Page 1

NuPRO-850

Full-Size ePCI-X System

Host Board

Intel® Pentium® 4 processor

User’s Manual

Recycled Paper

Page 2

Page 3

© Copyright 2004 ADLINK Technology Inc.

All Rights Reserved.

Manual Rev. 1.00: June 18, 2004

Part Number: 50-13045-100

The information in this document is subject to change without prior notice in

order to improve reliability, design, and function and does not represent a

commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special,

incidental, or consequential damages arising out of the use or inability to use

the product or documentation, even if advised of the possibility of such

damages.

This document contains proprietary information protected by copyright. All

rights are reserved. No part of this manual may be reproduced by any

mechanical, electronic, or other means in any form without prior written

permission of the manufacturer.

Trademarks

NuDAQ

®

, NuIPC®, NuDAM®, NuPRO® are registered trademarks of ADLINK

Technology Inc. Other product names mentioned herein are used for

identification purposes only and may be trademarks and/or registered

trademarks of their respective companies.

Page 4

Getting Service from ADLINK

Customer Satisfaction is top priority for ADLINK Technology Inc. If you need

any help or service, please contact us.

ADLINK TECHNOLOGY INC.

Web Site http://www.adlinktech.com

Sales & Service Service@adlinktech.com

TEL +886-2-82265877 FAX +886-2-82265717

Address 9F, No. 166, Jian Yi Road, Chungho City, Taipei, 235 Taiwan

Please email or FAX your detailed information for prompt, satisfactory, and

consistent service.

Detailed Company Information

Company/Organization

Contact Person

E-mail Address

Address

Country

TEL FAX

Web Site

Questions

Product Model

OS:

Computer Brand:

M/B: CPU:

Environment

Detail Description

Chipset: BIOS:

Video Card:

NIC:

Other:

Suggestions for ADLINK

Page 5

Table of Contents

Chapter 1 Introduction..................................................................1

1.1 Unpacking Checklist........................................................................ 2

1.2 Features .......................................................................................... 3

1.3 Functional Blocks and Main Board.................................................. 4

1.4 Specifications.................................................................................. 8

Chapter 2 Jumpers and Connectors.........................................11

2.1 NuPRO-850 Board Outline and Illustration................................... 12

2.2 NuPRO-850 Connector Pin Assignments...................................... 14

Chapter 3 Getting Started...........................................................25

3.1 CPU Installation ........................................................................... 25

3.2 Memory Installation....................................................................... 26

3.3 Connecting IDE Devices to the NuPRO-850................................. 27

3.4 BIOS Configuration Overview ....................................................... 28

3.5 Operating System Installation ....................................................... 29

Chapter 4 Device Driver Installation..........................................31

4.1 Intel® 875P/6300ESB Chipset......................................................31

4.2 Driver Installation .......................................................................... 32

Chapter 5 Watchdog Timer.........................................................35

5.1 Watchdog Timer............................................................................ 35

Chapter 6 ePCI-X Bus Details.....................................................41

6.1 NuPRO-850 ePCI-X Bus............................................................... 41

6.2 Global Signals............................................................................... 41

6.3 PCI-X Bus Signals......................................................................... 42

Warranty Policy ...........................................................................43

List of Tables and Figures • i

Page 6

How to Use This Guide

This manual is designed to help users configure the NuPRO-850 Full-Size

ePCI-X System Host Board with Dual Xeon CPU. It is divided into five

chapters.

Chapter 1

Chapter 2

Outlines all the connectors and its pin definitions.

Chapter 3

Summarization of what is required to setup an operational

Chapter 4

Detailed instructions on how to install the software drivers

Chapter 5

Introduction

Gives an overview of the product features, applications, and

specifications.

Connectors and Jumpers

Getting Started

system using the NuPRO-850. Hardware installation and BIOS

overview is discussed.

Driver Installation

successfully.

Utilities

Explains the operation of the WDT, PXE booting, and Hardware

Doctor.

ii • How to Use This Guide

Page 7

1

Introduction

The NuPRO-850 is a full-size ePCI-X System Host Board (SHB) based on the

Intel® Pentium® 4 processor and 875P Memory Controller Hub / 6300ESB I/O

Controller Hub chipset. It features AGP4X/8X VGA, Serial ATA I/F, Gigabit

Ethernet, and USB v2.0 I/F. It supports two PCI/PCI-X busses via the Intel

6300ESB chipset (one PCI-X 64-bit/66MHz bus and one PCI 32-bit/33MHz

bus). The NuPRO-850 is designed to run under Windows 2000/XP and Linux

operating systems as well as in embedded real time applications.

The NuPRO-850 is a System Host Board with premium computing

performance powered by an Intel® Pentium® 4 processor. The CPU module

supports a front side bus (FSB) of 533/800MHz and a maximum CPU clock

speed of 3.4GHz featuring 64-bit/66MHz PCI/PCI-X bus with up to 4GB high

performance DDR host SDRAM support.

It provides input/output via RS-232, four USB 2.0 ports, Dual IDE Channels

with ATA 100/66/33, Onboard Gigabit Ethernet, and video interfaces for LVDS

Digital LCD Display and dual CRT displays. The NuPRO-850 is designed to

meet the needs of applications which require the highest computing

performance and highest reliability and is designed to run Windows 2000/XP

and Linux operating systems, as well as embedded real-time applications. It is

the ideal solution for telecommunications, internet, and industrial networking

applications.

This chapter is designed to give the user with an overview of the NuPRO-850

SHB. This chapter covers the following topics:

• Unpacking and Checklist

• Features

• Specifications

Introduction • 1

Page 8

1.1 Unpacking Checklist

Check the shipping carton for any damage. If the shipping carton and contents

are damaged, notify the dealer for a replacement. Retain the shipping carton

and packing materials for inspection by the dealer. Obtain authorization before

returning any product to ADLINK.

Check the following items are included in the package, if there are any items

missing, contact your dealer.

• The NuPRO-850 module (May be equipped with different speed or

capacity CPU, RAM, and HDD).

• This User’s Manual

• ADLINK CD

• Com Cable

• Dual Ports USB Cable with bracket

• 1 set of Cooler kits

• 2 x ATA-100 Cables

• 2 x Serial ATA Cables

Note: The package of the NuPRO-850 OEM version non-standard

configuration may vary in function or contents according to

different configuration requests

CAUTION: This board must be protected from static discharge and

physical shock. Never remove any of the socketed parts except

at a static-free workstation. Use the anti-static bag shipped with

!

2 • Introduction

the product to handle the board. Wear a wrist strap grounded

through one of the system's ESD Ground jacks while servicing

system components.

Page 9

1.2 Features

• PICMG 1.2 Rev 1.0 Embedded PCI-X Specification compliant.

• PCI Local Bus Specification, Rev 2.2 compliant.

• Single Intel® Pentium® 4 processor with 1MB L2 cache,

533/800MHz FSB, Hyper-Threading Technology.

• Four 184-pin DIMM sockets, support single/dual channel DDR

DIMM. Up to four DIMMs of DDR 266/333/400 with ECC unbuffered.

Supports a maximum of 4GB of system memory.

• Intel® 82547GI Gigabit Ethernet Controller. Supports 1000Base-TX,

100Base-TX and 10Base-T (IEEE802.3, 802.3u, and 802.3ab).

• ATI Mobility M9/M10 with AGP4X/8X compliant, 64MB memory.

LVDS signal output connector supports LVDS Digital LCD Display

and dual CRT displays.

• AC'97 link Interface, AC’97 2.2 compliant with optional with ADLINK

DB-AC97 board.

• Supports all generic features include VGA, COM port, USB 2.0,

keyboard, mouse, and hardware monitoring.

• Built-in monitoring CPU temperatures, FAN speed, system

temperature, CPU voltage, and DC voltages.

• Supports Intel

• 2 x IDE channels, 2 x SATA ports.

®

Pre-boot Execution Environment (PXE).

Introduction • 3

Page 10

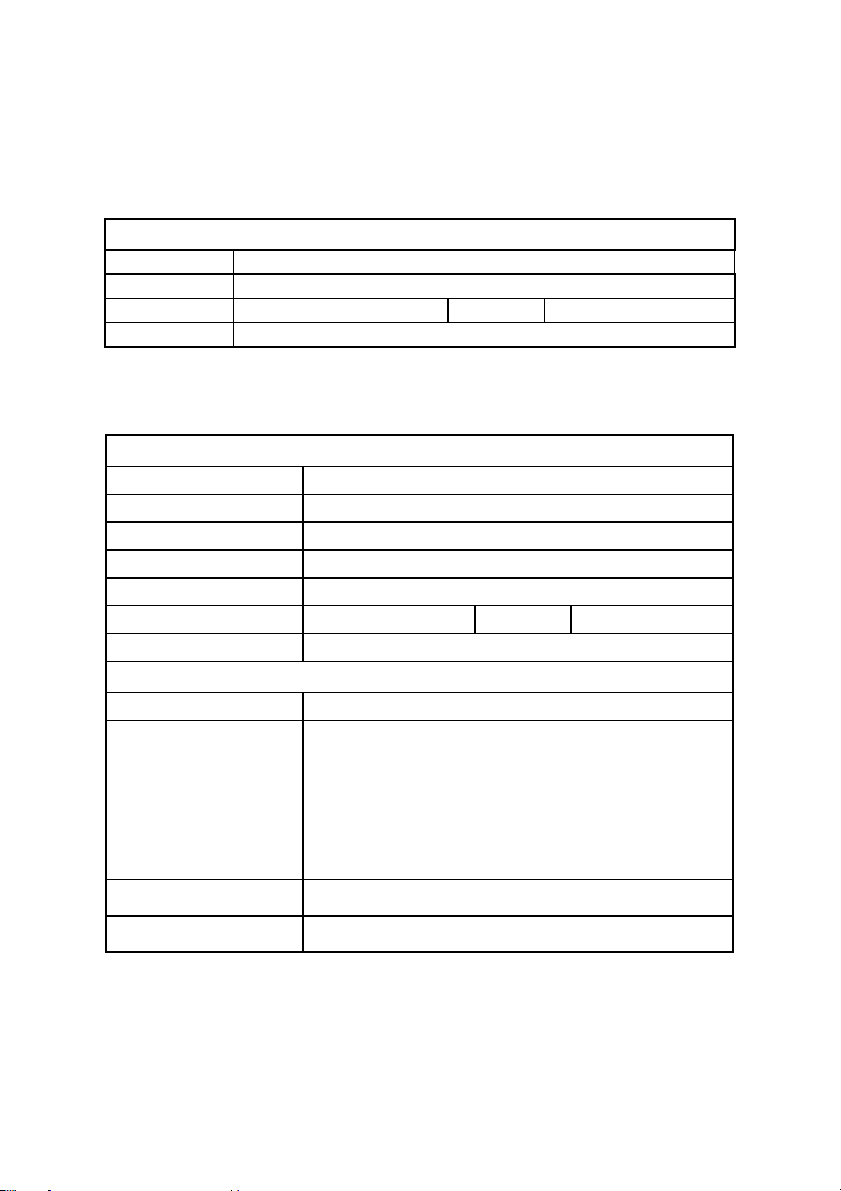

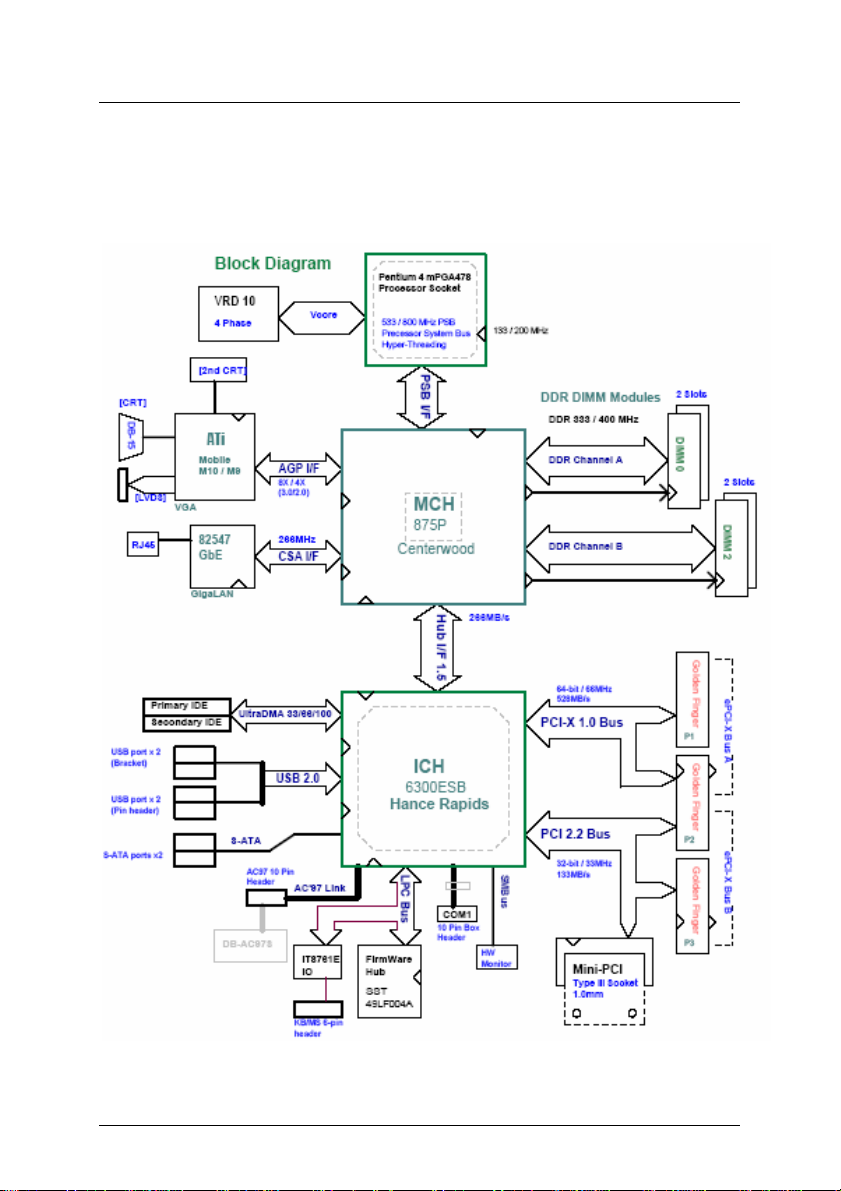

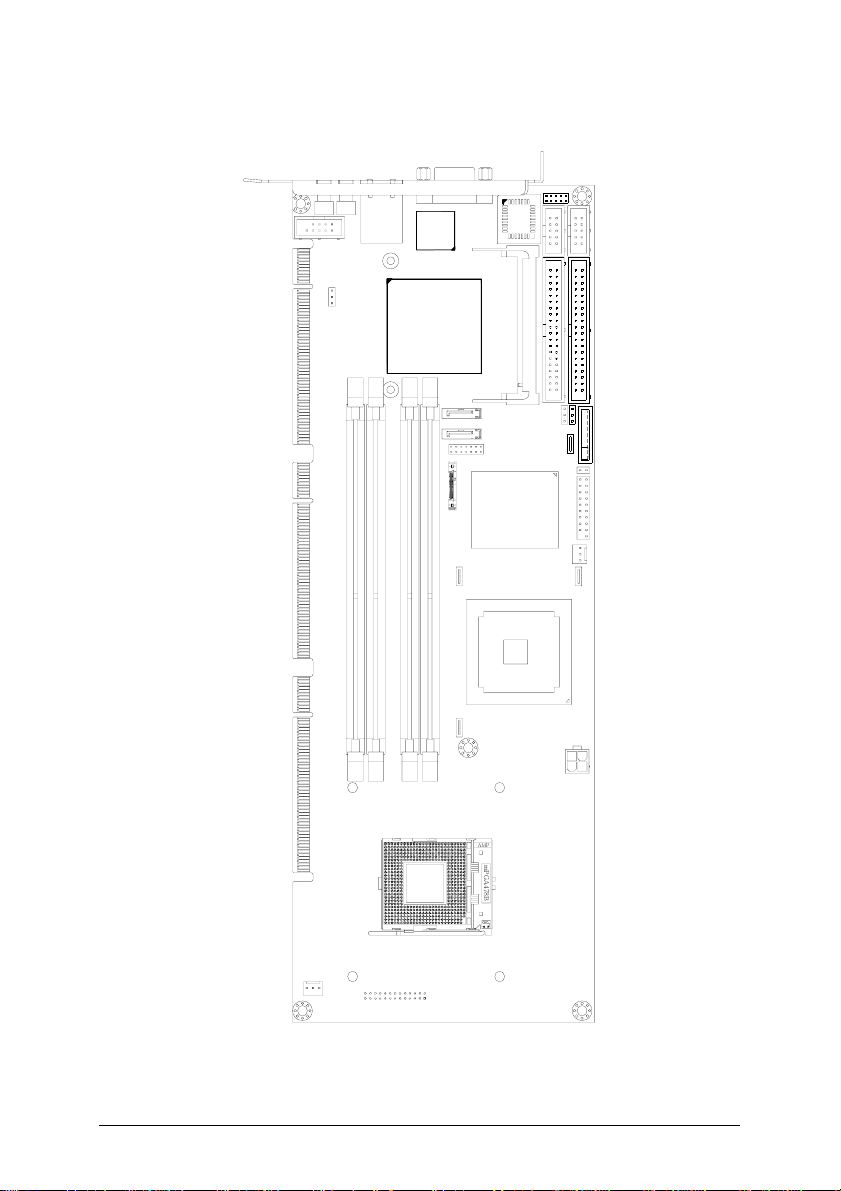

1.3 Functional Blocks and Main Board

The following topics provide an overview of the NuPRO-850 main features as

shown in the functional block diagram below and also the main board.

Functional Block Diagram

4 • Introduction

Figure 1: Functional Block Diagram

Page 11

Main Board Drawing

AMP

m

P

G

A

4

7

8

B

Figure 2: Main Board Drawing

Introduction • 5

Page 12

1.3.1 Intel® Pentium® 4 Processor

The Intel® Pentium® 4 processor is based on Intel® NetBurst®

microarchitecture and built with Intel®'s 0.13-micron and 90nm manufacturing

process and featuring Hyper-Threading technology, a 1MB level two-cache

size. The Intel® Pentium® 4 has a maximum clock speed of 3.4GHz and front

side bus frequency of 400/533/800MHz.

The Intel® NetBurst™ micro-architecture and Hyper-Threading Technology is

designed specifically for multi-tasking environments and provides outstanding

performance for multi-threaded applications.

1.3.2 Video

The NuPRO-850 provides standard SVGA CRT analog output on a bracket I/O

panel. The video function is provided via an ATI Mobility M9 (AGP4X) or M10

(AGP8X) VGA chip with 64MB video memory. NuPRO-850 also supports dual

CRT output (via one onboard 14-pin header) and one LVDS interface. The

NuPRO-850 has one jumper to disable the onboard video and BIOS options

are used to select the resolution of the LVDS panel

1.3.3 Ethernet Interfaces

The NuPRO-850 provides one 10/100/1000Mbps Ethernet interface via the

Intel® 82547GI Gigabit Ethernet Controller. The 82547GI is connected to the

CSA (Communicating Streaming Architecture) interface of the 875P MCH. The

Ethernet interface is routed to a RJ-45 w/LED all-in-one connector on bracket.

The LAN chip will be assigned one unique static MAC Address. LED drive

signals for Ethernet link status and activity are routed to the same connector.

1.3.4 Serial I/O

The NuPRO-850 has one RS-232 serial port with a 10-pin connector. The

16550 compatible serial port is provided by the SIU port on the Intel® 6300ESB

ICH.

1.3.5 Universal Serial Bus (USB)

The NuRPRO-850 supports four USB 2.0 ports, with two connectors (USB0 &

USB1) on bracket and the remaining (USB2 & USB3) routed to one onboard

9-pin header. USB allows for the easy addition of peripherals such as mouse,

keyboard, speakers, etc.

1.3.6 IDE and Serial ATA Controller Controller

The NuPRO-850 provides IDE and Serial ATA interfaces from the Intel®

6300ESB ICH. Two IDE connectors can support up to four drives Ultra DMA

100 Mode. Two serial ATA ports support up to two serial ATA devices for data

transfer rates up to 150Mbps.

6 • Introduction

Page 13

1.3.7 Software

The NuPRO-850 is compatible with all major PC operating systems. ADLINK

provides support, which may include additional drivers for ADLINK peripherals.

Software device drivers for the NuPRO-850 may be found in the ADLINK CD.

1.3.8 AC’97 Link

NuPRO-850 provides one AC’97 link 10-pin header, the AC’97 link is provided

by the 6300ESB ICH.

1.3.9 Serial I/O

NuPRO-850 provides one RS-232 serial port via one 10-pin connector. The

serial port is provided by the 16550 compatible SIU port in the 6300ESB ICH.

1.3.10 MiniPCI slot

NuPRO-850 provides one MiniPCI type III slot. The MiniPCI slot and ePCI-X

bus B share the 6300ESB PCI bus I/F.

Introduction • 7

Page 14

1.4 Specifications

Compliant Specifications

• PICMG 1.2 Rev 1.0 Embedded PCI-X Specification compliant.

• PCI Local Bus Specification, Rev 2.2 compliant.

Form Factor

• Standard Full-Size ePCI-X System Host Board, 338.6mm x 122mm

(13.33”x4.8”).

CPU/Cache

• Intel® Pentium® 4 processor. The socket supports CPUs manufactured

using Intel's 0.13-micron and 90nm manufacturing processes, FC-mPGA4

package (478-pin).

• The Intel

with a Front Side Bus (FSB) speed of 400/533/800MHz, and on-die 512KB

or 1MB Advanced Transfer L2 Cache.

Chipset

• Intel

• Intel® 82875P Memory Controller Hub (MCH)

Host Memory

• Four DDR DIMM sockets

®

Pentium® 4 processor runs at a core speed of up to 3.4GHz,

®

6300ESB I/O Controller Hub

• 266/333/400MHz DDR DIMM modules

• Dual-channel or single-channel DDR interface

• Non-ECC and ECC, un-buffered DIMMs only

• Each socket supports up to 1GB of DDR DIMM

• 128-Mb, 256-Mb, 512Mb technologies implemented as x8, x16 DDR

devices with four banks

• Up to 4GB system memory

• Registered DIMMs are not supported

DDR DIMM speed, type and size can be determined by the BIOS reading the

DIMM presence detect bits on the SMBus (System Management Bus). The

8 • Introduction

Page 15

DDR DIMM timing register, which provides the DIMM speed control for the

entire array, must be programmed to use the timings of the slowest DIMMs

installed. Note: DIMMs must be populated in identical pairs for dual-channel

operation

: Award / Phoenix BIOS advanced by ADLINK

BIOS

• NuPRO-850 supports BIOS memory size up to 8Mbytes (Firmware Hub

I/F).

• Flash write protection will be implemented under software control. This bit

must be set to 1 before any write will be allowed to the BIOS Flash.

Gigabit Ethernet

• One 10/100/1000Mbps Ethernet interfaces via the Intel® 82547GI Gigabit

Ethernet Controller. The 82547GI is connected to the CSA

(Communicating Streaming Architecture) interface of the 82875P MCH.

• Support 1000Base-T, 100Base-TX and 10Base-T (IEEE 802.3, 802.3u,

and 802.3ab).

• IEEE802.3x compliant flow control, support auto-negotiation and link

setup.

• Ethernet link status and activity LEDs on the RJ-45 connector.

Graphic Display

• AT I Mobility M9 (AGP4X) or M10 (AGP8X) VGA chip with 64MB video

memory.

• Standard SVGA CRT analog output on bracket I/O panel.

• Also supports 2

LVDS interface.

nd

CRT output (via one onboard 14-pin header) and one

USB Interface

• Supports four USB 2.0 ports, two connectors (USB0 & USB1) on bracket

and the others (USB2 & USB3) are routed to one onboard 9-pin header

IDE Ports

• Two IDE connectors support up to four drivers. Up to Ultra DMA 100

Mode.

Super I/O and WDT

• Built-in HanceRapids, support 2-stage WDT, programmable timer 1 - 255

seconds or 1 - 255 minutes.

Introduction • 9

Page 16

• The NuPRO-850 edge connector uses three standard 32-bit PCI

connectors. These three connectors carry two busses, one PCI-X

64-bit/66MHz bus and one PCI 32-bit/33MHz bus. Both busses are

provided by Intel 6300ESB ICH.

Hardware Monitor

• The W83L784R provides temperature, fans, and voltage monitors. It has

analog to digital converters that allow software to monitor the voltages on

NuPRO-850.

OS Compatibility

• MS-DOS 6.2+, Windows 2000/XP, Red Hat Linux 7.3 or higher

• Other OS support available upon request

Environment

• Operating temperature: 5 to 55 °C

• Storage temperature: -40 to 70 °C

• Humidity: 5% to 95% non-condensed

Safety Certificate and Test

• CE, FCC

• All plastic material used onboard are all UL-94V certified

10 • Introduction

Page 17

2

Jumpers and Connectors

This chapter will familiarize the user with the NuPRO-850 with the interfaces and

connections available before getting started. The chapter also contains

information about the board layout, connector definitions and jumper setup as

well as the following information:

• NuPRO-850 board outline and illustration

• NuPRO-850 connectors pin assignments

• NuPRO-850 jumpers setting

Jumpers and Connectors • 11

Page 18

2.1 NuPRO-850 Board Outline and Illustration

w

2.1.1 NuPRO-850 Top View

CN18

CN17

CN16

LAN1

CN13

CN3

CN6

ePCI-X bus A

ePCI-X bus B

FN2

U12

CN14

CN9

CN10

CN11

CN12

CN2

FN1

PN1

CN4

CN7

JP1

JPY1

CN1

DIMM1

DIMM2

DIMM3

DIMM4

Figure 3: NuPRO-850 Top Vie

12 • Jumpers and Connectors

Page 19

2.1.2 Front View

CN13

LAN1

CN17 CN16

Figure 4: View of Face Plate

Position Description

CN1 Case open pin header

CN2 Front panel pin header

CN3 COM1 connector

CN4 Secondary IDE connector

CN6 AC’97 link connector

CN7 Primary IDE connector

CN9 MiniPCI slot

CN10 SATA-1 connector

CN11 SATA-0 connector

CN12 VGA 2nd CRT pin header

CN13 VGA CRT connector

CN14 LVDS connector

CN16 USB-0 connector

CN17 USB-1 connector

CN18 USB-2/3 pin header

LAN1 Gigabit Ethernet RJ-45 connector

FN1 VGA Fan power connector

FN2 CPU Fan power connector

DIMM1 DDR DIMM B1 socket

DIMM2 DDR DIMM B2 socket

DIMM3 DDR DIMM A1 socket

DIMM4 DDR DIMM A2 socket

U12 CPU socket

PN1 ATX 12V 4-pin connector

JP1 Clear CMOS jumper

JPY1 VGA disable jumper

Jumpers and Connectors • 13

Page 20

Table 1: Description of Connector Locations

2.2 NuPRO-850 Connector Pin Assignments

A detailed description and pin-out for each connector is given in the following

section.

2.2.1 VGA CRT connector (CN13)

PIN SIGNAL FUNCTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Table 2: VGA Connector Pin Definition

RED Analog RED

GREEN Analog GREEN

BLUE Analog BLUE

NC No Connect

GND Ground

GND Ground

GND Ground

GND Ground

5VCC +5V

GND Ground

NC No connect

DDC_DATA DDC Data for

HSYNC Horizontal sync

VSYNC Vertical sync for

DDC_CLK DDC Clock for

2.2.2 USB 2.0 connector (CN16, CN17)

Pin # Signal Name

1 VCC

2 USB3 USB+

4 Ground

CRT

for Monitor

Monitor

CRT

Table 3: USB Connectors Pin Definition

14 • Jumpers and Connectors

Page 21

2.2.3 Gigabit Ethernet connector (LAN1)

Green / Orange LED

PIN SIGNAL

1 MDI[0]+

2 MDI[0]3 MDI[1]+

4 MDI[1]5 MDI[2]+

6 MDI[2]7 MDI[3]+

8 MDI[3]-

Table 4: Gigabit Ethernet Connector Pin Definition

LED Color Status Function

Green / Orange

(Speed status) Green 100Mbps

Yellow (Link status)

OFF No link

Blinking Data transfer in progress

Table 5: Ethernet Color LED Status

Orange 1000Mbps

ON Link

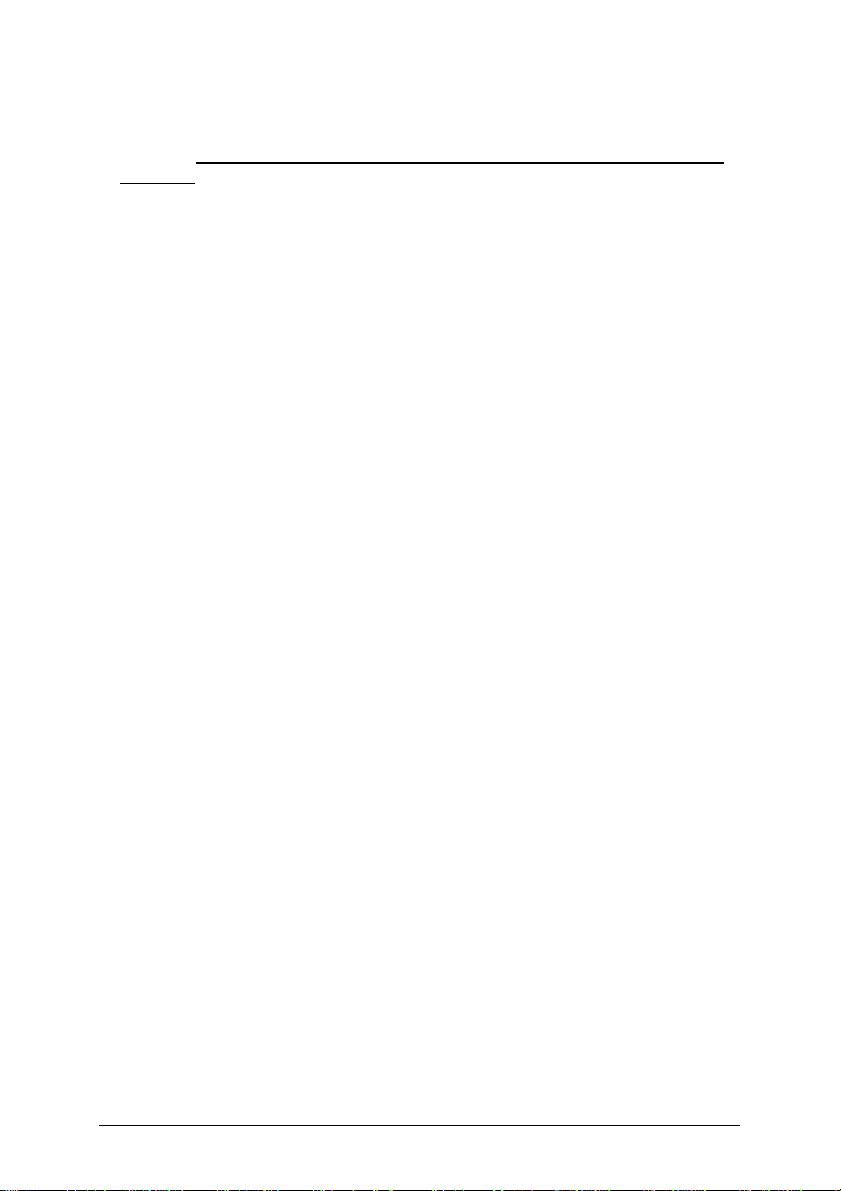

2.2.4 COM1 connector (CN3)

PIN SIGNAL FUNCTION

1 DCD Data Carrier Detect

2 RXD Receive Data

3 TXD Transmit Data

4 DTR Data Terminal Ready

5 GND Ground

6 DSR Data Set Ready

7 RTS Request to Send

8 CTS Clear to Send

9 RI Ring Indicate

10 NC No Connect

Table 6: Ethernet Color LED Status

Jumpers and Connectors • 15

Page 22

2.2.5 AC’97 connector (CN6)

PIN SIGNAL FUNCTION

1 GND Ground

2 GND Ground

3 5VCC +5V

4 5VCC +5V

5 AC_SYNC AC’97 Sync

6 AC_BITCLK AC’97 Bit Clock

7 AC_SDIN0 AC’97 Serial Data In 0

8 AC_SDOUT AC’97 Serial Data Out

9 AC_SDIN1 AC’97 Serial Data In 1

10 AC_RST# AC’97 Reset

Table 7: AC’97 connector (CN6)

2.2.6 Case Open connector (CN1)

Signal is connected to a limit switch sensor of the chassis to detect if the case

is open or closed.

1

PIN SIGNAL FUNCTION

1 CASEOPEN# Case Open Signal

2 GND Ground

Table 8: Case Open connector Pin Definition

16 • Jumpers and Connectors

Page 23

2.2.7 VGA 2nd CRT pin header (CN12)

8

1

10

7

Table 9: VGA 2

PIN SIGNAL FUNCTION

1 CRT2_DATA

2 CRT2_CLK

3 CRT2_RED

4 CRT2_GREEN

5 CRT2_BLUE

6 CRT2_HSYNC

DDC Data for CRT2

DDC Clock for CRT2

CRT2 Analog RED

CRT2 Analog GREEN

CRT2 Analog BLUE

CRTR2 Horizontal

sync for Monitor

7 CRT2_VSYNC

CRT2 Vertical sync for

Monitor

8 VCC_CRT2 +5V

9 NC No Connect

10 GND Ground

11 GND Ground

12 GND Ground

13 GND Ground

14 GND Ground

nd

CRT pin header (CN12)

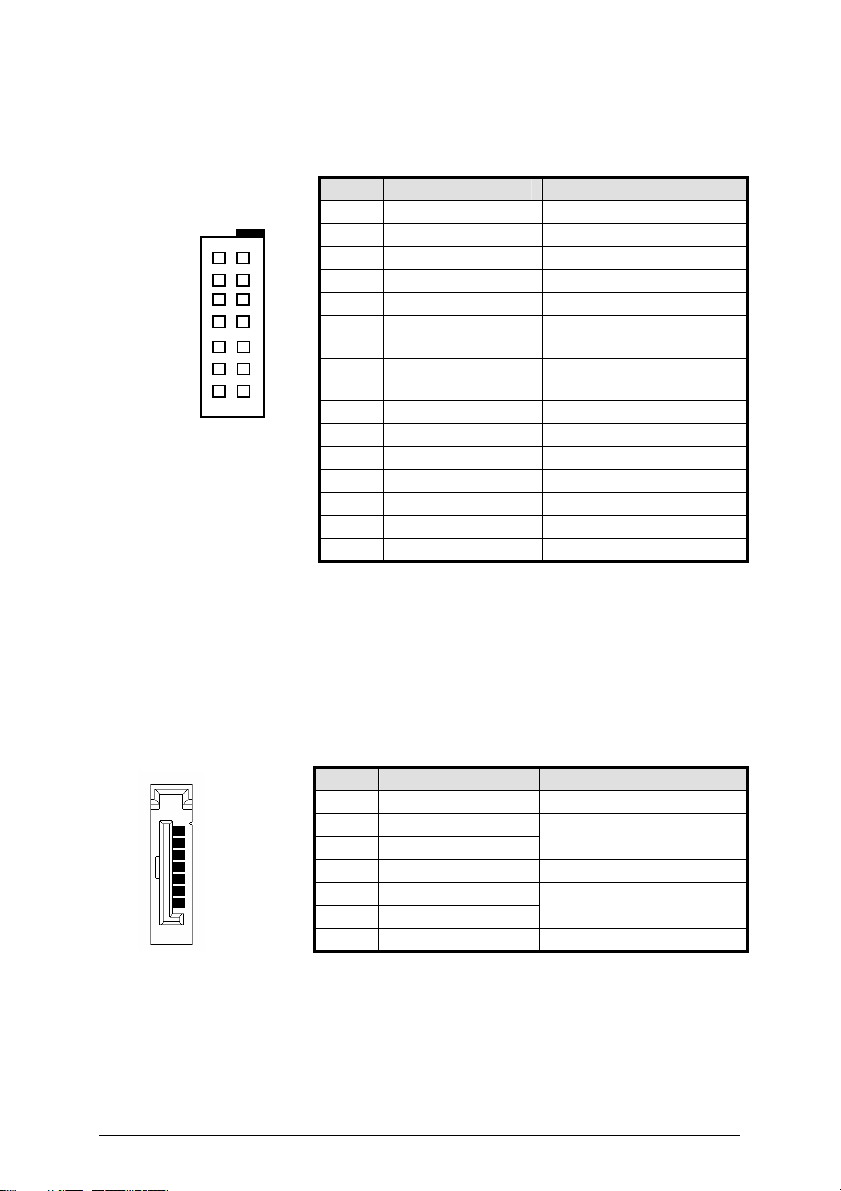

2.2.8 SATA-0 / SATA-1 connectors (CN11, CN10)

CN11: SATA-0

CN10: SATA-1

PIN SIGNAL FUNCTION

1 GND Ground

1

2 SATA_TXP

3 SATA_TXN

4 GND Ground

7

5 SATA_RXN

6 SATA_RXP

7 GND Ground

Serial ATA Transmit

Pair

Serial ATA Receive

Pair

Table 10: SATA-0 / SATA-1 connectors (CN11, CN10)

Jumpers and Connectors • 17

Page 24

2.2.9 LVDS connector (CN14)

1 20

PIN SIGNAL FUNCTION

1 LVDS_PWR LVDS Power

2 LVDS_PWR LVDS Power

3 GND Ground

4 GND Ground

5 LVDS_L0N LVDS lower data channel 0 (-)

6 LVDS_L0P LVDS lower data channel 0 (+)

7 GND Ground

8 LVDS_L1N LVDS lower data channel 1 (-)

9 LVDS_L1P LVDS lower data channel 1 (+)

10 GND Ground

11 LVDS_L2N LVDS lower data channel 2 (-)

12 LVDS_L2P LVDS lower data channel 2 (+)

13 GND Ground

14 LVDS_LCKN LVDS lower clock channel (-)

15 LVDS_LCKP LVDS lower clock channel (+)

16 GND Ground

17 LVDS_L3N LVDS lower data channel 3 (-)

18 LVDS_L3P LVDS lower data channel 3 (+)

19 GND Ground

20 GND Ground

Table 11: LVDS connector (CN14)

18 • Jumpers and Connectors

Page 25

2.2.11 ATX 12V 4-pin connector (PN1)

3 4 1

2

PIN SIGNAL FUNCTION

1 GND Ground

2 GND Ground

3 ATX12V +12V

4 ATX12V +12V

Table 12: Floppy Connector Pin Definition

2.2.12 Fan1 / Fan2 connector (FN1/FN2)

3

1

Table 13: Floppy Connector Pin Definition

Pin # Signal Name

1 GND

2 Fan power

3 Fan speed

Jumpers and Connectors • 19

Page 26

2.2.13 Primary/Secondary IDE Connector (CN7, CN4)

CN7: Primary IDE

CN4: Secondary IDE

Signal Name Pin # Pin # Signal Name

Reset IDE 1 2 Ground

Host data 7 3 4 Host data 8

Host data 6 5 6 Host data 9

Host data 5 7 8 Host data 10

Host data 4 9 10 Host data 11

Host data 3 11 12 Host data 12

Host data 2 13 14 Host data 13

Host data 1 15 16 Host data 14

Host data 0 17 18 Host data 15

Ground 19 20 No connect

DRQ0 / DRQ1 21 22 Ground

Host IOW 23 24 Ground

Host IOR 25 26 Ground

IOCHRDY 27 28 Host ALE

DACK0 / DACK1 29 30 Ground

IRQ14 / IRQ 15 31 32 No connect

Address 1 33 34 No connect

Address 0 35 36 Address 2

Chip select 0 37 38 Chip select 1

Activity 39 40 Ground

Table 14: IDE Connector Pin Definition

20 • Jumpers and Connectors

Page 27

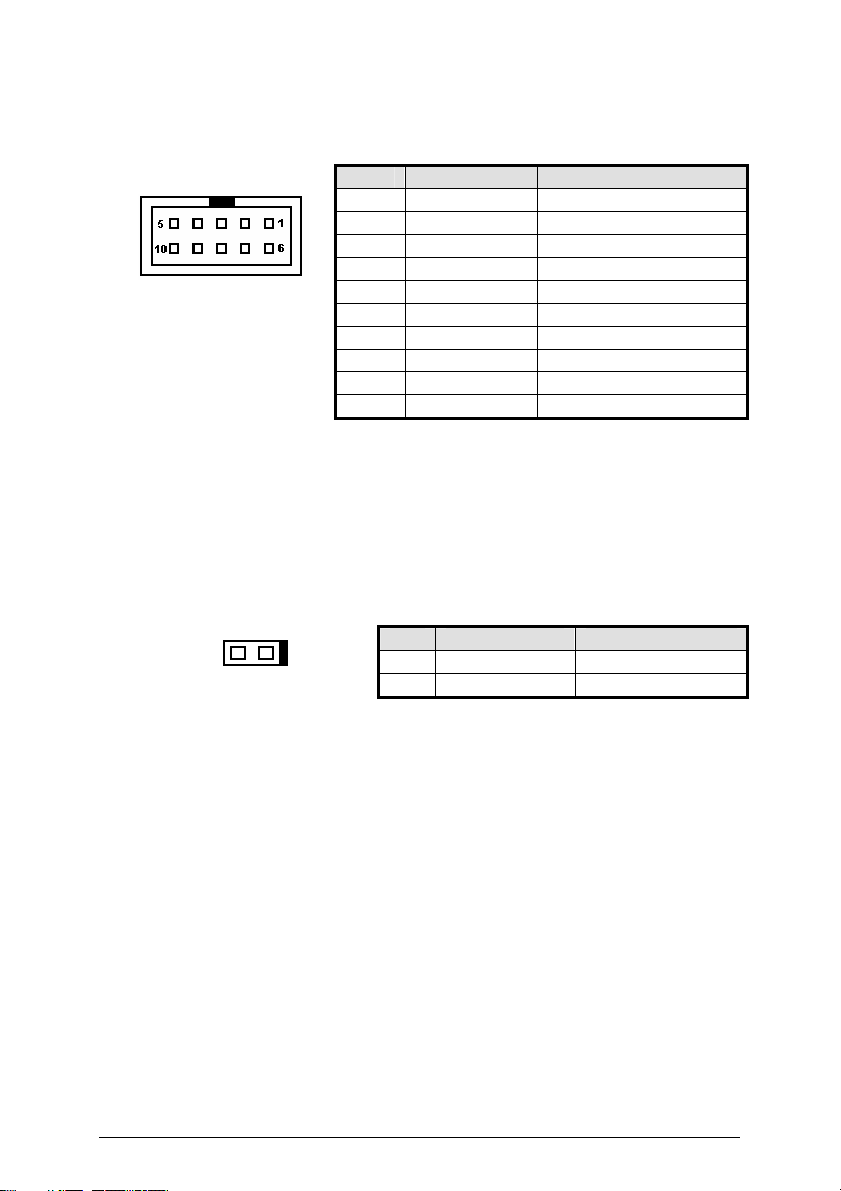

2.2.14 Front Panel Pin Header (CN2)

PI

1

10

SIGNAL FUNCTION PIN

N

1 +5V Power

2 WDTLED# Watch Dog

3 PLED Power LED

4 NC No Connect

5 GND Ground

6 GND Ground

7 NC No connect

8 PWRON Power-on

9 +5VSB +5V Standby

10 PME#

(Optional)

11 WDSPK Speaker

12 NC No connect

13 NC No connect

14 +5V Power

15 RESETBT RESET

16 GND Ground

17 HDDLED Hard Disk

18 +5V Power

19 PWRBT POWER

20 GND Ground

LED Signal

Signal

signal

Power

Power

Management

Event

signal

Button signal

LED signal

Button signal

GROUP

Power

LED

Key Lock

ATX

Power

connector

Chassis

Speaker

RESET

button

Hard Disk

LED

Power on

button

Table 15: Front Panel Pin Definition

Jumpers and Connectors • 21

Page 28

2.2.15 Mini PCI Socket (CN9)

PIN SIGNAL PIN SIGNAL

1 NC 2 NC

3 NC 4 NC

5 NC 6 NC

7

9 NC 10 NC

11 NC 12 NC

13 NC 14 NC

15 GND 16 EX_INTC#

17 INTB# 18 +5V

19 +3.3V 20 INTA#

21 EX_CLK 22 EX_INTD#

23 GND 24 +3.3VS

25 CLK 26 RESET#

27 GND 28 +3.3V

29 REQ# 30 GNT#

31 +3.3V 32 GND

33 AD[31] 34 PME#

35 AD[29] 36 EX_REQ#

37 GND 38 AD[30]

39 AD[27] 40 +3.3V

41 AD[25] 42 AD[28]

43 EX_IDSEL# 44 AD[26]

45 C/BE[3] 46 AD[24]

47 AD[23] 48 IDSEL#

49 GND 50 GND

51 AD[21] 52 AD[22]

53 AD[19] 54 AD[20]

55 GND 56 PAR

57 AD[17] 58 AD[18]

59 C/BE[2] 60 AD[16]

61 IRDY# 62 GND

NC

8 NC

22 • Jumpers and Connectors

Page 29

63 +3.3V 64 FRAME#

65 CLKRUN# 66 TRDY#

67 SERR# 68 STOP#

69 GND 70 +3.3V

71 PERR# 72 DEVSEL#

73 C/BE[1] 74 GND

75 AD[14] 76 AD[15]

77 GND 78 AD[13]

79 AD[12] 80 AD[11]

81 AD[10] 82 GND

83 GND 84 AD[9]

85 AD[8] 86 C/BE[0]

87 AD[7] 88 +3.3V

89 +3.3V 90 AD[6]

91 AD[5] 92 AD[4]

93 EX_GNT# 94 AD[2]

95 AD[3] 96 AD[0]

97 +5V 98 SMBCLK

99 AD[1] 100 SMBDATA

101 GND 102 GND

103 AC_SYNC 104 GND

105 AC_SDIN 106 AC_SDOUT

107 AC_BITCLK 108 AC_ID0#

109 AC_ID1# 110 AC_RST#

111 NC 112 NC

113 NC 114 GND

115 NC 116 NC

117 NC 118 NC

119 NC 120 NC

121 NC 122 NC

123 +5Analog 124 +3.3VSB

Table 16: Mini PCI Socket Pin Definition

Jumpers and Connectors • 23

Page 30

Page 31

3

Getting Started

This chapter gives a summary of what is required to setup an operational

system using the NuPRO-850, including hardware installation and an overview

of the BIOS.

3.1 CPU Installation

The NuPRO-850 CPU module supports single/dual FC-mPGA2 Intel®

Pentium® 4 processor with a front side bus (FSB) of 800MHz or 533MHz.

Users need to install highly efficient CPU fan/cooler to guarantee the systems

stability.

To install the CPU follow the steps below carefully:

1. Lift the lever on the CPU socket.

2. Insert the CPU in the socket, making sure that pin 1 of the CPU aligns

with pin 1 of the socket (both corners are marked with a triangle)

3. Press the lever down until you hear it “click” into the locked position.

4.

Apply the proper amount of thermal compound to the CPU die and

place the heatsink and fan on top of the CPU.

5. Connect the three wires of the CPU fan to the respective CPU fan

connector.

Note: Ensure that the CPU heat sink and the CPU top surface are in

tight contact to avoid CPU overheating problem that would

cause your system to hang or crash. The CPU heat sink and fan

should be installed tightly together. Please contact ADLINK

dealers for suitable heat sink and fan assemblies

Getting Started • 25

Page 32

3.2 Memory Installation

This section details the procedure for installing system memory on the

NuPRO-850. Correct memory configuration is critical for proper system

operation.

3.2.1 Memory Configuration Options

The NuPRO-850 has flexible memory configuration options. These include

support for 64MB, 128MB, 256MB, 512MB, 1GB Modules. Note that the

modules must all be the of the same type and density and must be installed in

pairs (DIMM1 and SIMM2 or DIMM3 and DIMM4) for dual-channel mode

operation.

3.2.2 Installing Memory Modules

Installing DIMM modules is simple. The modules insert in the sockets and are

held in place by the socket retaining arms. The edge connectors on the

modules are of different widths and there are key notches in each module.

These ensure that you do not insert a module incorrectly.

Before installing any modules, a configuration should be chosen. The required

number and type of DDR modules should then be prepared.

Figure 5: DIMM Sockets

26 • Getting Started

Page 33

To install either types of module, follow these procedures:

Figure 6: Inserting DIMM into Socket

1. Align the module to the socket so that the edge connectors on the

module match the socket sections.

2. Hold the module perpendicular to the motherboard and press the

edge connector into the socket.

3. Press the module fully into the socket so that the socket retaining

arms swing up and engage the retention notches at each end of the

module.

4. Following the configuration chosen, repeat for all other modules (if

any).

5. Once the modules are installed, system memory installation is

complete.

3.3 Connecting IDE Devices to the NuPRO-850

The NuPRO-850 supports two IDE channels, Primary and Secondary. It has

two IDE device connectors onboard supporting IDE devices running in any

data transfer mode up to ATA-100. Each IDE connector supports two drives, a

Master and a Slave. The drives connect to the NuPRO-850 with an IDE ribbon

cable.

To install an IDE drive, connect the drive to one of the drive connectors to a

suitable ribbon cable. Plug the board end of the cable into one of the IDE

connectors on the NuPRO-850. Make sure pin 1 of the ribbon cable connector

is aligned with pin 1 of the IDE device connector.

Getting Started • 27

Page 34

3.4 BIOS Configuration Overview

This section gives an introduction to the Phoenix/Award Plug and Play BIOS

Setup Utility. For more detailed information about the BIOS and other utilities,

please refer to the BIOS Manual.

The BIOS has many separately configurable features. These features are

selected by running the built-in Setup utility. System configuration settings are

saved in a portion of the battery-backed RAM in the real-time clock device and

are used by the BIOS to initialize the system at boot up or reset. The

configuration is protected by a checksum word for system integrity.

To access the Setup utility, press the "Del" key during system RAM check at

boot time. When Setup runs, an interactive configuration screen displays.

Setup parameters are divided into different categories. The available

categories are listed in a menu. The parameters within the highlighted (current)

category are listed in the bottom portion of the Setup screen. Context sensitive

help is displayed in the right portion of the screen for each parameter.

Use the arrow keys to select a category from the menu. To display a submenu,

highlight the category and then press the "Enter" key.

28 • Getting Started

Page 35

3.5 Operating System Installation

For more detailed information about your operating system, refer to the

documentation provided by the operating system vendor.

Install peripheral devices. NuPRO devices are automatically configured by the

BIOS during the boot sequence.

Most operating systems require initial installation on a hard drive from a floppy

or CDROM drive. These devices should be configured, installed, and tested

with the supplied drivers before attempting to load the new operating system.

Read the release notes and installation documentation provided by the

operating system vendor. Be sure to read any README files or documents

provided on the distribution disks, as these typically note documentation

discrepancies or compatibility problems.

Select the appropriate boot device order in the SETUP boot menu depending

on the OS installation media used. For example, if the OS includes a bootable

installation floppy, select Floppy as the first boot device and reboot the system

with the installation floppy installed in the floppy drive. (Note that if the

installation requires a non-bootable CD-ROM, it is necessary to boot an OS

with the proper CD-ROM drivers in order to access the CD-ROM drive).

Proceed with the OS installation as directed, be sure to select appropriate

device types if prompted. Refer to the appropriate hardware manuals for

specific device types and compatibility modes of ADLINK NuIPC products.

When installation is complete, reboot the system and set the boot device order

in the SETUP boot menu appropriately.

Getting Started • 29

Page 36

Page 37

4

Device Driver Installation

To install drivers for the NuPRO-850, refer to the installation information in this

chapter. Basic driver installation information for Windows XP/2000 is outlined

in this section. For installation information for non-Windows Operating

Systems, refer to the extensive explanations on the ADLINK CD. The drivers

are located in the following directories of the CD-Rom:

Chipset driver \NuPRO\NuPRO-850\chipset

LAN relative driver \NuPRO\NuPRO-850\LAN

WDT \NuPRO\NuPRO-850\

4.1 Intel® 875P/6300ESB Chipset

This section describes the installation procedure for the Intel® 6300ESB

chipset device driver under Windows 2000/XP.

4.1.1 System Requirements

One of the following operating systems must be fully installed on the system

before installing any other driver, utilities, or software:

¾ Windows® 2000

®

¾ Windows

XP

Device Driver Installation • 31

Page 38

4.1.2 Hardware Configuration File Installation

This section describes how to install the hardware configuration files into a

system operating Windows 2000/XP.

1. Check the System Requirements. Windows 2000/XP must be fully

installed and running on the system prior to running this software.

2. Close any running applications.

3. The files are stored in an integrated application setup program. This

program is designed for a Windows 2000/XP and can be executed from

Run

the

4. Place the ADLINK CD into the CD-ROM drive. Run Setup.exe under

X:\NuPRO\NuPRO-850\chipset. Where X is the CD drive letter.

5. The user will be prompted with a license agreement. Should the user not

agree with the terms and conditions for using the software, the Installer will

exit before extracting any files.

6. Follow the on-screen instructions and use the default settings to complete

the setup, once the operating system has rebooted. This completes the

installation of the Intel® Chipset Software Installation Utility.

command prompt.

4.2 Driver Installation

4.2.1 VGA Driver Installation

Windows 2000/XP will attempt to install a standard VGA driver automatically.

To guarantee compatibility, manually install the most updated VGA driver,

which is stored in the ADLINK CD. After installing Windows 2000/XP, update to

the most updated driver by following these steps:

1. Boot Windows 2000/XP, then run the program

\NuPRO\NuPRO-850\VGA\SETUP.EXE

2. The VGA driver will automatically be installed onto the system.

3. Restart the system.

32 • Driver Installation

Page 39

4.2.2 LAN Driver Installation

This section describes the LAN driver installation process for the Intel® 82547

Gigabit Ethernet controller under Windows 2000/XP. The Intel® software

utilities package include Diagnostics utility; Makedisk utility; and

10/100/1000Mbps Ethernet device drivers. All drivers and utilities are stored in

the ADLINK CD under the directory: X:\NuPRO\NuPRO-850\LAN, where X: is

the location of the CD-ROM drive. For driver installations of other OS, please

refer to the readme file on the CD.

The installation procedures for Windows 2000/XP are the same. During

Windows 2000/XP installation, the operating system will install a LAN driver

automatically. It is recommended that the most updated LAN driver be

installed, which is shipped with the ADLINK CD. This will ensure total

compatibility. After installing the OS, update to the newer driver by following

these steps:

1. Run the self-extracting pro2kxpm.exe file. The extracted files are stored

to the default location C:\IntelPRO.

2. To install or update the Ethernet drivers for the system, click ‘Install Now’.

All Ethernet devices on the computer will be updated.

3. Reboot the system for the new drivers to take effect.

Note: To check if there are newer updates of the drive, it is

recommended that the following website

http://www.intel.com/design/software/driver/platform/

checked out on a regular basis.

be

Device Driver Installation • 33

Page 40

Page 41

5

Watchdog Timer

5.1 Watchdog Timer

The operation of the Nupro-850’s watchdog timer is described in this chapter.

An overview of the watchdog operation and features, as well as the

programming procedure is provided to give the user an insight into the

workings of the watchdog timer.

5.1.1 WDT Overview

The primary function of the watchdog timer is to monitor the Nupro-850’s

operation and to generate IRQ or to reset the system should the software fail to

function as programmed. The major features of the watchdog timer are:

z Enabled and disabled through software control

z Armed and strobed through software control

The Nupro-850’s custom watchdog timer circuit is integrated in the south

bridge 6300ESB.

Watchdog Timer • 35

Page 42

The Intel 6300ESB ICH includes a two-stage Watchdog Timer (WDT) that

provides a resolution that ranging from 1 micro second to 10 minutes. The

timer uses a 35-bit Down-Counter. The counter is loaded with the value from

the first Preload register. The timer is then enabled and starts counting down.

The time at which the WDT first starts counting down is called the first stage. If

the host fails to reload the WDT before the 35-bit down counter reaches zero

the WDT generates an internal interrupt. After the interrupt is generated, the

WDT loads the value from the second Preload register into the WDT’s 35-bit

Down-Counter and starts counting down. The WDT is now in second stage. If

the host still fails to reload the WDT before the second timeout, the WDT drives

the WDT_TOUT# pin low. The WDT_TOUT# pin is held low until the system is

reset.

The WDT of 6300ESB also supports multiple modes, WDT and free-running.

Free-running mode is a one stage timer and it will toggle WDT_TOUT# after

programmable time. WDT mode is a two stage timer and its operation is

described as above.

5.1.2 Configuration Registers

The Intel® 6300ESB ICH WDT, appears to BIOS as PCI Bus 0, Device 29,

Function 4, and has the standard set of PCI Configuration register. The

following describes the configuration registers.

Offset 10H: Base Address Register (BAR)

This register determines the memory base for WDT down-counter setting. It

will be used to set Preload value 1 register, Preload value 2 register, General

Interrupt Status register and Reload register.

Preload Value 1 & 2 registers

These two registers are used to hold the preload value for the WDT timer. Its

value will be automatically transferred into the down-counter every time the

WDT enters the first and second stage. Preload Value 1 register is located at

Base + 00H and Preload Value 2 register is located at Base + 04H. Only bit

[19:0] are settable.

The register unlocking sequence is necessary whenever writing to the Preload

registers. Instructions for writing a value into preload value 1&2 register are as

follows:

1. Write 80H to offset BAR + 0CH.

2. Write 86H to offset BAR + 0CH.

3. Write desired value to preload register. (BAR + 00H or BAR + 04H)

36 • Watchdog Timer

Page 43

General Interrupt Status Register

This register is at Base + 08H. Bit 0 is set when the first stage of down-counter

reaches zero.

Bit 0 = 0 – No Interrupt

Bit 1 = 1 – Interrupt Active

NOTE: This bit is not set in free-running mode.

Reload Register

This register is at Base + 0CH. Write 1 to bit 8 will reload the down-counter’s

value. To prevent a timeout:

1. Write 80H to offset BAR + 0CH

2. Write 86H to offset BAR + 0CH

3. Write a ‘1’ to RELOAD[8] of the reload register

Offset 60 – 61H: WDT Configuration Register

Bit 5 indicates whether or not the WDT will toggle the WDT_TOUT# pin when

WDT times out. (0 = Enabled, 1 = Disabled)

Bit 2 provides two options for prescaling the main down-counter. (0 = 1ms –

10min, 1 = 1us – 1sec)

Bit [1:0] allows the user to choose the type of interrupt desired when the WDT

reached the end of the first stage without being reset. (00 = IRQ, 01 = reserved,

10 = SMI, 11 = Disabled)

NOTE: The WDT does not support SMI now. IRQ uses APIC 1, INT 10 and it is

active low, level triggered.

Offset 68H: WDT Lock Register

Bit 2 is used to choose the functionality of the timer. (0 = Watchdog Timer

mode, 1 = Free running mode) The free-running mode ignores the first stage

and only uses Preload Value 2. In free-running mode it is not necessary to

reload the timer as it is done automatically every time the down-counter

reaches zero.

Bit 1 enables or disables the WDT. (0 = Disabled, 1 = Enabled)

Bit 0 will lock the values of this register until a hard reset occurs or power is

cycled. (0 = unlocked, 1 = locked) The default is Unlocked.

Watchdog Timer • 37

Page 44

5.1.2 GPIO Control Registers

There are two GPIOs on Nupro-850 that relate to watchdog timer. They are

listed below. The GPIO control base port is 480H.

WDT_TOUT# pin selection

WDT_TOUT# signal is multiplexed with GPIO32. When using WDT, this signal

must be switched to WDT_TOUT# function. It used bit 0 of GPIOBASE + 30H

to set WDT_TOUT function. (0 = WDT_TOUT#, 1 = GPIO32)

WDT LED Control

GPO25 of 6300ESB is designed to control WDT LED. Two features of WDT

LED are supported on Nupro-850’s WDT LED lights or blinks.

WDT LED light

Set bit 25 of GPIOBASE + 04H to 0. Bit 25 of GPIOBASE + 0CH determines

the state of WDT LED. (0 = light, 1 = dark)

WDT LED blink

Set bit 25 of GPIOBASE + 04H to 0. Bit 25 of GPIOBASE + 18H enables WDT

LED blinking function. (0 = function normally, 1 = enable blinking) The high and

low times have approximately 0.5 seconds each.

5.1.3 The procedure of programming WDT

Step 1: Make sure WDT_TOUT# signal is workable. (Not GPIO32 function).

Step 2: Set WDT output enable, presecaler and interrupt type into WDT

configuration register.

Step 3: Get control base from Base Address register.

Step 4: Program Preload register’s value according to unlocking sequence.

Step 5: Set WDT timer mode into WDT Lock Register.

Step 6: Enable WDT from WDT Lock register and program which

functionality of WDT LED will be.

To keep the timer from causing an interrupt or driving WDT_TOUT#, the timer

must be reloaded periodically. The frequency of reloads required is dependent

on the value of the preload values. To reload the down-counter, the register

unlocking sequence must be performed.

To disable WDT, Set bit 1 of WDT Lock Register to 0.

38 • Watchdog Timer

Page 45

5.1.4 Utilities

ADLINK provides a demo DOS utility, HRWDT.EXE. It is included in the driver

CD. Run “hrwdt /?” under the following directory:

X:\CHIPDRV\WDT\HRWDT for a more detailed explanation.

User also can download the Intel WDT demo windows application from Intel

driver download center.

Watchdog Timer • 39

Page 46

Page 47

6

ePCI-X Bus Details

6.1 NuPRO-850 ePCI-X Bus

The NuPRO-850 provides PCI-X/PCI buses. Bus-A can run up to 64-bit PCI-X

66. Bus-B can run PCI 33MHz.

The ePCI-X Bus pin assignment is compatible with the PICMG 1.2 ePCI-X

specifications. In the following sections, we will describe the detail signal

definition and the design guide for the backplane designer to be compatible

with the NuPRO-850 ePCI-X bus.

6.2 Global Signals

6.2.1 Standby Supply (+3.3Vaux)

The NuPRO-850 onboard circuit generate 3.3Vaux power from the +5Vaux or

+5V. Therefore, NuPRO-850 does not require the backplane to provide

+3.3Vaux.

6.2.2 ATX Support

The ATX support signals include PWRGD, PSON#, PWRBT#, +5Vaux. The

NuPRO-850 design provides the ATX power control capability.

If the backplane did not provide the +5Vaux, then the PWRBT# and PSON#

will not work under ATX power mode. Users have to setup the external w iring to

switch on/off the power supply.

6.2.3 JTAG

NuPRO-850 does NOT implement the JTAG signals.

6.2.4 I2C Bus

The onboard SMBus is connected to the SER_SCL and SER_SDA pins.

ePCI-X Bus Details • 41

Page 48

6.2.5 PME#

The NuPRO-850 implement PME# signal and connect it to 6300ESB

6.3 PCI-X Bus Signals

6.3.1 Backplane Present

The a_PRSNT# and b_PRSNT# signals are connected to the super I/O chip’s

GP25 and GP26 pins respectively. These signal are pulled to +3.3V via 4.7k

resistors.

6.3.2 VIO Electrical Keying

NuPRO-850 monitors the VIO keying signals from backplane.

6.3.3 M66EN and PCIXCAP

The Bus-A supports up to PCI-X 66, the M66EN, and PCIXCAP of Bus-A and

Bus-B can be used to program the PCI mode.

42 • ePCI-X Bus Details

Page 49

Warranty Policy

Thank you for choosing ADLINK. To understand your rights and enjoy all the

after-sales services we offer, please read the following carefully.

1. Before using ADLINK’s products please read the user manual and follow the

instructions exactly. When sending in damaged products for repair, please

attach an RMA application form which can be downloaded from:

http://rma.adlinktech.com/policy/.

2. All ADLINK products come with a limited two-year warranty, one year for

products bought in China.

• The warranty period starts on the day the product is shipped from

ADLINK’s factory.

• Peripherals and third-party products not manufactured by ADLINK

will be covered by the original manufacturers' warranty.

• For products containing storage devices (hard drives, flash cards,

etc.), please back up your data before sending them for repair.

ADLINK is not responsible for any loss of data.

• Please ensure the use of properly licensed software with our

systems. ADLINK does not condone the use of pirated software

and will not service systems using such software. ADLINK will not

be held legally responsible for products shipped with unlicensed

software installed by the user.

• For general repairs, please do not include peripheral accessories. If

peripherals need to be included, be certain to specify which items

you sent on the RMA Request & Confirmation Form. ADLINK is not

responsible for items not listed on the RMA Request &

Confirmation Form.

3. Our repair service is not covered by ADLINK's guarantee in the following

situations:

• Damage caused by not following instructions in the User's Manual.

• Damage caused by carelessness on the user's part during product

transportation.

• Damage caused by fire, earthquakes, floods, lightening, pollution,

other acts of God, and/or incorrect usage of voltage transformers.

• Damage caused by inappropriate storage environments such as

with high temperatures, high humidity, or volatile chemicals.

• Damage caused by leakage of battery fluid during or after change

of batteries by customer/user.

Warran ty Policy • 43

Page 50

• Damage from improper repair by unauthorized ADLINK

technicians.

• Products with altered and/or damaged serial numbers are not

entitled to our service.

• This warranty is not transferable or extendible.

• Other categories not protected under our warranty.

4. Customers are responsible for all fees necessary to transport damaged

products to ADLINK.

For further questions, please e-mail our FAE staff: service@adlinktech.com

44 • Warranty Policy

Loading...

Loading...