Page 1

Intel® Server System R1000SPO

Revision 1.0

March 2016

Intel® Server Boards and Systems

Product Family

Technical Product Specification

A document providing an overview of product features, functions, architecture, and

support specifications

Page 2

Intel® Server System R1000SPO Product Family TPS

Date

Revision Number

Modifications

January 2016

0.7

First preliminary version

March 2016

1.0

First External Public Release

Changes:

Updated Illustrations

Appendix E - Added High Temperature Ambient Information

Section 3.3.4 - Added Holdup time for Fixed Power Supply

Section 3.2.3 - Added Information for Power Distribution Board

Added Glossary

Removed – AXXPRAIL from supported Rail kits

Updated Copyright data

Table 2 - Added info about PCIe riser slot

Revision History

i

Page 3

Intel® Server System R1000SPO Product Family TPS

Disclaimers

No license (express or implied, by estoppel or otherwise) to any intellectual property rights is granted by this

document.

Intel disclaims all express and implied warranties, including without limitation, the implied warranties of

merchantability, fitness for a particular purpose, and non-infringement, as well as any warranty arising from

course of performance, course of dealing, or usage in trade.

This document contains information on products, services and/or processes in development. All information

provided here is subject to change without notice. Contact your Intel representative to obtain the latest TPS.

The products and services described may contain defects or errors known as errata which may cause

deviations from published specifications. Current characterized errata are available on request.

Intel, and the Intel logo are trademarks of Intel Corporation in the U.S. and/or other countries.

*Other names and brands may be claimed as the property of others

© 2016 Intel Corporation.

ii

Page 4

Intel® Server System R1000SPO Product Family TPS

Table of Contents

1. Introduction ........................................................................................................................................ 1

1.1 Chapter Outline .................................................................................................................................... 1

1.2 Server Board Use Disclaimer ......................................................................................................... 2

1.3 Product Errata ....................................................................................................................................... 2

2. Product Family Overview ................................................................................................................ 3

2.1 Operating System Support............................................................................................................... 5

2.1.1 OS Validation Levels .......................................................................................................................... 5

2.1.2 OS Technical Support Levels ......................................................................................................... 6

2.2 System Features Overview.............................................................................................................. 6

2.3 Server Board Features Overview .................................................................................................. 8

2.4 Back Panel Features ....................................................................................................................... 10

2.5 Front Control Panel .......................................................................................................................... 11

2.6 Front Drive Bay Options ................................................................................................................. 11

2.7 Locking Front Bezel ......................................................................................................................... 12

2.8 System Dimensions ......................................................................................................................... 14

2.8.1 Chassis Dimensions ........................................................................................................................ 14

2.8.2 Label Emboss Dimensions ........................................................................................................... 15

2.8.3 Pull-out Tab Label Emboss Dimensions ................................................................................. 16

2.9 Available Rack Mounting Kit Options ....................................................................................... 16

2.10 System Level Environmental Limits .......................................................................................... 17

2.11 System Packaging ............................................................................................................................ 18

2.11.1 Intel Product Weight Information ................................................................................................ 18

3. System Power ................................................................................................................................. 19

3.1 Power Supply Configurations ...................................................................................................... 19

3.2 Power Supply Module Options .................................................................................................... 20

3.2.1 Power Supply Module Efficiency ................................................................................................ 20

3.2.2 Power Supply Module Mechanical Overview ........................................................................ 20

3.2.3 Power distribution board ................................................................................................................ 21

3.2.4 Power Cord Specification Requirements ................................................................................ 22

3.3 AC Power Supply Input Specifications ..................................................................................... 22

3.3.1 Power Factor ...................................................................................................................................... 22

3.3.2 AC Input Voltage Specification .................................................................................................... 23

3.3.3 AC Line Isolation Requirements ................................................................................................. 23

3.3.4 AC Line Dropout / Holdup ............................................................................................................. 23

3.3.5 AC Line Fuse ...................................................................................................................................... 24

3.3.6 AC Line Transient Specification .................................................................................................. 24

3.3.7 Susceptibility Requirements ......................................................................................................... 25

3.3.8 Electrostatic Discharge Susceptibility ....................................................................................... 25

3.3.9 Fast Transient/Burst ........................................................................................................................ 25

3.3.10 Radiated Immunity ........................................................................................................................... 25

iii

Page 5

Intel® Server System R1000SPO Product Family TPS

3.3.11 Power Recovery ................................................................................................................................ 25

3.3.12 Voltage Interruptions ....................................................................................................................... 25

3.3.13 Protection Circuits ............................................................................................................................ 25

3.3.14 Power Supply Status LED ............................................................................................................. 27

3.4 Server Board Power Connectors................................................................................................ 27

4. Thermal Management ................................................................................................................... 29

4.1 Thermal Operation and Configuration Requirements ........................................................ 30

4.2 Thermal Management Overview ................................................................................................ 30

4.2.1 Fan Speed Control ........................................................................................................................... 30

4.2.2 Programmable Fan PWM Offset ................................................................................................ 31

4.2.3 Fan Domains ...................................................................................................................................... 31

4.2.4 Nominal Fan Speed ......................................................................................................................... 32

4.2.5 Thermal and Acoustic Management ......................................................................................... 32

4.2.6 Thermal Sensor Input to Fan Speed Control ......................................................................... 32

4.3 System Fans ....................................................................................................................................... 34

5. System Storage and Peripheral Drive Bay Overview ........................................................... 36

5.1 Front Mount Drive Support............................................................................................................ 36

5.2 System Fan RVI and Hard Disk Drive Storage Performance ......................................... 36

5.3 Hot Swap Drive Carriers ................................................................................................................ 37

5.4 Storage Backplane Options .......................................................................................................... 39

5.4.1 I2C Functionality ............................................................................................................................... 40

5.4.2 4 x 3.5” Drive Hot-Swap Backplane Overview ...................................................................... 40

5.4.3 8 x 2.5” Drive SAS Backplane ..................................................................................................... 42

5.5 M.2 SSD Support .............................................................................................................................. 43

5.6 SATA DOM Support ........................................................................................................................ 44

6. Storage Controller Options Overview ...................................................................................... 45

6.1 Embedded SATA/SATA RAID Support ................................................................................... 45

6.2 Intel® Integrated RAID Module Support ................................................................................... 47

6.2.1 Intel® RAID Maintenance Free Backup Unit (RMFBU) Support .................................... 47

7. Front Control Panel and I/O Panel Overview .......................................................................... 48

7.1 I/O Panel Features ........................................................................................................................... 48

7.2 Control Panel Features .................................................................................................................. 48

7.2.1 System Status LED .......................................................................................................................... 49

8. PCIe* Riser Card Support ............................................................................................................ 51

9. Intel® I/O Module Support ........................................................................................................... 52

10. Basic and Advanced Server Management Features ............................................................ 53

10.1 IPMI 2.0 Features ............................................................................................................................. 54

10.2 Non-IPMI Features ........................................................................................................................... 54

10.2.1 Dedicated Management Port ....................................................................................................... 55

10.2.2 Embedded Web Server .................................................................................................................. 55

10.2.3 Advanced Management Feature Support (RMM4 Lite) .................................................... 57

Appendix A: Integration and Usage Tips ........................................................................................ 61

iv

Page 6

Intel® Server System R1000SPO Product Family TPS

Appendix B: POST Code Diagnostic LED Decoder ..................................................................... 62

Appendix C: POST Code Errors ........................................................................................................ 72

Appendix D: System Cable Routing Diagrams ............................................................................. 76

Appendix E: High Temperature Ambient Info ................................................................................ 77

Glossary .................................................................................................................................................. 79

v

Page 7

Intel® Server System R1000SPO Product Family TPS

List of Figures

Figure 1. System Components Overview ............................................................................................................. 6

Figure 2. Top Cover Features .................................................................................................................................... 7

Figure 3. Server Board Features ............................................................................................................................... 8

Figure 4. On-board Diagnostic LEDs ...................................................................................................................... 9

Figure 5. System Reset and Configuration Jumpers .................................................................................... 10

Figure 6. Back Panel Features ................................................................................................................................ 10

Figure 7. Front Control Panel Options ............................................................................................................... 11

Figure 8. 3.5" Drive Bay – 4 Drive Configuration (Model R1304SPxxxxx) ............................................ 11

Figure 9. 2.5" Drive Bay – 8 Drive Configuration (Model R1208SPxxxxx) ............................................ 11

Figure 10. Front Bezel ............................................................................................................................................... 12

Figure 11. Front Bezel Accessory with Optionally Installed Wave Feature ........................................ 12

Figure 12. Front Bezel Accessory with Optionally Installed Wave and ID Badge (1) ...................... 13

Figure 13. Front Bezel Accessory with Optionally Installed Wave and ID Badge (2) ...................... 13

Figure 14. Front Bezel Accessory ID Badge Mechanical Drawings ......................................................... 13

Figure 15. Chassis Dimensions .............................................................................................................................. 14

Figure 16. Label Emboss Dimensions ................................................................................................................. 15

Figure 17. Pull-out Tab Label Emboss Dimensions ...................................................................................... 16

Figure 18. 350W AC Fixed Power Supply ......................................................................................................... 19

Figure 19. 450W AC Power Supply...................................................................................................................... 19

Figure 20. 350W Power Supply Mechanical Drawings ................................................................................ 20

Figure 21. 450W Power Supply Mechanical drawings ................................................................................ 21

Figure 22. Power Distribution Board ................................................................................................................... 21

Figure 23. AC Power Cord ........................................................................................................................................ 22

Figure 24. System Air Flow and Fan Identification ........................................................................................ 29

Figure 25. Fan Control Model ................................................................................................................................ 33

Figure 26. System Fans ............................................................................................................................................. 34

Figure 27. System Fan Connector Locations on Server Board ................................................................ 35

Figure 28. 8x2.5" Drive Bay Configuration (Model R1208xxxxx) ............................................................. 36

Figure 29. 4x3.5" Drive Bay Configuration (Model R1304WTxxxx) ........................................................ 36

Figure 30. Hot Swap Storage Device Carrier Removal ................................................................................. 37

Figure 31. 2.5" SSD mounted to 3.5" Drive Tray ............................................................................................ 38

Figure 32. Drive Tray LED Identification ............................................................................................................ 38

Figure 33. Backplane Installation ......................................................................................................................... 40

Figure 34. 4 x 3.5” Drive Hot-Swap Backplane – front view ...................................................................... 41

Figure 35. 4 x 3.5” Drive Hot-Swap Backplane – rear view ........................................................................ 41

Figure 36. 8 x 2.5” Drive SAS/SATA Backplane – front view ..................................................................... 42

Figure 37. 8 x 2.5” Drive SAS/SATA Backplane – rear view ....................................................................... 42

Figure 38. Installing M.2 Device ............................................................................................................................ 43

Figure 39. Intel® Raid Upgrade Key ...................................................................................................................... 46

Figure 40. Intel® RAID Maintenance Free Backup Unit ................................................................................. 47

vi

Page 8

Intel® Server System R1000SPO Product Family TPS

Figure 41. Front I/O Panel Features .................................................................................................................... 48

Figure 42. Front Panel LEDs and Buttons ......................................................................................................... 48

Figure 43. Add-in Card Support ............................................................................................................................ 51

Figure 44. Riser Card Assembly............................................................................................................................. 51

Figure 45. Intel® I/O Module Placement ............................................................................................................ 52

Figure 46. Intel® RMM4 Lite Activation Key Installation .............................................................................. 55

Figure 47. POST Diagnostic LED Location ........................................................................................................ 62

Figure 48. Internal Cable Routing ......................................................................................................................... 76

vii

Page 9

Intel® Server System R1000SPO Product Family TPS

List of Tables

Table 1. Reference Documents ................................................................................................................................ 1

Table 2. Intel® Server System R1000SPO Product Family Feature Set ................................................... 3

Table 3. Operating System Support List .............................................................................................................. 5

Table 4. Operating System Validation Levels .................................................................................................... 5

Table 5. System Environmental Limits Summary .......................................................................................... 17

Table 6. Intel Product Weight Information ....................................................................................................... 18

Table 7. 350 Watt AC Power Supply Efficiency (Gold) ................................................................................ 20

Table 8. 450 Watt AC Power Supply Efficiency (Gold) ................................................................................ 20

Table 9. AC Power Cord Specifications .............................................................................................................. 22

Table 10. Input Voltage Range – 350W Power Supply ............................................................................... 23

Table 11. AC Input Voltage Range – 450W Power Supply ........................................................................ 23

Table 12. AC Line Holdup Time – 350W Power supply .............................................................................. 23

Table 13. AC Line Holdup Time – 450W Power Supply.............................................................................. 24

Table 14. AC Line Sag Transient Performance – 350W Power Supply ................................................ 24

Table 15. AC Line Surge Transient Performance – 350W Power Supply ............................................ 24

Table 16. AC Line Sag Transient Performance – 450W Power Supply ................................................ 24

Table 17. AC Line Surge Transient Performance – 450W Power Supply ............................................ 25

Table 18. Performance Criteria ............................................................................................................................. 25

Table 19. Over Current Protection – 350W Power Supply ........................................................................ 26

Table 20. Over Current Protection – 450 Watt Power Supply ................................................................. 26

Table 21. Over Voltage Protection - 350W Power Supply ........................................................................ 26

Table 22. Over Voltage Protection (OVP) Limits – 750W Power Supply ............................................. 27

Table 23. LED Indicators .......................................................................................................................................... 27

Table 24. Main Power Connector Pin-out ......................................................................................................... 28

Table 25. CPU Power Connector Pin-out .......................................................................................................... 28

Table 26. PMBUS SSI Connector Pin-out (PS_AUX) ..................................................................................... 28

Table 27. System Volumetric Air Flow ............................................................................................................... 29

Table 28. System Fan Connector Pin-out ......................................................................................................... 35

Table 29. Drive Status LED States ........................................................................................................................ 39

Table 30. Drive Activity LED States ...................................................................................................................... 39

Table 31. SATA/SATADOM capable Connector Pin-out ............................................................................ 44

Table 32. Front Control Panel Buttons And Indicators ............................................................................... 48

Table 33. System Status LED Indicator States ................................................................................................ 49

Table 34. Front panel LED indication of BMC state ...................................................................................... 50

Table 35. Supported Intel® I/O Modules ........................................................................................................... 52

Table 36. Intel® Remote Management Module 4 (RMM4) Options ......................................................... 53

Table 37. Basic and Advanced Server Management Features Overview ............................................. 53

Table 38. POST Progress Code LED Example ................................................................................................. 63

viii

Page 10

Intel® Server System R1000SPO Product Family TPS

Table 39. POST Progress Codes ........................................................................................................................... 63

Table 40. MRC Progress Codes ............................................................................................................................. 69

Table 41. POST Progress LED Codes .................................................................................................................. 70

Table 42. POST Error Codes and Messages..................................................................................................... 72

Table 43. POST Error Beep Codes ....................................................................................................................... 74

Table 44. Integrated BMC Beep Codes .............................................................................................................. 75

ix

Page 11

Page 12

Intel® Server System R1000SPO Product Family TPS

Document Title

Document

Classification

Intel® Server Board S1200SP Family BMC EPS 1.1

Intel Confidential

Intel® Server Board S1200SP Family BIOS EPS v1.0

Intel Confidential

Intel® Xeon® Processor E3-1200 v5 Product Family

Datasheet

Intel Confidential

Intel® Ethernet Controller I210: Datasheet

Intel® Server Board S1200SP Family Technical Product

Specification 1.0

1. Introduction

This Technical Product Specification (TPS) provides system level information for the Intel® Server System

R1000SPO product family.

This document describes the embedded functionality and available features of the integrated server system

which includes: the chassis layout, system boards, power subsystem, cooling subsystem, storage subsystem

options, and available installable options. Note that some system features are provided as configurable

options and may not be included standard in every system configuration offered. Please reference the Intel®

Server Board S1200SP Product Family Configuration Guide for a list of configurable options.

Server board specific detail can be obtained by referencing the Intel® Server Board S1200SP Technical

Product Specification.

NOTE: Some of the documents listed in the following table are classified as “Intel Confidential”. These

documents are made available under a Non-Disclosure Agreement (NDA) with Intel and must be ordered

through your local Intel representative.

Table 1. Reference Documents

1.1 Chapter Outline

This document is divided into the following chapters:

Chapter 1 – Introduction

Chapter 2 – Product Family Overview

Chapter 3 – System Power

Chapter 4 – Thermal Management

Chapter 5 – System Storage and Peripherals Drive Bay Overview

Chapter 6 – Storage Controller Options Overview

Chapter 7 – Front Control Panel and I/O Panel Overview

Chapter 8 – PCIe* Riser Card Support

Chapter 9 – Intel® I/O Module Support

Chapter 10 – Basic and Advanced Server Management Features

Appendix A – Integration and Usage Tips

Appendix B – POST Code Diagnostic LED Decoder

Appendix C – POST Code Errors

Appendix D – System Configuration Tables for Thermal Compatibility

Appendix E – High Temperature Ambient Info

Glossary

1

Page 13

Intel® Server System R1000SPO Product Family TPS

1.2 Server Board Use Disclaimer

Intel Corporation server boards support add-in peripherals and contain a number of high-density VLSI and

power delivery components that need adequate airflow to cool. Intel ensures through its own chassis

development and testing that when Intel® server building blocks are used together, the fully integrated

system will meet the intended thermal requirements of these components. It is the responsibility of the

system integrator who chooses not to use Intel-developed server building blocks to consult vendor

datasheets and operating parameters to determine the amount of airflow required for their specific

application and environmental conditions. Intel Corporation cannot be held responsible if components fail

or the server board does not operate correctly when used outside any of their published operating or nonoperating limits.

1.3 Product Errata

Shipping product may have features or functionality that may deviate from published specifications. These

deviations are generally discovered after the product has gone into formal production. Intel terms these

deviations as product Errata. Known product Errata will be published in the Monthly Specification Update for

the given product family which can be downloaded from the following Intel web site:

http://www.intel.com/support

2

Page 14

Intel® Server System R1000SPO Product Family TPS

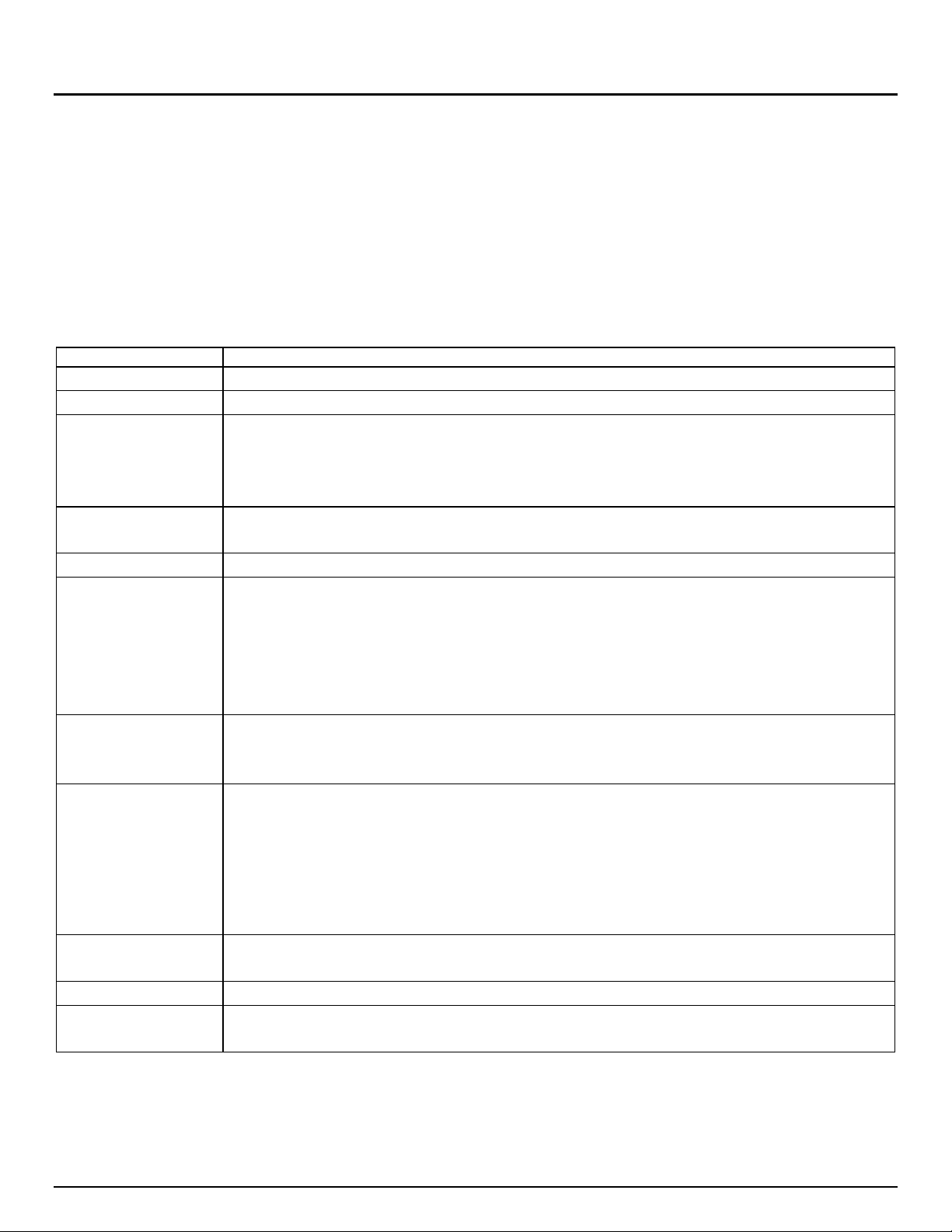

Feature

Description

Chassis Type

1U Rack Mount Chassis

Server Board

Intel® Server Board S1200SP – (Intel product code - S1200SPO)

Processor Support

One LGA1151 (Socket H4) processor socket

Support for one Intel® Xeon® E3-1200 V5 processor without processor graphics (GT0 or 4+0)

Maximum supported Thermal Design Power (TDP) of up to 80 W.

8 GT/s point-to-point DMI 3.0 interface to PCH

Memory

Two memory channels, four memory DIMM Slots (Two memory DIMMs per channel)

Support for 2133 MT/s Unbuffered DIMMs (UDIMM DDR4 ECC memory)

Chipset

Intel® C236 Platform Controller Hub (PCH) chipset

External I/O

connections

1x DB-15 video connector

Two Gigabit Ethernet Ports

Dedicated RJ-45 server management port

Two USB 2.0 connectors on back panel

Two USB 3.0 connectors on back panel

Two USB 3.0 connectors on front panel

Internal I/O connectors

/ headers

One Type-A USB 2.0 connector

One 2x5 pin connector providing front panel support for two USB 2.0 ports

One 2x10 pin connector providing front panel support for two USB 2.0 / 3.0 ports

Intel® I/O Module

Accessory Options

The server board includes a proprietary on-board connector allowing for the installation of a variety of

available Intel® I/O modules. An installed I/O module can be supported in addition to standard on-board

features and add-in PCIe* cards.

The Following Intel® I/O Modules are supported:

AXX4P1GBPWLIOM – Quad port 1GbE I/O based on Intel® Ethernet Controller I350

AXX10GBNIAIOM – Dual SFP+ port 10GbE based on Intel® 82599 10 Gigabit Ethernet Controller

AXX10GBTWLIOM3 – Dual RJ-45 port 10G BASE-T based on Intel® Ethernet Controller X540

System Fans

Three managed 40mm single rotor system fans

One power supply fan for each installed power supply module

Riser Card Support

One x16 PCIe* 3.0 Riser Card H87808-XXX on a x8 Riser slot (slot-6)

Video

Integrated 2D video controller

16 MB DDR3 Memory

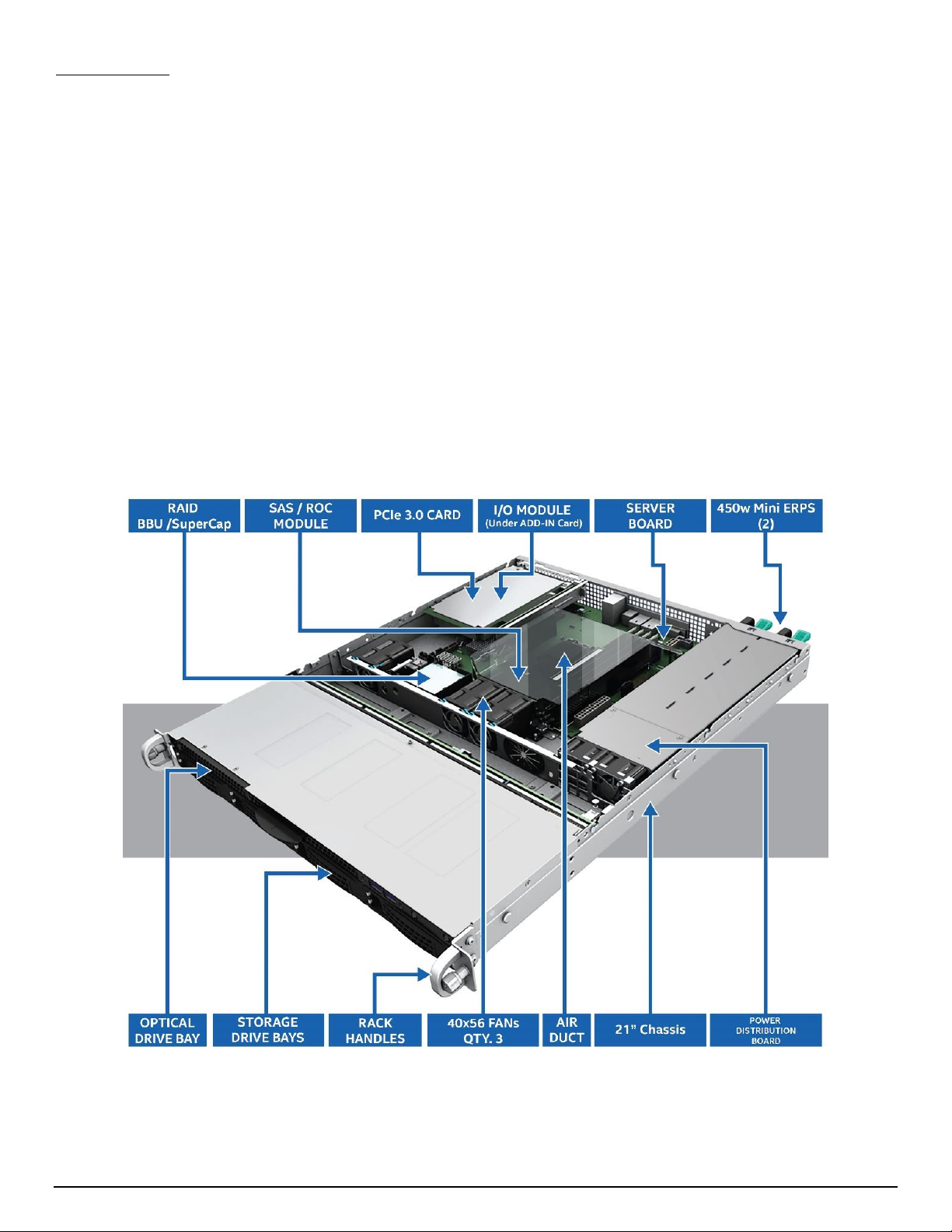

2. Product Family Overview

The Intel® Server System R1000SPO product family offers a variety of system options to meet the varied

configuration requirements of entry level computing environments, and includes several available 1U rack

mount server systems. Each integrated system within this product family is configured around the Intel®

Server Board S1200SPO.

This chapter provides a high-level overview of the system features and available options as supported in

different system models within this product family. Greater detail for each major sub-system, feature, or

option is provided in the following chapters.

Table 2. Intel

®

Server System R1000SPO Product Family Feature Set

3

Page 15

Intel® Server System R1000SPO Product Family TPS

Feature

Description

On-board storage

controllers and options

8x SATA connectors up to 6Gbps

1x SATADOM connector (SATA port 4)

1x 75 pin connector for M.2 SATA SSD (2242 form factor)

Embedded Software SATA RAID

o Intel® RSTe 4 SW RAID through onboard SATA connectors provides SATA RAID 0/1/10/5.

o Intel

®

Embedded Server RAID Technology II through onboard SATA connectors provides SATA

RAID 0/1/10 and optional RAID 5 support provided by the Intel® RAID Activation Key

RKSATA8R5.

Security

Intel® Trusted Platform Module (TPM) 1.2 based on LPC

Server Management

Integrated Baseboard Management Controller, IPMI 2.0 compliant

Support for Intel® Server Management Software

On-board RJ45 management port

Advanced Server Management via an Intel® Remote Management Module 4 Lite (Accessory Option)

Power Supply Options

The server system supports two options for Power Supply:

o 1 x 350w Power Supply (Fixed)

o 2 x 450w Power Supply Modules (Redundant, Hot-Swap capable)

Storage Bay Options

Hot Swap Backplane Options:

NOTE: All available backplane options have support for SAS 3.0 (12 Gb/sec)

4 x 3.5” SAS/SATA backplane

8 x 2.5” SAS/SATA backplane

Storage Bay Options:

4 x 3.5” SAS/SATA hot swap drive bays + front panel I/O

8 x 2.5” SAS/SATA hot swap drive bays + front panel I/O

Supported Rack Mount

Kit Accessory Options

AXXVPSRAIL - Value Plus Short Rail

4

Page 16

Intel® Server System R1000SPO Product Family TPS

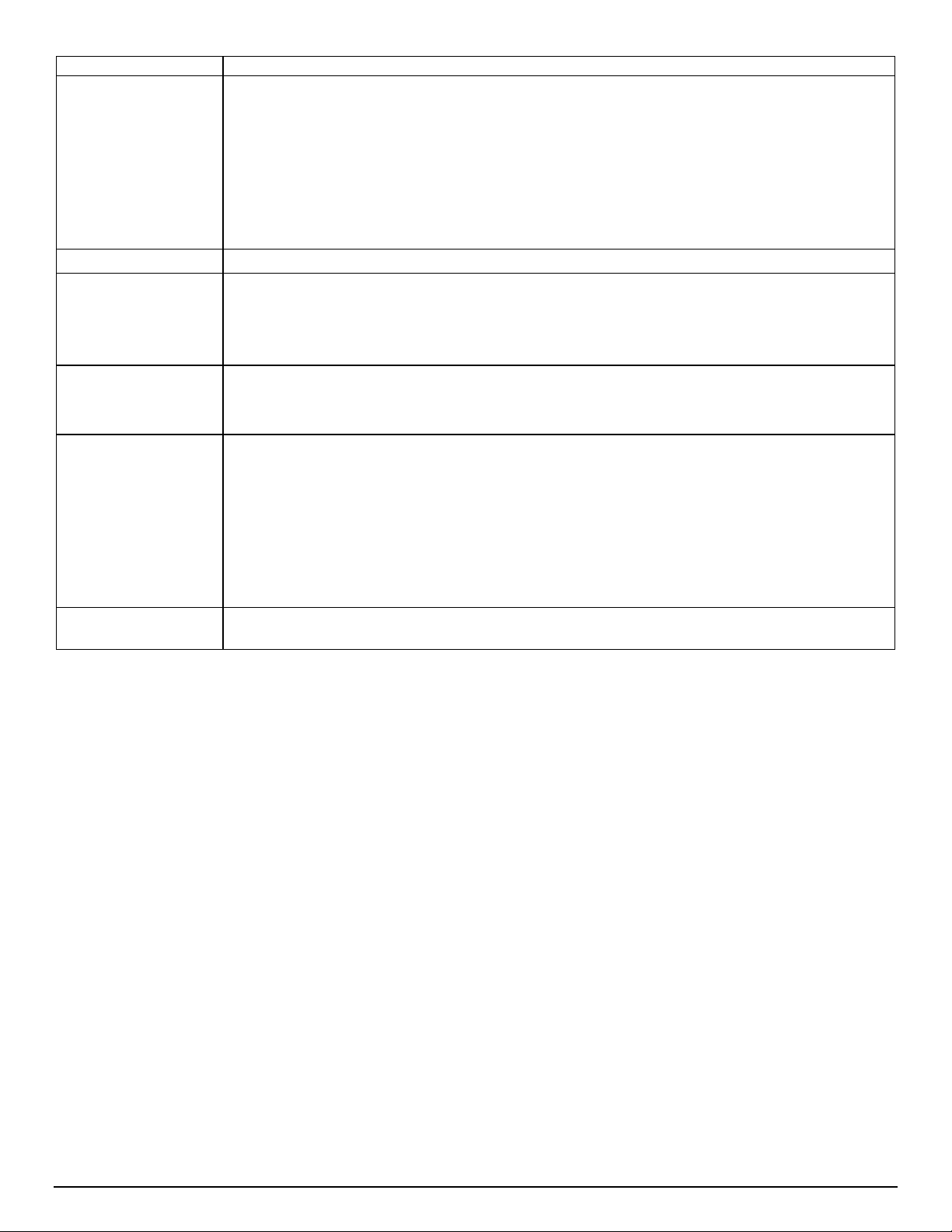

Operating System

Operating System

Validation Level

(P)

Windows Server 2012* R2 with Hyper-Vx64 & EFI

P1

Red Hat Enterprise Linux* 7.0 with KVM x64 & UEFI

P1

SuSE Linux Enterprise Server* 12 with XEN x64

P1

Red Hat Enterprise Linux 6U5 with KVM x64 & UEFI

P2

VMWare ESXi* 5.5 U3

P2

SuSE Linux Enterprise Server 11 SP4 with XEN x64

P2

Windows Server 2008 R2 SP1

P2

Windows 7*

P2

Ubuntu* 14.04

P2

FreeBSD* 10.1

P3

CentOS* 7.0

P3

Operating System Validation Levels

P1

P2

P3

Basic Installation testing

Yes

Yes

Yes

Test all on-board I/O features in all modes

Yes

Adapter\Peripheral Compatibility & Stress testing

Yes

Technical Support Level

T1

T2

T3

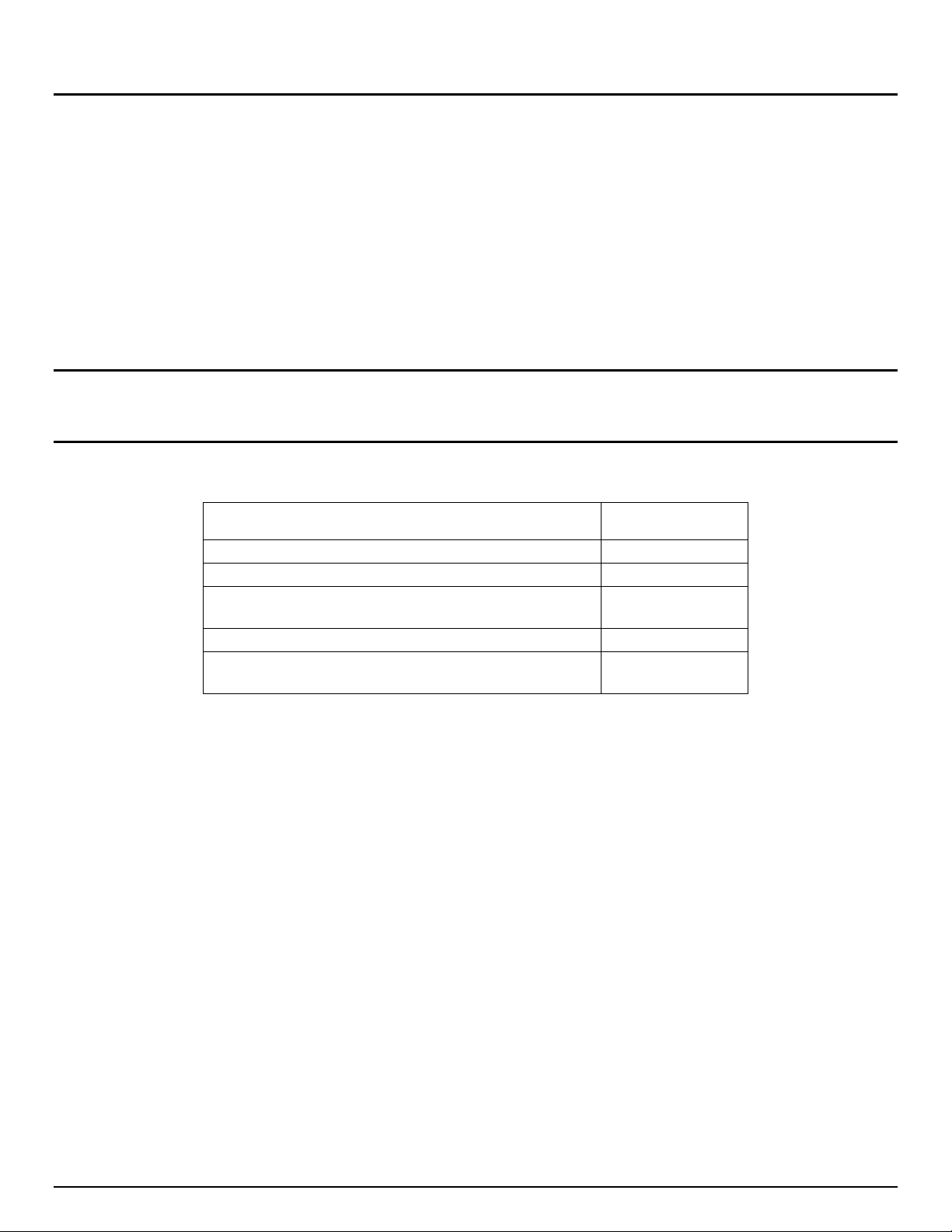

2.1 Operating System Support

As of this writing, the Intel® Server System R1000SPO product family provides support for the following

operating systems. This list will be updated as new operating systems are validated by Intel.

Table 3. Operating System Support List

Table 4. Operating System Validation Levels

See the following sections for additional information regarding validation levels and technical support levels

as referenced in Table 4.

2.1.1 OS Validation Levels

Basic installation testing is performed with each supported operating system. The testing validates that the

system can install the operating system and that the base hardware feature set is functional. A small set of

peripherals is used for installation purposes only. Add-in adapter cards are not tested.

Adapter compatibility validation (CV) testing uses test suites to gain an accurate view of how the server

performs with a wide variety of adapters under the primary supported operating systems. These tests are

designed to show hardware compatibility between the cards and the server platform and include functional

testing only. No heavy stressing of the systems or the cards is performed for CV testing.

5

Page 17

Intel® Server System R1000SPO Product Family TPS

Stress Testing uses configurations that include add-in adapters in all available slots for a 48-hour (two-day),

or a 72-hour (three-day) test run without injecting errors. Each configuration passes an installation test and a

Network/Disk Stress test. Any fatal errors that occur require a complete test restart.

2.1.2 OS Technical Support Levels

T1: Intel will provide support for issues involving the installation and/or functionality of a specified operating

system as configured with or without supported adapters and/or peripherals.

T2: Intel will provide and test operating system drivers for each of the server board’s integrated controllers,

provided that the controller vendor has a driver available upon request. Vendors will not be required by Intel

to develop drivers for operating systems that they do not already support. Intel will NOT provide support for

issues related to the use of any add-in adapters or peripherals installed in the server system when an

operating system that received only basic installation testing is in use.

T3: Intel will not provide technical support for an open source operating system. All questions and issues

related to an open source operating system must be submitted to and supported by the open source

community supporting the given operating system.

2.2 System Features Overview

Figure 1. System Components Overview

6

Page 18

Intel® Server System R1000SPO Product Family TPS

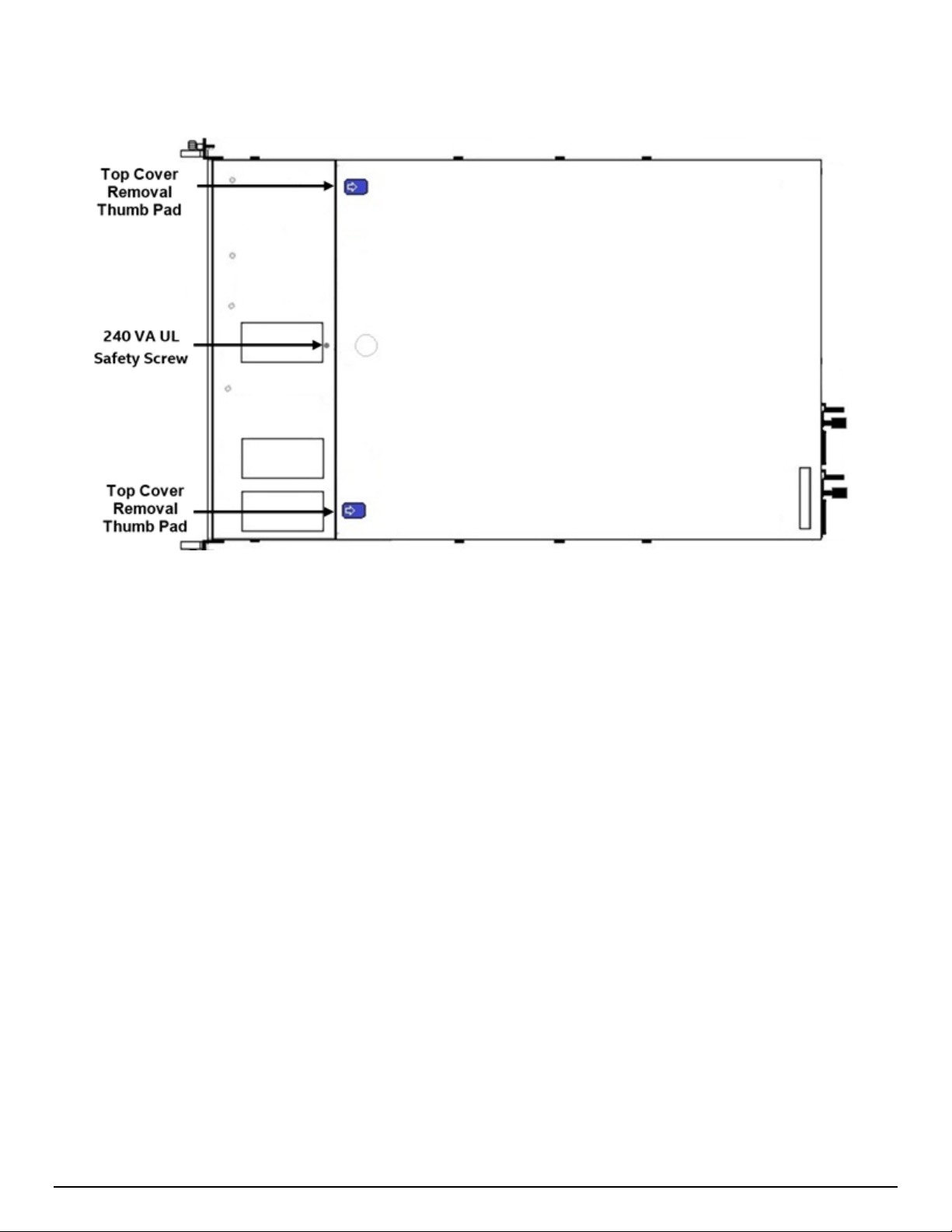

Figure 2. Top Cover Features

7

Page 19

Intel® Server System R1000SPO Product Family TPS

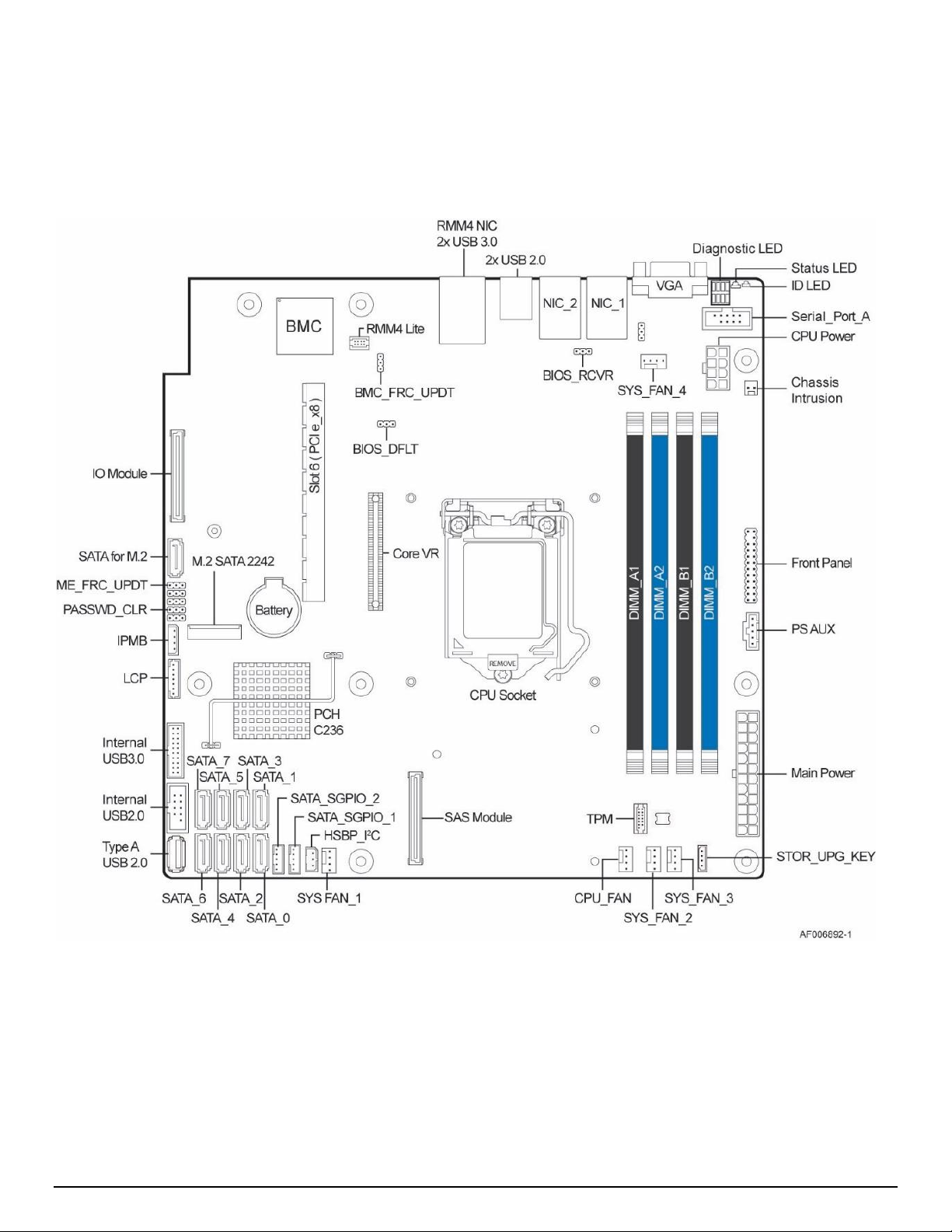

2.3 Server Board Features Overview

The following illustration provides a general overview of the server board, identifying key feature and

component locations. Please refer to Intel® Server Board S1200SP Technical Product Specification for more

information.

Figure 3. Server Board Features

8

Page 20

Intel® Server System R1000SPO Product Family TPS

The server board includes several LEDs to identify system status. The following illustrations define

supported LEDs and identify their location.

Figure 4. On-board Diagnostic LEDs

9

Page 21

Intel® Server System R1000SPO Product Family TPS

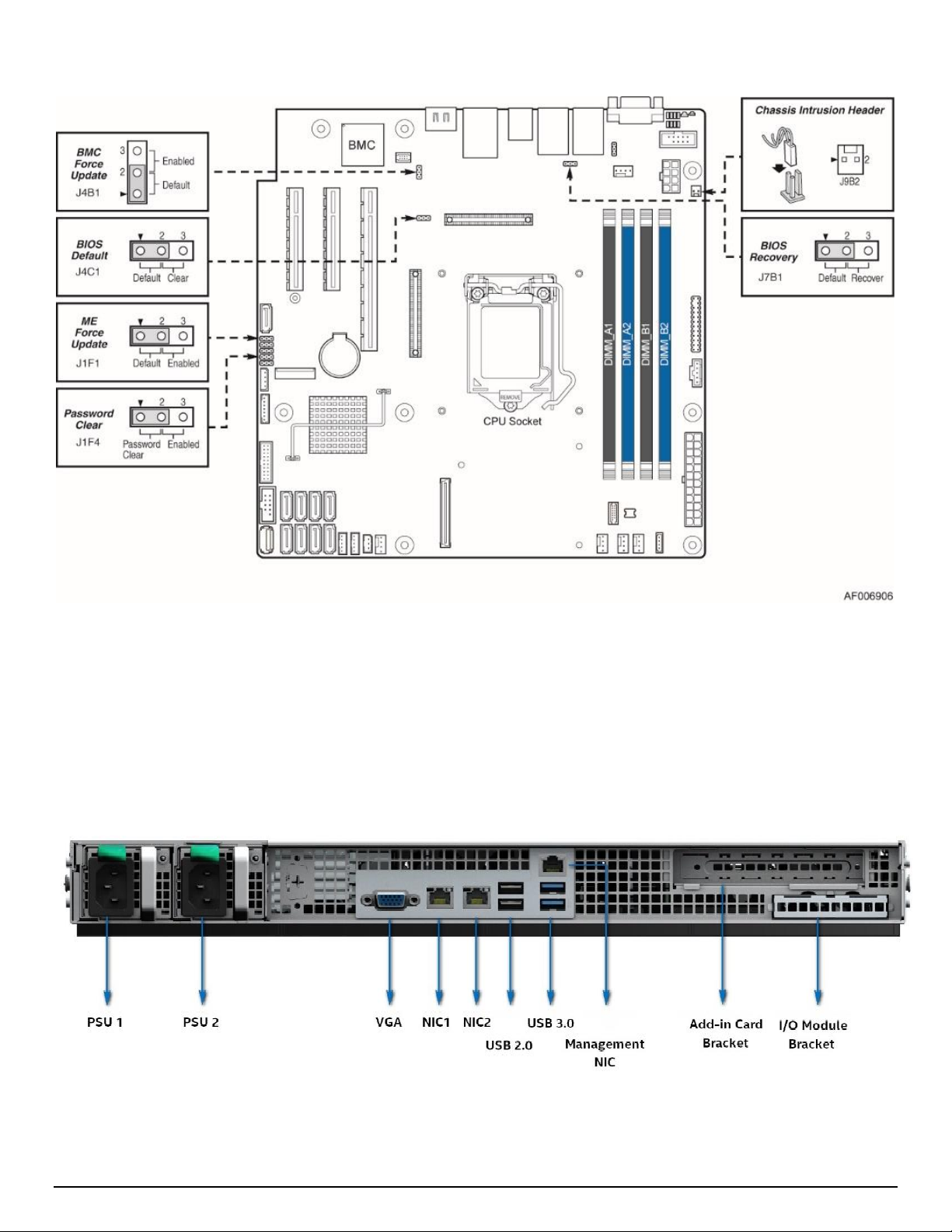

Figure 5. System Reset and Configuration Jumpers

2.4 Back Panel Features

Figure 6. Back Panel Features

10

Page 22

Intel® Server System R1000SPO Product Family TPS

Label

Description

A

System ID Button w/Integrated LED

B

NMI Button (recessed, tool required for use)

C

NIC 1 & 2 Activity LEDs

D

System Cold Reset Button (recessed, tool required for use)

E

System Status LED

F

Power Button w/Integrated LED

G

Drive Activity LED

2.5 Front Control Panel

Figure 7. Front Control Panel Options

2.6 Front Drive Bay Options

Figure 8. 3.5" Drive Bay – 4 Drive Configuration (Model R1304SPxxxxx)

Figure 9. 2.5" Drive Bay – 8 Drive Configuration (Model R1208SPxxxxx)

11

Page 23

Intel® Server System R1000SPO Product Family TPS

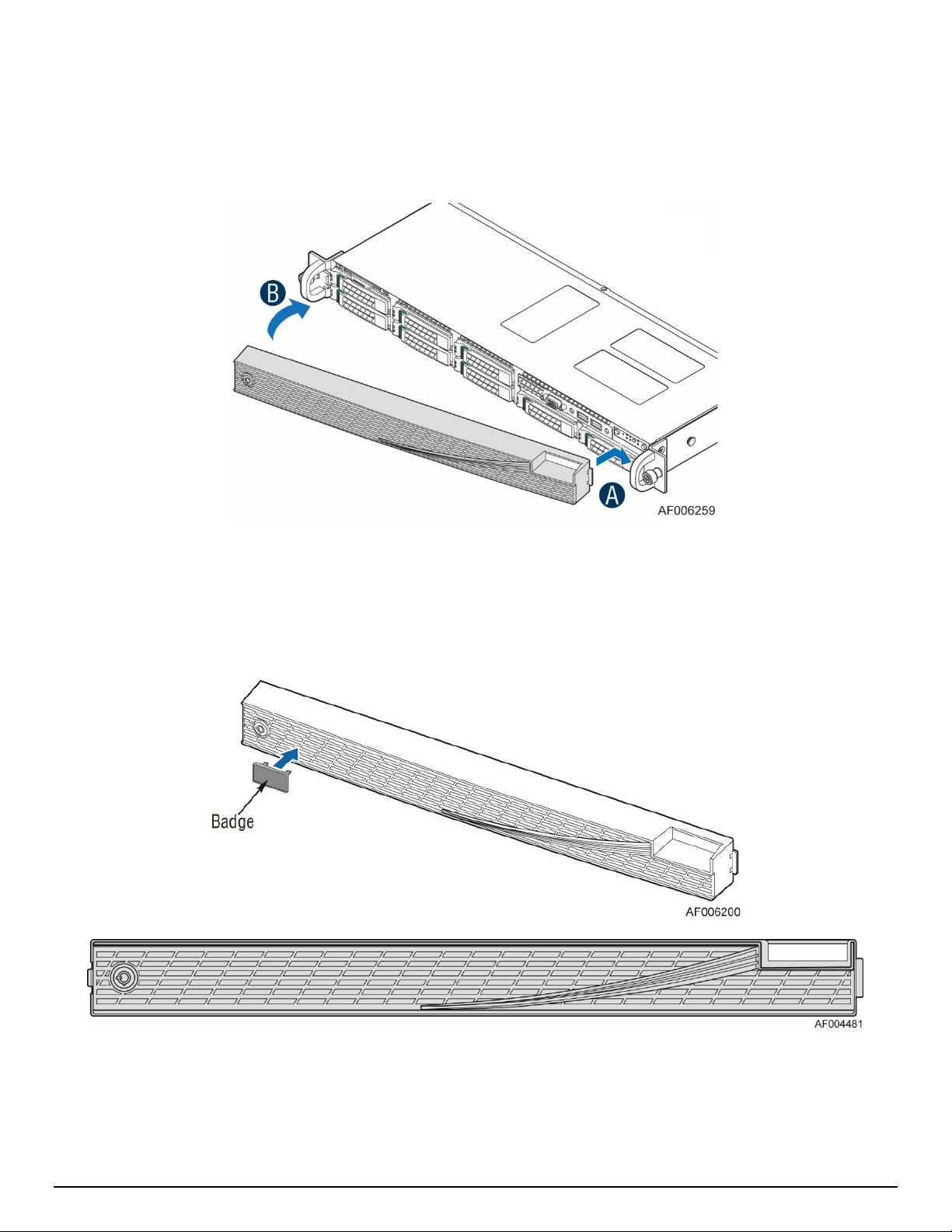

2.7 Locking Front Bezel

The optional front bezel is made of Black molded plastic and uses a snap-on design. When installed, its

design allows for maximum airflow to maintain system cooling requirements. The front bezel includes a

keyed locking mechanism which can be used to prevent unauthorized access to installed storage devices

and front I/O ports.

Figure 10. Front Bezel

(Intel Product Order Code – A1UBEZEL)

The face of the bezel assembly includes snap-in identification badge options and a wave feature option to

allow for customization.

Figure 11. Front Bezel Accessory with Optionally Installed Wave Feature

12

Page 24

Intel® Server System R1000SPO Product Family TPS

Figure 12. Front Bezel Accessory with Optionally Installed Wave and ID Badge (1)

Figure 13. Front Bezel Accessory with Optionally Installed Wave and ID Badge (2)

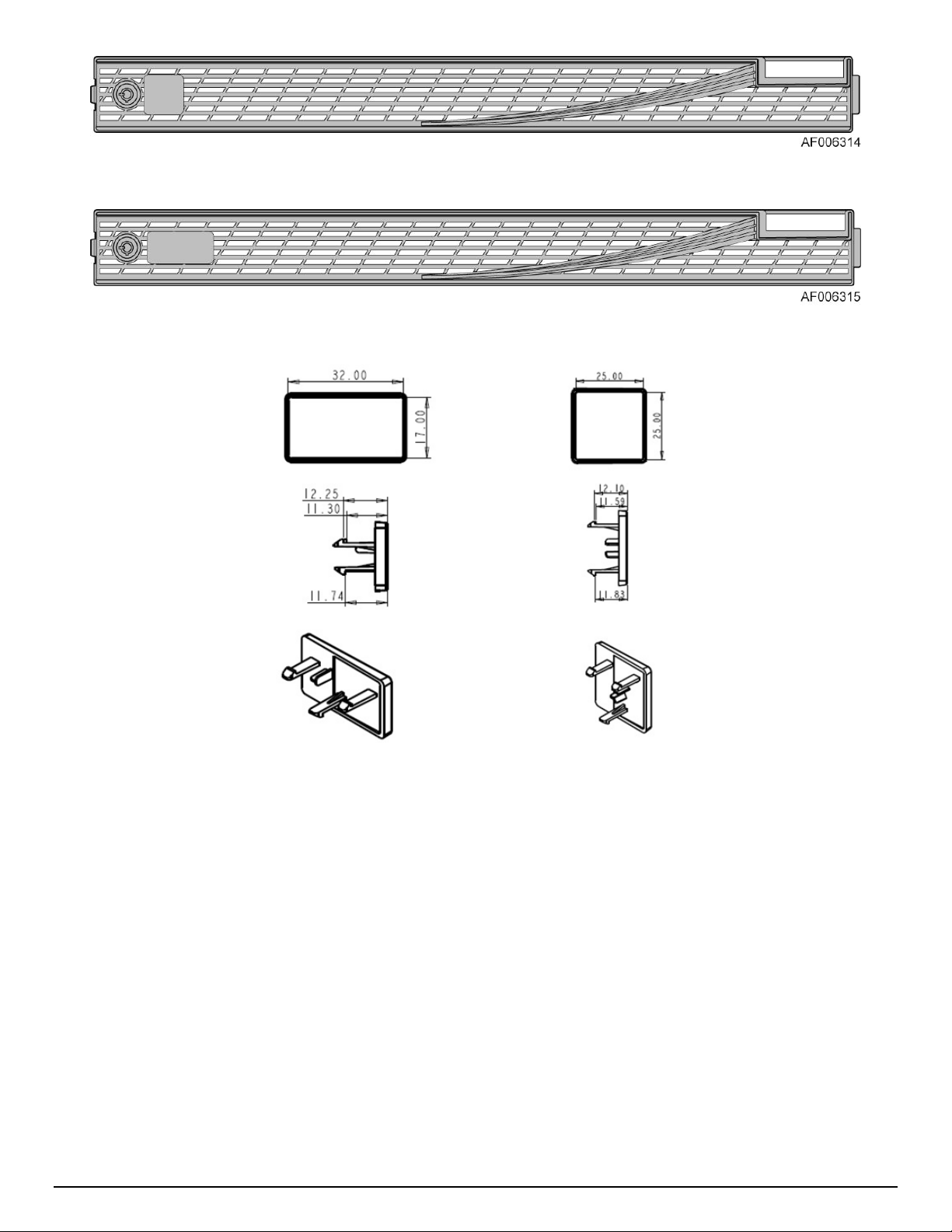

Figure 14. Front Bezel Accessory ID Badge Mechanical Drawings

13

Page 25

Intel® Server System R1000SPO Product Family TPS

1.7”

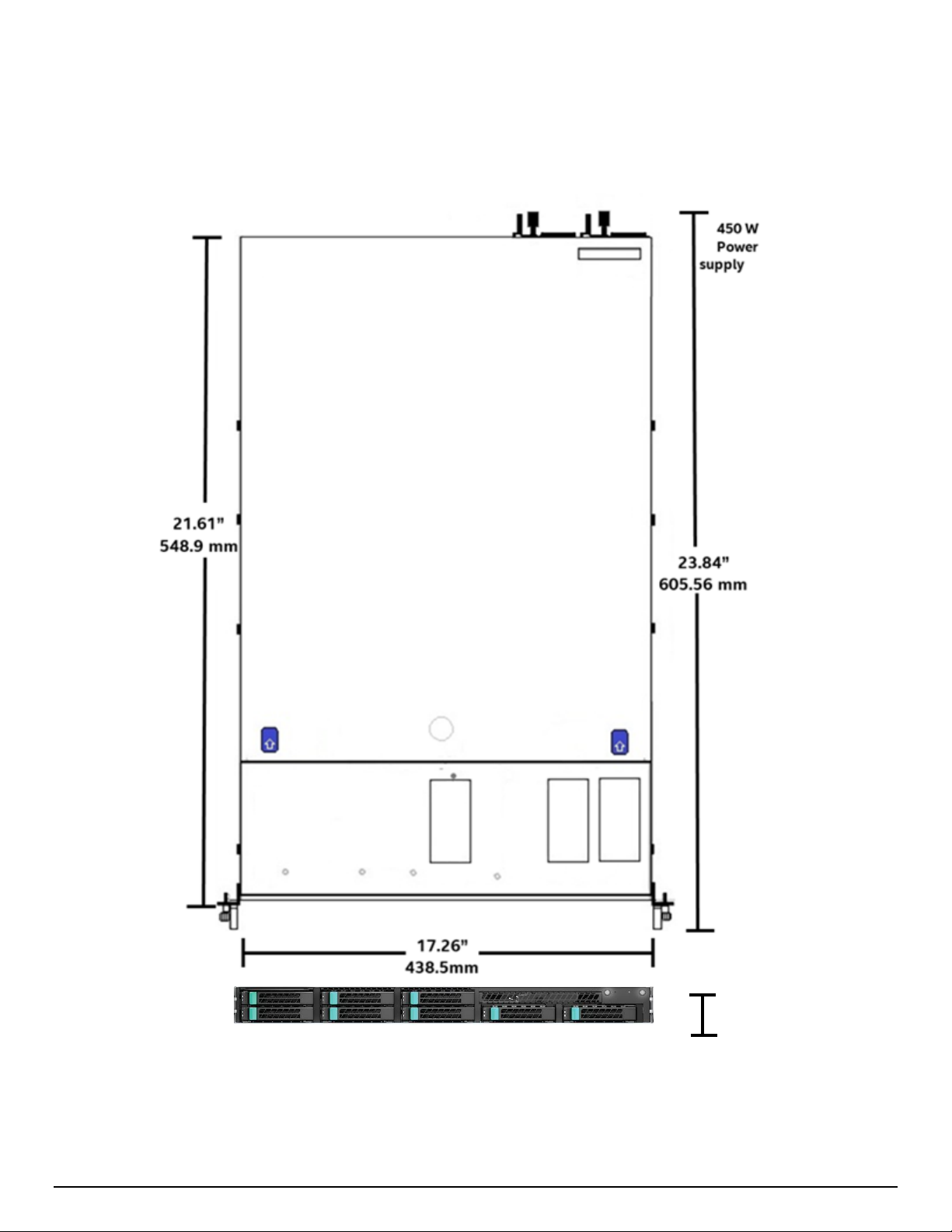

2.8 System Dimensions

2.8.1 Chassis Dimensions

Figure 15. Chassis Dimensions

14

Page 26

Intel® Server System R1000SPO Product Family TPS

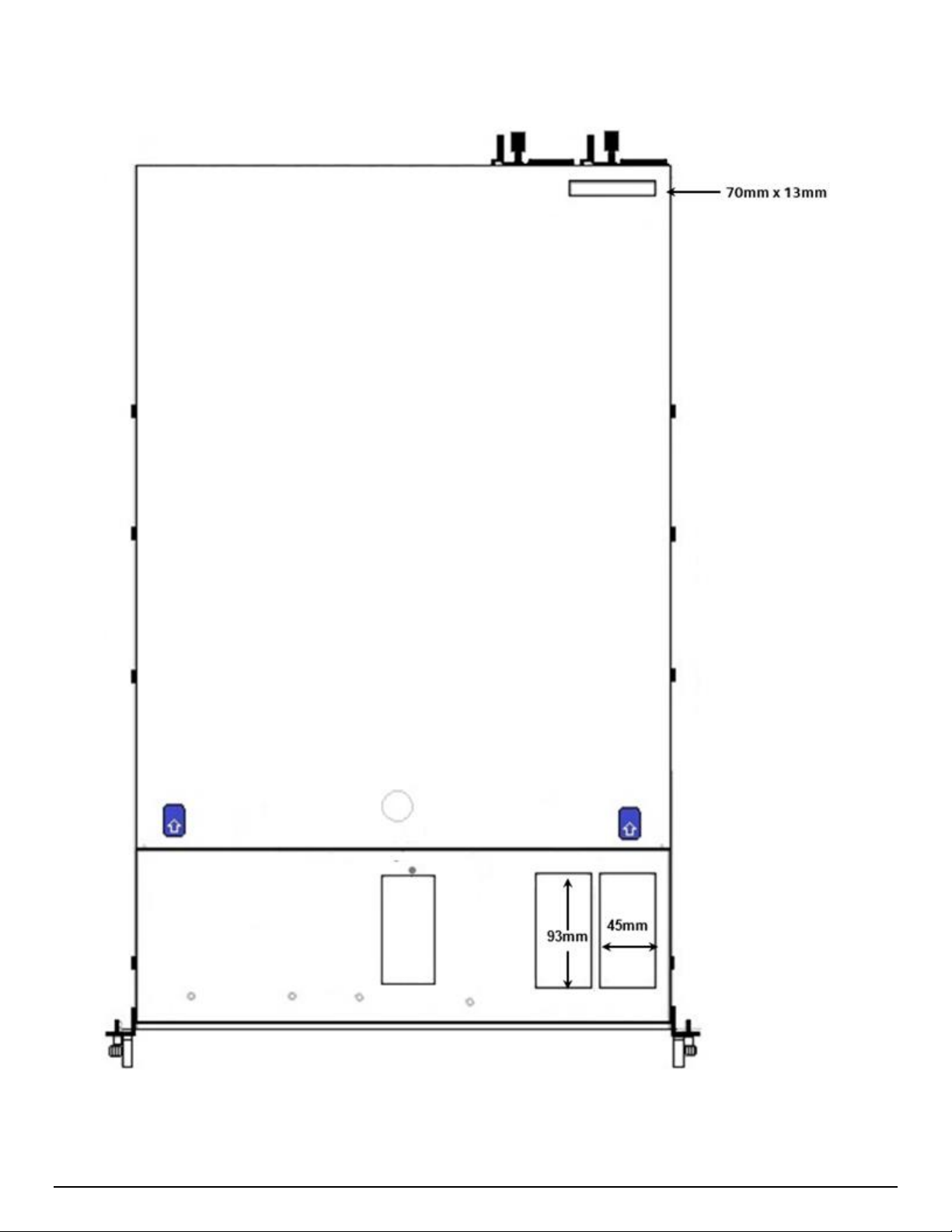

2.8.2 Label Emboss Dimensions

15

Figure 16. Label Emboss Dimensions

Page 27

Intel® Server System R1000SPO Product Family TPS

2.8.3 Pull-out Tab Label Emboss Dimensions

Figure 17. Pull-out Tab Label Emboss Dimensions

2.9 Available Rack Mounting Kit Options

Advisory Note – Available rack and cabinet mounting kits are not designed to support shipment of the

server system while installed in a rack. If you chose to do so, Intel advises you verify your shipping

configuration with appropriate shock and vibration testing, before shipment. Intel does not perform shipping

tests which cover the complex combination of unique rack offerings and custom packaging options.

Caution: Exceeding the rail kit’s specified maximum weight limit or misalignment of the server in the rack

may result in failure of the rack rails, resulting in damage to the system or personal injury. Two people or the

use of a mechanical assist tool to install and align the server into the rack is highly recommended.

Available Rack mounting kits:

AXXVPSRAIL – Vale plus short rail

- 424mm max travel length

- 129 lbs. (59 Kg) max support weight

- Front and rear mounting bracket adjustment distance: 609mm to 705mm

- Stab-in system install

- x8 #10-32 screws to mount rail kit on rack flange (screw kit come with rail kit assembling)

- No cable management arm support

16

Page 28

Intel® Server System R1000SPO Product Family TPS

Parameter

Limits

Temperature

Operating

ASHRAE Class A2 – Continuous Operation. 10º C to 35º C (50º F to 95º F) with the maximum

rate of change not to exceed 10°C per hour

ASHARE Class A3 – Includes operation up to 40°C for up to 900 hours per year. Refer to

Appendix E for detailed guidance.

Shipping

-40º C to 70º C (-40º F to 158º F)

Altitude

Operating

Support operation up to 3050m with ASHRAE class de-ratings.

Humidity

Shipping

50% to 90%, non-condensing with a maximum wet bulb of 28° C (at temperatures from 25°

C to 35° C)

Shock

Operating

Half sine, 2 g, 11 mSec

Unpackaged

Trapezoidal, 25 g, velocity change is based on packaged weight

Packaged

ISTA (International Safe Transit Association) Test Procedure 3A 2008

Vibration

Unpackaged

5 Hz to 500 Hz 2.20 g RMS random

Packaged

ISTA (International Safe Transit Association) Test Procedure 3A 2008

AC-DC

Voltage

90 V to 132 V and 180 V to 264 V

Frequency

47 Hz to 63 Hz

Source Interrupt

No loss of data for power line drop-out of 12 mSec

Surge Nonoperating and

operating

Unidirectional

Line to earth Only

AC Leads 2.0 kV

I/O Leads 1.0 kV

DC Leads 0.5 kV

ESD

Air Discharged

12.0 kV

Contact Discharge

8.0 kV

Acoustics

Sound Power

Measured

Power in Watts

<300 W ≥300 W ≥600 W ≥1000 W

Servers/Rack

Mount Sound

Power Level (in

BA)

7.0 7.0 7.0 7.0

2.10 System Level Environmental Limits

The following table defines the system level operating and non-operating environmental limits.

Table 5. System Environmental Limits Summary

17

Page 29

Intel® Server System R1000SPO Product Family TPS

Product code

Net Weight(kg)

Gross Weight(kg)

Net Weight (Lbs.)

Gross Weight (Lbs.)

R1304SPOSHBN

7.77

11.6

17.1

25.6

R1304SPOSHOR

8.87

12.8

19.6

28.2

R1208SPOSHOR

9.09

13

20

28.7

E1304SPOSHON

8.99

12.8

19.8

28.2

2.11 System Packaging

The original Intel packaging, in which the server system is delivered, is designed to provide protection to a

fully configured system and was tested to meet ISTA (International Safe Transit Association) Test Procedure

3A (2008). The packaging was also designed to be re-used for shipment after system integration has been

completed.

The original packaging includes – a small inner box for ship along accessories, the outer shipping main box,

and various protective inner packaging components. The boxes and packaging components are designed to

function together as a protective packaging system. When reused, all of the original packaging material must

be used, including both boxes and each inner packaging component. In addition, all inner packaging

components MUST be reinstalled in the proper location to ensure adequate protection of the system for

subsequent shipment.

Please refer to the Intel® Server System R1000SPO Product Family System Integration and Service Guide for

complete packaging assembly instructions.

NOTE: The design of the inner packaging components does not prevent improper placement within the

packaging assembly. There is only one correct packaging assembly that will allow the package to meet the

ISTA (International Safe Transit Association) Test Procedure 3A (2008) limits.

Failure to follow the specified packaging assembly instructions may result in damage to the system during

shipment.

2.11.1 Intel Product Weight Information

Table 6. Intel Product Weight Information

NOTE: An L6 system does not include processors, memory, drives, or add-in cards. It is the system

configuration as shipped from Intel. Integrated system weights (System configurations that include the items

above) will vary depending on the final system configuration. For the 1U product family, a fully integrated

un-packaged system can weigh up to 40 Lbs. (18+ Kg).

18

Page 30

Intel® Server System R1000SPO Product Family TPS

3. System Power

This chapter provides a high level overview of the features and functions related to system power.

3.1 Power Supply Configurations

Systems within this product family are offered with options to support a single fixed mount 350 watt power

supply or dual 450 watt power supply modules. Dual power supply configurations support the following

power configurations: 1+0 (single), and 1+1 (redundant).

1+1 redundant power is supported if the total system power draw remains below the maximum power

capacity of a single power supply module. If a power supply fails, the remaining power supply will allow the

system to remain fully operational. The power supplies are hot swap capable allowing the failed power

supply to be replaced without powering down the system.

In dual power supply configured systems, the power supplies are modular, allowing for tool-less insertion

and extraction from a bay in the back of the chassis. When inserted, the card edge connector of the power

supply mates blindly to a matching slot connector on the Power Distribution Board (PDB).

19

Figure 18. 350W AC Fixed Power Supply

Figure 19. 450W AC Power Supply

Page 31

Intel® Server System R1000SPO Product Family TPS

Loading

Efficiency

20% of maximum

85%

50% of maximum

88%

100% of maximum

85%

Loading

Efficiency

20% of maximum

88%

50% of maximum

92%

100% of maximum

88%

3.2 Power Supply Module Options

There are two power supply options available for this server product family: 350W AC (fixed mount) and

450W AC (Module).

3.2.1 Power Supply Module Efficiency

The following tables provide the required minimum efficiency level at various loading conditions. These are

provided at three different load levels: 100%, 50%, and 20%.

The AC power supply efficiency is tested over an AC input voltage of 230 VAC.

Table 7. 350 Watt AC Power Supply Efficiency (Gold)

Table 8. 450 Watt AC Power Supply Efficiency (Gold)

3.2.2 Power Supply Module Mechanical Overview

Figure 20. 350W Power Supply Mechanical Drawings

20

Page 32

Intel® Server System R1000SPO Product Family TPS

Figure 21. 450W Power Supply Mechanical drawings

3.2.3 Power distribution board

The dual power supply configuration option for the Intel® Server System R1000SPO product family

incorporates a Power Distribution Board (PDB), and is where the Redundant Power Supply modules are

attached. The Connections for Server Board power, communications for power supply monitoring, power for

the Backplane and Optical Disk Drive, come from the Power Distribution Board. For connector pinout and

power supply monitoring details, please refer to the Intel® Server Board S1200SP Product Family Technical

Product Specification. The PDB is designed to plug directly to the output connector of the power supply and

it contains two DC/DC power converters to produce other required voltages.

Figure 22. Power Distribution Board

21

Page 33

Intel® Server System R1000SPO Product Family TPS

Cable Type

SJT

Wire Size

16 AWG

Temperature Rating

105ºC

Amperage Rating

13 A

Voltage Rating

125 V

Output power (350w PSU)

20% load

50% load

100% load

Power factor

0.8

0.9

0.98

Output power (450w PSU)

20% load

50% load

100% load

Power factor

0.8

0.9

0.95

3.2.4 Power Cord Specification Requirements

The AC power cord used must meet the specification requirements listed in the following table.

Table 9. AC Power Cord Specifications

Figure 23. AC Power Cord

3.3 AC Power Supply Input Specifications

The following sections provide the AC Input Specifications for systems configured with AC power supply

modules.

3.3.1 Power Factor

The power supply must meet the power factor requirements stated in the Energy Star* Program

Requirements for Computer Servers. These requirements are stated below.

22

Page 34

Intel® Server System R1000SPO Product Family TPS

PARAMETER

MIN

RATED

MAX

Max Input AC Current

Line Voltage (110)

90V

rms

100-127 V

rms

140V

rms

6 A

rms

1

Line Voltage (220)

180V

rms

200-240 V

rms

264V

rms

3 A

rms

2

Frequency

47 Hz

50/60Hz

63 Hz

DC Voltage

237VDC

250VDC

262VDC

PARAMETER

MIN

RATED

VMAX

Start-up VAC

Power-off VAC

Voltage (110)

90 V

rms

100-127 V

rms

140 V

rms

1

85VAC +/-4VAC

70VAC +/-5VAC

Voltage (220)

180 V

rms

200-240 V

rms

264 V

rms

2

Frequency

47 Hz

50/60 Hz

63 Hz³

Loading

Holdup time

75%

12msec

3.3.2 AC Input Voltage Specification

The power supply must operate within all specified limits over the following input voltage range. Harmonic

distortion of up to 10% of the rated line voltage must not cause the power supply to go out of specified

limits. Application of an input voltage below 85VAC shall not cause damage to the power supply, including a

blown fuse.

Table 10. Input Voltage Range – 350W Power Supply

1. Maximum input current at low input voltage range shall be measured at 90VAC, at max load.

2. Maximum input current at high input voltage range shall be measured at 180VAC, at max load.

Table 11. AC Input Voltage Range – 450W Power Supply

1. Maximum input current at low input voltage range shall be measured at 90VAC, at max load.

2. Maximum input current at high input voltage range shall be measured at 180VAC, at max load.

3. This requirement is not to be used for determining agency input current markings.

3.3.3 AC Line Isolation Requirements

The power supply shall meet all safety agency requirements for dielectric strength. Transformers’ isolation

between primary and secondary windings must comply with the 3000Vac (4242Vdc) dielectric strength

criteria. If the working voltage between primary and secondary dictates a higher dielectric strength test

voltage the highest test voltage should be used. In addition the insulation system must comply with

reinforced insulation per safety standard IEC 950. Separation between the primary and secondary circuits,

and primary to ground circuits, must comply with the IEC 950 spacing requirements.

3.3.4 AC Line Dropout / Holdup

An AC line dropout is defined to be when the AC input drops to 0VAC at any phase of the AC line for any

length of time. An AC line dropout for less than 12ms shall not cause tripping of control signals or protection

circuits. If the AC dropout lasts longer than the holdup time the power supply should recover and meet all

turn on requirements. The power supply shall meet the AC dropout requirement over rated AC voltages and

frequencies. A dropout of the AC line for any duration shall not cause damage to the power supply.

23

Table 12. AC Line Holdup Time – 350W Power supply

Page 35

Intel® Server System R1000SPO Product Family TPS

Loading

Holdup time

75%

12msec

100%

10msec

AC Line Sag (10sec interval between each sagging)

Duration

Sag

Operating AC Voltage

Line Frequency

Performance Criteria

Continuous

10%

Nominal AC Voltage ranges

50/60Hz

No loss of function or performance

1 to 12ms

100%

Nominal AC Voltage ranges

50/60Hz

No loss of function or performance

> 12ms

>30%

Nominal AC Voltage ranges

50/60Hz

Loss of function acceptable, selfrecoverable

AC Line Surge

Duration

Surge

Operating AC Voltage

Line Frequency

Performance Criteria

Continuous

10%

Nominal AC Voltages

50/60Hz

No loss of function or performance

0 to ½ AC

cycle

30%

Nominal AC Voltages

50/60Hz

No loss of function or performance

AC Line Sag (10sec interval between each sagging)

Duration

Sag

Operating AC Voltage

Line Frequency

Performance Criteria

0 to 1/2 AC cycle

95%

Nominal AC Voltage ranges

50/60Hz

No loss of function or performance

> 1 AC cycle

>30%

Nominal AC Voltage ranges

50/60Hz

Loss of function acceptable, self-recoverable

Table 13. AC Line Holdup Time – 450W Power Supply

3.3.5 AC Line Fuse

The power supply shall have one line fused in the single line fuse on the line (Hot) wire of the AC input. The

line fusing shall be acceptable for all safety agency requirements. The input fuse shall be a slow blow type.

AC inrush current shall not cause the AC line fuse to blow under any conditions. All protection circuits in the

power supply shall not cause the AC fuse to blow unless a component in the power supply has failed. This

includes DC output load short conditions.

3.3.6 AC Line Transient Specification

AC line transient conditions shall be defined as “sag” and “surge” conditions. “Sag” conditions are also

commonly referred to as “brownout”, these conditions will be defined as the AC line voltage dropping below

nominal voltage conditions. “Surge” will be defined to refer to conditions when the AC line voltage rises

above nominal voltage.

Table 14. AC Line Sag Transient Performance – 350W Power Supply

Table 15. AC Line Surge Transient Performance – 350W Power Supply

Table 16. AC Line Sag Transient Performance – 450W Power Supply

24

Page 36

Intel® Server System R1000SPO Product Family TPS

AC Line Surge

Duration

Surge

Operating AC Voltage

Line Frequency

Performance Criteria

Continuous

10%

Nominal AC Voltages

50/60Hz

No loss of function or performance

0 to ½ AC cycle

30%

Mid-point of nominal AC Voltages

50/60Hz

No loss of function or performance

Level

Description

A

The apparatus shall continue to operate as intended. No degradation of performance.

B

The apparatus shall continue to operate as intended. No degradation of performance beyond spec limits.

C

Temporary loss of function is allowed provided the function is self-recoverable or can be restored by the

operation of the controls.

Table 17. AC Line Surge Transient Performance – 450W Power Supply

3.3.7 Susceptibility Requirements

The power supply shall meet the following electrical immunity requirements when connected to a cage with

an external EMI filter which meets the criteria defined in the SSI document EPS Power Supply Specification.

For further information on Intel standards please request a copy of the Intel Environmental Standards

Handbook.

Table 18. Performance Criteria

3.3.8 Electrostatic Discharge Susceptibility

The power supply shall comply with the limits defined in EN 55024: 1998/A1: 2001/A2: 2003 using the IEC

61000-4-2: Edition 1.2: 2001-04 test standard and performance criteria B defined in Annex B of CISPR 24.

3.3.9 Fast Transient/Burst

The power supply shall comply with the limits defined in EN55024: 1998/A1: 2001/A2: 2003 using the IEC

61000-4-4: Second edition: 2004-07 test standard and performance criteria B defined in Annex B of CISPR

24.

3.3.10 Radiated Immunity

The power supply shall comply with the limits defined in EN55024: 1998/A1: 2001/A2: 2003 using the IEC

61000-4-3: Edition 2.1: 2002-09 test standard and performance criteria A defined in Annex B of CISPR 24.

3.3.11 Power Recovery

The power supply shall recover automatically after an AC power failure. AC power failure is defined to be

any loss of AC power that exceeds the dropout criteria.

3.3.12 Voltage Interruptions

The power supply shall comply with the limits defined in EN55024: 1998/A1: 2001/A2: 2003 using the IEC

61000-4-11: Second Edition: 2004-03 test standard and performance criteria C defined in Annex B of CISPR

24.

3.3.13 Protection Circuits

Protection circuits inside the power supply cause only the power supply’s main outputs to shut down. If the

power supply latches off due to a protection circuit tripping, an AC cycle OFF for 15 seconds and a PSON#

cycle HIGH for one second reset the power supply.

25

Page 37

Intel® Server System R1000SPO Product Family TPS

Output Voltage

Continuous Load

Current Limit MIN

Current Limit MAX

+12V1

18.2A

20A

+12V2

18.2A

20A

+5V

19.2A

24A

+3.3V

12A

15A

-12V

4A

+5VSB

4.5A

Output

Min OCP

Max OCP

+12V

40 A

54 A

5Vstby

3.6A~8A

Output Voltage

OVP MIN (V)

OVP MAX (V)

+3.3V

3.7

4.5

+5V

5.7

6.5

+12V1/+12V2

13.3

15.6

-12V

-13.3

-15.6

+5VSB

5.7

6.5

3.3.13.1 Over-current Protection (OCP)

The power supply shall have current limit to prevent the outputs from exceeding the values shown in table

below. If the current limits are exceeded the power supply shall shutdown and latch off. The latch will be

cleared by toggling the PSON# signal or by an AC power interruption. The power supply shall not be

damaged from repeated power cycling in this condition. 5VSB will be auto-recovered after removing OCP

limit.

Table 19. Over Current Protection – 350W Power Supply

Table 20. Over Current Protection – 450 Watt Power Supply

3.3.13.2 Over-voltage Protection (OVP)

The power supply over voltage protection shall be locally sensed. The power supply shall shutdown and

latch off after an over voltage condition occurs. This latch shall be cleared by an AC power interruption. The

values are measured at the output of the power supply’s connectors. The voltage shall never exceed the

maximum levels when measured at the power connectors of the power supply connector during any single

point of fail. The voltage shall never trip any lower than the minimum levels when measured at the power

connector. 12VSB will be auto-recovered after removing OVP limit.

Table 21. Over Voltage Protection - 350W Power Supply

26

Page 38

Intel® Server System R1000SPO Product Family TPS

OUTPUT VOLTAGE

PROTECTION POINT [ V]

+12 V

13.6V ~ 15.0V

5VSB

5.6V ~ 6.5V

Power Supply Condition

LED State

Output ON and OK

GREEN

No AC power to all power supplies

OFF

AC present / Only 12VSB on (PS off) or PS in Cold

redundant state

1Hz Blink GREEN

AC cord unplugged or AC power lost; with a second

power supply in parallel still with AC input power.

AMBER

Power supply warning events where the power supply

continues to operate; high temp, high power, high

current, slow fan.

1Hz Blink Amber

Power supply critical event causing a shutdown; failure,

OCP, OVP, Fan Fail

AMBER

Power supply FW updating

2Hz Blink GREEN

Table 22. Over Voltage Protection (OVP) Limits – 750W Power Supply

3.3.13.3 Over-temperature Protection (OTP)

The power supply will be protected against over temperature conditions caused by loss of fan cooling or

excessive ambient temperature. In an OTP condition the PSU will shut down. When the power supply

temperature drops to within specified limits, the power supply shall restore power automatically, while the

12VSB remains always on. The OTP circuit must have built in margin such that the power supply will not

oscillate on and off due to temperature recovering condition. The OTP trip level shall have a minimum of 4C

of ambient temperature margin.

3.3.14 Power Supply Status LED

There is a single bi-color LED to indicate the power supply status on the Redundant Power Supply Modules.

The LED operation is defined in the following table.

Table 23. LED Indicators

3.4 Server Board Power Connectors

The server board provides several connectors to provide power to various system options. The following

sub-sections will provide the pin-out definition; and a brief usage description for each.

The main power supply connection uses an SSI-compliant 2x12 pin connector.

Two additional power-related connectors also exist:

One SSI-compliant 2x4 pin power connector to provide 12-V power to the CPU voltage regulators and

memory.

One SSI-compliant 1x5 pin connector to provide monitoring of the power supply.

27

Page 39

Intel® Server System R1000SPO Product Family TPS

Pin

IO

Signal Name

Pin

IO

Signal Name

1

PWR

+3.3V

13

PWR

+3.3V

2

PWR

+3.3V

14

PWR

-12V (NA for most designs)

3

GND

GND

15

GND

GND

4

PWR

+5V

16

I

PS_ON#

5

GND

GND

17

GND

GND

6

PWR

+5V

18

GND

GND

7

GND

GND

19

GND

GND

8 O PWR_GD

20

NC

NC

9

PWR

SB5V

21

PWR

+5V

10

PWR

+12V

22

PWR

+5V

11

PWR

+12V

23

PWR

+5V

12

PWR

+3.3V

24

GND

GND

Pin

IO

Signal Name

Pin

IO

Signal Name

1

GND

GND

5

PWR

P12V1

2

GND

GND

6

PWR

P12V1

3

GND

GND

7

PWR

P12V2

4

GND

GND

8

PWR

P12V2

Pin

IO

Signal Name

1 I PMBUS_CLK

2

IO

PMBUS_DATA

3 O IRQ_PMBUS_ALERT_N

4

GND

GND Return Sense

5 I P3V3 Sense

The following tables define the pin-out for the connectors:

Table 24. Main Power Connector Pin-out

Table 25. CPU Power Connector Pin-out

Table 26. PMBUS SSI Connector Pin-out (PS_AUX)

28

Page 40

Intel® Server System R1000SPO Product Family TPS

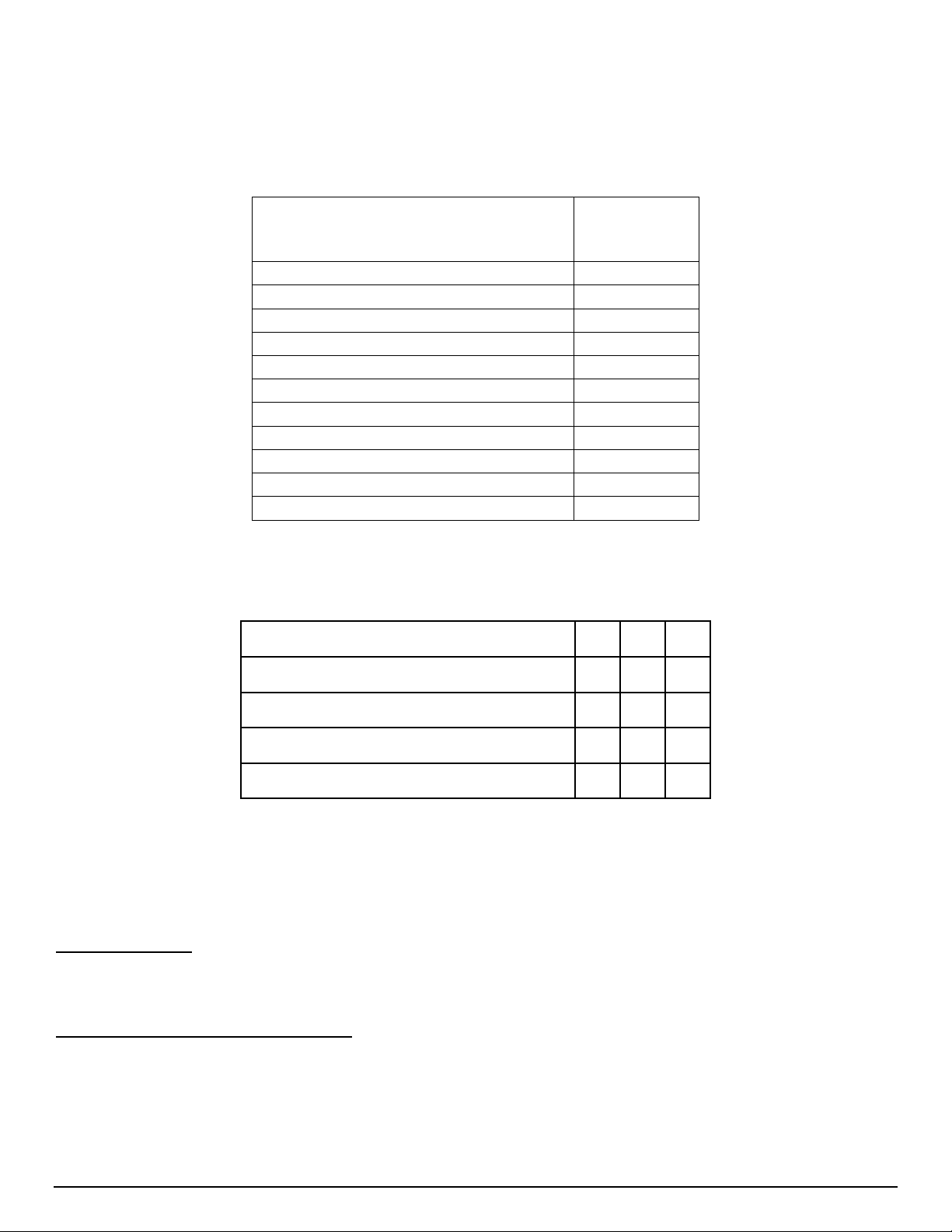

4X3.5'' Front End

All System Fan

PSU Fan

w/o

PSU(CFM)

w/

PSU(CFM)

100%

Auto

42.6

44.19

85%

35.3

37.2

75%

31.1

32.4

65%

26.7

27.6

55%

22.3

22.7

45%

18.1

18.2

35%

13.5

14.0

20%

7.5

7.7

4. Thermal Management

The fully integrated system is designed to operate at external ambient temperatures of between 10°C and

35°C. Working with integrated platform management, several features within the system are designed to

move air in a front to back direction, through the system and over critical components to prevent them from

overheating and allow the system to operate with best performance.

Figure 24. System Air Flow and Fan Identification

The following table provides air flow data associated with one of the system models within this 1U product

family, and is provided for reference purposes only. The data was derived from actual wind tunnel test

methods and measurements using fully configured (worst case) system configurations. Lesser system

configurations may produce slightly different data results. In addition, the CFM data was derived using server

management utilities that utilize platform sensor data, and may vary slightly from the data listed in the

tables.

Table 27. System Volumetric Air Flow

29

Page 41

Intel® Server System R1000SPO Product Family TPS

The Intel® Server System R1000SPO product family is thermally designed and developed in compliance with

ASHRAE Class A2 environment guidance; however, there is extra thermal margin for all components in the

system, so ASHRAE Class A3 environment conditions can be thermally supported.

Note: ASHARE Class A3 – Includes operation up to 40°C for up to 900 hours per year. Refer to Appendix E for

detailed HTA guidance.

The installation and functionality of several system components are used to maintain system thermals. They

include three managed 40mm single rotor system fans, fans integrated into each installed power supply

module, an air duct, populated drive carriers, and a CPU heat sink. Drive carriers can be populated with a

storage device (SSD or Hard Disk Drive) or supplied drive blank.

4.1 Thermal Operation and Configuration Requirements

To keep the system operating within supported maximum thermal limits, the system must meet the

following operating and configuration guidelines:

The system is designed for sustained operation on ambient temperature up to 35°C (ASHRAE Class

A2)

All externally accessed drive bays must be populated. Drive carriers can be populated with a storage

device (SSD or HDD) or supplied drive blank

When the system is operating, the air duct must be installed at all times

The system top cover must be installed at all times when the system is in operation in order to have

proper air flow

4.2 Thermal Management Overview

In order to maintain the necessary airflow within the system, all of the previously listed components need to

be properly installed. For best system performance, the external ambient temperature should remain below

35°C and all system fans (all rotors) should be operational.

NOTE: All system fans are controlled independent of each other. The fan control system may adjust fan

speeds for different fans based on increasing/decreasing temperatures in different thermal zones within the

chassis.

In the event that system temperatures should continue to increase with the system fans operating at their

maximum speed, platform management may begin to throttle bandwidth of either the memory subsystem or

the processors or both, in order to keep components from overheating and keep the system operational.

Throttling of these subsystems will continue until system temperatures are reduced below preprogrammed

limits.

The power supply will be protected against over temperature conditions caused by excessive ambient

temperature. In an over-temperature protection condition, the power supply module will shut down.

4.2.1 Fan Speed Control

The baseboard management controller (BMC) supports monitoring and control of fan speed (RPM). Each fan

is associated with a fan speed sensor that detects fan failure.

30

Page 42

Intel® Server System R1000SPO Product Family TPS

The system fans are divided into fan domains, each of which has a separate fan speed control signal and a

separate configurable fan control policy. A fan domain can have a set of temperature and fan sensors

associated with it. These are used to determine the current fan domain state.

A fan domain has three states:

The sleep and boost states have fixed (but configurable through OEM SDRs) fan speeds associated

with them

o The nominal state has a variable speed determined by the fan domain policy. An OEM SDR

record is used to configure the fan domain policy

The fan domain state is controlled by several factors. They are listed below in order of precedence, high to

low:

Boost

- Associated fan is in a critical state or missing. The SDR describes which fan domains are boosted

in response to a fan failure or removal in each domain. If a fan is removed when the system is in

‘Fans-off’ mode it will not be detected and there will not be any fan boost till system comes out of

‘Fans-off; mode.

- Any associated temperature sensor is in a critical state. The SDR describes which temperature

threshold violations cause fan boost for each fan domain.

- The BMC is in firmware update mode, or the operational firmware is corrupted.

- If any of the above conditions apply, the fans are set to a fixed boost state speed.

Nominal

- A fan domain’s nominal fan speed can be configured as static (fixed value) or controlled by the

state of one or more associated temperature sensors.

4.2.2 Programmable Fan PWM Offset

The system provides a BIOS Setup option to boost the system fan speed by a programmable positive offset

or a “Max” setting. Setting the programmable offset causes the BMC to add the offset to the fan speeds to

which it would otherwise be driving the fans. The Max setting causes the BMC to replace the domain

minimum speed with alternate domain minimums that also are programmable through SDRs.

This capability is offered to provide system administrators the option to manually configure fan speeds in

instances where the fan speed optimized for a given platform may not be sufficient when a high end add-in

adapter is configured into the system. This enables easier usage of the fan speed control to support Intel as

well as third party chassis and better support of ambient temperatures higher than 35°C.

4.2.3 Fan Domains

System fan speeds are controlled through pulse width modulation (PWM) signals, which are driven

separately for each domain by integrated PWM hardware. Fan speed is changed by adjusting the duty cycle,

which is the percentage of time the signal is driven high in each pulse.

The BMC controls the average duty cycle of each PWM signal through direct manipulation of the integrated

PWM control registers.

The same device may drive multiple PWM signals.

31

Page 43

Intel® Server System R1000SPO Product Family TPS

4.2.4 Nominal Fan Speed

A fan domain’s nominal fan speed can be configured as static (fixed value) or controlled by the state of one

or more associated temperature sensors.

OEM SDR records are used to configure which temperature sensors are associated with which fan control

domains and the algorithmic relationship between the temperature and fan speed. Multiple OEM SDRs can

reference or control the same fan control domain; and multiple OEM SDRs can reference the same

temperature sensors.

The PWM duty-cycle value for a domain is computed as a percentage using one or more instances of a

stepwise linear algorithm and a clamp algorithm. The transition from one computed nominal fan speed

(PWM value) to another is ramped over time to minimize audible transitions. The ramp rate is configurable by

means of the OEM SDR.

Multiple stepwise linear and clamp controls can be defined for each fan domain and used simultaneously.

For each domain, the BMC uses the maximum of the domain’s stepwise linear control contributions and the

sum of the domain’s clamp control contributions to compute the domain’s PWM value, except that a

stepwise linear instance can be configured to provide the domain maximum.

Hysteresis can be specified to minimize fan speed oscillation and to smooth fan speed transitions. If a

Tcontrol SDR record does not contain a hysteresis definition, for example, an SDR adhering to a legacy

format, the BMC assumes a hysteresis value of zero.

4.2.5 Thermal and Acoustic Management

This feature refers to enhanced fan management to keep the system optimally cooled while reducing the

amount of noise generated by the system fans. Aggressive acoustics standards might require a trade-off

between fan speed and system performance parameters that contribute to the cooling requirements and

primarily memory bandwidth. The BIOS, BMC, and SDRs work together to provide control over how this

trade-off is determined.

This capability requires the BMC to access temperature sensors on the individual memory DIMMs.

Additionally, closed-loop thermal throttling is only supported with buffered DIMMs.

4.2.6 Thermal Sensor Input to Fan Speed Control

The BMC uses various IPMI sensors as input to the fan speed control. Some of the sensors are IPMI models