Document or Software

Intel

Intel® Server System R2000WF Product Family Technical Product Specification

Intel® Remote Management Module 4 (Intel® RMM4) and Integrated BMC User

For in-depth technical information about

this product family

For system integration instructions and

service guidance

For server configuration guidance and

compatibility

For system power budget guidance

For system firmware updates, onboard

device drivers, and software to manage

your Intel® Server System

For a complete list of supported

processors, memory, add-in cards, and

peripherals

Intel® Remote Management Module 4 Technical Product Specification

Intel® Server System BIOS Setup Utility Guide

Product Safety and Regulatory Compliance - Intel® Xeon® processor Scalable

Intel® Server System R2000WF

Intel® S2600WF Product Family Configuration Guide

Intel on-line Server Configurator Tool

Intel

Configuration Guide

http://downloadcenter.intel.com/.

Intel online Server Configurator Tool

®

Server Board S2600WF Technical Product Specification

Guide

Family

Guide

®

Server Board S2600WF Product Family Power Budget Tool and Thermal

Product Family System Integration and Service

The server system has support for several software utilities which can be used to configure system

parameters and aid in troubleshooting system issues. All available utilities can be downloaded from the

following Intel web site: http://downloadcenter.intel.com/

.

Table 2. System Utility Software

To do this: Use this utility:

To obtain full system information Intel® SYSINFO Utility

To read System Event Log (SEL) Intel® SELVIEW Utility

Configure, Save and Restore various system options

Test onboard feature functionality Intel® Platform Confidence Test (PCT) – uEFI only

To update system software

To configure and manage Intel® RAID Controllers Intel® RAID Web Console 2 Utility – Various OS support

Server Management Software Intel® Active System Console

Intel® SYSCFG Utility

• System Update Package (SUP) – uEFI only

• Intel® One Boot Flash Update (OFU) – Various OS Support

Various OS support

Various OS support

Various OS support

8

Page 9

Intel® Server System R2000WF Product Family System Integration and Service Guide

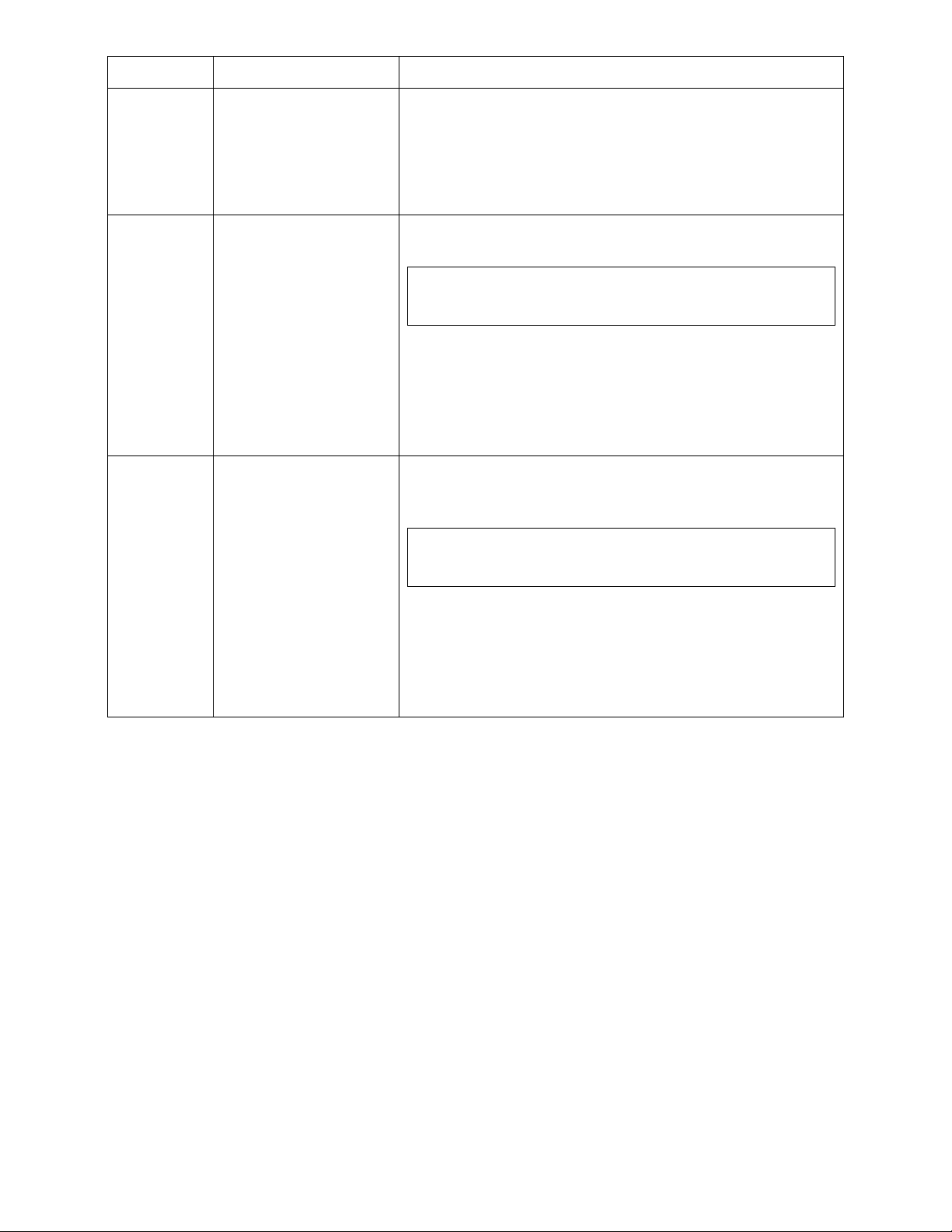

Table of Contents

1 Server Building Block System Integration .......................................................................................................... 17

®

1.1 Intel

1.1.1 Chassis Component Identification .......................................................................................................................... 18

1.2 Prepare Chassis for Assembly .................................................................................................................................. 19

1.3 System Assembly ........................................................................................................................................................... 21

1.3.1 8 x 2.5” Front Drive Bay Module Installation (Intel® Server Chassis R2000WFxxx and Intel®

Server System R2208WFxxxx) .................................................................................................................................................... 22

1.3.2 Internal Cable Routing and Connections ............................................................................................................. 24

1.3.3 PCIe NVMe Support ...................................................................................................................................................... 30

1.3.4 Riser Card Assembly ..................................................................................................................................................... 30

1.3.5 Power Supply Installation ........................................................................................................................................... 31

2. Essential System Component Installation and Service ................................................................................... 32

2.1 Internal Cable Routing Channels ............................................................................................................................. 33

2.2 System Cover Removal / Installation ..................................................................................................................... 34

2.2.1 System Cover Removal ................................................................................................................................................ 34

Server Chassis Identification ......................................................................................................................... 18

2.2.2 System Cover Installation ........................................................................................................................................... 34

2.3 Air Duct Removal / Installation ................................................................................................................................. 35

2.3.1 Air Duct Removal ............................................................................................................................................................ 35

2.3.2 Air Duct Installation ....................................................................................................................................................... 35

2.4 System Fan Module Removal / Installation......................................................................................................... 36

2.4.1 System Fan Module Removal .................................................................................................................................... 36

2.4.2 System Fan Module Installation............................................................................................................................... 37

2.5 Processor Assembly, Installation, and Replacement ...................................................................................... 38

2.5.1 PHM Assembly ................................................................................................................................................................ 39

2.5.2 Processor Installation ................................................................................................................................................... 41

2.5.3 Processor Replacement ............................................................................................................................................... 44

2.6 Memory Module (DIMM) Installation and Replacement ................................................................................ 46

2.6.1 DDR4 DIMM Installation .............................................................................................................................................. 48

2.6.2 DDR4 DIMM Replacement .......................................................................................................................................... 48

2.7 Drive Carrier Extraction, Installation, and Assembly ....................................................................................... 49

2.7.1 Drive Carrier Extraction ................................................................................................................................................ 49

2.7.2 Drive Carrier Installation ............................................................................................................................................. 49

2.7.3 2.5” HDD / SSD Drive Carrier Assembly ................................................................................................................ 50

2.7.4 3.5” HDD/SSD Drive Carrier Assembly .................................................................................................................. 51

2.7.5 2.5” SSD into a 3.5” Drive Carrier Assembly ....................................................................................................... 52

2.8 Internal Fixed Mount SATA SSD – Installation / Removal ............................................................................. 55

2.8.1 Internal Fixed Mount Solid State Drive Installation ......................................................................................... 55

2.8.2 Internal Fixed Mount Solid State Drive Removal .............................................................................................. 56

2.9 Riser Card Bracket Assembly - Removal / Integration / Installation ........................................................ 57

2.9.1 Riser Card Bracket Removal ....................................................................................................................................... 57

9

Page 10

Intel® Server System R2000WF Product Family System Integration and Service Guide

2.9.2 PCI Add-in Card Installation ...................................................................................................................................... 58

2.9.3 Riser Card Bracket Installation ................................................................................................................................. 59

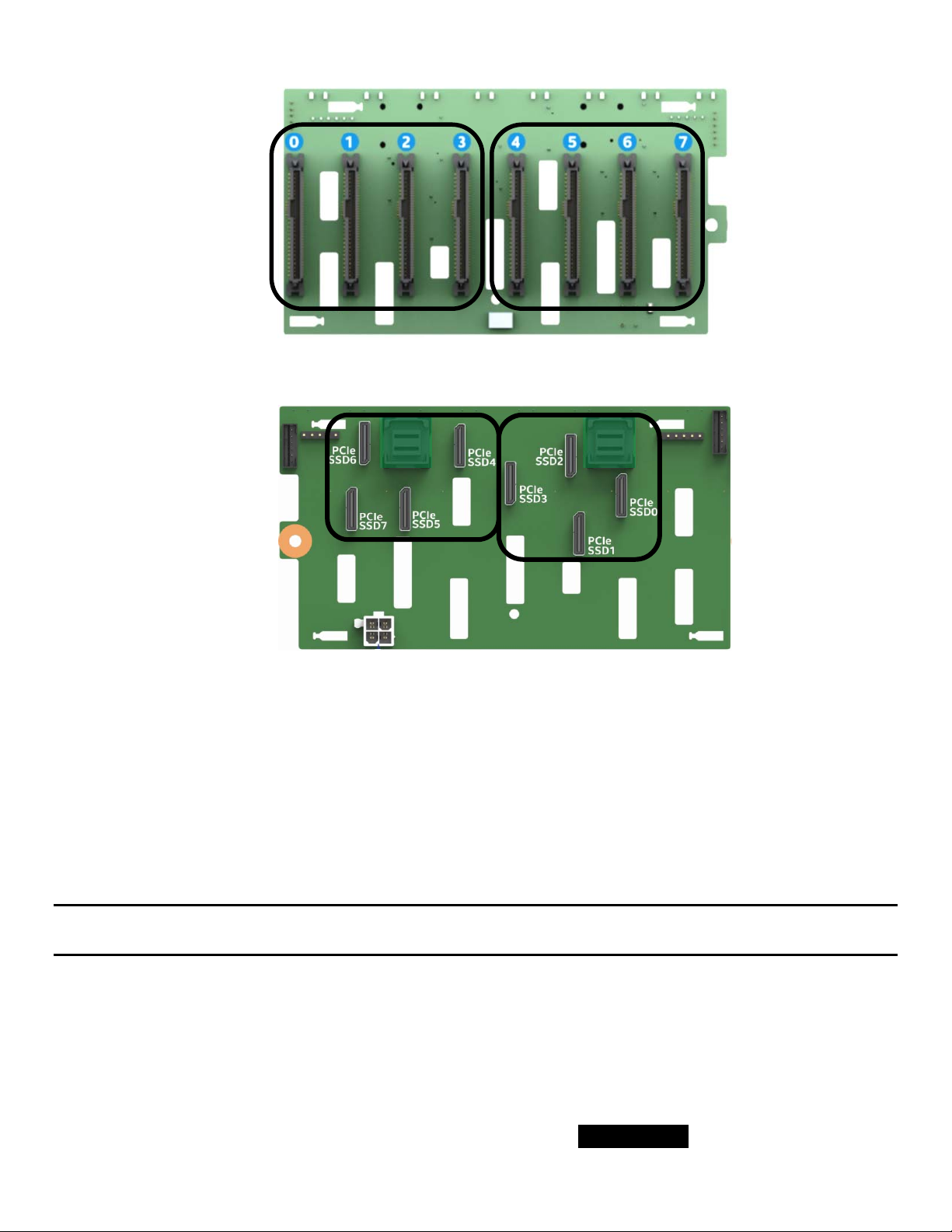

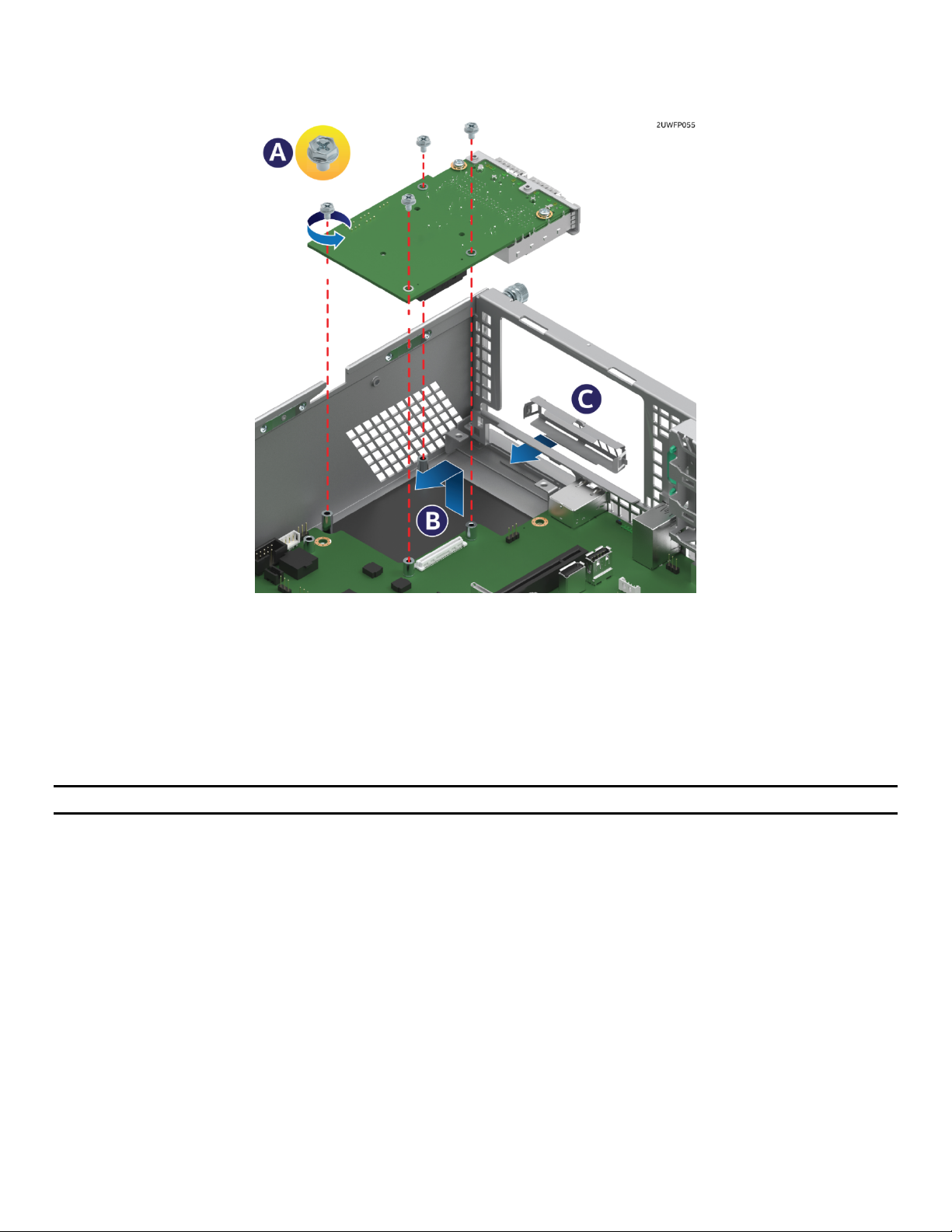

2.10 PCIe* NVMe SSD Support ........................................................................................................................................... 60

2.10.1 Installing the Intel® VROC Upgrade Key ............................................................................................................... 61

2.10.2 Removing the Intel® VROC Upgrade Key .............................................................................................................. 61

2.10.3 NVMe* Drive Population Rules for Intel® VROC ................................................................................................ 61

3. Configuration Options and Accessory Kit Integration and Service ............................................................... 66

3.1 Power Supply Module – Installation / Removal ................................................................................................ 67

3.1.1 2

nd

Power Supply Module Installation .................................................................................................................. 67

3.1.2 Power Supply Module Removal ............................................................................................................................... 67

3.1.3 Power Cord Retention Strap Installation ............................................................................................................. 68

3.2 ESRT2 SATA RAID 5 Upgrade Key – Installation / Removal ......................................................................... 69

3.2.1 ESRT2 SATA RAID 5 Upgrade Key Installation .................................................................................................. 69

3.2.2 ESRT2 SATA RAID 5 Upgrade Key Removal ....................................................................................................... 69

3.3 Intel

®

Remote Management Module 4 Lite Key – Installation / Removal ................................................ 70

3.3.1 Intel® RMM4 Lite Key Installation ............................................................................................................................ 70

3.3.2 Intel® RMM4 Lite Key Removal ................................................................................................................................. 70

3.4 Trusted Platform Module (TPM) Installation ...................................................................................................... 71

3.5 M.2 Memory Devices ..................................................................................................................................................... 71

3.5.1 M.2 Installation ................................................................................................................................................................ 71

3.5.2 M.2 Removal ..................................................................................................................................................................... 72

3.6 OCP Expansion Module – Installation / Removal ............................................................................................. 73

3.6.1 OCP Expansion Module Installation ....................................................................................................................... 73

3.6.2 OCP Expansion Module Removal ............................................................................................................................ 74

3.7 Intel® SAS RAID Module Installation/Removal ................................................................................................... 75

3.7.1 Intel® SAS RAID Module Installation ...................................................................................................................... 75

3.7.2 Intel® SAS RAID Module Removal............................................................................................................................ 75

3.8 Intel

®

RAID Maintenance Free Backup Unit (RMFBU) – Mounting Bracket Installation ..................... 76

3.9 Intel® Omni-Path IFT Carrier Accessory Kit Installation ................................................................................. 77

3.9.1 Intel® Omni-path IFT Carrier Kit (iPC AWF1PFABKITM) – Installation ..................................................... 77

3.9.2 Intel® Omni-path IFT Carrier Kit (iPC AWF1PFABKITP) – Installation ...................................................... 79

3.10 2 x 2.5” Rear Mount Backplane Module Accessory Kit (iPC- A2UREARHSDK1) ................................... 82

3.11 Intel® SAS Expander Card Installation ................................................................................................................... 85

3.11.1 2.5” Front Drive Bay Support .................................................................................................................................... 85

3.11.2 3.5” Front Drive Bay Support .................................................................................................................................... 86

3.11.3 Intel® RAID Expander Card Cabling Overview .................................................................................................... 86

3.12 R2208WF Upgrade to 16 Drive Configuration ................................................................................................... 87

3.13 24 Drive Upgrade Option ............................................................................................................................................ 88

4. System Software Updates and Configuration .................................................................................................... 93

4.1 Updating the System Software Stack .................................................................................................................... 93

4.2 Using the BIOS Setup Utility ...................................................................................................................................... 93

4.2.1 Entering BIOS Setup ..................................................................................................................................................... 93

10

Page 11

Intel® Server System R2000WF Product Family System Integration and Service Guide

4.2.2 No Access to the BIOS Setup Utility ....................................................................................................................... 93

4.2.3 Navigating the BIOS Setup Utility ............................................................................................................................ 94

5. System Packaging Assembly Instructions .......................................................................................................... 96

6. System Service- System Features Overview .................................................................................................... 101

6.1 System Feature Reference Diagrams .................................................................................................................. 101

6.1.1 Front Drive Bay Options ........................................................................................................................................... 102

6.1.2 Control Panel Features ............................................................................................................................................. 103

6.1.3 Front I/O Features (Non-Storage Systems) ...................................................................................................... 104

6.1.4 Back Panel Features ................................................................................................................................................... 105

6.1.5 Server Board Features ............................................................................................................................................... 105

6.2 System Configuration and Recovery Jumpers ............................................................................................... 107

6.2.1 BIOS Default Jumper Block .................................................................................................................................... 108

6.2.2 Password Clear Jumper Block ............................................................................................................................... 108

6.2.3 Management Engine (ME) Firmware Force Update Jumper Block ......................................................... 109

6.2.4 BMC Force Update Jumper Block ........................................................................................................................ 109

6.2.5 BIOS Recovery Jumper ............................................................................................................................................. 110

6.2.6 Serial Port ‘A’ Configuration Jumper .................................................................................................................. 111

7. System Service - FRU Replacement ................................................................................................................... 112

7.1 System Fan Replacement ........................................................................................................................................ 113

7.1.1 To remove a failed system fan............................................................................................................................... 113

7.1.2 To install a new system fan ..................................................................................................................................... 113

7.2 Replacing the System Battery ................................................................................................................................ 114

7.3 Standard Rack Handle – Installation / Removal ............................................................................................. 115

7.3.1 Standard Rack Handle Installation ...................................................................................................................... 115

7.3.2 Standard Rack Handle Removal ........................................................................................................................... 115

7.4 Standard Front Control Panel Replacement (R2308WFxxx) .................................................................... 116

7.4.1 Standard Front Control Panel Removal (R2308WFxxx) .............................................................................. 116

7.4.2 Standard Front Control Panel Installation (R2308WFxxx) ......................................................................... 117

7.5 Standard Front Control Panel Replacement (R2208WFxxx) .................................................................... 119

7.5.1 Standard Front Control Panel Removal (R2208WFxxx) .............................................................................. 119

7.5.2 Standard Front Control Panel Installation (R2208WFxxx) ......................................................................... 120

7.6 Replacing the Server Board .................................................................................................................................... 122

7.6.1 Server Board Removal .............................................................................................................................................. 122

7.6.2 Server Board Installation ......................................................................................................................................... 123

Appendix A. Getting Help ........................................................................................................................................ 125

Appendix B. System Status LED Operating States and Definition ................................................................. 126

Appendix C. POST Code Diagnostic LED Decoder Table ................................................................................. 128

Appendix D. POST Code Errors ..............................................................................................................

11

................ 134

Page 12

Intel® Server System R2000WF Product Family System Integration and Service Guide

List of Figures

Figure 1. Intel® Server Chassis R2000WFxxx – No Installed Front Drive Accessory Kit Options ............................. 18

Figure 2. Chassis Components ............................................................................................................................................................ 18

Figure 3. Chassis Cover Removal ........................................................................................................................................................ 19

Figure 4. System Fan Module Removal ............................................................................................................................................ 20

Figure 5. Server Board Installation .................................................................................................................................................... 21

Figure 6. Air Duct Side Wall Installation .......................................................................................................................................... 22

Figure 7. R2000WFxxx Drive Bay Retention Bracket Removal ............................................................................................... 22

Figure 8. Drive Bay Filler Panel Removal ......................................................................................................................................... 23

Figure 9. 8 x 2.5" Drive Bay Module Installation ........................................................................................................................... 23

Figure 10. Drive Bay Retention Bracket Installation ................................................................................................................... 24

Figure 11. Internal Cable Routing Channels .................................................................................................................................. 25

Figure 12. Front Control Panel and Front I/O Internal Cable Connections ...................................................................... 26

Figure 13. Hot Swap Backplane Connectors ................................................................................................................................. 27

Figure 14. 2.5” Drive Module Hot Swap Backplane Power Cable ......................................................................................... 27

Figure 15. HSBP POWER Connector ................................................................................................................................................. 27

Figure 16. I

Figure 17. Hot Swap Backplane I

Figure 18. Dual 8x2.5" Hot Swap Backplane I

2

C cable ................................................................................................................................................................................... 28

2

C Internal Cable Connector ............................................................................................... 28

2

C Jumper Cable Installation ..................................................................... 29

Figure 19. SATA Cable ............................................................................................................................................................................. 29

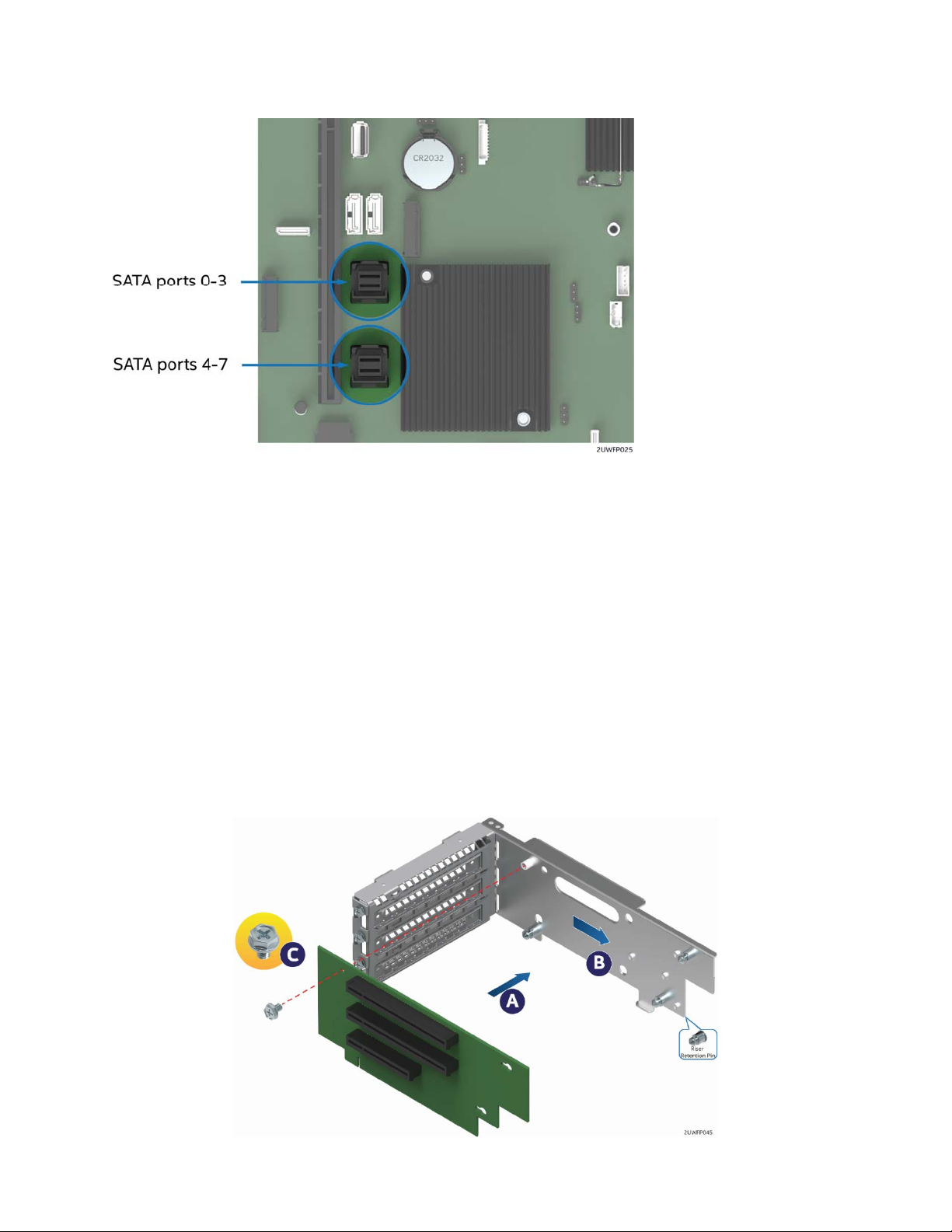

Figure 20. Onboard Connectors for Embedded SATA Support (S2600WFT and S2600WF0 only) ...................... 30

Figure 21. Riser Card Assembly........................................................................................................................................................... 30

Figure 22. Power Supply Installation ................................................................................................................................................ 31

Figure 23. Internal Cable Routing Channels .................................................................................................................................. 33

Figure 24. System Cover Removal ..................................................................................................................................................... 34

Figure 25. System Cover Installation ................................................................................................................................................ 34

Figure 26. Air Duct Removal ................................................................................................................................................................. 35

Figure 27. Air Duct Installation ............................................................................................................................................................ 35

Figure 28. System Fan Module Removal ......................................................................................................................................... 36

Figure 29. System Fan Module Installation .................................................................................................................................... 37

Figure 30. Processor Heat Sink Module (PHM) Reference Diagram ..................................................................................... 38

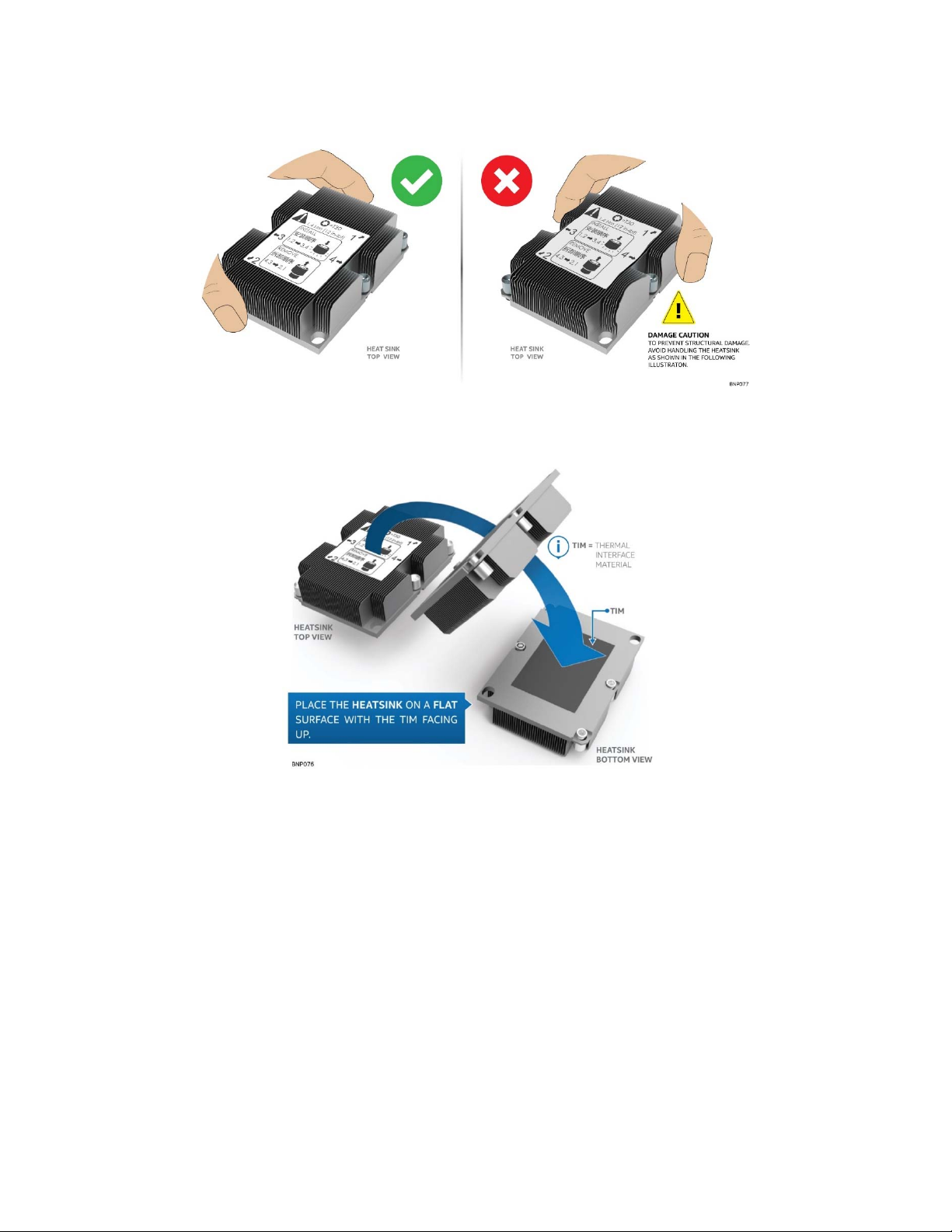

Figure 31. Processor Heat Sink Handling ........................................................................................................................................ 39

Figure 32. PHM Assembly – Heat Sink Orientation ..................................................................................................................... 39

Figure 33. Processor Carrier Clip Assembly ................................................................................................................................... 40

Figure 34. Processor Carrier Clip Sub-Assembly ......................................................................................................................... 40

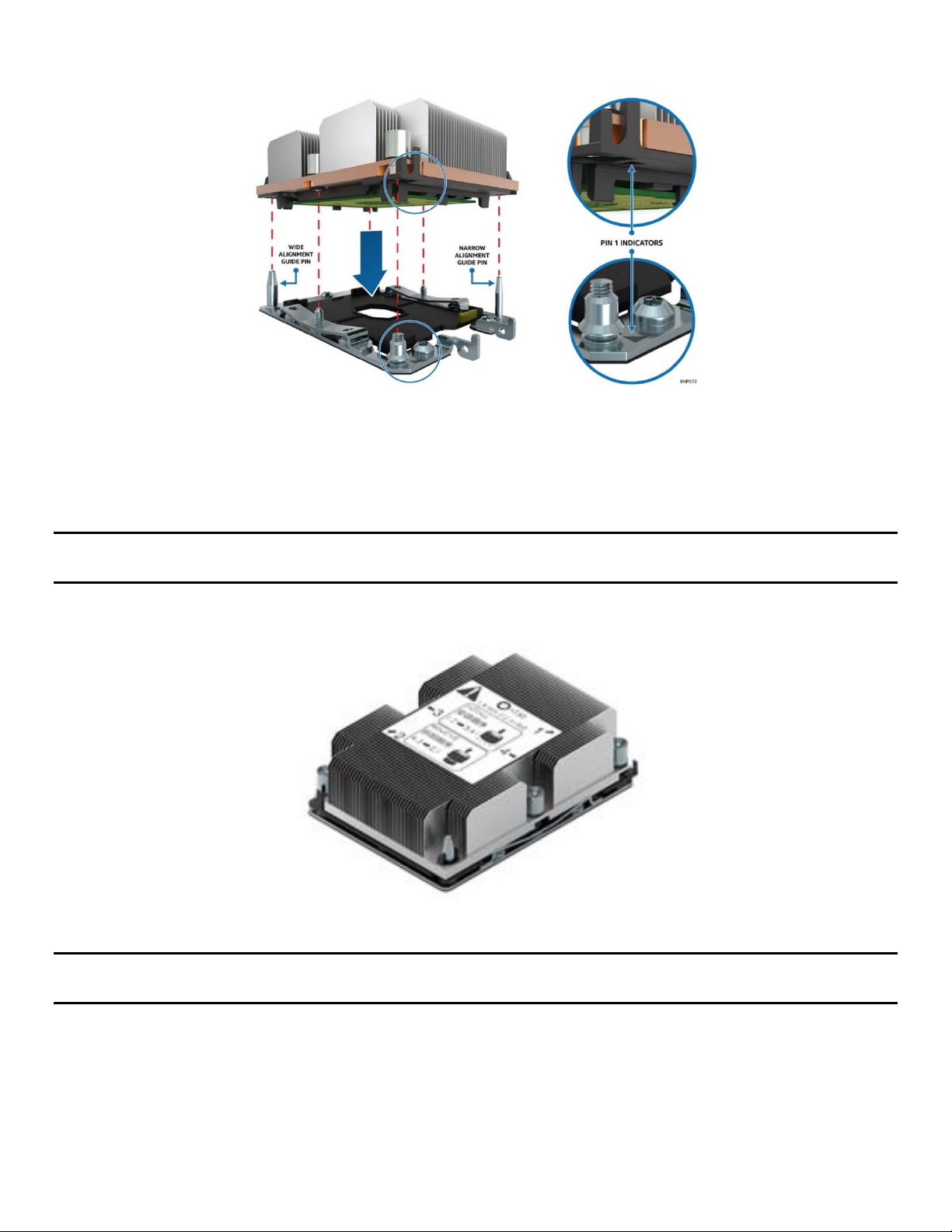

Figure 35. Processor Clip Sub-assembly to Heat Sink Orientation ..................................................................................... 41

Figure 36. Processor Heat Sink Module (PHM) ............................................................................................................................. 41

Figure 37. Plastic processor socket cover removal .................................................................................................................... 42

Figure 38. Processor Installation Alignment Features ............................................................................................................... 42

Figure 39. PHM Alignment to Bolster Plate .................................................................................................................................... 43

Figure 40. Correct PHM Placement ................................................................................................................................................... 43

12

Page 13

Intel® Server System R2000WF Product Family System Integration and Service Guide

Figure 41. Installing the PHM ............................................................................................................................................................... 44

Figure 42. Uninstalling the Processor Heat Sink Module (PHM) ........................................................................................... 44

Figure 43. Plastic Processor Socket Cover Installation ............................................................................................................. 45

Figure 44. PHM Disassembly ................................................................................................................................................................ 45

Figure 45. Releasing the Processor Carrier Clip from the Heat Sink ................................................................................... 46

Figure 46. Releasing Processor from Processor Clip ................................................................................................................. 46

Figure 47. DIMM Blank ............................................................................................................................................................................ 47

Figure 48. Memory Slot Population Requirements – 8x2.5, 16x2.5, 8x3.5 Front Drive Configurations ............... 47

Figure 49. Memory Slot Population Requirements – 24x2.5, 12x3.5 Front Drive Configurations .......................... 47

Figure 50. DIMM Installation ................................................................................................................................................................. 48

Figure 51. DIMM Removal ...................................................................................................................................................................... 48

Figure 52. Drive Carrier Extraction from Chassis ......................................................................................................................... 49

Figure 53. Drive Carrier into Chassis Installation ......................................................................................................................... 49

Figure 54. 2.5” Drive Carrier Assembly – Drive / Drive Blank Removal .............................................................................. 50

Figure 55. 2.5” Drive Carrier Assembly – Drive Installation to Carrier ................................................................................ 50

Figure 56. 2.5” Drive Carrier Assembly – Alignment Features ............................................................................................... 51

Figure 57. 3.5" Drive Carrier Assembly - Drive / Drive Blank Removal ............................................................................... 51

Figure 58. 3.5” Drive Carrier Assembly – Drive Installation to Carrier ................................................................................ 52

Figure 59. 3.5" Drive Carrier Assembly – Drive Blank Removal ............................................................................................. 52

Figure 60. 3.5" Drive Carrier to 2.5” SSD Bracket – Tab Removal ......................................................................................... 53

Figure 61. 3.5" Drive Carrier to 2.5” SSD Bracket – Mount SSD to Bracket ....................................................................... 53

Figure 62. 3.5" Drive Carrier to 2.5” SSD Bracket – Mount Bracket Assembly to Carrier ............................................ 54

Figure 63. 3.5" Drive Carrier to 2.5” SSD Bracket – Secure SSD to Carrier........................................................................ 54

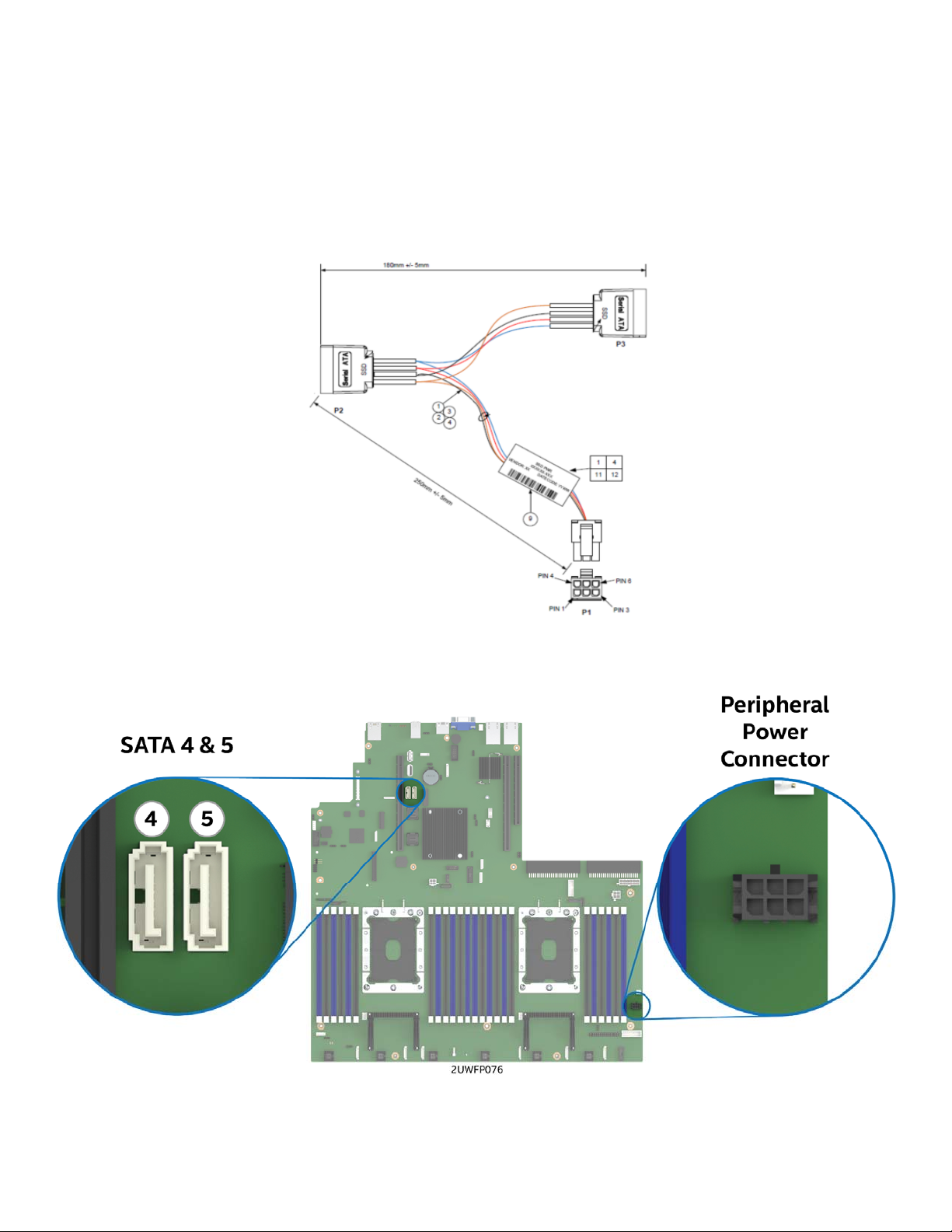

Figure 64. Peripheral Device Power Cable ..................................................................................................................................... 55

Figure 65. Onboard Peripheral Power and SATA Connectors for Internal SSD support ............................................ 55

Figure 66. Internal Fixed Mount SSD Placement ......................................................................................................................... 56

Figure 67. Internal Fixed Mount SSD Removal ............................................................................................................................. 56

Figure 68. Riser Card Brackets ............................................................................................................................................................. 57

Figure 69. Riser Card Bracket Removal ............................................................................................................................................ 57

Figure 70. PCI Add-In Card Installation ........................................................................................................................................... 58

Figure 71. Riser Card Bracket Installation ....................................................................................................................................... 59

Figure 72. Installing the Intel® VROC Upgrade Key ..................................................................................................................... 61

Figure 73. Backplane Cabling from Two PCIe Sources ............................................................................................................. 62

Figure 74. Power Supply Module Installation ............................................................................................................................... 67

Figure 75. Power Supply Module Removal .................................................................................................................................... 67

Figure 76. Power Cord Retention Strap Installation ................................................................................................................... 68

Figure 77. Plugging the Power Cable ................................................................................................................................................ 68

Figure 78. SATA RAID 5 Upgrade Key Installation ...................................................................................................................... 69

Figure 79. Intel

®

RMM4 Lite Key Installation .................................................................................................................................. 70

Figure 80. Trusted Platform Module (TPM) Installation ........................................................................................................... 71

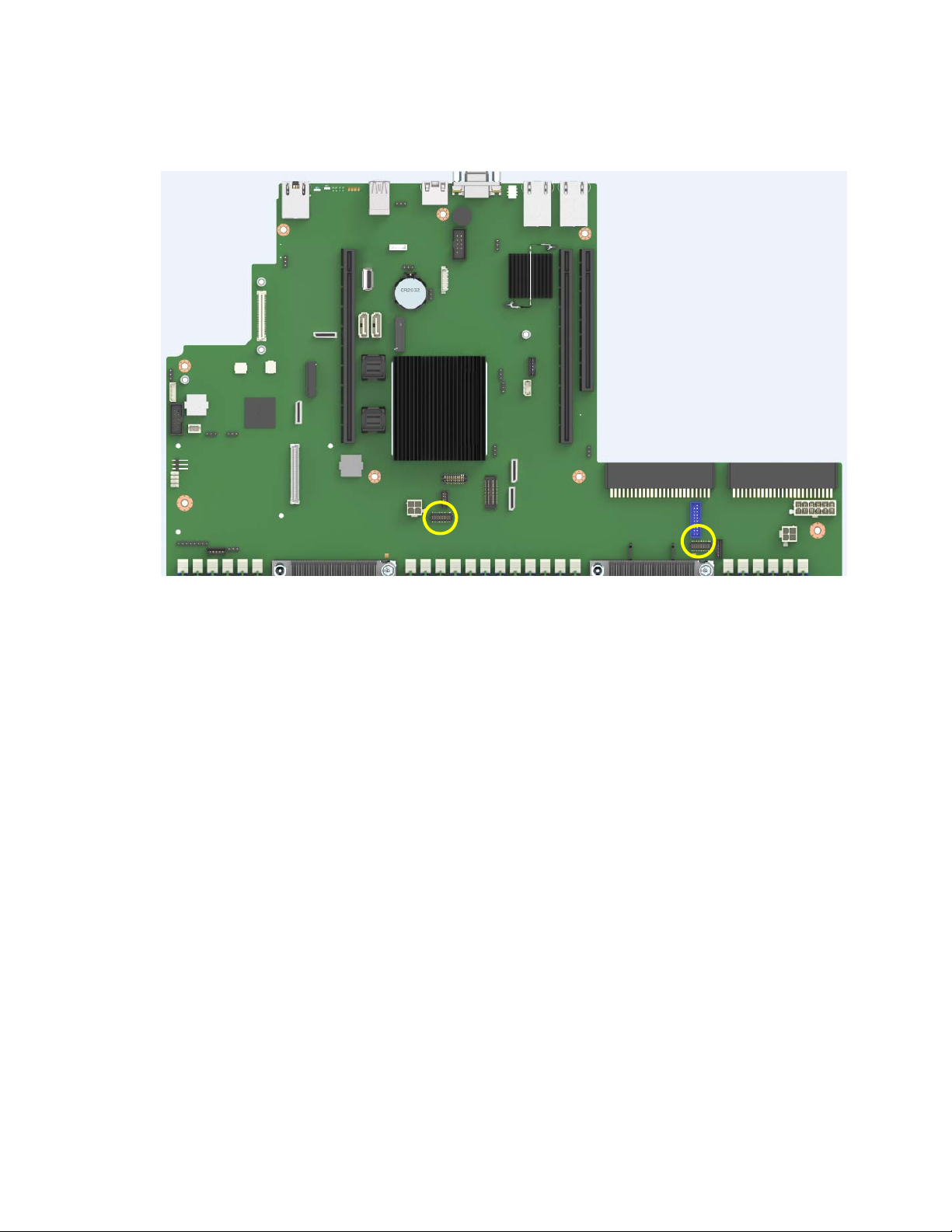

Figure 81. M.2 SSD Connector Locations ........................................................................................................................................ 71

Figure 82. M.2 Device Installation ...................................................................................................................................................... 72

13

Page 14

Intel® Server System R2000WF Product Family System Integration and Service Guide

Figure 83. M.2 Device Removal ........................................................................................................................................................... 72

Figure 84. OCP Expansion Module Installation ............................................................................................................................ 73

Figure 85. OCP Expansion Module Removal ................................................................................................................................. 74

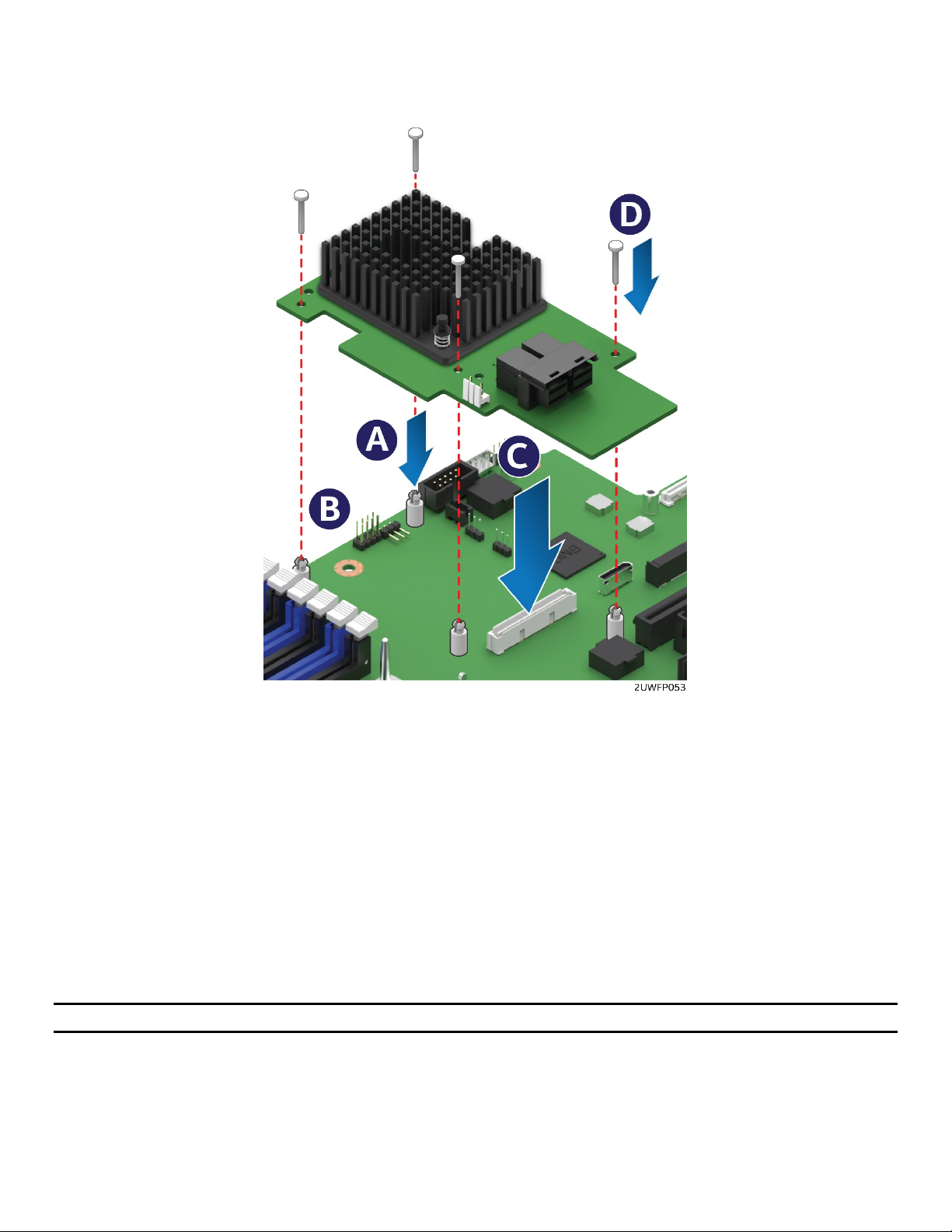

Figure 86. Intel® SAS RAID Module Installation ............................................................................................................................ 75

Figure 87. Intel® RMFBU Installation ................................................................................................................................................. 76

Figure 88. IFT Carrier Mezzanine Card Assembly ........................................................................................................................ 77

Figure 89. IFT Mezzanine Card Installation .................................................................................................................................... 78

Figure 90. Fabric Processor Cable Installation ............................................................................................................................. 78

Figure 91. Onboard Omni-path Sideband Signal Connectors ............................................................................................... 79

Figure 92. IFT Carrier Add-in Card Assembly ................................................................................................................................ 80

Figure 93. IFT Carrier Add-in Card Installation ............................................................................................................................. 80

Figure 94. Fabric Processor Cable Installation ............................................................................................................................. 81

Figure 95. 2 x 2.5" Rear Mount Backplane Module Installation ............................................................................................. 82

Figure 96. Rear HSBP Power Cable .................................................................................................................................................... 82

Figure 97. Rear HSBP I2C Cable .......................................................................................................................................................... 82

Figure 98. Rear HSBP SATA & SGPIO Cable Bundle ................................................................................................................... 83

Figure 99. Rear Backplane Cable Connectors ............................................................................................................................... 83

Figure 100. SAS Expander Mezzanine Card Installation ........................................................................................................... 85

Figure 101. 12 Gb Intel® RAID Expander Card RES3FV288 Connector Identification .................................................. 86

Figure 102. Internal 12 Gb Intel® RAID Expander Card RES3TV360 - Connector Identification Block Diagram

.................................................................................................................................................................................................................. 86

Figure 103. Standard Rack Handle Removal ................................................................................................................................. 88

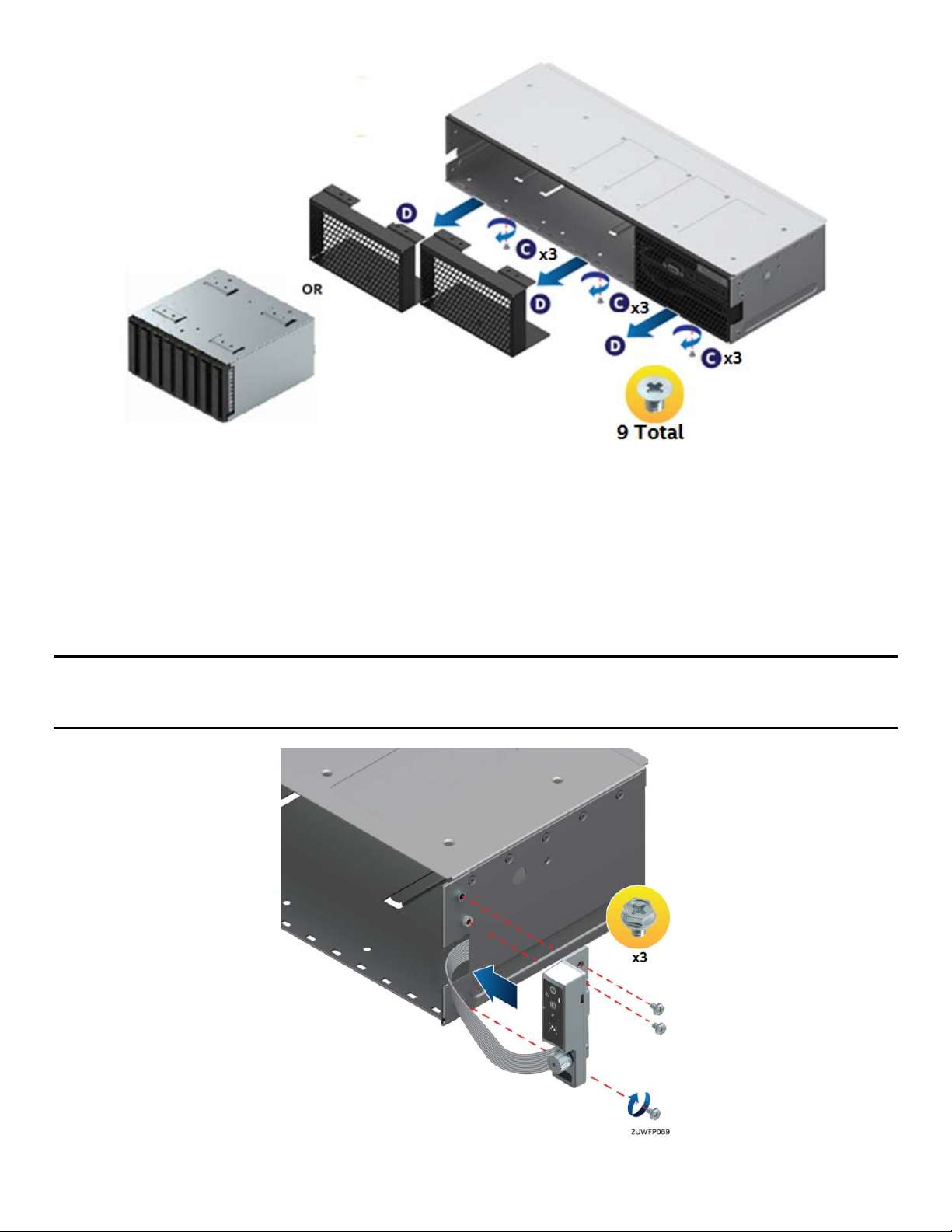

Figure 104. Drive Bay Disassemly – Retention Bracket Removal .......................................................................................... 89

Figure 105. Drive Bay Disassembly – Module Removal ............................................................................................................ 90

Figure 106. Storage Rack Handle Installation ............................................................................................................................... 90

Figure 107. Server Board USB 2.0 Header ...................................................................................................................................... 91

Figure 108. Installing the 8 x 2.5” Drive Bay Module(s) ............................................................................................................. 91

Figure 109. Installing Drive Bay Retention Bracket ..................................................................................................................... 92

Figure 110. Intel

®

Server System R2000WF Features Overview ......................................................................................... 101

Figure 111. No Drives – Chassis only building block (Intel® Server Chassis R2000WFXXX) .................................. 102

Figure 112. 8 x 3.5" Drive Bay Configuration (Intel® Server System R2308WF….) ...................................................... 102

Figure 113. 12 x 3.5" Drive Bay Configuration (Intel® Server System R2312WF… – Storage System) ............... 102

Figure 114. 8 x 2.5" Drive Bay Configuration (Intel® Server System R2208WF….) ...................................................... 102

Figure 115. 16 x 2.5" Drive Bay Configuration (Intel® Server System R2208WF…. + 8x2.5” drive option) ....... 103

Figure 116. 24 x 2.5" Drive Bay Configuration (Intel® Server System R2224WF…. – Storage System) .............. 103

Figure 117. Control Panel Features ................................................................................................................................................ 103

Figure 118. Front I/O Panel Features ............................................................................................................................................. 104

Figure 119. Hot Swap Drive Carrier LED Identification .......................................................................................................... 104

Figure 120. Back Panel Features ...................................................................................................................................................... 105

Figure 121. Server Board Feature Identification ....................................................................................................................... 105

Figure 122. Intel

®

Light-Guided Diagnostic LEDs - Server Board ....................................................................................... 106

Figure 123. DIMM Fault LEDs ............................................................................................................................................................ 107

14

Page 15

Intel® Server System R2000WF Product Family System Integration and Service Guide

Figure 124. System Configuration and Recovery Jumpers .................................................................................................. 107

Figure 125. System Fan Removal .................................................................................................................................................... 113

Figure 126. Replacing the Backup Battery ................................................................................................................................... 114

Figure 127. Standard Rack Handle Installation ......................................................................................................................... 115

Figure 128. Standard Rack Handle Removal .............................................................................................................................. 115

Figure 129. Removing the Drive Bay Module ............................................................................................................................. 116

Figure 130. Control Panel Board Removal .................................................................................................................................. 117

Figure 131. Control Panel Board Installation ............................................................................................................................. 117

Figure 132. 3.5”x8 Drive Bay Module Installation .................................................................................................................... 118

Figure 133. 3.5”x8 Drive Bay Module Retention Clip Installation ...................................................................................... 118

Figure 134. I/O Bay Module Remova ............................................................................................................................................. 120

Figure 135. Control Panel Board Installation ............................................................................................................................. 120

Figure 136. I/O Bay Module Installation ....................................................................................................................................... 121

Figure 137. Retention Bracket Installation .................................................................................................................................. 121

Figure 138. Server Board Removal ................................................................................................................................................. 122

Figure 139. Server Board Installation ............................................................................................................................................ 123

Figure 140. Air Duct Sidewall Installation .................................................................................................................................... 124

Figure 141. POST Diagnostic LED Location ................................................................................................................................ 128

15

Page 16

Intel® Server System R2000WF Product Family System Integration and Service Guide

List of Tables

Table 1. Server System References ...................................................................................................................................................... 8

Table 2. System Utility Software ............................................................................................................................................................ 8

Table 3. BIOS Setup: Keyboard Command Bar ............................................................................................................................ 94

Table 4. System Status LED State Definitions ............................................................................................................................ 126

Table 5. POST Progress Code LED Example ............................................................................................................................... 128

Table 6. MRC Progress Codes ........................................................................................................................................................... 129

Table 7. MRC Fatal Error Codes ....................................................................................................................................................... 130

Table 8. POST Progress Codes ......................................................................................................................................................... 131

Table 9. POST Error Messages and Handling ............................................................................................................................. 135

Table 10. POST Error Beep Codes .................................................................................................................................................. 139

Table 11. Integrated BMC Beep Codes ......................................................................................................................................... 139

16

Page 17

Intel® Server System R2000WF Product Family System Integration and Service Guide

1 Server Building Block System Integration

Purpose

This chapter provides instructions for the integration of the following Intel server building blocks:

®

Intel

Server Chassis R2000WFxxx

+ Any server board from the Intel® Server Board S2600WF product family

+ Available 2.5” drive bay options

If your system came with the server board pre-installed in the chassis, you can skip this chapter and proceed

to Chapter 2 - Essential System Component Installation and Service to continue the system integration.

In addition to the Intel Server building blocks defined above, the following system components (Sold

Separately) will also be needed to complete the full system integration:

Appropriate SAS/SATA Data Cables

Appropriate PCIe OCuLink Data Cables for NVMe support

Appropriate Riser Card(s)

Appropriate Power Supply Module(s)

Processor(s) – Intel® Xeon® processor Scalable family

Memory - DDR4 DIMMs

Appropriate Power Cable(s)

Storage Devices – HDDs, SSDs, M.2

PCIe Add-in Cards

Optional Server System Accessories

Reference the Intel® Server S2600WF Product Family Configuration Guide for a complete list of available

accessories and spares

Before You Begin

Before working with your server product, observe the safety and ESD precautions found in the Warnings

section at the beginning of this manual.

Tools and Supplies Needed

Anti-static wrist strap and conductive foam pad (recommended)

Phillips* (cross head) screwdriver (#1 and #2 bits)

Torx 30 screwdriver

System Reference

All references to left, right, front, top, and bottom assume the reader is facing the front of the chassis.

Instruction Format

Each procedure described in this chapter will follow an illustration first format. This format will give the

reader the option to follow a quicker path to system integration by first seeing an illustration of the intended

procedure. If necessary, the reader can then follow the step-by-step instructions that will accompany each

procedure.

17

Page 18

Intel® Server System R2000WF Product Family System Integration and Service Guide

System Integration Advisory Note

It is highly recommended that the system integration process defined in the following sections within this

chapter be performed in the order specified. Following these instructions will result in the proper

installation of critical system components and provide recommended cable routing. Deviating from the

prescribed process may result in improper system assembly, a longer integration process, and a less than

desired system appearance.

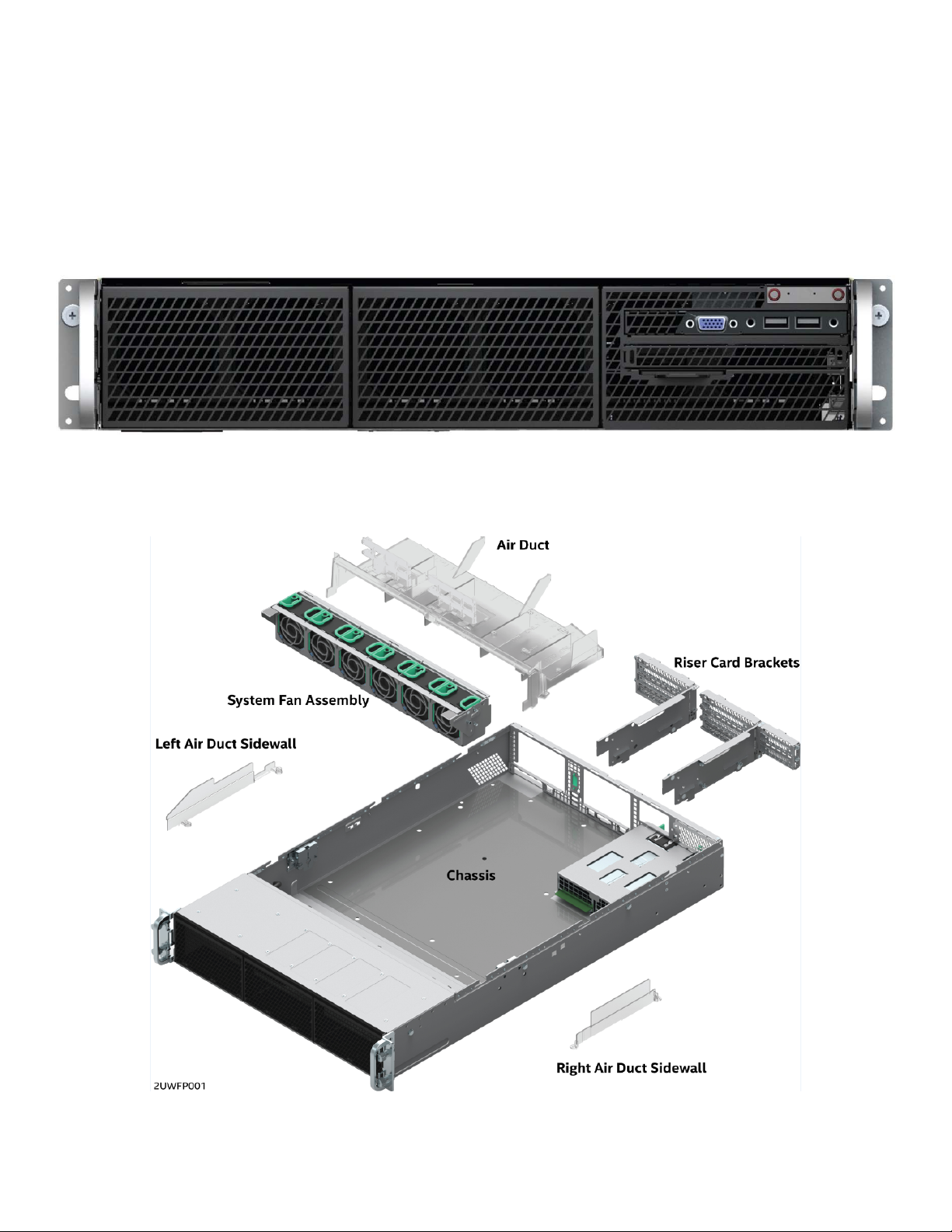

1.1 Intel® Server Chassis Identification

Figure 1. Intel® Server Chassis R2000WFxxx – No Installed Front Drive Accessory Kit Options

1.1.1 Chassis Component Identification

Figure 2. Chassis Components

18

Page 19

Intel® Server System R2000WF Product Family System Integration and Service Guide

1.2 Prepare Chassis for Assembly

As received, the Intel Server Chassis will include several components within a boxed accessory kit or placed

within the chassis.

1. Remove the System Cover

Note: A non-skid surface or a stop behind the server system may be needed to prevent the server system

from sliding on your work surface

Figure 3. Chassis Cover Removal

a) Loosen the two captive thumb screws located on the back edge of the system cover (See letter “A”)

Note: New chassis as shipped from Intel will require a screw driver to loosen the thumb screws

securing the top cover to the chassis.

b) Slide cover back and lift upward (see letter "B").

The accessory kit and or system packaging will include the following components:

The left and right black plastic air duct sidewalls

Separate bags of screws for mounting the server board and riser card module

RAID Maintenance Free Backup Unit (RMFBU) mounting plate and screws

DIMM Blanks

Black Mylar “No CPU” processor socket spacers

The following components will be found inside the chassis. Each should be removed:

Clear plastic air duct and sidewalls

A box with two processor heat sinks

Two riser card brackets

The system fan module

19

Page 20

Intel® Server System R2000WF Product Family System Integration and Service Guide

2. Remove the System Fan Module

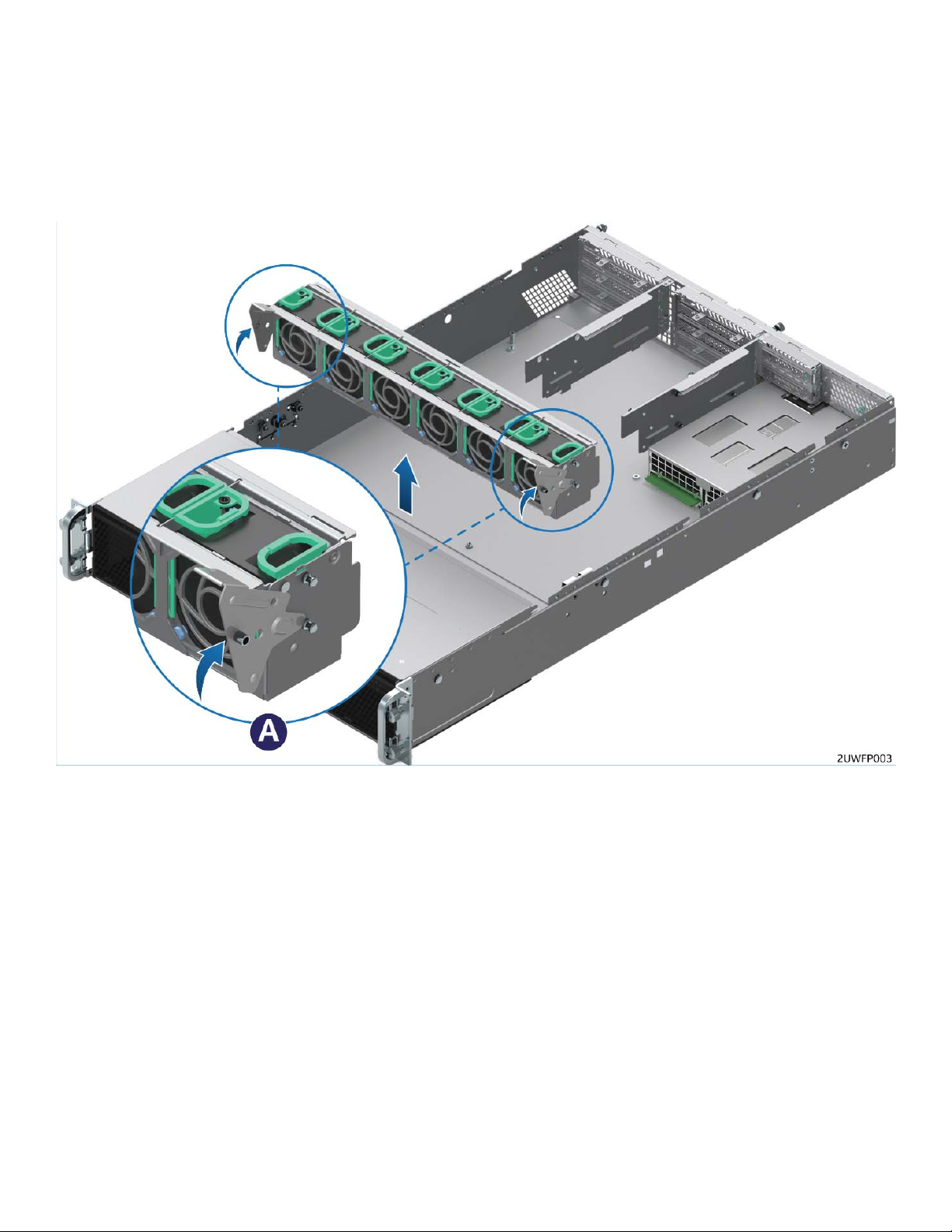

Figure 4. System Fan Module Removal

a) Lift the latches located on each end of the fan module until each latch is fully disengaged from the

latch receivers on the chassis side wall.

b) Grasp each end of the fan module and pull straight up until the module is fully disengaged from the

module receivers on the chassis side wall.

c) Carefully place the fan module face down onto a flat surface. Do NOT rest the fan module on the

fan connectors located on the bottom side of the fan module, doing so may damage the connectors.

20

Page 21

Intel® Server System R2000WF Product Family System Integration and Service Guide

1.3 System Assembly

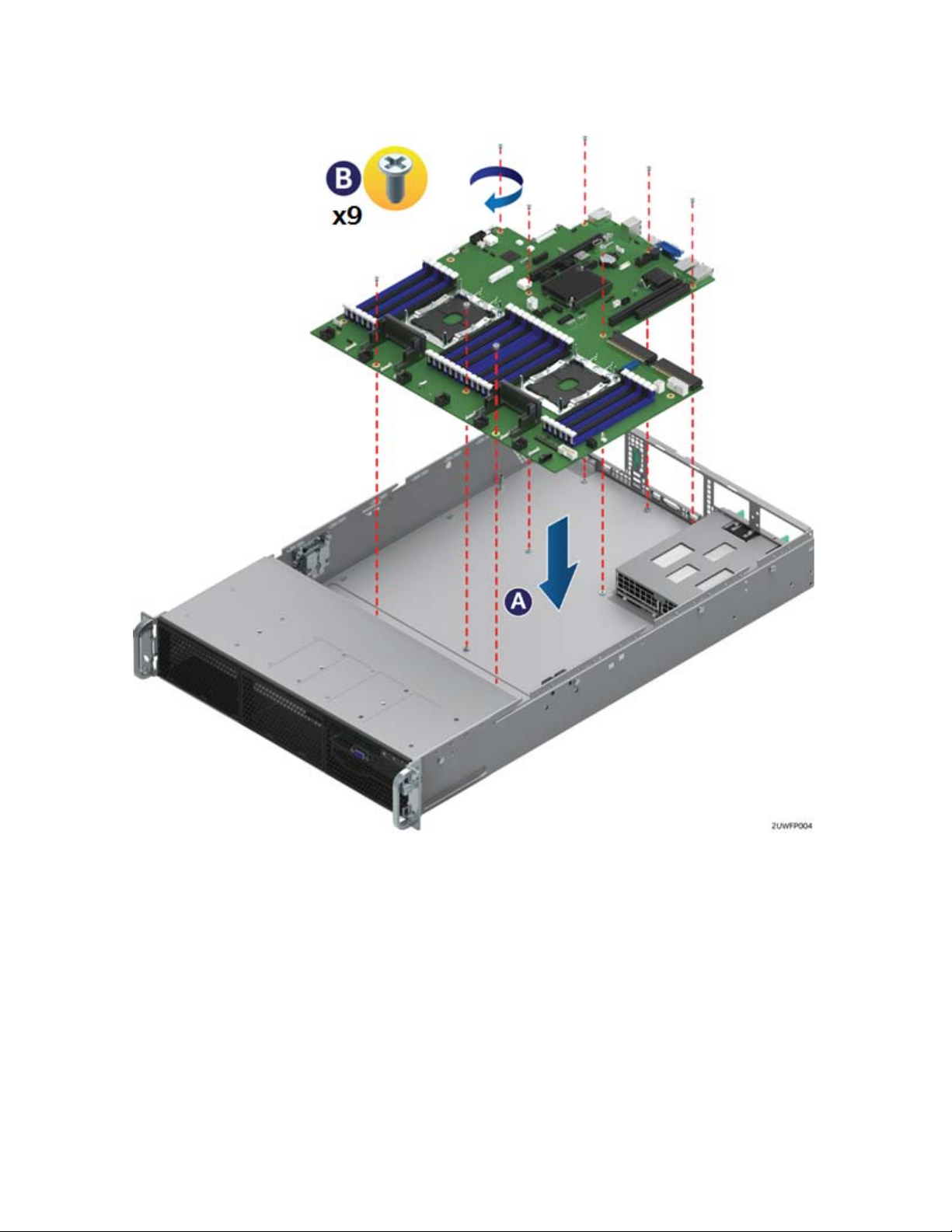

1. Install the Server Board

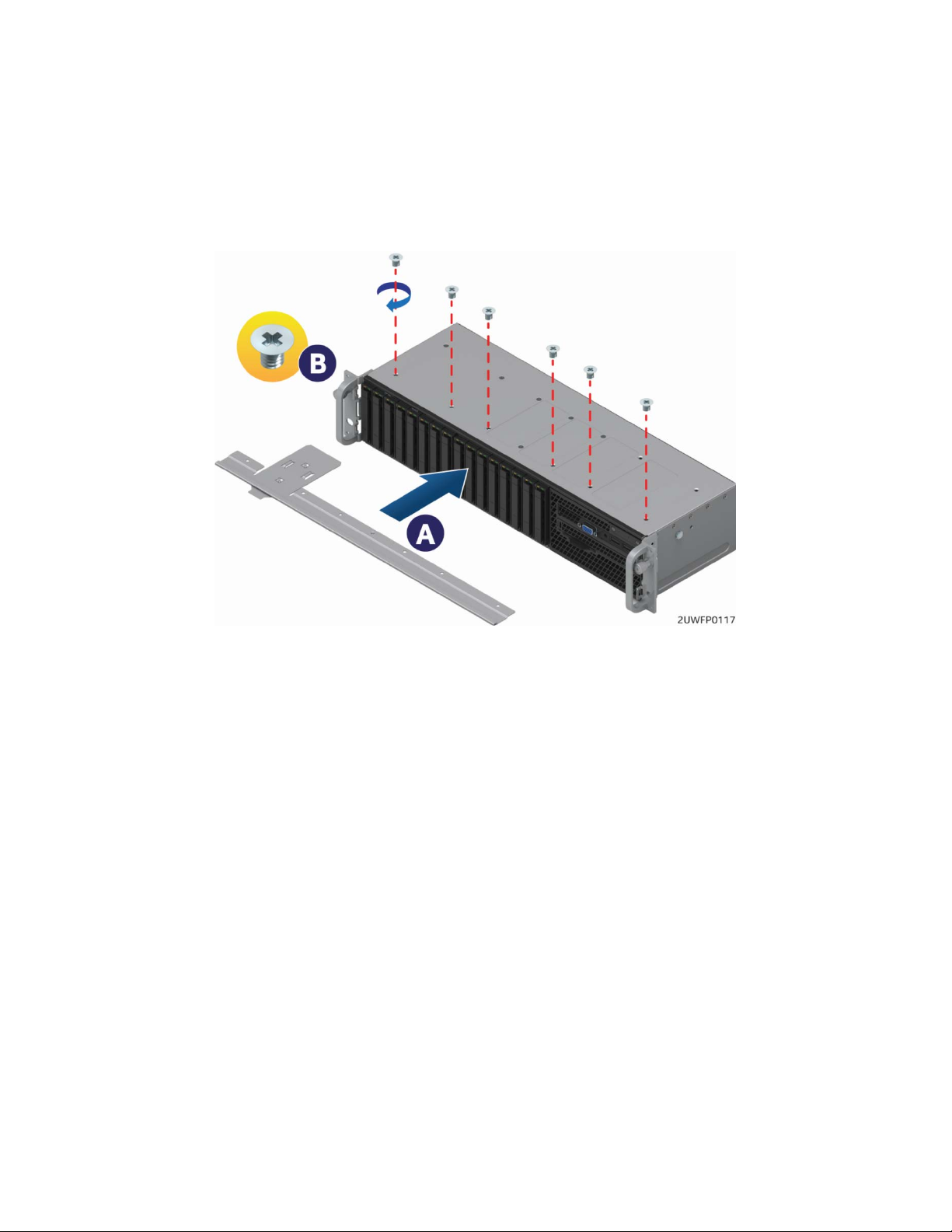

Figure 5. Server Board Installation

a) Clear the area for server board placement by carefully moving aside any cables that may be taped to

the chassis base.

b) Remove power supplies if present.

c) Remove the server board from its anti-static bag.

d) Holding the server board by its edges, carefully lower the server board into the chassis so that the

rear I/O connectors of the server board align with and are fully seated into the matching cut outs on

the chassis back panel and each server board mounting hole is aligned with a threaded chassis

standoff. (See letter “A”)

e) The server board is accurately placed when the two end screw holes nearest the front edge of the

server board sit securely onto the shouldered chassis standoffs.

f) Using 8 in-lb torque, fasten down the server board with 9 screws (See letter “B”)

21

Page 22

Intel® Server System R2000WF Product Family System Integration and Service Guide

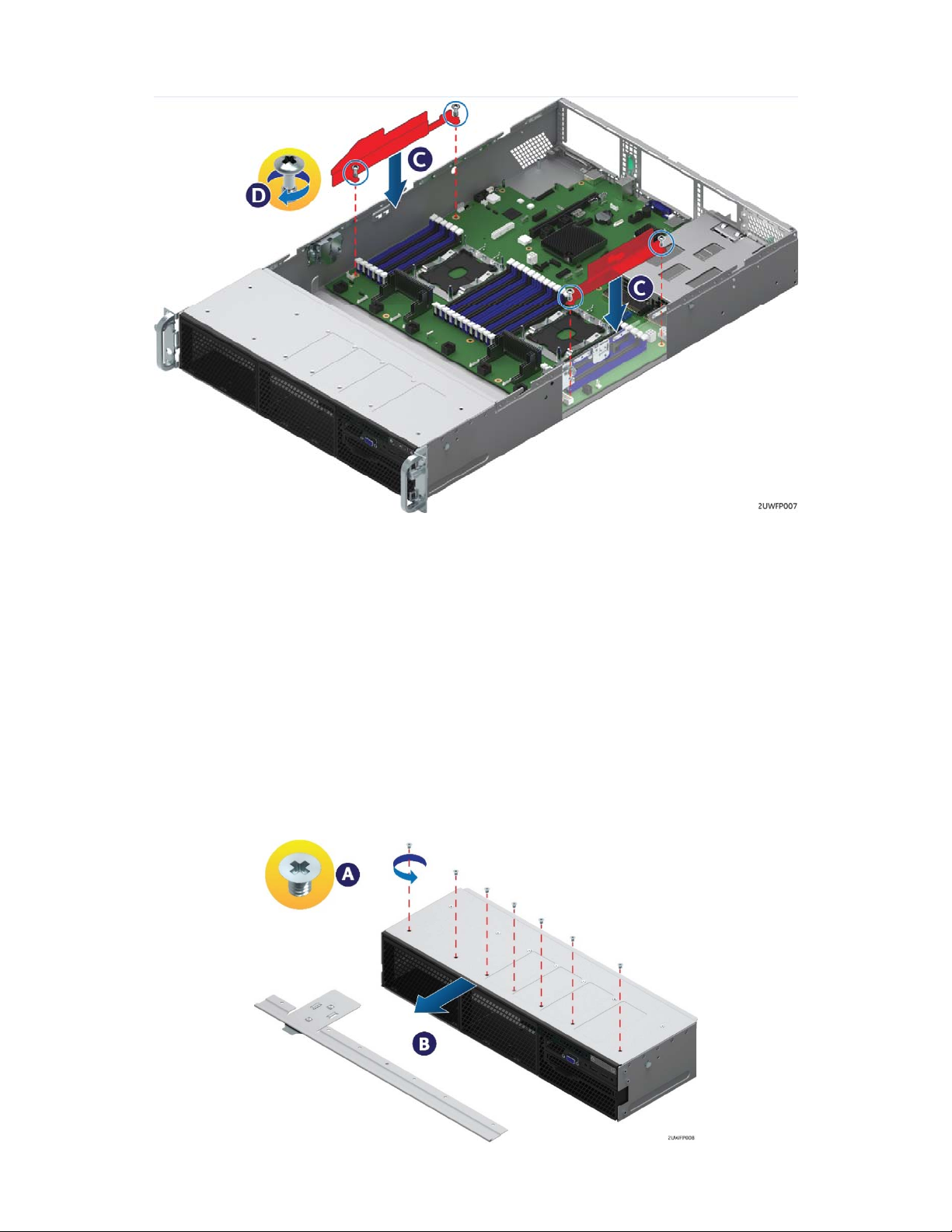

2. Install the Air Duct Side Walls

Figure 6. Air Duct Side Wall Installation

a) Locate the two black plastic air duct sidewalls from the chassis accessory kit

b) Following the illustration above, fasten down the appropriate air duct side wall onto each side of the

server board using 8 in/lbf torque for each screw. (See Letter “C”)

1.3.1 8 x 2.5” Front Drive Bay Module Installation (Intel® Server Chassis R2000WFxxx and

Intel® Server System R2208WFxxxx)

Continue with the instructions in this section for installation of several available 8 x 2.5” front drive bay

accessory kits into the system. If the final system configuration does not include front drive support, proceed

to section 1.3.2

1. Remove the Drive Bay Retention Bracket

The Drive Bay Retention Bracket must be removed in order to remove the Drive Bay Filler Panels.

Figure 7. R2000WFxxx Drive Bay Retention Bracket Removal

22

Page 23

Intel® Server System R2000WF Product Family System Integration and Service Guide

a) Remove the six (6) screws from the top front edge of the drive bay

b) Pull the metal bracket straight out.

c) Set aside the retention bracket and screws for re-installation at a later time.

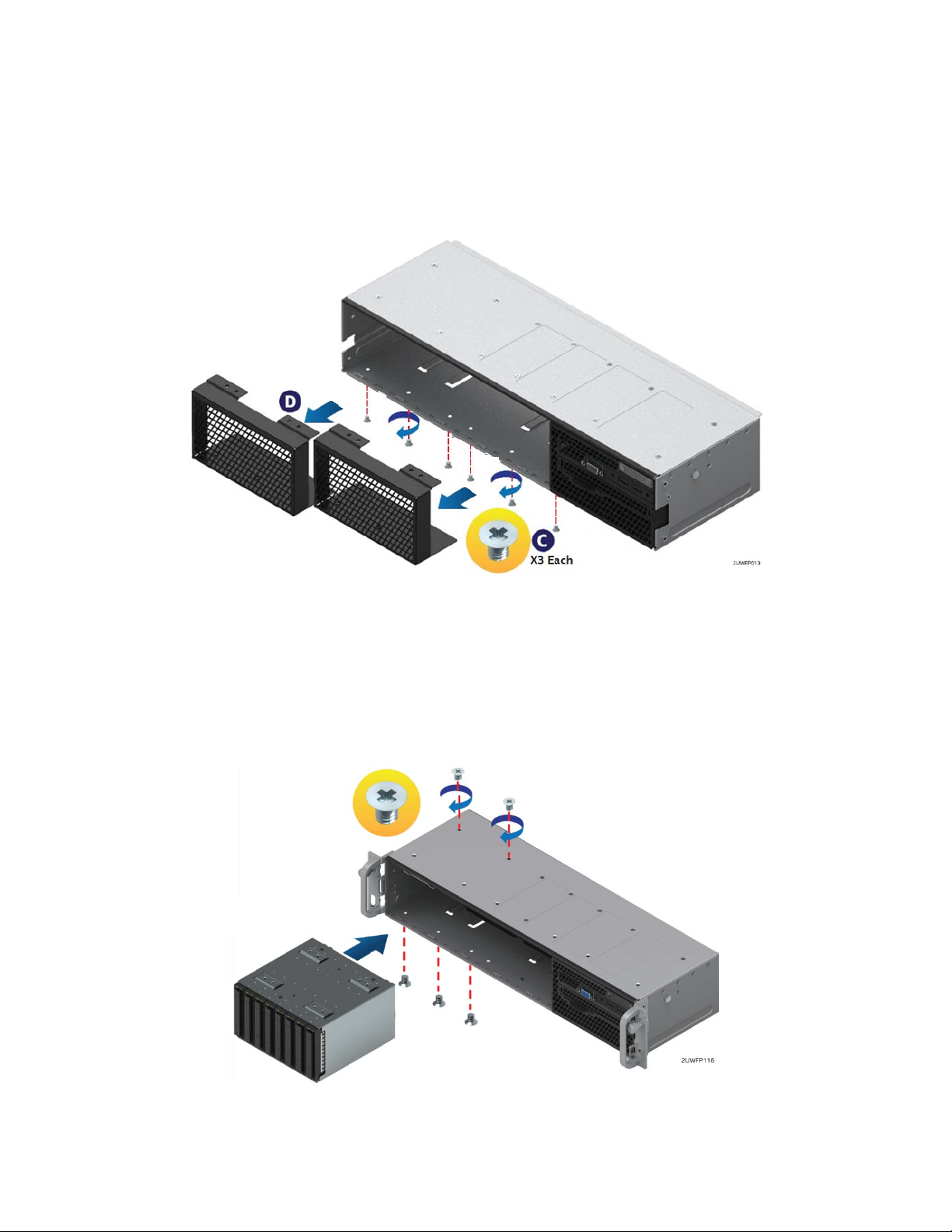

2. Remove Drive Bay Filler Panel(s)

The chassis includes a drive bay filler panel for each drive bay location that doesn’t have a drive bay preinstalled. Remove the filler panel for each 8 x 2.5” drive bay module to be installed.

Figure 8. Drive Bay Filler Panel Removal

a) Carefully turn the chassis onto its side, exposing the bottom side of the chassis.

b) From the bottom of the chassis, remove the three (3) screw securing the given drive bay filler panel

(see Letter ‘C’).

c) Carefully return the chassis to its original position.

d) Slide out the drive bay filler panel (see Letter ‘D’).

3. Insert 8 x 2.5” Drive Bay Module

Figure 9. 8 x 2.5" Drive Bay Module Installation

a) Carefully unpack the 8 x 2.5” drive bay module from the accessory kit.

b) Slide the 8 x 2.5” drive bay module into the server chassis

23

Page 24

Intel® Server System R2000WF Product Family System Integration and Service Guide

c) Using two screws on the top back edge of the drive bay, secure the drive bay to the chassis. (8 in/lbf

torque for each screw).

d) Repeat steps 1-3 for the second drive bay module (if applicable).

e) Carefully place the chassis on its side, and secure each installed drive bay module with three (3)

additional screws on the bottom of the chassis (8 in/lbf torque for each screw).

f) Carefully return the chassis to its original position.

4. Install Drive Bay Retention Bracket

Figure 10. Drive Bay Retention Bracket Installation

a) Locate the drive bay retention bracket and screws.

b) Carefully slide the drive bay retention bracket straight into the gap between the top of the drive bay

module(s) and the underside of the chassis sheet metal. (See Letter ‘A’).

c) Secure the retention bracket with six screws (see Letter ‘B’). (8 in/lbf torque for each screw).

1.3.2 Internal Cable Routing and Connections

All cables in the system that need to be routed from front-to-back, should be routed using the cable

channels between the chassis sidewalls and the air duct sidewalls as shown in the following illustration.

When routing cables front-to-back, none should be routed through the center of the system or in the area

between the system fans and the DIMM slots. Cable connection instructions provided in this section are

presented in the recommended order in which they should be installed. See Error! Reference source not

found. for additional System Cable routing illustrations.

24

Page 25

Intel® Server System R2000WF Product Family System Integration and Service Guide

Figure 11. Internal Cable Routing Channels

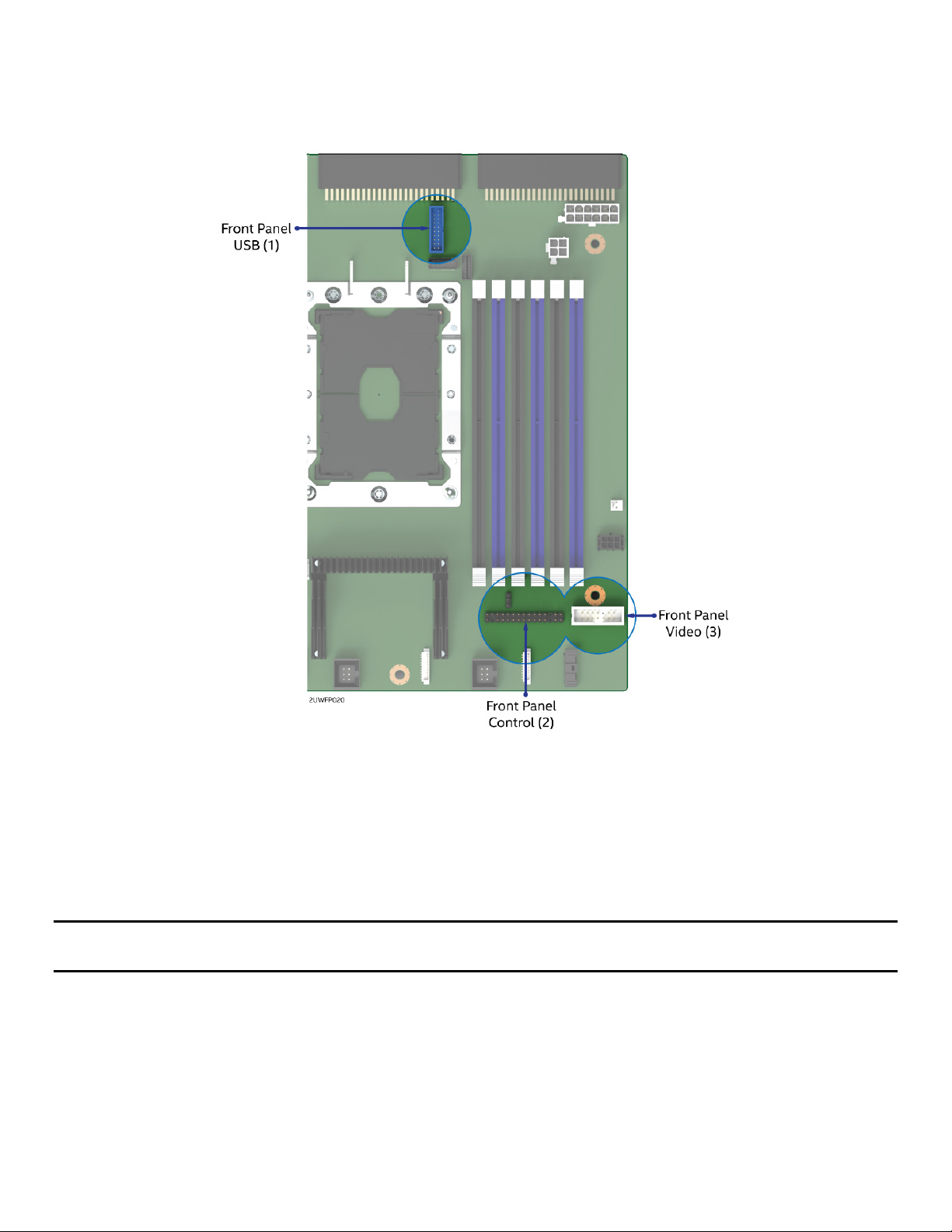

1. Connect Internal Cables for Front Control Panel and Front I/O Module

This system includes front panel USB, Video, Control Buttons, and various LED features that must be cabled

to the appropriate connectors on the server board. Cables should be routed in the following order: (1) Front

Panel USB, (2) Front Control Panel, and (3) Front Panel Video.

25

Page 26

Intel® Server System R2000WF Product Family System Integration and Service Guide

Figure 12. Front Control Panel and Front I/O Internal Cable Connections

a) Route the black round USB cable to the blue 20-pin connector on the server board labeled

“FP_USB2_11_13”. The cable should be routed as close to the chassis side wall as possible.

b) Route the folded 30-pin gray ribbon cable to the matching 30-pin header on the server board

labeled “SSI_FRONT_PANEL”.

c) Route the 14-pin gray folded ribbon cable to the 14-pin black shrouded connector on the server

board labeled “FP_VIDEO”.

Note: With the system fan module assembly removed from the chassis, all three front panel cables should

be routed beneath the fan module receiver feature on the right chassis sidewall.

System configurations with no front drive bay, can proceed to section 1.3.4

26

Page 27

Intel® Server System R2000WF Product Family System Integration and Service Guide

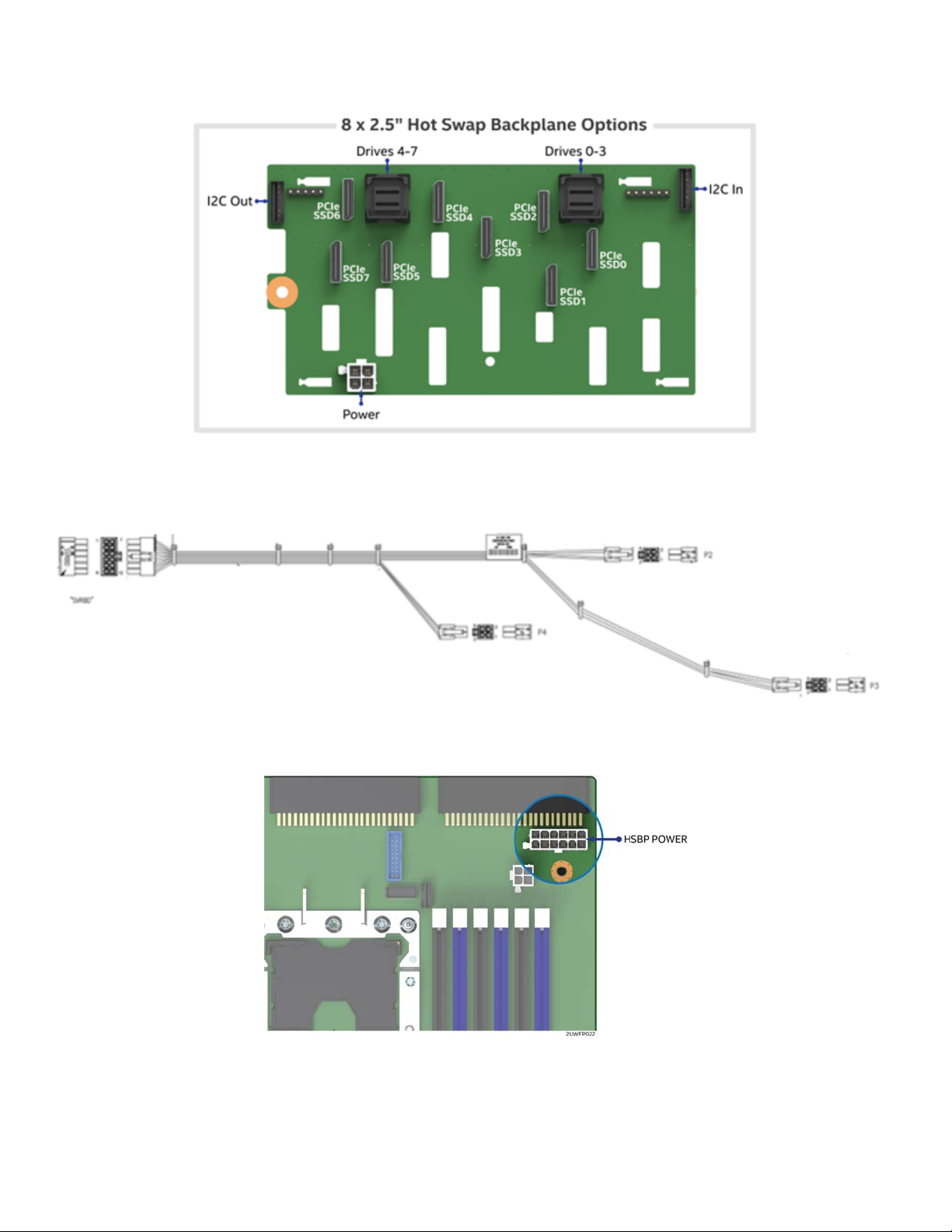

2. Connect the Hot Swap Backplane Power Cable and I

Figure 13. Hot Swap Backplane Connectors

a) Locate the backplane power cable.

2

C Cables

Figure 14. 2.5” Drive Module Hot Swap Backplane Power Cable

Figure 15. HSBP POWER Connector

b) Connect the 2x6 pin cable connector (labeled “SVRBRD”) to the matching 2x6 white power

connector on the server board (silk screened “HSBP PWR”)

27

Page 28

Intel® Server System R2000WF Product Family System Integration and Service Guide

c) Route the backplane power cable along the chassis sidewall, to the area behind the drive bay.

d) Connect the white 2x2 pin cable connector(s) (labeled ‘P#’) to the matching white 2x2 power

connector(s) on the backplane (silk screened ‘PWR’).

e) Once the cable is attached on both ends, carefully press the cable as low as possible into the cable

routing channel.

f) Locate the backplane I2C cable.

Figure 16. I

2

C cable

2

Figure 17. Hot Swap Backplane I

C Internal Cable Connector

g) Attach the connector (labeled “HSBP”) of the I2C cable to the matching HSBP pin connector (silk

screened “HSBP I2C”) on the backplane.

h) Route the backplane I2C cable next to the nearest chassis sidewall and connect the other end of the

I2C cable to the 1x4 pin connector (silk screened “HSBP I2C”) on the server board.

28

Page 29

Intel® Server System R2000WF Product Family System Integration and Service Guide

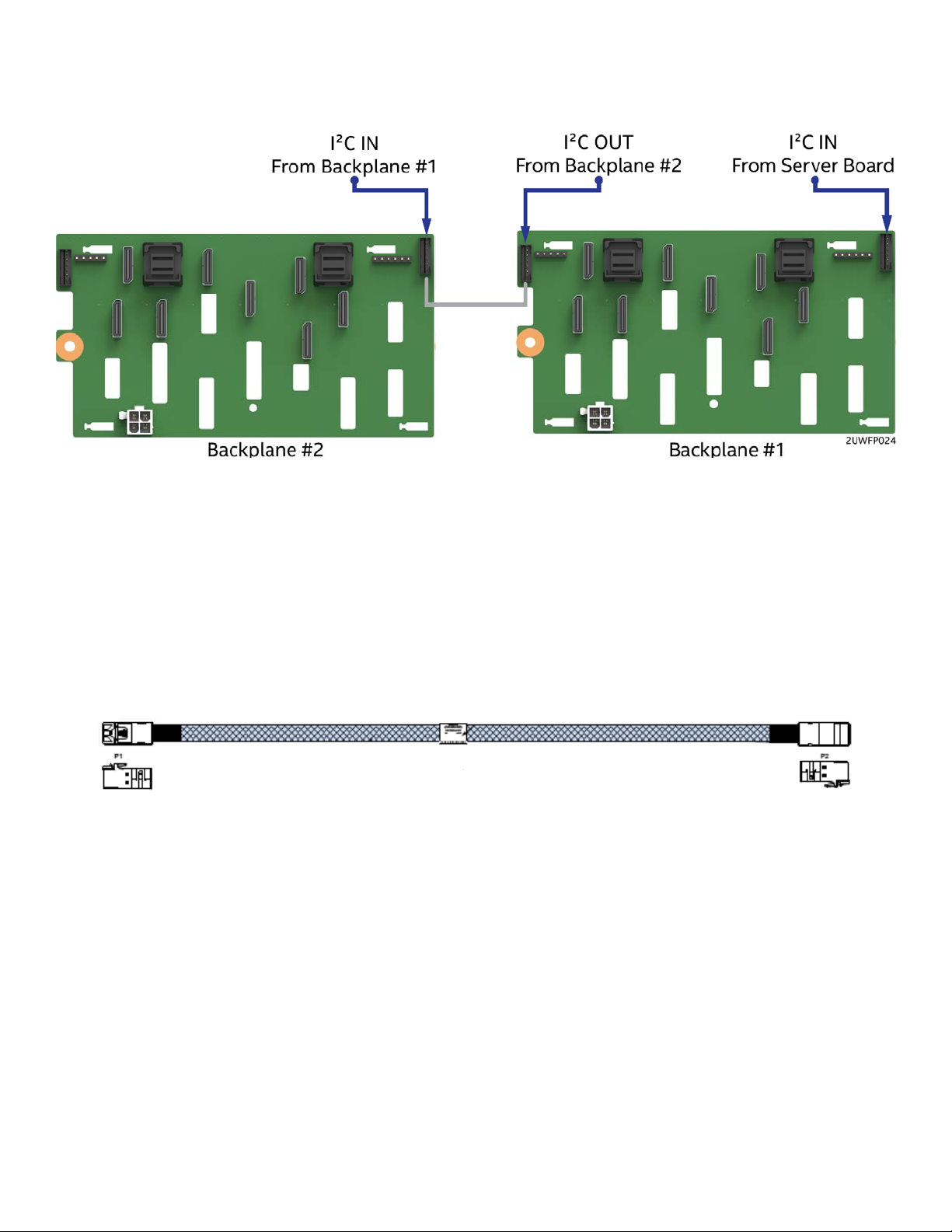

If more than one 8 x 2.5” backplane is being installed, locate the I

2

cable to the I

C -OUT connector of backplane #1 and the other end of the cable to the I2C - IN connector of

backplane #2.

Figure 18. Dual 8x2.5" Hot Swap Backplane I

2

2

C jumper cable and connect one end of the

C Jumper Cable Installation

3. Connect the SAS/SATA Data Cable(s)

SAS/SATA Data cable connections will vary depending on the system configuration. This section will only

describe cable connections when using the onboard SATA controllers. For other add-in storage options,

refer to the appropriate option installation sections available in this document.

a) Locate the appropriate SAS/SATA Data cables.

Figure 19. SATA Cable

b) Attach one side of the SAS/SATA Data cables to the mini-SAS HD connectors on the backplane.

c) Route the SAS/SATA DATA cables from the backplane to the back of the system via the cable

channels next to the chassis sidewalls.

29

Page 30

Intel® Server System R2000WF Product Family System Integration and Service Guide

Figure 20. Onboard Connectors for Embedded SATA Support (S2600WFT and S2600WF0 only)

d) Attach the P2 end of the SATA Data cables to the on-board Mini-SAS HD connectors for embedded

SATA support (see Figure 20).

1.3.3 PCIe NVMe Support

See Section 2.10

1.3.4 Riser Card Assembly

The server system can support up to three (3) PCIe riser cards via the two riser card brackets. This section

will provide instructions for mounting of a riser card option to the bracket only. Add-in card installation and

system integration procedures for the riser card assemblies are continued in Chapter 2 after the installation

of other required system components has been performed.

1. Attach Riser Card(s) to Riser Card Bracket(s)

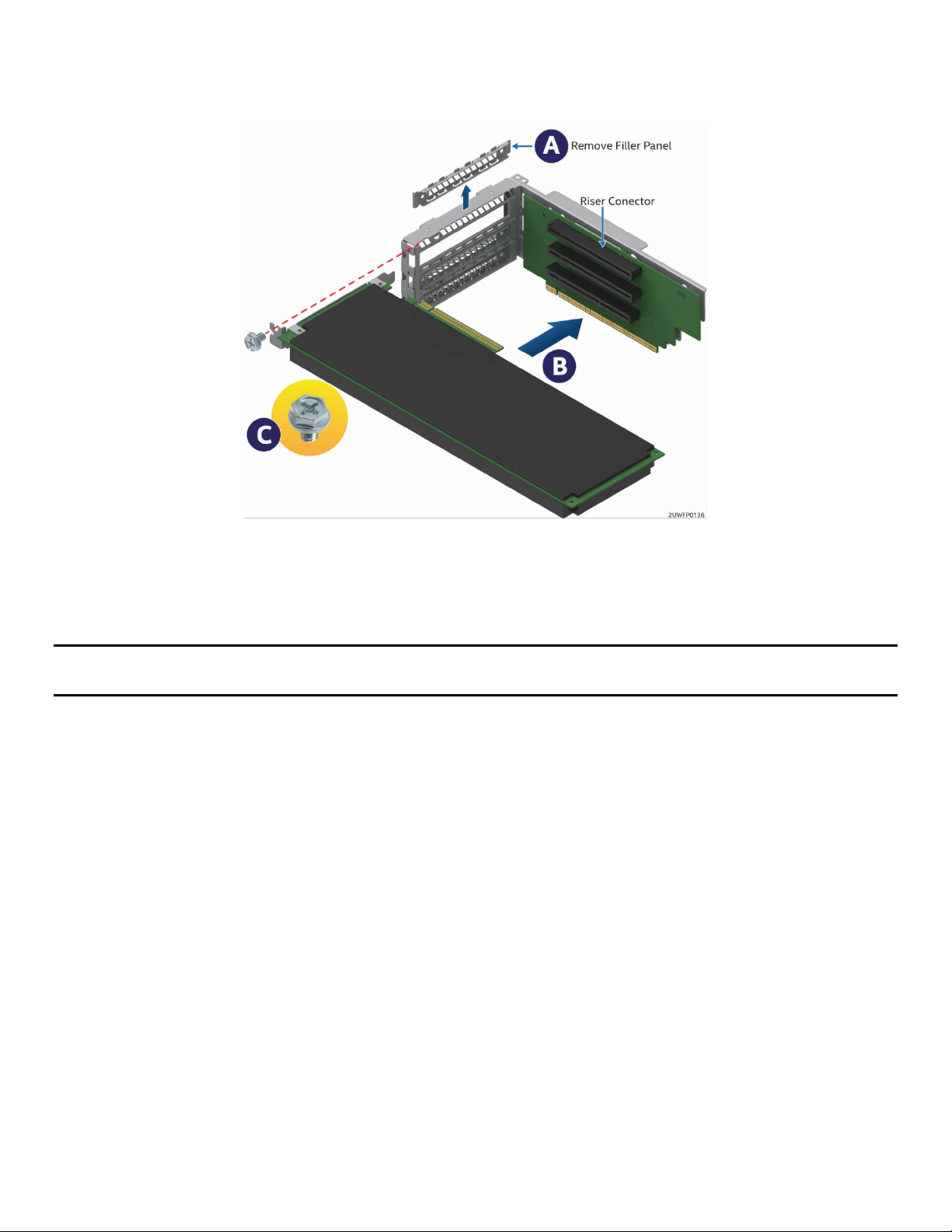

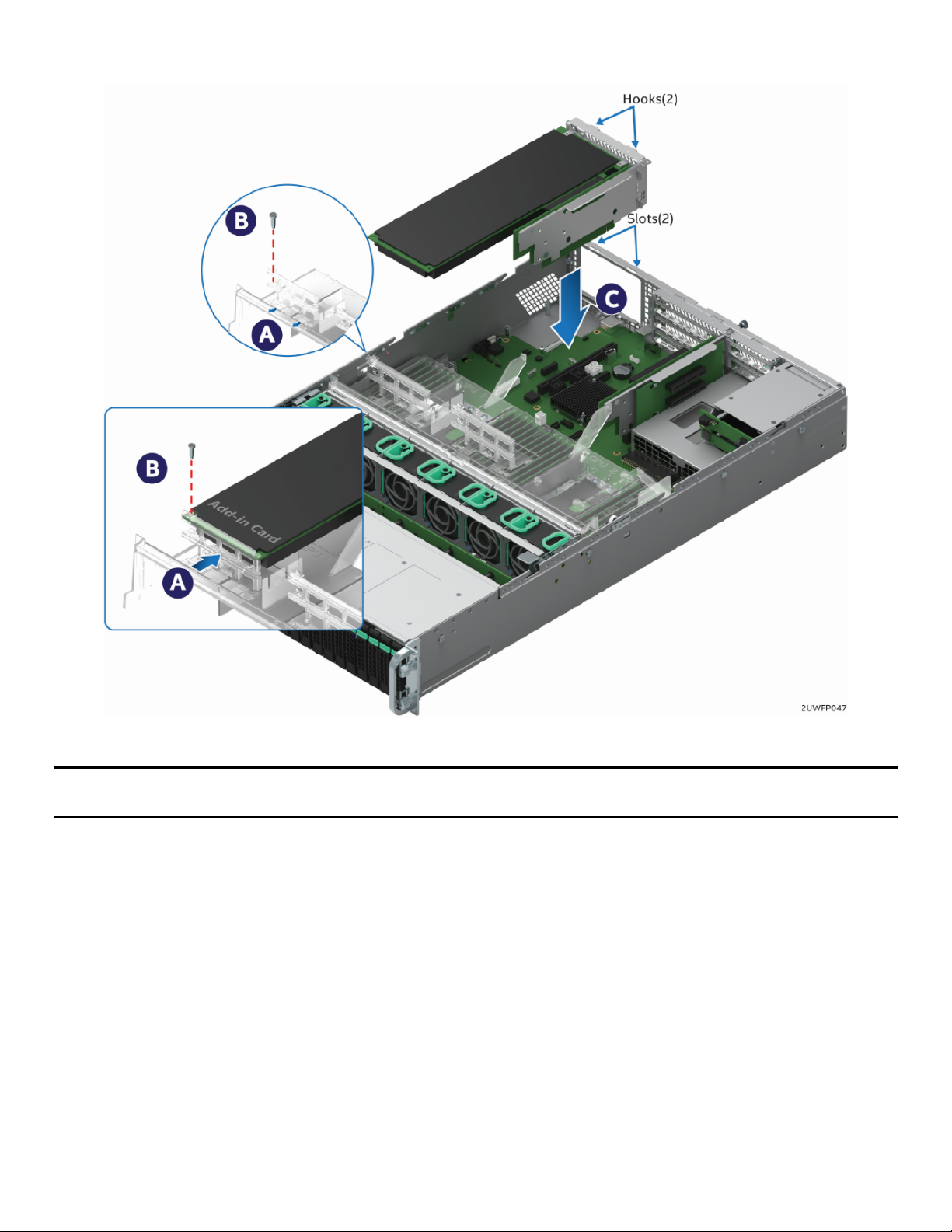

Figure 21. Riser Card Assembly

30

Page 31

Intel® Server System R2000WF Product Family System Integration and Service Guide

a) Locate the screw from chassis accessory kit

b) Locate and remove the riser card from its packaging

c) Position the mounting key holes of the riser card over the riser bracket mounting studs (see letter

“A”) and slide back (see letter “B”)

d) Using the screw from the chassis accessory kit, secure the riser card to the bracket (see Letter “C”).

e) See Section 0 for PCIe add-in card installation procedure

1.3.5 Power Supply Installation

The server system can support 1 or 2 power supply modules. Single power supply configurations must have

the power supply bay insert installed when the system is operational.

1. Install the Power Supply Module(s)

Figure 22. Power Supply Installation

st

a) Insert the 1

b) (Optional) To install a 2

c) (Optional) Install the 2

power supply into the left most power supply bay until it clicks and locks into place.

nd

power supply, remove the insert from the 2nd chassis power supply bay

nd

power supply

Note: A single power supply configuration requires that the power supply bay insert be installed when the

system is operational.

Continue on to Chapters 2 and 3 for installation of processors, memory, add-in cards, storage devices, and

other supported options.

31

Page 32

Intel® Server System R2000WF Product Family System Integration and Service Guide

2. Essential System Component Installation and Service

Purpose

This chapter provides instructions for the installation and removal of essential system components including

processors, memory, storage devices, and add-in cards.

If you are continuing the system integration from the previous chapter, you may skip ahead to section 2.5.

Before You Begin

Before working with your server product, observe the safety and ESD precautions found in the Warnings

section at the beginning of this manual.

Tools and Supplies Needed

T-30 Torx screwdriver

Flat head screwdriver

Adequate ESD protective gear (wrist strap, ESD mat)

System Reference

All references to left, right, front, top, and bottom assume the reader is facing the front of the chassis.

Instruction Format

Each procedure described in this section will follow an illustration first format. This format will give the

reader the option to follow a quicker path to system integration by first seeing an illustration of the intended

procedure. If necessary, the reader can then follow the step-by-step instructions that will accompany each

procedure.

32

Page 33

Intel® Server System R2000WF Product Family System Integration and Service Guide

2.1 Internal Cable Routing Channels

The system fan module must be removed when routing cables from front-to-back. All cables should be

routed using the cable channels in between the chassis sidewalls and the air duct side walls, as shown in the

following illustration. When routing cables front-to-back, none should be routed through the center of the

system or in the area between the system fans and the DIMMs slots.

Figure 23. Internal Cable Routing Channels

33

Page 34

Intel® Server System R2000WF Product Family System Integration and Service Guide

2.2 System Cover Removal / Installation

2.2.1 System Cover Removal