Page 1

Intel® 4 Series Chipset

Thermal and Mechanical Design Guidelines

September 2008

Document Number: 319972-004

Page 2

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR

IMPLIED, BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT

AS PROVIDED IN INTEL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY

WHATSOEVER, AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL

PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY,

OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS OTHERWISE AGREED IN WRITING BY INTEL, THE INTEL PRODUCTS ARE NOT DESIGNED NOR INTENDED FOR ANY

APPLICATION IN WHICH THE FAILURE OF THE INTEL PRODUCT COULD CREATE A SITUATION WHERE PERSONAL INJURY OR

DEATH MAY OCCUR.

Intel may make changes to specifications and product descriptions at any time, without notice. Designers must not rely on the

absence or characteristics of any features or instructions marked “reserved” or “undefined.” Intel reserves these for future

definition and shall have no responsibility whatsoever for conflicts or incompatibilities aris ing from future changes to them. The

information here is subject to change without notice. Do not finalize a design with th is information.

The products described in this document may contain design defects or errors known as errata which may cause the product to

deviate from published sp ecifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placin g your product order.

This document contains information on products in the design phase of development.

All products, platforms, dates, and figures specified are preliminary based on current expectations, and are subject to change

without notice. All dates specified are target dates, are provided for planning purposes only and are subject to change.

This document contains information on products in the design phase of development. Do not finalize a design with this

information. Revised information will be published when the product is available. Verify with your local sales office that you have

the latest datasheet before finalizing a design.

Code names featured are u sed internally within Intel to identify products that are in development and not yet publicly announced

for release. Customers, licensees and other third parties are not authorized by Intel to use code names in advertising,

promotion or marketing of any product or services and any such use of Intel’s internal code names is at the sole risk of the user.

Intel, Intel, Pentium, Intel Core, and the Intel logo and the Intel logo are trademarks of Intel Corporation in the U.S. and other

countries.

*Other names and brands may be claimed as the property of others.

Copyright © 2008, Intel Corporation. All rights reserved.

Thermal and Mechanical Design Guidelines 2

Page 3

Contents

1 Introduction.....................................................................................................7

1.1 Terminology ..........................................................................................8

1.2 Reference Documents.............................................................................9

2 Product Specifications......................................................................................11

2.1 Package Description..............................................................................11

2.1.1 Non-Grid Array Package Ball Placement......................................11

2.2 Package Loading Specifications...............................................................12

2.3 Thermal Specifications..........................................................................12

2.3.1 Thermal Design Power (TDP) ....................................................13

2.3.1.1 Definition ................................................................13

2.3.2 TDP Prediction Methodology......................................................13

2.3.2.1 Pre-Silicon...............................................................13

2.3.2.2 Post-Silicon..............................................................13

2.3.3 Thermal Specifications.............................................................14

2.3.4 T

2.4 Non-Critical to Function Solder Balls........................................................15

Limit..........................................................................15

CONTROL

3 Thermal Metrology..........................................................................................17

3.1 Case Temperature Measurements...........................................................17

3.1.1 Thermocouple Attach Methodology.............................................17

3.2 Airflow Characterization ........................................................................19

4 Reference Thermal Solution..............................................................................21

4.1 Operating Environment .........................................................................22

4.1.1 ATX Form Factor Operating Environment ....................................23

4.1.2 Balanced Technology Extended (BTX) Form Factor Operating

Environment...........................................................................

4.2 Reference Design Mechanical Envelope....................................................27

4.3 Thermal Solution Assembly....................................................................27

4.4 Environmental Reliability Requirements...................................................29

Appendix A Enabled Suppliers ...........................................................................................31

Appendix B Mechanical Drawings.......................................................................................33

26

3 Thermal and Mechanical Design Guidelines

Page 4

Figures

Figure 1. (G)MCH Non-Grid Array......................................................................11

Figure 2. Package Height .................................................................................12

Figure 3. Non-Critical to Function Solder Balls.....................................................15

Figure 4. 0° Angle Attach Methodology (top view, not to scale)..............................18

Figure 5. 0° Angle Attach Heatsink Modifications (generic heatsink side and

bottom view shown, not to scale).........................................................

Figure 6. Airflow &Temperature Measurement Locations.......................................19

Figure 7. Cross-Cut Dimension Change of PWSHS Reference Design.......................22

Figure 8. ATX Boundary Conditions....................................................................24

Figure 9. Side View of ATX Boundary Conditions..................................................25

Figure 10. Processor Heatsink Orientation to Provide Airflow to (G)MCH

Heatsink on an ATX Platform..............................................................

Figure 11. Processor Heatsink Orientation to Provide Airflow to (G)MCH

Heatsink on a Balanced Technology Extended (BTX) Platform.................

Figure 12. Design Concept for ATX (G)MCH Heatsink — Installed on Board..............28

Figure 13. Design Concept for Balanced Technology Extended (BTX) (G)MCH

Heatsink Design — Installed on Board.................................................

Figure 14. (G)MCH Package Drawing .................................................................34

Figure 15. (G)MCH Component Keep-Out Restrictions for ATX Platforms .................35

Figure 16. (G)MCH Component Keep-Out Restrictions for Balanced Technology

Extended (BTX) Platforms.................................................................

Figure 17. (G)MCH Reference Heatsink for ATX Platforms – Sheet 1.......................37

Figure 18. (G)MCH Reference Heatsink for ATX Platforms – Sheet 2.......................38

Figure 19. (G)MCH Reference Heatsink for ATX Platforms – Anchor ........................39

Figure 20. (G)MCH Reference Heatsink for ATX Platforms – Ramp Retainer Sheet 1..40

Figure 21. (G)MCH Reference Heatsink for ATX Platforms – Ramp Retainer Sheet 2..41

Figure 22. (G)MCH Reference Heatsink for ATX Platforms – Wire Preload Clip ..........42

Figure 23. (G)MCH Reference Heatsink for Balanced Technology Extended

(BTX) Platforms ...............................................................................

Figure 24. (G)MCH Chipsets Reference Heatsink for Balanced Technology

Extended (BTX) Platforms – Clip.........................................................

18

25

27

28

36

43

44

Tables

Table 1. Package Loading Specifications.............................................................12

Table 2. Thermal Specifications.........................................................................14

Table 3. (G)MCH Heatsink Boundary Condition Summary in ATX Platforms..............23

Table 4. (G)MCH Heatsink Boundary Condition Summary in BTX Platforms..............26

Table 5. ATX Reference Thermal Solution Environmental Reliability Requirements

(Board Level) .....................................................................................

Table 6. Balanced Technology Extended (BTX) Reference Thermal Solution

Environmental Reliability Requirements (System Level)............................

Table 7. ATX Intel Reference Heatsink Enabled Suppliers for (G)MCH .....................31

Table 8. BTX Intel Reference Heatsink Enabled Suppliers for (G)MCH .....................31

Table 9. Supplier Contact Information................................................................32

Thermal and Mechanical Design Guidelines 4

29

30

Page 5

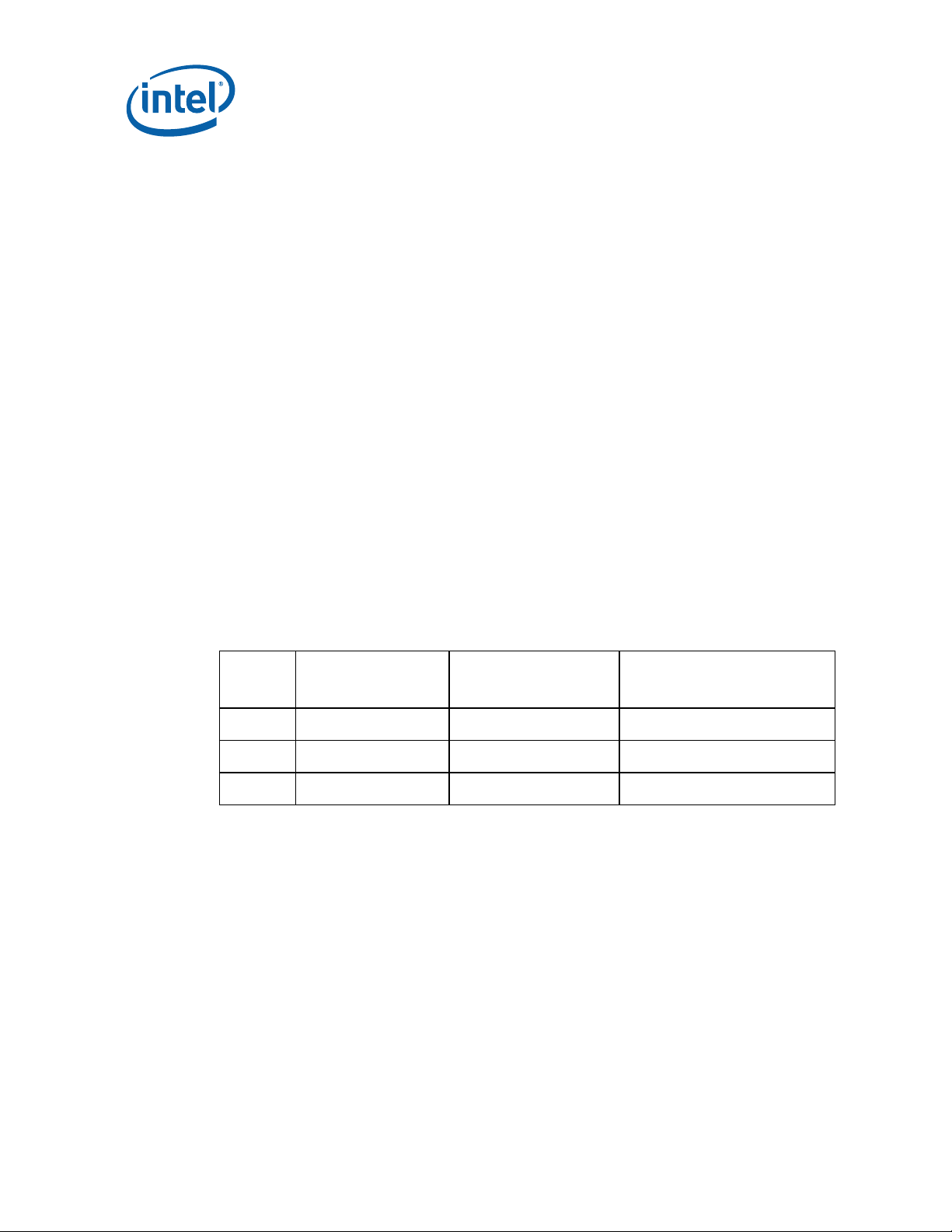

Revision History

Revision

Number

-001 Initial Release June 2008

-002 Minor edits and formatting throughout. June 2008

-003 Added Intel 82G41 GMCH September 2008

-004 Added Intel 82Q43 GMCH and 82Q45 GMCH September 2008

Description Date

§

5 Thermal and Mechanical Design Guidelines

Page 6

Thermal and Mechanical Design Guidelines 6

Page 7

Introduction

1 Introduction

As the complexity of computer systems increases, so do power dissipation

requirements. The additional power of next generation systems must be properly

dissipated. Heat can be dissipated using improved system cooling, selective use of

ducting, and/or passive heatsinks.

The objective of thermal management is to ensure that the temperatures of all

components in a system are maintained within functional limits. The functional

temperature limit is the range within which the electrical circuits can be expected to

meet specified performance requirements. Operation outside the functional limit can

degrade system performance, cause logic errors, or cause component and/or system

damage. Temperatures exceeding the maximum operating limits may result in

irreversible changes in the operating characteristics of the component.

This document is for the following devices:

®

• Intel

• Intel

• Intel

• Intel

P45 Chipset MCH (82P45 MCH)

®

P43 Chipset MCH (82P43 MCH)

®

G45 Chipset GMCH (82G45 GMCH)

®

G43 Chipset GMCH (82G43 GMCH)

• Intel® G41 Chipset GMCH (82G41 GMCH)

• Intel® Q45 Chipset GMCH (82Q45 GMCH)

• Intel® Q43 Chipset GMCH (82Q43 GMCH)

This document presents the conditions and requirements to properly design a cooling

solution for systems that implement the (G)MCH. Properly designed solutions provide

adequate cooling to maintain the (G)MCH case temperature at or below thermal

specifications. This is accomplished by providing a low local-ambient temperature,

ensuring adequate local airflow, and minimizing the case to local-ambient thermal

resistance. By maintaining the (G)MCH case temperature at or below those

recommended in this document, a system designer can ensure the proper

functionality, performance, and reliability of this component.

Note: Unless otherwise specified the information in this document applies to all

configurations of Intel

®

P45, P43, Q45, Q43, G45, G43, and G41 Chipsets. The Intel®

Q45, Q43, G45, G43, and G41 Chipsets are available with integrated graphics and

associated SDVO and digital display ports. In this document the integrated graphics

version is referred to as GMCH. In addition a version will be offered using discrete

graphics and is referred to as the MCH. The term (G)MCH will be used to when

referring to all configurations.

Note: In this document the Intel P45, P43, Q45, Q43, G45, and G43 Chipsets refer to the

combination of the (G)MCH and the Intel

®

ICH10. For ICH10 thermal details, refer to

the Intel® I/O Controller Hub 10 (ICH10) Thermal Design Guidelines. The Intel G41

Chipset refers to the combination of the GMCH and Intel ICH7. For ICH7 details, refer

to the Intel® I/O Controller Hub 7 (ICH7) Thermal Design Guidelines.

7 Thermal and Mechanical Design Guidelines

Page 8

1.1 Terminology

Term Description

FC-BGA Flip Chip Ball Grid Array. A package type defined by a plastic substrate where a

die is mounted using an underfill C4 (Controlled Collapse Chip Connection)

attach style. The primary electrical interface is an array of solder balls attached

to the substrate opposite the die. Note that the device arrives at the customer

with solder balls attached.

Intel® ICH7 Intel® I/O Controller Hub 7. The chipset component that contains the primary

PCI interface, LPC interface, USB2, SATA, and/or other legacy functions.

Intel® ICH10 Intel® I/O Controller Hub 10. The chipset component that contains the primary

PCI interface, LPC interface, HDA interface, USB2, SATA, and/or other legacy

functions.

GMCH Graphic Memory Controller Hub. The chipset component that contains the

processor and memory interface and integrated graphics core.

TA The local ambient air temperature at the component of interest. The ambient

temperature should be measured just upstream of airflow for a passive

heatsink or at the fan inlet for an active heatsink.

Introduction

TC The case temperature of the (G)MCH component. The measurement is made at

the geometric center of the die.

T

The maximum value of T

C-MAX

T

The minimum valued of T

C-MIN

TDP Thermal Design Power is specified as the maximum sustainable power to be

dissipated by the (G)MCH. This is based on extrapolations in both hardware and

software technology. Thermal solutions should be designed to TDP.

TIM Thermal Interface Material: thermally conductive material installed between two

surfaces to improve heat transfer and reduce interface contact resistance.

Ψ

Case-to-ambient thermal solution characterization parameter (Psi). A measure

CA

of thermal solution performance using total package power. Defined as (T

) / Total Package Power. Heat source size should always be specified for Ψ

T

A

measurements.

.

C

.

C

–

C

Thermal and Mechanical Design Guidelines 8

Page 9

Introduction

1.2 Reference Documents

Document Location

Intel® 4 Series Chipset Family Datasheet http://www.intel.com/assets/p

Intel® I/O Controller Hub 7 (ICH7) Thermal Design Guidelines http://www.intel.com/assets/p

Intel® I/O Controller Hub 10 (ICH10) Thermal Design Guidelines http://www.intel.com/assets/p

df/datasheet/319970.pdf

df/designguide/307015.pdf

df/designguide/319975.pdf

Intel® Core™2 Duo Processor E8000Δ and E7000Δ Series and Intel®

Pentium

Mechanical Design Guidelines

Intel® Core™2 Extreme Quad-Core Processor and Intel® Core™2

Quad Processor Thermal and Mechanical Design Guidelines

Balanced Technology Extended (BTX) Interface Specification http://www.formfactors.org

Various System Thermal and Mechanical Design Suggestions http://www.formfactors.org

Various Chassis Thermal and Mechanical Design Suggestions http://www.formfactors.org

®

Dual-Core Processor E5000Δ Series Thermal and

http://www.intel.comdesign/pro

cessor/designex/318734.pdf

http://www.intel.com/

design/processor/designex/

315594.htm

§

9 Thermal and Mechanical Design Guidelines

Page 10

Introduction

Thermal and Mechanical Design Guidelines 10

Page 11

Product Specifications

2 Product Specifications

2.1 Package Description

The (G)MCH is available in a 34 mm [1.34 in] x 34 mm [1.34 in] Flip Chip Ball Grid

Array (FC-BGA) package with 1254 solder balls. The die size is currently 10.80 mm

[0.425 in] x 9.06 mm [0.357 in] and is subject to change. A mechanical drawing of

the package is shown in

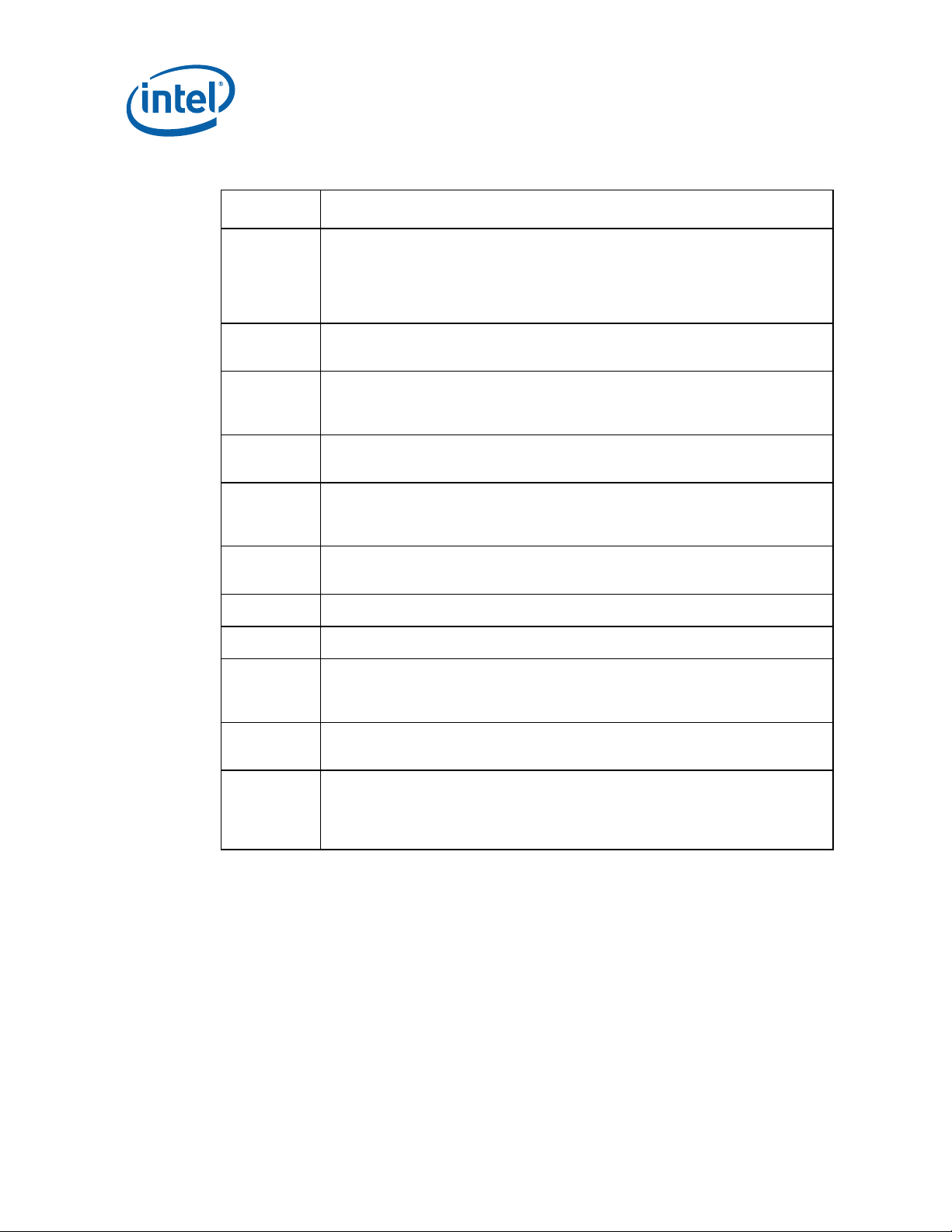

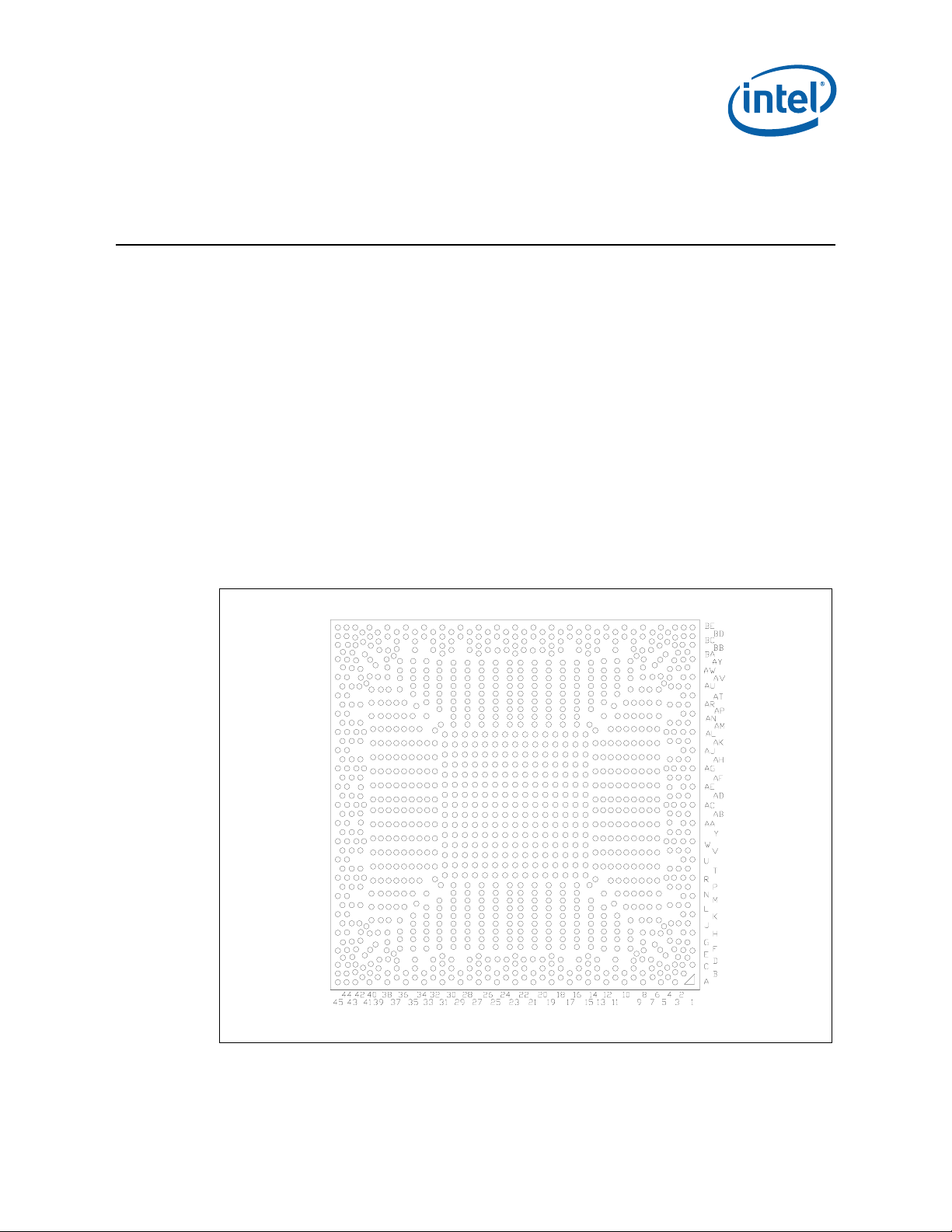

2.1.1 Non-Grid Array Package Ball Placement

The (G)MCH package utilizes a “balls anywhere” concept. Minimum ball pitch is

0.7 mm [0.028 in], but ball ordering does not follow a 0.7 mm grid. Board designers

should ensure correct ball placement when designing for the non-grid array pattern.

For exact ball locations relative to the package, refer to the Intel

Family Datasheet.

Figure 1. (G)MCH Non-Grid Array

Figure 14, Appendix B.

®

4 Series Chipset

34 x 34mm Substrate [1.34 x 1.34 in]

Non-standard grid ball pattern. Minimum Pitch 0.7mm [0.028 in]

11 Thermal and Mechanical Design Guidelines

Page 12

2.2 Package Loading Specifications

Table 1 provides static load specifications for the package. This mechanical maximum

load limit should not be exceeded during heatsink assembly, shipping conditions, or

standard use conditions. Also, any mechanical system or component testing should

not exceed the maximum limit. The package substrate should not be used as a

mechanical reference or load-bearing surface for the thermal and mechanical solution.

Table 1. Package Loading Specifications

Parameter Maximum Notes

Static

NOTES:

1. These specifications apply to uniform compressive loading in a direction normal to the

package.

2. This is the maximum force that can be applied by a heatsink retention clip. The clip

must also provide the minimum specified load on the package.

3. These specifications are based on limited testing for design characterization. Lo ading

limits are for the package only.

To ensure the package static load limit is not exceeded, the designer should

understand the post reflow package height. The following figure shows the nominal

post-reflow package height assumed for calculation of a heatsink clip preload of the

reference design. Refer to the package drawing in

analysis.

15 lbf

1,2,3

Appendix B to perform a detailed

Product Specifications

Figure 2. Package Height

2.3 Thermal Specifications

To ensure proper operation and reliability of the (G)MCH, the case temperature must

be at or below the maximum value specified in

thermal enhancements are required to dissipate the heat generated and maintain the

(G)MCH within specifications. Chapter 3 provides the thermal metrology guidelines for

case temperature measurements.

Table 2. System and component level

Thermal and Mechanical Design Guidelines 12

Page 13

Product Specifications

2.3.1 Thermal Design Power (TDP)

2.3.1.1 Definition

Thermal design power (TDP) is the estimated power dissipation of the (G)MCH based

on normal operating conditions including V

case power intensive applications. This value is based on expected worst-case data

traffic patterns and usage of the chipset and does not represent a specific software

application. TDP attempts to account for expected increases in power due to variation

in (G)MCH current consumption due to silicon process variation, processor speed,

DRAM capacitive bus loading and temperature. However, since these variations are

subject to change, there is no assurance that all applications will not exceed the TDP

value.

The system designer must design a thermal solution for the (G)MCH such that it

maintains T

specification is a requirement for a sustained power level equal to TDP, and that

T

C-MAX

below T

C

the case temperature must be maintained at temperatures less than T

operating at power levels less than TDP. This temperature compliance is to ensure

component reliability. The TDP value can be used for thermal design if the thermal

protection mechanisms are enabled. The (G)MCH incorporate a hardware-based failsafe mechanism to keep the product temperature in spec in the event of unusually

strenuous usage above the TDP power.

for a sustained power level equal to TDP. Note that the

C-MAX

and T

CC

while executing real worst-

C-MAX

C-MAX

when

2.3.2 TDP Prediction Methodology

2.3.2.1 Pre-Silicon

To determine TDP for pre-silicon products in development, it is necessary to make

estimates based on analytical models. These models rely on knowledge of the past

(G)MCH power dissipation behavior along with knowledge of planned architectural and

process changes that may affect TDP. Knowledge of applications available today and

their ability to stress various aspects of the (G)MCH is also included in the model. The

projection for TDP assumes (G)MCH operation at T

accounts for normal manufacturing process variation.

2.3.2.2 Post-Silicon

Once the product silicon is available, post-silicon validation is performed to assess the

validity of pre-silicon projections. Testing is performed on both commercially available

and synthetic high power applications and power data is compared to pre-silicon

estimates. Post-silicon validation may result in a small adjustment to pre-silicon TDP

estimates.

. The TDP estimate also

C-MAX

13 Thermal and Mechanical Design Guidelines

Page 14

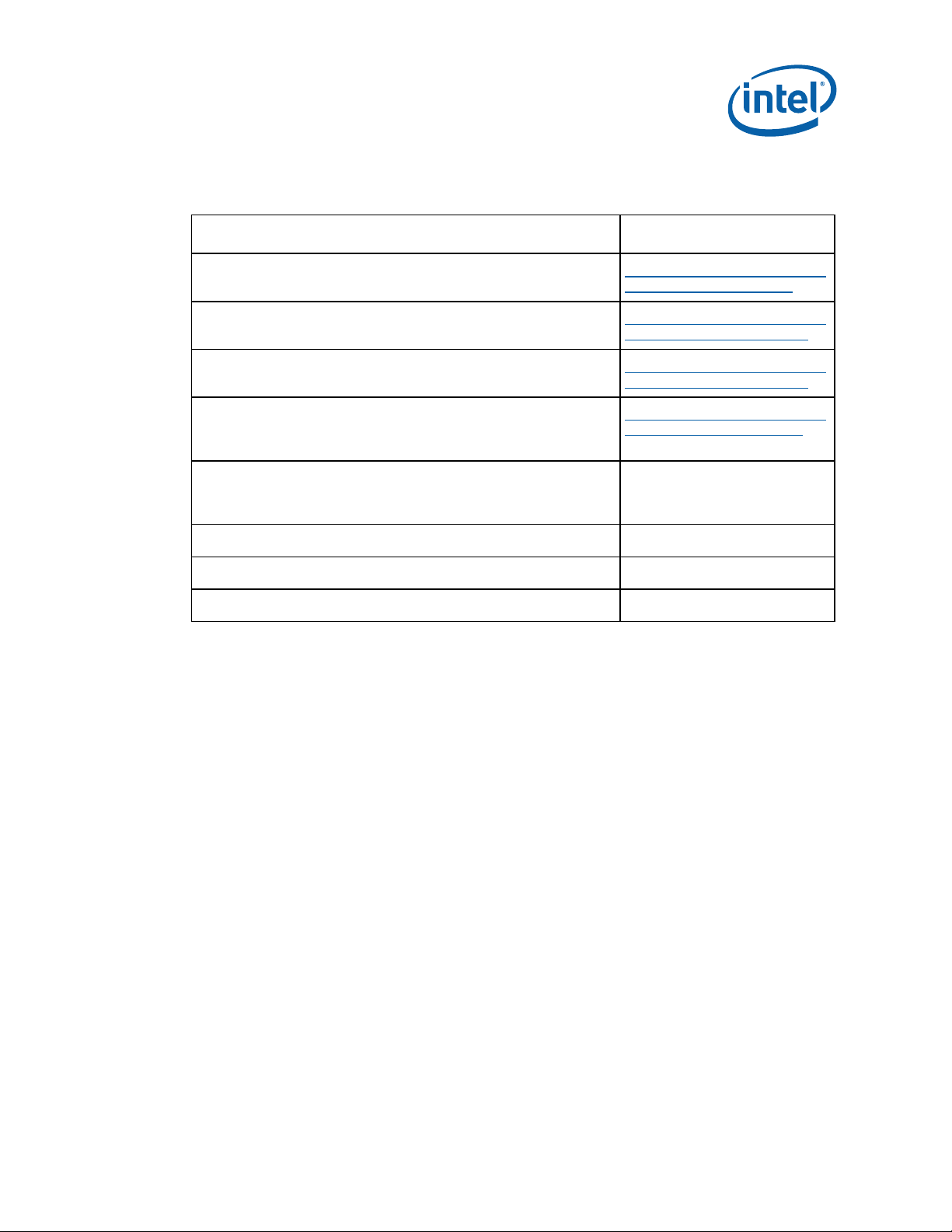

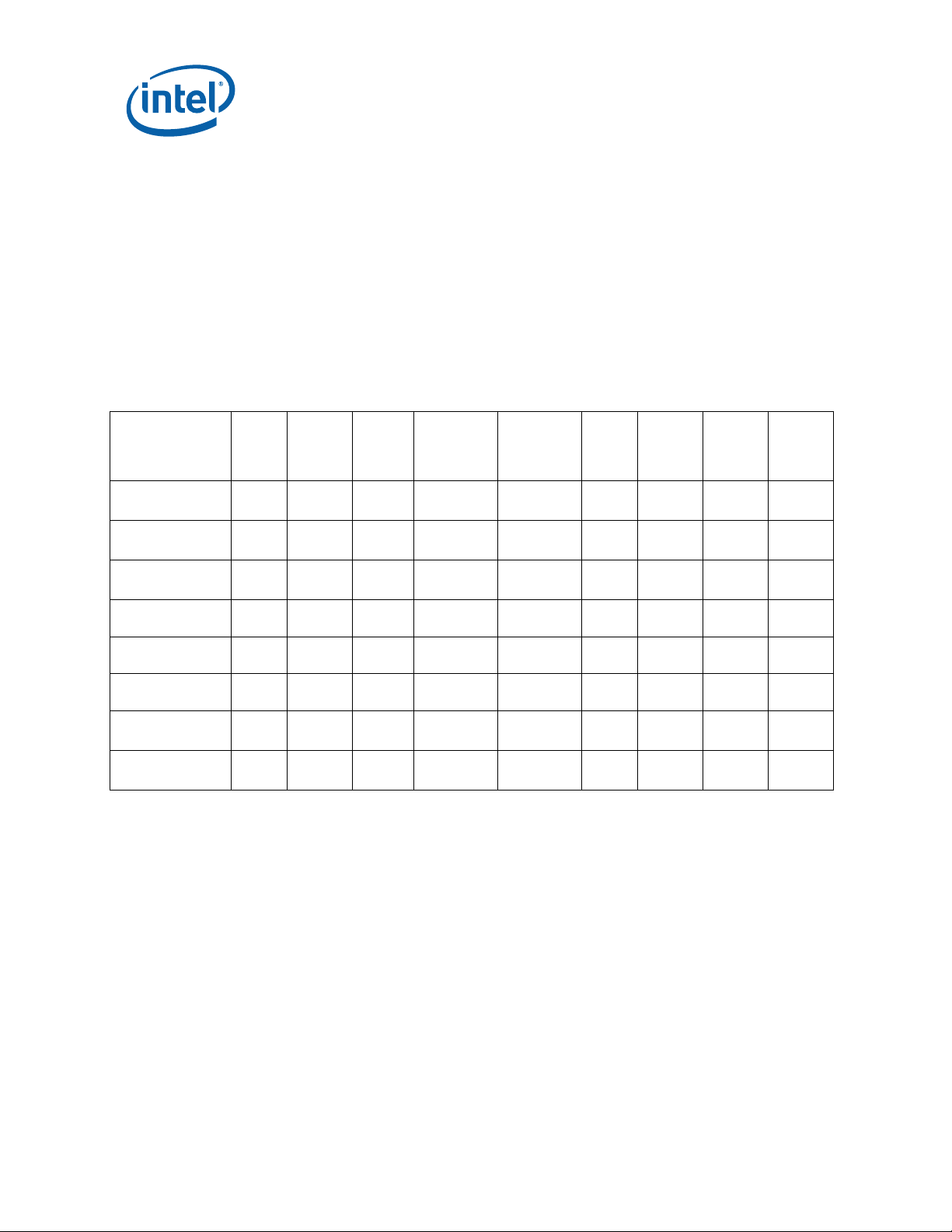

2.3.3 Thermal Specifications

The data in Table 2 is based on post-silicon power measurements for the (G)MCH. The

TDP values are based on system configuration with two (2) DIMMs per channel, DDR3

(or DDR2) and the FSB operating at the top speed allowed by the chipset with a

processor operating at that system bus speed. Intel recommends designing the

(G)MCH thermal solution to the highest system bus speed and memory frequency for

maximum flexibility and reuse. The (G)MCH packages have poor heat transfer

capability into the board and have minimal thermal capability without thermal

solutions. Intel requires that system designers plan for an attached heatsink when

using the (G)MCH.

Table 2. Thermal Specifications

Product Specifications

Component Mem

Intel® G45

Type

DDR3 1333

Chipset

Intel® G43

DDR3 1333

Chipset

Intel® G41

DDR3 1333

Chipset

Intel® Q45 /

DDR3 1333

Q43 Chipset

Intel® Q45 /

DDR2 1333

Q43 Chipset

Intel® Q43

DDR3 1333

Chipset

Intel® P45

DDR3 1333

Chipset

Intel® P43

DDR3 1333

Chipset

NOTES:

1. Thermal specifications assume an attached heatsink is present.

2. Max Idle power is the worst case idle power in the system booted to Windows* with no

3. Intel

4. When an external graphic card is installed in a system with the Intel

5. The Idle and TDP numbers are assuming Internal Graphics is disabled on the Intel Q43

6. Idle data is measured on Intel P45, P43 Chipset when an external graphics card is

Sys

Bus

Speed

MT/s

MT/s

MT/s

MT/s

MT/s

MT/s

MT/s

MT/s

background applications running.

®

P45, P43, G45, G43, Q45, and Q43 Chipset TDP is measured with DDR3 (or

DDR2) with 2 channels, 2 DIMMs per channel and Max Idle power is measured with

DDR3 (or DDR2) with 2 channels, 1 DIMM per channel. Intel

Idle power are measured with DDR3 with 2 channels, 1 DIMM per channel.

Mem

Freq

1333

MT/s

1067

MT/s

1067

MT/s

1067

MT/s

800

MT/s

1067

MT/s

1333

MT/s

1067

MT/s

Max Idle

Power

(C1/C2

Enabled)

Max Idle

Power

(C3/C4

Enabled)

TDP T

C-MIN

T

C-MAX

Notes

9 W 7.7 W 24 W 0 °C 103°C 1,2,3,4

9 W 7.7 W 24 W 0 °C 103 °C 1,2,3,4

11.5 W N/A 25 W 0 °C 102 °C 1,2,3

6W 4.7 W 17 W 0 °C 105 °C 1,2,3

6W 4.7 W 17 W 0 °C 105 °C 1,2,3

5W 3.8 W 13 W 0 °C 105 °C 1,2,3,5

9 W 7.5 W 22 W 0 °C 103 °C 1,2,3,6

9 W 7.5 W 22 W 0 °C 103 °C 1,2,3,6

®

G41 Chipset TDP and Max

®

G45, G43

Chipsets, the TDP for these parts will drop to approximately 22 W. The GMCH will

detect the presence of the graphics card and disable the on-board graphics resulting in

the lower TDP for these components.

Chipset.

installed in a system wherein this card must support L0s /L1 ASPM.

Thermal and Mechanical Design Guidelines 14

Page 15

Product Specifications

2.3.4 T

CONTROL

Limit

Intel® Quiet System Technology (Intel® QST) can monitor an embedded thermal

sensor. The maximum operating limit when monitoring this thermal sensor is T

For the (G)MCH this value is 99° C. This value should be programmed into the

appropriate register of Intel

®

QST, as the maximum sensor temperature for operation

of the (G)MCH.

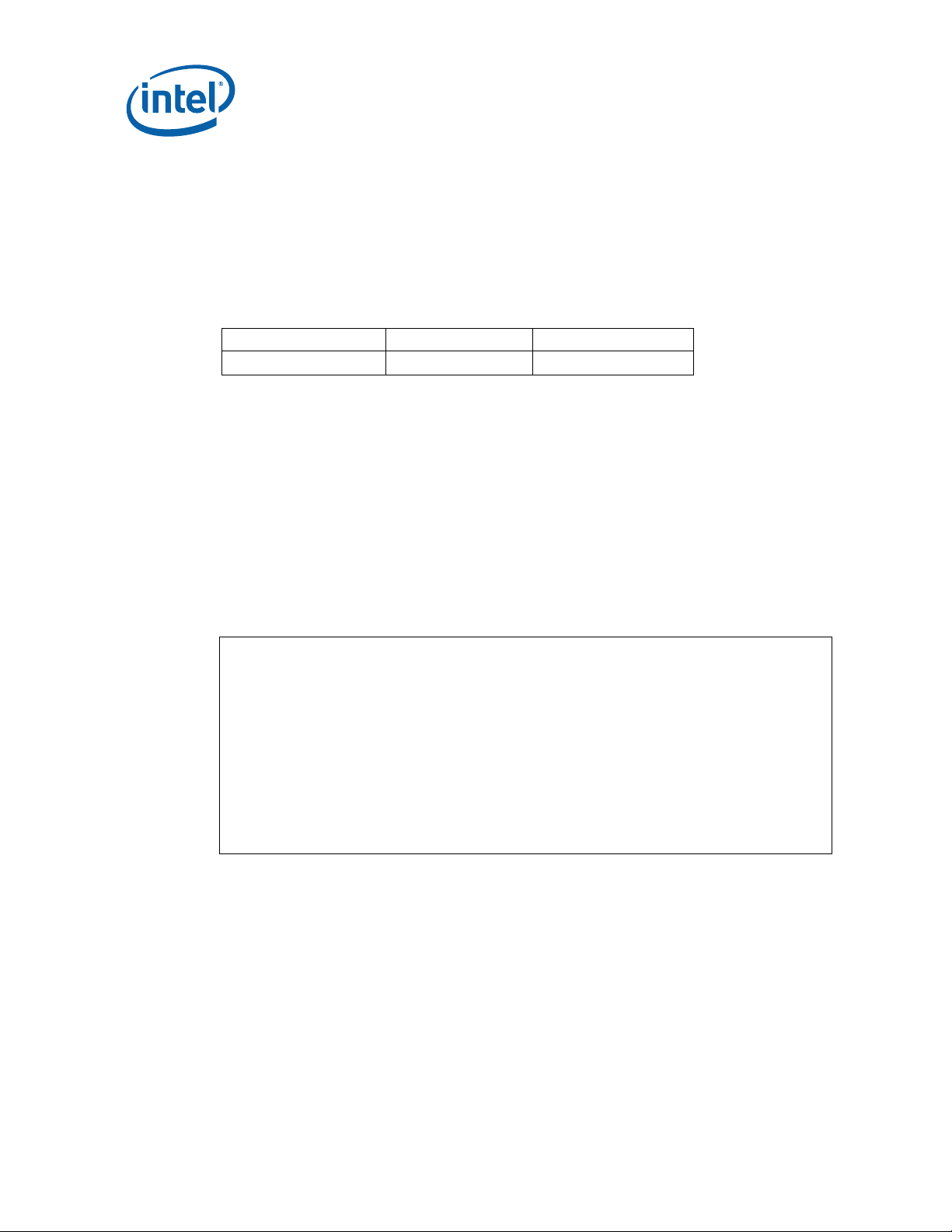

2.4 Non-Critical to Function Solder Balls

Intel has defined selected solder joints of the (G)MCH as non-critical to function

(NCTF) when evaluating package solder joints post environmental testing. The

(G)MCH signals at NCTF locations are typically redundant ground or non-critical

reserved, so the loss of the solder joint continuity at end of life conditions will not

affect the overall product functionality.

the (G)MCH package.

Figure 3. Non-Critical to Function Solder Balls

Figure 3 identifies the NCTF solder joints of

CONTROL

.

§

15 Thermal and Mechanical Design Guidelines

Page 16

Product Specifications

Thermal and Mechanical Design Guidelines 16

Page 17

Thermal Metrology

3 Thermal Metrology

The system designer must measure temperatures in order to accurately determine the

thermal performance of the system. Intel has established guidelines for proper

techniques of measuring (G)MCH component case temperatures.

3.1 Case Temperature Measurements

To ensure functionality and reliability of the (G)MCH the TC must be maintained at or

below the maximum temperature listed in

at the geometric center of the die corresponds to T

care to ensure an accurate temperature reading.

Temperature differences between the temperature of a surface and the surrounding

local ambient air can introduce error in the measurements. The measurement errors

could be due to a poor thermal contact between the thermocouple bead and the

surface of the package, heat loss by radiation and/or convection, conduction through

thermocouple leads, or contact between the thermocouple cement and the heatsink

base (if a heatsink is used). To minimize these measurement errors a thermocouple

attach with a zero-degree methodology is recommended.

Table 2. The surface temperature measured

. Measuring TC requires special

C

3.1.1 Thermocouple Attach Methodology

1. Mill a 3.3 mm [0.13 in] diameter hole centered on bottom of the heatsink base.

The milled hole should be approximately 1.5 mm [0.06 in] deep.

2. Mill a 1.3 mm [0.05 in] wide slot, 0.5 mm [0.02 in] deep, from the centered hole

to one edge of the heatsink. The slot should be in the direction parallel to the

heatsink fins (see

3. Attach thermal interface material (TIM) to the bottom of the heatsink base.

4. Cut out portions of the TIM to make room for the thermocouple wire and bead.

The cutouts should match the slot and hole milled into the heatsink base.

5. Attach a 36 gauge or smaller K-type thermocouple bead to the center of the top

surface of the die using a cement with high thermal conductivity. During this step,

make sure no contact is present between the thermocouple cement and the

heatsink base because any contact will affect the thermocouple reading. It is

critical that the thermocouple bead makes contact with the die

Figure 4).

(see

6. Attach heatsink assembly to the (G)MCH, and route thermocouple wires out

through the milled slot.

Figure 5).

17 Thermal and Mechanical Design Guidelines

Page 18

Thermal Metrology

Figure 4. 0° Angle Attach Methodology (top view, not to scale)

Figure 5. 0° Angle Attach Heatsink Modifications (generic heatsink side and bottom

view shown, not to scale)

Thermal and Mechanical Design Guidelines 18

Page 19

Thermal Metrology

3.2 Airflow Characterization

Figure 6 describes the recommended location for air temperature measurements

measured relative to the component. For a more accurate measurement of the

average approach air temperature, Intel recommends averaging temperatures

recorded from two thermocouples spaced about 25 mm [1.0 in] apart. Locations for

both a single thermocouple and a pair of thermocouples are presented.

Figure 6. Airflow &Temperature Measurement Locations

Airflow velocity can be measured using sensors that combine air velocity and

temperature measurements. Typical airflow sensor technology may include hot wire

anemometers.

Figure 6 provides guidance for airflow velocity measurement locations

which should be the same as used for temperature measurement. These locations are

for a typical JEDEC test setup and may not be compatible with chassis layouts due to

the proximity of the processor to the (G)MCH. The user may have to adjust the

locations for a specific chassis. Be aware that sensors may need to be aligned

perpendicular to the airflow velocity vector or an inaccurate measurement may result.

Measurements should be taken with the chassis fully sealed in its operational

configuration to achieve a representative airflow profile within the chassis.

§

19 Thermal and Mechanical Design Guidelines

Page 20

Thermal Metrology

Thermal and Mechanical Design Guidelines 20

Page 21

Reference Thermal Solution

4 Reference Thermal Solution

The design strategy for the reference thermal solution for the (G)MCH for use in ATX

platforms reuses the Intel

Wave Solder Heatsink (PWSHS), see

®

3 Series Chipsets reference thermal solution, Preload

Figure 18 and Figure 19. The ramp retainer, MB

anchors and the thermal interface material remains the same to meet the (G)MCH

thermal/mechanical requirements. The keep out zone remains the same as used with

the Intel 3 Series Chipsets, see

Figure 15.

The (G)MCH maximum TDP has been updated in Table 2. The TDP reduction may

allow system designers to lower thermal solution cost for McCreary and Boulder Creek

platforms. The reference design for the (G)MCH is a PWSHS which provides adequate

solder joint protection but may exceed thermal performance requirements in most

systems. Customers may save costs by reducing the heatsink size to meet the

lowered TDP.

The PWSHS reference design has the cross-cut dimension change from 3.75 mm to

3.90 mm (see

design (Intel

Note: The nominal height of (G)MCH package (see

Figure 7) to prevent the gapping issue for cross-products heatsink

®

3 Series Chipsets and Intel® 4 Series Chipsets).

Figure 2) is 0.25 mm lower compared to

Intel® 3 Series Chipsets package. Customers should analyze this gapping issue

resulting of thinner Intel® 4 Series Chipsets package (nominal height of 2.13 mm)

compared to Intel® 3 Series Chipsets package (nominal height of 2.38 mm) prior to

design.

Note: The PWSHS reference design retention requires zero gap (between anchor wire clip

and ramp retainer) to ensure effective top-side stiffening for solder joint protection.

This cross-cut dimension change design allows to be used on Intel

®

3 Series Chipsets

without assembly issue.

21 Thermal and Mechanical Design Guidelines

Page 22

Reference Thermal Solution

Figure 7. Cross-Cut Dimension Change of PWSHS Reference Design

The BTX reference design for the (G)MCH will reuse the Z-clip heatsink and MB

anchors from the Intel

®

3 Series Chipsets thermal solution. The thermal interface

material and extrusion design requirements are being evaluated for changes

necessary to meet the (G)MCH thermal requirements. The keep out zone remains the

same as used with the Intel

®

3 Series Chipsets, see Figure 16.

This chapter provides detailed information on operating environment assumptions,

heatsink manufacturing, and mechanical reliability requirements for the (G)MCH.

4.1 Operating Environment

The operating environment of the (G)MCH will differ depending on system

configuration and motherboard layout. This section defines operating environment

boundary conditions that are typical for ATX and BTX form factors. The system

designer should perform analysis in the expected platform operating environment to

assess impact on thermal solution selection.

Thermal and Mechanical Design Guidelines 22

Page 23

Reference Thermal Solution

4.1.1 ATX Form Factor Operating Environment

The (G)MCH reference design thermal solution has been optimized to meet all three

boundary conditions for 65W/95W/130W processor TDPs. The highest processor TDP

provide a boundary condition for the (G)MCH heatsink with higher air inlet speed and

temperature (T

temperature. The (G)MCH heatsink design is required to meet all of these boundary

conditions as specified in

Table 3. (G)MCH Heatsink Boundary Condition Summary in ATX Platforms

) while the lowest processor TDP provides lower air inlet speed and

A

Table 3.

Processor TDP

(TDP)

65 W 245

95 W 292

130 W 341

Airflow Speed

(LFM)

Air Inlet Temperature

)

(T

A,

47.2 °C

50.0 °C

51.6 °C

In ATX platforms using the 130 W TDP processor, an airflow speed of 1.73 m/s

[341 lfm] is assumed to be approaching the heatsink at a 30° angle from the

processor thermal solution, see

ambient air temperature, T

Figure 8 and Figure 9 for more details. The local

, at the (G)MCH heatsink in an ATX platform is assumed to

A

be 51.6 °C for the (G)MCH. The airflow assumed above can be achieved by using a

processor heatsink providing omni directional airflow, such as a radial fin or “X”

pattern heatsink. Such a heatsink can deliver airflow to both the (G)MCH and other

areas like the voltage regulator, as shown in

Figure 10. In addition, (G)MCH board

placement should ensure that the (G)MCH heatsink is within the air exhaust area of

the processor heatsink.

Note that heatsink orientation alone does not guarantee that airflow speed

will be achieved. The system integrator should use analytical or experimental means

to determine whether a system design provides adequate airflow speed for a

particular (G)MCH heatsink.

The thermal designer must carefully select the location to measure airflow to get a

representative sampling. ATX platforms need to be designed for the worst-case

thermal environment, typically assumed to be 35 °C ambient temperature external to

the system measured at sea level.

23 Thermal and Mechanical Design Guidelines

Page 24

Figure 8. ATX Boundary Conditions

Reference Thermal Solution

Thermal and Mechanical Design Guidelines 24

Page 25

Reference Thermal Solution

Figure 9. Side View of ATX Boundary Conditions

Figure 10. Processor Heatsink Orientation to Provide Airflow to (G)MCH Heatsink on an

ATX Platform

Airflow Direction

GMCH Heatsink

GMCH Heatsink

Airflow Direction

Airflow Direction

TOP VIEW

TOP VIEW

Airflow Direction

Airflow Directi on

Airflow Directi on

Omni Directional Flow

Omni Directional Flow

Processor Heatsink

Processor Heatsink

(Fan not Shown)

(Fan not Shown)

Airflow Direction

Airflow Direction

Other methods exist for providing airflow to the (G)MCH heatsink, including the use of

system fans and/or ducting, or the use of an attached fan (active heatsink).

25 Thermal and Mechanical Design Guidelines

Page 26

Reference Thermal Solution

4.1.2 Balanced Technology Extended (BTX) Form Factor Operating Environment

This section provides operating environment conditions based on what has been

exhibited on the Intel BTX Entertainment PC reference design, refer to the Balanced

Technology Extended (BTX) Entertainment PC Case Study for detail system study. On

a BTX platform, the (G)MCH obtains in-line airflow directly from the processor thermal

module. Since the processor thermal module provides lower inlet temperature airflow

to the processor, reduced inlet ambient temperatures are also often seen at the

(G)MCH as compared to ATX. An example of how airflow is delivered to the (G)MCH

on a BTX platform is shown in

A set of three system level boundary conditions will be established to determine

(G)MCH thermal solution requirement.

• Low external ambient (23 °C)/ idle power for the components (Case 3). This

covers the system idle acoustic condition

• Low external ambient (23 °C)/ TDP for the components (Case 2). The TMA fan

speed is limited by the thermistor in the fan hub.

• High ambient (35 °C)/ TDP for the components (Case 1). This covers the

maximum TMA fan speed condition.

Figure 11.

The values in

Table 4 correspond to the ePC configuration. For more details on the

TMA airflow set points, refer to the Balanced Technology Extended (BTX) System

Design Guide.

Table 4. (G)MCH Heatsink Boundary Condition Summary in BTX Platforms

Case Processor TDP

Case 1

Case 2

Case 3

(TDP)

65W 43.0 194

65W 38.2 117

65W 34.7 29.5

TA into MCH heatsink

(°C)

Airflow into the (G)MCH

heatsink

(LFM)

Note: The customer should analyze their system design to verify their applicable boundary

conditions prior to design. The thermal designer must carefully select the location to

measure airflow to get a representative sampling. BTX platforms need to be designed

for the worst-case thermal environment, typically assumed to be 35 °C ambient

temperature external to the system measured at sea level.

Note: The risk of the solder ball fracture can be minimized with good chassis structure

design on a BTX platform, refer to the Balanced Technology Extended (BTX) Chassis

Design Guide (or Balanced Technology Extended (BTX) System Design Guide) for

detail chassis mechanical design.

Thermal and Mechanical Design Guidelines 26

Page 27

Reference Thermal Solution

Figure 11. Processor Heatsink Orientation to Provide Airflow to (G)MCH Heatsink on a

Balanced Technology Extended (BTX) Platform

BTX Thermal

Airflow Direction

GMCH

Top View

Module Assembly

over processor

4.2 Reference Design Mechanical Envelope

The motherboard component keep-out restrictions for the (G)MCH on an ATX platform

are included in

restrictions for the (G)MCH on a BTX platform are included in Appendix B, Figure 16.

Appendix B, Figure 15. The motherboard component keep-out

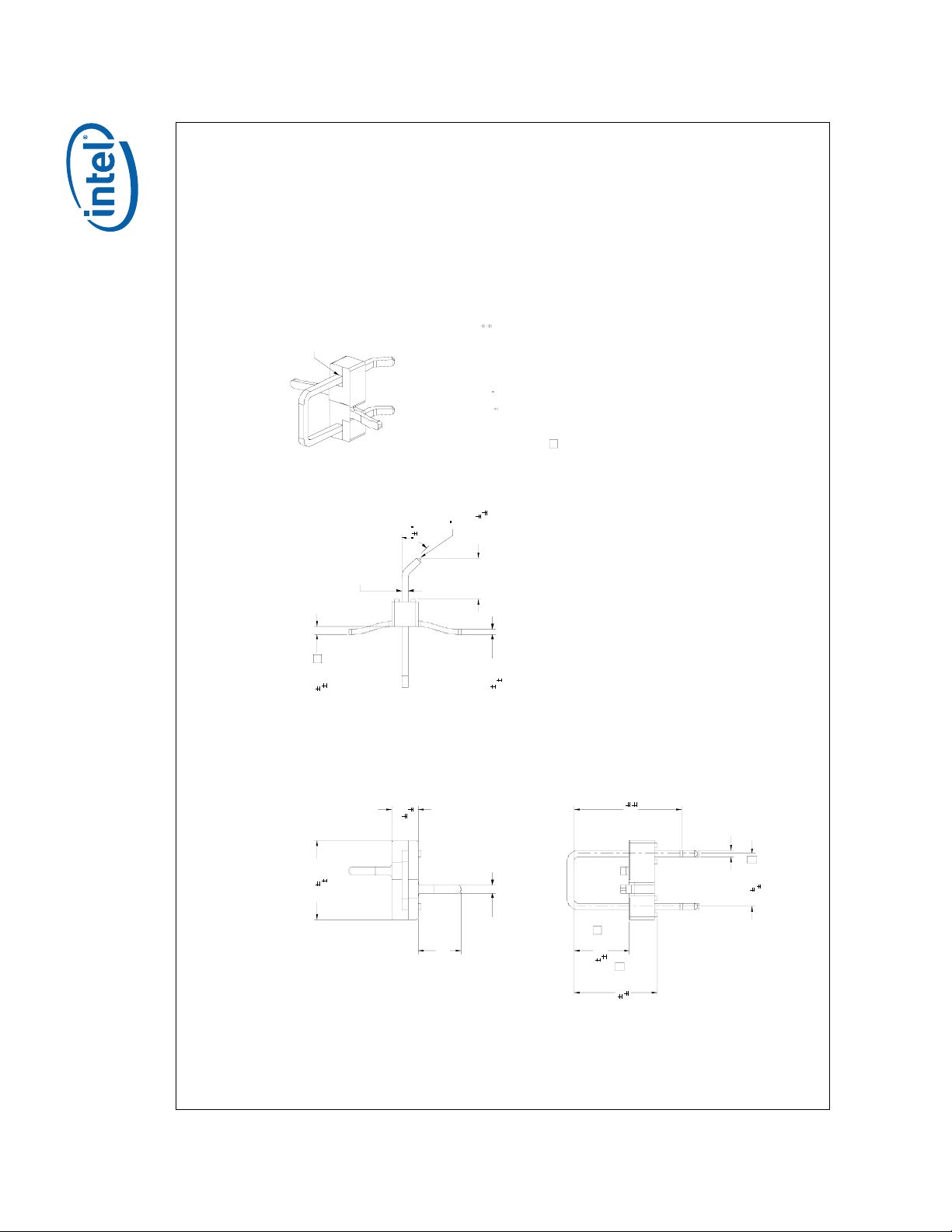

4.3 Thermal Solution Assembly

The reference thermal solution for the (G)MCH for an ATX chassis is shown in

Figure 12 and is an aluminum extruded heatsink that uses two ramp retainers, a wire

preload clip, and four motherboard anchors. Refer to

drawings. The heatsink is attached to the motherboard by assembling the anchors into

the board, placing the heatsink, with the wire preload clip over the (G)MCH and

anchors at each of the corners, and securing the plastic ramp retainers through the

anchor loops before snapping each retainer into the fin gap. Leave the wire preload

clip loose in the extrusion during the wave solder process. The assembly is then sent

through the wave process. Post wave, the wire preload clip is snapped into place on

the hooks located on each of the ramp retainers. The clip provides the mechanical

preload to the package. This mechanical preload is necessary to provide both

sufficient pressure to minimize thermal contact resistance and improvement for solder

ball joint reliability. The mechanical stiffness and orientation of the extruded heat sink

also provides protection to reduce solder ball reliability risk. A thermal interface

material (Honeywell PCM45F) is pre-applied to the heatsink bottom over an area

which contacts the package die.

The design concept for the (G)MCH in a BTX chassis is shown in

heatsink is aluminum extruded and utilizes a Z-clip for attach. The clip is secured to

the system motherboard via two solder down anchors around the (G)MCH. The clip

helps to provide a mechanical preload to the package via the heatsink. A thermal

interface material (Honeywell PCM45F) will be pre-applied to the heatsink bottom over

an area in contact with the package die.

Note: To minimize solder ball joint reliability risk, the BTX Z-clip heatsink is intended to be

used with the Support Retention Mechanism (SRM) described in the Balanced

Technology Extended (BTX) Interface Specification. For additional information on

designing the BTX chassis to minimize solder ball joint reliability, refer to the Balanced

Technology Extended (BTX) Chassis Design Guide.

Appendix B for the mechanical

Figure 13. The

27 Thermal and Mechanical Design Guidelines

Page 28

Reference Thermal Solution

Figure 12. Design Concept for ATX (G)MCH Heatsink — Installed on Board

Figure 13. Design Concept for Balanced Technology Extended (BTX) (G)MCH Heatsink

Design — Installed on Board

Thermal and Mechanical Design Guidelines 28

Page 29

Reference Thermal Solution

4.4 Environmental Reliability Requirements

The environmental reliability requirements for the reference thermal solution are

shown in

Validation test plans should be defined by the user based on anticipated use

conditions and resulting reliability requirements.

The ATX testing will be performed with the sample board mounted on a test fixture

and includes a processor heatsink with a mass of 550g. The test profiles are

unpackaged board level limits.

Table 5. ATX Reference Thermal Solution Environmental Reliability Requirements

(Board Level)

Table 5 and Table 6. These should be considered as general guidelines.

Test1 Requirement Pass/Fail

Mechanical

Shock

Random

Vibration

Thermal

Cycling

Humidity • 85 % relative humidity / 55 °C Visual Check

NOTES:

1. The above tests should be performed on a sample size of at least 12 assemblies from 3

different lots of material.

2. Additional Pass/Fail Criteria may be added at the discretion of the user.

• 3 drops for + and - directions in each of 3

perpendicular axes (i.e., total 18 drops).

• Profile: 50 G, Trapezoidal waveform, 4.3 m/s

[170 in/s] minimum velocity change

• Duration: 10 min/axis, 3 axes

• Frequency Range: 0.01 g2/Hz @ 5Hz ramping to

0.02 g2/Hz @20 Hz, 0.02 g2/Hz @ 20 Hz to 500 Hz

• Power Spectral Density (PSD) Profile: 3.13 g RMS

• Non-Operating, -40 °C to +70 °C Thermal

Criteria

Visual\Electrical

Check

Visual/Electrical

Check

Performance

2

The current plan for BTX reference solution testing is to mount the sample board

mounted in a representative BTX chassis with a thermal module assembly having a

mass of 900g. The test profiles are unpackaged system level limits.

29 Thermal and Mechanical Design Guidelines

Page 30

Reference Thermal Solution

Table 6. Balanced Technology Extended (BTX) Reference Thermal Solution

Environmental Reliability Requirements (System Level)

Test1 Requirement Pass/Fail

Mechanical

Shock

Random

Vibration

Thermal

Cycling

Humidity • 85 % relative humidity / 55 °C Visual Check

NOTES:

1. The above tests should be performed on a sample size of at least 12 assemblies from 3

different lots of material.

2. Additional Pass/Fail Criteria may be added at the discretion of the user.

3. Mechanical Shock minimum velocity change is based on a system weight of 20 to 29

lbs.

4. For the chassis level testing the system will include: 1 HD, 1 ODD, 1 PSU, 2 DIMMs and

the I/O shield.

• 3 drops for + and - directions in each of 3

perpendicular axes (i.e., total 18 drops).

• Profile: 25g, Trapezoidal waveform, 5.7 m/s

[225 in/sec] minimum velocity change.

• Duration: 10 min/axis, 3 axes

• Frequency Range: 0.001 g2/Hz @ 5Hz ramping to

0.01 g2/Hz @20 Hz, 0.01 g2/Hz @ 20 Hz to 500 Hz

• Power Spectral Density (PSD) Profile: 2.20 g RMS

• Non-Operating, -40 °C to +70 °C Thermal

Criteria2

Visual\Electrical

Check

Visual/Electrical

Check

Performance

§

Thermal and Mechanical Design Guidelines 30

Page 31

Enabled Suppliers

Appendix A Enabled Suppliers

Enabled suppliers for the (G)MCH reference thermal solution are listed in Table 7 and

Table 8. The supplier contact information is listed in Table 9.

Note: These vendors and devices are listed by Intel as a convenience to Intel's general

customer base, but Intel does not make any representations or warranties whatsoever

regarding quality, reliability, functionality, or compatibility of these devices. This list

and/or these devices may be subject to change without notice.

Table 7. ATX Intel Reference Heatsink Enabled Suppliers for (G)MCH

ATX

Items

Heatsink &

TIM D31682-002 S902Y10002 335I83330201

Plastic Clip C85370-001 P109000024 334C863501A 3EE77-002

Wire Clip D29082-001 A208000233 334I833301A 3KS02-155

Anchor C85376-001 2Z802-015 G2100C888-143

Intel PN AVC CCI Foxconn Wieson

Table 8. BTX Intel Reference Heatsink Enabled Suppliers for (G)MCH

BTX

Items

Heatsink

assembly

(HS/TIM &

Wire Clip) D34258-001 S905Y00001 00I833201A 2ZQ99-066

Anchor

(Lead

Free)

Intel PN AVC CCI Foxconn Wieson

A13494-008 HB9703E-

DW

G2100C888-064H

31 Thermal and Mechanical Design Guidelines

Page 32

Table 9. Supplier Contact Information

Supplier Contacts Phone Email

Enabled Suppliers

AVC (Asia Vital

Components)

CCI(Chaun Choung

Technology)

Foxconn

Wieson

Technologies

David Chao +886-2-2299-6930 ext.

7619

Raichel Hsu +886-2-2299-6930 ext.

7630

Monica Chih +886-2-2995-2666 monica_chih@ccic.com.tw

Harry Lin (714) 739-5797 hlinack@aol.com

Jack Chen (408) 919-6121 jack.chen@foxconn.com

Wanchi Chen (408) 919-6135

Chary Lee +886-2-2647-1896 ext.

6684

Henry Liu +886-2-2647-1896 ext.

6330

david_chao@avc.com.tw

raichel_hsi@avc.com.tw

wanchi.chen@foxconn.com

chary@wieson.com

henry@wieson.com

§

Thermal and Mechanical Design Guidelines 32

Page 33

Mechanical Drawings

Appendix B Mechanical Drawings

The following table lists the mechanical drawings available in this document:

Drawing Name Page

. (G)MCH Package Drawing 34

. (G)MCH Component Keep-Out Restrictions for ATX Platforms 35

. (G)MCH Component Keep-Out Restrictions for Balanced Technology Extended (BTX)

Platforms

. (G)MCH Reference Heatsink for ATX Platforms – Sheet 1 37

. (G)MCH Reference Heatsink for ATX Platforms – Sheet 2 38

. (G)MCH Reference Heatsink for ATX Platforms – Anchor 39

. (G)MCH Reference Heatsink for ATX Platforms – Ramp Retainer Sheet 1 40

. (G)MCH Reference Heatsink for ATX Platforms – Ramp Retainer Sheet 2 41

. (G)MCH Reference Heatsink for ATX Platforms – Wire Preload Clip 42

. (G)MCH Reference Heatsink for Balanced Technology Extended (BTX) Platforms 43

. (G)MCH Chipsets Reference Heatsink for Balanced Technology Extended (BTX)

Platforms – Clip

Number

36

44

33 Thermal and Mechanical Design Guidelines

Page 34

Mechanical Drawings

Thermal and Mechanical Design Guide

Figure 14. (G)MCH Package Drawing

Notes:

34

Page 35

D

C

1345678

5.27.04 CJK

.345[]

4X 8.76

REVISION HISTORY

C72156 1 2

COMP HEIGHT TO 38.1MM

KEEPOUT WIDTH TO 60.6MM

PRELIMINARY RELEASE 03/01/04

2 ADDED KEEPOUT FOR HS ASSEMBLY 9.27.04

1 ROLLED REVISION 7.16.04 CJK

0.1

0.4

DWG. NO SHT. REV

***

B4

D6

ZONE R EV DESCRIPTION DATE APPROVED

B-C

7&5

NO COMPONENTS THIS AREA

DETAIL A

.345[]

4X 8.76

.200[]

4X 5.08

DETAIL A

SCALE 8

.072[]

4X 1.84

2.9134[]

74

B

0.97 .038[]

8X 1.42[.056] TRACE KEEPOUT

8X PLATED THRU HOLE

EAST

COMPONENT CENTER

NOTES:

MAX 1.27 [.050]

A

2

REVDRAWING NUMBERCAGE CODE

123

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

CORP.

R

DESCRIPTIONPART NUMBER

TMD

DEPARTMENT

TITLE

PARTS LIST

4.30.04C BERMENSOLO

DATECHECKED BY

DATEDESIGNED BY

ATX LAKEPORT MCH HEAT SINK KEEP OUTC72156TOP

1 HOLE PLACEMENT FABRICATION

TOLERANCE PER INTEL 454979, CLASS 1,2,3

2. HEATSINK COMPONENT HEIGHT NOT TO EXCEED

38.1MM ABOVE M OTHERBOARD SURFACE.

MAX 25 [1.000]

COMPONENT HEIGHT

COMPONENT HEIGHT

(NON-MCH COMPONENTS)

ITEM NO

-001-002-003

QTY PER ASSY

UNLESS OTHERW IS E SPECIFIED

INTERPRET DIMENSIONS AND TOLERANCES

IN ACCORDANCE WI TH ASME Y14.5M-1994

DIMENSIONS ARE IN MIL LIMETERS

TOLERANCES:

LINEAR 0.1MM

SHEET 1 OF 1

C72156 D

DO NOT SCALE DRAWING

HEAT SINK KEEP OUT

ATX LAKEPORT MCH

SCALE: NONE

SIZE

5.27.04

DATEAPPROVED BY DATECHECKED BY

NA

FINISH:NAMATERIAL:

C KOEPSELL

THIRD ANGLE PROJECTION

4

2.398[]

60.92

.1575[]

4

5678

135

1.85[]

47

A

2.386[]

60.6

1.055[]

1.890[]

26.79

48

NORTH

1.803[]

45.79

2.638[]

67

THIS DRAWING CONTA I NS INTE L CO RP ORA T ION CONFID E NTIA L IN FOR MA TION . IT IS DISCLOSE D IN CONFI DE NC E AND IT S CONT ENTS

MAY NOT BE DISCLOSED, REPRODUCED, DI SPLAYED OR MODIFIED, WITHOUT THE PRI OR WRITTEN CONSENT OF INTEL CORPORAT ION.

D

C

3.189[]

81

B

Mechanical Drawings

Figure 15. (G)MCH Component Keep-Out Restrictions for ATX Platforms

Thermal and Mechanical Design Guide 35

Page 36

13

Mechanical Drawings

D24866 1 0.4

DWG. NO SHT. REV

4

REVISION HISTORY

*** 0.1 PRELIMINARY RELEASE mm/dd/yy X

ZONE REV DESCRIPTION DATE APPROVED

B6,C6 0.4 CHANGE MAX COMP HEIGHT FROM 1.27MM TO 1.55MM 06/24/05

D

.165[]

4X 4.19

4X D PLATED THRU HOLE

4X 1.42[.056] TRACE KEEPOUT

.345[]

4X 8.76

.200[]

4X 5.08

C

NO COMPONENTS THIS AREA

.082[]

4X 2.095

SEE DETAIL A

B

.130[]

2X 3.3

1 HOLE PLACEMENT FABRICATION

NOTES:

TOLERANCE PER INTEL 454979, CLASS 1,2,3

2. HEATSINK COMPONENT HEIGHT NOT TO EXCEED

.090[]

2X 2.29

DETAIL B

DETAIL A

SCALE 8

.225[]

2X 5.72

SCALE 6

.100[]

2X 2.54

34.3MM ABOVE MOTHERBOARD SURFACE.

MAX 1.78 [.070] COMPONENT HEIGHT

A

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

CORP.

R

DESCRIPTIONPART NUMBER

TMI

DEPARTMENT

PARTS LIST

mm/dd/yyKG TAN

DATEDRAWN BY

DATEDESIGNED BY

D24866TOP

ITEM NO

-001-002-003

QTY PER ASSY

UNLESS OTHERWISE SPECIFIED

INTERPRET DIMENSIONS AND TOLERANCES

IN ACCORDANCE WITH ASME Y14.5M-1994

DIMENSIONS ARE IN MILLIMETERS

0.4D24866 D

REVDRAWING NUMBERCAGE CODE

12345678

SHEET 1 OF 1

DO NOT SCALE DRAWING

BROADWATER BTX KEEP OUT ZONE

SCALE: 4

SIZE

TITLE

06/01/05KG TAN

mm/dd/yyDANA GRINDLE

mm/dd/yyX

DATEAPPROVED BY

DATECHECKED BY

NA

THIRD ANGLE PROJECTION

TOLERANCES:

LINEAR TOL 0.1

FINISH:NAMATERIAL:

Thermal and Mechanical Design Guide

MAX 1.55 [.060]

COMPONENT HEIGHT

COMPONENT CENTER

(NON-MCH COMPONENTS)

MAX 1.27 [.050]

COMPONENT HEIGHT

(NON-MCH COMPONENTS)

5678

1.900[]

48.26

SEE DETAIL B

A

THIS DRAWING CONTAINS INTEL CORPORAT ION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONT ENTS

MAY NOT BE DISCLOSED, REPRODUCED, DI SPLAYED OR MODIFIED, WITHOUT THE PRI OR WRITTEN CONSENT OF INTEL CORPORAT ION.

51.4

D

2.024[]

1.732[]

44

2.200[]

55.88

2.440[]

61.98

C

B

Figure 16. (G)MCH Component Keep-Out Restrictions for Balanced Technology Extended (BTX) Platforms

36

Page 37

13

REVISION HISTORY

D24866 1 0.4

DWG. NO SHT. REV

*** 0.1 PRELIMINARY RELEASE mm/dd/yy X

ZONE REV DESCRIPTION DATE APPROVED

4

B6,C6 0.4 CHANGE MAX COMP HEIGHT FROM 1.27MM TO 1.55MM 06/24/05

D

.165[]

4X 4.19

4X D PLATED THRU HOLE

4X 1.42[.056] TRACE KEEPOUT

.345[]

4X 8.76

.200[]

4X 5.08

C

NO COMPONENTS THIS AREA

.082[]

4X 2.095

SEE DETAIL A

B

.130[]

2X 3.3

1 HOLE PLACEMENT FABRICATION

NOTES:

TOLERANCE PER INTEL 454979, CLASS 1,2,3

2. HEATSINK COMPONENT HEIGHT NOT TO EXCEED

.090[]

2X 2.29

DETAIL B

DETAIL A

SCALE 8

.225[]

2X 5.72

SCALE 6

.100[]

2X 2.54

34.3MM ABOVE MOTHERBOARD SURFACE.

MAX 1.78 [.070] COMPONENT HEIGHT

A

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

CORP.

R

DESCRIPTIONPART NUMBER

TMI

DEPARTMENT

PARTS LIST

mm/dd/yyKG TAN

DATEDESIGNED BY

D24866TOP

ITEM NO

-001-002-003

QTY PER ASSY

UNLESS OTHERWISE SPECIFIED

INTERPRET DIMENSIONS AND TOLERANCES

IN ACCORDANCE WITH ASME Y14.5M-1994

DIMENSIONS ARE IN MILLIMETERS

0.4D24866 D

REVDRAWING NUMBERCAGE CODE

123

SANTA CLARA, CA 95052-8119

TITLE

06/01/05KG TAN

DATEDRAWN BY

TOLERANCES:

LINEAR TOL 0.1

SHEET 1 OF 1

DO NOT SCALE DRAWING

BROADWATER BTX KEEP OUT ZONE

SCALE: 4

SIZE

mm/dd/yyDANA GRINDLE

mm/dd/yyX

DATEAPPROVED BY

DATECHECKED BY

NA

FINISH:NAMATERIAL:

THIRD ANGLE PROJECTION

4

MAX 1.55 [.060]

COMPONENT HEIGHT

COMPONENT CENTER

5678

2.024[]

51.4

THIS DRAWING CONTAINS INTEL CORPORAT ION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONT ENTS

MAY NOT BE DISCLOSED, REPRODUCED, DI SPLAYED OR MODIFIED, WITHOUT THE PRI OR WRITTEN CONSENT OF INTEL CORPORAT ION.

D

C

(NON-MCH COMPONENTS)

1.732[]

44

2.200[]

55.88

2.440[]

61.98

MAX 1.27 [.050]

COMPONENT HEIGHT

(NON-MCH COMPONENTS)

5678

1.900[]

48.26

SEE DETAIL B

B

A

Mechanical Drawings

Figure 17. (G)MCH Reference Heatsink for ATX Platforms – Sheet 1

Thermal and Mechanical Design Guide 37

Page 38

Mechanical Drawings

D31682 2 A

DWG. NO SHT. REV

H

G

60.6

.024[]

F

TYP 135

.020[]

R0.5

E

.157[]

TYP 4

66.72 0.15

.005[]

.265

61.5 0.15

NO BURR ALL AROUND

TYP R 1

D

DETAIL B

SCALE 5

.005[]

.108

TYP 62.75 0.15

.005[]

.059

TYP DETAIL A

SCALE 5

.039[]

C

B

A

2

OF

2

SHEET

DO NOT SCALE DRAWING

2

SIZE DRAWING NUMBER REV

A1 D31682 A

SCALE:

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

R CORP.

TMI

DEPARTMENT

Thermal and Mechanical Design Guide

Figure 18. (G)MCH Reference Heatsink for ATX Platforms – Sheet 2

0.1 [.00]

G

.532[]

13.5

.787[]

20

20

F

8 7 6 5 4 3 2

THIS DRAWING CONTAINS INTEL CORPORATION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONTENTS

MAY NOT BE DISCLOSED, REPRODUCED, DISPLAYED OR MODIFIED, WITHOUT THE PRIOR WRITTEN CONSENT OF INTEL CORPORATION.

H

.787[]

2.598[]

66

E

.906[]

23

5 4X 45 X 1 [.039]

12

D

BOTTOM VIEW

C

8 7 6 5 4 3 2 1

B

A

38

Page 39

2X CHAMF ER A LL AROUND

CONT ACT T O INSULAT OR INT ERF ACE

AT SUPPLIERS OPTIO N

+.000

-.002

0

-0.07

.025

0.64

[]

.003[]

.030

2X 60.77 0.1

.005[]

.300

7.62 0.15

NOTES: 1. THIS DRA W ING T O B E USE D IN CO NJUNCT IO N W ITH SUP PLIED 3D

DATABASE FILE. ALL DIMENSIONS AND TOLERANCES ON THIS

DRAWING TAK E PRECEDENCE OVER SUPPLIED FILE AND ARE

APPLICABLE AT PART FREE, UNCONSTRAINED STATE UNLESS

INDICATE D OT HE RW ISE.

2. TO LERANCES O N DIME NSIO NED A ND UNDIMENS IO NED

FEATURES UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS.

FOR FEAT URE SIZES < 10MM: LINEAR .07

.005[]

.155

45 X 0.2 M IN

2X 45 2

.005[]

.098

2.5 0. 15

2X 3. 94 0.15

FOR FEAT URE SIZES > 10MM: LINEAR .08

ANGLES: 0.5

3. MATERIALS:

.001[]

.020

2X 0.5 0.05

6 CRIT ICAL T O FUNCT IO N DIM E NSIO N

INSULATOR: POLYCARBONATE THERMOPLASTIC, UL 94V-0, BLACK (739)

(REF. GE LEXAN 3412R-739)

CONTACT: BRASS OR EQUIVALENT UPON INTEL APPROVAL

CO NT A CT F IN IS H: .000050u" M IN . NI CK E L UND ER PLA T IN G ;

SOLDER TAILS, 0.000100" MIN TIN ONLY SOLDER (LEAD FREE).

5. MARK WITH INTEL P/N AND REVISION PER INTEL MARKING

ST A N DA RD 164997; P E R S E C 3.8 (P O LY E T HY LE N E B A G )

7. ALL DIMENSIO NS SHO W N SHALL BE M EA SURED FO R F AI

8. NOT E RE MO VED

9. DEGA TE : FLUSH T O 0.35 BELOW S TRUCT URAL T HICKNES S

(GATE W ELL OR GATE RECESS ACCEPTABLE)

10. FLASH: 0.15 MAX.

11. SINK: 0.25 MAX.

12. EJECTOR MARKS: FLUSH TO -0.25

13. PARTING LINE MISMATCH NOT TO EXCEED 0.25.

14. EJECTION PIN BOSSES, GATING, AND TOO LING INSERTS REQUIRE

INTEL'S APPROVAL PRIOR TO TO OL CONSTRUCTION.

ALL EJECTION PIN BOSSES AND GATE FEAT URES SHOWN

ARE F O R RE F ERENCE O NLY.

15. EDGES SHOW N AS SHARP R 0.1 MAX.

16. TOO LING REQUIRED TO MAKE T HIS PART SHALL BE THE

PROPERTY O F INTEL, AND SHALL BE PERMANENTLY MARKED

WITH INTEL'S NAME AND APPROPRIATE PART NUMBER.

17. ALL SECONDARY UNIT DIM ENS IO NS ARE FO R REF ERE NCE O NLY.

.004[]

.399

2X 10.13 0.12

+.000

-.002

0

-0.07

.025

0.64

[]

65.08 0.12

.004[]

.200

Mechanical Drawings

Figure 19. (G)MCH Reference Heatsink for ATX Platforms – Anchor

.157[]

2X 4

.030[]

2X 0.75

65.21 0. 12

.004[]

.205

.004[]

.308

4X 67.83 0.12

Thermal and Mechanical Design Guide 39

Page 40

Mechanical Drawings

NOTES: 1. THIS DRAW ING TO BE USED IN CO NJUNCTIO N W ITH SUP PLIED 3D

DATABASE FILE. ALL DIMENSIONS AND TOLERANCES ON THIS

DRAWING TAKE PRECEDENCE OVER SUPPLIED FILE AND ARE

APPLICABLE AT PART FREE, UNCONSTRAINED STATE UNLESS

INDICAT ED O T HERW IS E.

2. TO LERANCE S O N DIM ENS IONE D AND UNDIM ENS IO NED

FEATURES UNLESS OTHERWISE SPECIFIED:

670. 49

2.775[]

661.51

2.422[]

Thermal and Mechanical Design Guide

5 MARK PART W ITH INTEL P/N, REVISION, CAVITY NUMBER

DIMENSIONS ARE IN MILLIMETERS.

FOR FEAT URE SIZES < 10MM: LINEAR .07

FOR FEAT URE SIZES BETW EEN 10 AND 25 MM: LINEAR .08

FOR FEAT URE SIZES BETW EEN 25 AND 50 MM: LINEAR .10

FOR FEAT URE SIZES > 50MM: LINEAR .18

ANGLES: 0.5

3. MATE RIAL:

A) TYPE: ENVIRONMENTALLY COMPLIANT THERMO PLASTIC OR

EQUIVALENT UPON INTEL APPROVAL (REF. GE LEXAN 500ECR-739)

B) CRITICAL M ECHA NICAL MA TE RIAL PRO P ERT IES

FOR EQ UIVALENT MATERIAL SELECTION:

TENSILE YIELD ST RENG TH (AST M D638) > 57 MPa

TENSILE ELONGATIO N AT BREAK (ASTM D638) >= 46%

F LE X UR A L M O D ULU S (A ST M D 638) 3116 M P a 10%

SOF TE NING T EM P (VICAT , RATE B ): 154 C

C) COLOR: APPROXIMATING BLACK, (REF GE 739)

6 CRITICAL TO FUNCTION DIMENSION

D) REGRIND: 25% PERMISSIBLE.

E) V O LUM E - 1. 73e+ 03 CU BI C-M M (R EF )

WEIG HT - 2.16 GRAM S (REF )

AND DATE CODE APPROX WHERE SHOW N PER INTEL MARKING

ST A NDA R D 164997

7. ALL DIMENSIONS SHOW N SHALL BE MEASURED FOR FAI

8. NOTE REMO VED

9. DEG AT E: F LUSH T O 0.35 BELO W ST RUCT URAL T HICKNE SS

(GATE W ELL OR GAT E RECESS ACCEPTABLE)

10. FLASH: 0.15 MAX.

11. S IN K : 0. 25 M A X .

12. EJECTO R M ARK S: F LUSH TO -0.25

13. PARTING LINE M ISMA TCH NO T T O EXCE ED 0.25.

14. EJECTION PIN BOSSES, G ATING, AND TOO LING INSERTS REQUIRE

INTEL'S APPROVAL PRIOR TO TOOL CONSTRUCTION.

ALL EJECTION PIN BOSSES AND GATE FEAT URES SHOWN

ARE F O R REF ERENCE O NLY.

15. EDGES SHOW N AS SHARP R 0.1 MAX.

16. TOO LING REQ UIRED T O MA KE THIS P ART SHALL BE T HE

PROPERTY OF INTEL, AND SHALL BE PERMA NENTLY MARKED

WITH INTEL'S NAME AND APPROPRIATE PART NUMBER.

17. ALL SECONDA RY UNIT DIM ENSIO NS ARE F O R REF E RENCE O NLY.

Figure 20. (G)MCH Reference Heatsink for ATX Platforms – Ramp Retainer Sheet 1

5

62 0.05

SEE DETAIL C

SEE DETAIL C

1.100[]

.118[]

3

2X 27. 95

1.225[]

2X 31.1

.001[]

.079

SEE DETAIL ASEE DETAIL A

40

Page 41

.157[]

4

65.56

.219[]

DETA IL C

SCALE 10

.114[]

2X 62.9

.252[]

6.4

.227[]

2X 65.76

SECTION B-B

Mechanical Drawings

Figure 21. (G)MCH Reference Heatsink for ATX Platforms – Ramp Retainer Sheet 2

.047[]

1.19

60.5

61.75

.020[]

.069[]

63.15

.108[]

.124[]

2.75

B

64. 7 5

.187[]

.205[]

5.2

2X DE T A IL A

SCALE 20

6.55

.118[]

3

B

.258[]

Thermal and Mechanical Design Guide 41

Page 42

D29082 1 A

Mechanical Drawings

DWG. NO SHT. REV

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPROVED

H

- A INITIAL RELEASE 09/06/05 -

G

F

.110[]

4 2.8

E

NOTES: 1. THIS DRAWING TO BE USED IN CORRELATION WITH SUPPLIED 3D

.071[]

4X R 1.8

D

DATABASE FILE. ALL DIMENSIONS AND TOLERANCES ON THIS

DRAWING TAKE PRECEDENCE OVER SUPPLIED FILE AND ARE

APPLICABLE AT PART FREE, UNCONSTRAINED STATE UNLESS

INDICATED OTHERWISE.

2. TOLERANCES ON DIMENSIONED AND UNDIMENSIONED

FEATURES UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS.

4 CRITICAL TO FUNCTION DIMENSION

TOLERANCES: LINEAR 0.25

ANGLES: 3

3. MATERIAL:

TYPE: ASTM A228 MUSIC WIRE 1.8 0.1MM 4

PLATING: ELECTRO-LESS NICKEL OR EQUIVALENT UPON

INTEL APPROVAL.

5. MARK WITH INTEL P/N AND REVISION PER INTEL MARKING

C

STANDARD 164997; PER SEC 3.8 (POLYETHYLENE BAG)

6. REMOVE ALL SHARP EDGES AND BURRS.

7. ALL DIMENSIONS SHOWN SHALL BE MEASURED FOR FAI

8. ALL SECONDARY UNIT DIMENSIONS ARE FOR REFERENCE ONLY.

B

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

R CORP.

DESCRIPTIONPART NUMBER

TMI

DEPARTMENT

PARTS LIST

07/10/05KGTAN

DATEDESIGNED BY

SPRING, HSS, 8.00 LBI, 65.00MMD29082-001TOP

UNLESS OTHERWISE SPECIFIED

ITEM NO

IN ACCORDANCE WITH ASME Y14.5M-1994

INTERPRET DIMENSIONS AND TOLERANCES

QTY

PRELOAD, PWSH, BW, ATX

TITLE

09/06/05C.BERMENSOLO

DATECHECKED BY

08/08/05KGTAN

DATEDRAWN BY

THIRD ANGLE PROJECTION

09/06/05DANA GRINDLE

A

1

OF

1

SHEET

DO NOT SCALE DRAWING

3

SIZE DRAWING NUMBER REV

A1 D29082 A

SCALE:

SEE NOTESSEE NOTES

FINISHMATERIAL

09/06/05DANA GRINDLE

DATEAPPROVED BY

Thermal and Mechanical Design Guide

8 7 6 5 4 3 2

THIS DRAWING CONTAINS INTEL CORPORATION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONTENTS

MAY NOT BE DISCLOSED, REPRODUCED, DISPLAYED OR MODIFIED, WITHOUT THE PRIOR WRITTEN CONSENT OF INTEL CORPORATION.

H

Figure 22. (G)MCH Reference Heatsink for ATX Platforms – Wire Preload Clip

A

64.3

2X 90

.019[]

.760

19.3 0.5

.019[]

1.075

27.3 0.5

.019[]

0.5

1.835

46.6

G

F

E

4 128.6 3

1.445[]

2X 4 36.7

D

C

B

8 7 6 5 4 3 2 1

A

42

Page 43

D29080 1 A

D29080 1 A

DWG. NO SHT. REV

DWG. NO SHT. REV

REVISION HISTORY

REVISION HISTORY

- A INITIAL RELEASE 09/06/05 -

- -

ZONE REV DESCRIPTION DATE APPROVED

ZONE REV DESCRIPTION DATE APPROVED

H

G

F

E

NOTES: 1. THIS DRAWING TO BE USED IN CONJUNCTION WITH SUPPLIED 3D

D

5 MARK PART WITH INTEL P/N AND REVISION APPROX

DATABASE FILE. ALL DIMENSIONS AND TOLERANCES ON THIS

DRAWING TAKE PRECEDENCE OVER SUPPLIED FILE AND ARE

APPLICABLE AT PART FREE, UNCONSTRAINED STATE UNLESS

INDICATED OTHERWISE.

2. TOLERANCES ON DIMENSIONED AND UNDIMENSIONED

FEATURES UNLESS OTHERWISE SPECIFIED:

6 CRITICAL TO FUNCTION DIMENSION

DIMENSIONS ARE IN MILLIMETERS.

TOLERANCES:

LINEAR 0.25

ANGULAR 1

3. MATERIAL: 6063-T5 ALUMINUM

4. FINISH: NONE

WHERE SHOWN PER INTEL MARKING STANDARD 164997

7. EDGES SHOWN AS SHARP R 0.1 MAX.

8. TOOLING REQUIRED TO MAKE THIS PART SHALL BE THE

PROPERTY OF INTEL, AND SHALL BE PERMANENTLY MARKED

C

12 . APPLY HONEYWELL TIM PCM45F (STD SIZE 20MM x 20MM) AT

WITH INTEL'S NAME AND APPROPRIATE PART NUMBER.

9. ALL SECONDARY UNIT DIMENSIONS ARE FOR REFERENCE ONLY.

10. ALL DIMENSIONS SHOWN SHALL BE MEASURED FOR FAI

11. REMOVE ALL BURRS OR SHARP EDGES AROUND PERIMETER

OF PART. SHARPNESS OF EDGES SUBJECT TO HANDLING ARE

REQUIRED TO MEET UL1439 TEST.

HEAT SINK BASE WITH AN ASSEMBLY POSITIONAL TOLERANCE OF

1.0MM TOLERANCE

B

HTSNK,EXTD,FBGA,15,ALD29080-001TOP

HTSNK,EXTD,FBGA,15,ALD29080-001TOP

DESCRIPTIONPART NUMBER

DESCRIPTIONPART NUMBER

PARTS LIST

PARTS LIST

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

R CORP.

R CORP.

TMI

TMI

DEPARTMENT

DEPARTMENT

DATEDRAWN BY

08/08/05KGTAN

DATEDESIGNED BY

DATEDRAWN BY

KGTAN

DATEDESIGNED BY

BROADWATER MCH BTX HEAT SINK

BROADWATER MCH BTX HEAT SINK

TITLE

TITLE

09/06/05DANA GRINDLE

09/06/05C BERMENSOLO

DATECHECKED BY

08/12/05KG TAN

DATECHECKED BY

A

1

1

OF

OF

1

1

SHEET

SHEET

DO NOT SCALE DRAWING

DO NOT SCALE DRAWING

3:1

3:1

SIZE DRAWING NUMBER REV

SIZE DRAWING NUMBER REV

A1 D29080 A

A1 D29080 A

SCALE:

SCALE:

SEE NOTESSEE NOTES

FINISHMATERIAL

09/06/05DANA GRINDLE

DATEAPPROVED BY

SEE NOTESSEE NOTES

FINISHMATERIAL

DATEAPPROVED BY

8 7 6 5 4 3 2

1.732[]

44

.118[]

3

B

14 X EQUAL SPACES

15X FULL ROUND

1.232[]

31.3

R0 TO FULL

THIRD ANGLE PROJECTION

THIRD ANGLE PROJECTION

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN MILLIMETERS

ITEM NO

ITEM NO

IN ACCORDANCE WITH ASME Y14.5M-1994

INTERPRET DIMENSIONS AND TOLERANCES

QTY

0.25 [.00] B C

0.1 [.003]

QTY

5

12 HONEYWELL TIM-PCM45F

.007[]

.118

6 3 0.2

A

.142[]

3.6

8 7 6 5 4 3 2 1

2.110[]

.787[]

20

.787[]

20

2.000[]

50.8

53.6

Mechanical Drawings

Figure 23. (G)MCH Reference Heatsink for Balanced Technology Extended (BTX) Platforms

.039[]

15 X 1

THIS DRAWING CONTAINS INTEL CORPORATION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONTENTS

MAY NOT BE DISCLOSED, REPRODUCED, DISPLAYED OR MODIFIED, WITHOUT THE PRIOR WRITTEN CONSENT OF INTEL CORPORATION.

THIS DRAWING CONTAINS INTEL CORPORATION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONTENTS

MAY NOT BE DISCLOSED, REPRODUCED, DISPLAYED OR MODIFIED, WITHOUT THE PRIOR WRITTEN CONSENT OF INTEL CORPORATION.

H

G

F

E

.012[]

R0.3

.118[]

3

D

.276[]

7

C

C

B

A

Thermal and Mechanical Design Guide 43

Page 44

D29081 1 A

Mechanical Drawings

DWG. NO SHT. REV

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPROVED

H

G

F

E

D

C

B

DESCRIPTIONPART NUMBER

PARTS LIST

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

R CORP.

BROADWATER MCH BTX Z-CLIP

TMI

DEPARTMENT

TITLE

09/06/05DANA GRINDLE

O9/06/05C BERMENSOLO

DATECHECKED BY

08/12/05KGTAN

DATEDRAWN BY

08/08/05KGTAN

DATEDESIGNED BY

- A INITIAL RELEASE 09/06/05 -

WIRE CLIP, MCH, BW, BTXD29081-001TOP

6. REMOVE ALL SHARP EDGES AND BURRS.

7. ALL DIMENSIONS SHOWN SHALL BE MEASURED FOR FAI

8. ALL SECONDARY UNIT DIMENSIONS ARE FOR REFERENCE ONLY.

THIRD ANGLE PROJECTION

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN MILLIMETERS

ITEM NO

IN ACCORDANCE WITH ASME Y14.5M-1994

INTERPRET DIMENSIONS AND TOLERANCES

QTY

.189[]

4 4.8

.071[]

4X R 1.8

NOTES: 1. THIS DRAWING TO BE USED IN CORRELATION WITH SUPPLIED 3D

DATABASE FILE. ALL DIMENSIONS AND TOLERANCES ON THIS

DRAWING TAKE PRECEDENCE OVER SUPPLIED FILE AND ARE

APPLICABLE AT PART FREE, UNCONSTRAINED STATE UNLESS

INDICATED OTHERWISE.

2. TOLERANCES ON DIMENSIONED AND UNDIMENSIONED

4 CRITICAL TO FUNCTION DIMENSION

FEATURES UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS.

TOLERANCES: LINEAR 0.25

ANGLES: 3

3. MATERIAL:

TYPE: ASTM A228 MUSIC WIRE 1.8 0.1MM 4

PLATING: ELECTRO-LESS NICKEL OR EQUIVALENT UPON

INTEL APPROVAL.

5. MARK WITH INTEL P/N AND REVISION PER INTEL MARKING

STANDARD 164997; PER SEC 3.8 (POLYETHYLENE BAG)

A

1

OF

1

SHEET

DO NOT SCALE DRAWING

4:1

SIZE DRAWING NUMBER REV

A1 D29081 A

SCALE:

SEE NOTESSEE NOTES

FINISHMATERIAL

09/06/05DANA GRINDLE

DATEAPPROVED BY

Thermal and Mechanical Design Guide

8 7 6 5 4 3 2

.8[]

21.3

1.075[]

27.3

1.625[]

41.3

.019[]

0.5

2.465

62.6

.315[]

8

THIS DRAWING CONTAINS INTEL CORPORATION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONTENTS

MAY NOT BE DISCLOSED, REPRODUCED, DISPLAYED OR MODIFIED, WITHOUT THE PRIOR WRITTEN CONSENT OF INTEL CORPORATION.

H

G

F

Figure 24. (G)MCH Chipsets Reference Heatsink for Balanced Technology Extended (BTX) Platforms – Clip

10.0

WITHIN

WIRE TERMINATION

.161[]

2X 4.1

.283[]

2X 7.2

C

4 132.6 3

2X 90

E

D

.051[]

2X R 1.3

2X 90

A

66.3

.930[]

2X 4 23.63

B

8 7 6 5 4 3 2 1

A

44

Loading...

Loading...