Page 1

Intel® Celeron® Mobile Processor

P4000 and U3000 Series

Datasheet

Revision 001

October 2010

Document Number: 324471-001

Page 2

Legal Lines and Disclaimers

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED,

BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS

PROVIDED IN INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER,

AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING

LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY

PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS OTHERWISE AGREED IN WRITING BY INTEL, THE INTEL PRODUCTS ARE NOT DESIGNED NOR INTENDED FOR ANY

APPLICATION IN WHICH THE FAILURE OF THE INTEL PRODUCT COULD CREATE A SITUATION WHERE PERSONAL INJURY OR DEATH

MAY OCCUR.

Intel may make changes to specifications and product descriptions at any time, without notice. Designers must not rely on the

absence or characteristics of any features or instructions marked “reserved” or “undefined.” Intel reserves these for future

definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from future changes to them. The

information here is subject to change without notice. Do not finalize a design with this information.

Δ Intel processor numbers are not a measure of performance. Processor numbers differentiate features within each processor

family, not across different processor families. See http://www.intel.com/products/processor_number

Intel, Intel SpeedStep, Celeron, Intel vPro and the Intel logo are trademarks of Intel Corporation in the U.S. and other countries.

*Other names and brands may be claimed as the property of others.

Copyright © 2010, Intel Corporation. All rights reserved.

2 Datasheet

for details.

Page 3

Contents

1 Features Summary ....................................................................................................9

1.1 Introduction .......................................................................................................9

1.2 Processor Feature Details ...................................................................................11

1.2.1 Supported Technologies ..........................................................................11

1.3 Interfaces......................................................................................................... 11

1.3.1 System Memory Support ......................................................................... 11

1.3.2 PCI Express* .........................................................................................12

1.3.3 Direct Media Interface (DMI).................................................................... 13

1.3.4 Platform Environment Control Interface (PECI)...........................................14

1.3.5 Intel® HD Graphics Controller.................................................................. 14

1.3.6 Embedded DisplayPort* (eDP*) ................................................................ 15

1.3.7 Intel® Flexible Display Interface (Intel® FDI) ............................................ 15

1.4 Power Management Support ............................................................................... 15

1.4.1 Processor Core.......................................................................................15

1.4.2 System ................................................................................................. 15

1.4.3 Memory Controller.................................................................................. 16

1.4.4 PCI Express* .........................................................................................16

1.4.5 DMI...................................................................................................... 16

1.4.6 Integrated Graphics Controller .................................................................16

1.5 Thermal Management Support ............................................................................16

1.6 Package ........................................................................................................... 16

1.7 Terminology ..................................................................................................... 17

1.8 Related Documents............................................................................................19

2Interfaces................................................................................................................ 20

2.1 System Memory Interface................................................................................... 20

2.1.1 System Memory Technology Supported ..................................................... 20

2.1.2 System Memory Timing Support...............................................................21

2.1.3 System Memory Organization Modes ......................................................... 21

2.1.4 Rules for Populating Memory Slots............................................................23

2.1.5 Technology Enhancements of Intel

2.1.6 DRAM Clock Generation........................................................................... 24

2.1.7 System Memory Pre-Charge Power Down Support Details ............................ 24

2.2 PCI Express Interface.........................................................................................25

2.2.1 PCI Express Architecture .........................................................................25

2.2.2 PCI Express Configuration Mechanism ....................................................... 27

2.2.3 PCI Express Ports and Bifurcation ............................................................. 27

2.3 DMI.................................................................................................................28

2.3.1 DMI Error Flow.......................................................................................28

2.3.2 Processor/PCH Compatibility Assumptions.................................................. 28

2.3.3 DMI Link Down ...................................................................................... 28

2.4 Intel® HD Graphics Controller.............................................................................29

2.4.1 3D and Video Engines for Graphics Processing............................................ 29

2.4.2 Integrated Graphics Display Pipes.............................................................32

2.4.3 Intel Flexible Display Interface ................................................................. 34

2.5 Platform Environment Control Interface (PECI)...................................................... 34

2.6 Interface Clocking ............................................................................................. 35

2.6.1 Internal Clocking Requirements................................................................ 35

®

Fast Memory Access (Intel® FMA).......... 24

Datasheet 3

Page 4

3 Technologies............................................................................................................36

3.1 Intel® Virtualization Technology ..........................................................................36

3.1.1 Intel® VT-x Objectives............................................................................36

3.1.2 Intel® VT-x Features ..............................................................................36

3.2 Intel Graphics Dynamic Frequency .......................................................................37

4 Power Management .................................................................................................38

4.1 ACPI States Supported .......................................................................................38

4.1.1 System States........................................................................................38

4.1.2 Processor Core/Package Idle States...........................................................38

4.1.3 Integrated Memory Controller States.........................................................39

4.1.4 PCIe Link States .....................................................................................39

4.1.5 DMI States ............................................................................................39

4.1.6 Integrated Graphics Controller States ........................................................39

4.1.7 Interface State Combinations ...................................................................40

4.2 Processor Core Power Management......................................................................40

4.2.1 Enhanced Intel SpeedStep® Technology....................................................41

4.2.2 Low-Power Idle States.............................................................................41

4.2.3 Requesting Low-Power Idle States ............................................................43

4.2.4 Core C-states .........................................................................................44

4.2.5 Package C-States ...................................................................................45

4.3 IMC Power Management .....................................................................................48

4.3.1 Disabling Unused System Memory Outputs.................................................49

4.3.2 DRAM Power Management and Initialization ...............................................49

4.4 PCIe Power Management ....................................................................................50

4.5 DMI Power Management .....................................................................................51

4.6 Integrated Graphics Power Management ...............................................................51

4.6.1 Intel

®

Display Power Saving Technology 5.0 (Intel®DPST 5.0).....................51

4.6.2 Graphics Render C-State .........................................................................51

4.6.3 Graphics Performance Modulation Technology.............................................51

4.6.4 Intel

®

Smart 2D Display Technology (Intel® S2DDT)...................................51

4.7 Thermal Power Management ...............................................................................52

5 Thermal Management ..............................................................................................53

5.1 Thermal Design Power and Junction Temperature...................................................53

5.1.1 Intel Graphics Dynamic Frequency ............................................................53

5.1.2 Intel Graphics Dynamic Frequency Thermal Design Considerations and

Specifications.........................................................................................54

5.1.3 Idle Power Specifications .........................................................................56

5.1.4 Intelligent Power Sharing Control Overview ................................................57

5.1.5 Component Power Measurement/Estimation Error .......................................58

5.2 Thermal Management Features............................................................................58

5.2.1 Processor Core Thermal Features..............................................................58

5.2.2 Integrated Graphics and Memory Controller Thermal Features ......................65

5.2.3 Platform Environment Control Interface (PECI) ...........................................68

6 Signal Description....................................................................................................70

6.1 System Memory Interface ...................................................................................71

6.2 Memory Reference and Compensation ..................................................................73

6.3 Reset and Miscellaneous Signals ..........................................................................74

6.4 PCI Express Graphics Interface Signals .................................................................75

6.5 Embedded DisplayPort (eDP)...............................................................................76

6.6 Intel Flexible Display Interface Signals..................................................................76

4 Datasheet

Page 5

6.7 DMI.................................................................................................................77

6.8 PLL Signals....................................................................................................... 77

6.9 TAP Signals ...................................................................................................... 78

6.10 Error and Thermal Protection ..............................................................................79

6.11 Power Sequencing .............................................................................................80

6.12 Processor Power Signals..................................................................................... 81

6.13 Ground and NCTF ..............................................................................................83

6.14 Processor Internal Pull Up/Pull Down.................................................................... 83

7 Electrical Specifications........................................................................................... 85

7.1 Power and Ground Pins ...................................................................................... 85

7.2 Decoupling Guidelines........................................................................................ 85

7.2.1 Voltage Rail Decoupling........................................................................... 85

7.3 Processor Clocking (BCLK, BCLK#) ...................................................................... 85

7.3.1 PLL Power Supply ................................................................................... 86

7.4 Voltage Identification (VID) ................................................................................86

7.5 Reserved or Unused Signals................................................................................90

7.6 Signal Groups ................................................................................................... 91

7.7 Test Access Port (TAP) Connection....................................................................... 93

7.8 Absolute Maximum and Minimum Ratings ............................................................. 94

7.9 Storage Conditions Specifications ........................................................................94

7.10 DC Specifications...............................................................................................95

7.10.1 Voltage and Current Specifications............................................................96

7.11 Platform Environmental Control Interface (PECI) DC Specifications......................... 103

7.11.1 DC Characteristics ................................................................................ 103

7.11.2 Input Device Hysteresis......................................................................... 104

8 Processor Pin and Signal Information.................................................................... 105

8.1 Processor Pin Assignments................................................................................ 105

8.2 Package Mechanical Information........................................................................ 179

Figures

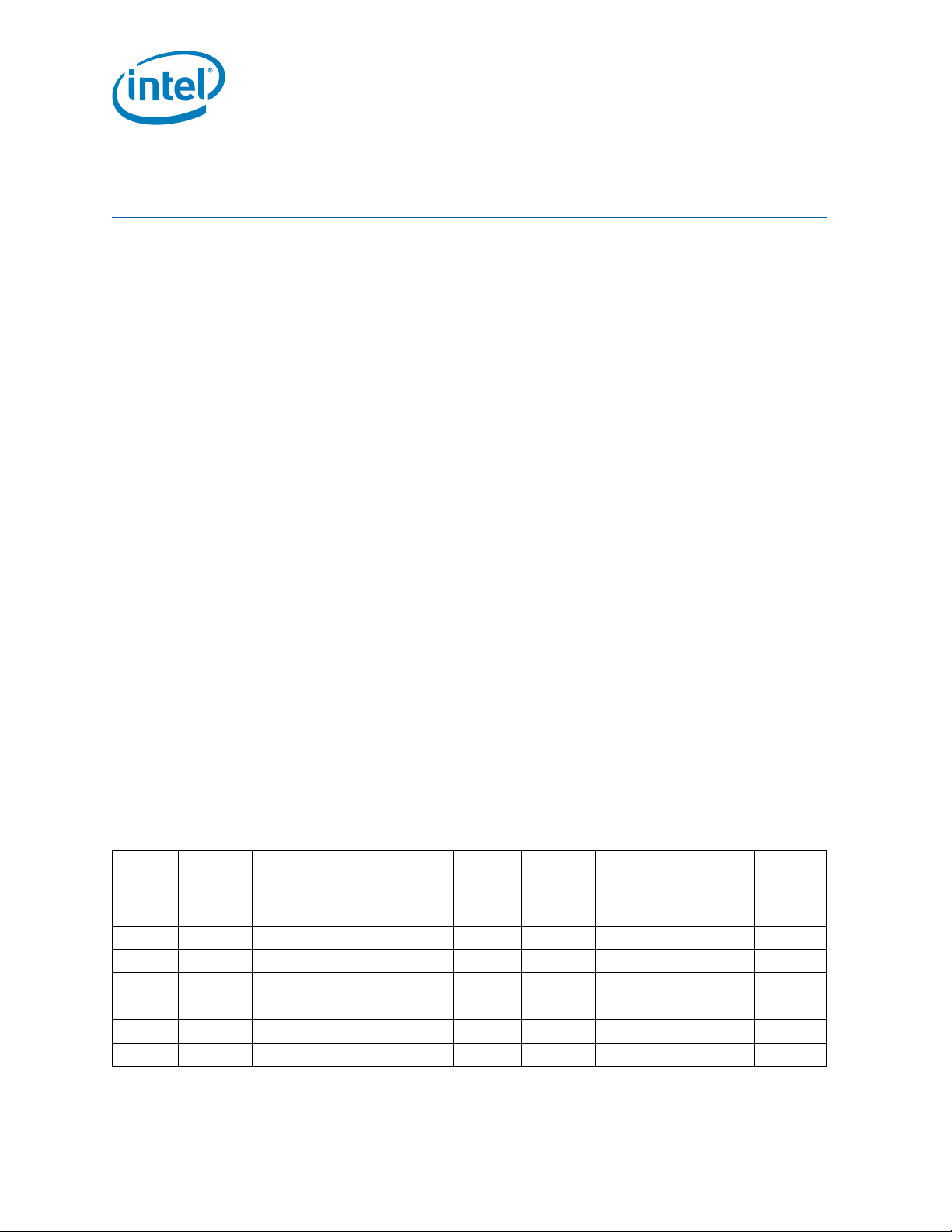

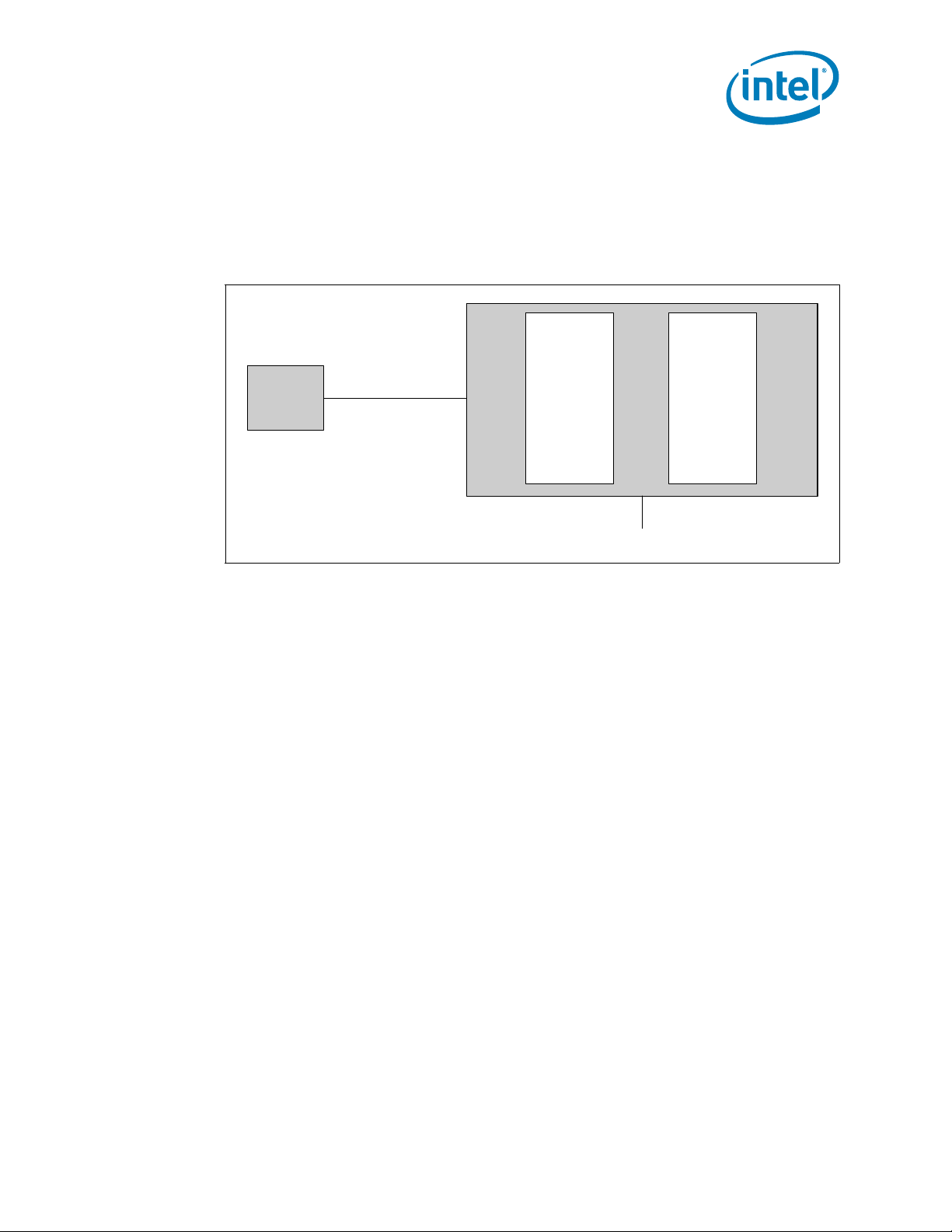

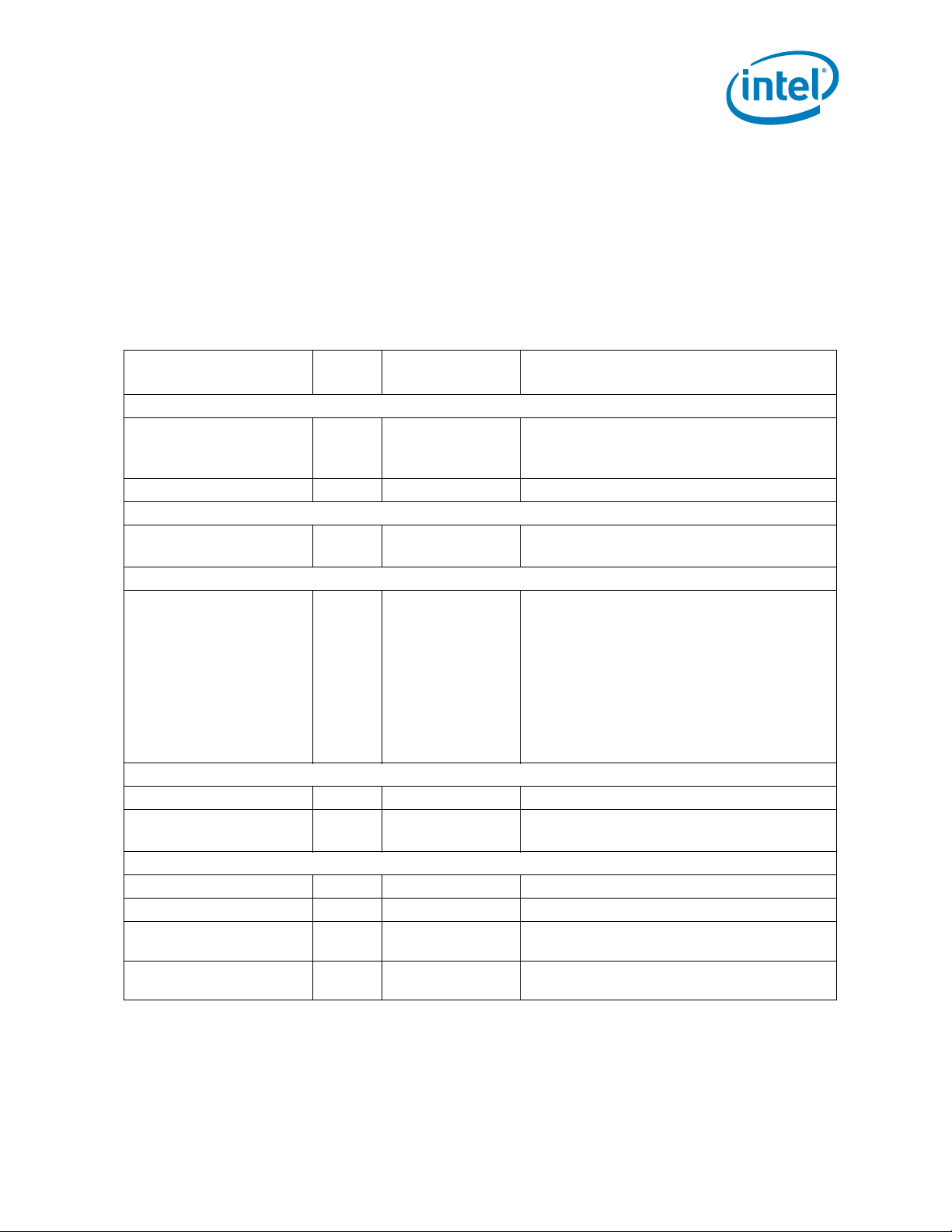

Figure 1-1 Intel® Celeron™ P4000 and U3000 mobile processor series on the Calpella

Platform................................................................................................ 10

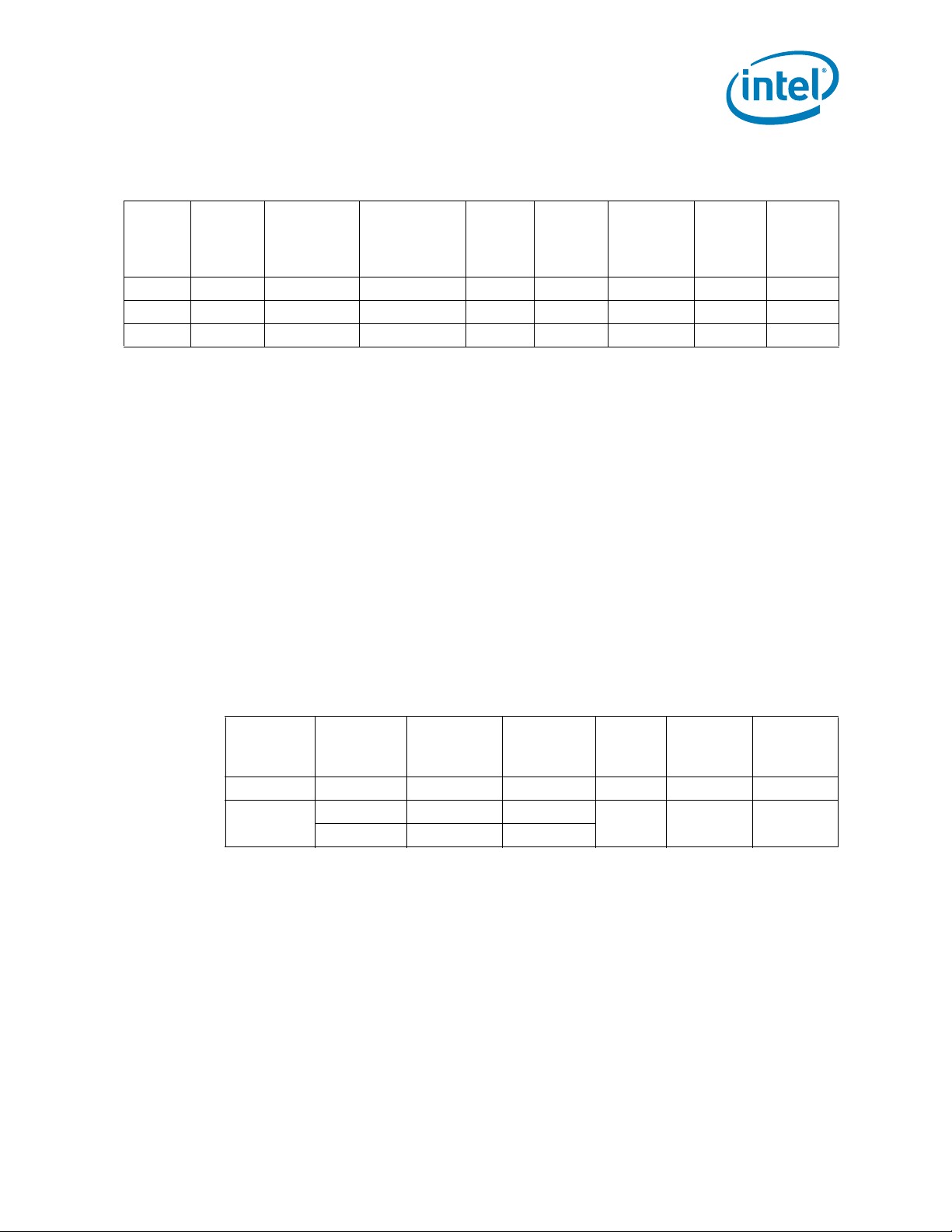

Figure 2-2 Intel Flex Memory Technology Operation ................................................... 22

Figure 2-3 Dual-Channel Symmetric (Interleaved) and Dual-Channel Asymmetric Modes. 23

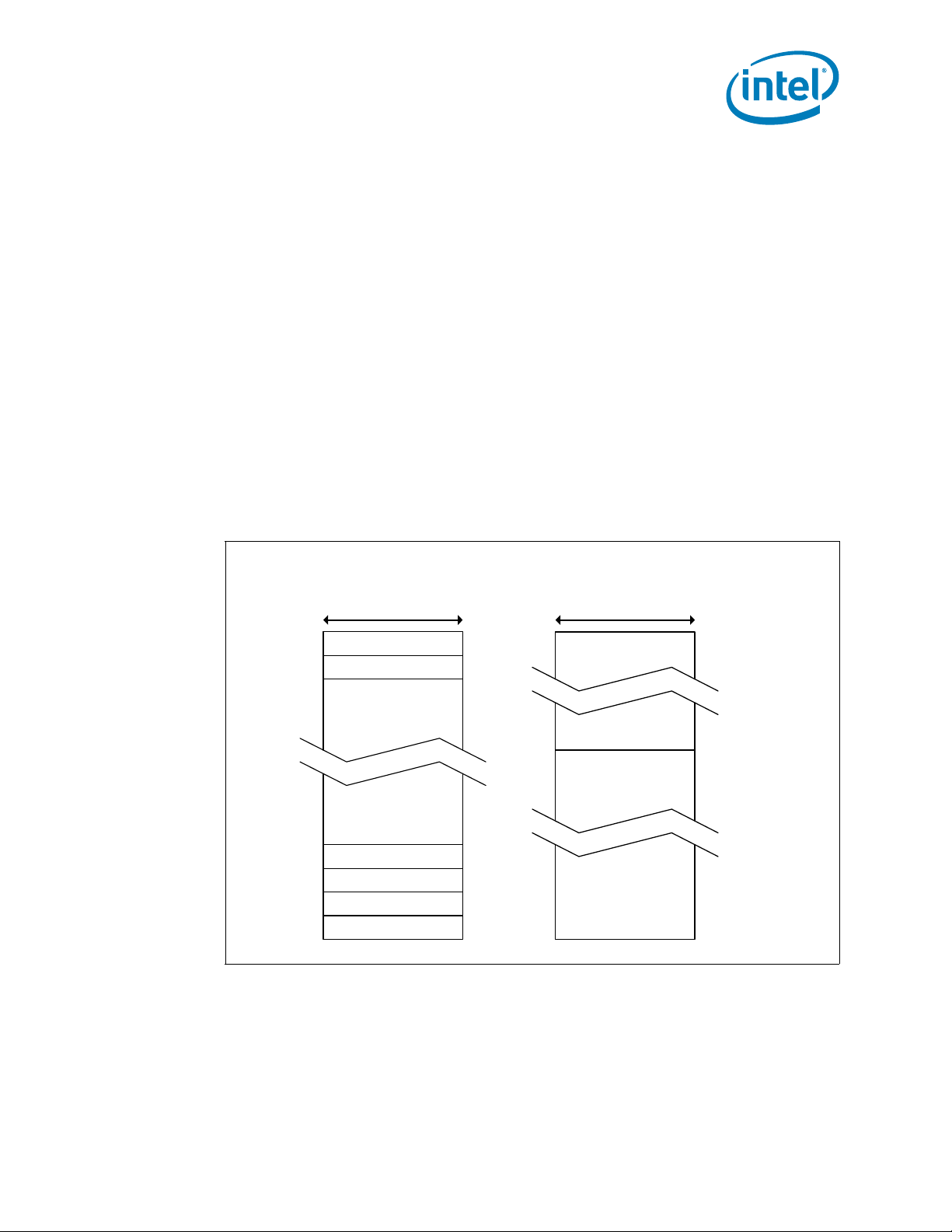

Figure 2-4 PCI Express Layering Diagram ................................................................. 25

Figure 2-5 Packet Flow through the Layers................................................................ 26

Figure 2-6 PCI Express Related Register Structures in the Processor ............................. 27

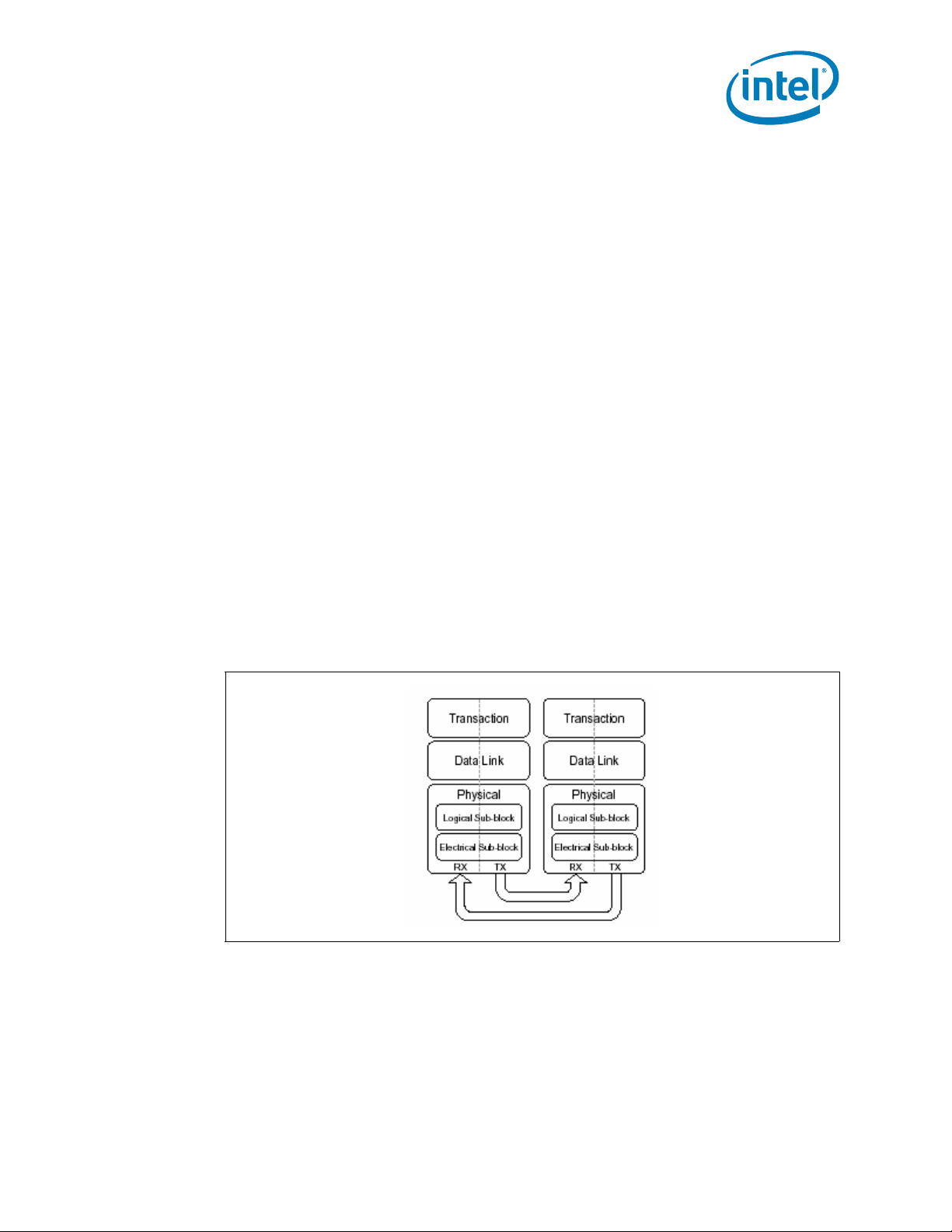

Figure 2-7 Integrated Graphics Controller Unit Block Diagram......................................29

Figure 2-8 Processor Display Block Diagram ..............................................................32

Figure 4-9 Idle Power Management Breakdown of the Processor Cores..........................42

Figure 4-10 Thread and Core C-State Entry and Exit ....................................................42

Figure 4-11 Package C-State Entry and Exit ................................................................47

Figure 5-12 Frequency and Voltage Ordering............................................................... 60

Figure 7-13 Active V

Figure 7-14 Active VCC and ICC Loadline (PSI# Not Asserted) ........................................ 97

Figure 7-15 VAXG/IAXG Static and Ripple Voltage Regulation ........................................ 99

Figure 7-16 Input Device Hysteresis......................................................................... 104

Figure 8-17 Socket-G (rPGA988A) Pinmap (Top View, Upper-Left Quadrant).................. 106

Figure 8-18 Socket-G (rPGA988A) Pinmap (Top View, Upper-Right Quadrant)................ 107

and ICC Loadline (PSI# Asserted) ..............................................97

CC

Datasheet 5

Page 6

Figure 8-19 Socket-G (rPGA988A) Pinmap (Top View, Lower-Left Quadrant) ..................108

Figure 8-20 Socket-G (rPGA988A) Pinmap (Top View, Lower-Right Quadrant) ................ 109

Figure 8-21 BGA1288 Ballmap (Top View, Upper-Left Quadrant) ..................................138

Figure 8-22 BGA1288 Ballmap (Top View, Upper-Right Quadrant) ................................139

Figure 8-23 BGA1288 Ballmap (Top View, Lower-Left Quadrant) ..................................140

Figure 8-24 BGA1288 Ballmap (Top View, Lower-Right Quadrant) ................................141

Figure 8-25 rPGA Mechanical Package (Sheet 1 of 2) ................................................. 179

Figure 8-26 rPGA Mechanical Package (Sheet 2 of 2) ..................................................180

Figure 8-27 BGA Mechanical Package (Sheet 2 of 2)...................................................181

Tables

Table 2-1 Supported SO-DIMM Module Configurations1..............................................20

Table 2-2 DDR3 System Memory Timing Support ......................................................21

Table 2-3 eDP/PEG Ball Mapping .............................................................................33

Table 2-4 Processor Reference Clocks ......................................................................35

Table 4-5 System States........................................................................................38

Table 4-6 Processor Core/Package State Support ......................................................38

Table 4-7 Integrated Memory Controller States.........................................................39

Table 4-8 PCIe Link States .....................................................................................39

Table 4-9 DMI States ............................................................................................39

Table 4-10 Integrated Graphics Controller States ........................................................39

Table 4-11 G, S and C State Combinations.................................................................40

Table 4-12 D, S, and C State Combination .................................................................40

Table 4-13 Coordination of Thread Power States at the Core Level ................................43

Table 4-14 P_LVLx to MWAIT Conversion ...................................................................43

Table 4-15 Coordination of Core Power States at the Package Level...............................46

Table 4-16 Targeted Memory State Conditions............................................................50

Table 5-17 Intel Celeron P4000 mobile processor series Dual-Core SV Thermal Power

Specifications.........................................................................................56

Table 5-18 18 W Ultra Low Voltage (ULV) Processor Idle Power ....................................56

Table 5-19 35 W Standard Voltage (SV) Processor Idle Power.......................................57

Table 6-20 Signal Description Buffer Types ................................................................70

Table 6-21 Memory Channel A..................................................................................71

Table 6-22 Memory Channel B..................................................................................72

Table 6-23 Memory Reference and Compensation .......................................................73

Table 6-24 Reset and Miscellaneous Signals ...............................................................74

Table 6-25 PCI Express Graphics Interface Signals ......................................................75

Table 6-26 Intel® Flexible Display Interface...............................................................76

Table 6-27 DMI - Processor to PCH Serial Interface .....................................................77

Table 6-28 PLL Signals ............................................................................................77

Table 6-29 TAP Signals............................................................................................78

Table 6-30 Error and Thermal Protection....................................................................79

Table 6-31 Power Sequencing ..................................................................................80

Table 6-32 Processor Power Signals ..........................................................................81

Table 6-33 Ground and NCTF ...................................................................................83

Table 6-34 Processor Internal Pull Up/Pull Down .........................................................83

Table 7-35 Voltage Identification Definition ................................................................86

Table 7-36 Market Segment Selection Truth Table for MSID[2:0] ..................................90

Table 7-37 Signal Groups1.......................................................................................91

Table 7-38 Processor Absolute Minimum and Maximum Ratings ....................................94

Table 7-39 Storage Condition Ratings........................................................................95

6 Datasheet

Page 7

Table 7-40 Processor Core (VCC) Active and Idle Mode DC Voltage and Current Specifications

96

Table 7-41 Processor Uncore I/O Buffer Supply DC Voltage and Current Specifications..... 98

Table 7-42 Processor Graphics VID based (VAXG) Supply DC Voltage and Current

Specifications.........................................................................................99

Table 7-43 DDR3 Signal Group DC Specifications ...................................................... 100

Table 7-44 Control Sideband and TAP Signal Group DC Specifications.......................... 101

Table 7-45 PCI Express DC Specifications ................................................................ 102

Table 7-46 eDP DC Specifications ........................................................................... 103

Table 7-47 PECI DC Electrical Limits ....................................................................... 104

Table 8-48 rPGA988A Processor Pin List by Pin Number ............................................. 110

Table 8-49 rPGA988A Processor Pin List by Pin Name................................................ 124

Table 8-50 BGA1288 Processor Ball List by Ball Name ............................................... 142

Table 8-51 BGA1288 Processor Ball List by Ball Number ............................................ 160

Datasheet 7

Page 8

Revision History

Revision

Number

001 Initial release October 2010

Description Revision Date

§

8 Datasheet

Page 9

Features Summary

1 Features Summary

1.1 Introduction

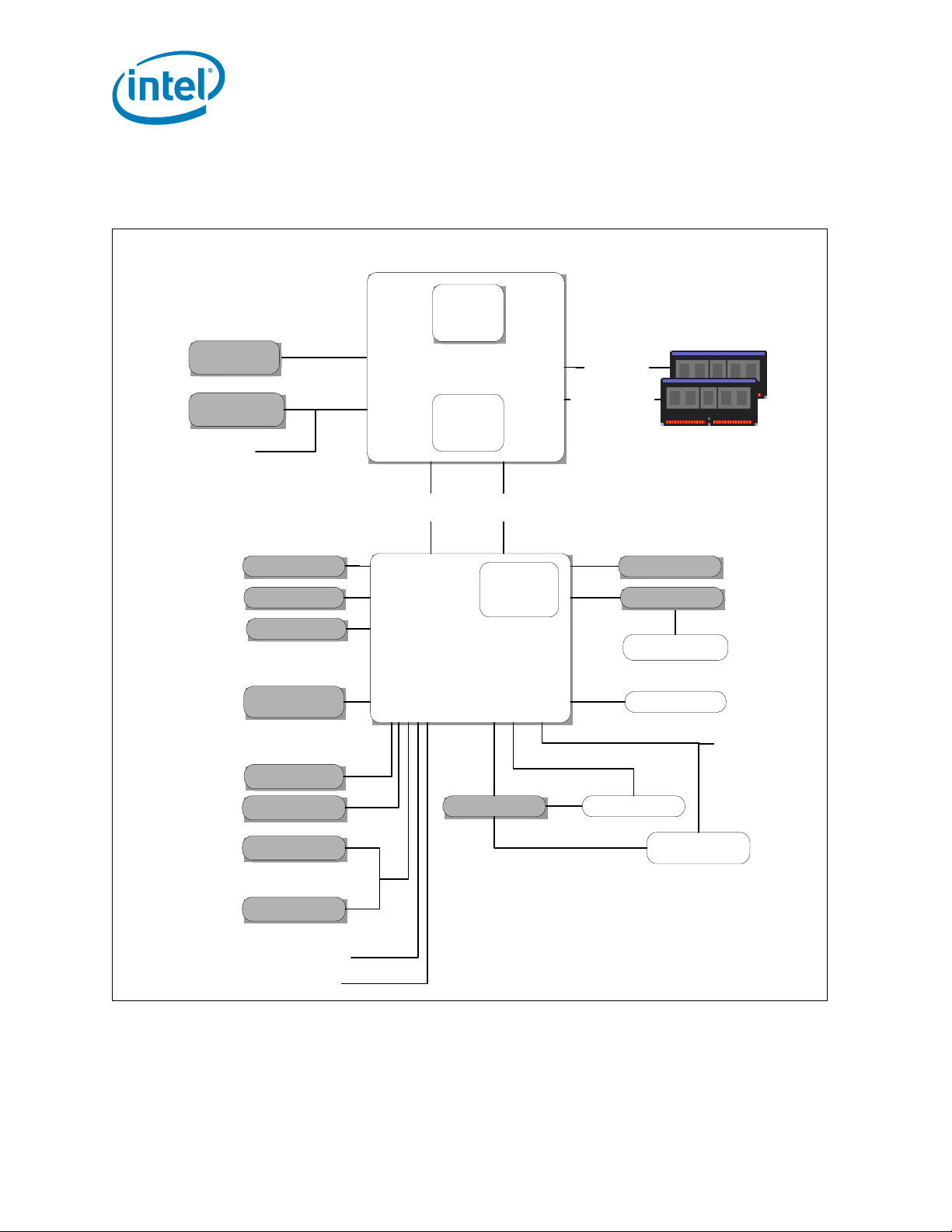

Intel® Celeron® P4000 and U3000 mobile processor seriesis the next generation of

64-bit, multi-core mobile processor built on 32-nanometer process technology. Based

on the low-power/high-performance Nehalem micro-architecture, the processor is

designed for a two-chip platform as opposed to the traditional three-chip platforms

(processor, GMCH, and ICH). The two-chip platform consists of a processor and the

Platform Controller Hub (PCH) and enables higher performance, lower cost, easier

validation, and improved x-y footprint. The PCH may also be referred to as Mobile

Intel® 5 Series Chipset (formerly Ibex Peak-M). Intel® Celeron® P4000 and U3000

mobile processor series is designed for the Calpella platform and is offered in rPGA988A

and BGA1288 package respectively.

Included in this family of processors is Intel® HD graphics and memory controller die

on the same package as the processor core die. This two-chip solution of a processor

core die with an integrated graphics and memory controller die is known as a multi-chip

package (MCP) processor.

Note:

1. Throughout this document, Intel® Celeron® P4000 and U3000 mobile processor

series is referred to as processor.

2. Throughout this document, Intel® HD graphics is referred as integrated graphics.

3. Integrated graphics and memory controller die is built on 45-nanometer process

technology

4. Intel® Celeron® P4000 and U3000 mobile processor seriesis not Intel® vPro™

eligible

Datasheet 9

Page 10

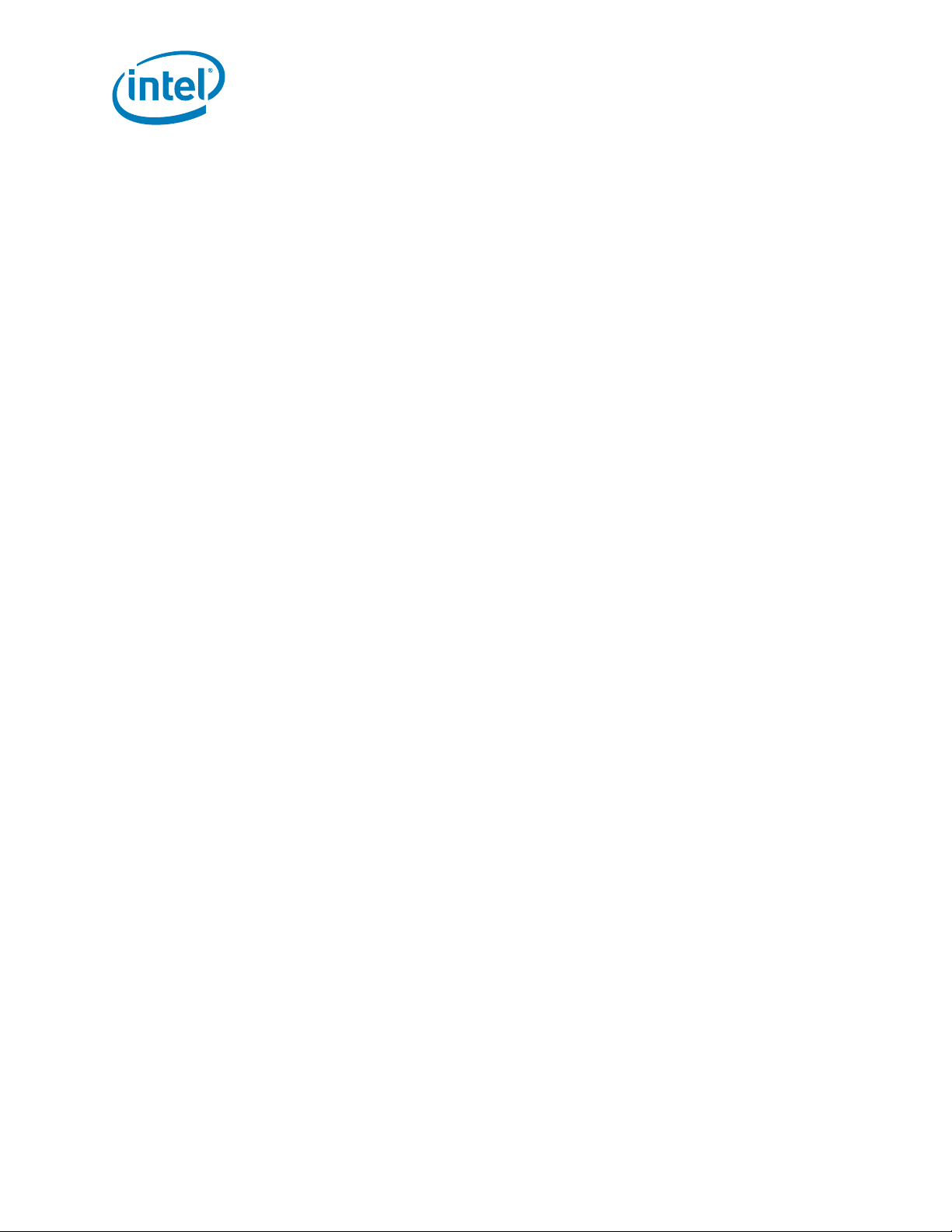

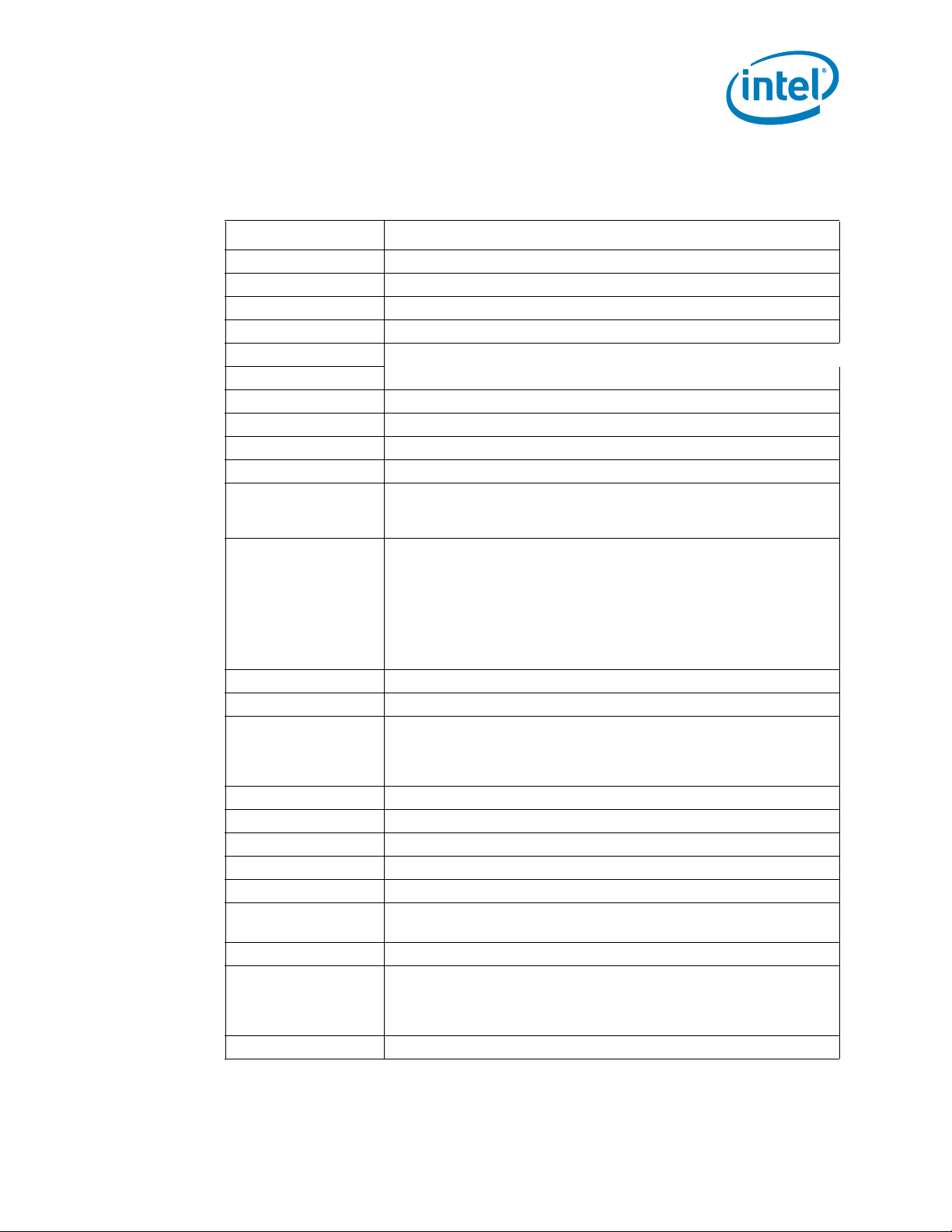

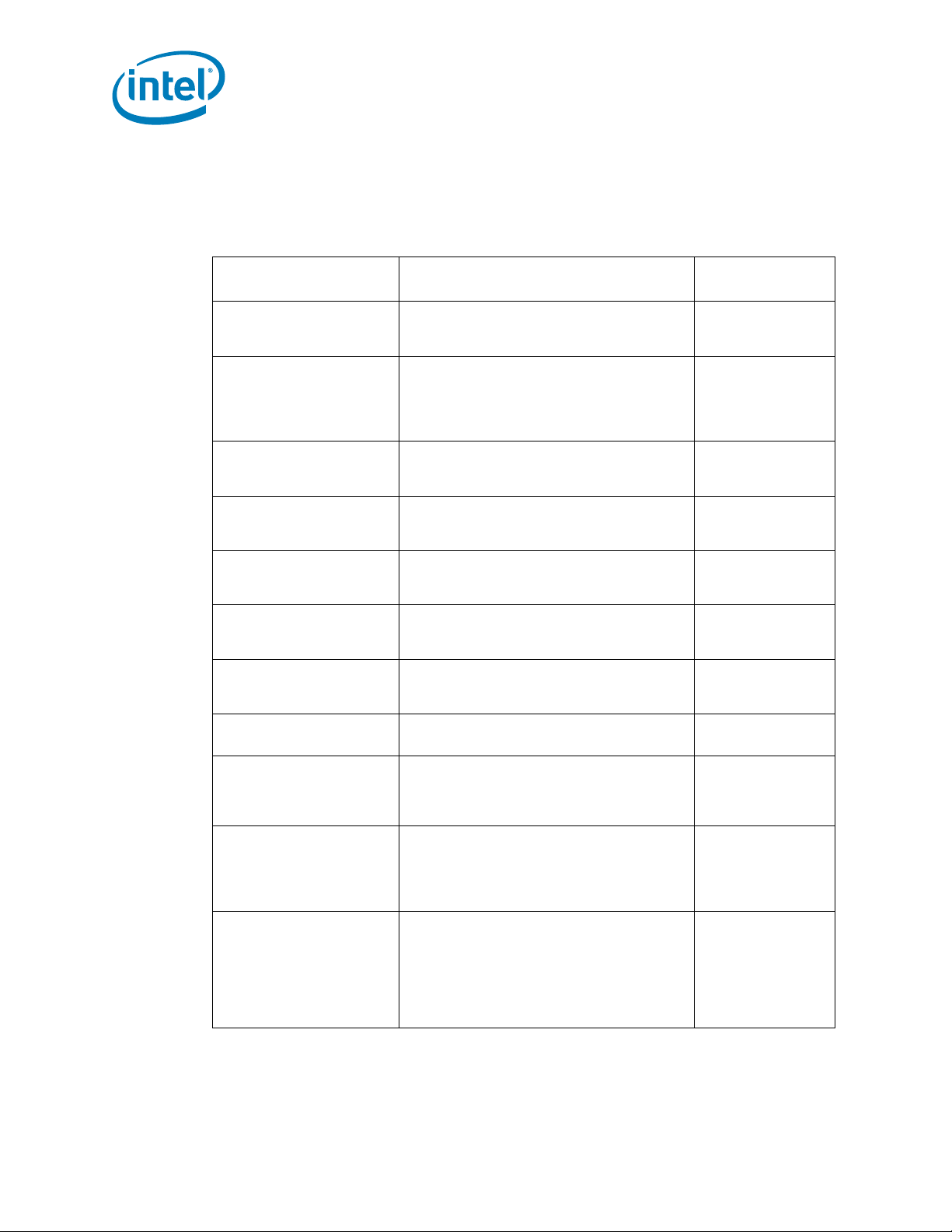

Features Summary

Processor

Discrete Graphics

(PEG)

Analog CRT

Gigabit

Network Connection

USB 2.0

Intel® HD Audio

FWH

Super I/O

PCI

Serial ATA

Mobile Intel® 5 Series Chipset

PCH

DDR3 SO-DIMMs

PCI Express* x16

8 PCI Express* x1

Ports

(2.5 GT/s)

14 Ports

PCI

6 Ports

3 Gb/s

SPI

Digital Display x 3

Intel® Flexible

Display Interface

PCI Express*

WiMax

SPI Flash

LPC

SMBUS 2.0

PECI

GPIO

OR

GPU, Memory

Controller

Dual Core

Processor

800/1066 MT/s

2 Channels

1 SO-DIMM / Channel

DMI2

(x4)

Dual Channel NAND

Interface

LVDS Flat Panel

Intel®

Management

Engine

WiFi

Controller Link 1

Embedded

DisplayPort* (eDP)

PCI Express x 1

Figure 1-1.Intel® Celeron® P4000 and U3000 mobile processor series on the Calpella

Platform

10 Datasheet

Page 11

Features Summary

1.2 Processor Feature Details

• Two execution cores

• A 32-KB instruction and 32-KB data first-level cache (L1) for each core

• A 512-KB shared instruction/data second-level cache (L2), 256-KB for each core

• Up to 2-MB shared instruction/data third-level cache (L3), shared among all cores

1.2.1 Supported Technologies

• Intel® Virtualization Technology (Intel® VT-x)

• Intel® 64 architecture

• Execute Disable Bit

Note: Please refer to the Intel® Celeron® P4000 and U3000 mobile processor series

Specification Update for feature support details

1.3 Interfaces

1.3.1 System Memory Support

• One or two channels of DDR3 memory with a maximum of one SO-DIMM per

channel

• Single- and dual-channel memory organization modes

• Data burst length of eight for all memory organization modes

• Memory DDR3 data transfer rates of 800 MT/s (SV/ULV) and 1066 MT/s (SV)

• 64-bit wide channels

• DDR3 I/O Voltage of 1.5 V

• Non-ECC, unbuffered DDR3 SO-DIMMs only

• Theoretical maximum memory bandwidth of:

— 12.8 GB/s in dual-channel mode assuming DDR3 800 MT/s

• 1-Gb, and 2-Gb DDR3 DRAM technologies are supported for x8 and x16 devices.

• Using 2-Gb device technologies, the largest memory capacity possible is 8 GB,

assuming dual-channel mode with two x8, double-sided, un-buffered, non-ECC,

SO-DIMM memory configuration.

• Up to 32 simultaneous open pages, 16 per channel (assuming 4 Ranks of 8 Bank

Devices)

• Memory organizations:

— Single-channel modes

— Dual-channel modes - Intel® Flex Memory Technology:

Datasheet 11

Page 12

Dual-channel symmetric (Interleaved)

Dual-channel asymmetric

• Command launch modes of 1n/2n

• Partial Writes to memory using Data Mask (DM) signals

• On-Die Termination (ODT)

• Intel® Fast Memory Access (Intel® FMA):

— Just-in-Time Command Scheduling

— Command Overlap

— Out-of-Order Scheduling

1.3.2 PCI Express*

• The Processor PCI Express ports are fully compliant to the PCI Express Base

Specification Revision 2.0.

— One 16-lane PCI Express* port intended for graphics attach.

• Gen1 (2.5 GT/s) PCI Express* frequency is supported.

Features Summary

• Gen1 Raw bit-rate on the data pins of 2.5 Gb/s, resulting in a real bandwidth per

pair of 250 MB/s given the 8b/10b encoding used to transmit data across this

interface. This also does not account for packet overhead and link maintenance.

• Maximum theoretical bandwidth on interface of 4 GB/s in each direction

simultaneously, for an aggregate of 8 GB/s when x16 Gen 1.

• Hierarchical PCI-compliant configuration mechanism for downstream devices.

• Traditional PCI style traffic (asynchronous snooped, PCI ordering).

• PCI Express extended configuration space. The first 256 bytes of configuration

space aliases directly to the PCI compatibility configuration space. The remaining

portion of the fixed 4-KB block of memory-mapped space above that (starting at

100h) is known as “extended configuration space”.

• PCI Express Enhanced Access Mechanism. Accessing the device configuration space

in a flat memory mapped fashion.

• Automatic discovery, negotiation, and training of link out of reset.

• Traditional AGP style traffic (asynchronous non-snooped, PCI-X Relaxed ordering).

• Peer segment destination posted write traffic (no peer-to-peer read traffic) in

Virtual Channel 0:

— DMI -> PCI Express Port 0

• 64-bit downstream address format, but the processor never generates an address

above 64 GB (Bits 63:36 will always be zeros).

• 64-bit upstream address format, but the processor responds to upstream read

transactions to addresses above 64 GB (addresses where any of Bits 63:36 are

12 Datasheet

Page 13

Features Summary

• Re-issues configuration cycles that have been previously completed with the

• PCI Express reference clock is 100-MHz differential clock buffered out of system

• Power Management Event (PME) functions.

• Static lane numbering reversal

• Supports Half Swing “low-power/low-voltage” mode.

• Message Signaled Interrupt (MSI and MSI-X) messages

• PEG Lanes shared with Embedded DisplayPort* (see eDP, Section 1.3.6).

• Polarity inversion

non-zero) with an Unsupported Request response. Upstream write transactions to

addresses above 64 GB will be dropped.

Configuration Retry status.

clock generator.

— Does not support dynamic lane reversal, as defined (optional) by the PCI

Express Base Specification.

— PCI Express 1x16 configuration

Normal (1x16): PEG_RX[15:0]; PEG_TX[15:0]

Reversal (1x16): PEG_RX[0:15]; PEG_TX[0:15]

1.3.3 Direct Media Interface (DMI)

• Compliant to Direct Media Interface second generation (DMI2).

• Four lanes in each direction.

• 2.5 GT/s point-to-point DMI interface to PCH is supported.

• Raw bit-rate on the data pins of 2.5 Gb/s, resulting in a real bandwidth per pair of

250 MB/s given the 8b/10b encoding used to transmit data across this interface.

Does not account for packet overhead and link maintenance.

• Maximum theoretical bandwidth on interface of 1 GB/s in each direction

simultaneously, for an aggregate of 2 GB/s when DMI x4.

• Shares 100-MHz PCI Express reference clock.

• 64-bit downstream address format, but the processor never generates an address

above 64 GB (Bits 63:36 will always be zeros).

• 64-bit upstream address format, but the processor responds to upstream read

transactions to addresses above 64 GB (addresses where any of Bits 63:36 are

nonzero) with an Unsupported Request response. Upstream write transactions to

addresses above 64 GB will be dropped.

• Supports the following traffic types to or from the PCH:

— DMI -> PCI Express Port 0 write traffic

—DMI -> DRAM

— DMI -> processor core (Virtual Legacy Wires (VLWs), Resetwarn, or MSIs only)

Datasheet 13

Page 14

— Processor core -> DMI

• APIC and MSI interrupt messaging support:

— Message Signaled Interrupt (MSI and MSI-X) messages

• Downstream SMI, SCI and SERR error indication.

• Legacy support for ISA regime protocol (PHOLD/PHOLDA) required for parallel port

DMA, floppy drive, and LPC bus masters.

• DC coupling – no capacitors between the processor and the PCH.

• Polarity inversion.

• PCH end-to-end lane reversal across the link.

• Supports Half Swing “low-power/low-voltage.”

1.3.4 Platform Environment Control Interface (PECI)

The PECI is a one-wire interface that provides a communication channel between a

PECI client (the processor) and a PECI master (the PCH).

Features Summary

1.3.5 Intel® HD Graphics Controller

• The integrated graphics controller contains a refresh of the fifth generation graphics

core

• Intel® Dynamic Video Memory Technology (Intel® DVMT) support

• Intel® Graphics Performance Modulation Technology (Intel® GPMT)

• Intel® Smart 2D Display Technology (Intel® S2DDT)

• Intel® Clear Video Technology

— MPEG2 Hardware Acceleration

— WMV9/VC1 Hardware Acceleration

— AVC Hardware Acceleration

—ProcAmp

— Advanced Pixel Adaptive De-interlacing

— Sharpness Enhancement

— De-noise Filter

— High Quality Scaling

— Film Mode Detection (3:2 pull-down) and Correction

—Intel® TV Wizard

• 12 EUs

• Dedicated analog and digital display ports are supported through the Intel 5 Series

Chipset PCH

14 Datasheet

Page 15

Features Summary

1.3.6 Embedded DisplayPort* (eDP*)

• Shared with PCI Express Graphics port

• Shared on upper four logical lanes, after any lane reversal

• eDP[3:0] map to PEG[12:15] (non-reversed)

• eDP[3:0] map to PEG[3:0] (reversed)

• Concurrent eDP and PEG x1 supported

1.3.7 Intel® Flexible Display Interface (Intel® FDI)

• Carries display traffic from the integrated graphics controller in the processor to the

legacy display connectors in the PCH.

• Based on DisplayPort standard.

• Two independent links - one for each display pipe.

• Four unidirectional downstream differential transmitter pairs:

— Scalable down to 3X, 2X, or 1X based on actual display bandwidth requirements

— Fixed frequency 2.7 GT/s data rate

• Two sideband signals for Display synchronization:

— FDI_FSYNC and FDI_LSYNC (Frame and Line Synchronization)

• One Interrupt signal used for various interrupts from the PCH:

— FDI_INT signal shared by both Intel FDI Links

• PCH supports end-to-end lane reversal across both links.

1.4 Power Management Support

1.4.1 Processor Core

• Full support of ACPI C-states as implemented by the following processor C-states:

— Ultra low voltage supports C0, C1, C1E, C3, Deep Power Down Technology (code

named C6)

— Standard voltage supports C0, C1, C1E, C3

• Enhanced Intel SpeedStep® Technology

1.4.2 System

• S0, S3, S4, S5

Datasheet 15

Page 16

1.4.3 Memory Controller

• Conditional self-refresh (Intel® Rapid Memory Power Management (Intel® RMPM))

• Dynamic power-down

1.4.4 PCI Express*

• L0s and L1 ASPM power management capability

1.4.5 DMI

• L0s and L1 ASPM power management capability

1.4.6 Integrated Graphics Controller

• Intel Smart 2D Display Technology (Intel S2DDT)

• Intel® Display Power Saving Technology (Intel® DPST)

• Graphics Render C-State (RC6)

Features Summary

1.5 Thermal Management Support

• Digital Thermal Sensor

• Adaptive Thermal Monitor

• THERMTRIP# and PROCHOT# support

• On-Demand Mode

• Open and Closed Loop Throttling

• Memory Thermal Throttling

• External Thermal Sensor (TS-on-DIMM and TS-on-Board)

• Render Thermal Throttling

• Fan speed control with DTS

1.6 Package

• The Intel® Celeron® P4000 and U3000 mobile processor series is available is

available on:

— A 37.5 x 37.5 mm rPGA package (rPGA988A) (Standard Voltage only)

— A 34 x 28 mm BGA package (BGA1288) (Ultra Low voltage only)

16 Datasheet

Page 17

Features Summary

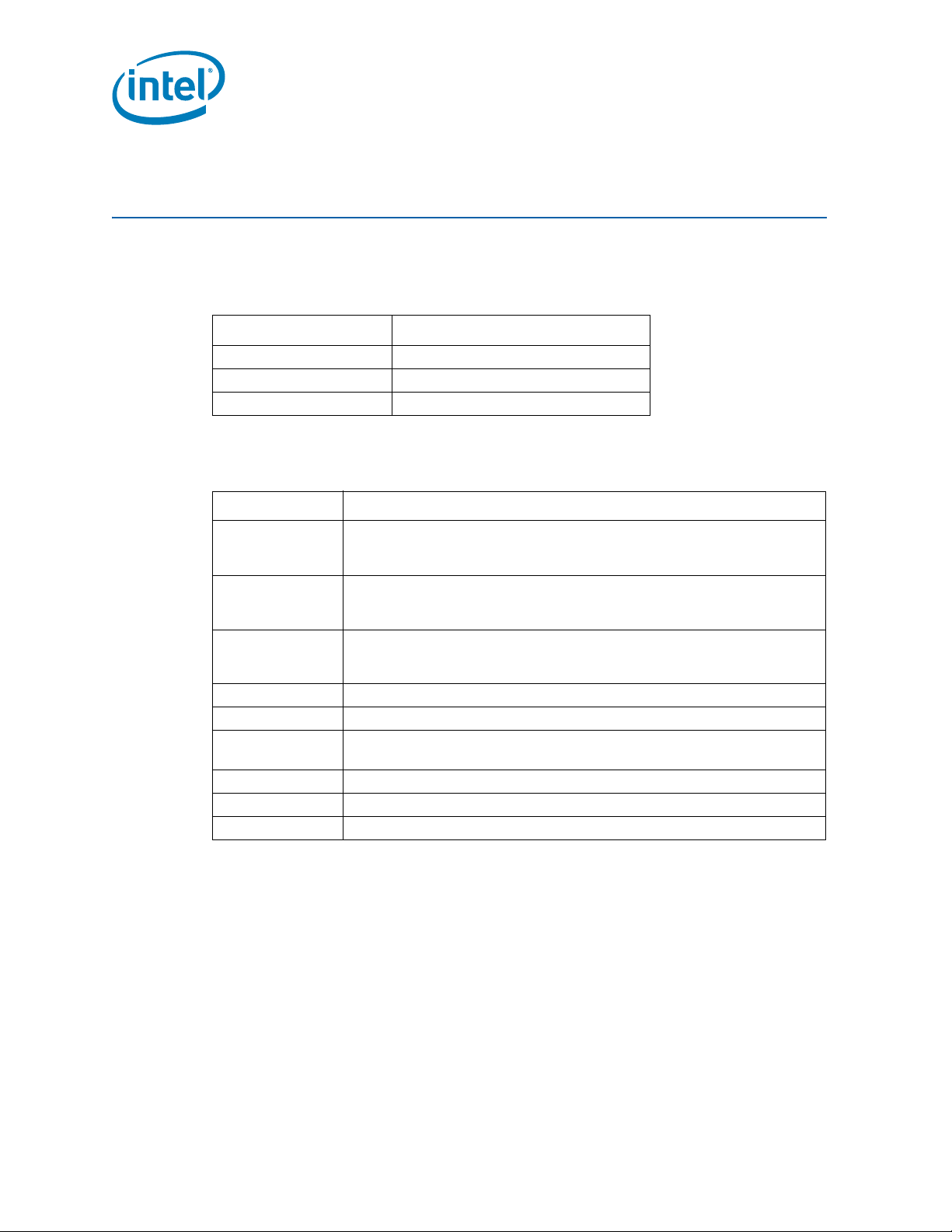

1.7 Terminology

Term Description

BLT Block Level Transfer

CRT Cathode Ray Tube

DDR3 Third-generation Double Data Rate SDRAM memory technology

DP DisplayPort*

DMA Direct Memory Access

DMI Direct Media Interface

DTS Digital Thermal Sensor

ECC Error Correction Code

eDP* Embedded DisplayPort*

Intel® DPST Intel

Enhanced Intel

SpeedStep®

Tech no logy

Execute Disable Bit The Execute Disable bit allows memory to be marked as executable or

(G)MCH Legacy component - Graphics Memory Controller Hub

GPU Graphics Processing Unit

ICH The legacy I/O Controller Hub component that contains the main PCI

IMC Integrated Memory Controller

Intel® 64 Technology 64-bit memory extensions to the IA-32 architecture

ITPM Integrated Trusted Platform Module

IOV I/O Virtualization

LCD Liquid Crystal Display

LVDS Low Voltage Differential Signaling. A high speed, low power data

MCP Multi-Chip Package.

NCTF Non-Critical to Function. NCTF locations are typically redundant

Nehalem Intel’s 45-nm processor design, follow-on to the 45-nm Penryn design.

®

Display Power Saving Technology

Technology that provides power management capabilities to laptops.

non-executable, when combined with a supporting operating system.

If code attempts to run in non-executable memory the processor

raises an error to the operating system. This feature can prevent some

classes of viruses or worms that exploit buffer overrun vulnerabilities

and can thus help improve the overall security of the system. See the

Intel® 64 and IA-32 Architectures Software Developer's Manuals for

more detailed information.

interface, LPC interface, USB2, Serial ATA, and other I/O functions. It

communicates with the legacy (G)MCH over a proprietary interconnect

called DMI.

transmission standard used for display connections to LCD panels.

ground or non-critical reserved, so the loss of the solder joint

continuity at end of life conditions will not affect the overall product

functionality.

Datasheet 17

Page 18

Features Summary

Term Description

PCH Platform Controller Hub. The new, 2009 chipset with centralized

platform capabilities including the main I/O interfaces along with

display connectivity, audio features, power management,

manageability, security and storage features. The PCH may also be

referred to using the name (Mobile) Intel® 5 Series Chipset

PECI Platform Environment Control Interface.

PEG PCI Express* Graphics. External Graphics using PCI Express

Architecture. A high-speed serial interface whose configuration is

software compatible with the existing PCI specifications.

Processor The 64-bit, single-core or multi-core component (package).

Processor Core The term “processor core” refers to Si die itself which can contain

multiple execution cores. Each execution core has an instruction

cache, data cache, and 256-KB L2 cache. All execution cores share the

L3 cache.

Rank A unit of DRAM corresponding four to eight devices in parallel, ignoring

ECC. These devices are usually, but not always, mounted on a single

side of a SO-DIMM.

SCI System Control Interrupt. Used in ACPI protocol.

Storage Conditions A non-operational state. The processor may be installed in a platform,

in a tray, or loose. Processors may be sealed in packaging or exposed

to free air. Under these conditions, processor landings should not be

connected to any supply voltages, have any I/Os biased or receive any

clocks. Upon exposure to “free air” (i.e., unsealed packaging or a

device removed from packaging material) the processor must be

handled in accordance with moisture sensitivity labeling (MSL) as

indicated on the packaging material.

TAC Thermal Averaging Constant.

TDP Thermal Design Power.

V

V

V

V

V

CC

SS

AXG

TT

DDQ

Processor core power supply.

Processor ground.

Graphics core power supply.

L3 shared cache, memory controller, and processor I/O power rail.

DDR3 power rail.

VLD Variable Length Decoding.

x1 Refers to a Link or Port with one Physical Lane.

x4 Refers to a Link or Port with four Physical Lanes.

x8 Refers to a Link or Port with eight Physical Lanes.

x16 Refers to a Link or Port with sixteen Physical Lanes.

18 Datasheet

Page 19

Features Summary

1.8 Related Documents

Document

Public Specifications

Advanced Configuration and Power Interface Specification 3.0 http://www.acpi.info/

PCI Local Bus Specification 3.0 http://www.pcisig.com/

PCI Express Base Specification 2.0 http://www.pcisig.com

DDR3 SDRAM Specification http://www.jedec.org

DisplayPort Specification http://www.vesa.org

Intel® 64 and IA-32 Architectures Software Developer's Manuals http://www.intel.com/

Volume 1: Basic Architecture 253665

Volume 2A: Instruction Set Reference, A-M 253666

Volume 2B: Instruction Set Reference, N-Z 253667

Volume 3A: System Programming Guide 253668

Volume 3B: System Programming Guide 253669

Document Number/

Location

specifications

products/processor/

manuals/index.htm

§

Datasheet 19

Page 20

2 Interfaces

This chapter describes the interfaces supported by the processor.

2.1 System Memory Interface

2.1.1 System Memory Technology Supported

The Integrated Memory Controller (IMC) supports DDR3 protocols with two,

independent, 64-bit wide channels each accessing one SO-DIMM. It supports a

maximum of one, unbuffered non-ECC DDR3 SO-DIMM per-channel thus allowing up to

two device ranks per-channel.

DDR3 Data Transfer Rates:

— 800 MT/s (PC3-6400) and 1066 MT/s (PC3-8500)

Interfaces

• DDR3 SO-DIMM Modules:

— Raw Card A – double-sided x16 unbuffered non-ECC

— Raw Card B – single-sided x8 unbuffered non-ECC

— Raw Card C – single-sided x16 unbuffered non-ECC

— Raw Card D – double-sided x8 (stacked) unbuffered non-ECC

— Raw Card F – double-sided x8 (planar) unbuffered non-ECC

• DDR3 DRAM Device Technology:

— Standard 1-Gb, and 2-Gb technologies and addressing are supported for x16

and x8 devices. There is no support for memory modules with different

technologies or capacities on opposite sides of the same memory module. If one

side of a memory module is populated, the other side is either identical or

empty.

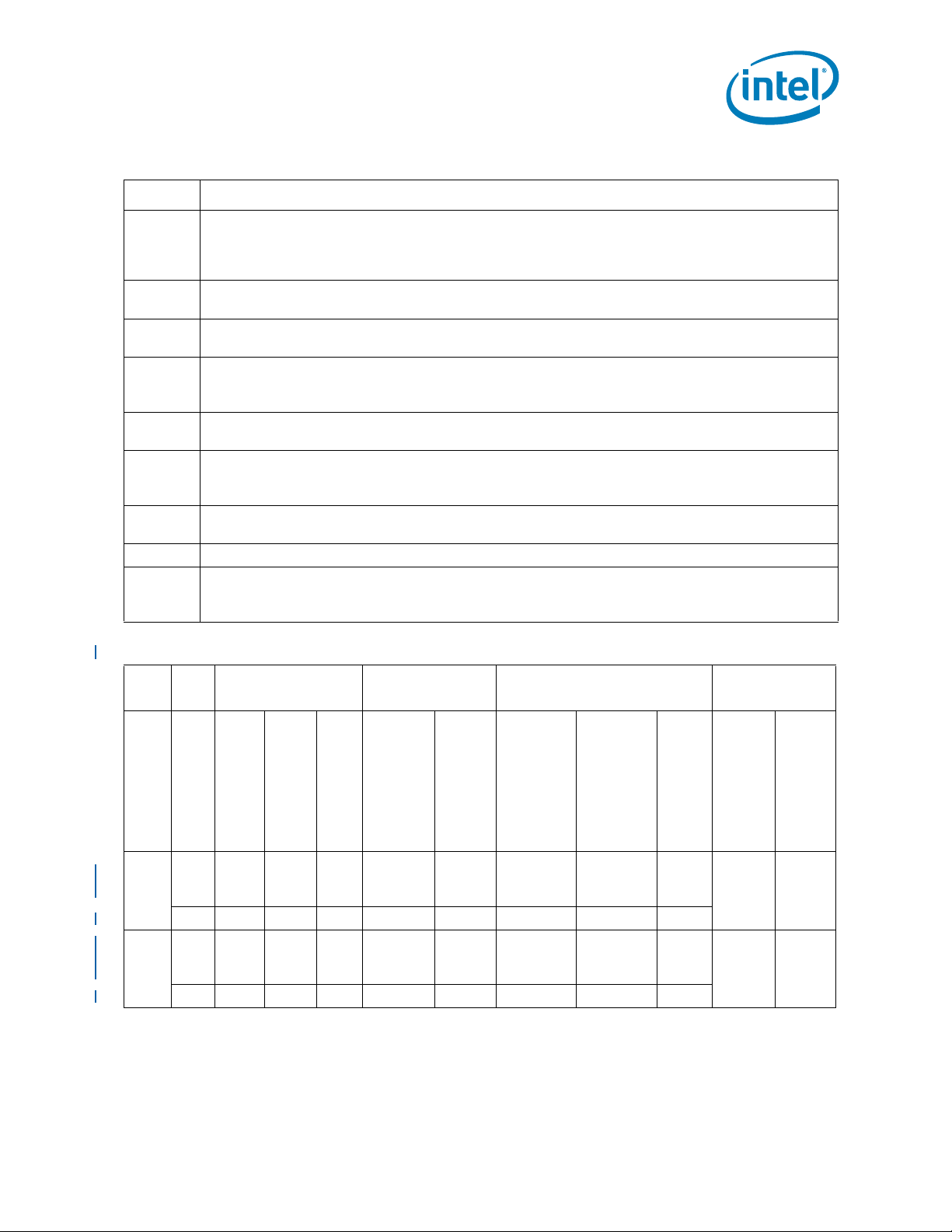

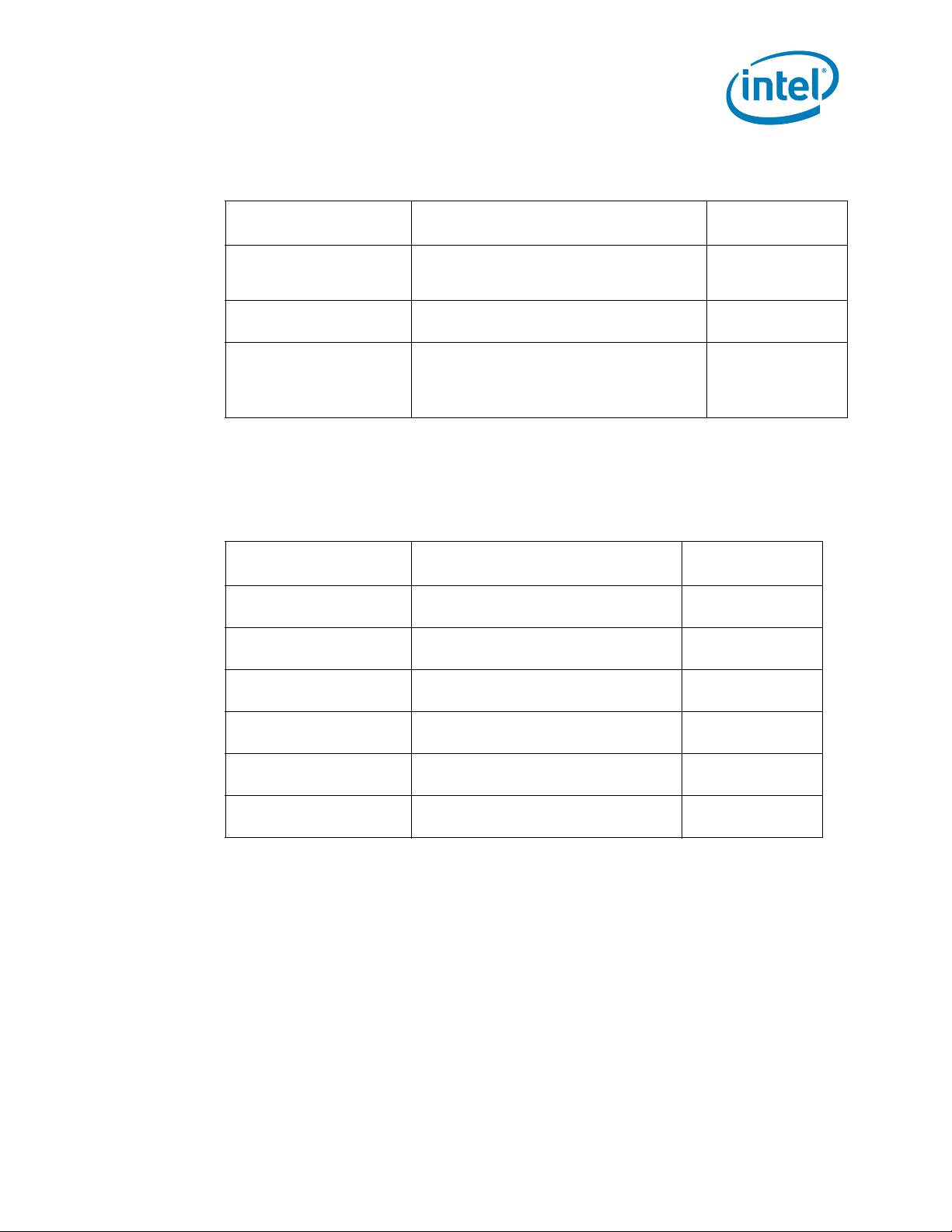

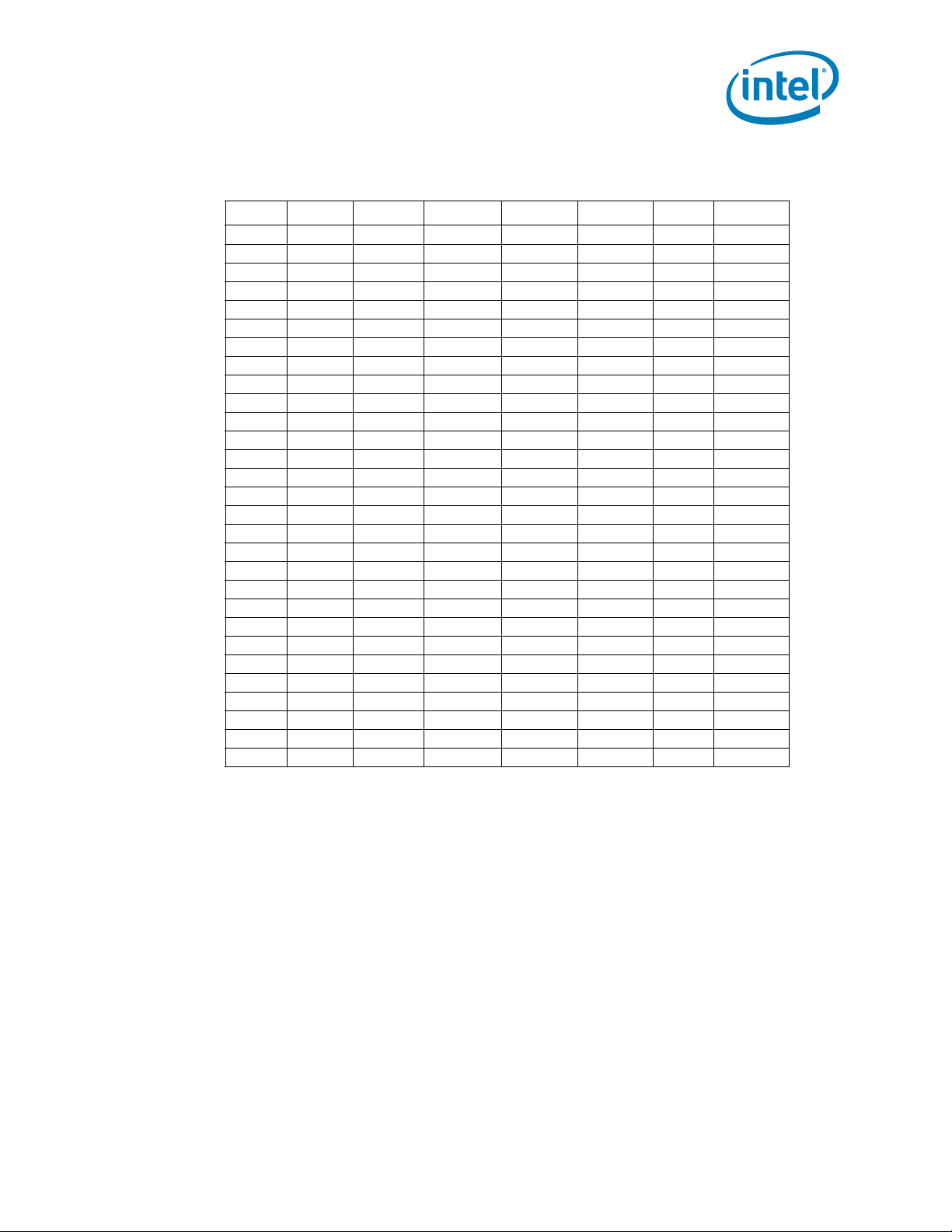

Table 2-1. Supported SO-DIMM Module Configurations

Raw

Card

Version

A 1 GB 1 Gb 64 M x 16 8 2 13/10 8 8K

A 2 GB 2 Gb 128 M x 16 8 2 14/10 8 8K

B 1 GB 1 Gb 128 M x 8 8 1 14/10 8 8K

B 2 GB 2 Gb 256 M x 8 8 1 15/10 8 8K

C 512 MB 1 Gb 64 M x 16 4 1 13/10 8 8K

C 1 GB 2 Gb 128 M x 16 4 1 14/10 8 8K

DIMM

Capacity

DRAM

Device

Technology

DRAM

Organization

# of

DRAM

Devices

1

# of

Physical

Device

Ranks

# of Row/

Col

Address

Bits

# of

Banks

Inside

DRAM

Page

Size

20 Datasheet

Page 21

Interfaces

Table 2-1. Supported SO-DIMM Module Configurations

Raw

Card

Version

2

D

F 2 GB 1 Gb 128 M x 8 16 2 14/10 8 8K

F 4 GB 2 Gb 256 M x 8 16 2 15/10 8 8K

NOTES:

1. System memory configurations are based on availability and are subject to change.

DIMM

Capacity

4 GB 2 Gb 256 M x 8 16 2 15/10 8 8K

2. Only Raw Card D SO-DIMMs at 1066 MT/s are supported.

DRAM

Device

Technology

DRAM

Organization

# of

DRAM

Devices

1

# of

Physical

Device

Ranks

# of Row/

Col

Address

Bits

# of

Banks

Inside

DRAM

2.1.2 System Memory Timing Support

The IMC supports the following DDR3 Speed Bin, CAS Write Latency (CWL), and

command signal mode timings on the main memory interface:

• tCL = CAS Latency

• tRCD = Activate Command to READ or WRITE Command delay

• tRP = PRECHARGE Command Period

• CWL = CAS Write Latency

• Command Signal modes = 1n indicates a new command may be issued every clock

and 2n indicates a new command may be issued every 2 clocks. Command launch

mode programming depends on the transfer rate and memory configuration.

Page

Size

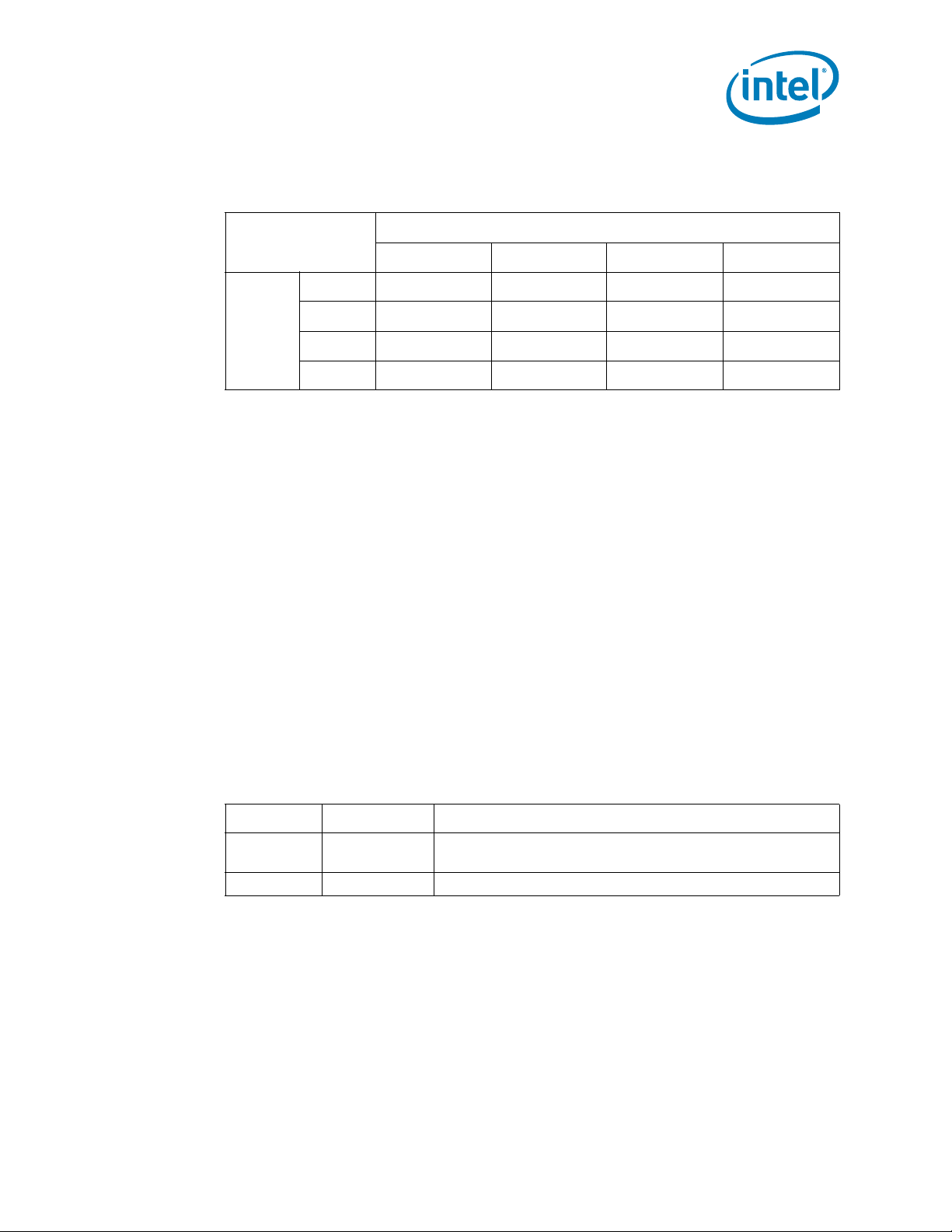

Table 2-2. DDR3 System Mem ory Timing Support

Transfer

Rate

(MT/s)

800 6 6 6 5 1n 1

1066 7 7 7 6 1n 1

NOTES:

1. System memory timing support is based on availability and is subject to change.

tCL

(tCK)

888

tRCD

(tCK)

tRP

(tCK)

CWL

(tCK)

CMD Mode Notes

2.1.3 System Memory Organization Modes

The IMC supports two memory organization modes, single-channel and dual-channel.

Depending upon how the SO-DIMM Modules are populated in each memory channel, a

number of different configurations can exist.

Datasheet 21

Page 22

2.1.3.1 Single-Channel Mode

CH BCH A

CH BCH A

B B

C

BB

C

B

B

C

Non interleaved

access

Dual channel

interleaved access

TOM

B – The largest physical mem ory amount of the smaller size mem ory module

C – The remaining physical mem ory amount of the larger size mem ory module

In this mode, all memory cycles are directed to a single-channel. Single-channel mode

is used when either Channel A or Channel B SO-DIMM connectors are populated in any

order, but not both.

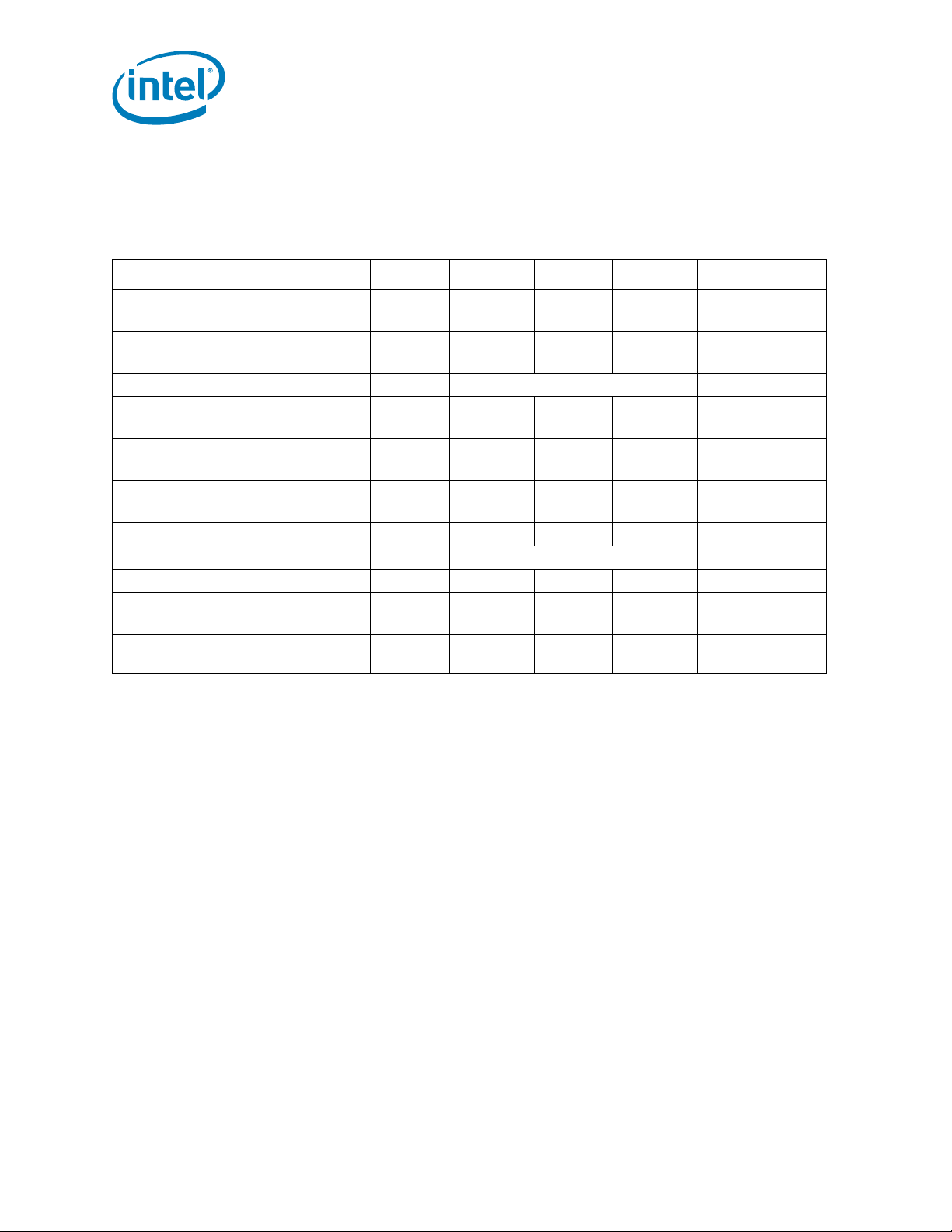

2.1.3.2 Dual-Channel Mode - Intel® Flex Memory Technology Mode

The IMC supports Intel Flex Memory Technology Mode. This mode combines the

advantages of the Dual-Channel Symmetric (Interleaved) and Dual-Channel

Asymmetric Modes. Memory is divided into a symmetric and a asymmetric zone. The

symmetric zone starts at the lowest address in each channel and is contiguous until the

asymmetric zone begins or until the top address of the channel with the smaller

capacity is reached. In this mode, the system runs with one zone of dual-channel mode

and one zone of single-channel mode, simultaneously, across the whole memory array.

Figure 2-2.Intel Flex Memory Technology Operation

Interfaces

2.1.3.2.1 Dual-Channel Symmetric Mode

Dual-Channel Symmetric mode, also known as interleaved mode, provides maximum

performance on real world applications. Addresses are ping-ponged between the

channels after each cache line (64-byte boundary). If there are two requests, and the

second request is to an address on the opposite channel from the first, that request can

be sent before data from the first request has returned. If two consecutive cache lines

are requested, both may be retrieved simultaneously, since they are ensured to be on

opposite channels. Use Dual-Channel Symmetric mode when both Channel A and

22 Datasheet

Channel B SO-DIMM connectors are populated in any order, with the total amount of

memory in each channel being the same.

Page 23

Interfaces

CH. B

CH. A

CH. B

CH. A

CH. B

CH. A

CL

0

Top of

Memory

CL

0

CH. B

CH. A

CH.A-top

DRB

Dual Channel Interleaved

(memory sizes must match)

Dual Channel Asymmetric

(memory sizes can differ)

Top of

Memory

When both channels are populated with the same memory capacity and the boundary

between the dual channel zone and the single channel zone is the top of memory, IMC

operates completely in Dual-Channel Symmetric mode.

Note: The DRAM device technology and width may vary from one channel to the other.

2.1.3.2.2 Dual-Channel Asymmetric Mode

This mode trades performance for system design flexibility. Unlike the previous mode,

addresses start at the bottom of Channel A and stay there until the end of the highest

rank in Channel A, and then addresses continue from the bottom of Channel B to the

top. Real world applications are unlikely to make requests that alternate between

addresses that sit on opposite channels with this memory organization, so in most

cases, bandwidth is limited to a single channel.

This mode is used when Intel Flex Memory Technology is disabled and both Channel A

and Channel B SO-DIMM connectors are populated in any order with the total amount

of memory in each channel being different.

Figure 2-3.Dual-Channel Symmetric (Interleaved) and Dual-Channel Asymmetric Modes

2.1.4 Rules for Populating Memory Slots

Datasheet 23

In all modes, the frequency of system memory is the lowest frequency of all memory

modules placed in the system, as determined through the SPD registers on the

memory modules. The system memory controller supports only one SO-DIMM

Page 24

Interfaces

connector per channel. For dual-channel modes both channels must have an SO-DIMM

connector populated. For single-channel mode, only a single-channel can have an

SO-DIMM connector populated.

2.1.5 Technology Enhancements of Intel® Fast Memory Access (Intel® FMA)

The following sections describe the Just-in-Time Scheduling, Command Overlap, and

Out-of-Order Scheduling Intel FMA technology enhancements.

2.1.5.1 Just-in-Time Command Scheduling

The memory controller has an advanced command scheduler where all pending

requests are examined simultaneously to determine the most efficient request to be

issued next. The most efficient request is picked from all pending requests and issued

to system memory Just-in-Time to make optimal use of Command Overlapping. Thus,

instead of having all memory access requests go individually through an arbitration

mechanism forcing requests to be executed one at a time, they can be started without

interfering with the current request allowing for concurrent issuing of requests. This

allows for optimized bandwidth and reduced latency while maintaining appropriate

command spacing to meet system memory protocol.

2.1.5.2 Command Overlap

Command Overlap allows the insertion of the DRAM commands between the Activate,

Precharge, and Read/Write commands normally used, as long as the inserted

commands do not affect the currently executing command. Multiple commands can be

issued in an overlapping manner, increasing the efficiency of system memory protocol.

2.1.5.3 Out-of-Order Scheduling

While leveraging the Just-in-Time Scheduling and Command Overlap enhancements,

the IMC continuously monitors pending requests to system memory for the best use of

bandwidth and reduction of latency. If there are multiple requests to the same open

page, these requests would be launched in a back to back manner to make optimum

use of the open memory page. This ability to reorder requests on the fly allows the IMC

to further reduce latency and increase bandwidth efficiency.

2.1.6 DRAM Clock Generation

Every supported SO-DIMM has two differential clock pairs. There are total of four clock

pairs driven directly by the processor to two SO-DIMMs.

2.1.7 System Memory Pre-Charge Power Down Support Details

The IMC supports and enables slow exit DDR3 DRAM Device pre-charge power down

DLL control. During a pre-charge power down, a slow exit is where the DRAM device

DLL is disabled after entering pre-charge power down for potential power savings.

24 Datasheet

Page 25

Interfaces

2.2 PCI Express Interface

This section describes the PCI Express interface capabilities of the processor. See the

PCI Express Base Specification for details of PCI Express.

The processor has one PCI Express controller that can support one external x16 PCI

Express Graphics Device or two external x8 PCI Express Graphics Devices. The primary

PCI Express Graphics port is referred to as PEG 0 and the secondary PCI Express

Graphics port is referred to as PEG 1.

2.2.1 PCI Express Architecture

Compatibility with the PCI addressing model is maintained to ensure that all existing

applications and drivers operate unchanged.

The PCI Express configuration uses standard mechanisms as defined in the PCI

Plug-and-Play specification. The initial recovered clock speed of 1.25 GHz results in

2.5 Gb/s/direction which provides a 250 MB/s communications channel in each

direction (500 MB/s total). That is close to twice the data rate of classic PCI. The fact

that 8b/10b encoding is used accounts for the 250 MB/s where quick calculations would

imply 300 MB/s.

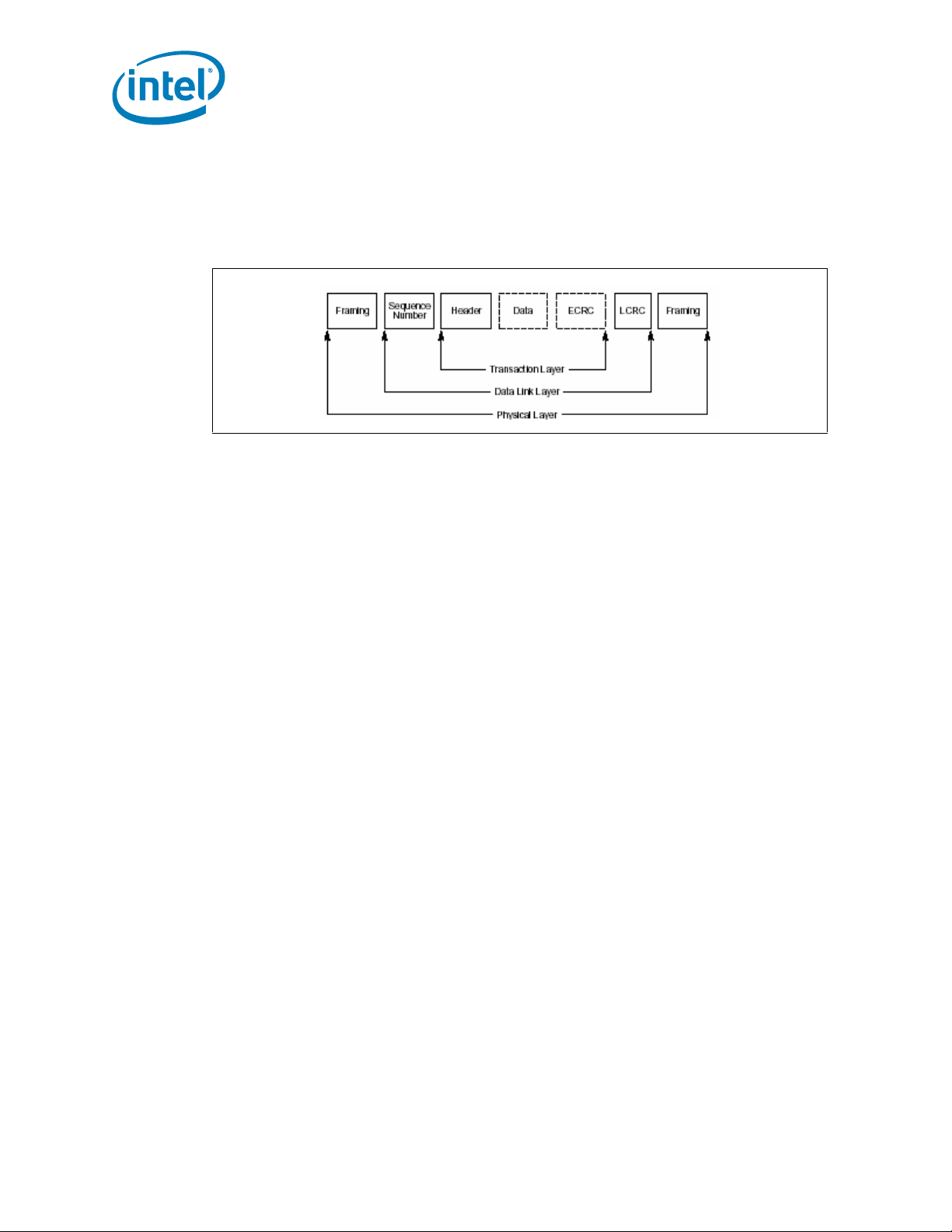

The PCI Express architecture is specified in three layers: Transaction Layer, Data Link

Layer, and Physical Layer. The partitioning in the component is not necessarily along

these same boundaries. Refer to Figure 2-4 for the PCI Express Layering Diagram.

Figure 2-4.PCI Express Layering Diagram

PCI Express uses packets to communicate information between components. Packets

are formed in the Transaction and Data Link Layers to carry the information from the

transmitting component to the receiving component. As the transmitted packets flow

through the other layers, they are extended with additional information necessary to

handle packets at those layers. At the receiving side, the reverse process occurs and

Datasheet 25

Page 26

packets get transformed from their Physical Layer representation to the Data Link

Layer representation and finally (for Transaction Layer Packets) to the form that can be

processed by the Transaction Layer of the receiving device.

Figure 2-5.Packet Flow through the Layers

2.2.1.1 Transaction Layer

The upper layer of the PCI Express architecture is the Transaction Layer. The

Transaction Layer's primary responsibility is the assembly and disassembly of

Transaction Layer Packets (TLPs). TLPs are used to communicate transactions, such as

read and write, as well as certain types of events. The Transaction Layer also manages

flow control of TLPs.

Interfaces

2.2.1.2 Data Link Layer

The middle layer in the PCI Express stack, the Data Link Layer, serves as an

intermediate stage between the Transaction Layer and the Physical Layer.

Responsibilities of Data Link Layer include link management, error detection, and error

correction.

The transmission side of the Data Link Layer accepts TLPs assembled by the

Transaction Layer, calculates and applies data protection code and TLP sequence

number, and submits them to Physical Layer for transmission across the Link. The

receiving Data Link Layer is responsible for checking the integrity of received TLPs and

for submitting them to the Transaction Layer for further processing. On detection of TLP

error(s), this layer is responsible for requesting retransmission of TLPs until information

is correctly received, or the Link is determined to have failed. The Data Link Layer also

generates and consumes packets which are used for Link management functions.

2.2.1.3 Physical Layer

The Physical Layer includes all circuitry for interface operation, including driver and

input buffers, parallel-to-serial and serial-to-parallel conversion, PLL(s), and impedance

matching circuitry. It also includes logical functions related to interface initialization and

maintenance. The Physical Layer exchanges data with the Data Link Layer in an

implementation-specific format, and is responsible for converting this to an appropriate

serialized format and transmitting it across the PCI Express Link at a frequency and

width compatible with the remote device.

26 Datasheet

Page 27

Interfaces

PCI-PCI

Bridge

representing

root PCI

Express port

(Device 1)

PCI

Compatible

Host Bridge

Device

(Device 0)

PCI

Express

Device

PEG0

DMI

2.2.2 PCI Express Configuration Mechanism

The PCI Express (external graphics) link is mapped through a PCI-to-PCI bridge

structure.

Figure 2-6.PCI Express Related Register Structures in the Processor

PCI Express extends the configuration space to 4096 bytes per-device/function, as

compared to 256 bytes allowed by the Conventional PCI Specification. PCI Express

configuration space is divided into a PCI-compatible region (which consists of the first

256 bytes of a logical device's configuration space) and an extended PCI Express region

(which consists of the remaining configuration space). The PCI-compatible region can

be accessed using either the mechanisms defined in the PCI specification or using the

enhanced PCI Express configuration access mechanism described in the PCI Express

Enhanced Configuration Mechanism section.

The PCI Express Host Bridge is required to translate the memory-mapped PCI Express

configuration space accesses from the host processor to PCI Express configuration

cycles. To maintain compatibility with PCI configuration addressing mechanisms, it is

recommended that system software access the enhanced configuration space using

32-bit operations (32-bit aligned) only. See the PCI Express Base Specification for

details of both the PCI-compatible and PCI Express Enhanced configuration

mechanisms and transaction rules.

2.2.3 PCI Express Ports and Bifurcation

The external graphics attach (PEG) on the processor is a single, 16-lane (x16) port that

can be:

• configured at narrower widths

• bifurcated into two x8 PCI Express ports that may train to narrower widths

The PEG port is being designed to be compliant with the PCI Express Base

Datasheet 27

Specification, Revision 2.0.

Page 28

2.2.3.1 PCI Express Bifurcated Mode

When bifurcated, the signals which had previously been assigned to Lanes 15:8 of the

single x16 Primary port are reassigned to lanes 7:0 of the x8 Secondary Port. This

assignment applies whether the lane numbering is reversed or not. PCI Express Port 0

is mapped to PCI Device 1 and PCI Express Port 1 is mapped to PCI Device 6.

2.2.3.2 Static Lane Numbering Reversal

Does not support dynamic lane reversal, as defined (optional) by the PCI Express Base

Specification.

PCI Express 1x16 configuration:

• Normal (1x16): PEG_RX[15:0]; PEG_TX[15:0]

• Reversal (1x16): PEG_RX[0:15]; PEG_TX[0:15]

2.3 DMI

Interfaces

DMI connects the processor and the PCH chip-to-chip. DMI2 is supported. The DMI is

similar to a four-lane PCI Express supporting up to 1 GB/s of bandwidth in each

direction.

Note: Only DMI x4 configuration is supported.

2.3.1 DMI Error Flow

DMI can only generate SERR in response to errors, never SCI, SMI, MSI, PCI INT, or

GPE. Any DMI related SERR activity is associated with Device 0.

2.3.2 Processor/PCH Compatibility Assumptions

The processor is compatible with the PCH and is not compatible with any previous

(G)MCH or ICH products.

2.3.3 DMI Link Down

The DMI link going down is a fatal, unrecoverable error. If the DMI data link goes to

data link down, after the link was up, then the DMI link hangs the system by not

allowing the link to retrain to prevent data corruption. This is controlled by the PCH.

Downstream transactions that had been successfully transmitted across the link prior

to the link going down may be processed as normal. No completions from downstream,

non-posted transactions are returned upstream over the DMI link after a link down

event.

28 Datasheet

Page 29

Interfaces

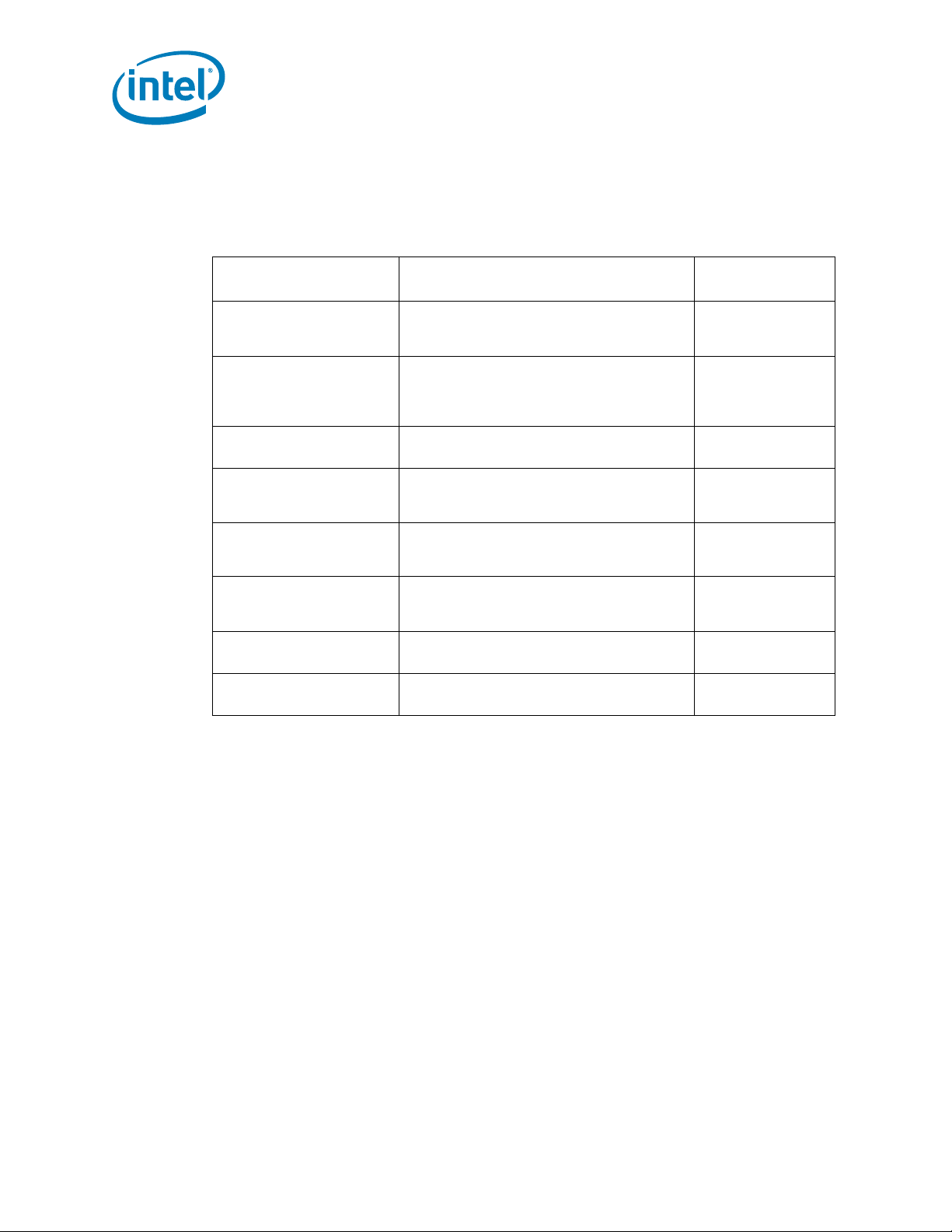

Plane A

Cursor B

Sprite B

Plane B

Cursor A

Sprite A

Pipe B

Pipe A

Memory

M

U

X

VGA

Video Engine

2D Engine

3D Engine

Clipper

Strip & Fan/Setup

Alpha

Blend/

Gamma

/Panel

Fitter

Geometry Shader

Vertex Fetch/Vertex

Shader

Windower/IZ

Intel®

FDI

eDP

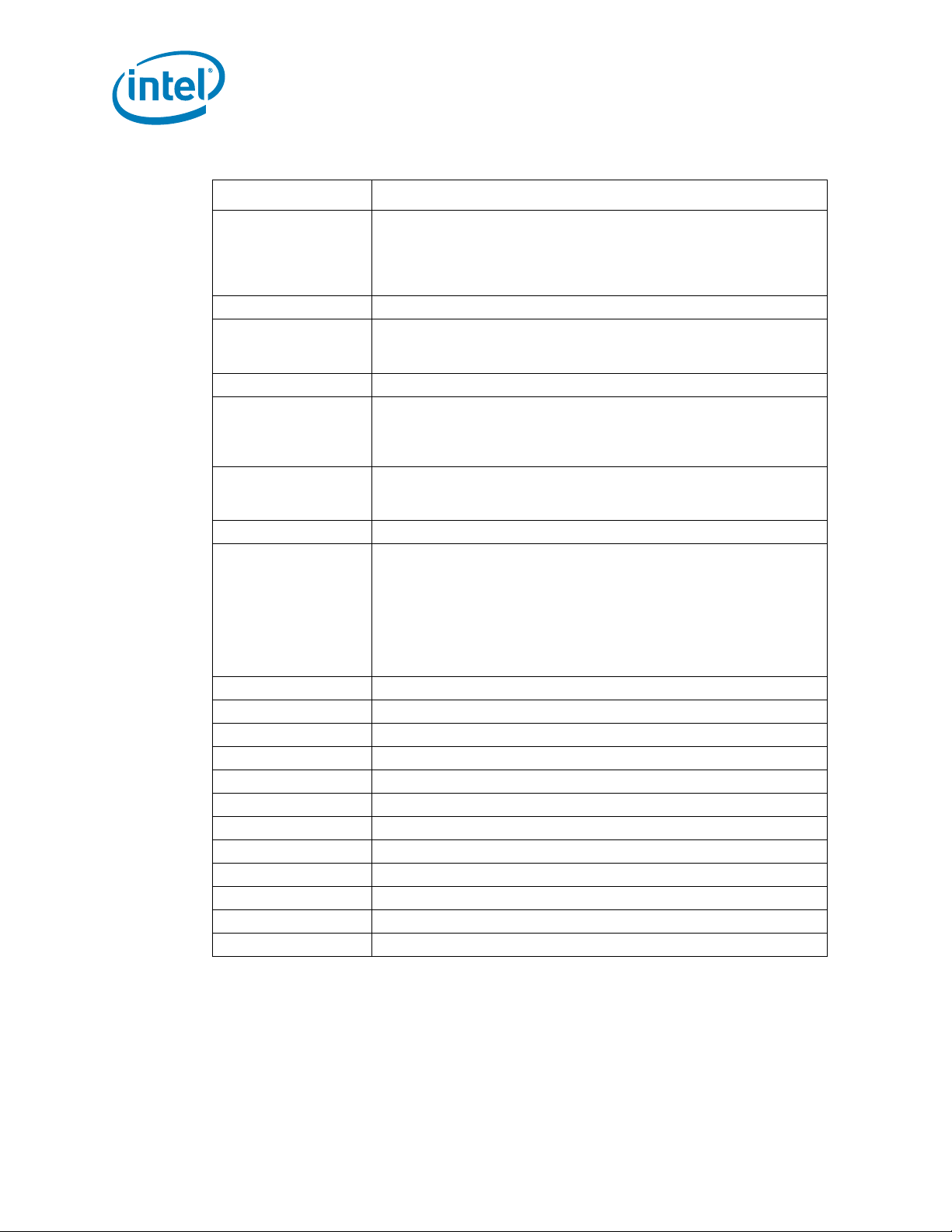

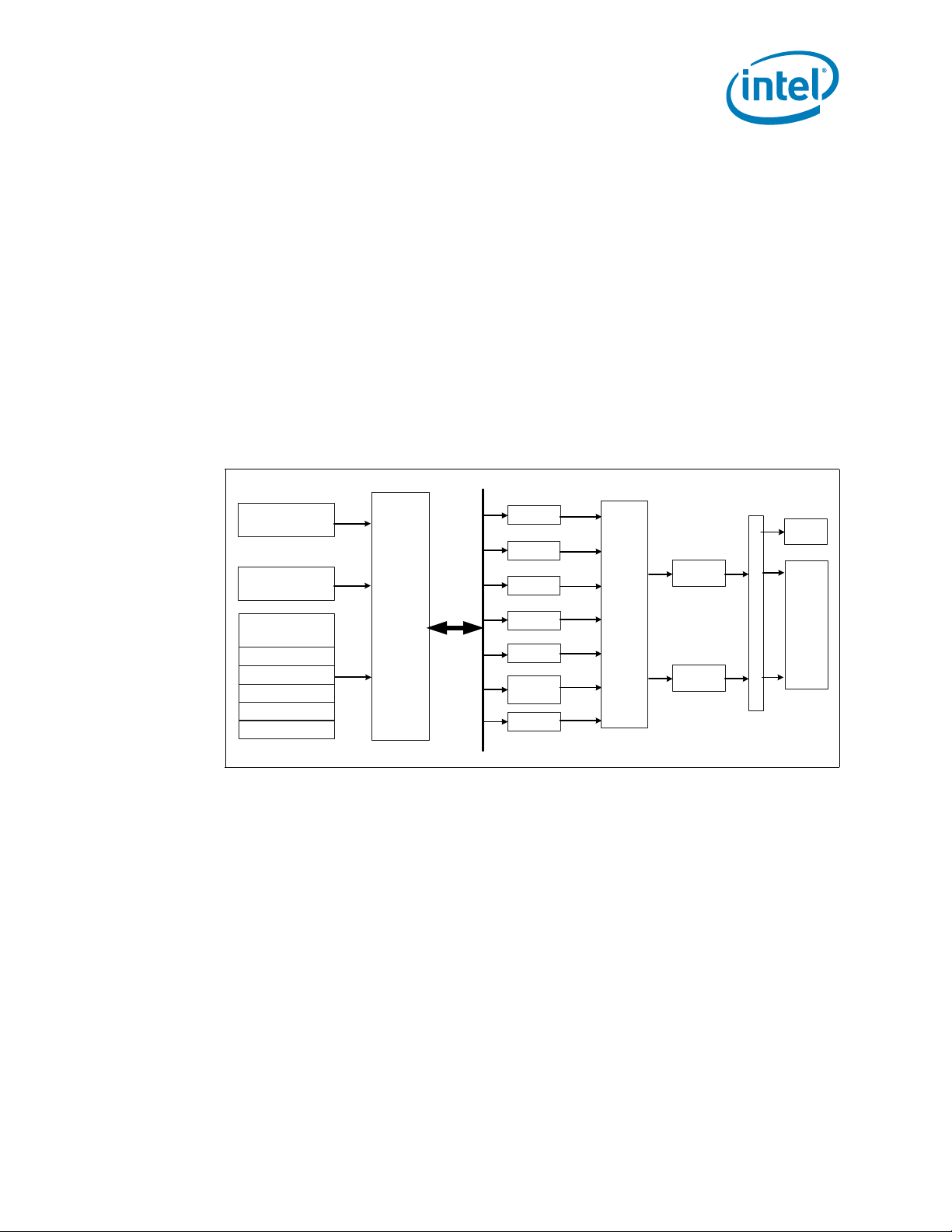

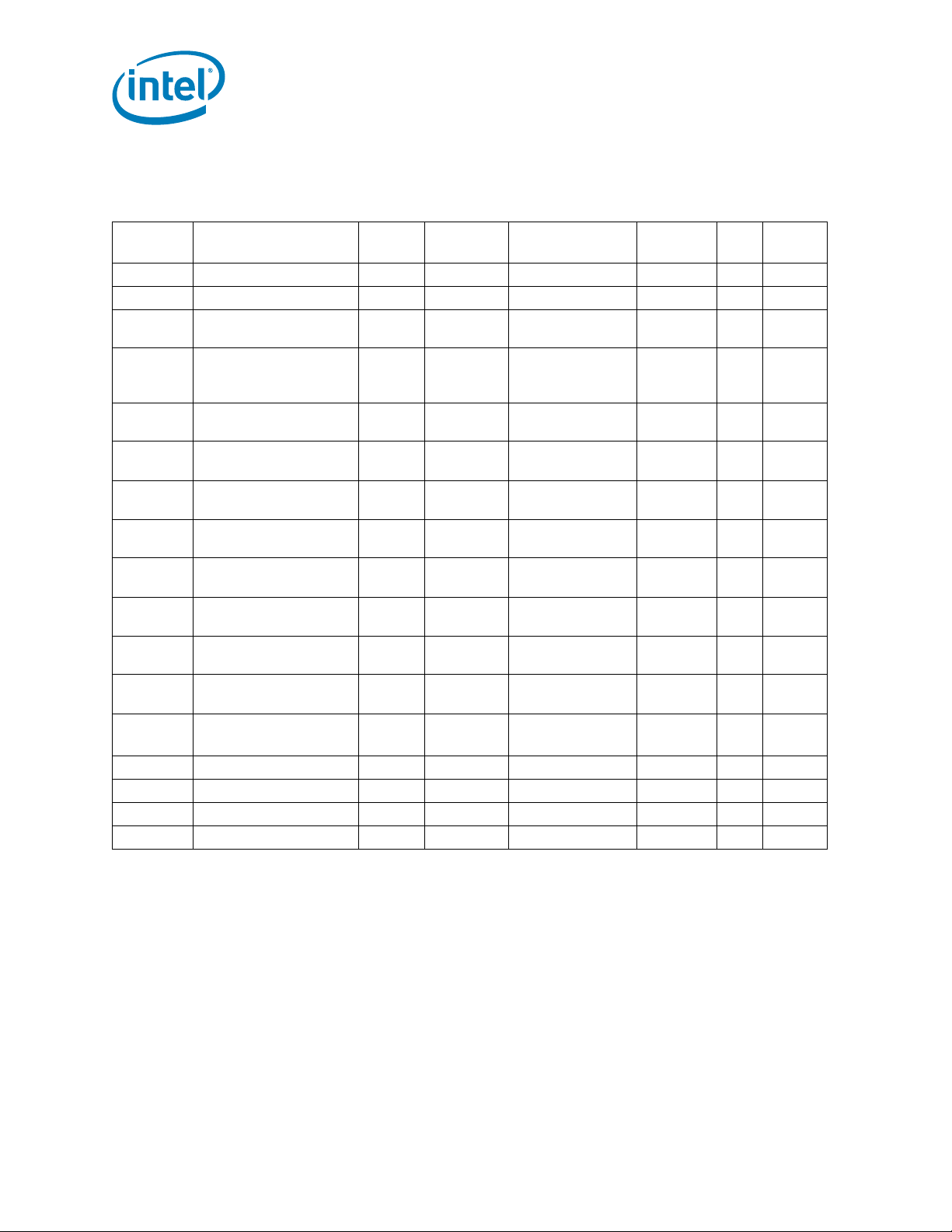

2.4 Intel® HD Graphics Controller

This section details the 2D, 3D and video pipeline and their respective capabilities.

The integrated graphics is powered by a refresh of the fifth generation graphics core

and supports twelve, fully-programmable execution cores. Full-precision, floating-point

operations are supported to enhance the visual experience of compute-intensive

applications.The integrated graphics controller contains several types of components;

the graphics engines, planes, pipes, port and the Intel FDI. The integrated graphics has

a 3D/2D Instruction Processing unit to control the 3D and 2D engines respectively. The

integrated graphics controller’s 3D and 2D engines are fed with data through the IMC.

The outputs of the graphics engine are surfaces sent to memory, which are then

retrieved and processed by the planes. The surfaces are then blended in the pipes and

the display timings are transitioned from display core clock to the pixel (dot) clock.

Figure 2-7.Integrated Graphics Controller Unit Block Diagram

2.4.1 3D and Video Engines for Graphics Processing

The 3D graphics pipeline architecture simultaneously operates on different primitives or

on different portions of the same primitive. All the cores are fully programmable,

increasing the versatility of the 3D Engine. The Gen 5.75 3D engine provides the

following performance and power-management enhancements:

• Execution units (EUs) increased to 12 from the previous 10 EUsin Gen 5.0.

• Includes Hierarchal-Z

• Includes video quality enhancements

2.4.1.1 3D Engine Execution Units

• Support 12 EUs. The EUs perform 128-bit wide execution per clock.

Datasheet 29

Page 30

• Support SIMD8 instructions for vertex processing and SIMD16 instructions for pixel

processing.

2.4.1.2 3D Pipeline

2.4.1.2.1 Vertex Fetch (VF) Stage

The VF stage executes 3DPRIMITIVE commands. Some enhancements have been

included to better support legacy D3D APIs as well as SGI OpenGL*.

2.4.1.2.2 Vertex Shader (VS) Stage

The VS stage performs shading of vertices output by the VF function. The VS unit

produces an output vertex reference for every input vertex reference received from the

VF unit, in the order received.

2.4.1.2.3 Geometry Shader (GS) Stage

The GS stage receives inputs from the VS stage. Compiled application-provided GS

programs, specifying an algorithm to convert the vertices of an input object into some

output primitives. For example, a GS shader may convert lines of a line strip into

polygons representing a corresponding segment of a blade of grass centered on the

line. Or it could use adjacency information to detect silhouette edges of triangles and

output polygons extruding out from the edges.

Interfaces

2.4.1.2.4 Clip Stage

The Clip stage performs general processing on incoming 3D objects. However, it also

includes specialized logic to perform a Clip Test function on incoming objects. The Clip

Test optimizes generalized 3D Clipping. The Clip unit examines the position of incoming

vertices, and accepts/rejects 3D objects based on its Clip algorithm.

2.4.1.2.5 Strips and Fans (SF) Stage

The SF stage performs setup operations required to rasterize 3D objects. The outputs

from the SF stage to the Windower stage contain implementation-specific information

required for the rasterization of objects and also supports clipping of primitives to some

extent.

2.4.1.2.6 Windower/IZ (WIZ) Stage

The WIZ unit performs an early depth test, which removes failing pixels and eliminates

unnecessary processing overhead.

The Windower uses the parameters provided by the SF unit in the object-specific

rasterization algorithms. The WIZ unit rasterizes objects into the corresponding set of

pixels. The Windower is also capable of performing dithering, whereby the illusion of a

higher resolution when using low-bpp channels in color buffers is possible. Color

dithering diffuses the sharp color bands seen on smooth-shaded objects.

30 Datasheet

Page 31

Interfaces

2.4.1.3 Video Engine

The Video Engine handles the non-3D (media/video) applications. It includes support

for VLD and MPEG2 decode in hardware.

2.4.1.4 2D Engine

The 2D Engine contains BLT (Block Level Transfer) functionality and an extensive set of

2D instructions. To take advantage of the 3D during engine’s functionality, some BLT

functions make use of the 3D renderer.

2.4.1.4.1 Integrated Graphics VGA Registers

The 2D registers consists of original VGA registers and others to support graphics

modes that have color depths, resolutions, and hardware acceleration features that go

beyond the original VGA standard.

2.4.1.4.2 Logical 128-Bit Fixed BLT and 256 Fill Engine

This BLT engine accelerates the GUI of Microsoft Windows* operating systems. The

128-bit BLT engine provides hardware acceleration of block transfers of pixel data for

many common Windows operations. The BLT engine can be used for the following:

• Move rectangular blocks of data between memory locations

• Data alignment

• To perform logical operations (raster ops)

The rectangular block of data does not change, as it is transferred between memory

locations. The allowable memory transfers are between: cacheable system memory

and frame buffer memory, frame buffer memory and frame buffer memory, and within

system memory. Data to be transferred can consist of regions of memory, patterns, or

solid color fills. A pattern is always 8 x 8 pixels wide and may be 8, 16, or 32 bits per

pixel.

The BLT engine expands monochrome data into a color depth of 8, 16, or 32 bits. BLTs

can be either opaque or transparent. Opaque transfers move the data specified to the

destination. Transparent transfers compare destination color to source color and write

according to the mode of transparency selected.

Data is horizontally and vertically aligned at the destination. If the destination for the

BLT overlaps with the source memory location, the BLT engine specifies which area in

memory to begin the BLT transfer. Hardware is included for all 256 raster operations

(source, pattern, and destination) defined by Microsoft, including transparent BLT.

The BLT engine has instructions to invoke BLT and stretch BLT operations, permitting

software to set up instruction buffers and use batch processing. The BLT engine can

perform hardware clipping during BLTs.

Datasheet 31

Page 32

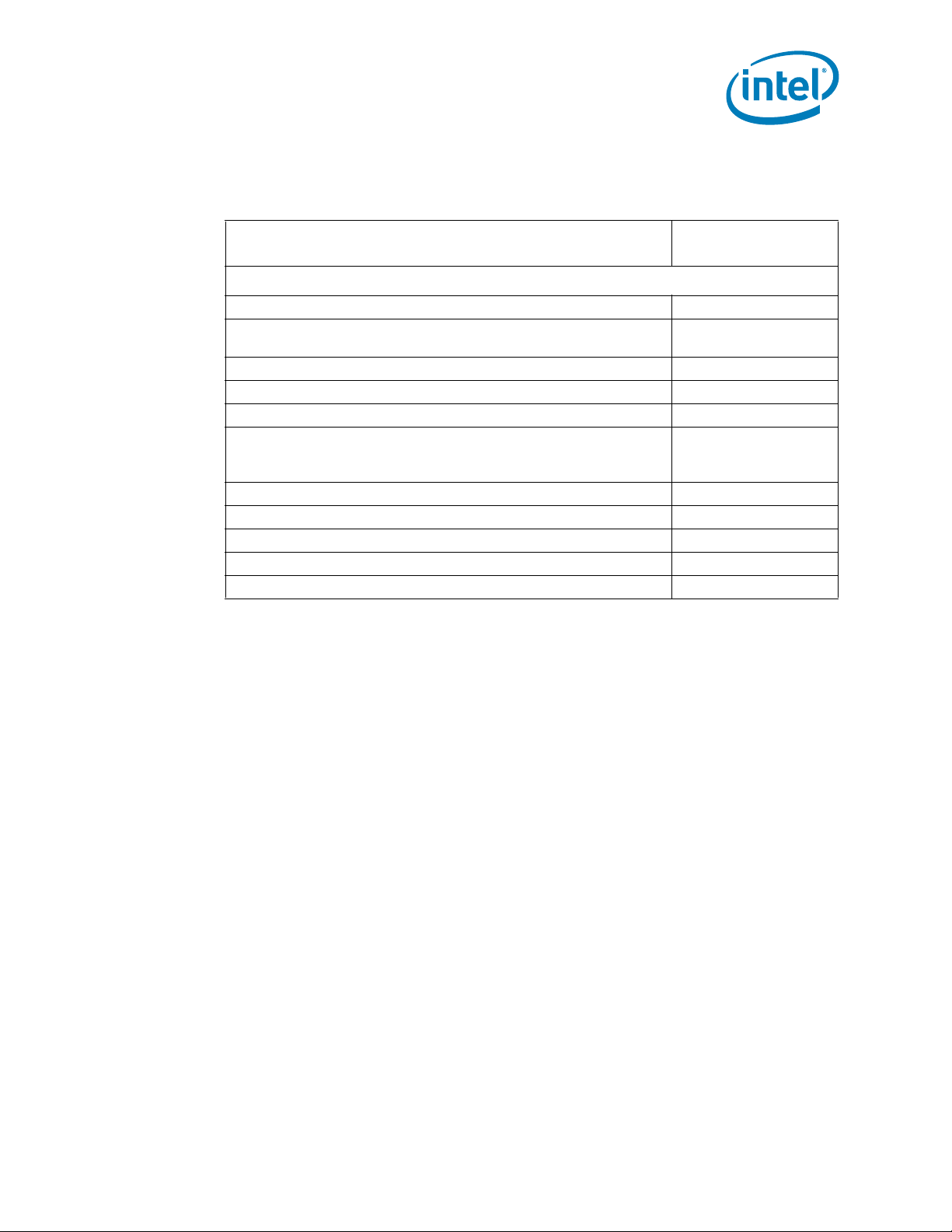

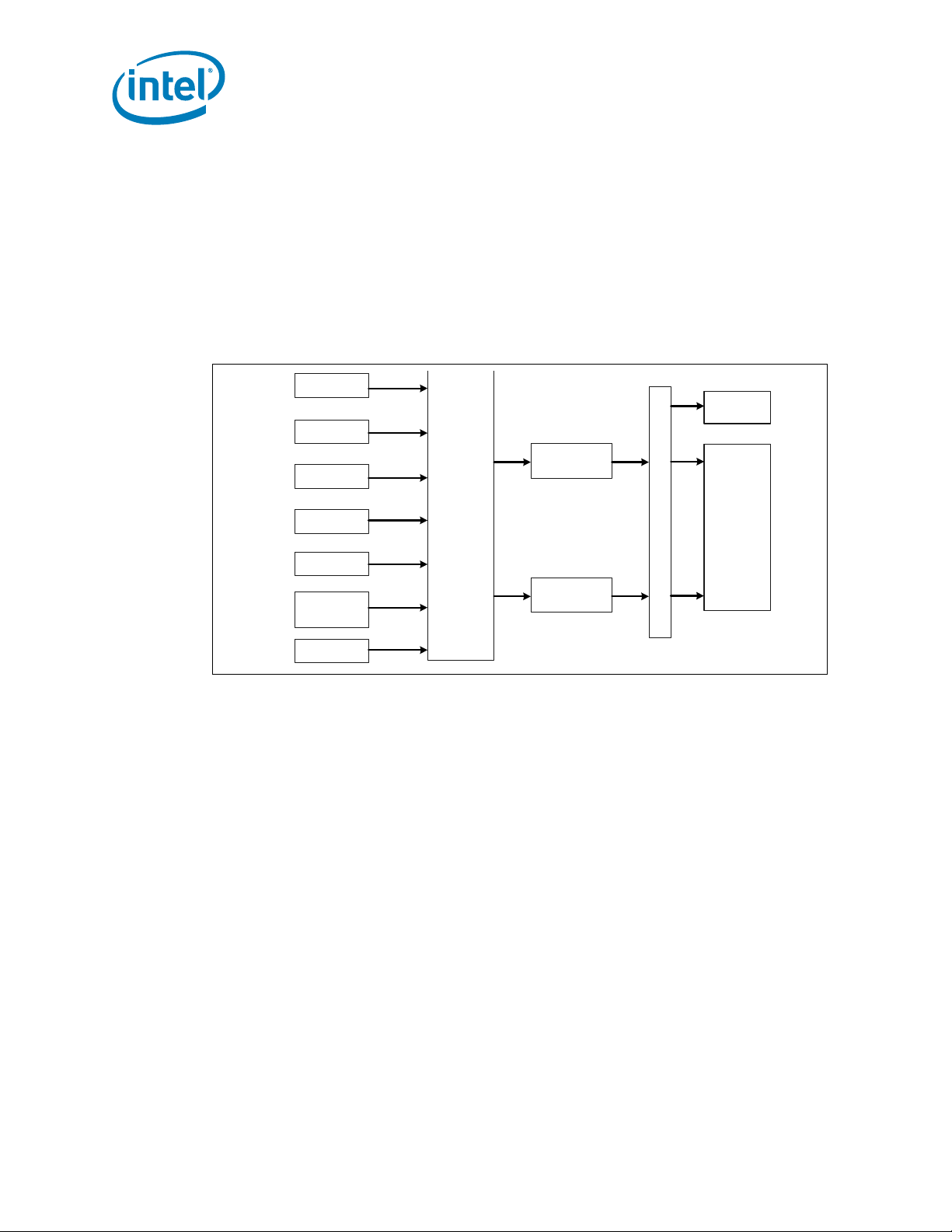

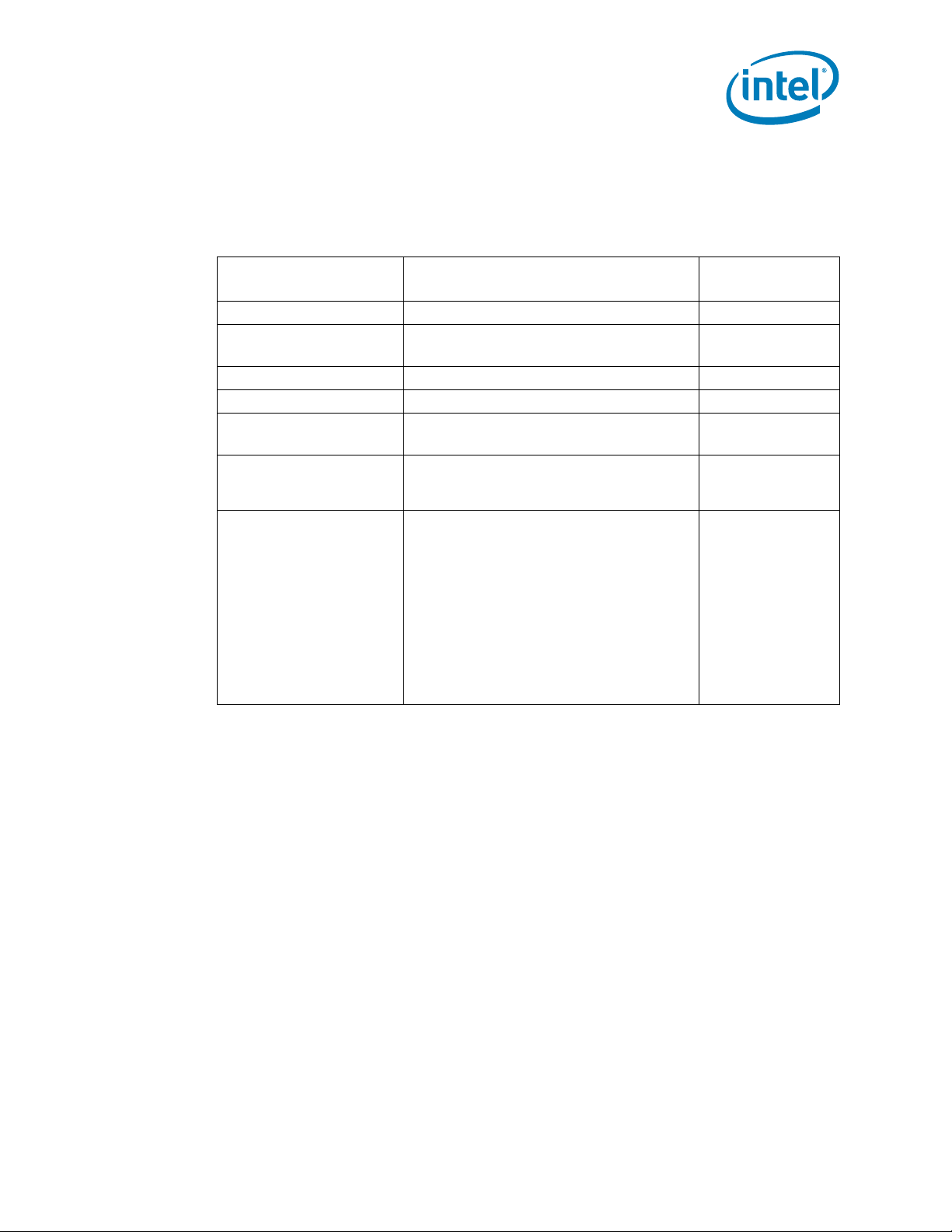

2.4.2 Integrated Graphics Display Pipes

Plane A

Cursor B

Sprite B

Plane B

Cursor A

Sprite A

Pipe B

Pipe A

Alpha

Blend/

Gamma/

Panel

Fitter

M

U

X

eDP

Intel®

FDI

VGA

The integrated graphics controller display pipe can be broken down into three

components:

• Display Planes

• Display Pipes

• Embedded DisplayPort and Intel FDI

Figure 2-8.Processor Display Block Diagram

Interfaces

2.4.2.1 Display Planes

A display plane is a single displayed surface in memory and contains one image

(desktop, cursor, overlay). It is the portion of the display HW logic that defines the

format and location of a rectangular region of memory that can be displayed on display

output device and delivers that data to a display pipe. This is clocked by the Core

Display Clock.

2.4.2.1.1 Planes A and B

Planes A and B are the main display planes and are associated with Pipes A and B

respectively. The two display pipes are independent, allowing for support of two

independent display streams. They are both double-buffered, which minimizes latency

and improves visual quality.

2.4.2.1.2 Sprite A and B

Sprite A and Sprite B are planes optimized for video decode, and are associated with

Planes A and B respectively. Sprite A and B are also double-buffered.

32 Datasheet

Page 33

Interfaces

2.4.2.1.3 Cursors A and B

Cursors A and B are small, fixed-sized planes dedicated for mouse cursor acceleration,

and are associated with Planes A and B respectively. These planes support resolutions

up to 256 x 256 each.

2.4.2.1.4 VGA

Used for boot, safe mode, legacy games, etc. Can be changed by an application without

OS/driver notification, due to legacy requirements.

2.4.2.2 Display Pipes

The display pipe blends and synchronizes pixel data received from one or more display

planes and adds the timing of the display output device upon which the image is

displayed. This is clocked by the Display Reference clock inputs.

The display pipes A and B operate independently of each other at the rate of 1 pixel per

clock. They can attach to any of the display ports. Each pipe sends display data to the

PCH over the Intel Flexible Display Interface (Intel FDI).

2.4.2.3 Display Ports

The display ports consist of output logic and pins that transmit the display data to the

associated encoding logic and send the data to the display device (i.e., LVDS, HDMI,

DVI, SDVO, etc.). All display interfaces connecting external displays are now

repartitioned and driven from the PCH with the exception of the eDP DisplayPort.

2.4.2.4 Embedded DisplayPort (eDP)

The DisplayPort abbreviated as DP (different than the generic term display port)

specification is a VESA standard. DisplayPort consolidates internal and external

connection methods to reduce device complexity, support cross industry applications,

and provide performance scalability. The integrated graphics supports an embedded

DisplayPort (eDP) interface for display devices that are integrated into the system

(e.g., laptop LCD panel). All other display interfaces connecting to the LVDS or external

panels are driven from the PCH.

The eDP interface is physically shared with a subset of the PCIe interface. Specifically,

eDP[3:0] map to Logical Lanes PEG[12:15] of the PCIe interface. Mapping for reversed

case is: eDP[3:0] maps to PEG[3:0], ex: eDP[0]=PEG[15] in non reversed case. In

reversed case: eDP[0] = PEG[0].

Table 2-3. eDP/PEG Ball Mapping

eDP Signal PEG Signal Lane Reversal

eDP_AUX PEG_RX[13] PEG_RX[2]

eDP_AUX# PEG_RX#[13] PEG_RX#[2]

eDP_HPD# PEG_RX[12] PEG_RX[3]

Datasheet 33

Page 34

Table 2-3. eDP/PEG Ball Mapping

eDP Signal PEG Signal Lane Reversal

eDP_TX[0] PEG_TX[15] PEG_TX[0]

eDP_TX#[0] PEG_TX#[15] PEG_TX#[0]

eDP_TX[1] PEG_TX[14] PEG_TX[1]

eDP_TX#[1] PEG_TX#[14] PEG_TX#[1]

eDP_TX[2] PEG_TX[13] PEG_TX[2]

eDP_TX#[2] PEG_TX#[13] PEG_TX#[2]

eDP_TX[3] PEG_TX[12] PEG_TX[3]

eDP_TX#[3] PEG_TX#[12] PEG_TX#[3]

When eDP is enabled, the lower logical lanes are still available for standard PCIe

devices, using the PEG 0 controller. PEG 0 is limited to x1. The board manufacture

chooses whether to use eDP and whether to use lane numbering reversal.

The eDP interface supports link-speeds of 1.62 Gbps and 2.7 Gbps on 1, 2 or 4 data

lanes. The eDP and PCI Express x1 may be supported concurrently. eDP interface may

support -0.5% SSC and non-SSC clock settings.

Interfaces

2.4.3 Intel Flexible Display Interface

The Intel Flexible Display Interface (Intel FDI) is a proprietary link for carrying display

traffic from the integrated graphics controller to the PCH display I/O’s. Intel FDI

supports two independent channels; one for pipe A and one for pipe B.

• Each channel has four transmit (Tx) differential pairs used for transporting pixel

and framing data from the display engine.

• Each channel has one single-ended LineSync and one FrameSync input (1-V CMOS

signaling).

• One display interrupt line input (1-V CMOS signaling).

• Intel FDI may dynamically scalable down to 2X or 1X based on actual display

bandwidth requirements.

• Common 100-MHz reference clock is sent to both processor and PCH.

• Each channel transports at a rate of 2.7 Gbps.

• PCH supports end-to-end lane reversal across both channels (no reversal support

required)

2.5 Platform Environment Control Interface (PECI)

The PECI is a one-wire interface that provides a communication channel between a

PECI client (processor) and a PECI master, usually the PCH. The processor implements

a PECI interface to:

34 Datasheet

Page 35

Interfaces

• Allow communication of processor thermal and other information to the PECI

master.

• Read averaged Digital Thermal Sensor (DTS) values for fan speed control.

2.6 Interface Clocking

2.6.1 Internal Clocking Requirements

Table 2-4. Processor Reference Clocks

Reference Input Clocks Input Frequency Associated PLL

BCLK/BCLK# 133 MHz Processor/Memory/Graphics

PEG_CLK/PEG_CLK# 100 MHz PCI Express*/DMI/Intel® FDI

DPLL_REF_SSCLK/DPLL_REF_SSCLK# 120 MHz Embedded DisplayPort* (eDP)

§

Datasheet 35

Page 36

3 Technologies

3.1 Intel® Virtualization Technology

Intel Virtualization Technology (Intel VT) makes a single system appear as multiple

independent systems to software. This allows multiple, independent operating systems

to run simultaneously on a single system. Intel VT comprises technology components

to support virtualization of platforms based on Intel architecture microprocessors and

chipsets. Intel Virtualization Technology (Intel VT-x) added hardware support in the

processor to improve the virtualization performance and robustness. Intel Virtualization

Technology for Directed I/O (Intel VT-d) adds chipset hardware implementation to

support and improve I/O virtualization performance and robustness.

Intel VT-x specifications and functional descriptions are included in the Intel

IA-32 Architectures Software Developer’s Manual, Volume 3B and is available at:

http://www.intel.com/products/processor/manuals/index.htm.

Technologies

® 64 and

3.1.1 Intel® VT-x Objectives

Intel VT-x provides hardware acceleration for virtualization of IA platforms. Virtual

Machine Monitor (VMM) can use Intel VT-x features to provide improved reliable

virtualized platforms. By using Intel VT-x, a VMM is:

• Robust—VMMs no longer need to use paravirtualization or binary translation. This

means that they will be able to run off-the-shelf OSs and applications without any