Page 1

Intel® Server System R2000WF

Product Family

Technical Product Specification

An overview of product features, functions, architecture, and support specifications

Revision 1.2

November 2017

Intel® Server Products and Solutions

Page 2

<Blank page>

Page 3

Intel® Server System R2000WF Product Family Technical Product Specification

Date

Revision

Modifications

July 2017

1.0

Production Release

September

1.1

Updated all tables from Appendix B and Appendix C

Updated S2600WF Architecture Block Diagram

Added QAT information:

Server Board Product Family Feature Set

S2600WFQ Architecture Block Diagram

Edited bullet on the section 4.1.1 Memory Slot Population Requirements

Added subsection 3.3.8 DC Output Specification

November 2017

1.2

Updated Trusted Platform Module (China version) iPC AXXTPMCHNE8 on table Intel® Server

Board S2600WF product family feature set

Added TPM definition on Glossary section

Added Retimer accessory to the sections: 6.5, 7.4 and 7.4.4

Document Revision History

3

Page 4

Intel® Server System R2000WF Product Family Technical Product Specification

Disclaimers

Intel technologies’ features and benefits depend on system configuration and may require enabled

hardware, software, or service activation. Learn more at Intel.com, or from the OEM or retailer.

You may not use or facilitate the use of this document in connection with any infringement or other legal

analysis concerning Intel products described herein. You agree to grant Intel a non-exclusive, royalty-free

license to any patent claim thereafter drafted which includes subject matter disclosed herein.

No license (express or implied, by estoppel or otherwise) to any intellectual property rights is granted by this

document.

The products described may contain design defects or errors known as errata which may cause the product

to deviate from published specifications. Current characterized errata are available on request.

Intel disclaims all express and implied warranties, including without limitation, the implied warranties of

merchantability, fitness for a particular purpose, and non-infringement, as well as any warranty arising from

course of performance, course of dealing, or usage in trade.

Copies of documents which have an order number and are referenced in this document may be obtained by

calling 1-800-548-4725 or by visiting www.intel.com/design/literature.htm.

Intel, the Intel logo, and Xeon are trademarks of Intel Corporation or its subsidiaries in the U.S. and/or other

countries.

*Other names and brands may be claimed as the property of others.

Copyright © Intel Corporation. All rights reserved.

4

Page 5

Intel® Server System R2000WF Product Family Technical Product Specification

Table of Contents

1. Introduction ............................................................................................................................................................... 15

1.1 Document Outline.......................................................................................................................................................... 16

1.2 Intel® Server Board Use Disclaimer......................................................................................................................... 16

1.3 Product Errata.................................................................................................................................................................. 16

2. Server System Family Overview............................................................................................................................ 17

2.1 System Features Overview ......................................................................................................................................... 21

2.2 Server Board Architecture .......................................................................................................................................... 22

2.3 Server Board Features Overview ............................................................................................................................. 24

2.4 Back Panel Features ...................................................................................................................................................... 27

2.5 Front Control Panel Options ..................................................................................................................................... 27

2.6 Front Drive Bay Options .............................................................................................................................................. 28

2.7 Locking Front Bezel Support ..................................................................................................................................... 29

2.8 System Dimensional Data ........................................................................................................................................... 30

2.8.1 Chassis Dimensions, 2.5” Drive Bay ........................................................................................................................ 30

2.8.2 Label Emboss Dimensions ......................................................................................................................................... 31

2.8.3 Pull-Out Tab Label Emboss Dimensions.............................................................................................................. 32

2.9 System Cable Routing Channels .............................................................................................................................. 33

2.10 Available Rack and Cabinet Mounting Kit Options .......................................................................................... 34

2.11 System Level Environmental Limits ....................................................................................................................... 35

2.12 System Packaging .......................................................................................................................................................... 36

3. System Power ............................................................................................................................................................ 37

3.1 Power Supply Configurations ................................................................................................................................... 37

3.2 Power Supply Module Options ................................................................................................................................ 38

3.2.1 Power Supply Module Efficiency ............................................................................................................................. 38

3.2.2 Power Supply Module Mechanical Overview ..................................................................................................... 39

3.2.3 Power Cord Specification Requirements ............................................................................................................. 41

3.3 AC Power Supply Input Specifications .................................................................................................................. 41

3.3.1 Power Factor .................................................................................................................................................................... 42

3.3.2 AC Input Voltage Specification ................................................................................................................................. 42

3.3.3 AC Line Isolation Requirements ............................................................................................................................... 42

3.3.4 AC Line Dropout/Holdup ............................................................................................................................................ 42

3.3.5 AC Line Fuse ..................................................................................................................................................................... 43

3.3.6 AC Inrush ........................................................................................................................................................................... 43

3.3.7 AC Line Transient Specification ............................................................................................................................... 43

3.3.8 Susceptibility Requirements ...................................................................................................................................... 44

3.3.9 Electrostatic Discharge Susceptibility ................................................................................................................... 44

3.3.10 Fast Transient/Burst...................................................................................................................................................... 44

3.3.11 Radiated Immunity ........................................................................................................................................................ 44

3.3.12 Surge Immunity ............................................................................................................................................................... 44

3.3.13 Power Recovery .............................................................................................................................................................. 45

5

Page 6

Intel® Server System R2000WF Product Family Technical Product Specification

3.3.14 Voltage Interruptions ................................................................................................................................................... 45

3.3.15 Protection Circuits ......................................................................................................................................................... 45

3.3.16 Power Supply Status LED ........................................................................................................................................... 46

3.4 DC Power Supply Input Specifications (iPC – AXX750DCCRPS) ................................................................ 46

3.4.1 DC Input Voltage ............................................................................................................................................................ 46

3.4.2 DC Input Fuse................................................................................................................................................................... 47

3.4.3 DC Inrush Current .......................................................................................................................................................... 47

3.4.4 DC Input under Voltage ............................................................................................................................................... 47

3.4.5 DC Holdup Time and Dropout .................................................................................................................................. 47

3.4.6 DC Line Surge Voltages (Line Transients) ............................................................................................................ 47

3.4.7 Susceptibility Requirements ...................................................................................................................................... 48

3.4.8 Protection Circuits ......................................................................................................................................................... 48

3.5 Cold Redundancy Support ......................................................................................................................................... 49

3.5.1 Powering on Cold Standby Supplies to Maintain Best Efficiency .............................................................. 49

3.5.2 Powering on Cold Standby Supplies during a Fault or Over Current Condition ................................. 50

3.5.3 BMC Requirements ........................................................................................................................................................ 50

3.5.4 Power Supply Turn on Function .............................................................................................................................. 50

3.6 Closed Loop System Throttling (CLST) ................................................................................................................. 50

3.7 Smart Ride Through (SmaRT) ................................................................................................................................... 51

3.8 Server Board Power Connectors ............................................................................................................................. 51

3.8.1 Power Supply Module Card Edge Connector ..................................................................................................... 51

3.8.2 Optional 12 V Power Connectors for High Power Add-in Cards ............................................................... 51

3.8.3 Hot Swap Backplane Power Connector ................................................................................................................ 52

3.8.4 Peripheral Power Connector ..................................................................................................................................... 53

4. Thermal Management ............................................................................................................................................. 54

4.1 Thermal Operation and Configuration Requirements .................................................................................... 56

4.1.1 Memory Slot Population Requirements ............................................................................................................... 57

4.2 Thermal Management Overview .............................................................................................................................. 58

4.2.1 Fan Speed Control ......................................................................................................................................................... 59

4.3 System Fans ..................................................................................................................................................................... 62

4.4 Power Supply Module Fans ....................................................................................................................................... 64

4.5 FRUSDR Utility ................................................................................................................................................................. 64

5. Intel® Xeon Phi™ Coprocessor and Non-Intel GPGPU Add-in Card Support ............................................... 65

5.1 Support Criteria .............................................................................................................................................................. 65

5.2 Intel® Xeon Phi™ Coprocessor Card – System Configuration Requirements ......................................... 68

6. System Storage and Peripheral Drive Bay Overview ........................................................................................ 69

6.1 Front Mount – Drive Bay Support ............................................................................................................................ 69

6.2 Hot Swap Drive Carriers .............................................................................................................................................. 71

6.3 Peripheral Power Sources .......................................................................................................................................... 73

6.4 Hot Swap Backplane Support ................................................................................................................................... 73

6.4.1 SGPIO Functionality ...................................................................................................................................................... 75

6.4.2 I2C Functionality ............................................................................................................................................................. 75

6

Page 7

Intel® Server System R2000WF Product Family Technical Product Specification

6.5 8 x 2.5” Drive SATA/SAS/NVMe* Combo Backplane ....................................................................................... 75

6.6 8 x 2.5” Drive Dual Port SAS Backplane ................................................................................................................ 77

6.7 8 x 3.5” Drive Hot-Swap Backplane Overview.................................................................................................... 79

6.8 12 x 3.5” Drive Hot-Swap Backplane Overview ................................................................................................. 80

6.9 2 x 2.5” Hot Swap Drive Bay Accessory Kit .......................................................................................................... 81

6.10 Internal Fixed Mount Solid State Drive (SSD) Support ................................................................................... 85

7. Storage Controller Options Overview ................................................................................................................. 86

7.1 Onboard SATA Support .............................................................................................................................................. 86

7.1.1 Staggered Disk Spin-Up .............................................................................................................................................. 88

7.2 Onboard SATA Software RAID Support ............................................................................................................... 88

7.2.1 Intel® Rapid Storage Technology Enterprise (Intel® RSTe) 5.0 .................................................................... 89

7.2.2 Intel® Embedded Server RAID Technology 2 (ESRT2) 1.60 for SATA ...................................................... 89

7.3 M.2 SSD Support ............................................................................................................................................................ 91

7.3.1 Embedded RAID Support ........................................................................................................................................... 91

7.4 PCIe NVMe* Drive Support ......................................................................................................................................... 92

7.4.1 Onboard PCIe* OCuLink Connectors ..................................................................................................................... 92

7.4.2 Intel® Volume Management Device (Intel® VMD) for NVMe* ....................................................................... 92

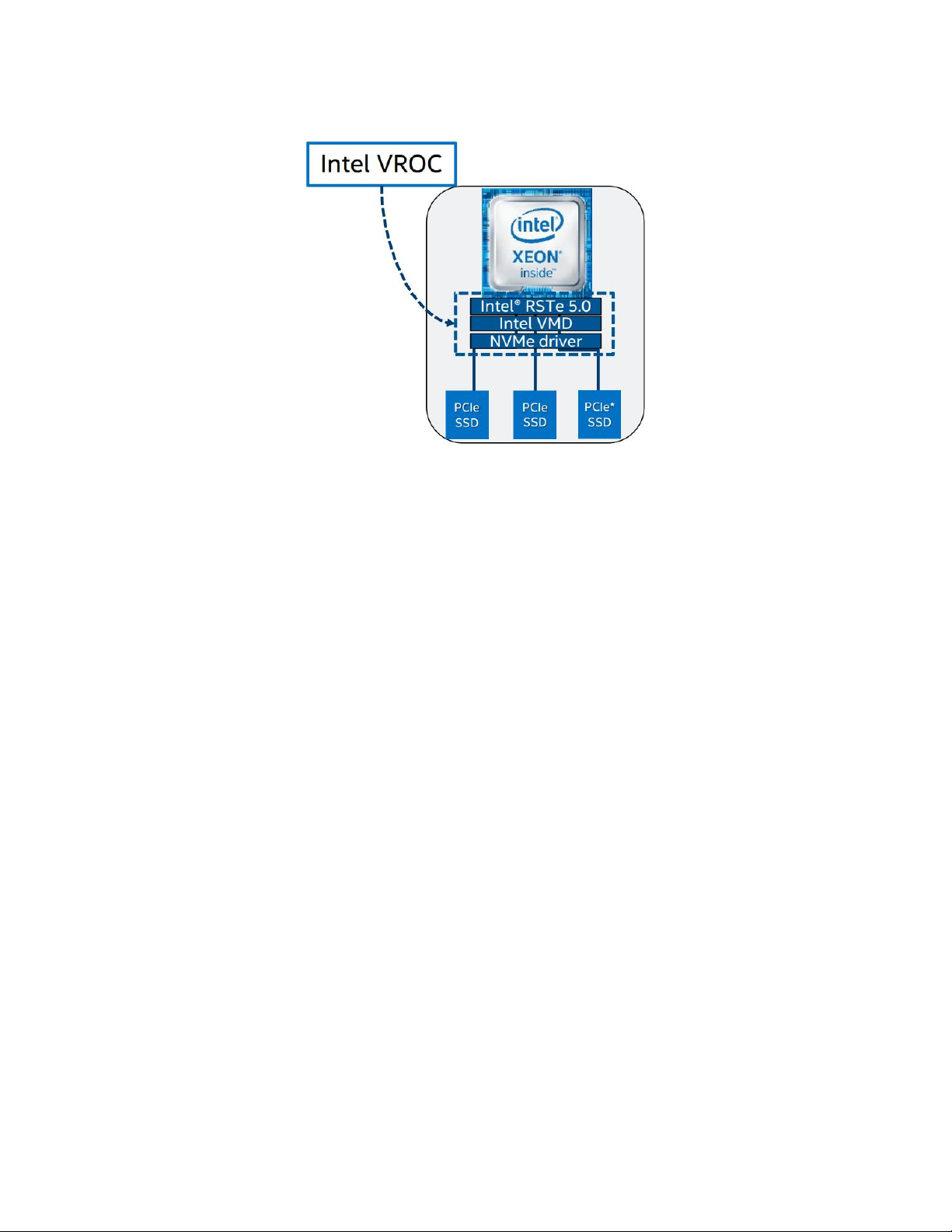

7.4.3 Intel® Virtual RAID on Chip (Intel® VROC) for NVMe* ...................................................................................... 96

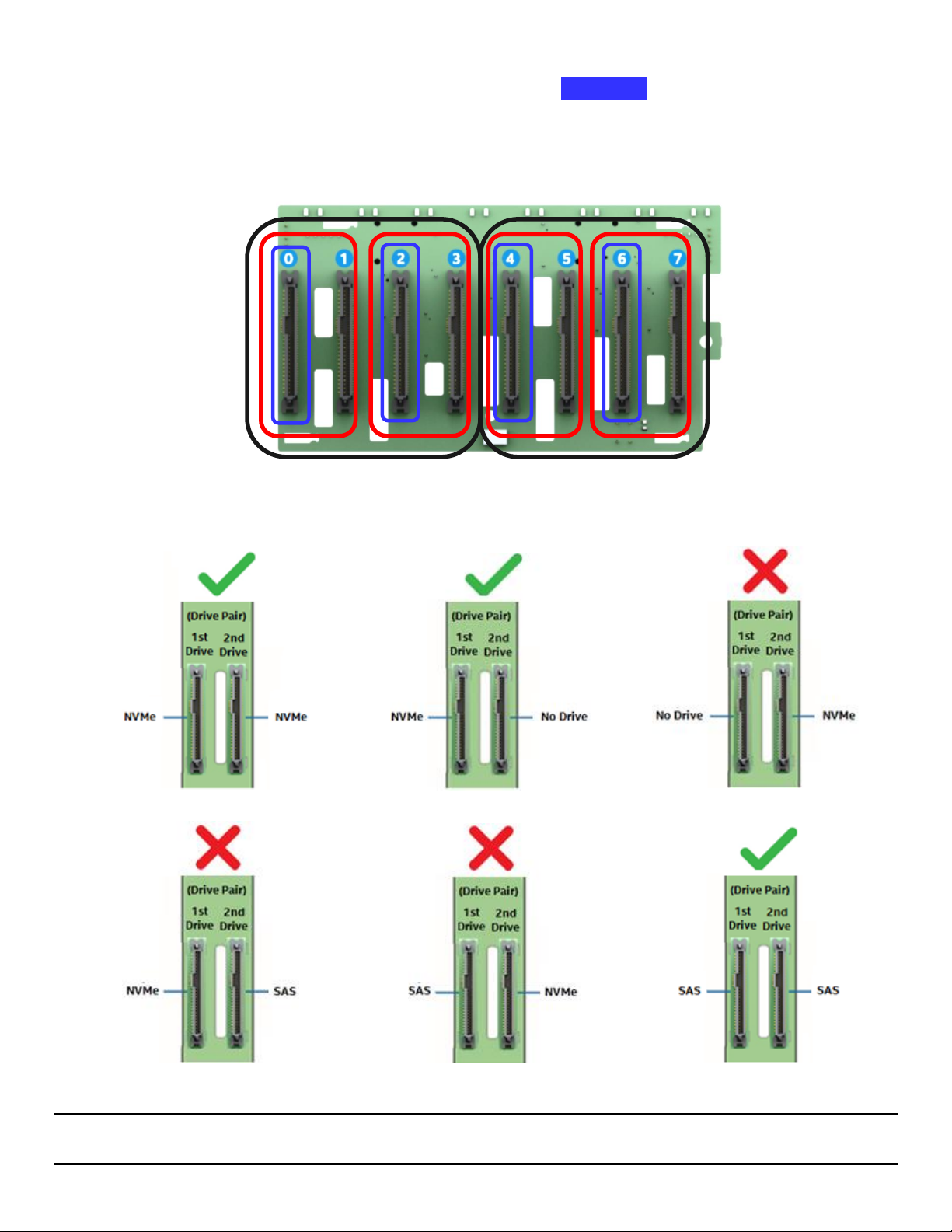

7.4.4 NVMe* Drive Population Rules for Intel® VROC ................................................................................................ 97

7.5 Intel® Integrated RAID Module Support ............................................................................................................. 101

7.5.1 RAID Maintenance Free Backup Unit (AXXRMFBUx) Support .................................................................. 102

7.6 Intel® RAID Expander Card Support .................................................................................................................... 103

8. Front Control Panel and I/O Panel Overview ................................................................................................... 107

8.1 I/O Panel Features ...................................................................................................................................................... 107

8.2 Control Panel Features ............................................................................................................................................. 108

9. PCIe* Riser Card Support ...................................................................................................................................... 111

9.1 Riser Card Assembly .................................................................................................................................................. 112

9.2 Riser Slot #1 and Riser Slot #2 Riser Card Options ...................................................................................... 114

9.2.1 Three-Slot PCIe Riser Card (iPC – A2UL8RISER2) ......................................................................................... 114

9.2.2 Two-Slot PCIe Riser Card (iPC – A2UL16RISER2) .......................................................................................... 114

9.3 Riser Slot #3 Riser Card Option (iPC – A2UX8X4RISER) ............................................................................. 115

10. OCP* Compatible Intel® Ethernet Network Adapter Support ....................................................................... 116

11. Basic and Advanced Server Management Features ........................................................................................ 117

11.1 Dedicated Management Port ................................................................................................................................. 118

11.2 Embedded Web Server ............................................................................................................................................. 118

11.3 Advanced Management Feature Support (Intel® RMM4 Lite) ................................................................... 120

11.3.1 Keyboard, Video, Mouse (KVM) Redirection .................................................................................................... 120

11.3.2 Remote Console .......................................................................................................................................................... 121

11.3.3 Performance .................................................................................................................................................................. 121

11.3.4 Availability ...................................................................................................................................................................... 122

11.3.5 Security ............................................................................................................................................................................ 122

11.3.6 Usage ................................................................................................................................................................................ 122

7

Page 8

Intel® Server System R2000WF Product Family Technical Product Specification

11.3.7 Force-enter BIOS Setup ........................................................................................................................................... 122

11.3.8 Media Redirection ....................................................................................................................................................... 122

Appendix A. Integration and Usage Tips .............................................................................................................. 124

Appendix B. POST Code Diagnostic LED Decoder ............................................................................................. 125

B.1. Early POST Memory Initialization MRC Diagnostic Codes ..................................................................... 126

B.2. BIOS POST Progress Codes .................................................................................................................................... 129

Appendix C. POST Code Errors .............................................................................................................................. 132

C.1. POST Error Beep Codes ........................................................................................................................................... 140

Appendix D. System Configuration Table for Thermal Compatibility ........................................................... 141

Appendix E. System Cable Routing Diagrams .................................................................................................... 158

Appendix F. Statement of Volatility...................................................................................................................... 163

Glossary ........................................................................................................................................................................... 166

8

Page 9

Intel® Server System R2000WF Product Family Technical Product Specification

List of Figures

Figure 1. System components overview.......................................................................................................................................... 21

Figure 2. 2U standard top cover ......................................................................................................................................................... 21

Figure 3. Server Board Architecture .................................................................................................................................................. 22

Figure 4. S2600WFQ Server Board Architecture ......................................................................................................................... 23

Figure 5. Server board component/feature identification ....................................................................................................... 24

Figure 6. Intel® Light Guided Diagnostics – LED identification ............................................................................................... 25

Figure 7. Intel® Light Guided Diagnostics - DIMM fault LEDs .................................................................................................. 26

Figure 8. System configuration and recovery jumpers ............................................................................................................. 26

Figure 9. Back panel feature identification ..................................................................................................................................... 27

Figure 10. Front control panel options ............................................................................................................................................ 27

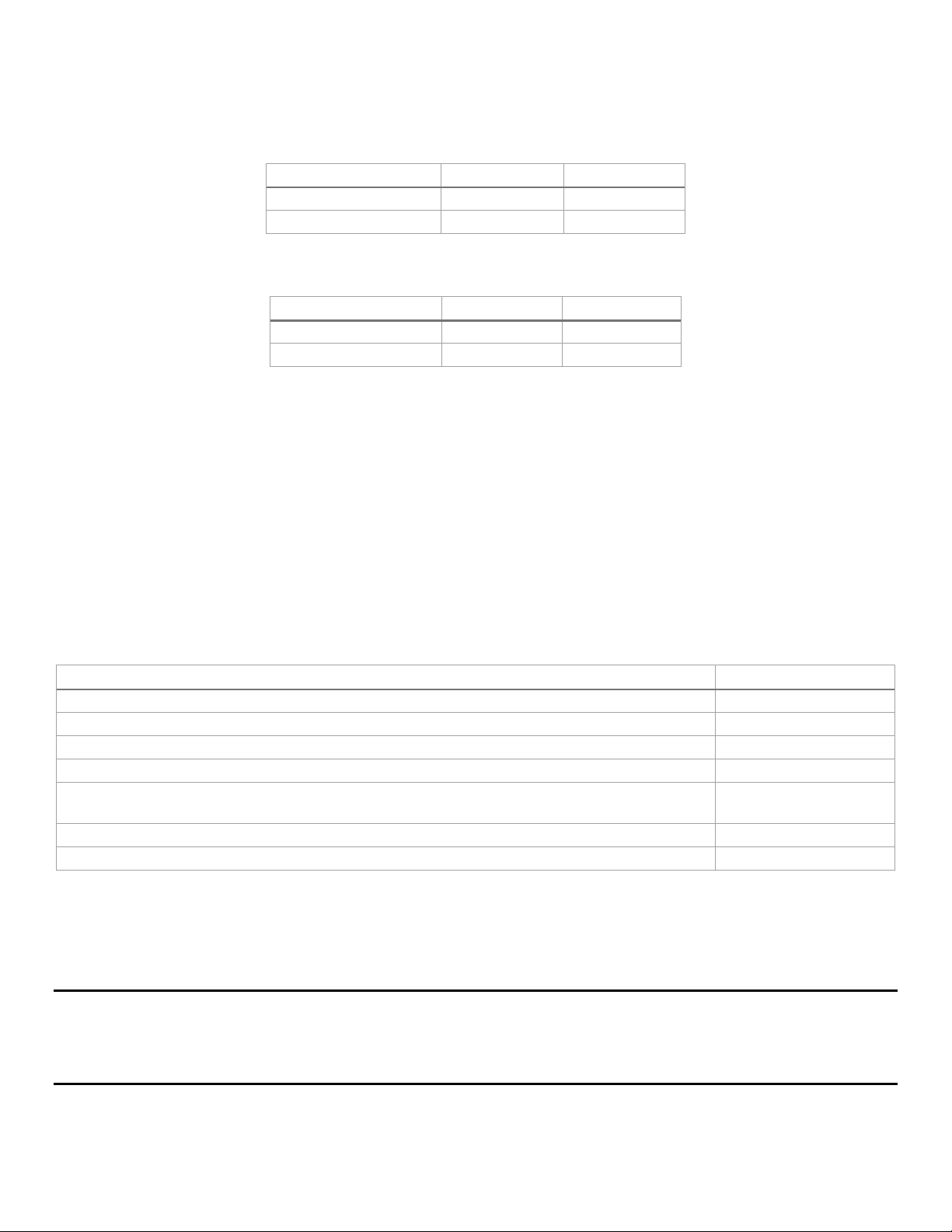

Figure 11. 3.5" x 8 front drive bay configuration – R2308WFxxxx ....................................................................................... 28

Figure 12. 3.5" x 12 front drive bay configuration – R2312WFxxxx ..................................................................................... 28

Figure 13. 2.5" x 8 front drive bay configuration – R2208WFxxxx ....................................................................................... 28

Figure 14. 2.5" x 16 front drive bay configuration – R2208WFxxxx + 8 Drive Accessory Kit .................................... 28

Figure 15. 2.5" x 24 front drive bay configuration – R2224WFxxxx ..................................................................................... 28

Figure 16. Concept Reference Design – Front Bezel Installation .......................................................................................... 29

Figure 17. Chassis dimensions, 2.5” drive bay .............................................................................................................................. 30

Figure 18. Label emboss dimensions ............................................................................................................................................... 31

Figure 19. Pull-out tab label emboss dimensions, non-storage models........................................................................... 32

Figure 20. Pull-out tab label area dimensions, storage models ............................................................................................ 32

Figure 21. System cable routing channels...................................................................................................................................... 33

Figure 22. Power supply module identification ........................................................................................................................... 37

Figure 23. Power supply module mechanical overview ........................................................................................................... 39

Figure 24. 1100W AC power supply module mechanical drawing ...................................................................................... 40

Figure 25. 1300W AC power supply module mechanical drawing ...................................................................................... 40

Figure 26. AC power cord specification ........................................................................................................................................... 41

Figure 27. DC power cord specification ........................................................................................................................................... 41

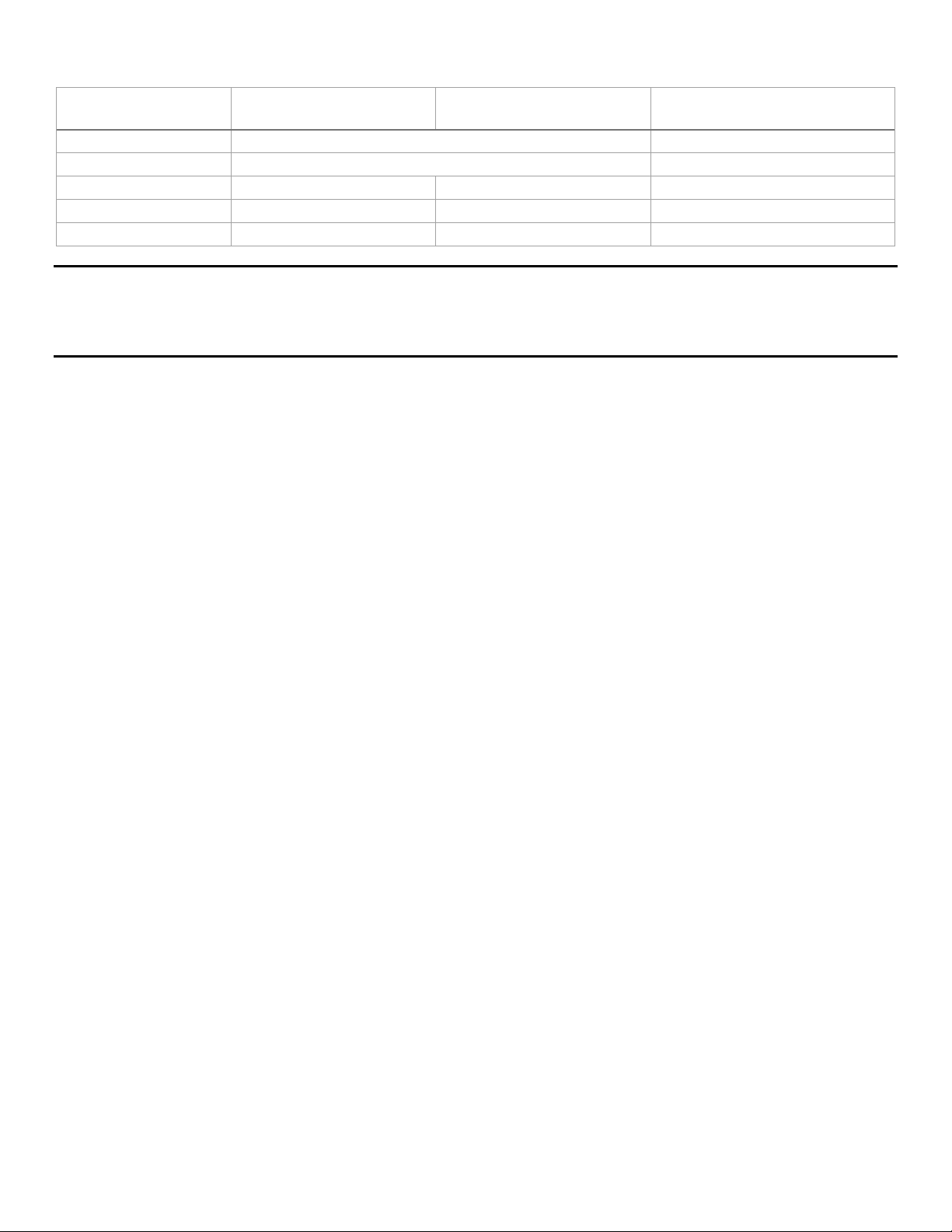

Figure 28. Power cable for the OPT_12V ........................................................................................................................................ 52

Figure 29. System Airflow and Fan Identification ........................................................................................................................ 54

Figure 30. System DIMM/DIMM blanks for 8x2.5, 16x2.5, and 8x3.5 drive configurations ....................................... 57

Figure 31. System DIMM/DIMM blanks for 24x2.5 and 12x3.5 drive configurations ................................................... 57

Figure 32. High-level fan speed control model ............................................................................................................................ 62

Figure 33. Server board 2U system fan connector locations ................................................................................................. 62

Figure 34. System fan assembly ......................................................................................................................................................... 63

Figure 35. 2-slot PCIe* riser card ........................................................................................................................................................ 65

Figure 36. Auxiliary 12 V power cable (iPC – AXXGPGPUCABLE) ......................................................................................... 66

Figure 37. High airflow air duct included in accessory kit AWFCOPRODUCTAD ........................................................... 66

Figure 38. Shipping bracket .................................................................................................................................................................. 67

Figure 39. Shipping bracket placement ........................................................................................................................................... 68

Figure 40. 2.5" front mount drive bay, 8 drive (R2208WFxxx) and 16 drive configuration option ......................... 69

9

Page 10

Intel® Server System R2000WF Product Family Technical Product Specification

Figure 41. 2.5" front mount drive bay, 24 drive (R2224WFxxx) configuration ................................................................ 69

Figure 42. 3.5" drive bay, 8 drive configuration ........................................................................................................................ 70

Figure 43. 3.5” drive bay, 12 drive configuration ......................................................................................................................... 70

Figure 44. Drive carrier removal .......................................................................................................................................................... 71

Figure 45. 2.5" SSD mounted to 3.5" drive carrier....................................................................................................................... 71

Figure 46. Drive tray LED identification ........................................................................................................................................... 72

Figure 47. Server board peripheral power connectors ............................................................................................................. 73

Figure 48. 3.5" backplane placement ............................................................................................................................................... 74

Figure 49. 2.5" drive bay module placement options ................................................................................................................ 74

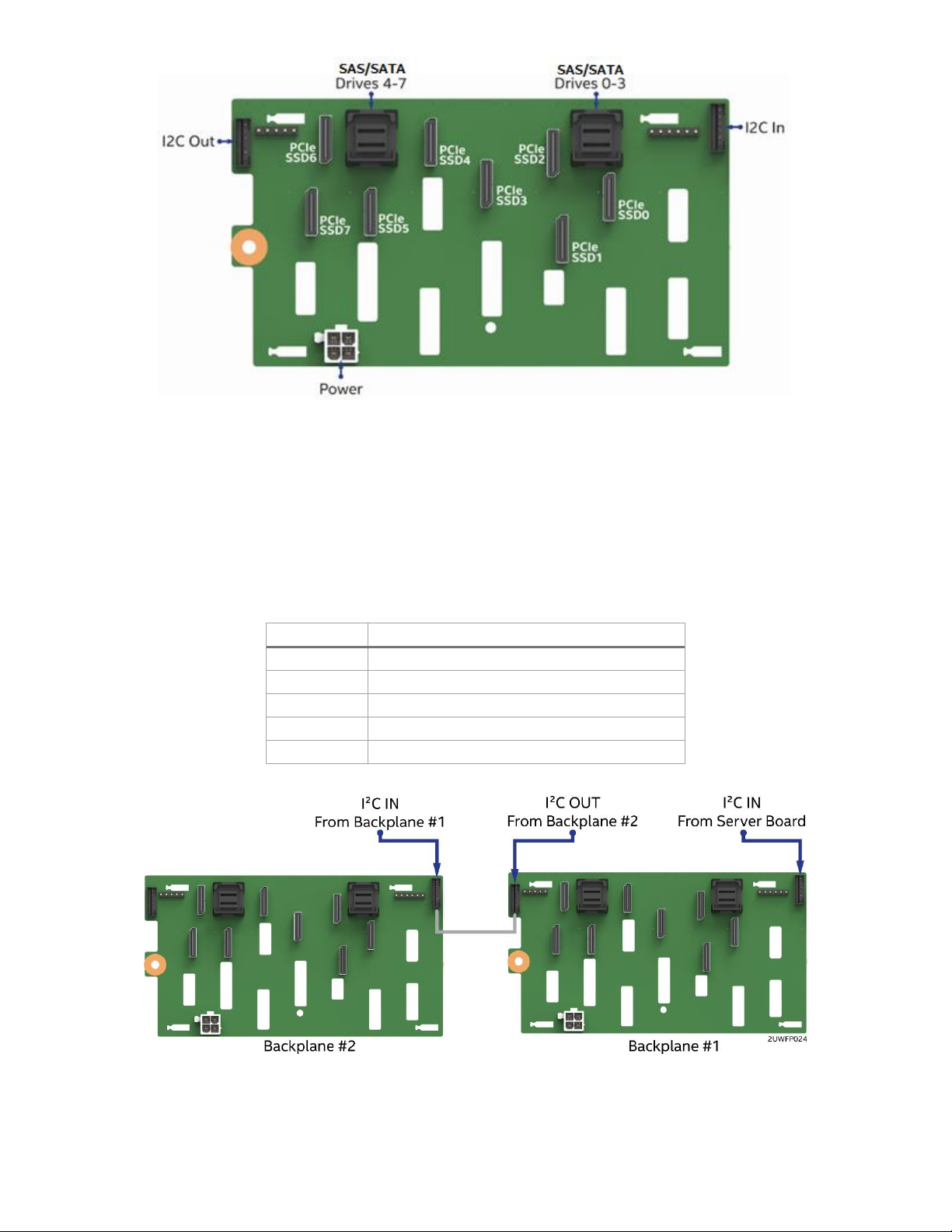

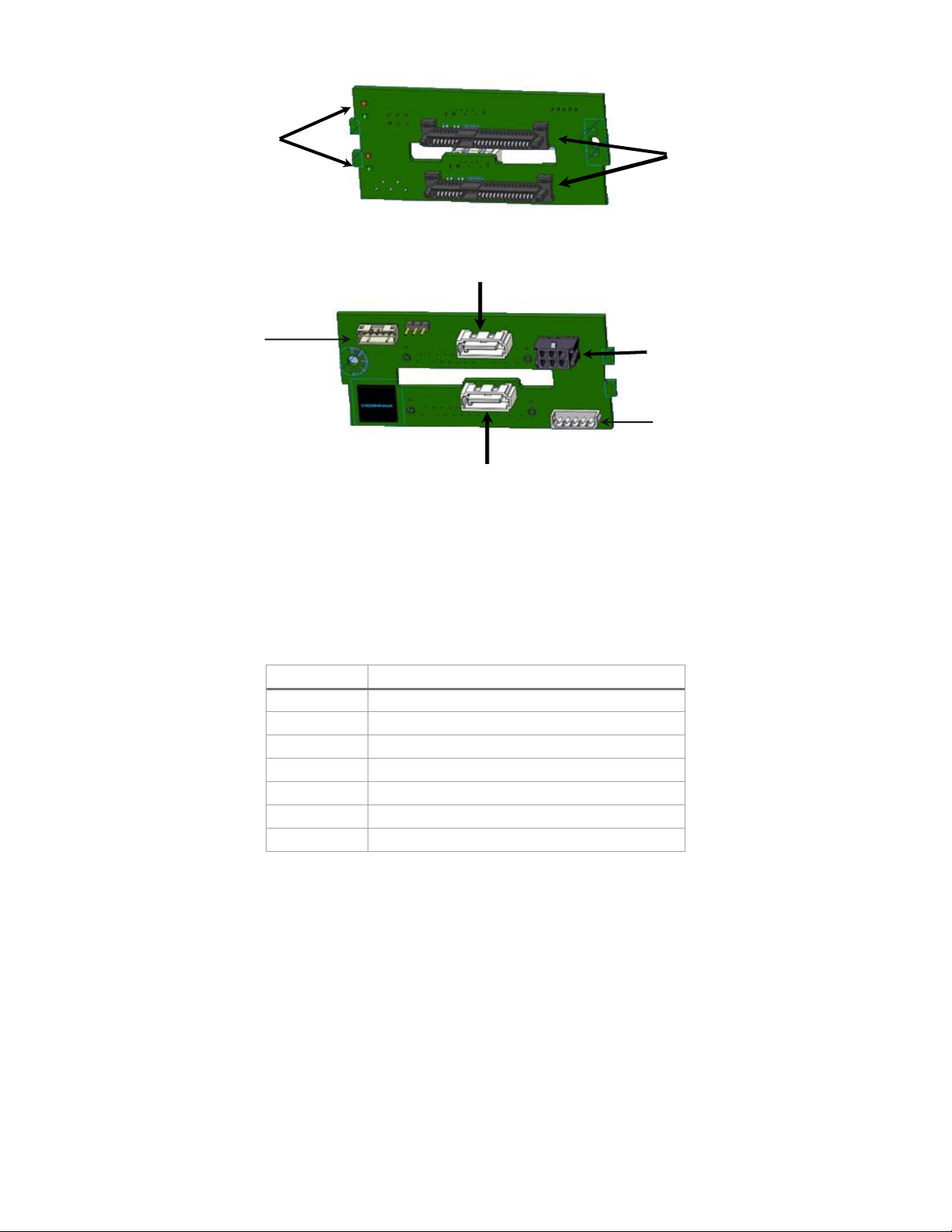

Figure 50. 8 x 2.5" SAS/SATA/NVMe* hot swap backplane, front side .............................................................................. 75

Figure 51. 8 x 2.5" SAS/SATA/NVMe* hot swap backplane, back side ............................................................................... 76

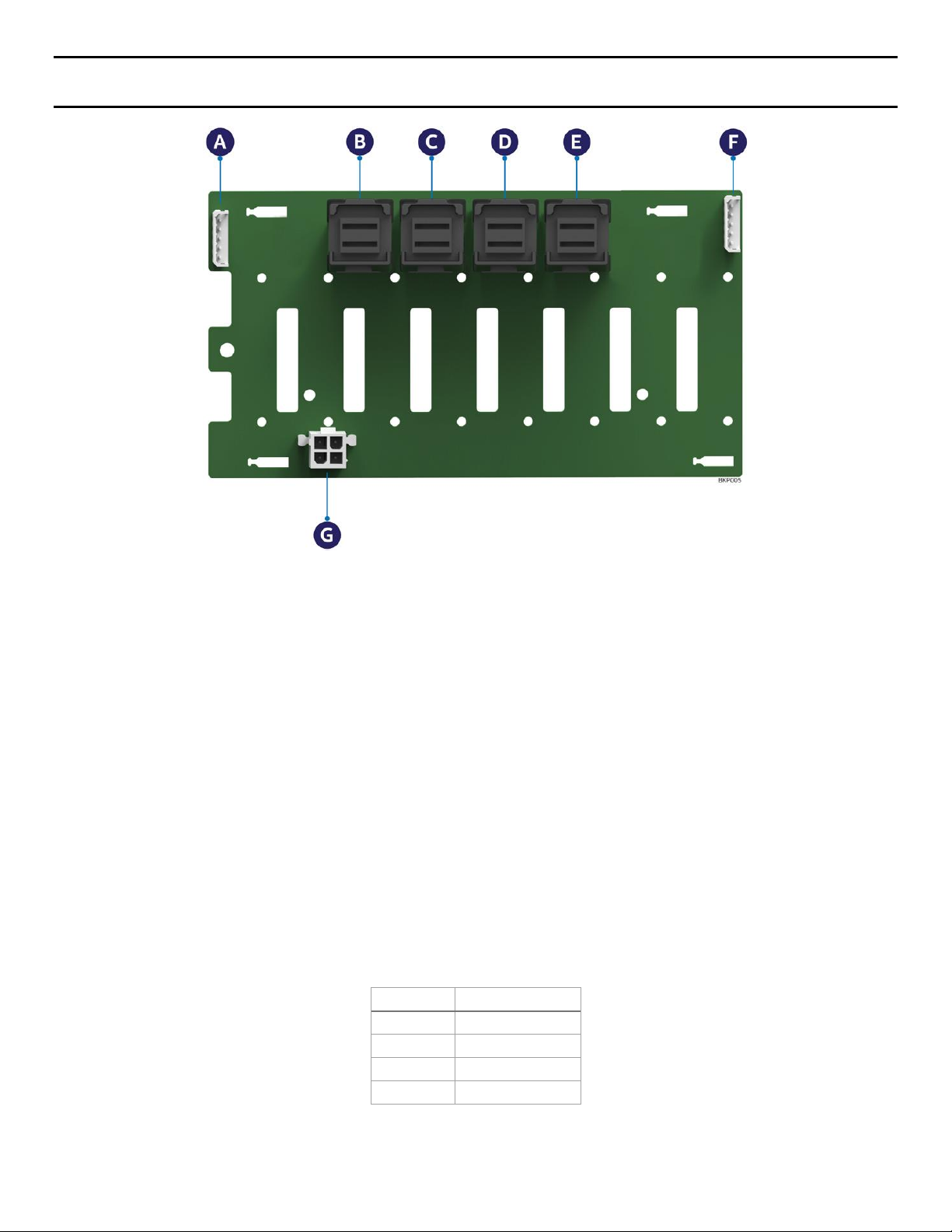

Figure 52. 8 x 2.5" dual port SAS backplane, back side ............................................................................................................ 76

Figure 53. 8 x 2.5" dual port SAS backplane, front side ............................................................................................................ 77

Figure 54 . 8 x 2.5" dual port SAS backplane, Back side ........................................................................................................... 78

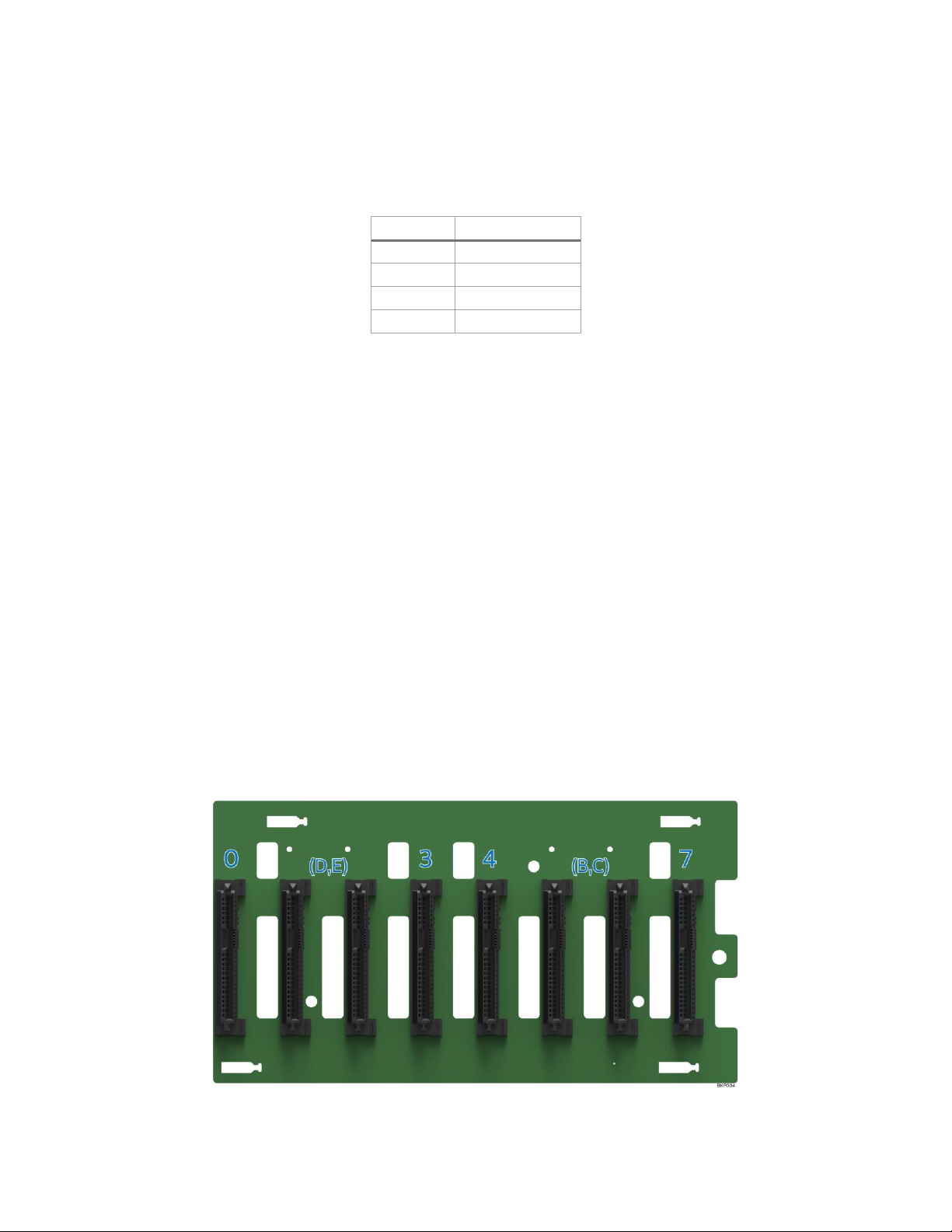

Figure 55. 8 x 3.5" HSBP Connector Identification ...................................................................................................................... 79

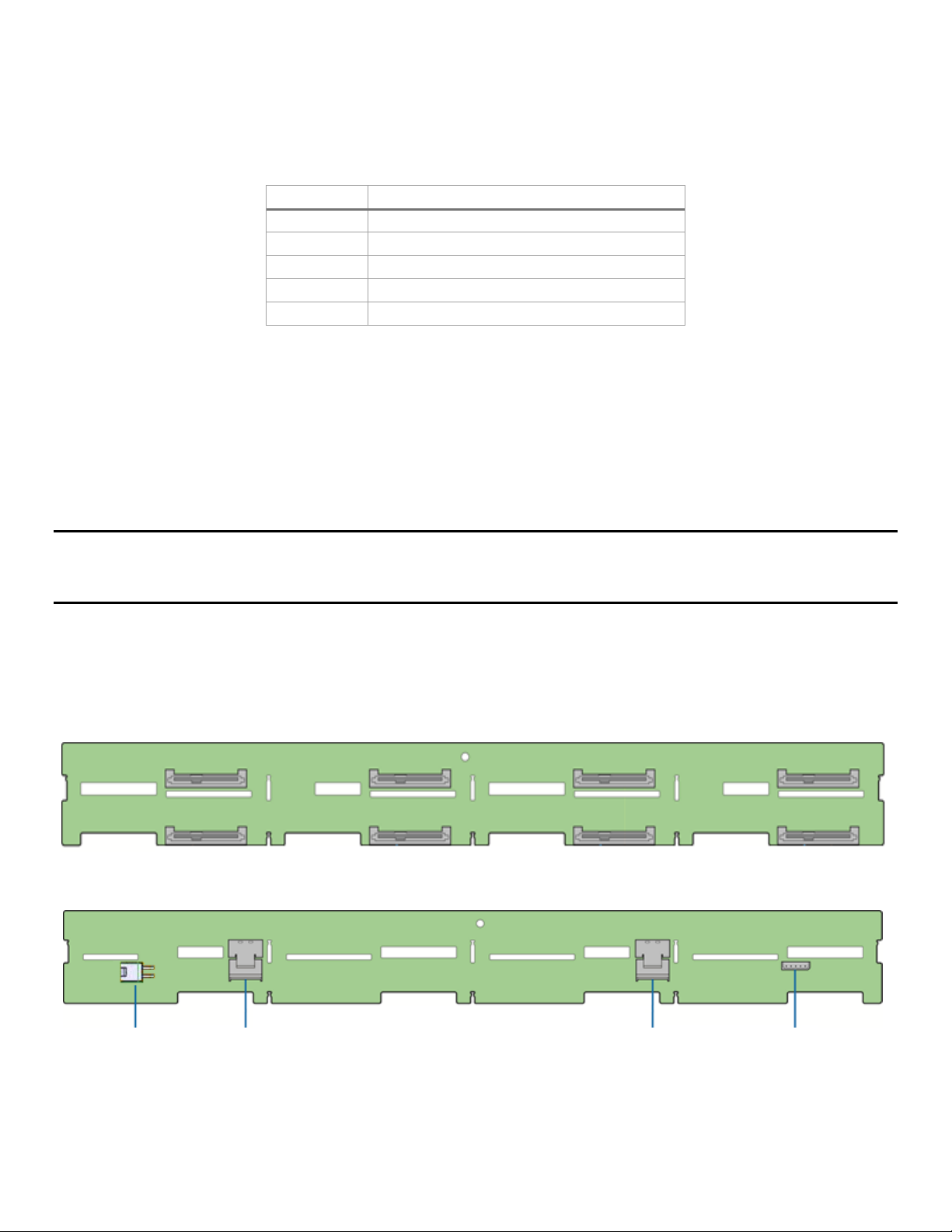

Figure 56. 12 x 3.5" hot swap backplane, front side ................................................................................................................... 80

Figure 57. 12 x 3.5" HSBP connector identification .................................................................................................................... 81

Figure 58. 2 x 2.5" rear mount backplane kit placement .......................................................................................................... 82

Figure 59. 2 x 2.5" hot swap backplane ........................................................................................................................................... 83

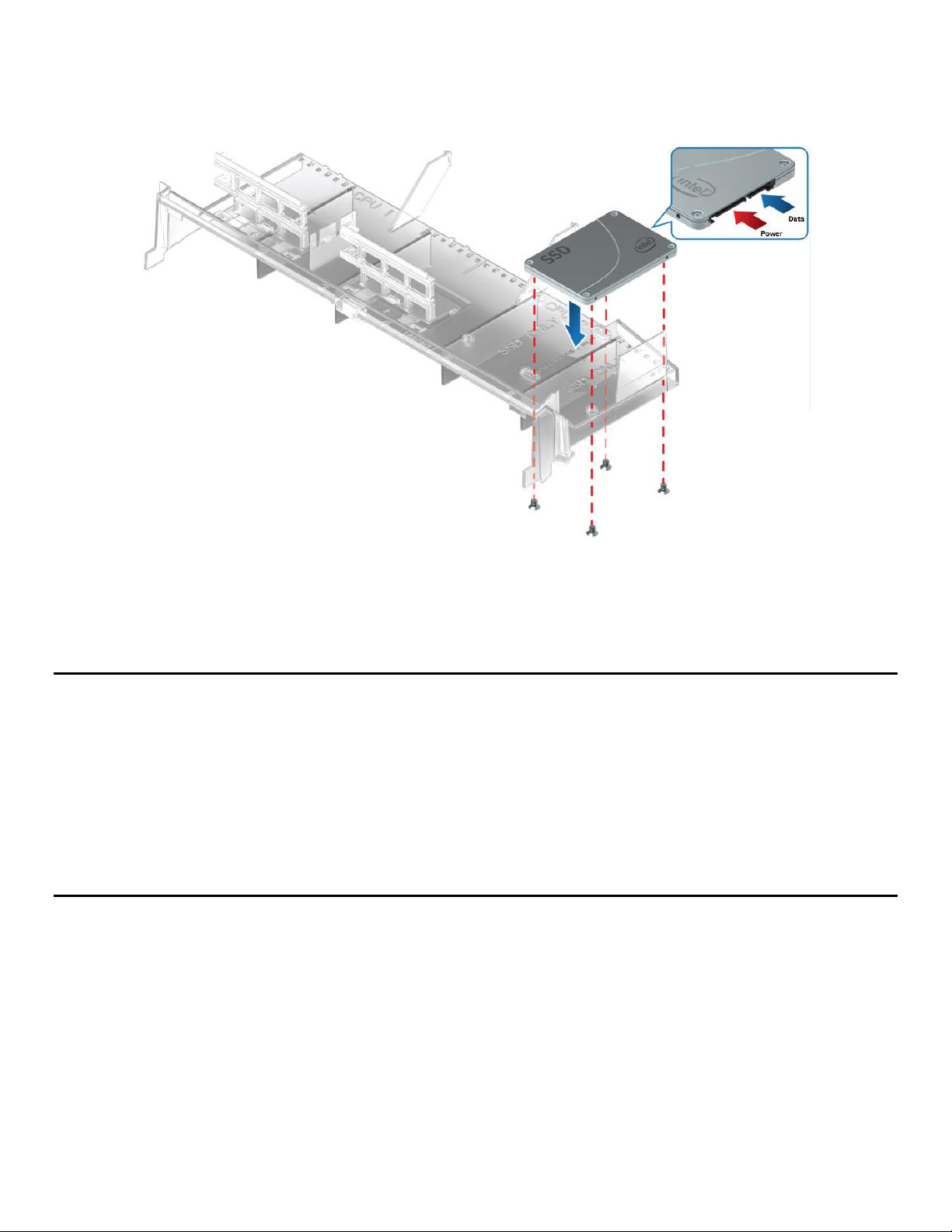

Figure 60. 2.5" Solid state drive (SSD) mounting option .......................................................................................................... 85

Figure 61. Onboard storage support features .............................................................................................................................. 86

Figure 62. BIOS setup Mass Storage Controller Configuration screen ............................................................................... 88

Figure 63. ESRT2 SATA RAID-5 upgrade key ................................................................................................................................ 90

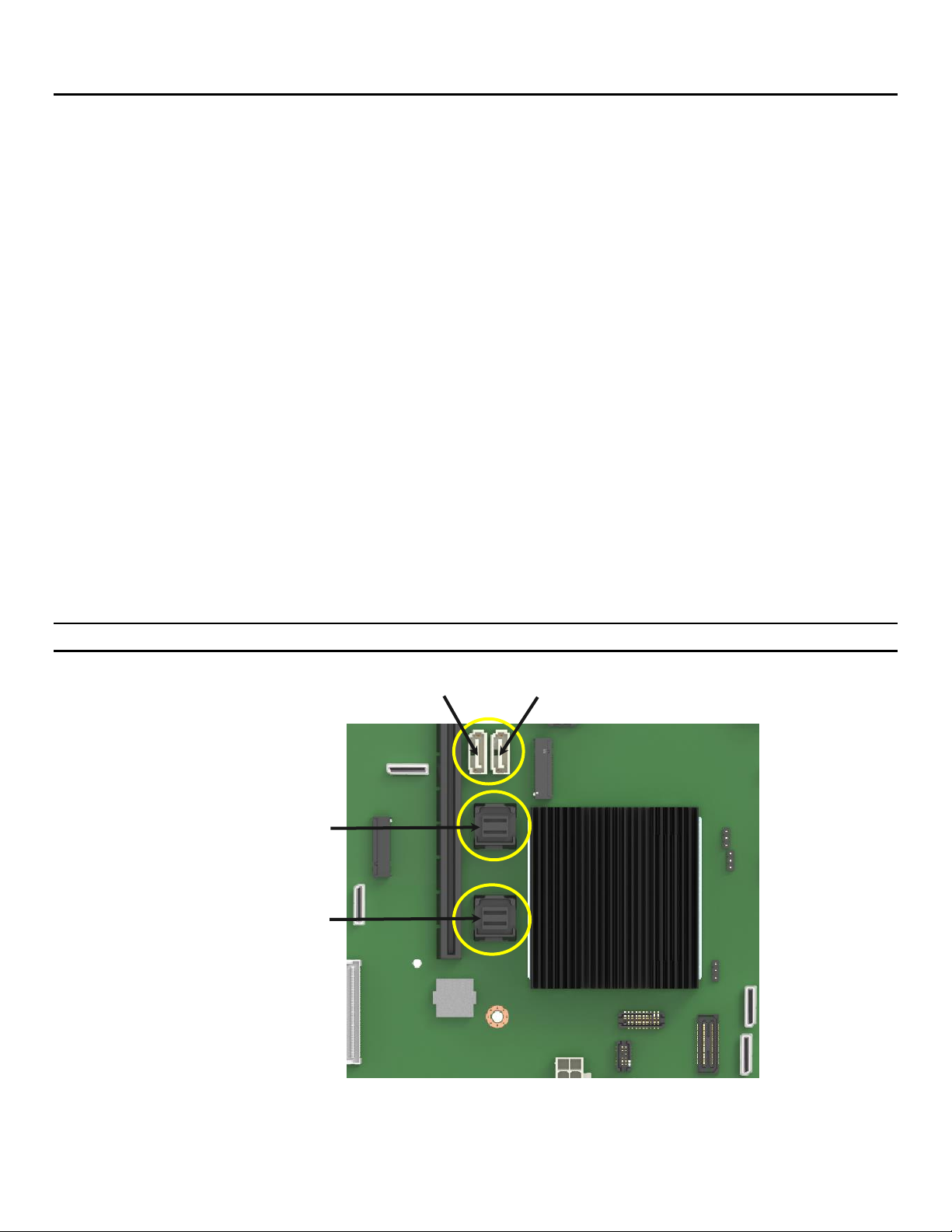

Figure 64. M.2 module connector locations .................................................................................................................................. 91

Figure 65. Onboard OCuLink connectors ....................................................................................................................................... 92

Figure 66. NVMe* storage bus event/error handling ................................................................................................................. 93

Figure 67. VMD support disabled in BIOS setup .......................................................................................................................... 95

Figure 68. Intel® VMD support enabled in BIOS setup .............................................................................................................. 95

Figure 69. Intel® VROC basic architecture overview ................................................................................................................... 96

Figure 70. Intel® VROC upgrade key .................................................................................................................................................. 97

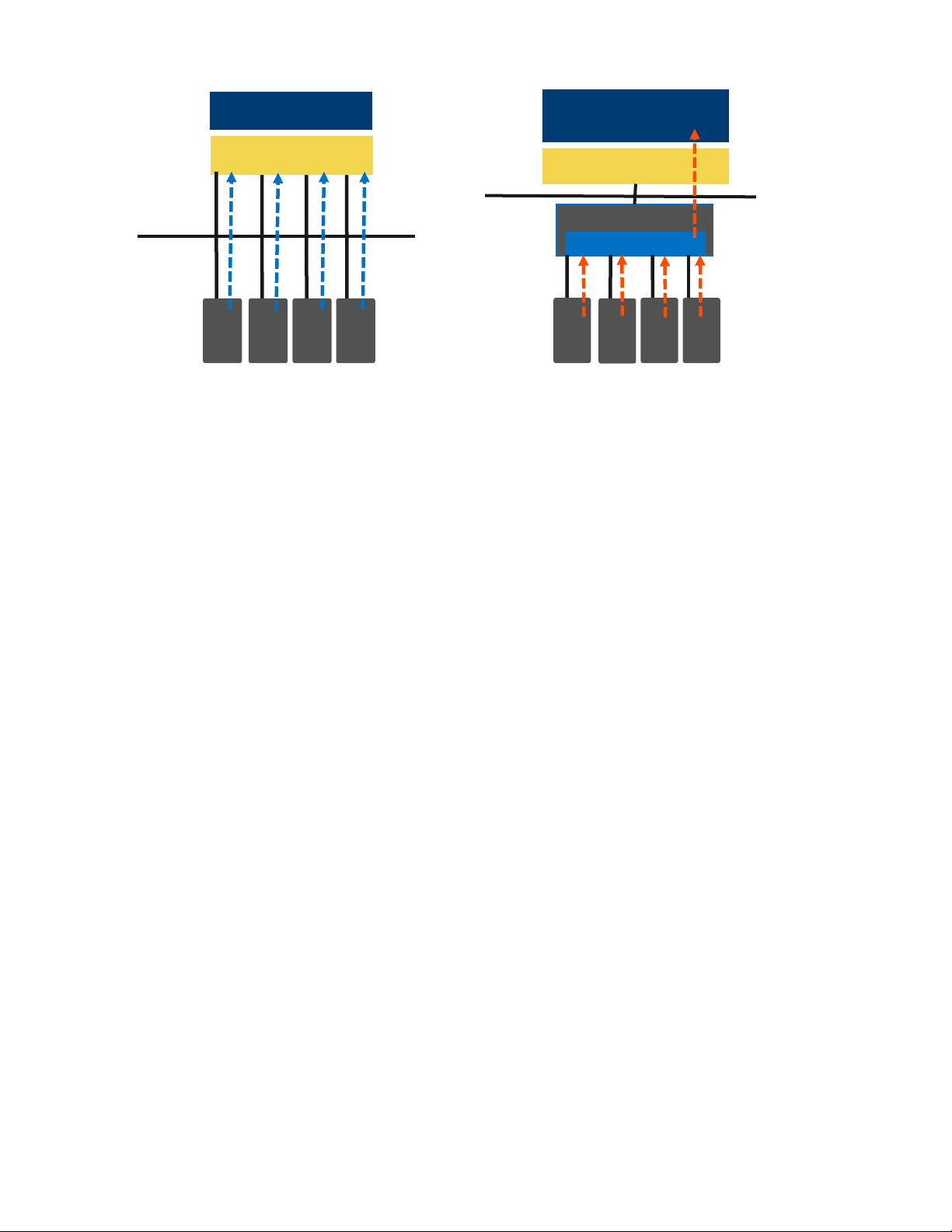

Figure 71. Backplane cabling from two PCIe sources ................................................................................................................ 98

Figure 72. Intel® Integrated RAID Module .................................................................................................................................... 102

Figure 73. Triple RMFBU (default) mounting bracket installation ..................................................................................... 103

Figure 74. Dual RMFBU mounting bracket installation .......................................................................................................... 103

Figure 75. SAS expander card installation ................................................................................................................................... 104

Figure 76. Intel® RAID Expander RES3FV288 connector identification .......................................................................... 105

Figure 77. 12 GB internal 36-Port Intel® RAID Expander Card RES3TV360 connector identification ............... 106

Figure 78. Front I/O panel features ................................................................................................................................................ 107

Figure 79. Front control panel features ........................................................................................................................................ 108

Figure 80. PCIe* add-in card support ............................................................................................................................................ 111

Figure 81. Riser card #1 bracket ...................................................................................................................................................... 112

Figure 82. Left and right views of riser card #2 and #3 bracket ......................................................................................... 113

10

Page 11

Intel® Server System R2000WF Product Family Technical Product Specification

Figure 83. Full height/full length add-in card support ........................................................................................................... 113

Figure 84. Three-slot PCIe* riser card (iPC – A2UL8RISER2) ............................................................................................... 114

Figure 85. Two-slot PCIe riser card (iPC – A2UL16RISER2) .................................................................................................. 114

Figure 86. Low profile riser card (iPC – A2UX8X4RISER) ....................................................................................................... 115

Figure 87. OCP module placement ................................................................................................................................................. 116

Figure 88. Intel® RMM4 Lite activation key placement ........................................................................................................... 118

Figure 89. Dedicated management port ....................................................................................................................................... 118

Figure 90. On-board POST Diagnostic LEDs .............................................................................................................................. 125

Figure 91. R2308WFxxx system cable routing diagram ........................................................................................................ 158

Figure 92. R2208WFxxx system cable routing diagram ........................................................................................................ 159

Figure 93. R2312WFxxx system cable routing diagram ........................................................................................................ 160

Figure 94. R2208WFxxx + 8 drives system cable routing diagram ................................................................................... 161

Figure 95. R2224WFxxx system cable routing diagram ........................................................................................................ 162

11

Page 12

Intel® Server System R2000WF Product Family Technical Product Specification

List of Tables

Table 1. Reference Documents ........................................................................................................................................................... 15

Table 2. Intel® Server Board S2600WF product family features ........................................................................................... 17

Table 3. Intel® Server System R2000WF product family configurations ........................................................................... 19

Table 4. System environmental limits summary.......................................................................................................................... 35

Table 5. Product weight information ................................................................................................................................................ 36

Table 6. 1100 Watt AC power supply efficiency (80 Plus Platinum) ................................................................................... 38

Table 7. 1300 Watt AC power supply efficiency (80 Plus Titanium) ................................................................................... 38

Table 8. 750 Watt DC power supply efficiency (80 Plus Gold) .............................................................................................. 38

Table 9. AC power cord specifications ............................................................................................................................................. 41

Table 10. DC power cable connector pin-out ............................................................................................................................... 41

Table 11. AC Power Factor – 1100W Power Supply .................................................................................................................. 42

Table 12 . AC Power Factor - 1300W Power Supply .................................................................................................................. 42

Table 13. AC input voltage range, 1100 W power supply ....................................................................................................... 42

Table 14. AC input voltage range, 1300 W power supply ....................................................................................................... 42

Table 15. AC line holdup time, 1100 W power supply .............................................................................................................. 43

Table 16. AC line holdup time, 1300 W power supply .............................................................................................................. 43

Table 17. AC line sag transient performance (10 sec interval between each sagging) ............................................... 43

Table 18. AC line surge transient performance ............................................................................................................................ 44

Table 18. Maximum Load Ratings ...................................................................................................................................................... 44

Table 19. Performance criteria ............................................................................................................................................................ 44

Table 20. Over current protection, 1300 W power supply ...................................................................................................... 45

Table 21. Over current protection, 1100 W power supply ...................................................................................................... 45

Table 22. Over voltage protection (OVP) limits, 1300 W power supply ............................................................................ 46

Table 23. Over voltage protection (OVP) limits, 1100 W power supply ............................................................................ 46

Table 24. LED indicators ........................................................................................................................................................................ 46

Table 25. DC input rating ....................................................................................................................................................................... 47

Table 26. DC holdup time ...................................................................................................................................................................... 47

Table 27. Line voltage transient limits ............................................................................................................................................. 47

Table 28. Performance criteria ............................................................................................................................................................ 48

Table 29. Over current protection ..................................................................................................................................................... 48

Table 30. Over voltage protection limits ......................................................................................................................................... 49

Table 31. Example load share threshold for activating supplies .......................................................................................... 50

Table 32. Power supply module output power connector pin-out ..................................................................................... 51

Table 33. Riser slot power pin-out (OPT_12V_PWR_#) ............................................................................................................ 52

Table 34. Hot swap backplane power connector pin-out (“HSBP PWR") .......................................................................... 52

Table 35. Peripheral drive power connector pin-out (“Peripheral PWR”) ......................................................................... 53

Table 36. System volumetric airflow, Intel® Server System R2308WFxxx ........................................................................ 54

Table 37 . System volumetric airflow, Intel® Server System R2308WFxxx w/Intel® Xeon Phi™ (passive) ............ 54

Table 38. System volumetric airflow, Intel® Server System R2312WFxxx ........................................................................ 55

Table 39. System volumetric airflow, Intel® Server System R2208WFxxx ........................................................................ 55

12

Page 13

Intel® Server System R2000WF Product Family Technical Product Specification

Table 40 . System volumetric airflow, Intel® Server System R2208WFxxx w/Intel® Xeon Phi™ (passive) ............ 55

Table 41. System volumetric airflow, Intel® Server System R2208WFxxx + 8 Drive Acc (16x2.5”) ........................ 55

Table 42 . System volumetric airflow, Intel® Server System R2208WFxxx + 8 Drive Acc (16x2.5”) w/Intel®

Xeon Phi™ (passive) .......................................................................................................................................................................... 55

Table 43. System volumetric airflow, Intel® Server System R2224WFxxx ........................................................................ 55

Table 44. PCIe* add-in card airflow (LFM) support limits – R2312WFxxx and R2224WFxxx ................................... 56

Table 45. PCIe* add-in card airflow (LFM) support limits – R2208WFxxx, R2208WFxxx + 8 drive accessory kit,

and R2308WFxxx .............................................................................................................................................................................. 57

Table 46. System fan connector pin-out......................................................................................................................................... 63

Table 47. 2-slot PCIe* riser card description and routing ........................................................................................................ 65

Table 48. Drive status LED states ....................................................................................................................................................... 72

Table 49. Drive activity LED states ..................................................................................................................................................... 72

Table 50. PCIe* SSD drive status LED states ................................................................................................................................. 72

Table 51. I2C cable connector pin-out ............................................................................................................................................ 76

Table 52. Power harness connector pin-out ................................................................................................................................. 77

Table 53. Power harness connector pin-out ................................................................................................................................. 78

Table 54. I2C cable connector pin-out ............................................................................................................................................ 79

Table 55. 7-pin SATA cable connector pin-out ............................................................................................................................ 83

Table 56. Power connector pin-out .................................................................................................................................................. 84

Table 57. I2C connector pin-out ......................................................................................................................................................... 84

Table 58. SGPIO connector pin-out .................................................................................................................................................. 84

Table 59. SATA and sSATA controller feature support ............................................................................................................ 87

Table 60. SATA and sSATA controller BIOS setup utility options ........................................................................................ 87

Table 61. CPU - PCIe* port routing .................................................................................................................................................... 94

Table 62. Intel® VROC upgrade key options .................................................................................................................................. 97

Table 63. Intel® SAS RAID expander card support ................................................................................................................... 105

Table 64. System status LED state definitions........................................................................................................................... 109

Table 65. Power/sleep LED functional states ............................................................................................................................ 110

Table 66. Riser slot #1 PCIe* root port mapping ...................................................................................................................... 112

Table 67. Riser slot #2 PCIe* root port mapping ...................................................................................................................... 112

Table 68. Riser slot #3 PCIe* root port mapping ...................................................................................................................... 112

Table 69. Three-slot PCIe* riser card slot description ........................................................................................................... 114

Table 70. Two-slot PCIe riser card slot description................................................................................................................. 114

Table 71. Low profile riser card slot description ...................................................................................................................... 115

Table 72. OCP* Compatible Intel® Ethernet Network Adapters ......................................................................................... 116

Table 73. Intel® Remote Management Module 4 (RMM4) options .................................................................................... 117

Table 74. Basic and advanced server management features overview .......................................................................... 117

Table 75. POST progress code LED example .......................................................................................................................... 125

Table 76. MRC progress codes ......................................................................................................................................................... 126

Table 77. MRC fatal error codes....................................................................................................................................................... 128

Table 78. POST progress codes ....................................................................................................................................................... 129

Table 79. POST Error Messages and Handling .......................................................................................................................... 133

13

Page 14

Intel® Server System R2000WF Product Family Technical Product Specification

Table 80. POST error beep codes ................................................................................................................................................... 140

Table 81. Integrated BMC beep codes .......................................................................................................................................... 140

Table 82. Thermal configuration table for system in “normal” operating mode ........................................................ 142

Table 83. Thermal configuration table for system in “fan fail” operating mode ......................................................... 150

Table 84. Intel® Server Board S2600WF (iPN – H48104-xxx) .............................................................................................. 164

Table 85. 2U 3-Slot PCIe* Riser Card (iPN – H20087-xxx) .................................................................................................... 164

Table 86. 2U 2-Slot PCIe* Riser Card (iPN – H20078-xxx) .................................................................................................... 164

Table 87. Riser Slot #3 Low Profile PCIe* Riser Card (iPN – G94347-xxx) ..................................................................... 164

Table 88. Common Front Panel Board (iPN – H29366-xxx) ................................................................................................. 164

Table 89. Storage System Model Mini- Front Panel Board (iPN – G28538-xxx) ......................................................... 164

Table 90. 2U 8 x 3.5” Hot Swap Back Plane (iPN – G97160-xxx) ....................................................................................... 164

Table 91. 2U 12 x 3.5” Hot Swap Back Plane (iPN – H88392-xxx) .................................................................................... 164

Table 92. 2U 8 x 2.5” SAS Hot Swap Back Plane (iPN –H95877-xxx) ............................................................................... 165

Table 93. Intel® 2U 8 x 2.5” Dual Port Hot Swap Back Plane Accessory Kit (iPC – A2U8X25S3DPDK) 2U 8 x

2.5” Dual Port Hot Swap Back Plane (iPN – G97166-xxx) ............................................................................................. 165

Table 94. Intel® 2U 2 x 2.5” Rear Hot Swap Back Plane Accessory Kit (iPC – A2UREARHSDK) 2U 2 x 2.5” Rear

Hot Swap Back Plane (iPN – G94339-xxx) ........................................................................................................................... 165

Table 95. Intel® Remote Management Module Lite Accessory Option (iPC – AXXRMM4LITE2)........................... 165

14

Page 15

Intel® Server System R2000WF Product Family Technical Product Specification

Document Title

Document Classification

Intel® Server Board S2600WF Product Family Technical Product Specification

Public

Intel® Server S2600WF Product Family Configuration Guide

Public

Intel® Server System R1000WF Product Family System Integration and Service Guide

Public

Intel® Server S2600WF Product Family Power Budget & Thermal Configuration Tool

Public

Intel® Servers System BMC Firmware EPS for Intel® Xeon® processor Scalable Family

Intel Confidential

Intel® Server System BIOS EPS for Intel® Xeon® processor Scalable Family

Intel Confidential

Intel® Chipset C62X Product Family External Design Specification

Intel Confidential

Intel® Ethernet Connection X557-AT2 Product Brief

Public

Advanced Configuration and Power Interface Specification, Revision 3.0, http://www.acpi.info/.

Public

Intelligent Platform Management Interface Specification, Version 2.0. 2004.

Public

Intelligent Platform Management Bus Communications Protocol Specification, Version 1.0. 1998

Public

Platform Support for Serial-over-LAN (SOL), TMode, and Terminal Mode External Architecture

Specification, Version 1.1, 02/01/02

Public

Intel® Remote Management Module User’s Guide, Intel Corporation.

Public

Alert Standard Format (ASF) Specification, Version 2.0, 23 April 2003, ©2000-2003, Distributed

Management Task Force, Inc., http://www.dmtf.org.

Public

SmaRT & CLST Architecture on Intel Systems and Power Supplies Specification

Public

Intel® Remote Management Module 4 Technical Product Specification

Public

Intel® Remote Management Module 4 and Integrated BMC Web Console Users Guide

Public

1. Introduction

This Technical Product Specification (TPS) provides system level information for the Intel® Server System

R2000WF product family.

This document describes the embedded functionality and available features of the integrated server system

which includes: the chassis layout, system boards, power subsystem, cooling subsystem, storage subsystem

options, and available installable options. Note that some system features are provided as configurable

options and may not be included standard in every system configuration offered. Please reference the Intel®

Server Board S2600WF Product Family Configuration Guide for a list of configured options for all system

models made available.

For more additional product information, refer to the documents listed in Table 1.

Table 1. Reference Documents

EPS and EDS documents are made available under NDA with Intel and must be ordered through an Intel

representative.

15

Page 16

Intel® Server System R2000WF Product Family Technical Product Specification

1.1 Document Outline

This document is divided into the following chapters:

Chapter 1 – Introduction

Chapter 2 – Product Family Overview

Chapter 3 – System Power

Chapter 4 – Thermal Management

Chapter 5 – System Storage and Peripherals Drive Bay Overview

Chapter 6 – Storage Controller Options Overview

Chapter 7 – Front Control Panel and I/O Panel Overview

Chapter 8 – PCIe* Riser Card Support

Chapter 9 – Intel® I/O Module Support

Chapter 10 – Basic and Advanced Server Management Features

Appendix A – Integration and Usage Tips

Appendix B – POST Code Diagnostic LED Decoder

Appendix C – Post Code Errors

Appendix D – System Configuration Tables for Thermal Compatibility

Appendix E – System Cable Routing Diagrams

Glossary

1.2 Intel® Server Board Use Disclaimer

Intel® Server Boards support add-in peripherals and contain a number of high-density very large scale

integration (VLSI) and power delivery components that need adequate airflow to cool. Intel ensures through

its own chassis development and testing that when Intel server building blocks are used together, the fully

integrated system will meet the intended thermal requirements of these components. It is the responsibility

of the system integrator who chooses not to use Intel developed server building blocks to consult vendor

datasheets and operating parameters to determine the amount of airflow required for their specific

application and environmental conditions. Intel Corporation cannot be held responsible if components fail

or the server board does not operate correctly when used outside any of its published operating or nonoperating limits.

1.3 Product Errata

Product that is currently shipping may have features or functionality that deviate from published

specifications. These deviations are generally discovered after the product has gone into formal production.

Intel terms these deviations as product errata. Known product errata are published in the Monthly

Specification Update for the given product family which can be downloaded from

http://www.intel.com/support .

16

Page 17

Intel® Server System R2000WF Product Family Technical Product Specification

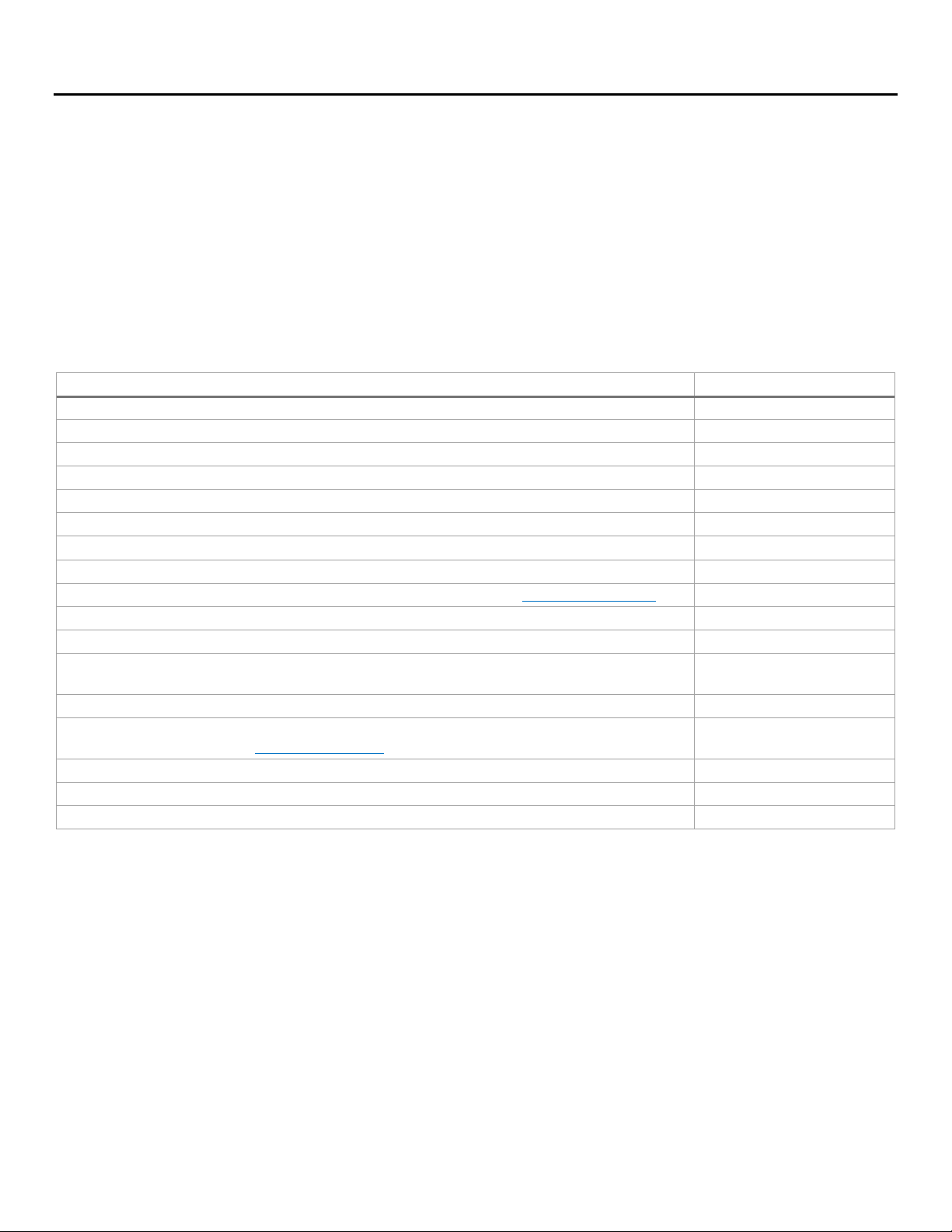

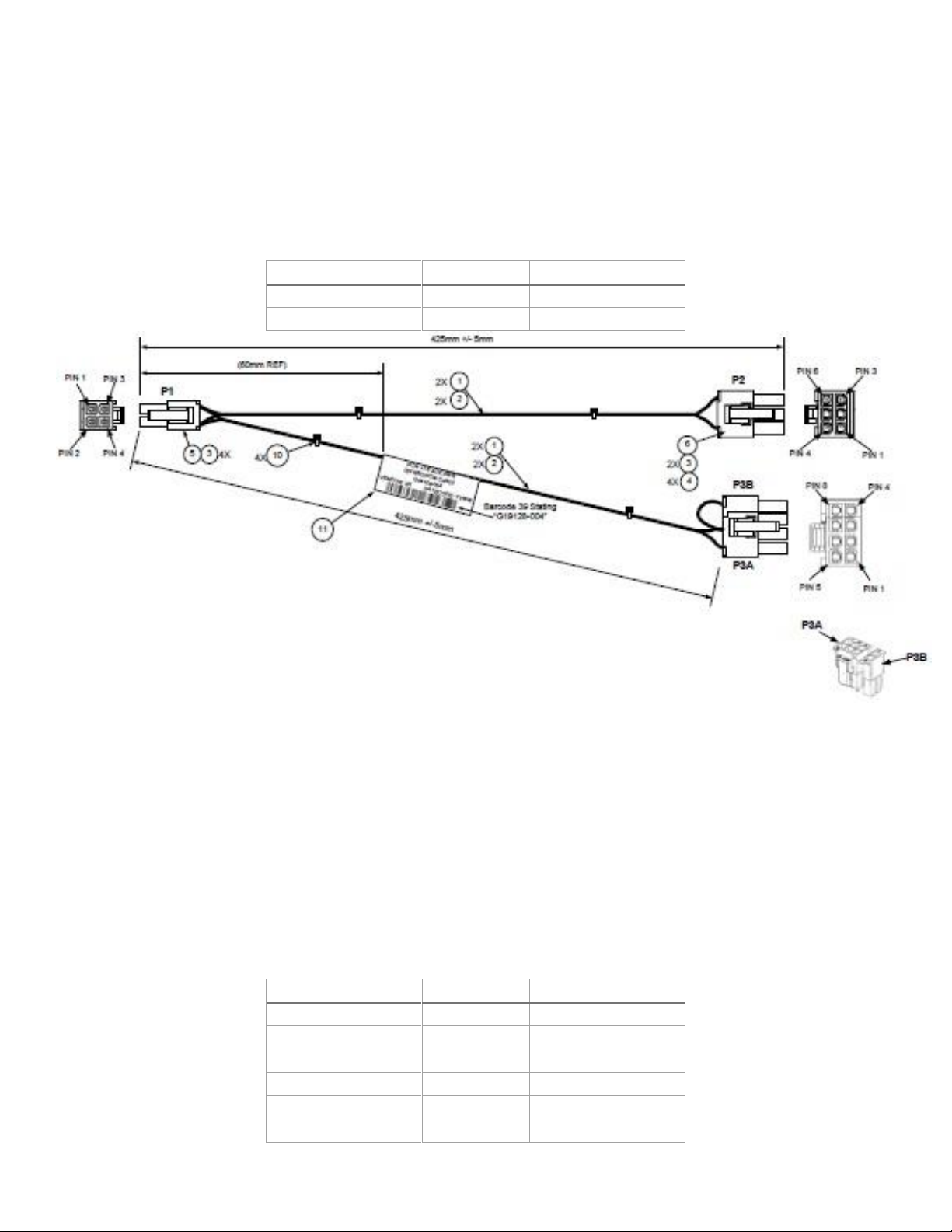

Intel Server Board

Product Code

S2600WFT

S2600WF0

S2600WFQ

Processor Support

Two LGA3647-0 (Socket P) processor sockets

Support for one or two Intel

®

Xeon® processor Scalable family (Platinum, Gold, Silver, and Bronze)

o Previous generation Intel

®

Xeon® processors are not supported

Maximum supported Thermal Design Power (TDP) of up to 205W (Board Only)

Note: Intel Server Systems based on this server board family may support a lower maximum Thermal

Design Power (TDP). See appropriate Intel System TPS for max supported TDP

Memory

24 Total DIMM slots (12 DIMMs per processor)

o 6 Memory Channels per processor / 2 DIMMs per Channel

Registered DDR4 (RDIMM), Load Reduced DDR4 (LRDIMM)

Memory Capacity

o Up to 1.5TB for Gold and Platinum CPUs; Up to 768GB for Silver and Bronze CPUs

Memory data transfer rates:

o Up to 2666 MT/s @ 1 DPC and 2 DPC (Processor SKU Dependent) DPC = DIMMs Per

Channel

DDR4 standard voltage of 1.2V

Intel® C62x Series

Chipset

Intel® C624 Chipset

Intel® C624 Chipset

Intel® C628 Chipset

Intel® Quick Assist

Technology (QAT)

No

No

Yes

Intel® Omni-Path

Fabric Support

Yes

Yes

Yes

On-board LAN

Dual Port RJ45 10GbE

No

No

Intel® OCP Module

Support

iPC = Intel Product

Code

iPC 557T2OCPG1P5 –

Dual Port 10Gb RJ45

iPC

527DA2OCPG1P5–

Dual Port SFP+

iPC I357T4OCPG1P5 – Quad Port

1Gb RJ45

iPC X527DA4OCPG1P5 – Quad

Port SFP+

iPC X557T2OCPG1P5 – Dual Port

10Gb RJ45

iPC X527DA2OCPG1P5 – Dual Port

SFP+

iPC I357T4OCPG1P5 – Quad Port

1Gb RJ45

iPC X527DA4OCPG1P5 – Quad

Port SFP+

iPC X557T2OCPG1P5 – Dual Port

10Gb RJ45

iPC X527DA2OCPG1P5 – Dual Port

SFP+

Intel® Integrated SAS

Module Support

Yes

Yes

Yes

Onboard PCIe* NVMe

Support

4 – PCIe OCuLink

Connectors

Intel® VMD Support

Intel® RSTe VROC

Support – Acc. Option

4 – PCIe OCuLink Connectors

Intel® VMD Support

Intel® RSTe VROC Support – Acc.

Option

2 – OCuLink Connectors

Intel® VMD Support

Intel® RSTe VROC Support – Acc.

Option

2. Server System Family Overview

The 2U server platforms within the Intel® Server System R2000WF product family offer a variety of system

options to meet varied configuration requirements of high-density, high-performance computing

environments.

This chapter provides a high-level overview of the system features and available options supported in

different system models within this product family. Greater detail for each major sub-system, feature or

option is provided in following chapters.

The following table identifies the feature set of each supported server board.

Table 2. Intel® Server Board S2600WF product family features

17

Page 18

Intel® Server System R2000WF Product Family Technical Product Specification

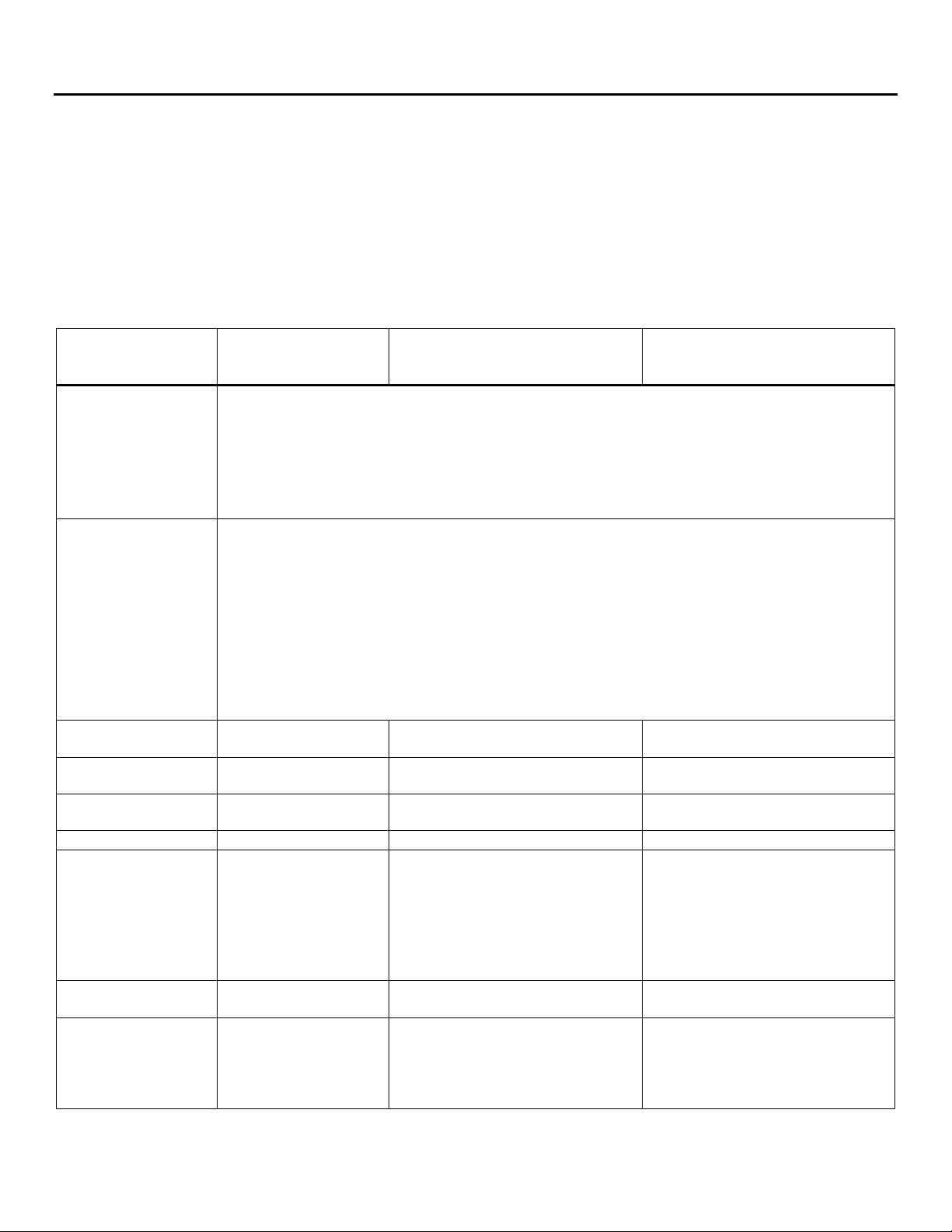

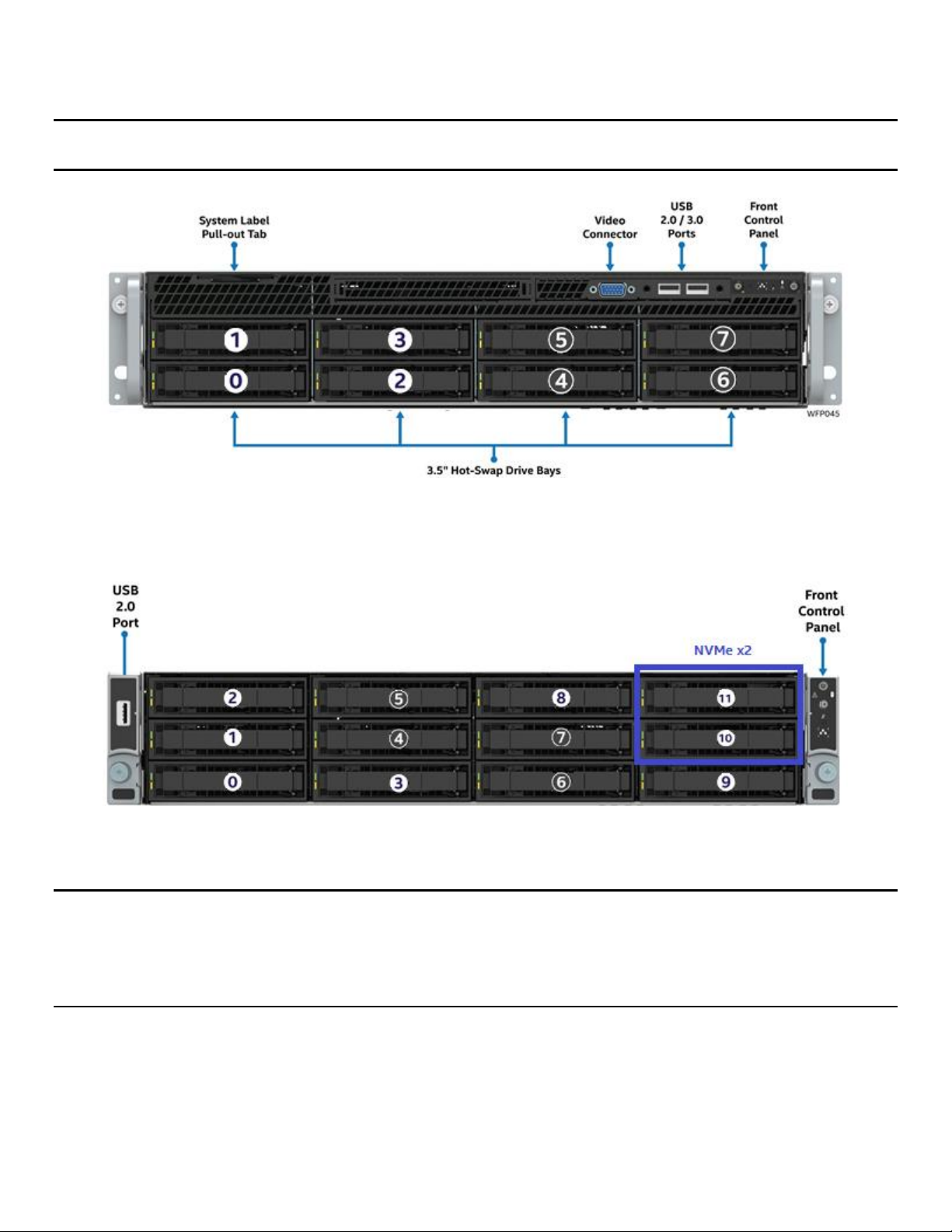

Intel Server Board

Product Code

S2600WFT

S2600WF0

S2600WFQ

Onboard SATA

Support

12 x SATA 6Gbps ports (6Gb/s, 3 Gb/s and 1.5Gb/s transfer

rates are supported)

o Two single port 7-pin SATA connectors

o Two M.2 connectors – SATA / PCIe*

o Two 4-port mini-SAS HD (SFF-8643) connectors

Embedded SATA Software RAID

o Intel® Rapid Storage RAID Technology (RSTe) 5.0

o Intel® Embedded Server RAID Technology 2

(ESRT2) 1.60 with optional RAID 5 key support

NOTE: ESRT2 is only supported on S2600WFT and S2600WF0

boards

4 x SATA 6Gbps ports (6Gb/s, 3

Gb/s and 1.5Gb/s transfer rates

are supported)

o Two single port 7-pin

SATA connectors

o Two M.2 connectors –

SATA / PCIe*

Embedded SATA Software RAID

o Intel® Rapid Storage

RAID Technology

(RSTe) 5.0

NOTE: 4-port mini-SAS HD

connectors are present on

S2600WFQ but are not configure as

SATA, these cables are used only for

Intel® Quick Assist Technology (QAT).

Riser Card Support

Concurrent support for up to three riser cards

Riser #1 – PCIe* 3.0 x24 (CPU1 x16, CPU2 x8) – 2 and 3 slot riser card options available

Riser #2 – PCIe* 3.0 x24 (CPU2 x24) – 2 and 3 slot riser card options available

Riser #3 (2U systems only) – PCIe* 3.0 (CPU 2 x12) – 2 slot riser card available

Video

Integrated 2D Video Controller

16MB of DDR4 Video Memory

One DB-15 External Connector

One 14-Pin Internal connector for optional Front Panel Video support

USB Support

Three external USB 3.0 ports

One internal Type-A USB 2.0 port

One internal 20-pin connector for optional 2x USB 3.0 port Front Panel support

One Internal 10-pin connector for optional 2x USB 2.0 port Front Panel support

Serial Port Support

One external RJ-45 Serial-A port connector

One internal DH-10 Serial-B port header for optional front or rear serial port support

Server Management

Integrated Baseboard Management Controller, IPMI 2.0 compliant

Support for Intel

®

Server Management Software

On-board dedicated RJ45 management port

Support for Advanced Server Management features via an Intel® Remote Management Module 4 Lite

Accessory Option (iPC – AXXRMM4LITE2)

Security

Intel® Trusted Platform Module 2.0 (Rest of World) – iPC- AXXTPMENC8 (Accessory Option)

Intel® Trusted Platform Module 2.0 (China Version) – iPC- AXXTPMCHNE8 (Accessory Option)

System Fan Support

Six System fans supported in two different connector formats hot swap (2U) and cabled (1U)

o Six 10-pin managed system fan headers (Sys_Fan 1-6) – Used for 1U system configuration

o Six 6-pin hot swap capable managed system fan connectors (Sys_Fan 1-6) – Used for 2U

system Configuration

18

Page 19

Intel® Server System R2000WF Product Family Technical Product Specification

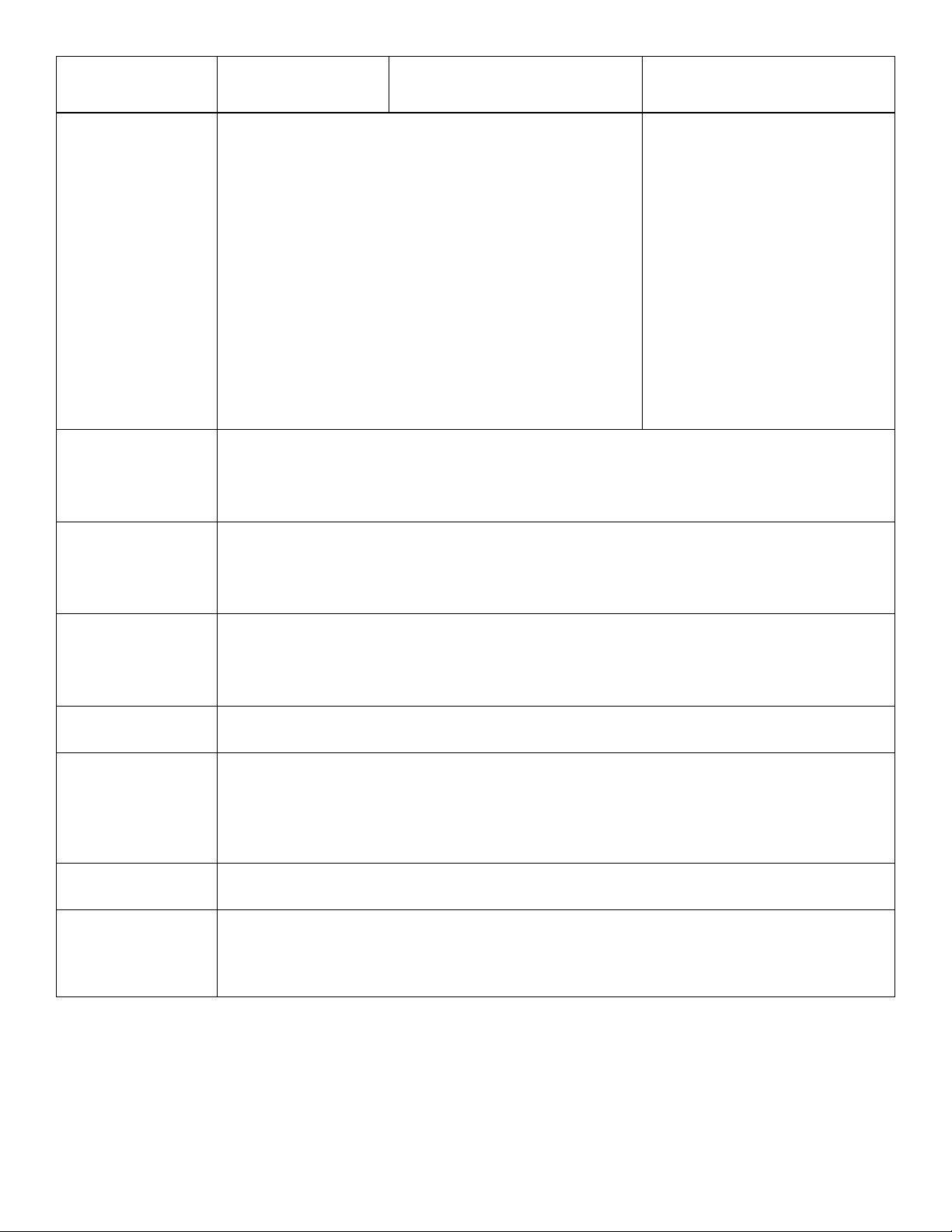

Feature

Description

Chassis Type

2U rack mount chassis

Server Board

Intel® Server Board S2600WF product family

Maximum Supported Processor

Thermal Design Power (TDP)

Up to 140 W in all Intel system configuration options

165 W processors supported on Intel® Server Chassis R2208WFxxxx and R2308WFxxxx

configurations only

See Thermal Config Tables at end of this document for more information

External I/O Connections

DB-15 video connectors

o Front and back (non-storage system configurations only)

RJ-45 serial port A connector

Dual RJ-45 network interface connectors (S2600WFT-based systems only)

Dedicated RJ-45 server management NIC

(3) – USB 3.0 connectors on back panel

(2) – USB 3.0 connectors on front panel (non-storage system configurations only)

(1) – USB 2.0 connector on rack handle (storage configurations only)

Internal I/O

Connectors/Headers

(1) – Type-A USB 2.0 connector

(1) – DH-10 serial port B connector

System Fans

(6) – managed 60 mm hot swap capable system fans

Integrated fans included with each installed power supply module

Riser Card Support

Support for three riser cards:

Riser #1 – PCIe* 3.0 x24 - up to 3 PCIe slots

Riser #2 – PCIe* 3.0 x24 - up to 3 PCIe slots

Riser #3 – PCIe* 3.0 x16 – up to 2 PCIe slots – Low profile cards only (optional)

With three riser cards installed, up to eight possible add-in cards can be supported:

(4) full height/half-length + (2) full height/half-length add-in cards via Risers #1 and #2

(2) low profile add in cards via riser #3 (option)

Power Supply Options

The server system can have up to two power supply modules installed, providing support for

the following power configurations: 1+0, 1+1 redundant power, and 2+0 combined power.

(3) power supply options:

AC 1100W Platinum

AC 1300W Titanium

DC 750W Gold

The following table describes the features of the server system configurations. Storage system

configurations include R2312WFxxxx and R2224WFxxxx. Non-storage system configurations include

R2308WFxxxx, R2208WFxxxx, and R2208WFxxxx +8 (base 8 drive system with 8 drive add in module).

Table 3. Intel® Server System R2000WF product family configurations

19

Page 20

Intel® Server System R2000WF Product Family Technical Product Specification

Feature

Description

Drive Bay Options

Hot Swap Backplane Options:

Note: All available backplane options have support for SAS 3.0 (12 Gb/sec)

8 x 3.5” SAS/ SATA

8 x 2.5” combo backplane – SAS/SATA/NVMe

8 x 2.5” Dual Port SAS

12 x 3.5” SAS/ SATA (supports up to 2 NVMe drives)

Storage Bay Options:

8 x 3.5” SAS/SATA hot swap drive bays

12 x 3.5” SAS/SATA hot swap drive bays (supports up to 2 NVMe drives)

8 x 2.5” SAS/SATA/NVMe hot swap drive bays

16 x 2.5” SAS/SATA/NVMe hot swap drive bays

24 x 2.5” SAS/SATA/NVMe swap drive bays

2 x 2.5” SATA SSD Back of Chassis Hot Swap Drive Bays (accessory Option)

2 x internal fixed mount 2.5” SSDs (all SYSTEM MODELs)

Supported Rack Mount Kit

Accessory Options

AXXELVRAIL – Enhanced value rack mount rail kit - 424mm max travel length, 59kgs

(130lbs.) max supported weight

AXXFULLRAIL- 2U Premium rail with CMA support – 800mm max travel length, 45kgs

(99lbs.) max supported weight

AXXSHRTRAIL - 2U Premium rail without CMA support - 788mm max travel length, 45kgs

(99lbs.) max supported weight

AXX2POSTBRCKT – Two post fixed mount bracket kit

AXXCMA2– Cable Management Arm – (*supported with AXXFULLRAIL only)

20

Page 21

Intel® Server System R2000WF Product Family Technical Product Specification

2.1 System Features Overview

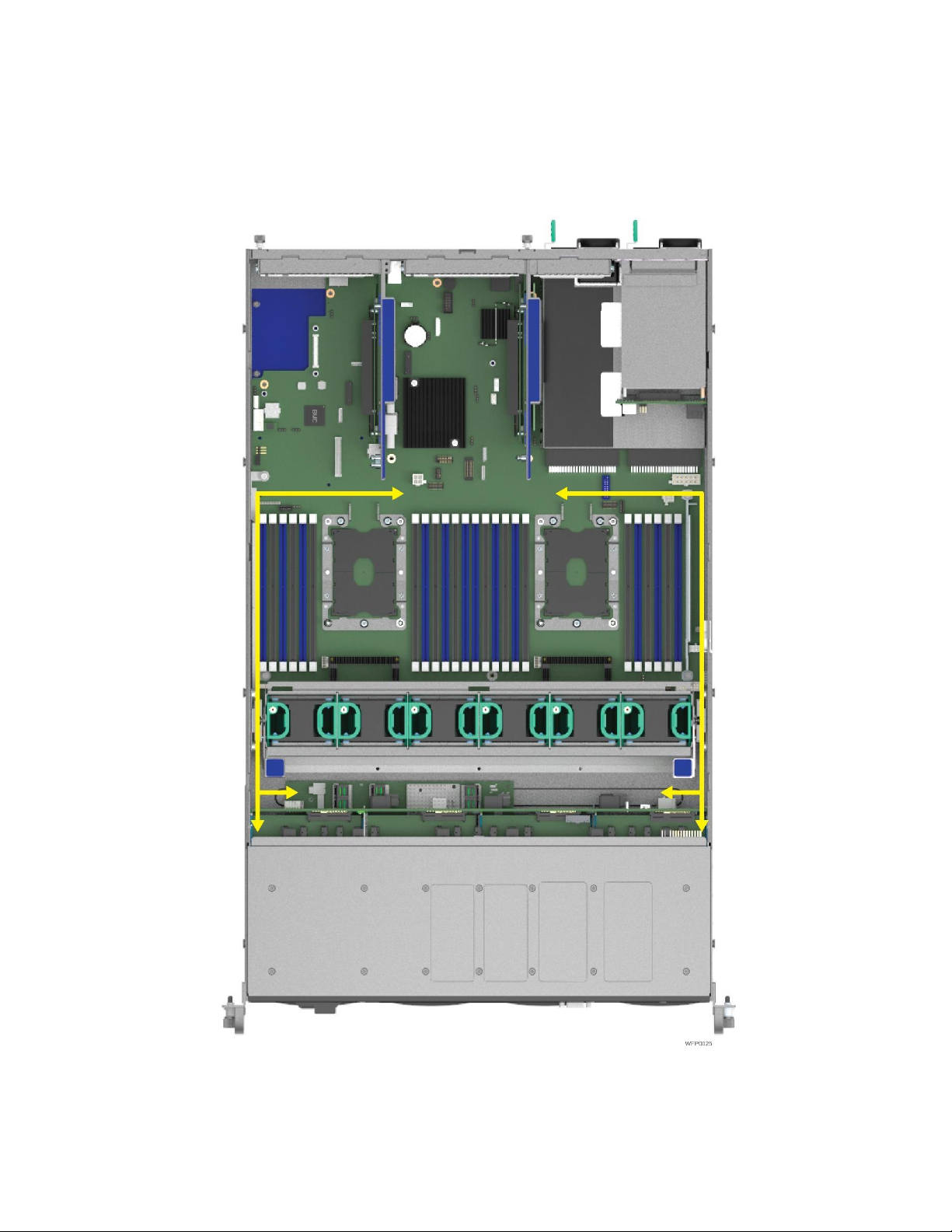

Figure 1. System components overview

Most 2U systems within this product family include the standard top cover shown in Figure 2.

Figure 2. 2U standard top cover

21

Page 22

Intel® Server System R2000WF Product Family Technical Product Specification

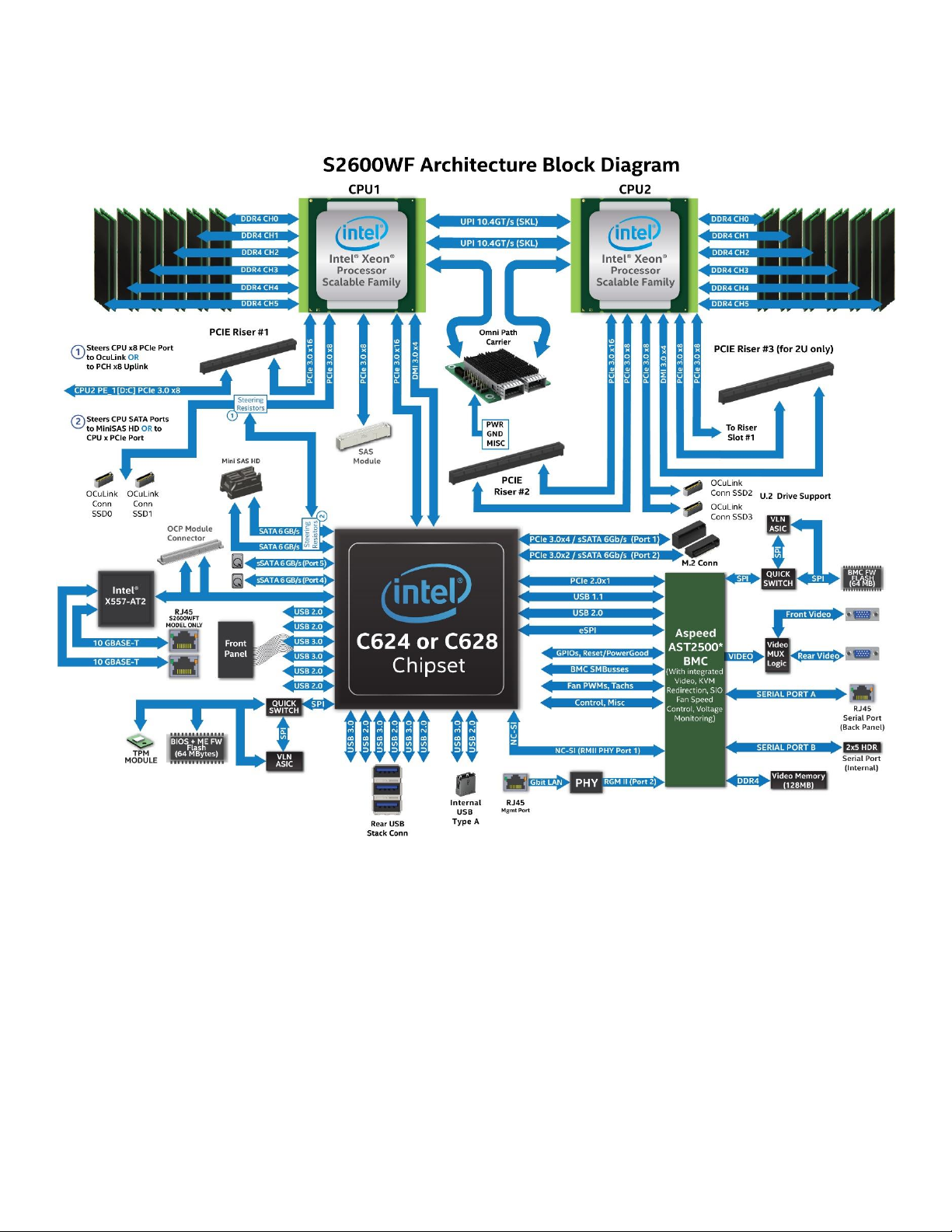

2.2 Server Board Architecture

Figure 3. Server Board Architecture

22

Page 23

Intel® Server System R2000WF Product Family Technical Product Specification

Figure 4. S2600WFQ Server Board Architecture

23

Page 24

Intel® Server System R2000WF Product Family Technical Product Specification

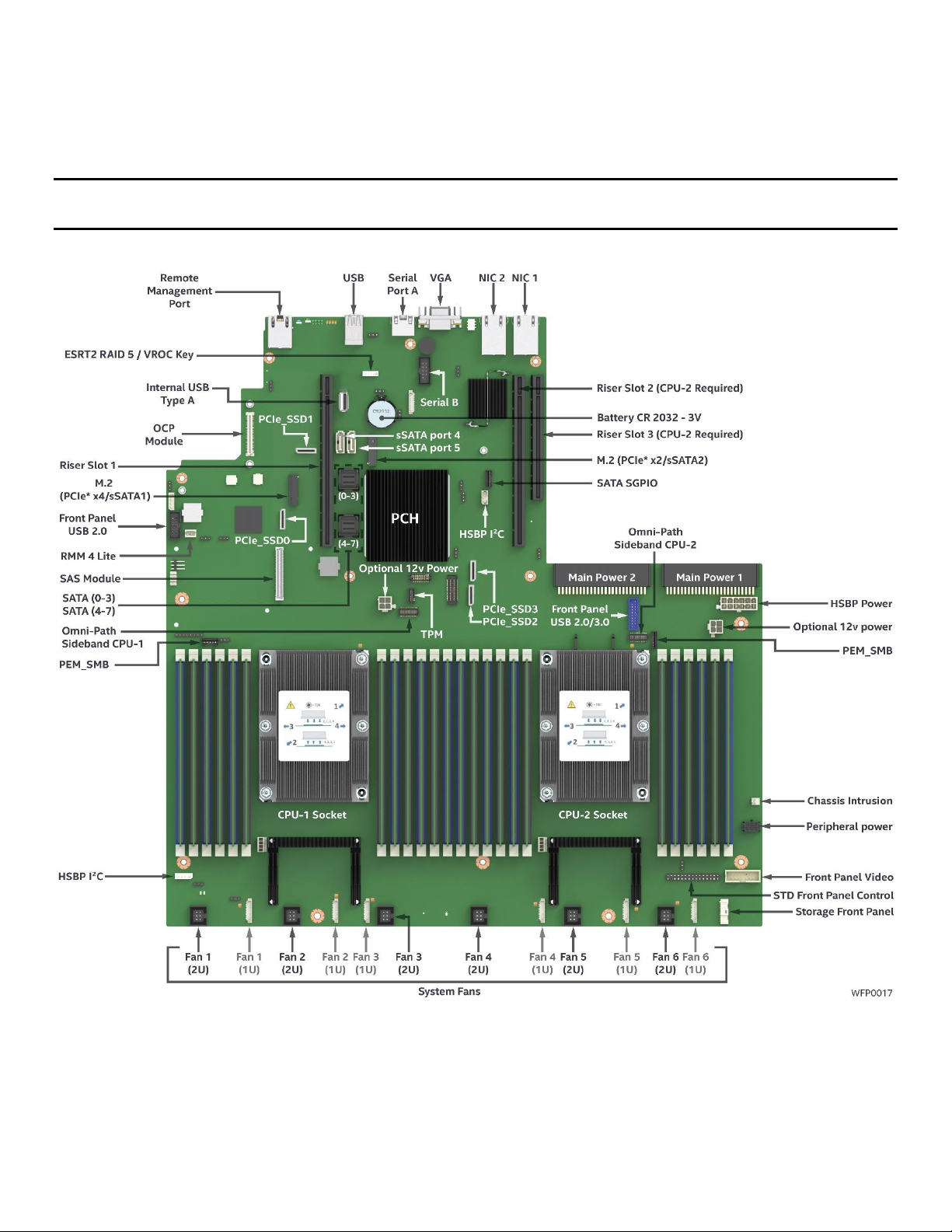

2.3 Server Board Features Overview

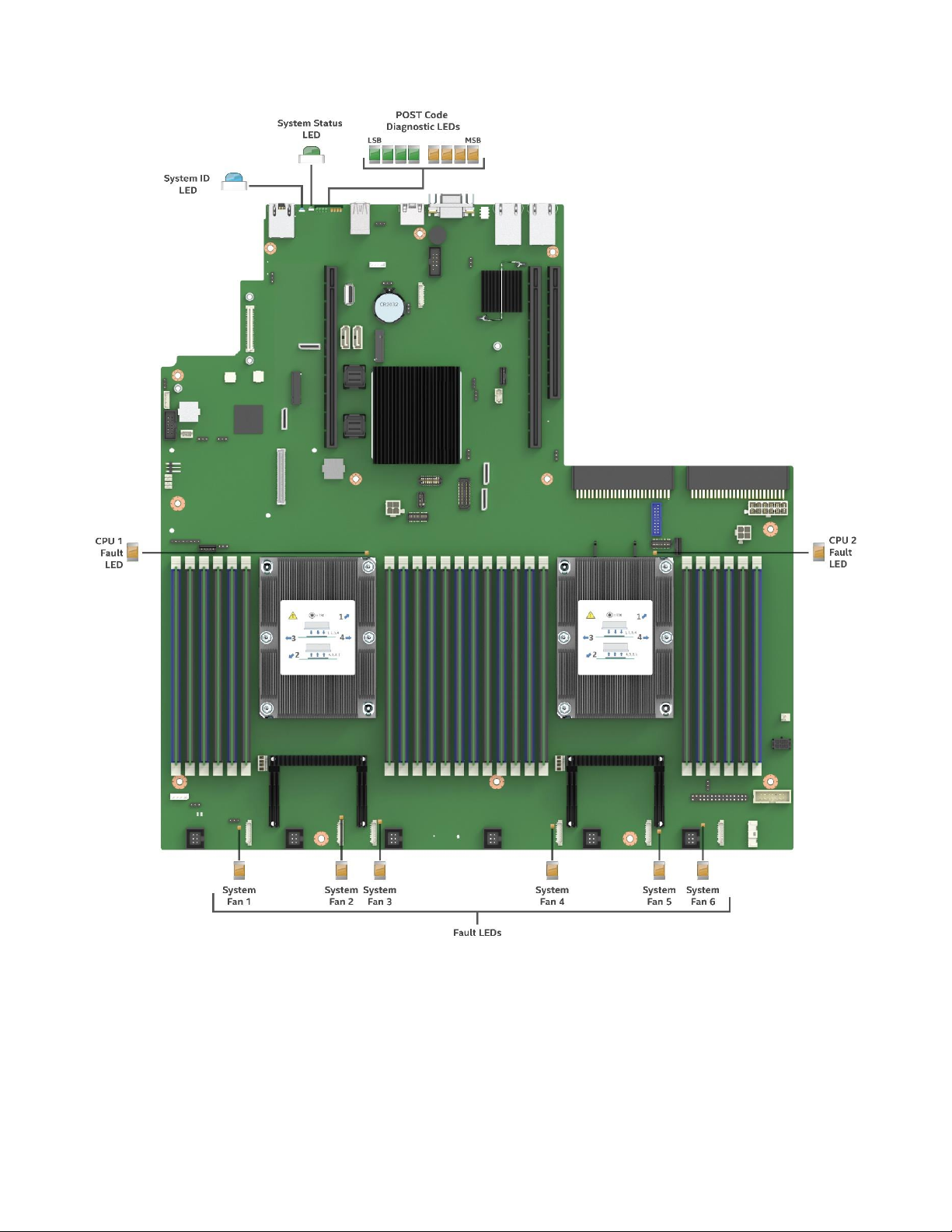

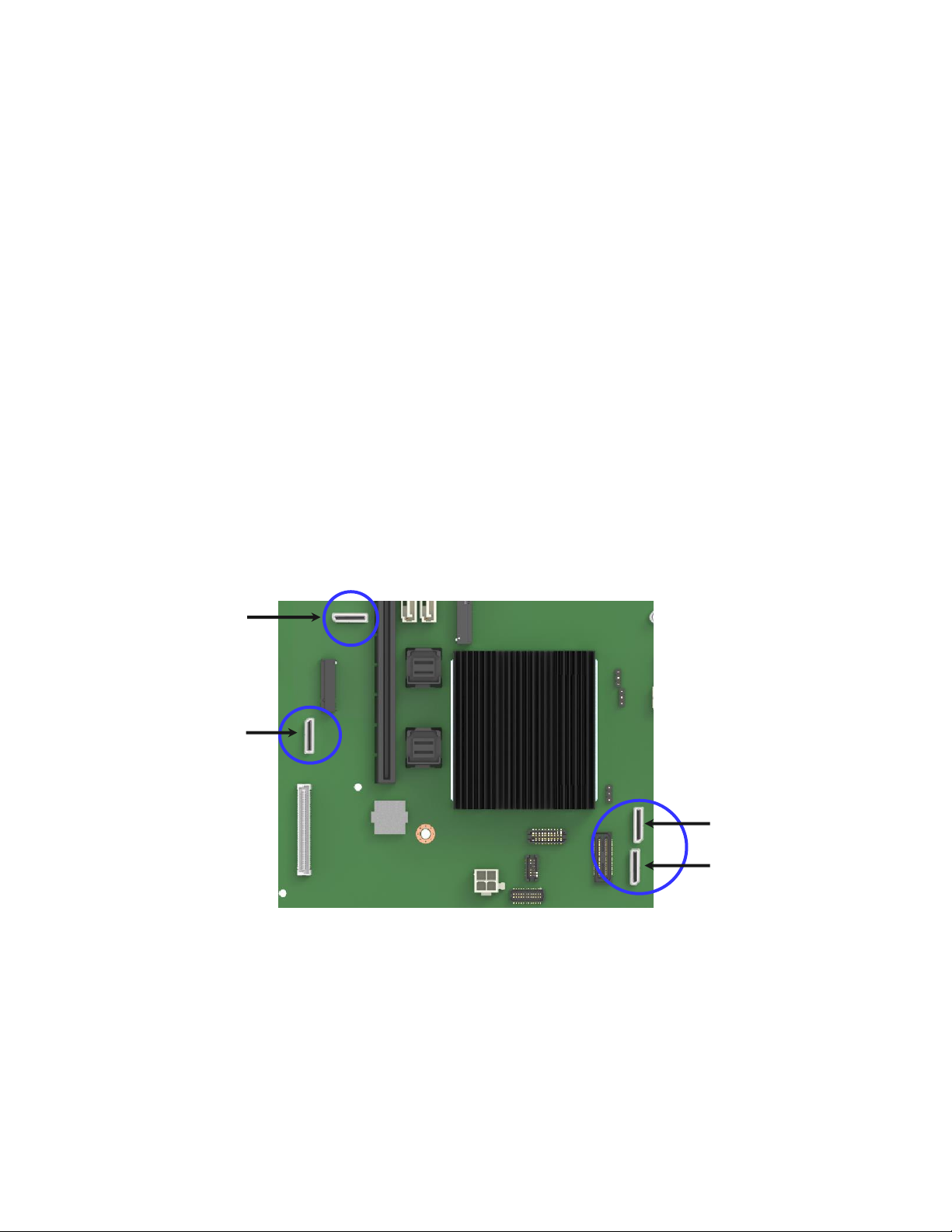

The illustration in Figure 5 provides a general overview of the server board, identifying key feature and

component locations. For more information, refer to Intel® Server Board S2600WF Technical Product

Specification.

Note: Intel® Server Board S2600WFT shown. Some features may not be present on Intel® Server Board

S2600WF0.

Figure 5. Server board component/feature identification

24

Page 25

Intel® Server System R2000WF Product Family Technical Product Specification

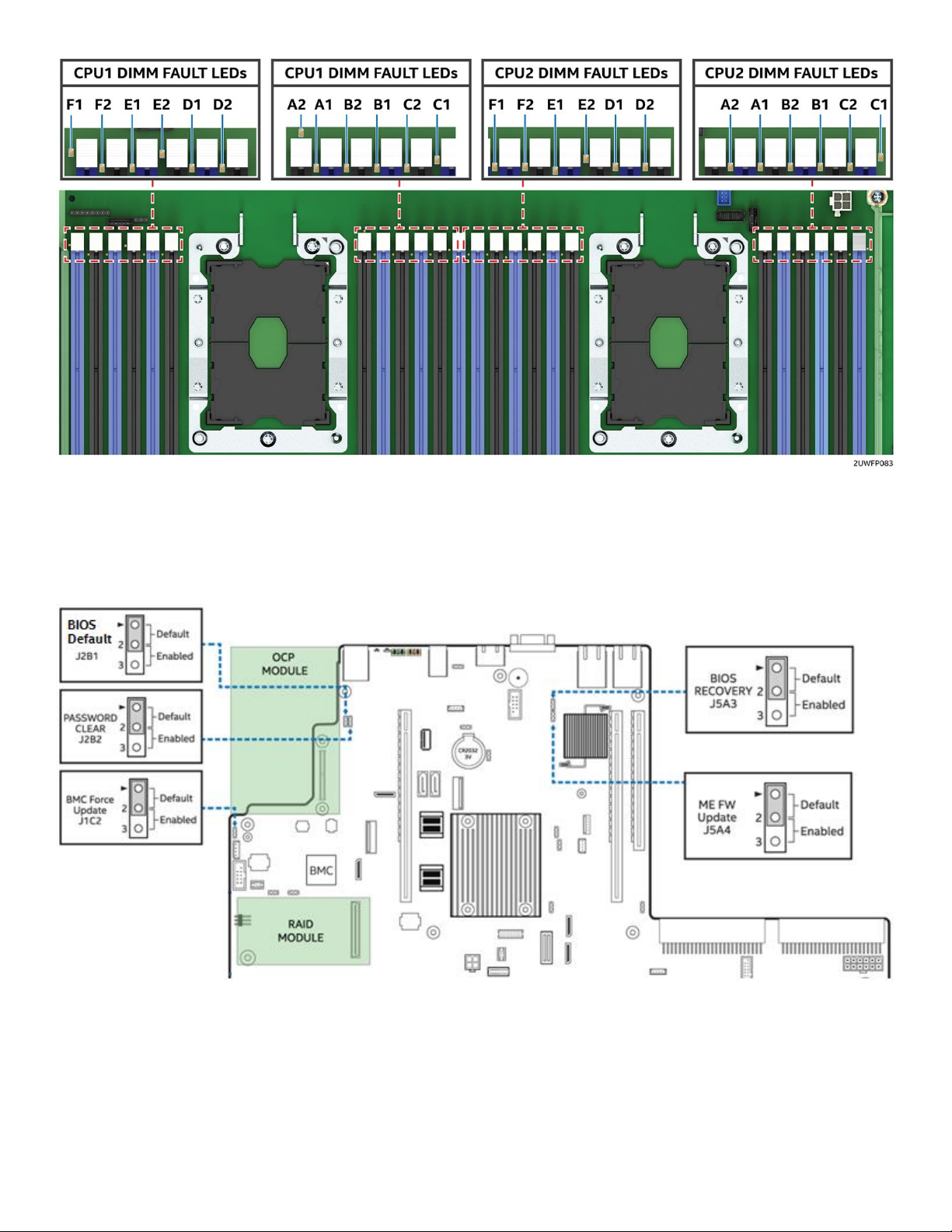

The server board includes a number of LEDs to identify system status and/or indicate a component fault.

Figure 6 and Figure 7 identify each diagnostic LED and their location.

Figure 6. Intel® Light Guided Diagnostics – LED identification

25

Page 26

Intel® Server System R2000WF Product Family Technical Product Specification

Figure 7. Intel® Light Guided Diagnostics - DIMM fault LEDs

Figure 8. System configuration and recovery jumpers

26

Page 27

Intel® Server System R2000WF Product Family Technical Product Specification

2.4 Back Panel Features

Figure 9. Back panel feature identification

2.5 Front Control Panel Options

Figure 10. Front control panel options

27

Page 28

Intel® Server System R2000WF Product Family Technical Product Specification

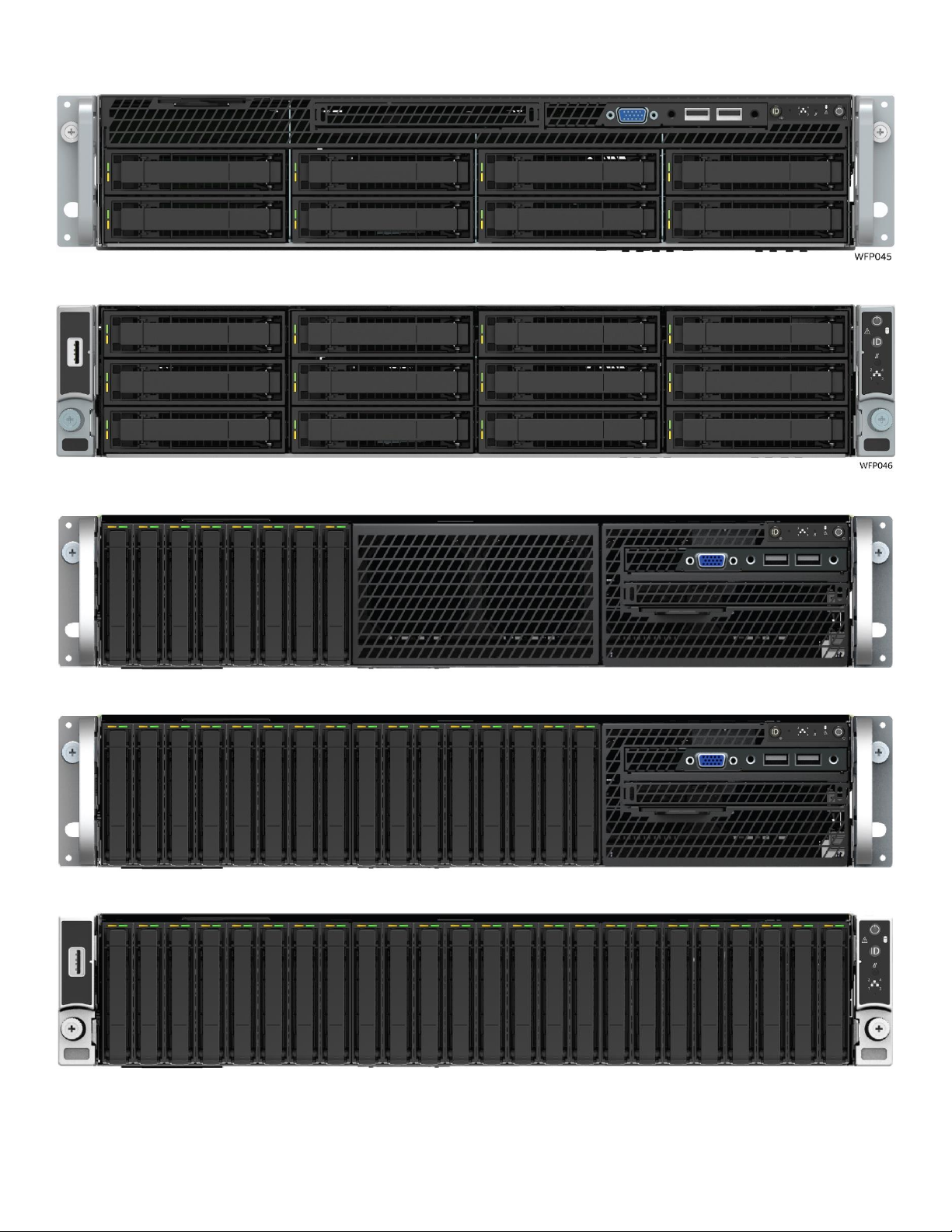

2.6 Front Drive Bay Options

Figure 11. 3.5" x 8 front drive bay configuration – R2308WFxxxx

Figure 12. 3.5" x 12 front drive bay configuration – R2312WFxxxx

Figure 13. 2.5" x 8 front drive bay configuration – R2208WFxxxx

Figure 14. 2.5" x 16 front drive bay configuration – R2208WFxxxx + 8 Drive Accessory Kit

Figure 15. 2.5" x 24 front drive bay configuration – R2224WFxxxx

28

Page 29

Intel® Server System R2000WF Product Family Technical Product Specification

2.7 Locking Front Bezel Support

The Intel 2U chassis includes features designed into the rack handles and front drive bay by to support a

locking front bezel.

Note: Intel will not offer a front bezel accessory option. OEMs looking to develop a locking front bezel can

obtain necessary CAD files of the chassis from Intel to aid with front bezel development. Contact your local

Intel representative for additional information.

Figure 16. Concept Reference Design – Front Bezel Installation

29

Page 30

Intel® Server System R2000WF Product Family Technical Product Specification

3.5”

89 mm

19”

482.6 mm

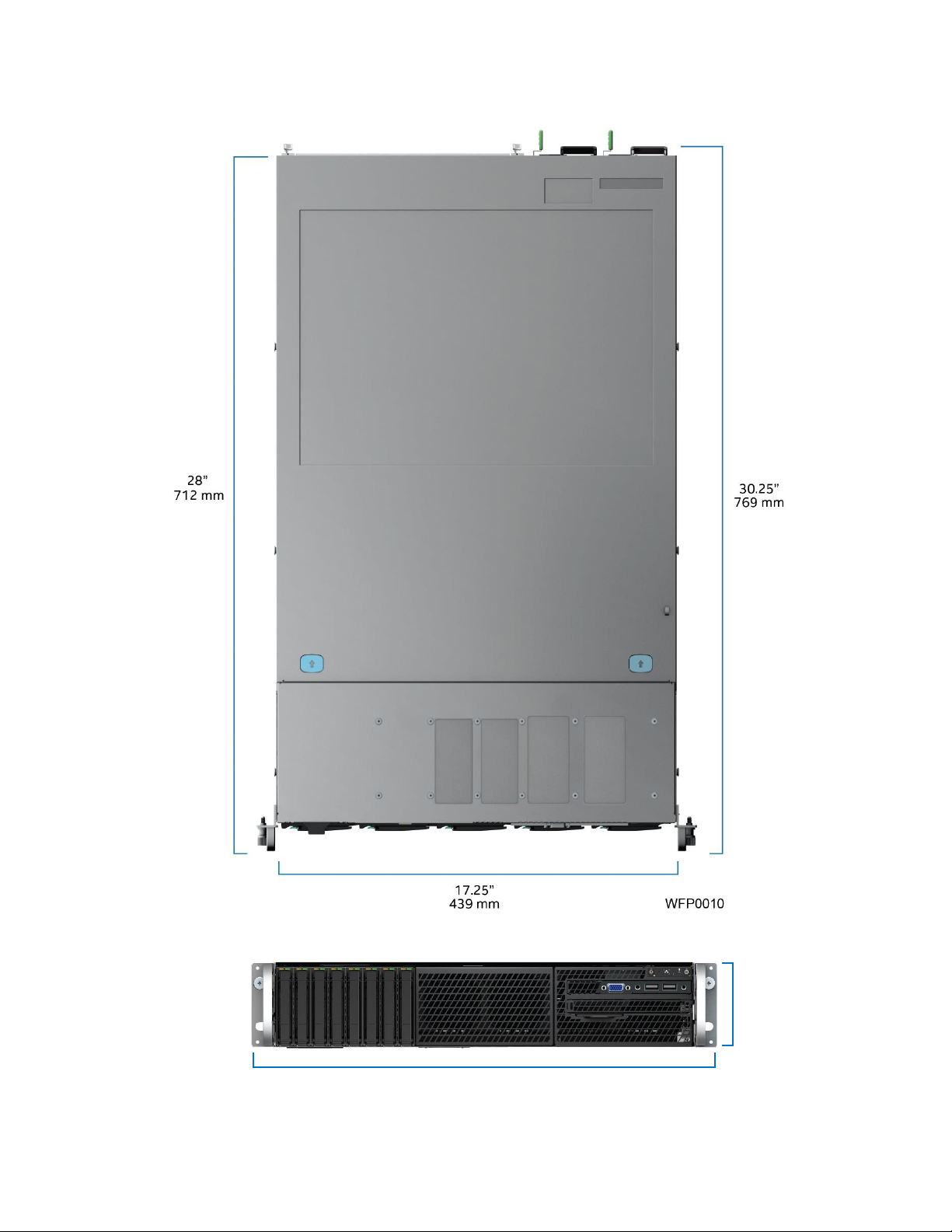

2.8 System Dimensional Data

2.8.1 Chassis Dimensions, 2.5” Drive Bay

Figure 17. Chassis dimensions, 2.5” drive bay

30

Page 31

Intel® Server System R2000WF Product Family Technical Product Specification

2.8.2 Label Emboss Dimensions

Figure 18. Label emboss dimensions

31

Page 32

Intel® Server System R2000WF Product Family Technical Product Specification

45 x 19 mm

46mm x 26 mm

2.8.3 Pull-Out Tab Label Emboss Dimensions

Figure 19. Pull-out tab label emboss dimensions, non-storage models

Figure 20. Pull-out tab label area dimensions, storage models

32

Page 33

Intel® Server System R2000WF Product Family Technical Product Specification

2.9 System Cable Routing Channels