Page 1

5

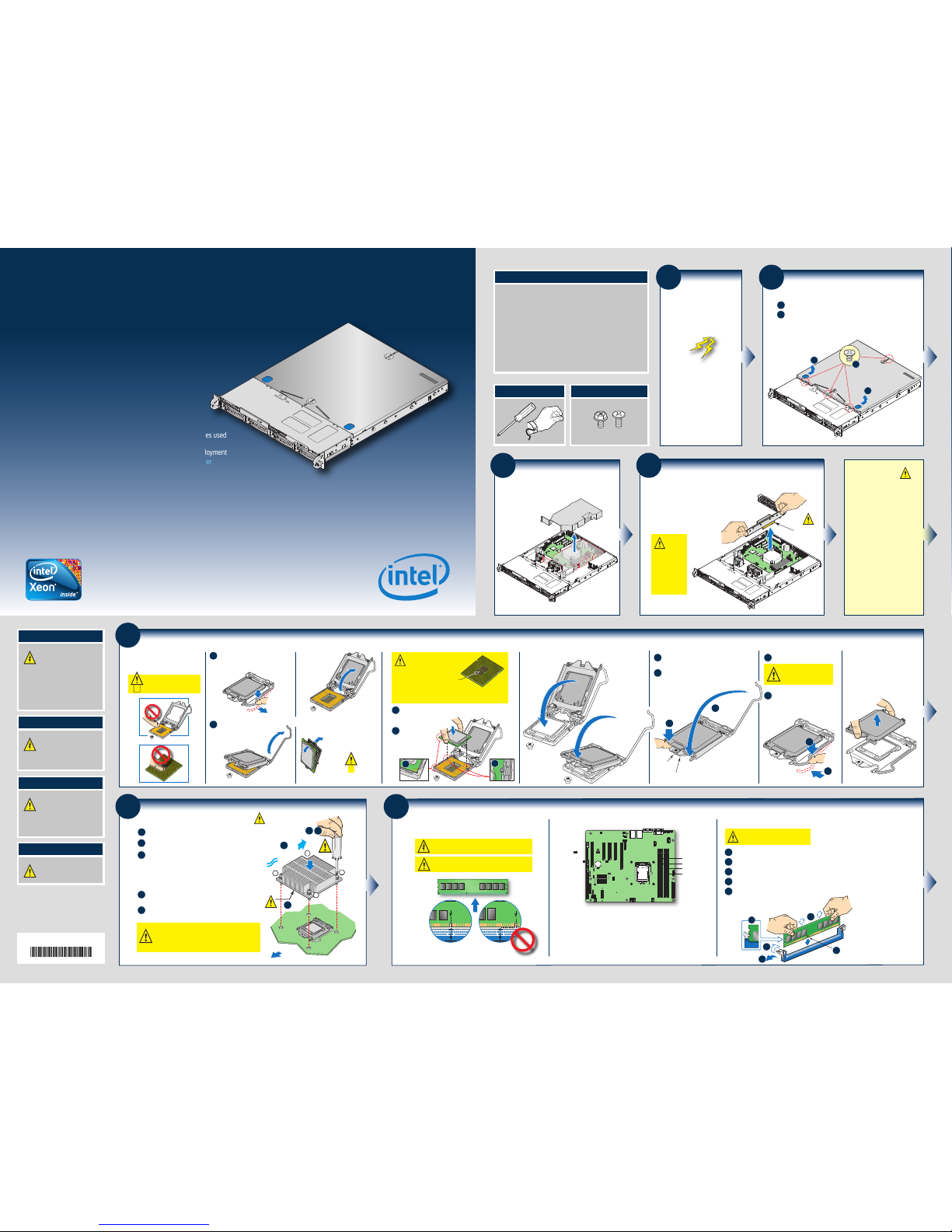

Install the

Processor

A. Open the Socket Lever

Rotate the lever open all the way.

B. Open the Load Plate

C.

Unpack the Processor

Open the

load

plate as

shown.

A

B

D. Install the Processor

Orient the processor with the socket so that the processor

cutouts match the two

socket pins.

A

Note location

of gold key at

corner of

processor.

B

Cautions:

CAUTION: The underside of

the processor has components

that may damage the socket wires if

installed improperly.

Processor must align correctly with

the socket opening before installation. DO NOT DROP processor into socket!

DO NOT DROP processor into socket!

Components

When unpacking a processor,

hold by the edges only to avoid

touching the gold contact wires.

A

A

Carefully remove

protective cover

as shown.

Save the

protective

cover.

Make sure the front edge of the load plate slides

under the shoulder screw as the lever is lowered.

Carefully lower the load plate over the processor.

E. Close the Load Plate F. Engage the Load Plate

A

Close the load plate locking lever.

B

Push down on the locking lever.

G. Latch the Locking Lever

A

Slide the tip of the lever under the

notch in the load plate. Make sure

the lever is securely latched.

B

H.

Remove the Cover

CAUTION: DO NOT damage the

server board with the tip of the

locking lever.

1

Push the lever handle down and away

from the socket to release it.

A

B

B

A

Load Plate

Front Edge

Shoulder

Screw

Save the

protective

cover.

A

B

Carefully lift the cover straight up

as shown.

1

Preparing

the Chassis

Observe normal ESD (Electrostatic

Discharge) procedures.

Place your Intel® Server Chassis

on a flat anti-static surface to

perform the following integration

procedures. Always touch the

chassis frame first, before

reaching inside to make server

board connections or to install

components.

IMPORTANT!

Before proceeding

further, do the

following:

Check your Intel® Server System

for disconnected or loose cables

and components that may have

occurred during shipping.

3

Remove Air Duct

Removing air duct by lifting straight up.

4

Remove Add-in Card

Riser Assembly

CAUTION:

Place the riser

assembly

upsidedown to

avoid damage

to the riser card

connector.

Grasp riser with both

hands and pull straight

up to release riser card

connector from server

board socket.

Riser Card

Connector

2

Remove Top Cover

B

Remove the four security screws.

Slide cover back and lift upward.

A

A

B

B

Intel® Server System

R1304BTLSHBN

Quick Start User's Guide

Thank you for buying an Intel® Server System. The following

information will help you assemble your Intel® Server System

R1304BTLSHBN and install components.

This guide and other supporting documents are located on the

web at http://www.intel.com/support/motherboards/server

If you are not familiar with ESD (Electrostatic Discharge) procedures used

during system integration, please see the Intel® Server System

R1304BTLSHBN Service Guide, available on the Intel® Server Deployment

Toolkit CD or at http://www.intel.com/support/motherboards/server

Read all cautions and warnings first before starting your server system integration.

7

Install DIMM Memory Modules

To Install DIMMs:

DDR3 DIMM Memory Identification:

Open both DIMM socket levers.

C

A

D

E

Note location of alignment notch.

B

CAUTION: Avoid touching contacts when

handling or installing DIMMs.

DIMM

notch and

socket

bump must

align as

shown.

Other

Memory

DDR3

This server board supports up to 4 DDR3 1066/1333 ECC

UDIMM.

CAUTION: Observe normal ESD (ElectroStatic Discharge) procedures

to avoid possible damage to system components.

Memory Configurations and Population Order:

Memory Type: Minimum of one 1 GB, DDR3 1066/1333 MHz ECC UDIMM.

A

C

D

B

E

Note: For additional memory configurations, see the Techinical Product Specification

on the Intel

®

Server Deployment Toolkit CD that accompanied your Intel® Server

Board S1200BT, or go to:

http://www.intel.com/support/motherboards/server

Memory sizing and configuration is supported only for qualified DIMMs approved by

Intel

®

. For a list of supported memory, see the tested memory list at

http://serverconfigurator.intel.com/default.aspx

DIMM A2

DIMM A1

DIMM B2

DIMM B1

Insert DIMM making sure the connector edge of the DIMM aligns correctly with the slot.

Push down firmly on the DIMM until it snaps into place and both levers close.

IMPORTANT! Visually check that each latch is fully closed and correctly engaged with each DIMM edge slot.

6

Install Heat Sink

Get heat sink from the shipping position.

A

Remove the protective film on the TIM if present.

E

D

B

C

CAUTION:

Do not

over-tighten

fasteners.

D

C

TIM

Processor

Socket

AIRFLOW

B

2

3

1

4

Chassis Front

E

Securely re-tighten each fastener again in the same order as

performed in Step E.

Using a #2 Phillips* screwdriver, finger-tighten each fastener

diagonally, according to the numbers shown.

Align heat sink fins to the front and back of the chassis

for correct airflow. Airflow goes from front-to-back of

chassis.

The heat sink has four captive fasteners and should be

tightened using the following procedure:

CAUTION: The heat sink has thermal interface

material (TIM) on the underside of it. Use caution so

that you do not damage the thermal interface material.

Use gloves to avoid sharp edges.

Intel is a registered trademark of Intel Corporation or its

subsidiaries in the United States and other countries.

*Other names and brands may be claimed as the

property of others. Copyright © 2011, Intel Corporation.

All rights reserved.

Warning

Read all caution and safety

statements in this document

before performing any of the

instructions. Also see the Intel®

Server Board and Server Chassis

Safety Information document at:

http://www.intel.com/support/

motherboards/server/sb/cs-010770

.htm for complete safety information.

Warning

Installation and service of

this product should only be

performed by qualified service

personnel to avoid risk of injury from

electrical shock or energy hazard.

Caution

Observe normal ESD

[Electrostatic Discharge]

procedures during system

integration to avoid possible

damage to server board and/or

other components.

G20489-005

Caution

Low Power Unit, Please

Check Power Budget Tool

For Supported Configuration.

Tools Required

Anti-static

wrist strap

Phillips*

screwdriver

Minimum Hardware Requirements

■ Heat Sink:

• 1U passive heat sink.

■ Memory:

•

Memory Type:

Minimum of one 1 GB,

240-pin DDR3 1066/1333 MHz ECC UDIMM.

■ Hard Disk Drives:

• SATA

■ Power:

• Minimum of 250W with 2A of standby current, which meets the SSI EPS

12V specification.

To avoid integration difficulties and possible damage to your system, make

sure you have components from each category below.

Fastener Identification Guide

Loading...

Loading...