Page 1

Intel® E7500 and Intel® E7501

Chipsets MCH

Thermal Design Guide for Embedded Applications

March 2003

Order Number: 273819-002

Page 2

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED, BY

ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED IN

INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER, AND INTEL DISCLAIMS

ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING LIABILITY OR WARRANTIES

RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER

INTELLECTUAL PROPERTY RIGHT. Intel products are not intended for use in medical, life saving, life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked “reserved” or “undefined.” Intel reserves these for

future definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from future changes to them.

®

The Intel

published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an ordering number and are referenced in this document, or other Intel literature may be obtained by calling

1-800-548-4725 or by visiting Intel's website at http://www.intel.com.

AlertVIEW, AnyPoint, AppChoice, BoardWatch, BunnyPeople, CablePort, Celeron, Chips, CT Connect, CT Media, Dialogic, DM3, EtherExpress,

ETOX, FlashFile, i386, i486, i960, iCOMP, InstantIP, Intel, Intel logo, Intel386, Intel486, Intel740, IntelDX2, IntelDX4, IntelSX2, Intel Create & Share,

Intel GigaBlade, Intel InBusiness, Intel Inside, Intel Inside logo, Intel NetBurst, Intel NetMerge, Intel NetStructure, Intel Play, Intel Play logo, Intel

SingleDriver, Intel SpeedStep, Intel StrataFlash, Intel TeamStation, Intel Xeon, Intel XScale, IPLink, Itanium, LANDesk, LanRover, MCS, MMX, MMX

logo, Optimizer logo, OverDrive, Paragon, PC Dads, PC Parents, PDCharm, Pentium, Pentium II Xeon, Pentium III Xeon, Performance at Your

Command, RemoteExpress, Shiva, SmartDie, Solutions960, Sound Mark, StorageExpress, The Computer Inside., The Journey Inside,

TokenExpress, Trillium, VoiceBrick, Vtune, and Xircom are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United

States and other countries.

*Other names and brands may be claimed as the property of others.

Copyright © Intel Corporation, 2003

E7500 and Intel® E7501 Chipsets MCH may contain design defects or errors known as errata which may cause the product to deviate from

2 Thermal Design Guide

Page 3

Contents

Contents

1.0 Introduction....................................................................................................................................5

1.1 Document Goals....... .................................................. ..........................................................5

1.2 Document Scope.................................................................................................................. 5

1.3 Design Flow.......................................................................................................................... 5

1.4 Definition of Terms................................................................................................................6

1.5 Reference Documents........................................................................................................ ..6

2.0 Packaging Technology .................................................................................................................7

3.0 Thermal Simulation .......................................................................................................................9

4.0 Thermal Specifications ...............................................................................................................11

4.1 Power..................................................................................................................................11

4.2 Die Temperature.................................................................................................................11

5.0 Therm al Metrology ......................................................................................................................13

5.1 Die Temperature Measurements........................................................................................13

5.1.1 90° Angle Attach Methodology ..............................................................................13

5.1.2 0° Angle Attach Methodol o g y............ ......................................................... ...........14

5.2 Power Simulat ion Software....... ...................................................................................... ....16

6.0 Referen ce Th erm al So lution....................................................................................................... 17

6.1 Operating Environment and Thermal Performance ............................................................17

6.2 Mechanical Design Envelope .............................................................................................18

6.3 Thermal Solution Assembly................................................................................................19

6.3.1 Retention Method A ...............................................................................................20

6.3.1.1 Heat Sink Orientations...........................................................................20

6.3.1.2 B oard Lev el Keep-out Dimens ions ........................................................ 20

6.3.1.3 Heat Sink Clip........................................................................................22

6.3.1.4 Solder-Down Anch o rs........ ....................................................................22

6.3.2 Retention Method B ...............................................................................................22

6.3.2.1 Heat Sink Orientations...........................................................................23

6.3.2.2 B oard Lev el Keep-Ou t Dimensions........................................................23

6.3.2.3 Heat Sink Push-Pin................................................................................24

6.3.3 Mechanical Interface Material................................................................................24

6.3.4 Thermal Interface Material..................................................................................... 24

6.4 Reliability Requirements.....................................................................................................25

7.0 Con clu sion...................................................................................................................................27

A Thermal Solution Component Suppliers...................................................................................29

A.1 Extru d ed Pi n Fin Heat Sink.......................................... ...............................................................29

A.2 Materials for Retention Method A...............................................................................................29

A.3 Materials for Retention Method B...............................................................................................29

A.4 Attach Hardware.........................................................................................................................30

B Mechanical Drawings..................................................................................................................31

Thermal Design Guide 3

Page 4

Contents

Figures

1 Thermal Design Process..............................................................................................................5

2Intel

®

E7500 and Intel® E7501 Chipsets MCH Package Dimensions..........................................7

3 90° Angle Attach Methodology...................................................................................................14

4 0° Ang l e Att a ch Met h odology.....................................................................................................15

5 0° Ang l e Att a ch Heat Si nk Modification s............ ........................................................................15

6 Thermal Solution Deci sion Flowchart.........................................................................................16

7 Theta ja versus Airflow for the Reference Thermal Solution......................................................18

8 Reference Heat Sink Volumetric Envelope for the MCH............................................................ 19

9 Reference Thermal Solution Assembly Using Retention Method A ...........................................20

10 Heat Sink Retention Mechanism Layout for Retention Method A ..............................................21

11 Retention Mechanism Compone nt Keep-out Zones fo r Retention Metho d A.............................21

12 Reference Thermal Solution Assembly Using Retention Method B...........................................22

13 Board Component Keep-o ut for Retention Method B. ................................................................23

14 Heat Sink Mechanical Gasket, Optional Two-Pie ce . ..................................................................24

15 MCH Heat Sink...... .....................................................................................................................32

16 Heat Sink Clip.......... ..................................................................................................... ..............33

17 Push-pin.....................................................................................................................................34

Tables

1 Definition of Terms .......................................................................................................................6

2 Refer e n ce Documents..................................................................................................................6

3Intel

4 Theta ja Required versus Device and Configuration..................................................................17

5 Reliability Requirements.............................................................................................................25

6 Mechanical Drawing List.............................................................................................................31

®

E7500 and Intel® E7501 Chipsets MCH Thermal Speci fications .....................................11

Revision History

Date Revision Description

Revised Table 3, “Intel

March 2003 002

November 2002 001 Initial rele ase of this document.

MCH Thermal Specifications.”

Revised Table 4, “Theta ja Required versus Dev ice and

Configuration.”

4 Thermal Design Guide

®

E7500 and Intel® E7501 Chipsets

Page 5

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

1.0 Introduction

1.1 Document Goals

The objective of thermal management is to ensure that the temperatures of all components in a

system are maint ai ned within f u nction al limit s . The func tional te mper ature li mit i s the ra nge withi n

which the electric al circuits may be expec ted to meet specified performance requirements.

Operation outs ide the functional li mi t ma y degrade system performance , ca us e logic errors, or

cause component and /or s ystem damage. Temperatures exceeding the maximum operating limits

may result in irreversible changes in the operating characteristics of the component. Th e goal of

this document is to provide an understanding of the operating limits of the Intel

E7501 chipset MCHs and describe a re ference thermal solution for embedded applications.

1.2 Document Scope

This document addres ses thermal design and specifications for the Intel E7500 and I ntel E7501

chipset MCH components on ly. For thermal design information on other chipset components, refer

to the respective com ponent thermal design gu ides. For the Intel

®

PCI-64 Hub 2 (P64H2) Thermal Design Guidelines.

Intel

®

E7500 and Intel®

®

P64H2, refer to the

For general thermal enabling of the Intel E7501 chipset, refer to the Intel

and Intel

®

E7505 Chipsets MCH Thermal Design Guidelines.

1.3 Desig n Flo w

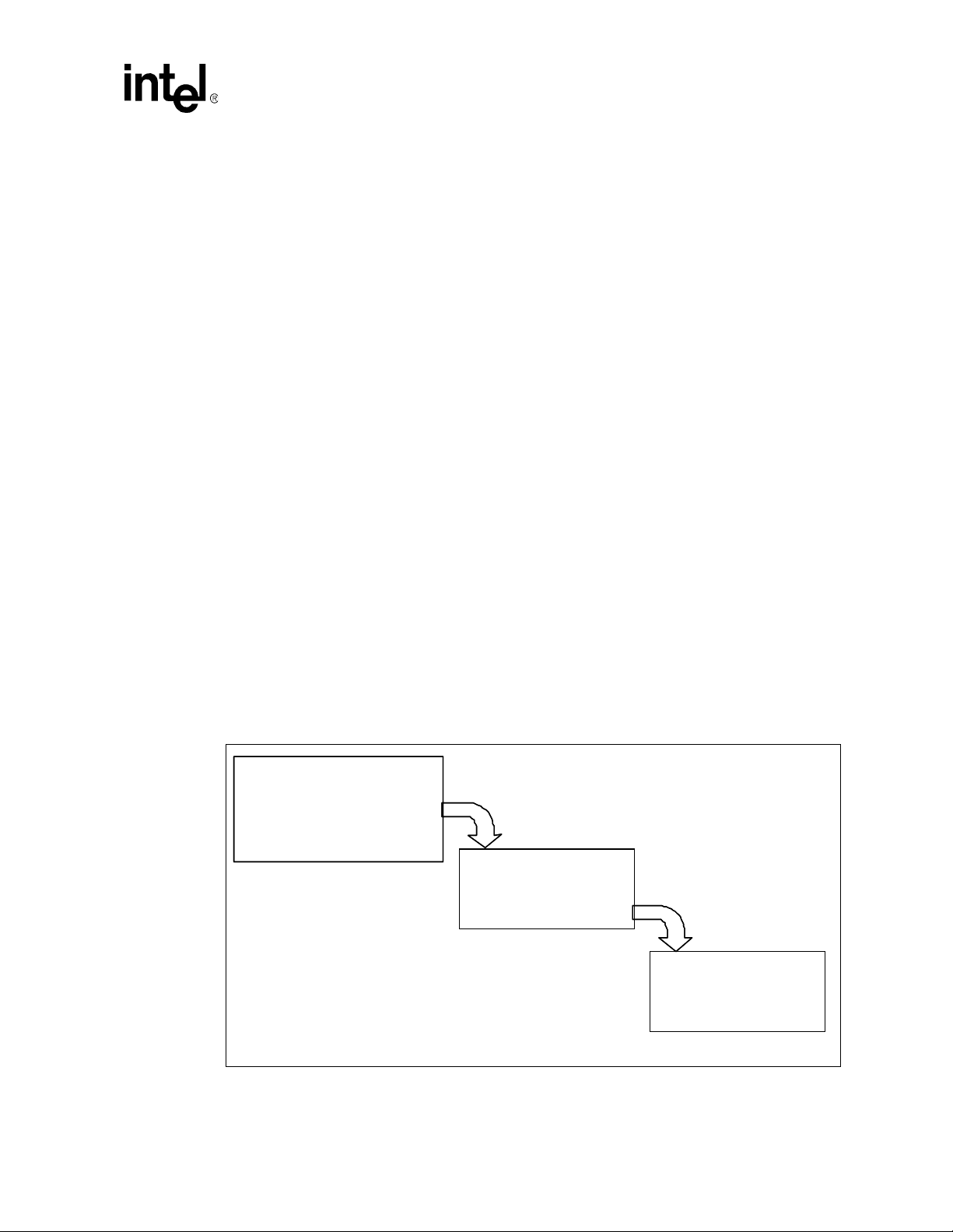

To develop a reliable, cost-effective thermal solution, several tools have been provided to the

system designer. Figure 1 shows the design process implicit to this document and the tools

appropriate for eac h st ep.

Figure 1. Thermal Design P roc ess

Step 1 : Thermal Simulation

Step 1 : Thermal Simulation

• Therma l model

• Therma l model

• Therma l model user’s gui de

• Therma l model user’s gui de

Step 2: Heat Sink Selection

• Thermal reference

• Thermal reference

•

• Mechanical reference

®

E7500, Intel® E7501,

Step 3: Thermal Validatio n

Step 3: Thermal Validatio n

• Thermal testing software

• Thermal testing software

•

•

Software user’s guide

Thermal Design Guide 5

Page 6

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

1.4 D ef initio n of Terms

Table 1 lists the definitions of terms us ed in this document.

Table 1. Definition of Term s

Term Definition

BGA

ICH3-S

MBGA Mini Ball Grid Array. A version of the BGA wit h a small er ball pitch.

MCH

FC-BGA

P64H2 Bus Controller Hub. The chip set component tha t interfaces the PCI-X buses.

T

case-nhs

T

die-nhs

T

die-hs

TDP

Ball Grid Array. A package type defined by a resin-fiber substrate, onto which a die is

mounted, bo nd ed and encap s ul at ed in mol di ng com po un d. Th e pri ma ry el ectr i cal in ter fac e is

an array of solder balls attached to the substrate opposite the die and molding compound.

I/O Controller Hub. The chipset component that contains the primary PCI interface, LPC

interface, USB , ATA-100, and other legacy functions.

Memory Controller Hub. The chipset component that contains the processor interface and

the memory inte rfa ce .

Flip Ch ip Bal l Gr id A r ray. A packagi ng t echno l ogy us ed fo r th e Int e l

chipset MCHs.

The maximum package case te mperature without any package thermal soluti on. This

temperature is measured at the geometric center of the top of the package case.

The maximum die temperature withou t any package thermal solution. This temperature is

measured at the geometric cente r of the top of the package die.

The maximum die temperatur e with the reference thermal solution attached. This

temperature is measured at the geometric center of the top of the package die.

Thermal Design Power. Thermal solutions should be designed to dissipate this target power

level.

1.5 Reference Documents

Table 2 lists the reference documents an d related document number or source.

®

E7500 and In te l® E7501

Table 2. Reference Documents

Document Document Number

®

Intel

E7500, Intel® E7501, and Intel® E7505 Chipsets MCH Thermal

Design Guidelines

Low Voltage Intel

Thermal Design Guidelines

®

Intel

Xeon™ Processor MP Thermal Design Guidelines 298650

®

PCI-64 Hub 2 (P64H2) Thermal Design Guidelines Contact your local Intel Representative

Intel

®

82801CA I/O Controlle r Hub 3 (ICH3-S) Datasheet 290733

Intel

®

E7500 and Intel® E7501 Chipset Flother m * Model and User’s

Intel

Guide

Thermal Design Su ggestions for Various Fo rm Factors Available at http://www.formfactors.org

®

Intel

E7500 Chipset MCH Thermal Testing Software Contact your local Intel Representative

®

Xeon™ Processor Thermal Design Guidelines 298348

Intel

®

XeonTM Processor for Embedded Applications

Contact your local Intel Representative

298647

273764

6 Thermal Design Guide

Page 7

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

2.0 Packaging Technology

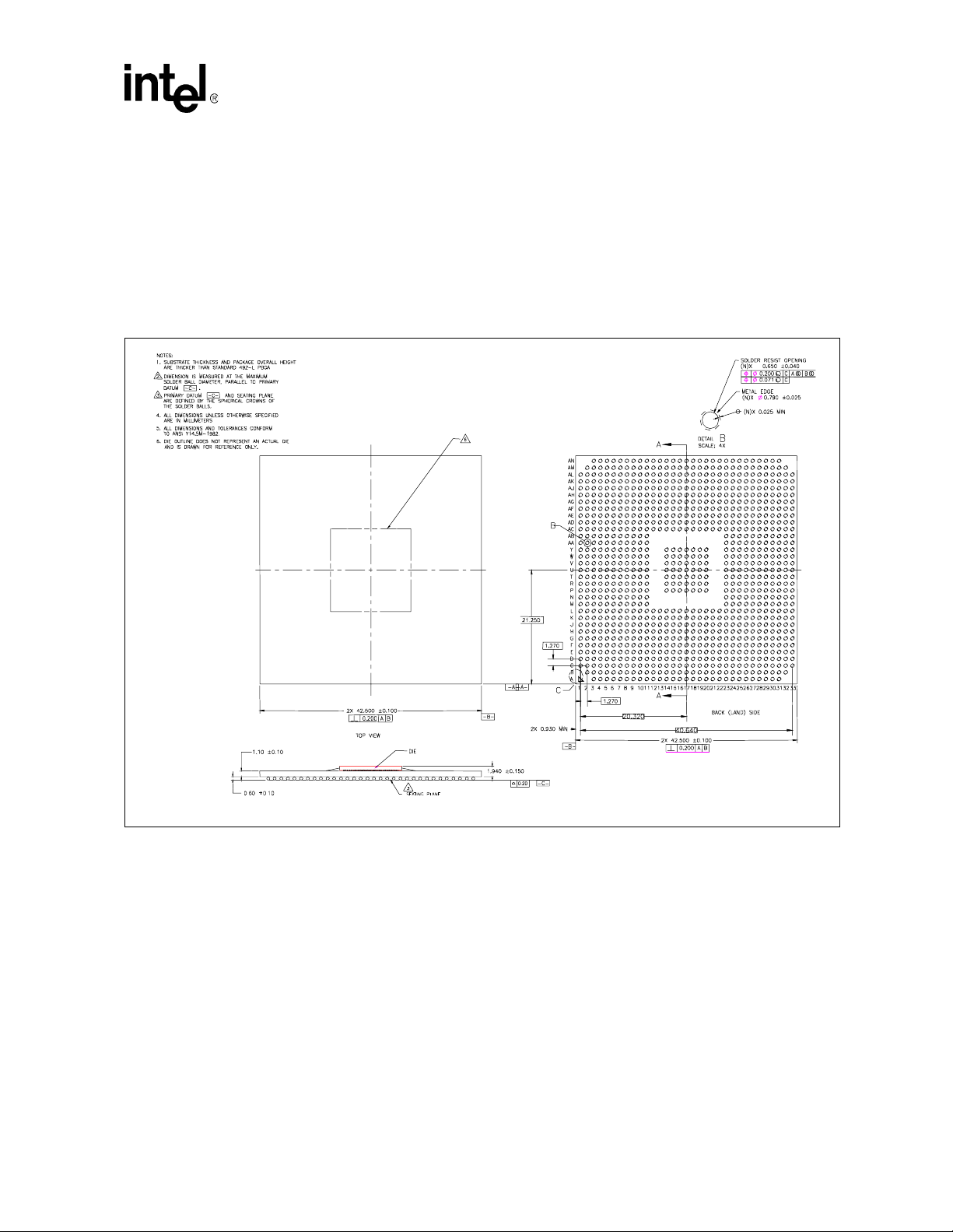

The Intel® E7500 and Intel® E7501 chipsets consist of thre e individual components, the memory

controller hub (MCH), bus controller hub (P64H2), and I/O controller hub (ICH3-S). Th e Inte l

E7500 and E7501 MCHs utilize a 42.5 mm, 6-layer FC-BGA package shown in Figure 2. Refer to

the Intel

component and to the Intel

on the ICH3-S component.

Figure 2. Intel

®

PCI-64 Hub 2 (P64H2) Thermal Design Guidelines for information on the P64H2

®

E7500 and Intel® E7501 Chipsets MCH Package Dimensions

®

82801CA I/O Controller Hub 3 (ICH3-S) Datasheet for information

®

NOTE: Dimensions are in mm.

Thermal Design Guide 7

Page 8

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

This page intentionally left blank.

8 Thermal Design Guide

Page 9

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

3.0 Thermal Simulatio n

Intel provides thermal simulation models of the Intel® E7500 chipset MCH and associated user’s

guides to aid sys tem designers in simulating, analyz ing, and optimizing their thermal so lutions in

an integrated system-level environment. The models are for use with the commercially available

Computation al Fluid Dynamics (CFD)-based thermal analys is tool FLOTHERM* (version 3.1 or

higher) by F lom erics Inc. Contact your Intel Field Sales represe ntative to order the therm al models

and user’s guides. The Intel E7500 chi pset MCH thermal model may also be us ed for simulating

the Intel

E7501 chipset MCH.

Thermal Design Guide 9

Page 10

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

This page intentionally left blank.

10 Thermal Design Guide

Page 11

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

4.0 Thermal Specifications

4.1 Power

See Table 3 for TDP specifications for the Intel® E7500 MCH and the Intel® E7501 chips et MCH.

FC-BGA packages have poor heat transfer capability into the board and have minimal the rma l

capability without thermal solutions. Intel recommends that sys tem designers pl an for one or more

heat sinks when using the Intel E7500 or Intel E7 501 chipset components.

4.2 Die Temper ature

To ensure proper operation and reliability of the Intel E7500 and Intel E7501 chipset MCHs, the

die temperature s must be at or below the values speci f ied in Table 3. Refer to Section 5.0 for

guidelines on accurately measuring package die temperatures.

Table 3. Intel

Intel

Intel

(Paired with Intel

Intel

configuration)

Intel E7501 Chipset MCH

(Paired with Intel Xeon processor or Low Voltage

Intel

configuration)

Intel E7501 Chipset MCH

(Paired with Intel

channel memory configuration)

Intel E7501 Chipset MCH

(Paired with Intel Pentium M processor, single

channel memory configuration)

†T

®

E7500 and Intel® E7501 Chipsets MCH Thermal Specifications

Device

®

E7500 Chipset MCH 102° C 7.5 W

®

E7501 Chipset MCH

Xeon processor, dual channel memory

Xeon processor, single chan ne l me mo r y

die-hs

®

Xeon™ proces sor or Low Voltage

®

Pentium® M proces sor, dual

is defined as the maximum die temperature with the ref erence thermal solution attached.

Parameter (Maximum)

†

T

die-hs

105° C 8.5 W

105° C 7.8 W

105° C 7.1 W

105° C 6.2 W

TDP

Thermal Design Guide 11

Page 12

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

This page intentionally left blank.

12 Thermal Design Guide

Page 13

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

5.0 Thermal Metrology

The system designer must obtain temperature measurements in order to accurately determine the

thermal performance of the system. Intel has established guidelines for proper techniques of

measurin g c h i pset MC H die temperatures . Sec tion 5.1 provides guidelines on how to accurately

measur e th e MCH die temperatures. Section 5.2 contains information on running an application

program that will emulate anticipat ed maximum thermal design powe r. The flowchart in Figure 6

offers useful guidelines for the r mal performance and evaluation.

5.1 Die Temperature Measurements

T o ensure functio nal ity and reli abi lity, the chipset MCH is specifi ed for prope r operati on whe n T

is mainta ined at or below its respectiv e ma ximum temperature listed in Table 3. The surface

temperature at the ge ome tric center of the die corresponds to T

care to en su r e an acc u ra t e tempera tur e m e asu r ement.

Temperature differences between the temperature of a surface and the surrounding local ambient

air may introduc e erro r in the measur ement s. The measure ment err ors may be due to a p oor therm al

contact between the thermocouple junction and the surface of the package, heat loss by radiation

and/or convection, conduc tion through thermocouple leads, or conta ct between the thermocouple

cement and the heat sink base (when a heat sink is used). To minimize these measurement errors,

the following approaches are recommended for thermocouple attach.

5.1.1 90° Angle Attach Methodology

1. Use 36-gauge or smaller diameter K-type thermocouples.

2. Ensure that the thermocouple has be en properly calibrated.

3. Attach the ther mocoupl e b ead or j unctio n to the top su rface of th e di e in th e cent er using a high

thermal conductivity cement. It is critical that the thermocouple bead makes contact with

the die.

4. The thermocouple should be attached at a 90° angle when no interference exi sts between the

thermocouple wire and retention mechanism (see Figure 3). This is the preferred method and

is recommended for use with both bare packages as well as pack ages employing a thermal

solution.

5. The hole size through the heat sink ba se to route the therm ocouple wires out shoul d be smalle r

than 3.3 mm [0.13 in] in diameter.

. Measuring T

die

requires spe cial

die

die

6. Make sure no cont act e xist s bet ween th e therm ocoupl e cem ent a nd heat sink base . This c ont act

will affect the thermocouple reading.

Thermal Design Guide 13

Page 14

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

Figure 3 shows the 90° angle attach methodology.

Figure 3. 90° Angle Attach Methodology

NOTE: Drawing is not to scale.

5.1.2 0° Angle Attach Methodology

1. Mill a 3.3-mm [0.13 in] diameter hole centered on bottom of the heat sink base. The milled

hole should be approximately 1.5 mm [0.06 in] dee p.

2. Mill a 1.3 mm [0.05 i n] wid e slot , 0.5 mm [0.02 in] d eep, fr om the c enter ed hole to one ed ge of

the heat sink. The slot should be in the direction parallel to the heat sink fins (see Figure 5).

3. Attach thermal interface material (TIM) to the bottom of the heat sink base.

4. Cut out portions of the TIM to make room for the thermocouple wire and bead. The cutouts

should match the slot and hole milled into the heat sink bas e.

5. Attach a 36-gauge or smaller calibrated K-type the rmoc ouple bead or junction to the cent er of

the top surface of the die using a high thermal conductivity cement. During this step, make

sure no contact is pres ent between the the r mocouple cement and the hea t s ink base because

any contact will affect the thermocouple reading. It is critical that the thermocouple bead

makes contact with the die (see Figure 4).

6. Attach heat sink assembly to the MCH, and route thermocouple wires out through the milled

slot.

14 Thermal Design Guide

Page 15

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

Figure 4 shows the 0° angle attach methodology.

Figure 4. 0° Angle Attach Met h odology

NOTE: Drawing repres ents the top view and is not to scale.

Figure 5 shows the 0° angle attach heat sink modifications.

Figure 5. 0° Angle Attach Heat Sink Modifications

NOTE: Drawing dimensions are not to scale.

Thermal Design Guide 15

Page 16

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

5.2 Power Simulation Software

The power simulation software is a utility designed to dissipate the thermal design power on an

®

Intel

E7501 chipset MCH when used in conjunction with Intel® Xeon™ processor(s) with 512

Kbytes L2 ca che o r a Low Voltage Intel

the therm al performan ce of the chipset MCH thermal solut ion under “worst-case realistic

application” conditions, Intel has develope d a software utility that operates the chipset at near

worst-case power dis sipation.

The utility has been developed solely for testing customer thermal solutions at near the thermal

design power. Figure 6 shows a decision flowchart for det erm ining thermal solution needs. Real

future applications may exceed the thermal design power limit for transient time periods. For

power supply current re quirements under these transient conditions, please refer to each

component’s EDS or EDS Addendum for the I

Contact your Intel Field Sales representative to obtain a copy of thi s software.

Figure 6. Thermal Solution Decision Flowchart

Start

®

Xeon™ processor with 512 Kbytes L2 cache. To assess

(Max Power Supply Current) specification.

CC

Attach device

to board using

normal reflow

process.

Attach thermocouples using

recommended metrology.

Setup the system in the

desired configuration.

Run the Power

program and

monitor the device

die temperature.

Heatsink requiredSelect Heatsink

Tdie >

Specification?

Yes

No

End

16 Thermal Design Guide

Page 17

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

6.0 Reference Thermal Solution

Intel has developed a reference thermal solution designed to meet the cooling needs of the In tel®

E7500 and Intel

®

E7501 chipset MCHs at worst- ca se embedded condi tions. This section describes

the overall requirements for the refe rence thermal solution, including critical-to-function

dimensions, operating environment, and validation criteria. Other chipset components may or may

not need attached thermal solutions, depending on your specific system local-ambient operating

conditions. Refer to the Intel

®

PCI-64 Hub 2 (P64H2) Thermal Design Guidelines and Intel® I/O

Controller Hub 4 (ICH4) Thermal Design Guidelines for information on therm al solution

requirements and reference thermal solutions.

6.1 Operating Environment and Thermal Performance

The reference thermal solution was designe d assuming a maximum local-ambient temperature of

55° C with a minimum airflow velocity directly upstream of the heatsink of 50 L FM. Assuming

these boundary conditions are met, the refe rence thermal solution will meet the thermal

specifications for the Intel E7500 and Intel E7501 chips et MCHs in all memory and Hub Interface

configurations. See Figure 7 for a plot of the theta ja versus airflow for the reference heatsink

design, and Table 4 for the required theta ja heatsink performances for the Intel E7500 and Intel

E7501 chipset MCHs.

The reference thermal solution provides enough thermal capability to meet the required theta ja for

all of the configurations listed in Table 4 with 50 LFM airflow.

Table 4. Theta ja Required versus Device and Configuration

Device Theta ja Max (° C/W) at TLA = 55° C

®

Intel

E7500 Chipset MCH 6.27° C/W

®

E7501 Chipset MCH

Intel

(Paired with Intel

processor, dual channel memory configuration)

Intel E7501 Chipset MCH

(Paired with Intel Xeon processor or Low Voltage Intel

processor, single channel memory configuration)

Intel E7501 Chipset MCH

(Paired with Intel

configuration)

Intel E7501 Chipset MCH

(Paired with Intel Pentium M processor, single channel memory

configuration)

is defined as the local (internal) ambient temperature directly upstream of the chipset.

†T

LA

®

Xeon™ proces sor or Low Voltage Int el Xeon

Xeon

®

Pentium® M proces sor, dual channel memory

5.88° C/W

6.41° C/W

7.04° C/W

8.06° C/W

Thermal Design Guide 17

Page 18

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

E7500 and E7501 MCH Refer ence Thermal Solut ion

Figure 7 shows the theta ja versus airflow for the referen ce ther mal solution.

Figure 7. Theta ja versus Airfl ow for t he Reference Th erm al So lu t io n

Theta ja vs. Airflow

7.00

6.00

5.00

4.00

3.00

5.8

Theta ja (C/W)

2.00

1.00

0.00

50 100 200

Airflow (LFM)

6.2 Mechanical Design Envelope

Though each design may have unique mechanical volume and height restrictions or

implementa tion requirements, the height, width, and depth constraints typicall y placed on the Intel

E7500 chipset and Intel E7501 chipset MCHs in em bedded environments are shown in Figure 8.

These constraints assume the use of the CompactPCI

4.4

*

blade form factor.

3.4

When using heat sinks that extend beyond the MCH refer ence heat sink envelope shown in

Figure 8, any motherboard components placed betwe en the underside of the heat sink and

motherboard cannot exceed 2.286 mm [0.090 in] in height.

18 Thermal Design Guide

Page 19

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

Figure 8 shows the reference heat sink volumetric e nvelope for the MCH.

Figure 8. Reference Heat Sink Volumetric Envelope for the MCH

NOTE: Drawing dimensions are not to scale.

6.3 Thermal Solution Assembly

The reference thermal solution is a passive extruded heat sink with thermal and mechanical

interfaces. Ther e ar e tw o met h od s f o r at ta ch i n g th e he at sin k to th e motherbo ar d . Th e f irst method

(Retention Met hod A) uses a clip with each end hooked through an anchor soldered to the board.

The second method (Retention Method B) employs the use of four push-pins through the board

using the four holes provided on the heat sink. This method might face layout constraints as the

four holes through the motherboard must be accounted for during board layout. Full mechanical

drawings of the the rma l solution assem bly and the heat sink clip may be found in Appendix B,

“Mechani cal Drawings. ”

Appendix A, “Thermal Solut ion Com ponent Suppliers” lists the Bill-of-Materials and ve ndor

information for each thermal solution component.

Thermal Design Guide 19

Page 20

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

6.3.1 Retention Method A

Retention Method A employs the use of a clip and two solde r-down through board anchors for

mechanical retention. This method is preferred when layout constraints hamper the use of

Retention Me thod B.

Figure 9 shows the reference thermal solution assembly using Retention Method A.

Figure 9. Reference Thermal Soluti on Assembly Us in g Re te n tion Method A

Clip

Heat Sink

Thermal Interface

Mechanical In t er face

Solder-Down Anch or

FC-BGA Package

6.3.1.1 Heat Sink Orientations

When using Ret entio n Met hod A, the heat si nk mus t be al ign ed as sho wn in Figure 9. The heat sink

holes on the same side of the heat sink must be parallel with the clip that applies pressure thro ugh

the center of the hea t s ink.

The airflow m ay approach the heat sink from either perpendicular direct ion. Aligning the heat sink

45° relative to the airflow is acceptable but delivers reduced thermal performance.

6.3.1.2 Board Level Keep-out Dimensio ns

The locations of hole patterns and keep-out zones for the reference thermal solution are shown in

Figure 10 and Figure 11.

20 Thermal Design Guide

Page 21

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

56.34 [2.218]

MCH PIN1

.100" MAX COMPONENT

.070" COMPO NENT

Figure 10 shows the heat sink retention mec hanism layout for Retent ion Method A.

Figure 10. H eat Sink Retent i on Mechanism La yout for Retention Meth od A

60.91 [2.398]

2X 30.45 [1.199]

2X 28.17

[1.109]

NOTE: Drawing dimensions are in milli m eters [in] and are not to scale.

Figure 11 shows the retention mechanism componen t keep-out zones for Retention Method A.

Figure 11. Retention Mechanism Component Keep-out Zones for Retention Method A

.165

.083

2X

.038

PLATED THROUGH HOLE

.173

DETAIL

(.165)

A

KEEPOUT

2X .060

(.345)

.225

.100

SEE DETAIL A

.200

.100

.896

.120

1.156

COMPONENT

KEEPOUT

TRACE KEEPOUT

HEIGHT KEEPOUT

345

.

(.345)

2X

.056

NOTE: Drawing dimensions are in inches and are not to scale.

.170

Thermal Design Guide 21

Page 22

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

6.3.1.3 Heat Sink Clip

Retention Method A employs the use of a wire clip with hooke d ends. The hook s attach to anchors

to fasten the clip to the board. See Figure 16 in Appendix B, “Mechanical Drawings” for a

mechanical drawing of the clip.

6.3.1.4 Solder-Down Anchors

For platforms that have very limited board spa ce , a cl ip retention solde r-down anchor has been

developed t o minimize the im pact of clip ret ention on the board. It is based on a stan dard three-pin

jumper and is soldered to t he board like any common through-hol e header. A new anchor design is

available with 45° bent le ads to increase the anchor attach reliability over time. See Appendix A,

“Thermal Solution Component Suppliers” for the part number and supplier infor mation.

6.3.2 Retention Method B

Retention Method B employ s the use of four push-pins mounted through the four holes on the heat

sink and the mother board. This method requires advance layout noti fication for the four through

holes on the motherboard.

Figure 12 shows the reference thermal solution assembly using Retention Method B.

Figure 12. Reference Thermal Solution Assembly Using Retention Method B

Heat Sink

Push-pin

Thermal Interface Material

Mechanical Interface

FC-BGA Package

22 Thermal Design Guide

Page 23

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

6.3.2.1 Heat Sink Orientations

Retention Met hod B supports an omni-direc tional placement for the heat sink. Airflow may pass

either perpen dicular direction over the fins and the heat sink may be mounted in either the vert ical

or horizontal pos ition atop the MCH, depending on hole placement.

Aligning the heat sink 45° relative to the airflow is acceptable but delivers reduced thermal

performance.

6.3.2.2 Board Level Keep-Out Dimensions

Figure 13 shows the board component keep-out for Retention Method B.

Figure 13. Boar d C om ponent Keep-o ut for Retention Method B

Intel® E7500 Chipset MCH

Intel® E7501 Chipset MCH

NOTE: Draw i ng dim en si ons are in inches and are not to sc al e.

Thermal Design Guide 23

Page 24

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

6.3.2.3 Heat Sink Push-Pin

Four push-pins are required to imple me nt Retention Method B. Vendor information and a detailed

mechanical drawing are located in Appendix B. Currently, the push-pin is available for 0.096 inch

thick motherboards. Other size motherboards might require custom parts from the vendor.

6.3.3 Mechanical Interface Material

Intel recommends the use of a mechanical interface material to avoid cracking of the exposed die

under loading. The interface material reduces mechanical loads experienced by the die. The

reference thermal solution uses a pictu r e fra me gasket of 0.813 mm [0.032 in] thick Poron* foa m.

The foam gasket is a two-piece design, with diagonal cuts at two corners, as shown in Figure 14.

A one-piece gasket design may be used instead without any impact to mechanical performance.

Figure 14. Heat Sink Mechanical Gasket, Optional Two-Piece

NOTE: Drawing dimensions are in millimeters [in] and are not to scale.

6.3.4 Thermal Interface Material

A thermal interface material provides improved conductivity between the die and heat sink. The

reference thermal sol ution is delivered with Powerstrate 51* (manufactured by Po wer Devi ce s,

Inc.) p h ase change material attached.

24 Thermal Design Guide

Page 25

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

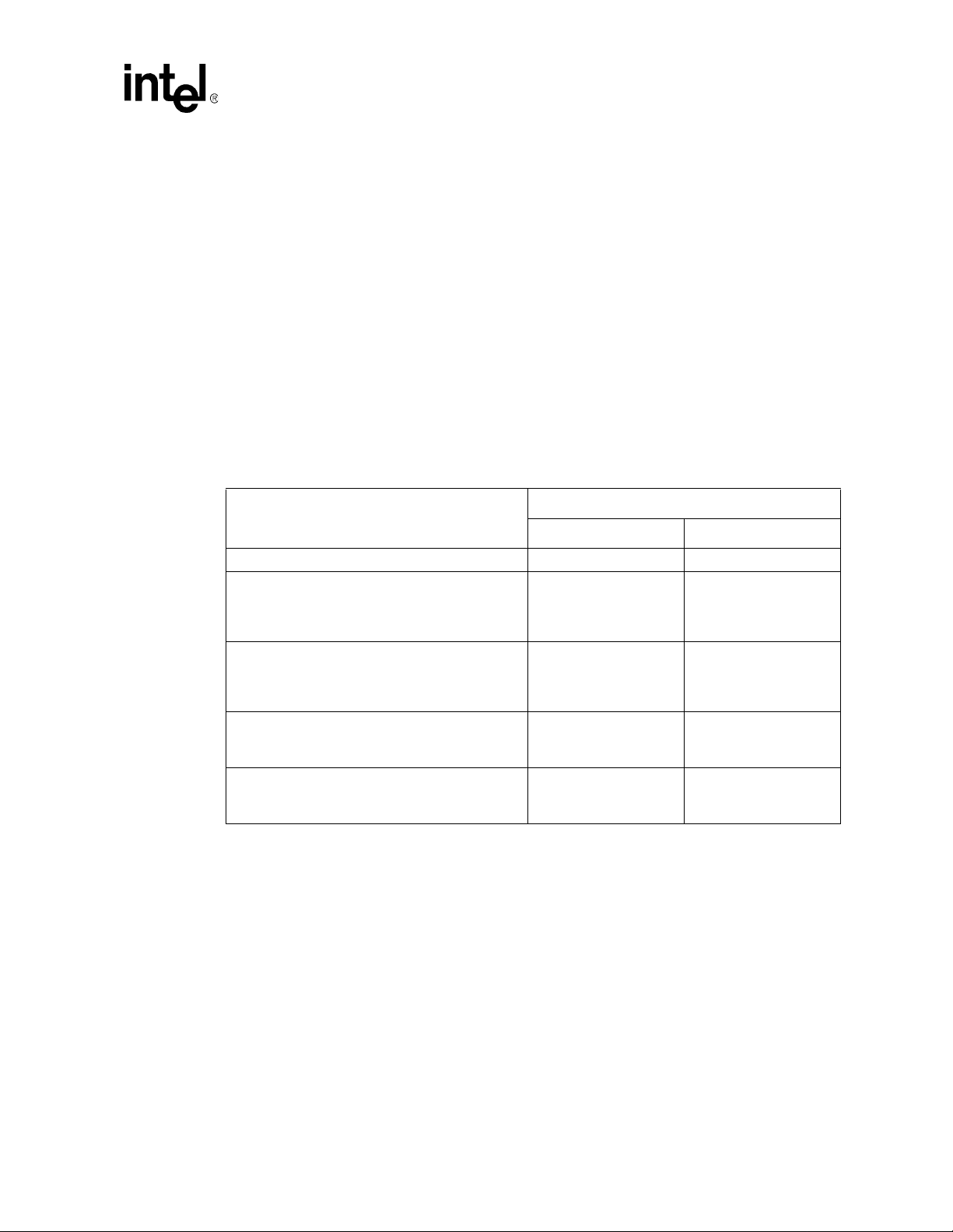

6.4 Reliability Requirements

Each motherboard, heat sink, and attach combination may vary the mechanical loading of the

component. The user should carefully evaluate the reliability of the completed assembly prior to

use in high volume. Some general recommendations are pre sented in Table 5.

Table 5. Reliability Requirements

1

Test

Requirement Pass/Fail Criteria

2

Mechan ical Shock 50 g, boar d level, 11 msec, 3 shocks/axis

Random Vibration 7.3 g, board level, 45 min/axis, 50 Hz to 2000 Hz

Temperature Life

Thermal Cycli ng -5° C to +70° C, 500 cycles Visual Check

Humidity 85% relative humidity, 55° C, 1000 hours Visual Check

NOTES:

1. The above tests should be performed on a sample size of at least 12 assemblies from three lots of

material.

2. Additional Pass/Fail Criteria may be added at the discretion of the user.

85° C, 2000 hours total, checkpoints at 16 8, 500,

1000, an d 20 00 hours

Visual Check and Electrical

Functional Test

Visual Check and Electrical

Functional Test

Visual Check

Thermal Design Guide 25

Page 26

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

This page intentionally left blank.

26 Thermal Design Guide

Page 27

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

7.0 Conclusion

As the complexity of computer systems increases, so do the power dissipation requirements. Care

must be taken to ensure that the additional power is properly dissipated. Heat may be dissipated

using improved system cooling, selective use of ducting, and/or passive heat sinks.

The simplest and most cost effective method is to improve the inhere nt system cooling

characteristics through careful design and placement of fans, vents, and ducts. When additional

cooling is req uired, component the rmal solutions may be im plemented in conjunction with system

thermal solutions. The size of the fan or heat s ink may be varied to balance si ze and space

constraints with acoustic noise.

This document has presen ted the c onditio ns and req uireme nts to properly de sign a co oling s olut ion

for systems implementing Intel

Properly desi gned solut ions pro vide ad equate co oling to maint ai n the ch ipse t die te mpera tur es at or

below thermal specifications. This is accompli shed by providing a low local-ambient temperature,

ensuring adequate local airflow, and minimizing the die to local-ambient thermal resistance. By

maintaining the chipset MCH die temper ature at or below those recommende d in this document, a

system designer m ay ensure the proper functionality, performance, and reliability of these chipsets.

®

E7500 or Intel® E7501 chipsets in a n emb edded application.

Thermal Design Guide 27

Page 28

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

This page intentionally left blank.

28 Thermal Design Guide

Page 29

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

Appendix A Thermal So lution Compone nt Suppliers

A.1 Extruded Pin Fin Heat Sink

Part Supplier (Part Number) Contact Information

Pin Fin Heat Sink

(Includes heat sink and attac hed

thermal interface material)

Cooler Master (ECB-00028-01)

A.2 Materials for Retention Method A

Part

Heatsink Clip 1 A69230-001

Board Mount Solder-Down Anchors

(Two anchors required per heat sink.)

Qty Required

(per assy )

2 A13494-005 Foxconn

A.3 Materials for Retention Method B

Intel Part

Number

Wendy Lin

886-2- 34 3 4- 0 05 0, x3 33

wendy@coolermaster.com.tw

Supplier Contact Information

Harry Lin

CCI/ACK

Foxconn

714-739-5797

hlinack@aol.com

Bob Hall

503-693-3509 x235

bhall@foxconn.com

Julia Jiang

(408) 919-6178

juliaj@foxconn.com

Part Supplier (Part Number) Contact Information

Steve Blan k

Push-Pin Peninsula Components (PL 1674)

NOTE: Four pu sh-pins ar e requir ed per heat sink.

(562) 694-4477

steve@pencomsf.com

Thermal Design Guide 29

Page 30

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

A.4 Attach Hardware

Part Intel Part Numbe r Supp lie r Contact Information

Therm al Interfac e

(Powerstrate 51*)

Mechanical Interface

(Poron*)

-- Power Devices, Inc.

A69141-001 Boyd

Mike McPherson

916-686-1432

Mike.McPherson@loctite.com

Rhoda Kennedy

503-972-3170

rkennedy@boydcorp.com

Note: The enabled components may not be currently available from all suppliers. Contact the supplier

directly to ve rify time of component avai lability.

30 Thermal Design Guide

Page 31

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

Appendix B Mechanical Drawings

Table 6 lists the mechanical drawings included in thi s section.

Table 6. Mechanical Drawing List

Drawing Desc r iption Page Number

MCH Heat Sink 32

Heat Sink Clip (for Retentio n Method A) 33

Push-pin (for Retention Method B) 34

Thermal Design Guide 31

Page 32

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

Figure 15. MCH Heat Sink

Used by permission.

32 Thermal Design Guide

Page 33

Figure 16. Heat Sink Clip

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

Thermal Design Guide 33

Page 34

Intel® E7500 and Intel® E7501 Chipsets MCH Thermal Design Guide

Figure 17. Push-pin

Used by permission.

34 Thermal Design Guide

Loading...

Loading...