Page 1

7

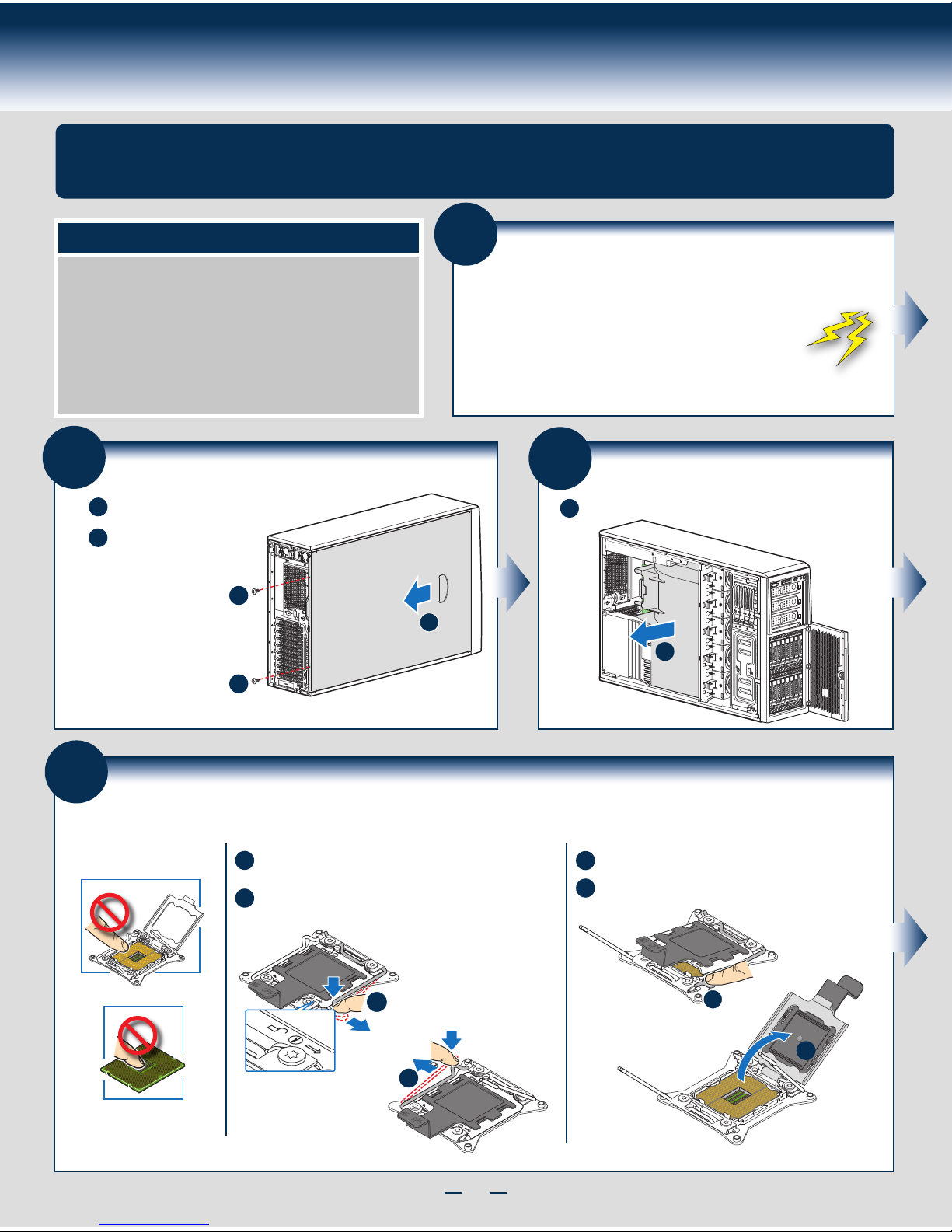

General Installation Process

The installation instructions in this section are for general components of Intel® Server System P4000IP and Intel®

Workstation System P4000CR family, but the illustrations are based on the Intel® Server System P4216IP4LHJC.

Minimum Hardware Requirements

■ Processor

■ Heat Sink

■ Memory

■ Hard Disk Drives

■ Power

■ Air Duct

To avoid integration difficulties and possible damage to your system,

make sure you have components from each category below.

Remove the Side Cover

B

Remove the screws.

A

Note:

A non-skid surface or a

stop behind the chassis

may be needed to prevent

the chassis from sliding on

your work surface.

Slide the side cover

back and lift the cover

outward to remove it.

2

Server

Board

A

A

B

1

Preparing the System

Observe normal ESD (Electrostatic Discharge) procedures.

Place your Intel® Server System on a flat anti-static

surface to perform the following integration procedures.

Observe ESD procedures before reaching inside to make

server board connections or install components.

3

Remove the Air Duct

A

Remove the air duct.

A

4

Install the Processor(s)

A. Open the Socket Lever B. Open the Load Plate

A

B

Repeat the steps to release the lever on the other side.

Push down the lever handle on the open 1st side and away

from the socket to release it.

A

B

Open the load plate all the way.

Press the locking lever slightly to raise the load plate .

NOTE: Release the

levers in the order

as shown.

B

OPEN 1st

A

FOXCONN LGA2011 ILM 17562

NO CPU

B

NO CPU

FOXCONN LGA2011 ILM 17562

A

NO CPU

Page 2

8

General Installation Process

A

B

C

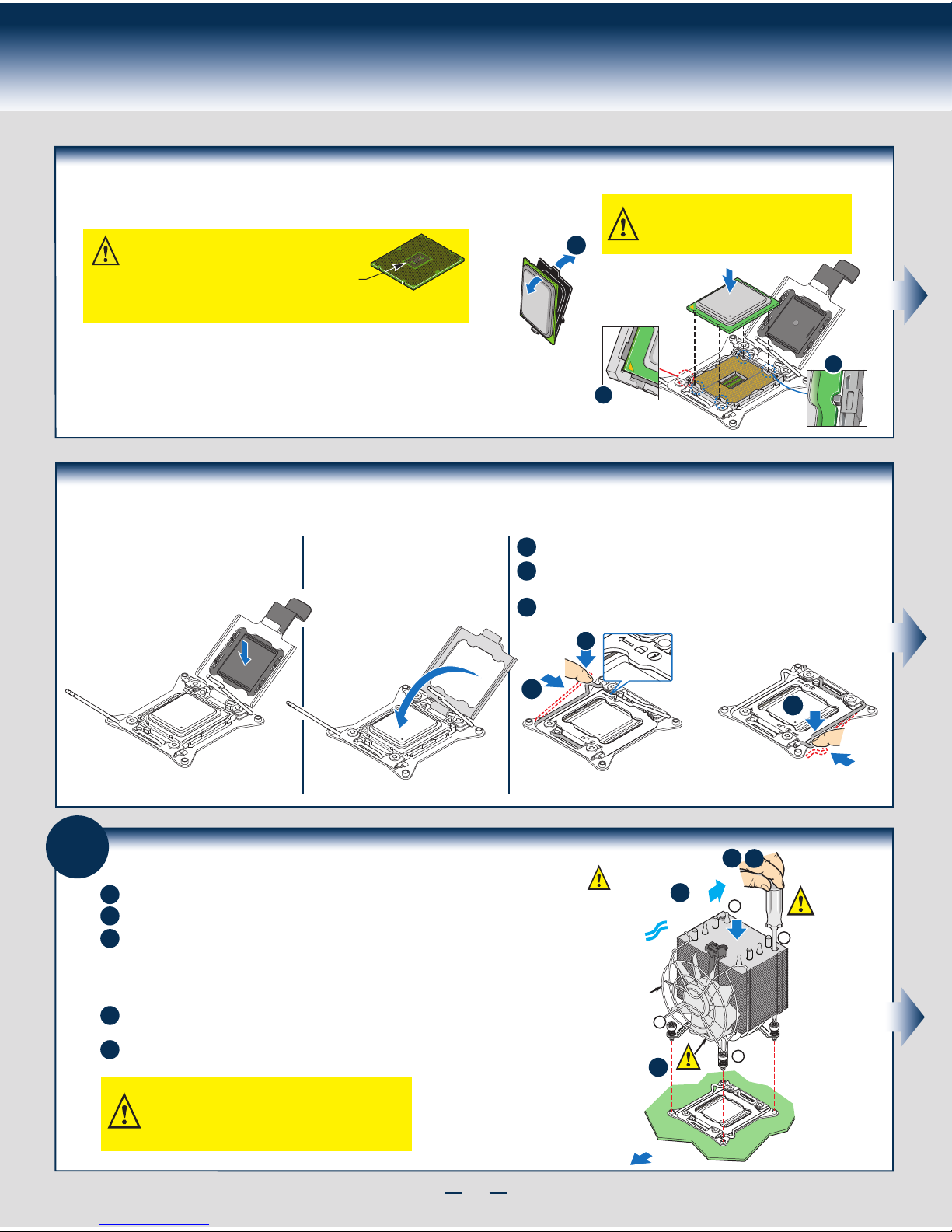

5

Install Heat Sink(s)

Get heat sink from the shipping position.

A

Remove the protective film on the TIM if present.

E

D

B

C

Securely re-tighten each fastener again in the same order as performed in Step D.

Using a #2 Phillips* screwdriver, finger-tighten each fastener diagonally,

according to the numbers shown.

Align heat sink fins to the front and back of the chassis for correct airflow.

Airflow goes from front-to-back of chassis.

The heat sink has four captive fasteners and should be tightened using the following procedure:

CAUTION: The heat sink has thermal interface

material (TIM) on the underside of it. Use caution so

that you do not damage the thermal interface material.

Use gloves to avoid sharp edges.

C

TIM

Processor

Socket

AIRFLOW

B

2

3

1

4

Chassis Front

D

E

CAUTION:

Do not

over-tighten

fasteners.

Fan Kit

(Only available

for W2600CR)

Install the Processor(s) ... continued

C. Install the Processor

Take the processor out of the box and remove the protective shipping cover.

CAUTION: When unpacking a

processor, hold by the edges only to

avoid touching the gold contact pins.

Save the

protective

cover.

A

CAUTION: The underside of the processor has

components that may damage the socket pins

if installed improperly.

Processor must align correctly with the socket opening before installation.

DO NOT DROP processor into socket!

Components

Note location of gold key at corner of processor.

Orient the processor with the socket so that the processor cutouts match the four orientation

posts on the socket.

B

C

Install the Processor(s) ... continued

D. Remove the Cover

Press the cover to

remove it.

Carefully lower the load plate over

the processor.

E. Close the Load Plate

Push down on the locking lever on the close 1st side.

F. Latch the Locking Lever

A

B

Slide the tip of the lever under the notch in the load plate. Make sure

the load plate tab engages under the socket lever when fully closed.

C

Repeat the steps to latch the locking lever on the other side.

NOTE: Latch

the levers in the

order as shown.

Save the

protective

cover.

FOXCONN LGA2011 ILM 17562

B

A

C

Page 3

9

General Installation Process

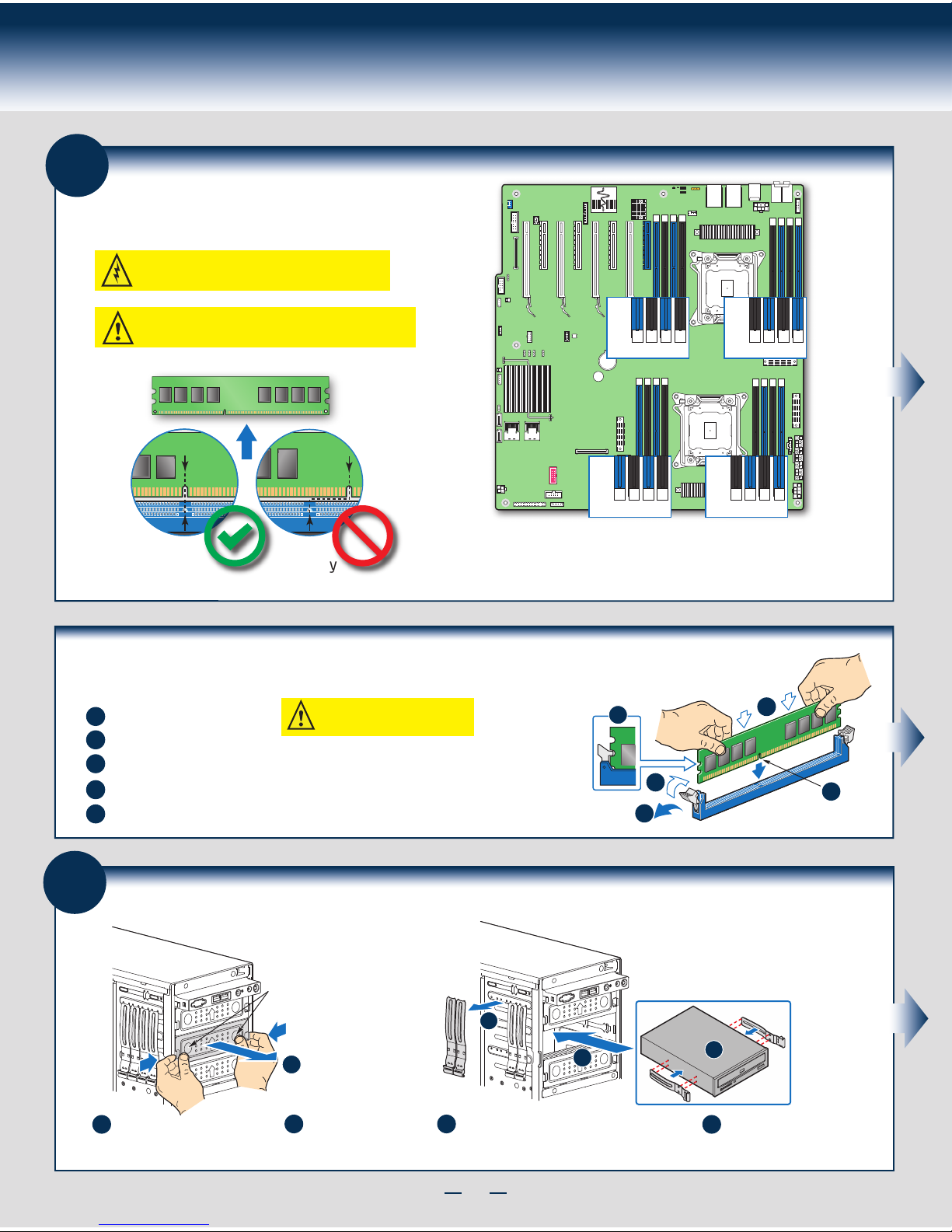

Install DIMM Memory Modules ... Continued

To Install DIMMs:

Open both DIMM socket levers.

C

A

D

E

Note location of alignment notch.

B

CAUTION: Avoid touching contacts

when handling or installing DIMMs.

A

C

D

B

E

IMPORTANT! Visually check that each latch is fully closed and correctly engaged with each DIMM edge slot.

Push down firmly on the DIMM until it snaps into place and both levers close.

Insert DIMM making sure the connector edge of the DIMM aligns correctly with the slot.

7

Install Tool-less CD-ROM or DVD-ROM Drive

C

Attach slides to the DVD or CD-ROM drive

by pressing the slides firmly into the side

dimples on the DVD or CD-ROM drive.

B

Get the slides from the

chassis side.

D

Insert the drive/slide assembly

into the device bay until the

slides lock into place.

A

Press the release latch and use

the finger holes to Pull out the

EMI shield.

Finger Holes

A

D

B

C

6

Install DIMM Memory Modules

DDR3 DIMM Memory Identification:

DIMM

notch and

socket

bump must

align as

shown.

Other

Memory

DDR3

This server board supports up to 16 DDR3 800/1066/1333/1600 ECC

UDIMM/RDIMM/LRDIMM.

CAUTION: Observe normal ESD (ElectroStatic Discharge) procedures

to avoid possible damage to system components.

Memory sizing and configuration is supported only for qualified DIMMs approved by Intel. For a list of

supported memory, see the tested memory list at

http://serverconfigurator.intel.com/default.aspx

Memory Type: Minimum of one 1 GB, DDR3 800/1066/1333/1600 MHz ECC UDIMM/RDIMM/LRDIMM.

C1DIMM C2 D1 D2

B2DIMM B1 A2 A1

E1DIMM E2 F1 F2

H2DIMM H1 G2 G1

Page 4

10

General Installation Process

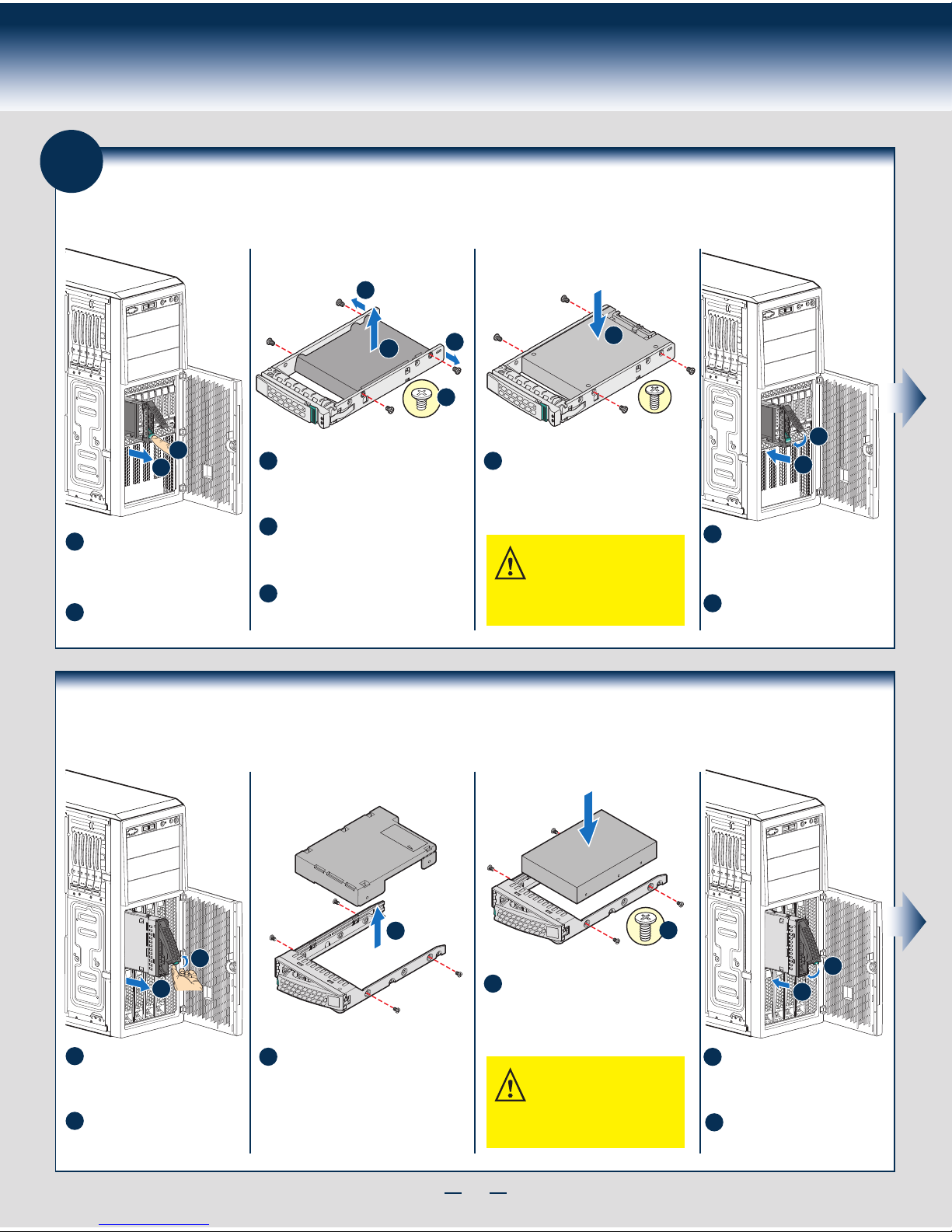

H

G

A

B

Install Hard Drive

2.5" Hot-Swap Hard Drive Carrier (For system with 2.5" hot-swap hard drive bay only)

A

Open the Hot-swap door and

remove the drive carrier by

pressing the green button and

opening the lever.

Slide the carrier out.

B

D

D

E

C

2.5" HDD

F

Remove the four screws securing the

plastic retention device to the 2.5"

HDD carrier.

Disengage the plastic retention device

from the HDD carrier slides by

pulling the slides.

Remove the plastic retention device

from the 2.5" HDD carrier.

C

D

E

Install the hard disk drive using the

four screws as shown. Make sure the

connector end of the drive matches

the backplane connector.

F

CAUTION: If you don’t install all

drives, empty drive bays must

be occupied by carriers with

plastic drive blank provided to maintain

proper system cooling.

With the lever open, insert the

hard disk drive assembly into the

cage opening and push until the

locking lever engaged.

Push in the lever to lock it into

place, then close the door.

G

H

8

E

F

B

A

Install Hard Drive ... Continued

3.5" Hot-Swap Hard Drive Carrier (For system with 3.5" hot-swap hard drive bay only)

A

Open the Hot-swap door and

remove the drive carrier by

pressing the green button and

opening the lever.

Slide the carrier out.

B

Remove the four screws securing the

HDD interface bracket and remove the

HDD interface bracket.

C

Install the hard disk drive using the

same four screws as shown. Make

sure the connector end of the drive

matches the backplane connector.

D

CAUTION: If you don’t install all

drives, empty drive bays must

be occupied by carriers with

plastic drive blank provided to maintain

proper system cooling.

With the lever open, insert the

hard disk drive assembly into the

cage opening and push until the

locking lever engaged.

Push in the lever to lock it into

place, then close the door.

E

F

TOP

BREAK OFF TAB

BEFORE MOUTING

2.5´´ HARD DRIVE

C

3.5´´ HDD

D

Page 5

11

General Installation Process

Install PCI Card Assembly ... Continued

From inside of

chassis, press open

the back panel PCI

add-in board

retention device.

D

E

While holding the PCI

add-in board by its

top edge or upper

corners, firmly press

the add-in board into

the expansion slot.

Server

Board

D

Server

Board

E

Install PCI Card Assembly ... Continued

F G

Close the PCI add-in board retention device. Rotate the PCI card

retainer until the

PCI card retainer is

secured by the

chassis.

Make sure the PCI

card is secured into

the slot under the

PCI Card Retainer.

Server

Board

F

Server

Board

G

9

Install PCI Card Assembly

A

Remove the PCI slot shield by pushing the

shield out from inside the chassis.

B

Rotate the

PCI retainer

all the way

to open.

C

Install the optional PCI-e card fixture

with screws. The card fixture helps

to hold heavy PCI-e cards

(that is GPGPU card).

The card fixture is

ordered seperately.

Server

Board

A

B

Server

Board

C

Page 6

12

General Installation Process

11

Install RMM4 EMI Cover

(optional)

A

Install the RMM4 EMI cover with thumb screws.

Server

Board

A

10

Install Intel® Remote Management Module 4 NIC (optional)

Top View

A

A

Attach the metal fastening bracket to Intel® Dedicated Server

Management NIC module and secure the bracket with two screws.

B

Remove the alternate RMM4 knock out by pressing the knock out

from inside the chassis.

C

Connect the cable to the cable connector on the Intel® Dedicated Server

Management NIC module.

D

Mount the NIC module to the rear panel of the chassis and secure the

bracket with two screws.

E

Connect the cable to the RMM4 NIC connector to the RMM4 NIC connector

on your server board.

Server

Board

RMM4

NIC Connector

Server

Board

C

E

Chassis

Back

Opening

Filler

D

B

CAUTION: Carefully remove the knock out with

screwdriver, directly removing it with finger has

potential risk.

CAUTION: Care should be used when attaching or removing this cable.

Mishandling the cable could cause damage.

12

Install Alternate Serial Port (optional)

A

Remove the alternate serial port knockout by pressing the

knockout from inside the chassis.

B

Mount the serial port on the rear panel of the chassis.

C

Secure the port with two screws.

D

Connect the cable to the Serial B Connector on your server board.

CAUTION: Carefully remove the knock out with screwdriver,

directly removing it with finger has potential risk.

CAUTION: Care should be used when attaching or removing

this cable. Mishandling the cable could cause damage.

Server

Board

Serial B

Connector

B

D

Filler

Chassis

Back

Opening

A

C

Page 7

13

General Installation Process

A

14

Install Second Power Supply Module (optional)

Latch

Handle

Finger

Hole

A

B

A

B

Use the 'finger hole' to remove the

filler panel.

Insert the power supply module into the power

supply cage and push all the way until it clicks

into place.

To remove a power supply module, push the

green latch in the direction shown while pulling

out of the system by the handle.

Note: Applies only to the chassis with hot-swap power supply configuration.

16

Install Feet (pedestal only)

Insert rubber foot into chassis hole.

A

Secure foot by inserting pin through the rubber foot.

B

A

B

Note: This step applies to your chassis if configured as a pedestal system. If

you plan to configure your chassis as a rack-mount system, disregard this step.

Note: Repeat

above steps until

all four feet are

installed.

13

Install Intel® RAID Smart Battery (optional)

Align the tabs on the plastic battery holder

with the mounting holes in the chassis and

slide the plastic battery holder toward the

front of the chassis until the tabs engage with

the mounting holes.

A

15

Rack Mount Configuration

(optional)

If you intend to configure your server as a pedestal

system, disregard this step.

If you intend to configure your server as a rack mount

system, go to the instructions that came with your Rack

Mount Kit to complete your server assembly.

•

•

Page 8

14

General Installation Process

17

Install Air Duct

A

B

Install the air duct. Ensure that alignment holes and tabs

match up.

Align the air duct and chassis rail.

Note: Please order the air duct that is compatible with your server

board and chassis.

Chassis

alignment holes

Air Duct

alignment tabs

B

A

18

Install Side Cover

B

A

Slide the chassis cover on the chassis.

Secure the chassis cover with the screws .

CAUTION: This chassis must be operated with the

SIDE COVERS installed to ensure proper cooling.

Server

Board

B

B

A

19

Finishing Up

2.

1.

CAUTION:

power supply

requires a

16-gauge

power cord.

Connect the AC

power cable last.

See your Intel

®

Server

Board Quick Start

User's Guide to connect

your keyboard, mouse,

video, and other I/O cables.

AC

Power

I/O Connections

20

Install Software

• BIOS, Drivers, and Operating System Install

A. Confirm BIOS Version:

Look on the Server/System

Management screen in the BIOS Setup Utility to determine the

installed BIOS version.

Compare this to the versions at:

http://www.intel.com/support

If new versions are available, update the BIOS on your server.

See the User Guide on the Intel

®

Server Deployment and

Management DVD for update instructions.

B. Configure your RAID Controller:

Use the instructions

provided with the RAID controller.

C. Install your Operating System:

Use the instructions

provided with the RAID controller and with the operating system.

D. Install Operating System Drivers:

With the operating

system running, insert the Intel

®

Server Deployment and Management

DVD. If using a Microsoft* Windows* operating system, the

Express Installer will autorun and allow you to select the

appropriate drivers to install. On other operating systems, browse

the DVD folders to locate and install the driver files.

Page 9

15

Reference

HDD Cage Cable Connection

A

C

C

D

D

B

B

Connect the I2C cable to I2C_IN connector on bottom 8x2.5" backplane.

A

Connect Mini SAS data cables.

B

Connect power cables* (1 x 4 to 2 x 2 Power adapter cable is needed).

C

Connect the I2C cable to I2C_IN connector on bottom 8x2.5" backplane.

A

Connect Mini SAS data cables.

B

Connect power cables* (1 x 4 to 2 x 2 Power adapter cable is needed).

C

Connect I2C_OUT connector on bottom 8x2.5" backplane to I2C_IN connector

on top 8x2.5" backplane for backplane cascade.

D

Connect the I2C cable to I2C_IN connector

on bottom 8x2.5" backplane.

A

Connect Mini SAS data cables.

B

Connect power cables* (1 x 4 to 2 x 2

Power adapter cable is needed).

C

Connect the I2C cable to I2C_IN

connector on bottom 8x2.5"

backplane.

A

Connect Mini SAS data cables.

Connect the two power cables.

B

C

Connect I2C_OUT connector on bottom

8x2.5" backplane to I

2

C_IN connector

on top 8x2.5" backplane for backplane

cascade.

D

Note: Refer to the documentation that came with your server board and/or RAID controller card for instructions on connecting backplane cables to your server board or

RAID controller card.

8 x 2.5" HDD Cage

8 x 3.5" HDD Cage

16 x 2.5" HDD Cage

24 x 2.5" HDD Cage

A

C

B

A

C

D

B

C

D

B

C

D

B

D

A

B

C

Page 10

16

Reference

Front Panel Controls and Indicators

Cable Routing Diagram

A

B C

D

E F

G

H

I

A

B

C

D

E

F

G

H

I

ID Button with ID LED Integrated

USB Connectors

Reservation(Optional VGA/Serial Port)

System Reset Button

NIC LED System Power Button with Power LED

HDD Activity LED

System Status LEDNMI Button

RED indicates power cable routing

BLUE indicates data cable routing

Figure 1 Figure 2

A. CPU1/CPU2 Power Cable

B. Server Board Main Power Cable

C. Fixed HDD Power Cable

D. ODD Power Cable

E. Front Panel Cable, USB Cable

F. ODD Data Cable (Connect To White SATA 6G Connectors On Server Board)

G. Fixed HDD Data Cable

H. System FAN 1

I. System FAN 2

Description

A. CPU1/CPU2 Power Cable

B. Server Board Main Power Cable

C. Backplane Power Cable

D. ODD Power Cable

E. Front Panel Cable, USB Cable

F. ODD Data Cable (Connect To White SATA 6G Connectors On Server Board)

G. MiniSAS (with SGPIO) Cable

H. PMBus Cable

I. HSBP_I

2

C Cable (From Server Board To First Backplane)

J. HSBP_I

2

C Cable (From First Backplane To Second Backplane when Second

Backplane Available)

K. System FAN 1

L. System FAN 2

M. System FAN 3

N. System FAN 4

O. System FAN 5

Description

FAN_3

FAN_2

FAN_1

FAN_4

FAN_5

Server Board

Power Supply

CPU2

CPU1

Main Power

Front

Panel

SAS/SATA

ODD

SAS/SATA

HSBP_I

2

C

USB

PMBus

B

A

A

D

C

I

J

G

E

F

K

L

N

M

O

H

FAN_2

FAN_1

Server Board

Power Supply

CPU2

Main Power

Front

Panel

SAS/SATA

ODD

SAS/SATA

USB

PMBus

CPU1

B

A

A

D

C

G

E

F

H

I

Page 11

G49309-003

Loading...

Loading...