Intel Omni-Path Switch 100 Series, Omni-Path Edge Switch Series, Omni-Path Director Class Switch Series Installation Manual

Page 1

Intel® Omni-Path Fabric Switches

Hardware

Installation Guide

Rev. 10.0

June 2019

Doc. No.: H76456, Rev.: 10.0

Page 2

You may not use or facilitate the use of this document in connection with any infringement or other legal analysis concerning Intel products described

herein. You agree to grant Intel a non-exclusive, royalty-free license to any patent claim thereafter drafted which includes subject matter disclosed

herein.

No license (express or implied, by estoppel or otherwise) to any intellectual property rights is granted by this document.

All information provided here is subject to change without notice. Contact your Intel representative to obtain the latest Intel product specifications and

roadmaps.

The products described may contain design defects or errors known as errata which may cause the product to deviate from published specifications.

Current characterized errata are available on request.

Intel technologies’ features and benefits depend on system configuration and may require enabled hardware, software or service activation.

Performance varies depending on system configuration. No computer system can be absolutely secure. Check with your system manufacturer or

retailer or learn more at intel.com.

Intel, the Intel logo, Intel Xeon Phi, and Xeon are trademarks of Intel Corporation in the U.S. and/or other countries.

*Other names and brands may be claimed as the property of others.

Copyright © 2015–2019, Intel Corporation. All rights reserved.

®

Omni-Path Fabric Switches Hardware

Intel

Installation Guide June 2019

2 Doc. No.: H76456, Rev.: 10.0

Page 3

Revision History—Intel® Omni-Path Fabric

Revision History

For the latest documentation, go to: http://www.intel.com/omnipath/SwitchPublications.

Date Revision Description

June 2019 10.0 • Updated the FM Switch LED description.

April 2019 9.0 Added Appendix B Director Switch Cable Management on page 90.

February 2019 8.0 • Added an Edge switch cable port connection limitation statement to

April 2018 7.0 • Added Figure 57, "48-Port Leaf Module Port Numbering"

April 2017 6.0 • Updated Air Baffle information in "Installing the Airflow Baffles"

December 2016 5.0 Document updated for Revision 5.0

August 2016 4.0 Document updated for Revision 4.0

May 2016 3.0 Document updated for Revision 3.0

February 2016 2.0 Document updated for Revision 2.0

November 2015 1.0 Document updated for Revision 1.0

• Edge switch product naming. Updated remaining instances of

"unmanaged" to "externally-managed" wherever applicable.

the section Cable Distances on page 28.

• The section Updating the Management Module IP Addresses in a

Director Class Redundant Management Configuration on page 75

was updated to use the boot command moduleip.

• Added Q7 BIOS Update on page 86

• Added module installation information for the Omni-Path Fabric

Edge Hot Swap in "Installing the Edge Switch Hot-Swap Power and

Fan Modules".

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 3

Intel® Omni-Path Fabric Switches Hardware

Page 4

®

Omni-Path Fabric—Contents

Intel

Contents

Revision History..................................................................................................................3

Preface............................................................................................................................... 9

Intended Audience....................................................................................................... 9

Intel® Omni-Path Documentation Library.........................................................................9

How to Search the Intel® Omni-Path Documentation Set........................................ 11

Cluster Configurator for Intel® Omni-Path Fabric.............................................................12

Documentation Conventions........................................................................................ 12

Laser Safety Information.............................................................................................13

Electrostatic Discharge Sensitivity (ESDS) Precautions.................................................... 13

License Agreements....................................................................................................13

Technical Support.......................................................................................................13

1.0 Introduction................................................................................................................14

1.1 Safety Information................................................................................................14

1.1.1 Statement 1.............................................................................................15

1.1.2 Statement 2.............................................................................................17

1.1.3 Statement 3.............................................................................................19

1.1.4 Statement 4.............................................................................................20

1.1.5 Statement 5.............................................................................................22

1.1.6 Statement 6.............................................................................................24

1.1.7 Statement 7.............................................................................................25

2.0 Installation................................................................................................................. 28

2.1 Planning the Installation........................................................................................ 28

2.1.1 Cable Requirements.................................................................................. 28

2.1.2 Uninterruptible Power Supply Equipment......................................................31

2.2 Installation Tasks Checklist.....................................................................................31

2.2.1 Tools and Equipment Required.................................................................... 32

2.2.2 Check the Installation Site......................................................................... 32

2.2.3 Mark the Rack.......................................................................................... 32

2.3 Intel® Omni-Path Fabric Edge Switch Installation...................................................... 33

2.3.1 Mounting Hardware Kit Contents................................................................. 33

2.3.2 Rack Mounting..........................................................................................33

2.3.3 Installing the Airflow Baffles....................................................................... 37

2.3.4 Installing the Switch Fascia........................................................................ 40

2.3.5 Reversing the Fan Airflow...........................................................................41

2.3.6 Installing the Q7 Management Module......................................................... 43

2.4 Intel® Omni-Path Director Class Switch 100 Series Installation................................... 45

2.4.1 Mounting Hardware Kit Contents................................................................. 45

2.4.2 Unpacking the Switch................................................................................ 45

2.4.3 Installation Tasks...................................................................................... 51

2.4.4 Installing the Optional Cable Management Guide........................................... 59

2.4.5 Installing Director Class Modules.................................................................61

2.4.6 Installing the Edge Switch Hot-Swap Power and Fan Modules.......................... 65

2.5 Connect Equipment to the Ports and Power On the System.........................................68

2.5.1 Director Class Switch Port and Slot Numbering..............................................69

2.5.2 Leaf Module Port Numbering.......................................................................70

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

4 Doc. No.: H76456, Rev.: 10.0

Page 5

Contents—Intel® Omni-Path Fabric

2.5.3 Edge Switch Cabling Recommendations........................................................71

2.6 Setting Up the USB Console................................................................................... 73

2.7 Bringing Up the System For the First Time................................................................73

2.7.1 Start-up Procedures.................................................................................. 73

2.7.2 Changing the Switch IP Address and Default Gateway through the CLI............. 73

2.7.3 Updating the Management Module IP Addresses in a Director Class

Redundant Management Configuration........................................................75

2.8 Component LEDs.................................................................................................. 75

2.8.1 Edge Switch LEDs..................................................................................... 76

2.8.2 Director Class LEDs................................................................................... 79

Appendix A Q7 BIOS Update............................................................................................. 86

A.1 Before Getting Started.......................................................................................... 86

A.1.1 Prior to Upgrading.....................................................................................86

A.2 Displaying the Current Version................................................................................86

A.3 SFTP Server Configuration..................................................................................... 87

A.4 Updating the Edge Switches................................................................................... 87

A.4.1 Performing the Upgrade.............................................................................87

A.5 Updating Director Class Switches............................................................................ 88

A.5.1 Performing the Upgrade.............................................................................88

Appendix B Director Switch Cable Management................................................................ 90

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 5

Intel® Omni-Path Fabric Switches Hardware

Page 6

®

Omni-Path Fabric—Figures

Intel

Figures

1 Edge Switch Port Connection Limitations.....................................................................29

2 QSFP Cable Connector Orientation............................................................................. 29

3 Copper Cable Bend Radius ....................................................................................... 30

4 Fiber Optic Bend Radius ...........................................................................................31

5 Intel® Omni-Path Edge Switch Rail.............................................................................33

6 Rail Installation Pin.................................................................................................. 34

7 Installed the Rack Rails............................................................................................ 34

8 Intel® Omni-Path Fabric Edge Switch Mounted in a Four Post Standard Rack....................35

9 Switch Rail Adjustments........................................................................................... 36

10 Rail Adjustment Notches...........................................................................................36

11 Edge Baffle (Top View)............................................................................................. 38

12 Secure the Top Baffle to the Switch............................................................................39

13 Remove Rail Post.....................................................................................................39

14 Insert Clamp on Baffles............................................................................................ 39

15 Clamp over Rail Post................................................................................................ 40

16 Reattach the Rail Post.............................................................................................. 40

17 Switch Fascia.......................................................................................................... 41

18 Rail Posts for Fascia Installation................................................................................. 41

19 Switch Cover Thumbscrews (Top View).......................................................................42

20 Fan Assembly Rotation............................................................................................. 42

21 Wire Assembly Strain Relief and Airflow Direction Indicators..........................................43

22 Q7 Management Module........................................................................................... 43

23 Switch Cover Thumbscrews (Top View).......................................................................44

24 Installing the Q7 Module...........................................................................................44

25 Q7 Module Mounting Screw.......................................................................................45

26 Unpacking the Switch (1)......................................................................................... 46

27 Unpacking the Switch (2)......................................................................................... 47

28 Unpacking the Switch (3)......................................................................................... 48

29 Unpacking the Switch (4)......................................................................................... 48

30 Unpacking the Switch (5)......................................................................................... 49

31 Unpacking the Switch (6)......................................................................................... 50

32 Unpacking the Switch (7)......................................................................................... 51

33 Measure the Rack.................................................................................................... 52

34 Preset the Adjustable Rails........................................................................................52

35 Install Fixture Brackets.............................................................................................53

36 Secure Shelf to Rack................................................................................................53

37 Secure the Baffles to Top of Shelf Rails....................................................................... 54

38 Secure the Top of the Baffles to the Rack Rails.............................................................55

39 Completed Shelf Assemblies......................................................................................56

40 Slide the Chassis into the Rack..................................................................................57

41 Fasten the Chassis to the Rack.................................................................................. 58

42 Completed Switch Installations..................................................................................59

43 Installing Cable Management.................................................................................... 60

44 Module Installation 1................................................................................................62

45 Module Installation 2................................................................................................63

46 Module Installation 3................................................................................................63

47 Module Installation 4................................................................................................64

48 Module Installation 5................................................................................................64

49 Edge Power Supply Install 1......................................................................................66

50 Edge Power Supply Install 2......................................................................................67

51 Edge Fan Supply Install 1......................................................................................... 67

52 Edge Fan Supply Install 2......................................................................................... 68

53 Edge Switch Serial and Ethernet Ports........................................................................ 68

54 Director Switch Serial and Ethernet Ports ...................................................................68

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

6 Doc. No.: H76456, Rev.: 10.0

Page 7

Figures—Intel® Omni-Path Fabric

55 Director Class Leaf Slot Numbering............................................................................ 69

56 Leaf Module Port Numbering..................................................................................... 70

57 48-Port Leaf Module Port Numbering ......................................................................... 70

58 Chassis Viewer GUI Leaf Port Stats Scree....................................................................71

59 48-Port Edge Switch Cabling Recommendations...........................................................72

60 Edge Switch LEDs.................................................................................................... 76

61 Ports, Fabric Manager (FM), Managed (M), and FM Switch LEDs..................................... 77

62 Activating the FM Enable Switch LED.......................................................................... 78

63 Power Supply LEDs.................................................................................................. 79

64 Airflow Direction LED............................................................................................... 79

65 Management Module LEDs........................................................................................ 80

66 Leaf Module LEDs.................................................................................................... 81

67 Spine Module LEDs.................................................................................................. 82

68 SEEB Module LEDs...................................................................................................83

69 Director Class Fan LEDs............................................................................................84

70 Director Class Power Supply LEDs..............................................................................85

71 Leaf Cabling............................................................................................................90

72 Using Velcro Ties and the Cable Management Hanger................................................... 90

73 Tying Off All Cables..................................................................................................91

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 7

Intel® Omni-Path Fabric Switches Hardware

Page 8

®

Omni-Path Fabric—Tables

Intel

Tables

1 Cable Bend Radius Guidelines....................................................................................30

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

8 Doc. No.: H76456, Rev.: 10.0

Page 9

Preface—Intel® Omni-Path Fabric

Preface

This manual is part of the documentation set for the Intel® Omni-Path Fabric (Intel

OP Fabric), which is an end-to-end solution consisting of Intel® Omni-Path Host Fabric

Interfaces (HFIs), Intel® Omni-Path switches, and fabric management and

development tools.

The Intel® OP Fabric delivers the next generation, High-Performance Computing (HPC)

network solution that is designed to cost-effectively meet the growth, density, and

reliability requirements of large-scale HPC clusters.

Both the Intel® OP Fabric and standard InfiniBand* (IB) are able to send Internet

Protocol (IP) traffic over the fabric, or IPoFabric. In this document, however, it may

also be referred to as IP over IB or IPoIB. From a software point of view, IPoFabric

behaves the same way as IPoIB, and in fact uses an ib_ipoib driver to send IP traffic

over the ib0/ib1 ports.

Intended Audience

The intended audience for the Intel® Omni-Path (Intel® OP) document set is network

administrators and other qualified personnel.

Intel® Omni-Path Documentation Library

Intel® Omni-Path publications are available at the following URLs:

• Intel® Omni-Path Switches Installation, User, and Reference Guides

http://www.intel.com/omnipath/SwitchPublications

• Intel® Omni-Path Software Installation, User, and Reference Guides (includes HFI

documents)

http://www.intel.com/omnipath/FabricSoftwarePublications

• Drivers and Software (including Release Notes)

http://www.intel.com/omnipath/Downloads

®

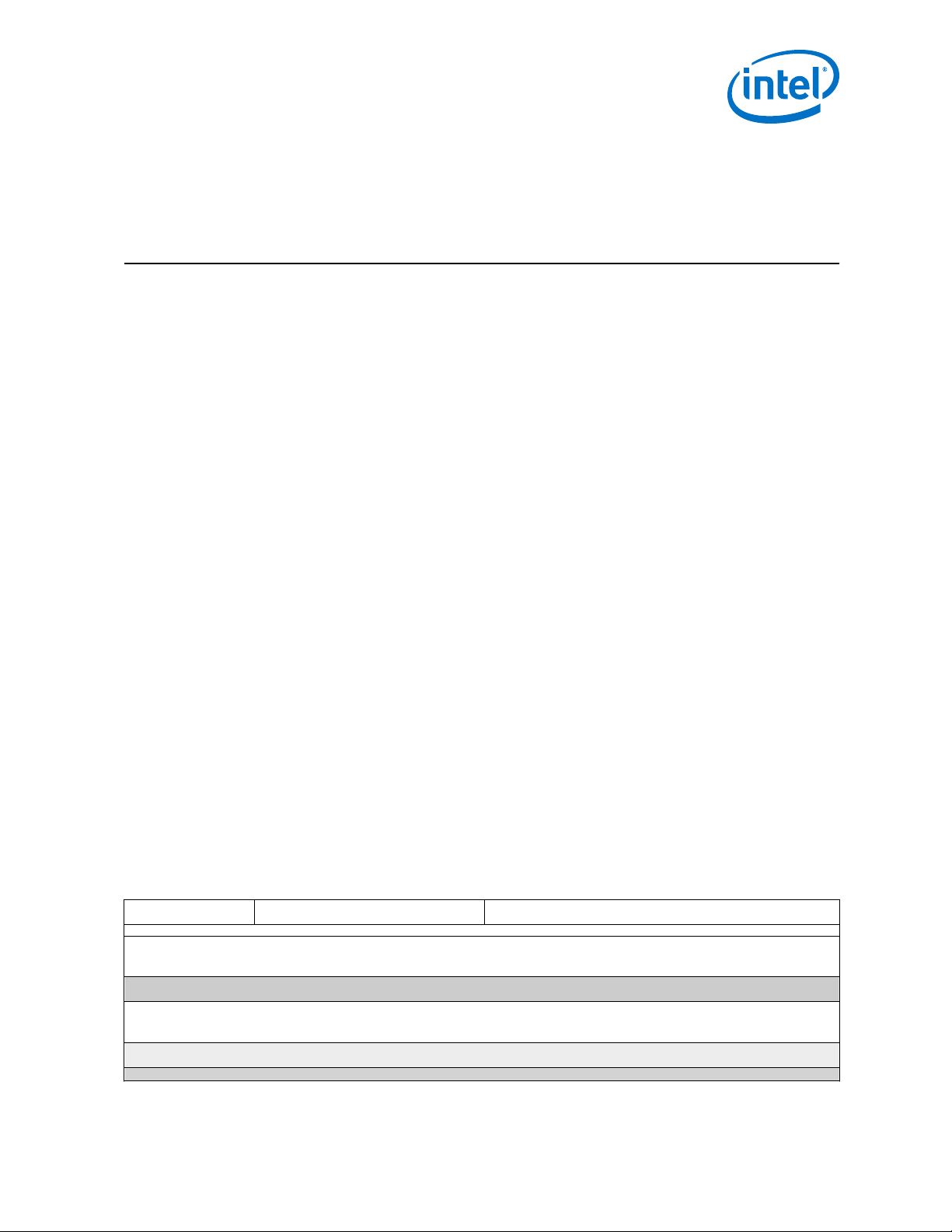

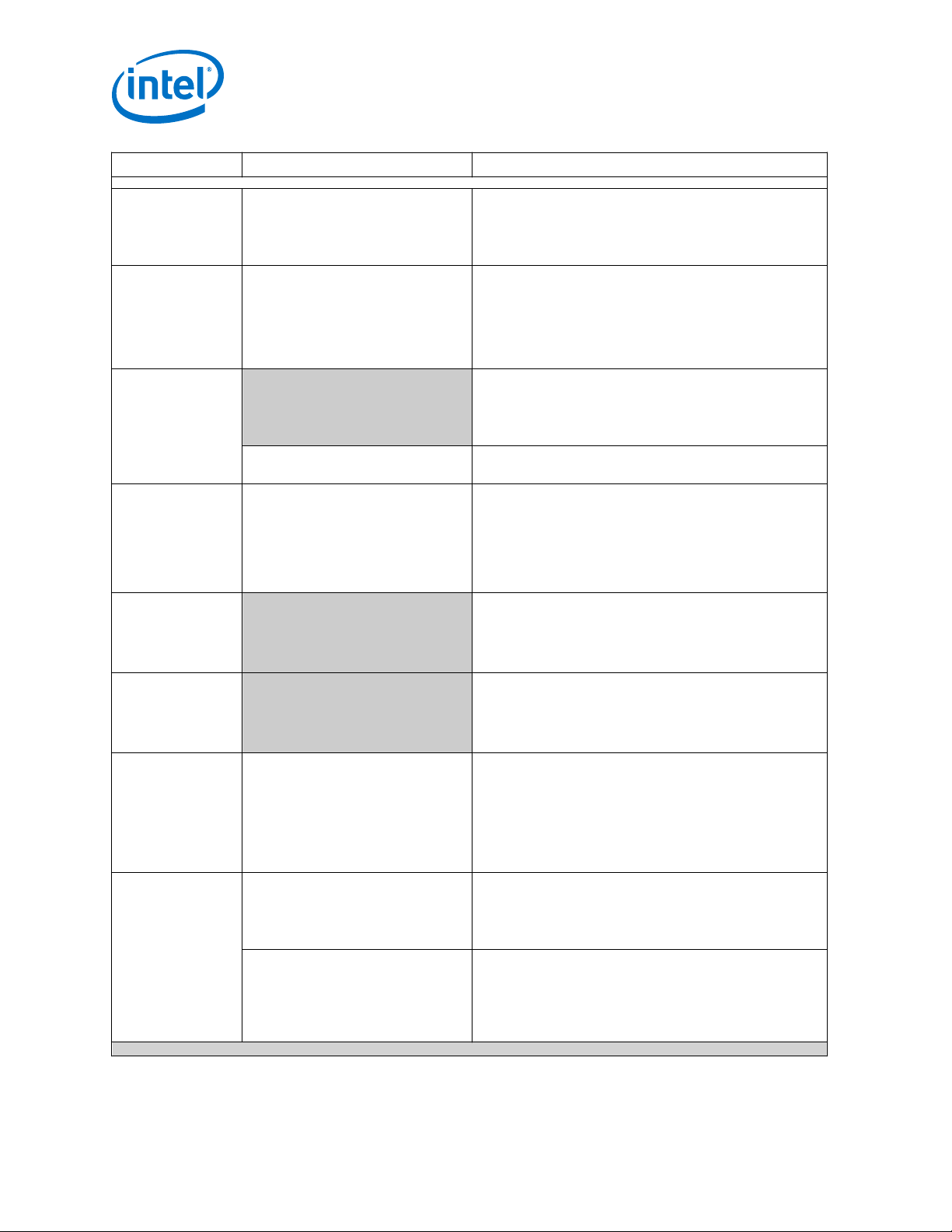

Use the tasks listed in this table to find the corresponding Intel® Omni-Path

document.

Task

Key:

Shading indicates the URL to use for accessing the particular document.

• Intel® Omni-Path Switches Installation, User, and Reference Guides: http://www.intel.com/omnipath/SwitchPublications

• Intel® Omni-Path Software Installation, User, and Reference Guides (includes HFI documents):

http://www.intel.com/omnipath/FabricSoftwarePublications (no shading)

• Drivers, Software, and Firmware (including Release Notes): http://www.intel.com/omnipath/Downloads

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 9

Document Title Description

continued...

Intel® Omni-Path Fabric Switches Hardware

Page 10

Task Document Title Description

A roadmap to Intel's comprehensive library of publications

Using the Intel® OPA

documentation set

Intel® Omni-Path Fabric Quick Start

Guide

describing all aspects of the product family. This document

outlines the most basic steps for getting your Intel® OmniPath Architecture (Intel® OPA) cluster installed and

operational.

Provides a high level overview of the steps required to stage

a customer-based installation of the Intel® Omni-Path Fabric.

Setting up an Intel

OPA cluster

®

Intel® Omni-Path Fabric Setup Guide

Procedures and key reference documents, such as Intel

Omni-Path user guides and installation guides, are provided

to clarify the process. Additional commands and best known

methods are defined to facilitate the installation process and

troubleshooting.

Describes the hardware installation and initial configuration

tasks for the Intel® Omni-Path Switches 100 Series. This

includes: Intel® Omni-Path Edge Switches 100 Series, 24 and

48-port configurable Edge switches, and Intel® Omni-Path

Director Class Switches 100 Series.

Contains instructions for installing the HFI in an Intel® OPA

cluster.

Installing hardware

Intel® Omni-Path Fabric Switches

Hardware Installation Guide

Intel® Omni-Path Host Fabric Interface

Installation Guide

Installing host

software

Installing HFI

firmware

Installing switch

firmware (externally-

Intel® Omni-Path Fabric Software

Installation Guide

Describes using a Text-based User Interface (TUI) to guide

you through the installation process. You have the option of

using command line interface (CLI) commands to perform the

installation or install using the Linux* distribution software.

managed switches)

Managing a switch

using GUI

Installing switch

firmware (managed

switches)

Describes the graphical user interface (GUI) of the Intel

Omni-Path Fabric GUI. This document provides task-oriented

procedures for configuring and managing the Intel® OmniPath Switch family.

Help: GUI embedded help files

Managing a switch

using the CLI

Installing switch

firmware (managed

Intel® Omni-Path Fabric Switches

Command Line Interface Reference

Guide

Describes the command line interface (CLI) task information

for the Intel® Omni-Path Switch family.

Help: -help for each CLI

switches)

Provides instructions for using the set of fabric management

tools designed to simplify and optimize common fabric

management tasks. The management tools consist of Text-

Managing a fabric

using FastFabric

Intel® Omni-Path Fabric Suite

FastFabric User Guide

based User Interface (TUI) menus and command line

interface (CLI) commands.

Help: -help and man pages for each CLI. Also, all host CLI

commands can be accessed as console help in the Fabric

Manager GUI.

The Fabric Manager uses a well defined management protocol

Intel® Omni-Path Fabric Suite Fabric

Manager User Guide

to communicate with management agents in every Intel

Omni-Path Host Fabric Interface (HFI) and switch. Through

these interfaces the Fabric Manager is able to discover,

configure, and monitor the fabric.

Managing a fabric

using Fabric Manager

Intel® Omni-Path Fabric Suite Fabric

Manager GUI User Guide

Provides an intuitive, scalable dashboard and set of analysis

tools for graphically monitoring fabric status and

configuration. This document is a user-friendly alternative to

traditional command-line tools for day-to-day monitoring of

fabric health.

Help: Fabric Manager GUI embedded help files

Intel® Omni-Path Fabric—Preface

®

®

®

continued...

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

10 Doc. No.: H76456, Rev.: 10.0

Page 11

®

Preface—Intel

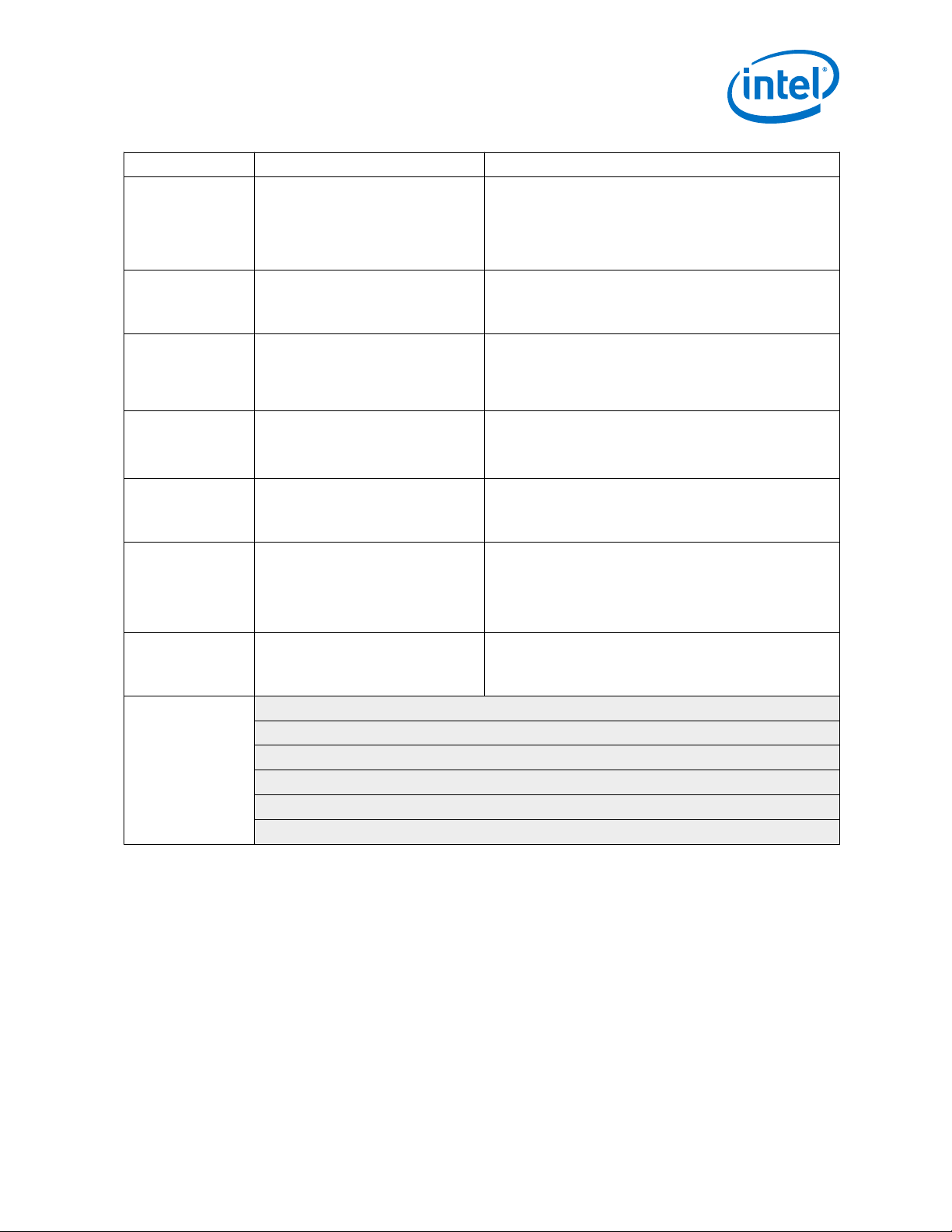

Configuring and

administering Intel

HFI and IPoIB driver

Running MPI

applications on

Intel® OPA

Writing and running

middleware that

uses Intel® OPA

Optimizing system

performance

Designing an IP or

LNet router on Intel

OPA

Building Containers

for Intel® OPA

fabrics

Writing management

applications that

interface with Intel

OPA

Using NVMe* over

Fabrics on Intel

OPA

Learning about new

release features,

open issues, and

resolved issues for a

particular release

Omni-Path Fabric

Task Document Title Description

®

®

Intel® Omni-Path Fabric Host Software

User Guide

Intel® Performance Scaled Messaging

2 (PSM2) Programmer's Guide

Intel® Omni-Path Fabric Performance

Tuning User Guide

Intel® Omni-Path IP and LNet Router

Design Guide

®

(Old title: Intel® Omni-Path IP and

Storage Router Design Guide)

Building Containers for Intel® OmniPath Fabrics using Docker* and

Singularity* Application Note

Intel® Omni-Path Management API

®

Programmer’s Guide

Configuring Non-Volatile Memory

Express* (NVMe*) over Fabrics on

Intel® Omni-Path Architecture

Application Note

Intel® Omni-Path Fabric Software Release Notes

Intel® Omni-Path Fabric Manager GUI Release Notes

Intel® Omni-Path Fabric Switches Release Notes (includes managed and externally-managed switches)

Intel® Omni-Path Fabric Unified Extensible Firmware Interface (UEFI) Release Notes

Intel® Omni-Path Fabric Thermal Management Microchip (TMM) Release Notes

Intel® Omni-Path Fabric Firmware Tools Release Notes

Describes how to set up and administer the Host Fabric

Interface (HFI) after the software has been installed. The

audience for this document includes cluster administrators

and Message-Passing Interface (MPI) application

programmers.

Provides a reference for programmers working with the Intel

PSM2 Application Programming Interface (API). The

Performance Scaled Messaging 2 API (PSM2 API) is a lowlevel user-level communications interface.

Describes BIOS settings and parameters that have been

shown to ensure best performance, or make performance

more consistent, on Intel® Omni-Path Architecture. If you are

interested in benchmarking the performance of your system,

these tips may help you obtain better performance.

Describes how to install, configure, and administer an IPoIB

router solution (Linux* IP or LNet) for inter-operating

between Intel® Omni-Path and a legacy InfiniBand* fabric.

Provides basic information for building and running Docker*

and Singularity* containers on Linux*-based computer

platforms that incorporate Intel® Omni-Path networking

technology.

Contains a reference for programmers working with the

Intel® Omni-Path Architecture Management (Intel OPAMGT)

Application Programming Interface (API). The Intel OPAMGT

API is a C-API permitting in-band and out-of-band queries of

the FM's Subnet Administrator and Performance

Administrator.

Describes how to implement a simple Intel® Omni-Path

Architecture-based point-to-point configuration with one

target and one host server.

®

How to Search the Intel® Omni-Path Documentation Set

Many PDF readers, such as Adobe* Reader and Foxit* Reader, allow you to search

across multiple PDFs in a folder.

Follow these steps:

1. Download and unzip all the Intel® Omni-Path PDFs into a single folder.

2. Open your PDF reader and use CTRL-SHIFT-F to open the Advanced Search

window.

3. Select All PDF documents in...

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 11

Intel® Omni-Path Fabric Switches Hardware

Page 12

4. Select Browse for Location in the dropdown menu and navigate to the folder

containing the PDFs.

5. Enter the string you are looking for and click Search.

Use advanced features to further refine your search criteria. Refer to your PDF reader

Help for details.

Cluster Configurator for Intel® Omni-Path Fabric

The Cluster Configurator for Intel® Omni-Path Fabric is available at: http://

www.intel.com/content/www/us/en/high-performance-computing-fabrics/omni-pathconfigurator.html.

This tool generates sample cluster configurations based on key cluster attributes,

including a side-by-side comparison of up to four cluster configurations. The tool also

generates parts lists and cluster diagrams.

Documentation Conventions

The following conventions are standard for Intel® Omni-Path documentation:

• Note: provides additional information.

• Caution: indicates the presence of a hazard that has the potential of causing

damage to data or equipment.

• Warning: indicates the presence of a hazard that has the potential of causing

personal injury.

• Text in blue font indicates a hyperlink (jump) to a figure, table, or section in this

guide. Links to websites are also shown in blue. For example:

See License Agreements on page 13 for more information.

For more information, visit www.intel.com.

• Text in bold font indicates user interface elements such as menu items, buttons,

check boxes, key names, key strokes, or column headings. For example:

Click the Start button, point to Programs, point to Accessories, and then click

Command Prompt.

Press CTRL+P and then press the UP ARROW key.

•

Text in Courier font indicates a file name, directory path, or command line text.

For example:

Enter the following command: sh ./install.bin

• Text in italics indicates terms, emphasis, variables, or document titles. For

example:

Refer to Intel® Omni-Path Fabric Software Installation Guide for details.

In this document, the term chassis refers to a managed switch.

®

Omni-Path Fabric—Preface

Intel

Procedures and information may be marked with one of the following qualifications:

• (Linux) – Tasks are only applicable when Linux* is being used.

• (Host) – Tasks are only applicable when Intel® Omni-Path Fabric Host Software or

Intel® Omni-Path Fabric Suite is being used on the hosts.

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

12 Doc. No.: H76456, Rev.: 10.0

Page 13

®

Preface—Intel

Omni-Path Fabric

• (Switch) – Tasks are applicable only when Intel® Omni-Path Switches or Chassis

are being used.

• Tasks that are generally applicable to all environments are not marked.

Laser Safety Information

This product may use Class 1 laser optical transceivers to communicate over the fiber

optic conductors. The U.S. Department of Health and Human Services (DHHS) does

not consider Class 1 lasers to be hazardous. The International Electrotechnical

Commission (IEC) 825 Laser Safety Standard requires labeling in English, German,

Finnish, and French stating that the product uses Class 1 lasers. Because it is

impractical to label the transceivers, the following label is provided in this manual.

Electrostatic Discharge Sensitivity (ESDS) Precautions

The assemblies used in the switch chassis are ESD sensitive. Observe ESD handling

procedures when handling any assembly used in the switch chassis.

License Agreements

This software is provided under one or more license agreements. Please refer to the

license agreement(s) provided with the software for specific detail. Do not install or

use the software until you have carefully read and agree to the terms and conditions

of the license agreement(s). By loading or using the software, you agree to the terms

of the license agreement(s). If you do not wish to so agree, do not install or use the

software.

Technical Support

Technical support for Intel® Omni-Path products is available 24 hours a day, 365 days

a year. Please contact Intel Customer Support or visit http://www.intel.com/omnipath/

support for additional detail.

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 13

Intel® Omni-Path Fabric Switches Hardware

Page 14

1.0 Introduction

This manual describes the hardware installation and initial configuration tasks for the

Intel® Omni-Path Switch 100 Series. This includes:

• Intel® Omni-Path Edge Switch 100 Series, 24 and 48-port configurable edge

switches

• Intel® Omni-Path Director Class Switch 100 Series

This manual is organized as follows:

This Introduction describes the product safety information.

Installation describes the hardware installation and initial configuration tasks.

Appendix Q7 BIOS Update provides instructions for updating the Q7 BIOS on Edge and

Director Class Switches.

Intel® Omni-Path Fabric—Introduction

1.1

Safety Information

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

14 Doc. No.: H76456, Rev.: 10.0

Page 15

Introduction—Intel® Omni-Path Fabric

Statement 11.1.1

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 15

Intel® Omni-Path Fabric Switches Hardware

Page 16

Intel® Omni-Path Fabric—Introduction

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

16 Doc. No.: H76456, Rev.: 10.0

Page 17

Introduction—Intel® Omni-Path Fabric

Statement 21.1.2

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 17

Intel® Omni-Path Fabric Switches Hardware

Page 18

Intel® Omni-Path Fabric—Introduction

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

18 Doc. No.: H76456, Rev.: 10.0

Page 19

Introduction—Intel® Omni-Path Fabric

Statement 31.1.3

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 19

Intel® Omni-Path Fabric Switches Hardware

Page 20

Intel® Omni-Path Fabric—Introduction

1.1.4

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

20 Doc. No.: H76456, Rev.: 10.0

Statement 4

Page 21

Introduction—Intel® Omni-Path Fabric

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 21

Intel® Omni-Path Fabric Switches Hardware

Page 22

Intel® Omni-Path Fabric—Introduction

1.1.5

Statement 5

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

22 Doc. No.: H76456, Rev.: 10.0

Page 23

Introduction—Intel® Omni-Path Fabric

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 23

Intel® Omni-Path Fabric Switches Hardware

Page 24

Intel® Omni-Path Fabric—Introduction

Statement 61.1.6

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

24 Doc. No.: H76456, Rev.: 10.0

Page 25

Introduction—Intel® Omni-Path Fabric

Statement 71.1.7

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 25

Intel® Omni-Path Fabric Switches Hardware

Page 26

Intel® Omni-Path Fabric—Introduction

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

26 Doc. No.: H76456, Rev.: 10.0

Page 27

Introduction—Intel® Omni-Path Fabric

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 27

Intel® Omni-Path Fabric Switches Hardware

Page 28

2.0 Installation

This section describes how to install and configure for first-time use:

• The Intel® Omni-Path Fabric Series switches in a network environment.

Intel® Omni-Path Fabric—Installation

2.1

Planning the Installation

The Intel® Omni-Path switches are designed for installation in standard 19-inch

equipment racks.

Racks should conform to conventional standards. Use the American National

Standards Institute (ANSI)/Electronic Industries Association (EIA) standard ANSI/

EIA-310-D-92 and International Electrotechnical Commission (IEC) 297

Racks should meet the following mechanical recommendations:

• Four-post, 19" rack to facilitate easy maintenance

• Universal mounting rail hole pattern identified in IEC Standard 297

• Mounting holes flush with the rails to accommodate the chassis

NOTE

Operation is subject to the following conditions:

NOTE

Use a rack grounding kit and a ground conductor that is carried back to earth or to

another suitable building ground. Ground the equipment rack to earth ground.

NOTE

Provide enough room to work on the equipment. Clear the work site of any

unnecessary materials. Make sure the equipment will have enough clearance for front

and rear access.

2.1.1

2.1.1.1

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

28 Doc. No.: H76456, Rev.: 10.0

Cable Requirements

Cable Distances

When planning the location of the switches, consider the distance limitations for

signaling, EMI, and connector compatibility. It is recommended that the user does not

exceed specified transmission rate and distance limits.

NOTE

When connecting the outer ports of two (2) 48-port Edge switches (highlighted green

in Figure 1 below), make certain to use active optical cables (AOC) for distances

greater than 2 meters.

Page 29

Installation—Intel® Omni-Path Fabric

Figure 1. Edge Switch Port Connection Limitations

2.1.1.2

Cable Guidelines

NOTE

Building and electrical codes vary depending on the location. Comply with all code

specifications when planning the site and installing cable.

When running cable to the equipment, consider the following:

• Do not run cables where they can be stepped on or rolled over.

• Be sure cables are intact with no cuts, bends, or nicks.

• If the user is making a cable, ensure that the cable is properly crimped.

• Provide proper strain relief for cables.

• Support cables using a cable manager mounted above connectors to avoid

unnecessary weight on the cable bundles.

• Bundle cable using Velcro straps to avoid injuring cables.

• Keep all ports and connectors free of dust.

• Untwisted Pair (UTP) cables can build up Electrostatic Discharge (ESD) charges

when being placed into a new installation. Before installing category 5 UTP cables,

discharge ESD from the cable by plugging it into a port on a system that is not

powered on.

• When required for safety and fire rating requirements, plenum-rated cable can be

used. Check the local building codes to determine when it is appropriate to use

plenum-rated cable, or refer to IEC standard 850.

• In order to create enough space, QSFP cables connectors may need to be rotated

when plugging into alternate rows of switch components.

Figure 2. QSFP Cable Connector Orientation

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 29

Intel® Omni-Path Fabric Switches Hardware

Page 30

Intel® Omni-Path Fabric—Installation

2.1.1.3

Cable Handling and Bend Radius

• Intel® Omni-Path Copper Cable 100 Series:

— Recommended minimum bend radius is >69mm

• Intel® Omni-Path Active Optical Cable 100 Series:

— Recommended minimum bend radius is >105 mm within 100 mm of either

cable end module, and >60 mm on the rest of the cable

Table 1. Cable Bend Radius Guidelines

Intel® Omni-Path Copper Cable 100 Series

American Wire Gauge (AWG) Size Cable Bend Radius

26 >69 mm

30 >66 mm

Intel® Omni-Path Active Optical Cable 100 Series

Gauge Bend Radius

Optical >105 mm within 100 mm of either cable end module

Figure 3. Copper Cable Bend Radius

>60 mm on the rest of the cable

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

30 Doc. No.: H76456, Rev.: 10.0

Page 31

Installation—Intel® Omni-Path Fabric

Figure 4. Fiber Optic Bend Radius

2.1.2

2.2

Uninterruptible Power Supply Equipment

Consider the following when selecting uninterruptible power supply (UPS) equipment:

• The minimum amperage requirements for a UPS:

— Calculate VA (volt-amps): Locate the voltage and amperage requirements for

each piece of equipment (usually located on a sticker on the back or bottom of

the equipment). Multiply the numbers together to get VA.

— Add the VA from each piece of equipment together to find the total VA

requirement. Then add 30% to determine the minimum amperage

requirements for the UPS.

• Transition time (the time necessary for the UPS to transfer from utility power to

full-load battery power).

• The longest potential time period the UPS might be required to supply backup

power.

• Whether the UPS unit provides online protection.

Installation Tasks Checklist

To perform the actual switch installation, the site implementation engineer must

perform the following tasks, which are detailed in this section.

CAUTION

Be sure to review the safety information before starting the installation and during the

installation process (refer to Safety Information on page 14).

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 31

Intel® Omni-Path Fabric Switches Hardware

Page 32

Intel® Omni-Path Fabric—Installation

1. Check the installation site to verify the installation of cabinet power feeds, rails,

and grounding.

2. Unpack the equipment and inspect for any shipping damage. Any shipping damage

should be reported to the shipping company.

3. Verify that the equipment shipped matches the packing list.

4. Mark the rack and install the mounting rails.

5. Physically install the switch in the rack.

2.2.1

2.2.2

Tools and Equipment Required

• An ESD wrist strap

• A #0 and #2 Phillips screwdriver

• An M6 HEX nut wrench

• M6 screws

• Torque wrench

• Open sockets or open wrenches

• Lifting device (e.g., pallet jack) for the Intel® Omni-Path Director Class Switch 100

Series

Check the Installation Site

The switches are designed to be installed in an existing server cabinet (not a telco

cabinet), where it can be mounted in a standard equipment rack.

Be sure of the following:

• The cabinet has a full earth ground to provide reliable grounding.

• There is enough room to work on the equipment.

• The equipment will have enough clearance for front and rear access.

• The cables can be accessed easily.

• Water or moisture cannot enter the switch.

• The ambient temperature stays between 50–113 °F (5–40 °C).

• Cabinet doors do not interfere with front-to-back air flow.

The cabinet should have its own switchable power distribution. If the switch has two

power supplies, it is suggested that a cabinet with dual power distribution units is

used.

It is recommended that cabinet anti-tip devices are used. This is especially true if

installing or removing a switch in the upper half of the cabinet when the lower half is

empty.

2.2.3

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

32 Doc. No.: H76456, Rev.: 10.0

Mark the Rack

Allow enough vertical space in the rack for each specific switch installation.

1. Determine the location in the rack of the bottom of the switch.

Page 33

Installation—Intel® Omni-Path Fabric

2. Mark the upper (if applicable) and lower mounting positions on the vertical rails on

the front of the rack.

3. Mark the upper (if applicable) and lower mounting positions on the vertical rails on

the back of the rack.

2.3

2.3.1

2.3.2

Figure 5. Intel® Omni-Path Edge Switch Rail

Intel® Omni-Path Fabric Edge Switch Installation

This section describes the rack mounting instructions for the 24- and 48-port Intel

Omni-Path Fabric Edge Switches in a four-post standard-depth rack. The installation of

either switch is very similar; the majority of steps apply to both switches. Where

applicable, any specifics for either switch are called out.

In a standard-depth rack, the distance between the front and back mounting posts is

~28" (700 mm). Mounting rails for the switch are adjustable to accommodate racks

with 26"–32" between mounting posts.

Mounting Hardware Kit Contents

The Mounting Kit contains:

• ESD wrist strap

• One pair of mounting rails adjustable for 26"–32" installation range

• M6 hex head screws

• Front 1U perforated cover

Rack Mounting

®

1. Insert the rail installation pin in to the rack hole as shown in the following figure.

This holds the rail in place so the user can install the fan side screws.

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 33

Intel® Omni-Path Fabric Switches Hardware

Page 34

Figure 6. Rail Installation Pin

a. Fasten the rail using two (2) M6 screws.

b. Torque screws to 30 in-lb.

c. Repeat this step for the second rail.

2. Fasten the port-side rails using four (4) M6 screws.

a. Torque screws to 30 in-lb.

Note the orientation of mounting rails in the following figure. The rails are

shown from the front side of the rack.

®

Omni-Path Fabric—Installation

Intel

Figure 7. Installed the Rack Rails

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

34 Doc. No.: H76456, Rev.: 10.0

Page 35

®

Installation—Intel

Omni-Path Fabric

Figure 8. Intel® Omni-Path Fabric Edge Switch Mounted in a Four Post Standard Rack

3. The rails are designed for different mounting positions, from flush mount to

recessed (in 1 inch increments) as shown in the following figure.

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 35

Intel® Omni-Path Fabric Switches Hardware

Page 36

Figure 9. Switch Rail Adjustments

®

Omni-Path Fabric—Installation

Intel

4. To change the depth of the switch, insert your fingers into the rail adjustment

notches and pull away from the switch as shown in the following figure.

This disengages the rail latches from the switch hat section.

Figure 10. Rail Adjustment Notches

5. Slide the switch to the desired depth in the rack.

The switch is adjustable in increments of 1 inch. When the switch is at the proper

depth, push the rail adjustment notches back to their original position to secure in

place.

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

36 Doc. No.: H76456, Rev.: 10.0

Page 37

Installation—Intel® Omni-Path Fabric

2.3.3

Installing the Airflow Baffles

For rack cabinet installations of high-powered servers and associated fabric

equipment, it is critical for proper cooling of the equipment that air recirculation from

the air outlet side of the equipment to the inlet side of the equipment be minimized.

Following are some general requirements:

• All equipment in a given cabinet must be configured to the same flow pattern

• All unused 'U' increments must have some type of closeout installed

• Cabinet side spaces must be closed off

• Any front-to-back cable pass-through paths must be configured with flexible fillers

allowing for the cable to pass through-but not air. This is also true for patch

panels.

• Top-of-rack and bottom-of-rack transitions must be closed out

The Intel® Omni-Path Edge switch is generally shorter than the associated servers

installed in the same cabinet. Therefore, the following additional considerations should

be considered:

• The mounting rails supplied with the edge switch are adequate for closing off the

left-and-right side spaces on the cabinet from the 'U' increment the edge switch

occupies. If full-depth servers are installed directly above and below the edge

switch this will generally suffice to close off the space, minimizing recirculation.

However, if the space above and/or below the Edge switch is empty-or occupied by

racks that are not full depth-then the Air Baffle Kit that is available for the edge

product needs to be installed. This kit closes out the space between the fan grill

end of the switch and the front of the cabinet. The condition requiring the air

baffle may also exist in top-of-rack or bottom-of-rack installations, depending on

the cabinet geometry in these regions.

• The Edge Air Baffle Kit mounts to the mounting rails supplied with the switch and

is adjustable for various cabinet depths.

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 37

Intel® Omni-Path Fabric Switches Hardware

Page 38

Figure 11. Edge Baffle (Top View)

®

Omni-Path Fabric—Installation

Intel

NOTE

Installation of the baffle(s) take place after the edge switch has been rack mounted.

1. Unlock the rail system by pulling the handles out.

2. Guide the baffle onto the rails, then slide the baffle into the rack until it stops

against the edge switch.

a. Baffle Extension(s): Each baffle (i.e., top and bottom) has an extension

(shown in yellow below). If not pre-configured, insert 4 screws (2 on each

side) to secure the extension to the main baffle. The location of the screws

depends upon the depth that the edge has been mounted.

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

38 Doc. No.: H76456, Rev.: 10.0

Page 39

®

Installation—Intel

Omni-Path Fabric

Figure 12. Secure the Top Baffle to the Switch

3. After baffle is fully inserted, push the handles back until the rail locks in place.

To vertically secure the baffles, insert the baffle clamp (one on each side) as shown:

1. Unscrew the end of the rail post.

Figure 13. Remove Rail Post

2. Slide the clamp into place on the top and bottom baffles.

Figure 14. Insert Clamp on Baffles

3. Push the clamp into place over the rail post.

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 39

Intel® Omni-Path Fabric Switches Hardware

Page 40

Figure 15. Clamp over Rail Post

4. Reattach the rail post, which locks the clamp into place.

Figure 16. Reattach the Rail Post

Intel® Omni-Path Fabric—Installation

2.3.4

Installing the Switch Fascia

The Edge switch fascia guards against ESD as well as accidental contact with the fans

and power supplies.

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

40 Doc. No.: H76456, Rev.: 10.0

Page 41

Installation—Intel® Omni-Path Fabric

Figure 17. Switch Fascia

The fascia is installed by snapping it in place onto the switch rail posts.

Figure 18. Rail Posts for Fascia Installation

2.3.5

Reversing the Fan Airflow

This section details the procedure to reverse the airflow on the switch fan assembly

from the default port-side exhaust position.

Tools Required

• ESD wrist strap

• #0 Phillips screwdriver

Procedure

NOTE

Before removing the cover from the switch, first disconnect the power cord(s).

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 41

Intel® Omni-Path Fabric Switches Hardware

Page 42

1. Loosen the 4 thumbscrews from the switch cover. There are 3 screws on the top,

and 5 screws on the back. Lift the cover on a 45-degree angle, then pull to

remove.

Figure 19. Switch Cover Thumbscrews (Top View)

®

Omni-Path Fabric—Installation

Intel

2. Holding the fan assembly on the sides lift straight up and rotate the fan assembly

180 degrees as shown in the following figure.

Figure 20. Fan Assembly Rotation

3. Lower the fan assembly straight down. The airflow direction indicators should now

face towards the rear of the chassis as shown in the following figure.

NOTE

Make certain to provide strain relief for the wire assembly.

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

42 Doc. No.: H76456, Rev.: 10.0

Page 43

Installation—Intel® Omni-Path Fabric

Figure 21. Wire Assembly Strain Relief and Airflow Direction Indicators

4. Reattach the switch cover.

2.3.6

Installing the Q7 Management Module

This section details the procedure to install the Q7 Management Module into an

existing externally-managed edge switch.

Figure 22. Q7 Management Module

Tools Required

• ESD wrist strap

• #0 Phillips screwdriver

• Regular screwdriver

Procedure

NOTE

Before removing the cover from the switch, first disconnect the power cord(s).

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 43

Intel® Omni-Path Fabric Switches Hardware

Page 44

1. Loosen the 4 thumbscrews from the switch cover. There are 3 screws on the top,

and 5 screws on the back. Lift the cover on a 45-degree angle, then pull to

remove.

Figure 23. Switch Cover Thumbscrews (Top View)

2. Holding the module at approximately a 45-degree angle, slide the connector into

module slot. Make certain to line up the notch on the module and the connector

(see following figure).

®

Omni-Path Fabric—Installation

Intel

Figure 24. Installing the Q7 Module

3. Once the module is seated properly in the connector, secure screw to the chassis

using a regular screwdriver.

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

44 Doc. No.: H76456, Rev.: 10.0

Page 45

Installation—Intel® Omni-Path Fabric

Figure 25. Q7 Module Mounting Screw

4. Reattach the switch cover.

NOTE

For information on upgrading Q7 board controller firmware (BCFW) and BIOS, refer to

Q7 BIOS Update on page 86.

2.4

2.4.1

2.4.2

Intel® Omni-Path Director Class Switch 100 Series Installation

Mounting Hardware Kit Contents

The Mounting Kit contains:

• Support Shelf (1)

• Baffles (2)

• #10 Mounting screws

• #10 Mounting nuts

• M6 Mounting Screws

Unpacking the Switch

NOTE

Set aside packaging materials in the event that the switch requires return shipment.

The following images and descriptions give a high-level overview for unpacking a

Director Switch (24-slot model in this example).

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 45

Intel® Omni-Path Fabric Switches Hardware

Page 46

Figure 26. Unpacking the Switch (1)

Intel® Omni-Path Fabric—Installation

1. Remove the banding.

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

46 Doc. No.: H76456, Rev.: 10.0

Page 47

®

Installation—Intel

Omni-Path Fabric

Figure 27. Unpacking the Switch (2)

2. Remove the lid.

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 47

Intel® Omni-Path Fabric Switches Hardware

Page 48

Figure 28. Unpacking the Switch (3)

®

Omni-Path Fabric—Installation

Intel

3. Remove the accessory kit box and white packing form. The accessory kit contains

required hardware, power cables, documentation, etc.

Figure 29. Unpacking the Switch (4)

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

48 Doc. No.: H76456, Rev.: 10.0

Page 49

Installation—Intel® Omni-Path Fabric

Figure 30. Unpacking the Switch (5)

4. Lift the box up out of the base.

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 49

Intel® Omni-Path Fabric Switches Hardware

Page 50

Figure 31. Unpacking the Switch (6)

®

Omni-Path Fabric—Installation

Intel

5. Remove the baffle boxes.

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

50 Doc. No.: H76456, Rev.: 10.0

Page 51

Installation—Intel® Omni-Path Fabric

Figure 32. Unpacking the Switch (7)

2.4.3

2.4.3.1

6. Remove the plastic bag, then remove the support shelf from the top of the switch.

Installation Tasks

The following section details rack mounting instructions for the 6-slot and 24-slot

Intel® Omni-Path Director Class Switch 100 Series. The installations are very similar;

the majority of steps apply to both switches. Where applicable, any specifics for either

the 6-slot or 24-slot Director are called out.

Installing the Support Shelf

1. Measure the inside distance between the front and middle rails on the cabinet (27"

in the following example).

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 51

Intel® Omni-Path Fabric Switches Hardware

Page 52

Figure 33. Measure the Rack

2. Before installing into the cabinet, preset the adjustable rails on the baffle base,

leaving the screws loose to the dimension measured on the cabinet (27" in this

example). In order to be able to fit the baffle base into the cabinet, set the rails to

slightly less than the measured size (i.e., < 27"). See the following figure.

®

Omni-Path Fabric—Installation

Intel

Figure 34. Preset the Adjustable Rails

3. Install the fixture brackets to the cabinet at the desired height (see the following

figure). The brackets support and help locate the installation of the baffle base.

Remove and discard/recycle the brackets after baffle base has been installed.

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

52 Doc. No.: H76456, Rev.: 10.0

Page 53

®

Installation—Intel

Omni-Path Fabric

Figure 35. Install Fixture Brackets

4. Secure the shelf to the rack using M6 mounting screws, 3 per shelf rail (1 in the

front and 2 in the back) as displayed in the following figure. Torque screws to 30

in-lb.

Figure 36. Secure Shelf to Rack

5. Attach the baffles to the top of each shelf rail using 10 mounting nuts, 5 per shelf

rail as displayed in the following figure. Torque nuts to 30 in-lb.

NOTE

Make certain to tighten the adjustable rail screws (from Step 2) at this time.

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 53

Intel® Omni-Path Fabric Switches Hardware

Page 54

Figure 37. Secure the Baffles to Top of Shelf Rails

®

Omni-Path Fabric—Installation

Intel

6. Secure the top of the baffles to the rack rail as displayed in the following figure:

• 6-Slot Chassis: use 2 mounting nuts, 1 per rail.

• 24-Slot Chassis: use the lower of the 2 openings, 1 mounting nut per rail.

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

54 Doc. No.: H76456, Rev.: 10.0

Page 55

®

Installation—Intel

Omni-Path Fabric

Figure 38. Secure the Top of the Baffles to the Rack Rails

7. The completed Shelf assemblies for both the 6- and 24-slot switches are displayed

in the following figure.

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 55

Intel® Omni-Path Fabric Switches Hardware

Page 56

Figure 39. Completed Shelf Assemblies

Intel® Omni-Path Fabric—Installation

2.4.3.2

Installing the Director Switch Chassis

WARNING

To avoid injury, do not lift a fully-loaded Director Class switch manually. Use a

mechanized lift only.

1. Align the chassis with the rack.

2. Using a pallet jack, raise the unit until the bottom of the chassis is at (or slightly

higher than) the surface of the support shelf installed in Steps 1 through 6. Lock

the pallet jack wheels.

3. Use a group of people to push the chassis from the front to slide it off the pallet

and on the support shelf. The chassis should be inserted into the rack until the

rear of the chassis base is against the rear support bracket.

NOTE

If you are installing the cable management guides (see Installing the Optional

Cable Management Guide on page 59), install the cage nuts into the rack rails

before fully sliding the chassis into the rack.

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

56 Doc. No.: H76456, Rev.: 10.0

Page 57

®

Installation—Intel

Omni-Path Fabric

Figure 40. Slide the Chassis into the Rack

4. Fasten the chassis to the rack with M6 screws:

• 6-Slot Director: six (6).

• 24-Slot Director: twelve (12).

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 57

Intel® Omni-Path Fabric Switches Hardware

Page 58

Figure 41. Fasten the Chassis to the Rack

Intel® Omni-Path Fabric—Installation

5. The completed switch installations for both the 6- and 24-slot switches are

displayed in the following figure.

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

58 Doc. No.: H76456, Rev.: 10.0

Page 59

Installation—Intel® Omni-Path Fabric

Figure 42. Completed Switch Installations

2.4.4

Installing the Optional Cable Management Guide

The optional Cable Management Guides are attached to the rack rails with M6 cage

nuts and screws as shown in the following figure.

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 59

Intel® Omni-Path Fabric Switches Hardware

Page 60

Figure 43. Installing Cable Management

®

Omni-Path Fabric—Installation

Intel

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

60 Doc. No.: H76456, Rev.: 10.0

Page 61

Installation—Intel® Omni-Path Fabric

2.4.5

Installing Director Class Modules

2.4.5.1

Spine, Leaf and Management Modules

NOTE

In order to maintain thermal integrity, all open Spine and Leafs slots must be

populated with filler panels.

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 61

Intel® Omni-Path Fabric Switches Hardware

Page 62

®

Omni-Path Fabric—Installation

Intel

NOTE

When installing the Leaf Module, there is no "correct" orientation (i.e., no top or

bottom).

These modules all have release arms that function in a similar way during installation.

The Management Module (MM) is used here as the example.

1. Grasp and pull the release arms out and away from the module body as shown in

the following figure.

Figure 44. Module Installation 1

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

62 Doc. No.: H76456, Rev.: 10.0

Page 63

®

Installation—Intel

Omni-Path Fabric

Figure 45. Module Installation 2

2. Slide the module straight into an applicable open slot until it engages with the

backplane connector.

CAUTION

Never push on the release arms when sliding the modules into the applicable

slots. Always apply pressure to the middle of the module as shown below.

Figure 46. Module Installation 3

3. Push the release arms in until they lock in place.

NOTE

The 48-port leaf module release arms will lock in place correctly; however the

module will protrude slightly from the leaf slot. This is normal.

4. Management Module only: Lower the MRL latch into the holes of the release

arms. Doing this allows the MM to communicate with the SEEB module on the

other side of chassis as shown in the following figure.

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 63

Intel® Omni-Path Fabric Switches Hardware

Page 64

Figure 47. Module Installation 4

5. Chassis management slot leaf only: If the leaf module is in one of the chassis

management slots (i.e., L101 or L102) the mechanical release latch (MRL) must

be moved in order to install the leaf. To move the MRL, loosen the thumbscrew

attached to the Serial, Ethernet, Chassis EEPROM Board (SEEB) module, then pull

down to release the MRL as shown in the following figure. This allows enough

clearance for leaf module to be installed.

Figure 48. Module Installation 5

®

Omni-Path Fabric—Installation

Intel

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

64 Doc. No.: H76456, Rev.: 10.0

Page 65

Installation—Intel® Omni-Path Fabric

2.4.5.2

2.4.5.3

Fans

1. Slide the fan module straight into an applicable open slot until it engages with the

backplane connector.

Power Supplies

1. Loosen the thumbscrew until it disengages from the power supply unit.

2. Pull the handle down.

3. Slide the module straight into an applicable open slot until it engages with the

backplane connector.

4. Push the handle back up and reconnect the thumbscrew.

2.4.6

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 65

Installing the Edge Switch Hot-Swap Power and Fan Modules

Intel® Omni-Path Fabric Switches Hardware

Page 66

Intel® Omni-Path Fabric—Installation

NOTE

The following instructions are for the Intel® Omni-Path Edge Switch with hot swap

power and fan modules (Part Numbers 100SWE48UFH and 100SWE48QFH).

2.4.6.1

Power Supply

1. Grasp the module by the handle and slide into an open slot until the unit engages

with the connector.

Figure 49. Edge Power Supply Install 1

2. When fully inserted, the module sits flush with the chassis and the thumb tab is

locked as shown.

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

66 Doc. No.: H76456, Rev.: 10.0

Page 67

Installation—Intel® Omni-Path Fabric

Figure 50. Edge Power Supply Install 2

2.4.6.2

Fans

1. Grasp the module by the handle and slide into an open slot until the unit engages

with the connector.

Figure 51. Edge Fan Supply Install 1

2. When fully inserted, the module sits flush with the chassis and the thumb tab is

locked as shown.

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 67

Intel® Omni-Path Fabric Switches Hardware

Page 68

Figure 52. Edge Fan Supply Install 2

Intel® Omni-Path Fabric—Installation

2.5

Connect Equipment to the Ports and Power On the System

NOTE

Before connecting equipment, it is important to understand the locations of the serial

and Ethernet ports on the Intel® Omni-Path Fabric series switches. For the edge

switch, these are located on the switch port side.

Figure 53. Edge Switch Serial and Ethernet Ports

Figure 54. Director Switch Serial and Ethernet Ports

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

68 Doc. No.: H76456, Rev.: 10.0

Page 69

Installation—Intel® Omni-Path Fabric

1. Connect a Category 5 or 6 (Cat 5/6) Ethernet cable to the RJ-45 connector(s) on

the switch. Connect the other end of the Cat 5/6 to an OOB LAN workstation,

another switch or a hub.

2. Connect the switch to host(s)/switch(es) using QSFP cables.

CAUTION

It is important to provide strain relief for the cable connector.

2.5.1

Director Class Switch Port and Slot Numbering

The graphic below details the leaf slot numbering schema for each Director switches.

Note:

Leaf slots 101 and 102 are referred to "Management" slots, meaning a leaf module

must be present whenever a management module is installed in the corresponding

slot on the front of the chassis.

Figure 55. Director Class Leaf Slot Numbering

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 69

Intel® Omni-Path Fabric Switches Hardware

Page 70

Intel® Omni-Path Fabric—Installation

2.5.2

Leaf Module Port Numbering

The physical module contains two 16-port leafs-A and B-stacked on top of each other.

The physical port numbering is shown below.

Figure 56. Leaf Module Port Numbering

Figure 57. 48-Port Leaf Module Port Numbering

NOTE

When cabling the 48-port leaf module, make certain to firmly seat the cable into the

port, otherwise only one of two ports may connect.

2.5.2.1

Chassis Viewer GUI Leaf Port Stats Screen

The Port Name column schema is a follows:

• Lxxx = Chassis leaf module slot (i.e. L101 - L124 for the 24-slot Director)

• A/B = Leaf A or B

• Pxx = Physical port number (e.g., 01 - 16)

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

70 Doc. No.: H76456, Rev.: 10.0

Page 71

Installation—Intel® Omni-Path Fabric

Figure 58. Chassis Viewer GUI Leaf Port Stats Scree

2.5.3

Edge Switch Cabling Recommendations

To minimize complexity, the following figure details cabling recommendations for the

48-port edge switch:

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 71

Intel® Omni-Path Fabric Switches Hardware

Page 72

Figure 59. 48-Port Edge Switch Cabling Recommendations

Intel® Omni-Path Fabric—Installation

2.5.3.1

Connecting Power

NOTE

For each power supply installed, a power cord must be installed in corresponding

power inlet.

1. Provide strain relief for the power cable(s).

2. If necessary, replace the closeout over the switch fan side.

3. Connect the power cables to a power distribution unit (PDU) or a proper AC power

outlet.

4. When the switch is plugged into an AC power outlet:

a. The system powers up.

b. The fans start.

c. The system performs a power-on self test.

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

72 Doc. No.: H76456, Rev.: 10.0

Page 73

Installation—Intel® Omni-Path Fabric

NOTE

For the Director switches, make certain the DC ON/OFF switch is illuminated.

If it is not, press the button to supply power. The switch is located in the lower

left corner on the chassis spine side.

5. The switch, power supply(s), and fan LEDs light up.

2.6

2.7

2.7.1

Setting Up the USB Console

1.

Download the driver file CDM v2.12.00 WHQL Certified.exe from http://

www.ftdichip.com/Drivers/VCP.htm.

2.

Open the FTDI Drivers Folder and Right click on the CDMv2.12 driver file and

select Run As Administrator to install the necessary driver to access the USB

serial console of the switch.

3. Open Putty, under Category, select Serial and enter the following parameters:

• Serial Line to connect to: <Enter COM>

• Speed: 115200

• Data Bits: 8

• Stop Bits: 1

• Parity: None

• Flow Control: None

Bringing Up the System For the First Time

Start-up Procedures

1. Power up the switch.

2. From its flash image on the management module, the switch begins its boot

process.

3.

Verify the IP address with the CLI command showChassisIpAddr command. The

system returns information similar to the following:

Chassis IP Address: 192.168.100.9 Net mask: 255.255.252.0

2.7.2

Changing the Switch IP Address and Default Gateway through the CLI

The CLI can be accessed two ways:

• Using the switch serial port:

— Edge switch (with optional management module): connects through the

USB serial port

— Director series: connects through the USB port on the SEEB modules

• Through Ethernet, using Telnet or SSH

June 2019 Installation Guide

Doc. No.: H76456, Rev.: 10.0 73

Intel® Omni-Path Fabric Switches Hardware

Page 74

Intel® Omni-Path Fabric—Installation

NOTE

If using a serial port on a Director switch, make certain to connect to the SEEB serial

port associated with the Management Module (MM) on the opposite side of the

chassis.

2.7.2.1

2.7.2.2

Using the Serial Connection

1. When a serial port connection is established, the user will see a prompt. To change

the chassis IP address type:

setChassisIpAddr -h <ipaddress> -m <netMask>

where -h <ipaddress> is the new IP address in dotted decimal format (that is,

xxx.xxx.xxx.xxx), and -m <netMask> is the new subnet mask in dotted

decimal format.

2. To change the switch default gateway IP address type:

setDefaultRoute -h <ipaddress>

where -h <ipaddress> is the new default gateway IP address in dotted decimal

format.

3. The changes are effective immediately.

Using Ethernet

1. Access the switch with one of the following commands using the default IP

address:

Telnet: telnet 192.168.100.9

SSH: ssh 192.168.100.9

2. The system prompts for a user name. In order to change the IP address and

default gateway, the user must be logged in as the administrator. At the prompt

type admin and press ENTER.

3.

The system prompts for a password. At the prompt type adminpass and press

ENTER. The system responds with:

Welcome to the <SWITCH> CLI. Type 'list' for the list of

commands.

4. To change the switch IP address type:

setChassisIpAddr -h <ipaddress> -m <netMask>

where -h <ipaddress> is the new IP address in dotted decimal format (that is,

xxx.xxx.xxx.xxx), and -m <netMask> is the new subnet mask in dotted

decimal format.

5. To change the switch default gateway IP address type:

setDefaultRoute -h <ipaddress>

Intel® Omni-Path Fabric Switches Hardware

Installation Guide June 2019

74 Doc. No.: H76456, Rev.: 10.0

Page 75