Page 1

Document Number: 337029-009

Intel® RealSense

TM

Product Family D400 Series

Datasheet

Intel® RealSense™ Vision Processor D4, Intel® RealSense™ Vision

Processor D4 Board, Intel® RealSense™ Vision Processor D4 Board V2,

Intel® RealSense™ Vision Processor D4 Board V3, Intel® RealSense™

Depth Module D400, Intel® RealSense™ Depth Module D410, Intel®

RealSense™ Depth Module D415, Intel® RealSense™ Depth Camera D415,

Intel® RealSense™ Depth Module D420, Intel® RealSense™ Depth Module

D430, Intel® RealSense™ Depth Module D450, Intel® RealSense™ Depth

Camera D435, Intel® RealSense™ Depth Camera D435i, Intel®

RealSense™ Depth Camera D455

Revision 009

June 2020

Page 2

2 337029-009

Intel products described herein. You agree to grant Intel a non-exclusive, royalty-free license to any patent claim thereafter

drafted which includes subject matter disclosed herein.

No license (express or implied, by estoppel or otherwise) to any intellectual property rights is granted by this document.

Intel technologies’ features and benefits depend on system configuration and may require enabled hardware, software or servic e

activation. Performance varies depending on system configuration. No computer system can be absolutely secure. Check with

your system manufacturer or retailer or learn more at intel.com.

Intel technologies may require enabled hardware, specific software, or services activation. Check with your system manufactur er

or retailer.

The products described may contain design defects or errors known as errata which may cause the product to deviate from

published specifications. Current characterized errata are available on request.

Intel disclaims all express and implied warranties, including without limitation, the implied warranties of merchantability, fitness

for a particular purpose, and non-infringement, as well as any warranty arising from course of performance, course of dealing, or

usage in trade.

All information provided here is subject to change without notice. Contact your Intel representative to obtain the latest Intel

product specifications and roadmaps.

Copies of documents which have an order number and are referenced in this document may be obtained by calling 1-800-5484725 or visit www.intel.com/design/literature.htm.

Intel and the Intel logo, Intel® Core™, Intel® Atom™, trademarks of Intel Corporation in the U.S. and/or other countries.

*Other names and brands may be claimed as the property of others.

© 2020 Intel Corporation. All rights reserved.

Page 3

Description and Features

337029-009 3

Contents

1 Description and Features .................................................................................. 14

2 Introduction .................................................................................................... 15

2.1 Purpose and Scope of this Document ....................................................... 15

2.2 Terminology ......................................................................................... 15

2.3 Stereo Vision Depth Technology Overview ................................................ 16

2.4 Camera System Block Diagram ............................................................... 18

2.5 Intel® RealSense™ Depth Module D400 series Product SKUs ...................... 19

2.6 Intel® RealSense™ Depth Camera D400 series Product SKUs ..................... 20

3 Component Specification .................................................................................. 21

3.1 Vision Processor D4 Camera System Components ..................................... 21

3.2 Host Processor ..................................................................................... 21

3.3 Intel® RealSense™ Vision Processor D4 ................................................... 21

3.3.1 Vision Processor D4 Features .................................................... 21

3.3.2 Vision Processor D4 Signal Description ....................................... 22

3.3.3 Vision Processor D4 Package Mechanical Attributes ...................... 27

3.3.4 Vision Processor D4 Power Requirements .................................... 33

3.3.5 Vision Processor D4 Power Sequencing ....................................... 33

3.3.6 Vision Processor D4 Spec Code .................................................. 34

3.3.7 Vision Processor D4 Storage and Operating Conditions ................. 34

3.3.8 Vision Processor D4 Thermals ................................................... 35

3.4 Clock ................................................................................................... 35

3.5 Serial (SPI) Flash Memory ...................................................................... 35

3.6 Stereo Depth Module ............................................................................. 35

3.6.1 Left and Right Imagers ............................................................. 37

3.6.2 Infrared Projector .................................................................... 38

3.6.3 Color Sensor ........................................................................... 39

3.6.4 Depth Module Connector .......................................................... 40

3.6.5 Stereo Depth Module Label ....................................................... 40

3.6.6 Stiffener ................................................................................. 41

3.6.7 Temperature Sensor ................................................................ 41

3.6.8 Other Stereo Depth Module Components .................................... 41

3.6.9 Mechanical Dimensions ............................................................. 42

3.6.10 Stereo Depth Module Power Sequence........................................ 43

3.6.11 Stereo Depth Module Storage and Powered Conditions ................. 43

3.7 Intel® RealSense™ Vision Processor D4 Board .......................................... 44

3.7.1 Mechanical Dimensions ............................................................. 45

3.7.2 Depth Module Receptacle .......................................................... 45

3.7.3 Flex and Rigid Interposer Interconnect ....................................... 45

3.7.4 External Sensor Sync Connector ................................................ 50

3.7.5 USB Peripheral Connector – Type-C ........................................... 50

3.7.6 Color Image Signal Processor (ISP) ............................................ 52

3.7.7 Vision Processor D4 Board Power Requirements .......................... 52

3.7.8 Vision Processor D4 Board Thermals .......................................... 52

3.7.9 Vision Processor D4 Board Storage and Powered Conditions .......... 53

3.7.10 Intel® RealSense™ Vision Processor D4 Board Product Identifier and

Material Code .......................................................................... 54

3.8 Intel® RealSense™ Depth Camera D400 Series ......................................... 54

Page 4

4 337029-009

3.8.1 Depth Camera D400 Series Mechanical Dimensions ..................... 55

3.8.2 Depth Camera D400 Series Thermals ......................................... 56

3.8.3 Depth Camera D400 Series Product Identifier and Material Code ... 58

3.8.4 Camera Lens Cleaning Procedure ............................................... 58

4 Functional Specification .................................................................................... 59

4.1 Vendor Identification (VID) and Device Identification (DID) ........................ 59

4.2 Vision Processor D4 Data Streams .......................................................... 59

4.3 Depth Field of View (FOV) ...................................................................... 62

4.4 Depth Field of View at Distance (Z) ......................................................... 63

4.5 Invalid Depth Band ............................................................................... 64

4.6 Minimum-Z Depth ................................................................................. 65

4.7 Depth Quality Specification .................................................................... 65

4.8 Depth Start Point (Ground Zero Reference) .............................................. 67

4.8.1 Depth Origin X-Y Coordinates .................................................... 69

4.9 Depth Camera Functions ........................................................................ 70

4.10 Color Camera Functions ......................................................................... 71

4.11 IMU Specifications ................................................................................. 72

5 Firmware ........................................................................................................ 73

5.1 Update ................................................................................................ 73

5.1.1 Update Limits .......................................................................... 73

5.2 Recovery ............................................................................................. 73

6 Software ......................................................................................................... 74

6.1 Intel® RealSense™ Software Development Kit 2.0 ..................................... 74

7 System Integration .......................................................................................... 75

7.1 System Level Block Diagram .................................................................. 75

7.2 Vision Processor D4 System Integration ................................................... 75

7.2.1 Vision Processor D4 Board ........................................................ 75

7.2.2 Vision Processor D4 on Motherboard .......................................... 76

7.3 D4 Camera System Power Delivery ......................................................... 77

7.4 Vision Processor D4 Board for Integrated Peripheral .................................. 78

7.4.1 USB 3.1 Gen 1 Receptacle ........................................................ 78

7.4.2 USB 3.1 Gen 1 High Speed Cable Assembly ................................ 78

7.4.3 Transmit to Receive Crossover .................................................. 79

7.4.4 Motherboard Receptacle ........................................................... 80

7.4.5 Vision Processor D4 Board for Integrated Peripheral Power

Requirements .......................................................................... 80

7.5 Thermals ............................................................................................. 80

7.6 Stereo Depth Module Flex ...................................................................... 82

7.7 Stereo Depth Module Mounting Guidance ................................................. 82

7.7.1 Screw Mount ........................................................................... 82

7.7.2 Bracket Mount ......................................................................... 83

7.7.3 Stereo Depth Module Air gap ..................................................... 84

7.8 Thermal Interface Material ..................................................................... 85

7.9 Heat Sink ............................................................................................. 85

7.10 Cover Design and Material Guidance ....................................................... 85

7.11 Gaskets ............................................................................................... 86

7.11.1 Optical Isolation ...................................................................... 87

7.11.2 Dust Protection ....................................................................... 88

7.12 Firmware Recovery ............................................................................... 88

Page 5

Description and Features

337029-009 5

7.13 Calibration Support ............................................................................... 89

7.14 Multi-Camera Hardware Sync ................................................................. 89

7.15 Handling Conditions .............................................................................. 90

8 Platform Design Guidelines ............................................................................... 91

8.1 Vision Processor D4 on Motherboard ....................................................... 91

8.2 Kaby Lake U and Kaby Lake Y platforms .................................................. 92

8.2.1 Kaby Lake Platform Introduction ................................................ 92

8.2.2 Supported PCB Stack-Up and Routing Geometries ....................... 92

8.2.3 Vision Processor D4 on Motherboard with USB Host Interface ........ 93

8.2.4 Vision Processor D4 on Motherboard with MIPI Host Interface ....... 94

8.2.5 Vision Processor D4 Board for Integrated Peripheral (USB 3.1 Gen 1

Host to Vision Processor D4 Routing) ......................................... 96

8.2.6 USB2.0 Design Guidelines (USB2 Host to Vision Processor D4

Routing) ................................................................................. 97

8.3 Cherry Trail T4 Platform ......................................................................... 98

8.3.1 Cherry Trail T4 Platform Introduction ......................................... 98

8.3.2 Vision Processor D4 Platform Design Guidelines ........................... 98

9 Regulatory Compliance ..................................................................................... 99

9.1 System Laser Compliance ...................................................................... 99

9.1.1 Certification Statement............................................................. 99

9.1.2 Explanatory Label .................................................................... 99

9.1.3 Cautionary Statements ............................................................. 99

9.1.4 US FDA Accession Number ....................................................... 100

9.2 Regulatory Compliance ......................................................................... 100

9.2.1 Manufacturer’s Information ...................................................... 100

9.2.2 EU Single Place of Contact ....................................................... 100

9.2.3 NRTL Statement ..................................................................... 101

9.2.4 FCC Part 15 Declaration of Conformity ...................................... 101

9.2.5 Canada ................................................................................. 102

9.2.6 European Directives ................................................................ 102

9.2.7 Japan .................................................................................... 102

9.2.8 South Korea ........................................................................... 102

9.3 Ecology Compliance ............................................................................. 103

9.3.1 China RoHS Declaration ........................................................... 103

9.3.2 Waste Electrical and Electronic Equipment (WEEE) ...................... 105

10 Mechanical Drawings ....................................................................................... 106

11 Connector Drawings ........................................................................................ 115

12 Appendix A – Vision Processor D4 on Motherboard Schematic Checklist ................. 117

12.1 Power Delivery .................................................................................... 124

13 Appendix B- Cover Material .............................................................................. 127

Figures

Figure 2-1. Active Infrared (IR) Stereo Vision Technology ......................................................... 17

Figure 2-2. Depth Measurement (Z) versus Range (R) .............................................................. 17

Figure 2-3. Vision Processor D4 Camera System Block Diagram ................................................ 18

Figure 3-1. Vision Processor D4 Package Drawing .................................................................... 29

Page 6

6 337029-009

Figure 3-2. Vision Processor D4 Ball-out ................................................................................. 30

Figure 3-3. Vision Processor D4 Power Sequencing .................................................................. 34

Figure 3-4. Stereo Depth Module (Intel® RealSense™ Depth Module D410)................................. 36

Figure 3-5. Stereo Depth Module (Intel® RealSense™ Depth Module D430)................................. 36

Figure 3-6. Stereo Depth Module Power Sequence ................................................................... 43

Figure 3-7. Vision Processor D4 Board (USB Peripheral Type-C)................................................. 44

Figure 3-8. Flex Interposer (Illustration) ................................................................................. 46

Figure 3-9. Rigid Interposer (Illustration) ............................................................................... 46

Figure 3-10. Depth Module Receptacle and Plug Connector Pin Position ...................................... 47

Figure 3-11. Depth Module Connector Orientation and Pin Position ............................................. 49

Figure 3-12. USB Type-C Receptacle Pin Map .......................................................................... 51

Figure 3-13. Intel® RealSenseTM Depth Camera D415 ............................................................... 54

Figure 3-14. Intel® RealSense™ Depth Camera D435/D435i ..................................................... 54

Figure 3-15. Intel® RealSense™ Depth Camera D455 ............................................................... 55

Figure 4-1. Depth Field of View to Depth Map illustration .......................................................... 63

Figure 4-2. Left Invalid Depth Band ....................................................................................... 64

Figure 4-3. Depth Module Depth Start Point Reference ............................................................. 67

Figure 4-4. Depth Camera Depth Start Point Reference ............................................................ 68

Figure 4-5. Depth Module X-Y Depth Origin Reference .............................................................. 69

Figure 4-6. Depth Camera X-Y Depth Origin Reference ............................................................. 70

Figure 7-1. System Block Diagram ......................................................................................... 75

Figure 7-2. Intel® RealSense™ Vision Processor D4 Board ........................................................ 76

Figure 7-3. Vision Processor D4 on Motherboard (Illustration) ................................................... 76

Figure 7-4. D4 Camera System Power Scheme ........................................................................ 77

Figure 7-5. Host Motherboard USB 3.1 Gen 1 Routing .............................................................. 79

Figure 7-6. Receptacle Ground Bar Motherboard Connections .................................................... 80

Figure 7-7. Bottom Stiffener Depth Module D410 ..................................................................... 82

Figure 7-8. Bottom Stiffener Depth Module D430 ..................................................................... 82

Figure 7-9. Stereo Depth Module Screw Mount ........................................................................ 83

Figure 7-10. Stereo Depth Module Bracket .............................................................................. 83

Figure 7-11. Stereo Depth Module Bracket Mount .................................................................... 84

Figure 7-12. Stereo Depth Module Bracket Install .................................................................... 84

Figure 7-13. Stereo Depth Module Air Gap .............................................................................. 85

Figure 7-14. Illustration of Gasket Placement and Cover Material ............................................... 87

Figure 7-15. Example of Light Leakage Effects......................................................................... 88

Figure 7-16. Firmware Recovery Sequence ............................................................................. 89

Figure 7-17. External Sensor Sync Connector Location on D4 Vision Processor D4 Board .............. 89

Figure 7-18. External Sensor Sync Connector Location on Depth Camera D435/D435i/D455 ......... 90

Figure 8-1. Vision Processor D4 with USB Host Interface .......................................................... 91

Figure 8-2. Vision Processor D4 with MIPI Host Interface .......................................................... 91

Figure 8-3. Vision Processor D4 on Board for USB Integrated Peripheral ..................................... 92

Figure 8-4. Host Processor - Vision Processor D4 ..................................................................... 93

Figure 8-5. Vision Processor D4 Transmit - Host Receive ......................................................... 94

Figure 8-6. Stereo Depth Transmit - Vision Processor D4 Receive .............................................. 95

Figure 8-7. Flex Interposer PCB Stack-Up ............................................................................... 96

Figure 8-8. USB 3.1 Gen 1 Host to Vision Processor D4 Topology ............................................... 96

Figure 8-9. USB2.0 Host to Vision Processor D4 ....................................................................... 97

Figure 9-1. NRTL Certifications ............................................................................................. 101

Figure 10-1. Intel® RealSense™ Depth Module D400 ............................................................... 106

Figure 10-2. Intel® RealSense™ Depth Module D410 ............................................................... 107

Figure 10-3. Intel® RealSense™ Depth Module D415 ............................................................... 108

Figure 10-4. Intel® RealSense™ Depth Module D420 ............................................................... 109

Figure 10-5. Intel® RealSense™ Depth Module D430 ............................................................... 110

Figure 10-6. Vision Processor D4 Board USB Type-C (Intel® RealSense™ Vision Processor D4 Board)

.................................................................................................................... 111

Page 7

Description and Features

337029-009 7

Figure 10-7. Intel® RealSense™ Depth Camera D415 .............................................................. 112

Figure 10-8. Intel® RealSense™ Depth Camera D435/D435i .................................................... 113

Figure 10-9. Intel® RealSense™ Depth Camera D455 .............................................................. 114

Figure 11-1. Receptacle Mechanical Drawing (50 Pin Depth Module Receptacle).......................... 115

Figure 11-2. Plug Mechanical Drawing (50 pin Depth Module Plug) ............................................ 116

Figure 12-1. Vision Processor D4 Laser PWM Reference Platform Schematic ............................... 124

Figure 12-2. Vision Processor D4 24MHz Crystal Clock Reference Platform Schematic .................. 124

Figure 12-3. DC-DC Reference Platform Schematic (3.3V, 1.8V, 0.9V) ....................................... 125

Figure 12-4. Vision Processor D4 VDD_PG and AVDD Reference Platform Schematic ................... 126

Tables

Table 2-1. Depth Module Product SKU Descriptions .................................................................. 19

Table 2-2. Depth Camera Product SKU Descriptions ................................................................. 20

Table 3-1. Component Descriptions ........................................................................................ 21

Table 3-2. Vision Processor D4 Signal Descriptions .................................................................. 22

Table 3-3. Hardware Straps .................................................................................................. 27

Table 3-4. Vision Processor D4 Package Mechanical Attributes ................................................... 28

Table 3-5. Vision Processor D4 Ball-out by Signal Name ........................................................... 30

Table 3-6. Vision Processor D4 Power Requirements ................................................................ 33

Table 3-7. Vision Processor D4 Power Sequencing Timing Parameters ........................................ 33

Table 3-8. Vision Processor D4 SPEC Code .............................................................................. 34

Table 3-9. Vision Processor D4 Storage and Operating Conditions .............................................. 34

Table 3-10. Stereo Depth Module........................................................................................... 35

Table 3-11. Stereo Depth Module SKU Properties ..................................................................... 36

Table 3-12. Standard Left and Right Imager Properties ............................................................ 37

Table 3-13. Wide Left and Right Imager Properties .................................................................. 37

Table 3-14. Standard Infrared Projector Parameters ................................................................ 38

Table 3-15. Wide Infrared Projector Parameters ...................................................................... 38

Table 3-16. Color Sensor Properties ....................................................................................... 39

Table 3-17. Depth Module 50-pin Connector Plug Details .......................................................... 40

Table 3-18. Stereo Depth Module Product Labeling .................................................................. 40

Table 3-19. Stereo Depth Module Label Fields ......................................................................... 40

Table 3-20. Intel® RealSense™ Depth Module D400 Series Product Identifier Code and Product

Material Code .................................................................................................. 41

Table 3-21. Other Stereo Depth Module Components ............................................................... 41

Table 3-22. Intel® RealSense™ Depth Module D400 Mechanical Dimensions ............................... 42

Table 3-23. Intel® RealSense™ Depth Module D410 Mechanical Dimensions ............................... 42

Table 3-24. Intel® RealSense™ Depth Module D415 Mechanical Dimensions ............................... 42

Table 3-25. Intel® RealSense™ Depth Module D420 Mechanical Dimensions ............................... 42

Table 3-26. Intel® RealSense™ Depth Module D430 Mechanical Dimensions ............................... 43

Table 3-27. Stereo Depth Module Storage and Powered Conditions ............................................ 43

Table 3-28. Vision Processor D4 Board .................................................................................. 44

Table 3-29. Vision Processor D4 Board Components ................................................................. 44

Table 3-30. Vision Processor D4 USB Type-C Board Mechanical Dimensions ................................ 45

Table 3-31. Depth Module Receptacle Details .......................................................................... 45

Table 3-32. Interposer Interconnect Signal Description............................................................ 47

Table 3-33. Custom Flex Interposer Ordering Logistics ............................................................. 49

Table 3-34. External Sensor Connector Details ........................................................................ 50

Table 3-35. External Sensor Sync Connector Pin List ................................................................ 50

Table 3-36. USB Peripheral Connector Pin List ......................................................................... 51

Table 3-37. Recommended USB Type C cable Assemblies Ordering Logistics ............................... 52

Table 3-38. ISP Properties .................................................................................................... 52

Page 8

8 337029-009

Table 3-39. Vision Processor D4 Board Power Requirements ..................................................... 52

Table 3-40. Vision Processor D4 Board Storage and Powered Conditions ..................................... 53

Table 3-41. Vision Processor D4 Board Product Identifier and Material Code ................................ 54

Table 3-42. Depth Camera SKU properties .............................................................................. 55

Table 3-43. Intel® RealSense™ Depth Camera D415 Mechanical Dimensions ............................... 55

Table 3-44. Intel® RealSense™ Depth Camera D435, D435i Mechanical Dimensions .................... 56

Table 3-45. Intel® RealSense™ Depth Camera D455 Mechanical Dimensions ............................... 56

Table 3-46. Depth Camera D400 Series Storage and Powered Conditions ................................... 56

Table 3-47. Depth Camera D400 Series Product Identifier and Material Code .............................. 58

Table 4-1. Vendor ID and Device ID Table .............................................................................. 59

Table 4-2. Image Formats (USB 3.1 Gen1) ............................................................................. 59

Table 4-3. Image Formats (USB 3.1 Gen1) – D455 .................................................................. 60

Table 4-4. Simultaneous Image Streams (USB 3.1 Gen1 & USB2.0) ........................................... 62

Table 4-5. Depth Field of View ............................................................................................... 62

Table 4-6. Minimum-Z Depth ................................................................................................ 65

Table 4-7: Depth Quality Metric ............................................................................................. 65

Table 4-8: Depth Quality Metric Illustration ............................................................................. 66

Table 4-9. Depth Quality Specification .................................................................................... 66

Table 4-10. Depth Module Depth Start Point .......................................................................... 67

Table 4-11. Depth Cameras Depth Start Point ........................................................................ 68

Table 4-12. Depth Module X-Y Depth Origin Coordinates.......................................................... 69

Table 4-13. Depth Camera X-Y Depth Origin Coordinates ......................................................... 70

Table 4-14. Depth Camera Controls ....................................................................................... 70

Table 4-15. RGB Exposed Controls ......................................................................................... 71

Table 4-16. IMU Specifications .............................................................................................. 72

Table 7-1. USB 3.1 Gen 1 Receptacle Characteristics................................................................ 78

Table 7-2. USB 3.1 Gen 1 Receptacle Pin Out .......................................................................... 78

Table 7-3. USB 3.1 Gen 1 Plug Characteristics ......................................................................... 78

Table 7-4. Cable Assembly Specification ................................................................................. 79

Table 7-5. Motherboard Receptacle Properties ......................................................................... 80

Table 7-6. Vision Processor D4 Board as Embedded Peripheral Power Requirements .................... 80

Table 7-7. Vision Processor D4 Board – Component Power and TDP at Max Operating Mode

(1)

....... 81

Table 7-8. Stereo Depth Module (Standard) – Component Power and TDP at Max Operating Mode

(1)

..................................................................................................................... 81

Table 7-9. Stereo Depth Module (Wide) – Component Power and TDP at Max Operating Mode

(1)

.... 81

Table 7-10. Vision Processor D4 Board Components – Case Temperature Limits (Still Air) ............ 81

Table 7-11. Component Transmission ..................................................................................... 86

Table 7-12. Electrostatic Discharge Caution ............................................................................ 90

Table 8-1. Host Transmit – Vision Processor D4 Receive Routing Guidelines ................................ 93

Table 8-2. Vision Processor D4 Transmit - Host Receive Routing Guidelines ................................ 93

Table 8-3. Vision Processor D4 Transmit – Host Receive Routing Guidelines ................................ 94

Table 8-4. Stereo Depth Module Transmit - Vision Processor D4 Receive Routing Guidelines ........ 95

Table 8-5. USB 3.1 Gen 1 Host to Vision Processor D4 Routing Guidelines ................................. 97

Table 9-1. U.S. FDA Accession Number.................................................................................. 100

Table 12-1. Vision Processor D4 on Motherboard Schematic Checklist ....................................... 117

Table 12-2. Vision Processor D4 Decoupling and Filter Requirements ........................................ 126

Table 13-1. Example: Cover Material Parameters .................................................................... 127

Page 9

Description and Features

337029-009 9

Revision History

Document Number

Revision Number

Description

Revision Date

337029

001

Initial release

January 2018

002

Tracking Module 1 removal, NRTL

certification, 7.2.2.1 Firmware Update

March 2018

003

• Added USB2.0 support

• Removed VBUS0 from Table 3 6.Vision

Processor D4 Power Requirements

• Table 3 12. Standard Left and Right

Imager Properties

• Table 3 13. Wide Left and Right

Imager Properties

• Table 3 9. Vision Processor D4 Storage

and Operating Conditions

• Table 3 27 Stereo Depth Module

Storage and Operating Conditions

• Table 3 38. Vision Processor D4 Board

Storage and Operating Conditions

• Table 3 44. Depth Camera D400 Series

Storage and Operating Conditions

• Table 4 3. Image Formats (USB 2.0)

• Table 4 5. Simultaneous Image

Streams (USB3.1 Gen1, USB 2.0)

• 4.7 Depth Origin Point (Ground Truth

Zero)

• 7.14 Multi-Camera hardware sync for

multi-camera configuration

July 2018

Page 10

10 337029-009

Document Number

Revision Number

Description

Revision Date

004

• Description and Features

• Terminology

• Table 2-2. Depth Camera Product SKU

Descriptions

• Table 3-11. Stereo Depth Module SKU

Properties

• Table 3-33. Custom Flex Interposer

Ordering Logistics

• Table 3-35. External Sensor Sync

Connector Pin List

• Table 3-42. Depth Camera SKU

properties

• Table 3-47. Depth Camera D400 Series

Product Identifier and Material

Code

• Table 4-1. Vendor ID and Device ID

Table

• Table 4-2. Image Formats (USB 3.1

Gen1)

• Table 4-3. Image Formats (USB 2.0)

• Table 4-9. Depth Quality Specification

• Section 4-12 IMU Specification

November 2018

005

• Table 3-11. Stereo Depth Module SKU

Properties

• Table 3-42. Depth Camera SKU

Properties

• Table 4-4. Simultaneous Image

Streams (USB 3.1 Gen 1 & USB

2.0)

• Table 4-18. IMU Specifications

January 2019

006

• Table 3-28. Vision Processor D4 Board

• Table 4-2. Image Formats (USB 3.1

Gen1)

• Table 4-4. Simultaneous Image

Streams (USB 3.1 Gen1 & USB 2.0)

• Table 4-17. RGB Exposed Controls

• Figure 10-7. Intel® RealSense™ Depth

Camera D415

• Figure 10-8. Intel® RealSense™ Depth

Camera D435/D435i

• Figure 4-1. Depth Field of View to

Depth Map illustration

June 2019

Page 11

Description and Features

337029-009 11

Document Number

Revision Number

Description

Revision Date

007

• Table 3-19. Stereo Depth Module

Label Fields

• Table 3 43. Intel® RealSense™ Depth

Camera D415 Mechanical

Dimensions

• Table 3 44. Intel® RealSense™ Depth

Camera D435, D435i Mechanical

Dimensions

• Table 4-9. Depth Quality Specification

• Section 7.6. Stereo Depth Module Flex

• Remove Table 7-11. Bracket Ordering

Logistics

October 2019

Page 12

12 337029-009

Document Number

Revision Number

Description

Revision Date

008

• Support for Intel® RealSense™ Vision

Processor D4 Board V2 (IMU

version for MM#954010)

• Table 2-1. Depth Module Product SKU

Descriptions

• Table 3-9. Vision Processor D4 Storage

and Operating Conditions

• Table 3-15. Wide Infrared Projector

Parameters

• Table 3-27. Stereo Depth Module

Storage and Powered Conditions

• Table 3-37. Recommended USB Type C

cable Assemblies Ordering Logistics

• Table 3-40. Vision Processor D4 Board

Storage and Powered Conditions

• Table 3-41. Vision Processor D4 Board

Product Identifier and Material

Code

• Table 3-45. Depth Camera D400 Series

Storage and Powered Conditions

• Table 4-2. Image Formats (USB 3.1

Gen 1)

• Table 4-15. RGB Exposed Controls

• Table 4-16. IMU Specifications

• Table 7-10. Vision Processor D4 Board

Components – Case Temperature

Limits (Still Air)

• Table 13-1. Example: Cover Material

Parameters

• Section 1. Description and Features

• Section 3.6.7. Temperature Sensor

• Section 3.7.5. USB Peripheral

Connector – Type-C

• Section 3.8.2.2. Depth Camera D400

Series Thermal Solution Guidance

• Remove Table 4-3. Image Formats

(USB 2.0)

• Remove Section 4.8. Measured Power

April 2020

Page 13

Description and Features

337029-009 13

Document Number

Revision Number

Description

Revision Date

009

• Section 1. Description and Features

• Section 3.8.4. Camera Lens Cleaning

Procedure

• Section 9. Regulatory Compliance

• Table 2-2. Depth Camera Product SKU

Descriptions

• Table 3-42. Depth Camera SKU

properties

• Table 3-45. Intel® RealSense™ Depth

Camera D455 Mechanical

Dimensions

• Table 3-47. Depth Camera D400 Series

Product Identifier and Material

Code

• Table 4-3. Image Formats (USB 3.1

Gen1) – D455

• Table 4-1. Vendor ID and Device ID

Table

• Table 4-4. Simultaneous Image

Streams (USB 3.1 Gen1 & USB2.0)

• Table 4-5. Depth Field of View

• Table 4-6. Minimum-Z Depth

• Table 4-9. Depth Quality Specification

• Table 4-13. Depth Camera X-Y Depth

Origin Coordinates

• Table 4-11. Depth Cameras Depth

Start Point

• Table 4-16. IMU Specifications

• Figure 3-15. Intel® RealSense™ Depth

Camera D455

• Figure 10-9. Intel® RealSense™ Depth

Camera D455

June 2020

§ §

Page 14

Description and Features

Datasheet 14

1 Description and Features

Description

The Intel® RealSense

TM

D400 series is a stereo vision depth

camera system. The subsystem assembly contains stereo depth

module and vision processor with USB 2.0/USB 3.1 Gen 1 or

MIPI1 connection to host processor.

The small size and ease of integration of the camera sub system

provides system integrators flexibility to design into a wide

range of products.

The Intel® RealSenseTM D400 series also offers complete depth

cameras integrating vision processor, stereo depth module, RGB

sensor with color image signal processing and Inertial

Measurement Unit2 (IMU). The depth cameras are designed for

easy setup and portability making them ideal for makers,

educators, hardware prototypes and software development.

The Intel® RealSenseTM D400 series is supported with crossplatform and open source Intel® RealSense™ SDK 2.0

Usages/Markets

• Drones

• Robots

• Home and Surveillance

• Virtual Reality

• PC Peripherals

Minimum System Requirements

USB 2.0/USB 3.1 Gen 1

Ubuntu*16.xx/Windows*10

Intel® RealSense™ Depth Camera D415 Features

• Intel® RealSense™ Vision Processor D4

• Up to 1280x720 active stereo depth resolution

• Up to 1920x1080 RGB resolution

• Depth Diagonal Field of View over 70°

• Dual rolling shutter sensors for up to 90 FPS depth

streaming

• Range 0.3m to over 10m (Varies with lighting conditions)

Intel® RealSense™ Depth Camera D435/D435i Features

• Intel® RealSense™ Vision Processor D4

• Up to 1280x720 active stereo depth resolution

• Up to 1920x1080 RGB resolution

• Depth Diagonal Field of View over 90°

• Dual global shutter sensors for up to 90 FPS depth

streaming

• Range 0.2m to over 10m (Varies with lighting conditions)

• Intel® RealSense™ Depth Camera D435i includes Inertial

Measurement Unit (IMU) for 6 degrees of freedom (6DoF)

data

Intel® RealSense™ Depth Camera D455 Features

• Intel® RealSense™ Vision Processor D4

• Up to 1280x720 active stereo depth resolution

• Up to 1280x800 RGB resolution

• Diagonal Field of View over 90°

• Dual global shutter sensors for up to 90 FPS depth

streaming

• RGB global shutter sensor for up to 90 FPS

• Range 0.4m to over 10m (Varies with lighting conditions)

• Intel® RealSense™ Depth Camera D455 includes Inertial

Measurement Unit (IMU) for 6 degrees of freedom (6DoF)

data

Features

• 2nd Generation Stereo Depth Camera System

• 2nd Generation dedicated Intel® RealSense™ Vision

Processor D4 with advanced algorithms

• Infrared (IR) Laser Projector System (Class 1)

• Full HD resolution Image sensors

• Active Power Management

• Selection of Stereo Depth Module options to meet your

usage requirements

1. MIPI is not currently supported. Please contact your

Intel representative on MIPI enablement timelines.

2. Module and Camera SKU dependent

§ §

Page 15

Introduction

337029-009 15

2 Introduction

2.1 Purpose and Scope of this Document

This document captures the specifications and the design–in details for the Intel®

RealSense™ D400 series family of products. This document provides information

necessary to understand and implement an Intel® RealSense™ D400 series based

camera system.

Note: Intel® RealSense™ D400 series is alternately referred as “D4 Camera System”

in this document. Intel® RealSense™ Vision Processor D4 is alternately referred as

“D4” in this document.

2.2 Terminology

Term

Description

6DOF

Six degrees of freedom (6DoF) refers to the freedom of movement of a rigid

body in three-dimensional space. Forward/back, up/down, left/right, pitch,

yaw, roll

Stereo Depth

Baseline

The distance between the center of the left and right imagers in a stereo

camera

MIPI CSI-2

The Camera Serial Interface (CSI) is a specification of the Mobile Industry

Processor Interface (MIPI) Alliance and CSI-2 is the 2nd generation

specification defining the interface between a camera and a host processor

Depth

Depth video streams are like color video streams except each pixel has a

value representing the distance away from the camera instead of color

information

D4 (DS5)

If the term D4 is used alone, it refers to the entire D4 camera system

consisting of various modules and components.

If the term D4 is used with an appropriate qualifier (i.e. D4 Vision Processor,

D4 Vision Processor Board), it refers to the specific module or component

within the D4 camera system.

FOV

Field Of View (FOV) describes the angular extent of a given scene that is

imaged by a camera. A camera's FOV can be measured horizontally,

vertically, or diagonally

Host System

Computer or SOC connected to D4 camera

I2C

I²C (Inter-Integrated Circuit), pronounced I-squared-C, is a multi-master,

multi-slave, single-ended, serial computer bus invented by Philips

Semiconductor (now NXP Semiconductors). It is typically used to allow easy

control and data communication between components.

IR Projector

This refers to the source of infrared (IR) light used for illuminating a scene,

object, or person to collect depth data.

Page 16

Introduction

16 337029-009

Term

Description

Imagers

Depth camera system uses a pair of cameras referred as imagers to calculate

depth. They are identical cameras configured with identical settings.

Image Signal

Processor (ISP)

Image processing functions to enhance color image quality

Left imager

From the perspective of the stereo camera looking out at the world, the left

imager is on the left side of the camera module. Thus, when the user is

facing the D4 camera, the left imager is actually on the right side of the

camera module.

Lens

This refers to the optical component of an imager in the D4 camera. Its

purpose is to focus the incoming light rays onto the CMOS chip in the imager.

MIPI

MIPI (Mobile Industry Processor Interface) is a global, open membership

organization that develops interface specifications for the mobile ecosystem

Platform

camera

This refers to the two-dimensional (2D) color camera on platform

System On

Chip (SoC)

Integrated circuit (IC) that integrates all components of a computer

Stereo Depth

Module

This refers to a stiffened module containing at least two imagers. The

distance between the imagers, which is referred to as the baseline or

intraocular spacing, is typically in the range of 20 mm to 70 mm.

Stereo camera

This refers to a pair of imagers looking at the same subject from slightly

different perspectives. The difference in the perspectives is used to generate

a depth map by calculating a numeric value for the distance from the imagers

to every point in the scene.

SKU

Stock Keeping Unit (SKU) is a unique identifier for distinct products. It is

often used in the scope of naming different versions of a device

TBD

To Be Determined. In the context of this document, information will be

available in a later revision.

2.3 Stereo Vision Depth Technology Overview

The Intel® RealSense™ D400 series depth camera uses stereo vision to calculate

depth. The stereo vision implementation consists of a left imager, right imager, and an

optional infrared projector. The infrared projector projects non-visible static IR pattern

to improve depth accuracy in scenes with low texture. The left and right imagers

capture the scene and sends imager data to the depth imaging (vision) processor,

which calculates depth values for each pixel in the image by correlating points on the

left image to the right image and via shift between a point on the Left image and the

Right image. The depth pixel values are processed to generate a depth frame.

Subsequent depth frames create a depth video stream.

Page 17

Introduction

337029-009 17

Figure 2-1. Active Infrared (IR) Stereo Vision Technology

Image

Sensors

IR Projector

1) Capture

2) Search

3) Depth

The depth pixel value is a measurement from the parallel plane of the imagers and not

the absolute range as illustrated.

Figure 2-2. Depth Measurement (Z) versus Range (R)

Page 18

Introduction

18 337029-009

2.4 Camera System Block Diagram

The camera system has two main components, Vision processor D4 and Depth

module. The Vision processor D4 is either on the host processor motherboard or on a

discrete board with either USB2.0/USB 3.1 Gen1 or MIPI connection to the host

processor. The Depth module incorporates left and right imagers for stereo vision with

the optional IR projector and RGB color sensor. The RGB color sensor data is sent to

vision processor D4 via the color Image Signal Processor (ISP) on Host Processor

motherboard or D4 Board.

Figure 2-3. Vision Processor D4 Camera System Block Diagram

Page 19

Introduction

337029-009 19

2.5 Intel

®

RealSense™ Depth Module D400 series

Product SKUs

Table below describes main components that make up the different depth module

SKUs

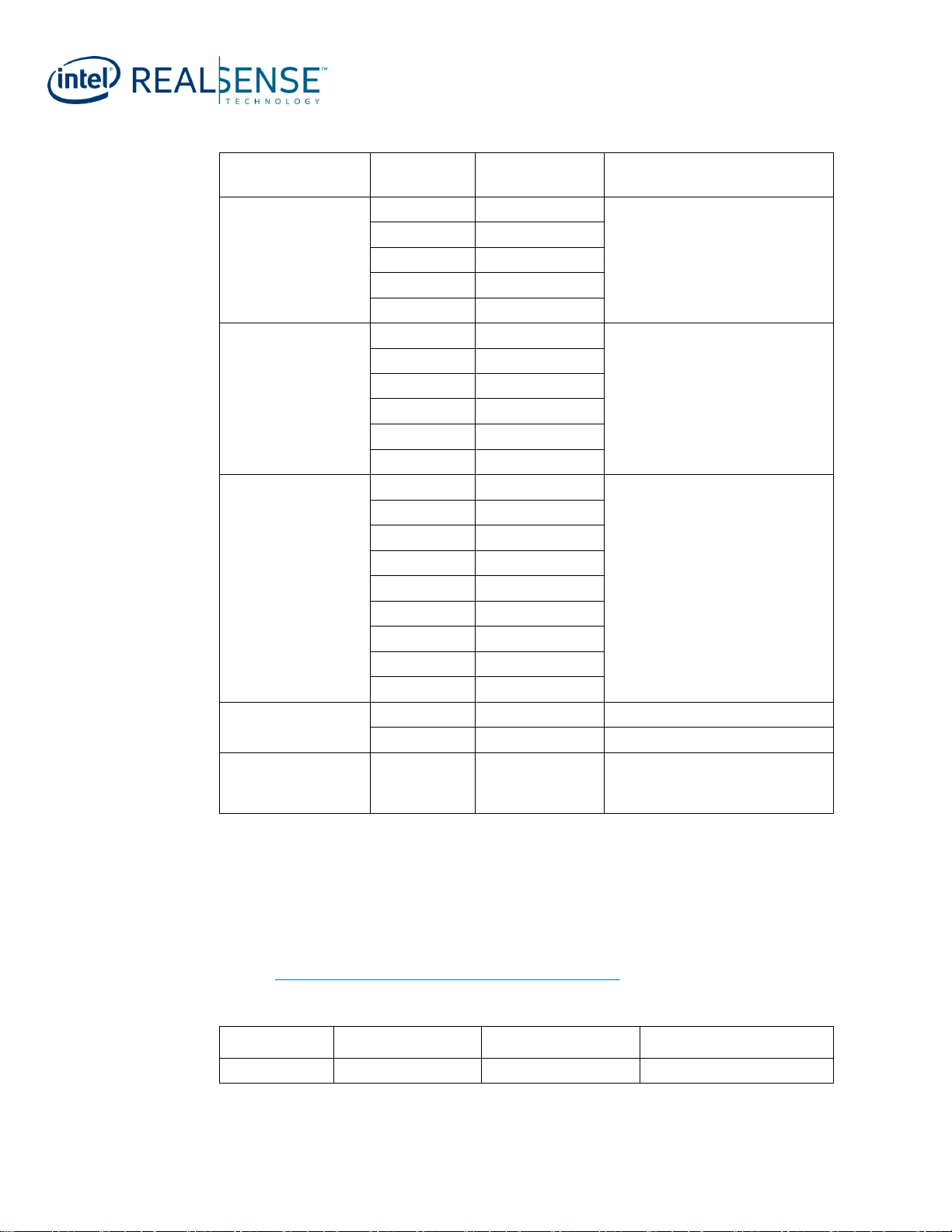

Table 2-1. Depth Module Product SKU Descriptions

Component

Subcomponent

D400

D410

D415

D420

D430

D450

Intel® RealSense™

Vision Processor D4

-

√ √ √ √ √

√

Intel® RealSense™

Vision Processor D4

Board

-

√ √ √ √ √

X

Intel® RealSense™

Vision Processor D4

Board V2 (IMU

Version)

-

X X X

X √ X

Intel® RealSense™

Vision Processor D4

Board V3 (IMU

Version)

-

X X X X X

√

Intel® RealSense™

Depth Module

Standard Stereo Imagers

√ √ √ X X X Wide Stereo Imagers

X X X √ √

√

Standard Infrared

Projector

X √ √ X X

X

Wide Infrared Projector

X X X X √

√

RGB color sensor

X X √ X X

√

D400 - Intel® RealSense™ Depth Module D400

D410 - Intel® RealSenseTM Depth Module D410

D415 - Intel® RealSenseTM Depth Module D415

D420 - Intel® RealSenseTM Depth Module D420

D430 - Intel® RealSenseTM Depth Module D430

D450 - Intel® RealSenseTM Depth Module D450

Page 20

Introduction

20 337029-009

2.6 Intel

®

RealSense™ Depth Camera D400 series

Product SKUs

Table below describes main components that make up the different camera SKUs:

Table 2-2. Depth Camera Product SKU Descriptions

Component

Subcomponent

Intel®

RealSenseTM

Depth

Camera

D415

Intel®

RealSenseTM

Depth

Camera

D435

Intel®

RealSenseTM

Depth

Camera

D435i

Intel®

RealSenseTM

Depth

Camera

D455

Intel®

RealSense™

Vision

Processor D4

- √ √ √ √

Intel®

RealSense™

Depth

Module

Standard Stereo

Imagers

√ X X

X

Wide Stereo

Imagers

X √ √

√

Standard Infrared

Projector

√ X X

X

Wide Infrared

Projector

X √ √

√

RGB color sensor

√ √ √

√

Inertial

Measurement

Unit (IMU)

X X √

√

§ §

Page 21

Component Specification

337029-009 21

3 Component Specification

3.1 Vision Processor D4 Camera System Components

Table 3-1. Component Descriptions

Component

Description

Host Processor

Host Processor that receives Depth and other data streams from Vision

Processor D4

Vision

Processor D4

(DS5 ASIC)

Depth Imaging Processor with USB 2.0/USB 3.1 Gen 1 or MIPI interface

connection to Host Processor

Clock

24MHz clock source for Vision Processor D4

Serial Flash

Memory

SPI 16Mb Serial Flash memory for firmware storage

Stereo Depth

Module

Camera module with left and Right Imager, Color Sensor†, IR projector†

enclosed in a stiffener

Power Delivery

Circuitry on motherboard/Vision processor D4 Board to deliver and manage

power to Vision Processor D4 and Stereo Depth Module.

Stereo Depth

Connector and

Interposer

50 pin connector on motherboard/Vision Processor D4 Board and Stereo

Depth module with interposer for connection

(†) SKU dependent

3.2 Host Processor

The host processor interface to Vision Processor D4 is either USB 2.0/USB 3.1 Gen 1

or MIPI. To ensure the best of quality of service, the Vision Processor D4 must be

connected to a dedicated USB 3.1 Gen 1 root port within the host processor system.

3.3 Intel

®

RealSense™ Vision Processor D4

The primary function of Vision Processor D4 is to perform depth stereo vision

processing. The Vision Processor D4 on Host Processor motherboard or on Vision

Processor D4 Board communicates to the host processor through USB2.0/USB 3.1 Gen

1 or MIPI and receives sensor data from stereo depth module. The Vision Processor

D4 supports MIPI CSI-2 channels for connection to image sensors.

3.3.1 Vision Processor D4 Features

• 28nm Process Technology.

Page 22

Component Specification

22 337029-009

• 5 MIPI camera ports with each MIPI lane capable of handling data transfers of up

to 750 Mbps.

• USB2.0/USB 3.1 Gen 1 or MIPI interface to host system.

• Image rectification for camera optics and alignment compensation

• IR Projector (Laser) controls

• Serial Peripheral Interface for fast data transfer with external SPI flash.

• Integrated I2C ports

• General purpose Input Output pins

• Active power gating

3.3.2 Vision Processor D4 Signal Description

Table 3-2. Vision Processor D4 Signal Descriptions

RESERVED – Signal reserved for future usage

IO Type- Input Output Buffer type

A – Analog

I – Input

O - Output

Signal Name

Description

IO

Type

After

RESET

Host MIPI

H_DATAP0

H_DATAN0

Host MIPI Data Lane 0 Differential Pair

A

I

H_DATAP1

H_DATAN1

Host MIPI Data Lane 1 Differential Pair

A

I

H_DATAP2

H_DATAN2

Host MIPI Data Lane 2 Differential Pair

A

I

H_DATAP3

H_DATAN3

Host MIPI Data Lane 3 Differential Pair

A

I

H_CLKP

H_CLKN

Host MIPI Clock Differential Transmit Pair

A

I

H_SDA

H_SCL

Host I2C Bus Data and Clock

I/O

IO

H_REXT

Host MIPI External Reference 6.04K 1% resistor pull down

to ground)

A

I

Imager A MIPI

A_DATAP0

A_DATAN0

Imager A MIPI Data Lane 0 Differential Receive Pair

A

I

A_DATAP1

A_DATAN1

Imager A MIPI Data Lane 1 Differential Receive Pair

A

I

Page 23

Component Specification

337029-009 23

Signal Name

Description

IO

Type

After

RESET

A_CLKP

A_CKLN

Imager A MIPI Clock Differential Receive Pair

A

I

A_SDA

A_SCL

Imager A I2C Bus Data and Clock

I/O

IO

A_RCLK

Imager A Reference Clock

I/O

O

A_PDOWN

(RESERVED) Imager A Power Down Signal

I/O

O

A_VSYNC

Imager A Vertical/Frame Sync

I/O

I

A_RESETN

Imager A Reset

I/O

O

A_REXT

Imager A MIPI External Reference (6.04K 1% resistor pull

down to ground)

A

I

Imager B MIPI

B_DATAP0

B_DATAN0

(RESERVED) Imager B MIPI Data Lane 0 Differential

Receive Pair

A

I

B_DATAP1

B_DATAN1

(RESERVED) Imager B MIPI Data Lane 1 Differential

Receive Pair

A

I

B_CLKP

B_CKLN

(RESERVED) Imager B MIPI Clock Differential Receive Pair

A

I

B_SDA

B_SCL

(RESERVED) Imager B I2C Bus Data and Clock

I/O

IO

B_RCLK

(RESERVED) Imager B Reference Clock

I/O

O

B_PDOWN

(RESERVED) Imager B Power Down

I/O

O

B_VSYNC

(RESERVED) Imager B Vertical/Frame Sync

I/O

I

B_RESETN

(RESERVED) Imager B Reset

I/O

O

B_REXT

Imager B MIPI External Reference (6.04K 1% resistor pull

down to ground)

A

I

Imager M MIPI

M_DATAP0

M_DATAN0

Imager M MIPI Data Lane 0 Differential Receive Pair

A

I

M_DATAP1

M_DATAN1

Imager M MIPI Data Lane 1 Differential Receive Pair

A

I

M_CLKP

M_CKLN

Imager M MIPI Clock Differential Receive Pair

A

I

M_SDA

M_SCL

Imager M I2C Bus Data and Clock

I/O

IO

M_RCLK

Imager M Reference Clock

I/O

O

M_PDOWN

(RESERVED) Imager M Power Down

I/O

O

M_VSYNC

Imager M Vertical/Frame Sync

I/O

I

Page 24

Component Specification

24 337029-009

Signal Name

Description

IO

Type

After

RESET

M_RESETN

Imager M Reset

I/O

O

M_REXT

Imager M MIPI External Reference (6.04K 1% resistor pull

down to ground)

A

I

Imager Y MIPI

Y_DATAP0

Y_DATAN0

Imager Y MIPI Data Lane 0 Differential Receive Pair

A

I

Y_DATAP1

Y_DATAN1

Imager Y MIPI Data Lane 1 Differential Receive Pair

A

I

Y_CLKP

Y_CKLN

Imager Y MIPI Clock Differential Receive Pair

A

I

Y_SDA

Y_SCL

Imager Y I2C Bus Data and Clock

I/O

IO

Y_RCLK

Imager Y Reference Clock

I/O

O

Y_PDOWN

(RESERVED) Imager Y Power Down

I/O

O

Y_VSYNC

Imager Y Vertical/Frame Sync

I/O

I

Y_RESETN

Imager Y Reset

I/O

O

Y_REXT

Imager Y MIPI External Reference (6.04K 1% resistor pull

down to ground)

A

I

Imager Z MIPI

Z_DATAP0

Z_DATAN0

(RESERVED) Imager Z MIPI Data Lane 0 Differential

Receive Pair

A

I

Z_DATAP1

Z_DATAN1

(RESERVED) Imager Z MIPI Data Lane 1 Differential

Receive Pair

A

I

Z_CLKP

Z_CKLN

(RESERVED) Imager Z MIPI Clock differential Receive Pair

A

I

Z_SDA

Z_SCL

(RESERVED) Imager Z I2C Bus Data and Clock

I/O

IO

Z_RCLK

(RESERVED) Imager Z Reference Clock

I/O

O

Z_PDOWN

(RESERVED) Imager Z Power Down

I/O

O

Z_VSYNC

Depth Vertical/Frame Sync

I/O

O

Z_RESETN

(RESERVED) Imager Z Reset

I/O

O

Z_REXT

Imager Z MIPI External Reference (6.04K 1% resistor pull

down to ground)

A

I

Serial Peripheral Interconnect (SPI)

SPI_DI

SPI Data Input

I/O

I

SPI_DO

SPI Data Output

I/O

O

SPI_CLK

SPI Clock

O

O

Page 25

Component Specification

337029-009 25

Signal Name

Description

IO

Type

After

RESET

SPI_CS

SPI Chip Select

O

O

SPI_WP

Flash Write Protect

O

O

General Purpose Input Output (GPIO)

GPIO[0]

(RESERVED) Not Defined

I/O

I

GPIO[1]

(RESERVED) Not Defined

I/O

I

GPIO[2]

Laser PWM – Controls Laser Power for IR projector on

Stereo Module

I/O

O

GPIO[3]

(RESERVED) Not Defined

I/O

I

GPIO[4]

(RESERVED) Not Defined

I/O

I

GPIO[5]

(RESERVED) Not Defined

I/O

I

GPIO[6]

(RESERVED) Not Defined

I/O

I

GPIO[7]

(RESERVED) Not Defined

I/O

I/O

EGPIO[0]

(RESERVED) Not Defined

I/O

I/O

EGPIO[1]

(RESERVED) Not Defined

I/O

I/O

EGPIO[2]

(RESERVED) Not Defined

I/O

I/O

EGPIO[3]

Laser_PWRDN - IR projector Power Down Signal

I/O

O

EGPIO[4]

(RESERVED) Not Defined

I/O

I/O

EGPIO[5]

FLAGB – IR Projector Fault Detect

I/O

I

EGPIO[6]

(RESERVED) Not Defined

I/O

I/O

EGPIO[7]

(RESERVED) Not Defined

I/O

I/O

EGPIO[8]

ISP_FCS (Color ISP)

I/O

O

EGPIO[9]

(RESERVED) Not Defined

I/O

I/O

EGPIO[10]

(RESERVED) Not Defined

I/O

I/O

EGPIO[11]

(RESERVED) Not Defined

I/O

I/O

EGPIO[12]

(RESERVED) Not Defined

I/O

I/O

EGPIO[13]

(RESERVED) - For Intel test purpose only

I/O

I/O

Miscellaneous

LD_ON_OUT_XX

(RESERVED) Laser Enable

O

O

MODSTROB

(RESERVED) Modulation current strobe

O

O

MODSIGN

(RESERVED) Modulation current sign

O

O

LD_ERR

Laser Error (Active High)

I

I

CLKXI

24MHz XTAL

I

I

CLKXO

24MHz XTAL

I

I

PRSTN

D4 Reset

I

I

CW_CSR_PRSTn

Hardware reset without debug port reset

I/O

I

Page 26

Component Specification

26 337029-009

Signal Name

Description

IO

Type

After

RESET

PMU_PWR_EN

Switchable domain (VDD_PG) power control signal

I/O

O

DFU

Dynamic FW update, used for FW recovery

I/O

I

ISP_SCL

ISP_SDA

I2C Bus Data and Clock

I/O

IO

VQPSQ

(RESERVED) – For Intel test purpose only

O

O

VQPSM

(RESERVED) – For Intel test purpose only

O

O

REFPADCLKP

(RESERVED) – For Intel test purpose only

I

I

REFPADCLKM

(RESERVED) – For Intel test purpose only

I

I

JTAG

TDI

Test Data Input

I/O

I

TDO

Test Data Output

I/O

O

TCLK

Test Clock Input

I/O

I

TMS

Test Mode Select

I/O

I

TRSTN

Test Reset

I/O

I

USB

USB_RXP

USB 3.1 Gen 1 receive, positive side

A

I

USB_RXN

USB 3.1 Gen 1 receive, negative side

A

I

USB_TXP

USB 3.1 Gen 1 Transmit, positive side

A

O

USB_TXN

USB 3.1 Gen 1 Transmit, negative side

A

O

USB_DP

USB 2.0 D+ line

A

IO

USB_DN

USB 2.0 D- line

A

IO

USB_ID

Mini-receptacle identifier and test point

USB_RESREF

Reference Resistor input. 200 Ohm 1%

A

I

Power and Ground

VDD

0.9V (Core Voltage)

Power

VDD_PG

0.9V (Switched Core Voltage)

Power

USB_DVDD

0.9V (USB Core Voltage)

Power

VPTX0

0.9V (USB Core Voltage)

Power

VP

0.9V (USB Core Voltage)

Power

*_AVDD

1.8V (MIPI Core and IO Voltage)

Power

VDDPLL

0.9V (PLL Voltage)

Power

VDDTS

1.8V (Temperature Sensor Voltage)

Power

VDDPST18

1.8V (IO Voltage)

Power

USB_VDD330

3.3V (USB Core Voltage)

Power

Page 27

Component Specification

337029-009 27

Signal Name

Description

IO

Type

After

RESET

VBUS0

3.3V (VBUS power monitor)

Power

VSS

Ground

GND

*_AGND

Ground

GND

Table 3-3. Hardware Straps

Pin

Boot

Load

HW/FW

Description

EPGPIO0

No

FW

USB connection type:

0: Peripheral (default)

1: Integrated

EGPIO4

Yes

HW

SPI Interface:

0: SPI on “Z”

1: SPI connected (default)

EPGPIO7

Yes

FW

Flash

00: 64Mbit

01: 8Mbit

10: 16 Mbit (default)

11: 32 Mbit

EPGPIO8

EPGPIO9

No

FW

Host interface:

0: USB (default)

1: MIPI

EPGPIO10

No

FW

Board version [0] (default: 0)

EPGPIO11

No

FW

Board version [1] (default: 0)

EPGPIO12

No

FW

Board version [2] (default: 0)

DFU

Yes

HW

Go to DFU

0: Disabled (default)

1: Go to DFU mode (Recovery)

NOTES:

• Boot Load – Read during Boot

• Hardware (HW) Strap – External hardware pin state directly configures D4 functionality

• Firmware (FW) Strap – External hardware pin state is read by firmware and firmware

configures D4 functionality

3.3.3 Vision Processor D4 Package Mechanical Attributes

Table below provides an overview of the mechanical attributes of the package.

Page 28

Component Specification

28 337029-009

Table 3-4. Vision Processor D4 Package Mechanical Attributes

Pin

Boot Load

HW/FW

Package Technology

Package Type

FlipChip CSP (Chip Scale Package)

Interconnect

Ball Grid Array (BGA) Ball

Lead Free

Yes

Halogenated Flame Retardant Free

Yes

Package Configuration

Solder Ball Composition

SAC125Ni

Ball/Pin Count

225 solder balls

Grid Array Pattern

15 x 15

Package Dimensions

Nominal Package Size (mm)

6.40 x 6.40

Min Ball/Pin pitch (mm)

0.42

Weight ~1 gm

Page 29

Component Specification

337029-009 29

Figure 3-1. Vision Processor D4 Package Drawing

Page 30

Component Specification

30 337029-009

Figure 3-2. Vision Processor D4 Ball-out

A B C D E F G H J K L M N P R

15

VSS

Y_DATAN0

Y_REXT Y_SCL GPIO_0 GPIO_1 GPIO_5 GPIO_6

MODSTROB

TMS TRSTN SPI_WPN SPI_MISO

CW_CSR_RSTN

VSS

15

14

Y_CLKN Y_CLKP

Y_DATAP0

Y_RCLK Y_SDA

Y_RESETN

GPIO_2 GPIO_3

MODSIGN

TCLK TDO SPI_CLK SPI_MOSI

Z_RESETN

Z_VSYNC

14

13

Y_DATAN1 Y_DATAP1

VSS VSS

Y_PDOWN

Y_VSYNC GPIO_4 GPIO_7 LD_ERR

LD_ON_OUT_XX

TDI SPI_CS Z_SDA

Z_DATAP0

Z_RCLK

13

12

B_DATAN0

B_SCL B_SDA Y_AVDD V SS VSS

VDDPST18_LEFT

VSS VSS

VDDPST18_LEFT

VSS VSS Z_SCL Z_CLKP

Z_DATAN0

12

11

B_CLKN

B_DATAP0

B_REXT VSS VSS VSS V DD VDD V DD VSS VS S Z_AVDD

Z_PDOWN Z_DATAP1

Z_CLKN

11

10

B_DATAN1

B_CLKP

B_RESETN

B_AVDD VDD_PG VDD_PG V DD_PG V DD VDD VDD_PG VDD_PG ISP _SCL Z_REXT

M_DATAP1 Z_DATAN1

10

9

H_DATAN3 B_DATAP1 B_PDOWN

VSS V DD_PG VDD_PG VDD_PG VSS VSS VDD_PG VDD_PG VSS ISP_SDA M_CLKP

M_DATAN1

9

8

H_DATAN2 H_DATAP3

B_VSYNC VSS VSS VDD_PG VDD_PG VSS VSS VSS VSS VSS V SS

M_DATAP0

M_CLKN

8

7

H_CLKN

H_DATAP2

B_RCLK H_AVDD V SS VSS V SS VSS V SS VDD_PG V DD_PG M_AVDD

M_RESETN M_PDOWN M_DATAN 0

7

6

H_DATAN1

H_CLKP H_AVDD

REFPADCLKP REFPADCLKM

VSS VDD V DD VSS VDD_PG VDD_PG M_REXT

M_VSYNC

M_SDA M_RCLK

6

5

H_DATAN0 H_DATAP1

H_REXT VP USB_ID VDD VDD VDD VSS VSS VSS V SS VSS

A_DATAP1

M_SCL

5

4

H_SCL

H_DATAP0

USB_VDD330

VPTX0

USB_RESREF

USB_DVDD

VSS VSS

VDDPST18_RIGHT

VSS VSS A_AVDD A_REXT A_CLKP

A_DATAN1

4

3

USB_RXN H_SDA PRSTN USB_DP EGPIO_1 EGPIO_11 VDDTS VSSTS

VDDPST18_RIGHT

PMU_PWR_EN

VQPSQ VQPSM

A_PDOWN A_DATAP0

A_CLKN

3

2

USB_TXN USB_RXP DFU USB_DN EGPIO_9 EGPIO_13 VDDPLL VSSPLL EGPIO_5 EGPIO_12 EGPIO_3 EGPIO_4 A _SCL A_RCLK

A_DATAN0

2

1

VSS USB_TXP VBUS0 EGPIO_6 EGPIO_7 EGPIO_8 CLK_XIN

CLK_XOUT

EGPIO_10 EGPIO_2 EGPIO_0 A _VSYNC A_SDA

A_RESETN

VSS

1

A B C D E F G H J K L M N P R

Table 3-5. Vision Processor D4 Ball-out by Signal Name

Ball

Name

Ball

Name

Ball

Name

A01

H_AGND

B01

USB_TXP

C01

VBUS0

A02

USB_TXN

B02

USB_RXP

C02

DFU

A03

USB_RXN

B03

H_SDA

C03

PRSTN

A04

H_SCL

B04

H_DATAP0

C04

USB_VDD330

A05

H_DATAN0

B05

H_DATAP1

C05

H_REXT

A06

H_DATAN1

B06

H_CLKP

C06

H_AVDD

A07

H_CLKN

B07

H_DATAP2

C07

B_RCLK

Page 31

Component Specification

337029-009 31

Ball

Name

Ball

Name

Ball

Name

A08

H_DATAN2

B08

H_DATAP3

C08

B_VSYNC

A09

H_DATAN3

B09

B_DATAP1

C09

B_PDOWN

A10

B_DATAN1

B10

B_CLKP

C10

B_RESETN

A11

B_CLKN

B11

B_DATAP0

C11

B_REXT

A12

B_DATAN0

B12

B_SCL

C12

B_SDA

A13

Y_DATAN1

B13

Y_DATAP1

C13

Y_AGND

A14

Y_CLKN

B14

Y_CLKP

C14

Y_DATAP0

A15

Y_AGND

B15

Y_DATAN0

C15

Y_REXT

D01

EGPIO_6

E01

EGPIO_7

F01

EGPIO_8

D02

USB_DN

E02

EGPIO_9

F02

EGPIO_13

D03

USB_DP

E03

EGPIO_1

F03

EGPIO_11

D04

VPTX0

E04

USB_RESREF

F04

USB_DVDD

D05

VP

E05

USB_ID

F05

VDD

D06

REFPADCLKP

E06

REFPADCLKM

F06

VSS

D07

H_AVDD

E07

H_AGND

F07

VSS

D08

B_AGND

E08

VSS

F08

VDD_PG

D09

B_AGND

E09

VDD_PG

F09

VDD_PG

D10

B_AVDD

E10

VDD_PG

F10

VDD_PG

D11

VSS

E11

VSS

F11

VSS

D12

Y_AVDD

E12

VSS

F12

VSS

D13

VSS

E13

Y_PDOWN

F13

Y_VSYNC

D14

Y_RCLK

E14

Y_SDA

F14

Y_RESETN

D15

Y_SCL

E15

GPIO_0

F15

GPIO_1

G01

CLK_XIN

H01

CLK_XOUT

J01

EGPIO_10

G02

VDDPLL

H02

VSSPLL

J02

EGPIO_5

G03

VDDTS

H03

VSSTS

J03

VDDPST18_RIGHT

G04

VSS

H04

VSS

J04

VDDPST18_RIGHT

G05

VDD

H05

VDD

J05

VSS

G06

VDD

H06

VDD

J06

VSS

G07

VSS

H07

VSS

J07

VSS

G08

VDD_PG

H08

VSS

J08

VSS

G09

VDD_PG

H09

VSS

J09

VSS

G10

VDD_PG

H10

VDD

J10

VDD

G11

VDD

H11

VDD

J11

VDD

G12

VDDPST18_LEFT

H12

VSS

J12

VSS

Page 32

Component Specification

32 337029-009

Ball

Name

Ball

Name

Ball

Name

G13

GPIO_4

H13

GPIO_7

J13

LD_ERR

G14

GPIO_2

H14

GPIO_3

J14

MODSIGN

G15

GPIO_5

H15

GPIO_6

J15

MODSTROB

K01

EGPIO_2

L01

EGPIO_0

M01

A_VSYNC

K02

EGPIO_12

L02

EGPIO_3

M02

EGPIO_4

K03

PMU_PWR_EN

L03

VQPSQ

M03

VQPSM

K04

VSS

L04

VSS

M04

A_AVDD

K05

VSS

L05

VSS

M05

VSS

K06

VDD_PG

L06

VDD_PG

M06

M_REXT

K07

VDD_PG

L07

VDD_PG

M07

M_AVDD

K08

VSS

L08

VSS

M08

M_AGND

K09

VDD_PG

L09

VDD_PG

M09

M_AGND

K10

VDD_PG

L10

VDD_PG

M10

ISP_SCL

K11

VSS

L11

VSS

M11

Z_AVDD

K12

VDDPST18_LEFT

L12

VSS

M12

VSS

K13

LD_ON_OUT_XX

L13

TDI

M13

SPI_CS

K14

TCLK

L14

TDO

M14

SPI_CLK

K15

TMS

L15

TRSTN

M15

SPI_WPN

N01

A_SDA

P01

A_RESETN

R01

A_AGND

N02

A_SCL

P02

A_RCLK

R02

A_DATAN0

N03

A_PDOWN

P03

A_DATAP0

R03

A_CLKN

N04

A_REXT

P04

A_CLKP

R04

A_DATAN1

N05

A_AGND

P05

A_DATAP1

R05

M_SCL

N06

M_VSYNC

P06

M_SDA

R06

M_RCLK

N07

M_RESETN

P07

M_PDOWN

R07

M_DATAN0

N08

VSS

P08

M_DATAP0

R08

M_CLKN

N09

ISP_SDA

P09

M_CLKP

R09

M_DATAN1

N10

Z_REXT

P10

M_DATAP1

R10

Z_DATAN1

N11

Z_PDOWN

P11

Z_DATAP1

R11

Z_CLKN

N12

Z_SCL

P12

Z_CLKP

R12

Z_DATAN0

N13

Z_SDA

P13

Z_DATAP0

R13

Z_RCLK

N14

SPI_MOSI

P14

Z_RESETN

R14

Z_VSYNC

N15

SPI_MISO

P15

CW_CSR_RSTN

R15

Z_AGND

Page 33

Component Specification

337029-009 33

3.3.4 Vision Processor D4 Power Requirements

The Vision Processor D4 requires the following power supplies for operation.

Table 3-6. Vision Processor D4 Power Requirements

Voltage Ball Name

Min.

(V)

Nominal

(V)

Max.

(V)

Peak Current

(Icc)

VDD

0.85

0.9

0.95

0.4A

VDD_PG

0.85

0.9

0.95

1.6A

USB_DVDD

0.81

0.9

0.99

0.2A

VPTX0

0.81

0.9

0.99

0.2A

VP

0.81

0.9

0.99

0.2A

*AVDD

1.71

1.8

1.89

0.2A

VDDPLL

0.85

0.9

0.95

0.2A

VDDTS

1.71

1.8

1.89

0.2A

VDDPST18 (Left and

Right)

1.71

1.8

1.89

0.2A

USB_VDD330

3.13

3.3

3.46

0.2A

3.3.5 Vision Processor D4 Power Sequencing

The timing requirement for power sequencing is listed below and shown in the

following figure.

• Hold Vision Processor D4 in reset

• Ramp up power in the 3.3V

• Ramp up power in the 0.9V

• Ramp up power in the 1.8V

• Release Vision Processor D4 Reset

Table 3-7. Vision Processor D4 Power Sequencing Timing Parameters

Parameter

Value

Units

Label

0.9V stable to 3.3V stable

>=50

us

T1

PMU_PWR_EN to 0.9V Stable

>=50

us

T2

1.8V stable to 0.9V Stable

>=50

us

T3

PRSTN (D4 RESET) assertion to 1.8V stable

15

us

T4

Page 34

Component Specification

34 337029-009

Figure 3-3. Vision Processor D4 Power Sequencing