Intel BX80580Q9400 - Core 2 Quad 2.66 GHz Processor, Core 2 Duo SL9400, Core 2 Duo SU9400 User Manual

Page 1

TM

Intel® Core

2 Duo Processor

®

and Intel

GS45 Express Chipset

(with DDR3 System Memory)

Development Kit User’s Manual

September 2008

Document Number: 320503-001

Page 2

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR

IMPLIED, BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT

AS PROVIDED IN INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY

WHATSOEVER, AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL

PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY,

OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. Intel products are not intended

for use in medical, life saving, life sustaining, critical control or safety systems, or in nuclear facility applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

Intel Corporation may have patents or pending patent applications, trademarks, copyrights, or other intellectual property rights

that relate to the presented subject matter. The furnishing of documents and other materials and information does not provide

any license, express or implied, by estoppel or otherwise, to any such patents, trademarks, copyrights, or other intellectual

property rights.

Designers must not rely on the absence or characteristics of any features or instructions marked “reserved” or “undefined.” Intel

reserves these for future definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from

future changes to them.

Intel processor numbers are not a measure of performance. Processor numbers differentiate features within each processor

family, not across different processor families. See http://www.intel.com/products/processor_number

The Intel

may cause the product to deviate from published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an order number and are referenced in this document, or other Intel literature may be obtained

by calling 1-800-548-4725 or by visiting Intel's website at http://www.intel.com

BunnyPeople, Celeron, Celeron Inside, Centrino, Centrino logo, Core Inside, Dialogic, FlashFile, i960, InstantIP, Intel, Intel logo,

Intel386, Intel486, Intel740, IntelDX2, IntelDX4, IntelSX2, Intel Core, Intel Inside, Intel Inside logo, Intel. Leap ahead., Intel.

Leap ahead. logo, Intel NetBurst, Intel NetMerge, Intel NetStructure, Intel SingleDriver, Intel SpeedStep, Intel StrataFlash, Intel

Viiv, Intel vPro, Intel XScale, IPLink, Itanium, Itanium Inside, MCS, MMX, Oplus, OverDrive, PDCharm, Pentium, Pentium Inside,

skoool, Sound Mark, The Journey Inside, VTune, Xeon, and Xeon Inside are trademarks or registered trademarks of Intel

Corporation or its subsidiaries in the United States and other countries.

*Other names and brands may be claimed as the property of others.

Copyright © 2007-2008, Intel Corporation. All Rights Reserved.

®

CoreTM 2 Duo processor and Intel® GS45 Express Chipset may contain design defects or errors known as errata which

.

for details.

2 Development Kit User’s Manual

Page 3

Contents

1 About This Manual ............................................................................................8

1.1 Content Overview...................................................................................8

1.2 Text Conventions ...................................................................................9

1.3 Glossary of Terms and Acronyms............................................................10

1.4 Development Kit Technical Support......................................................... 14

1.4.1 Online Support........................................................................14

1.4.2 Additional Technical Support ..................................................... 14

1.5 Related Documents...............................................................................15

1.5.1 Ordering Hard Copies of Documents........................................... 15

2 Getting Started...............................................................................................17

2.1 Overview ............................................................................................17

2.2 Development Kit Contents .....................................................................17

2.3 Additional Required Hardware (Not Included in the Development Kit)...........18

2.4 Additional Required Software (Not included in the Development Kit) ............ 19

2.5 Workspace Preparation..........................................................................20

2.6 System Setup and Power-Up.................................................................. 21

2.6.1 Using the AC to DC Power Supply (Mobile Power Mode) ................ 22

2.7 Power Down ........................................................................................23

2.8 System BIOS ....................................................................................... 23

2.8.1 Configuring the BIOS ...............................................................23

2.8.2 Programming BIOS Using a Bootable USB Device......................... 24

3 Development Board Features............................................................................26

3.1 Block Diagram .....................................................................................26

3.2 Mechanical Form Factor......................................................................... 26

3.3 Development Board Key Features ...........................................................26

3.4 Software Key Features ..........................................................................30

3.4.1 AMI BIOS............................................................................... 30

3.5 Thermal Management ...........................................................................31

3.6 System Features and Operation..............................................................31

3.6.1 Processor Support ...................................................................31

3.6.2 Processor Voltage Regulators ....................................................32

3.6.3 Front-Side Bus (FSB) ...............................................................32

3.6.4 Processor Power Management ...................................................32

3.6.5 Processor Active Cooling...........................................................32

3.6.6 Manual Processor Voltage ID (VID) Support ................................ 32

3.6.7 Chipset .................................................................................. 33

3.6.8 System Memory ...................................................................... 33

3.6.9 Video Display..........................................................................34

3.6.10 PCIe Slots ..............................................................................34

3.6.11 PCI Slots................................................................................ 35

3.6.12 On-Board LAN.........................................................................35

3.6.13 Serial Peripheral Interface (SPI) ................................................36

3.6.14 Soft Audio/Soft Modem ............................................................36

Development Kit User’s Manual 3

Page 4

SATA Storage .........................................................................36

3.6.15

3.6.16 USB Connectors ......................................................................37

3.6.17 LPC Super I/O (SIO)/LPC Slot ...................................................38

3.6.18 Serial, IrDA ............................................................................38

3.6.19 Intel® 82802 Firmware Hub Device Support ...............................38

3.6.20 System Management Controller (SMC)/Keyboard Controller (KBC)..39

3.6.21 Clocks ...................................................................................39

3.6.22 Real Time Clock ...................................................................... 39

3.6.23 Thermal Monitoring .................................................................39

3.6.24 Power Supply Solution ............................................................. 40

3.6.25 Manual VID support for Graphics VR...........................................40

3.6.26 Debug Interfaces.....................................................................41

3.6.27 Board Form-Factor ..................................................................41

3.7 Power Management ..............................................................................41

3.7.1 Power Management States........................................................41

3.8 Testability ...........................................................................................42

3.9 Power Measurement Support..................................................................42

3.10 Power Supply Usage and Recommendation ..............................................47

4 Development Board Physical Reference ..............................................................48

4.1 Board Components ...............................................................................48

4.2 Connectors..........................................................................................51

4.2.1 Back Panel Connectors ............................................................. 51

4.3 Configuration Settings...........................................................................53

4.3.1 Configuration Jumpers/Switches................................................53

4.3.2 BSEL Jumper Settings.............................................................. 56

4.4 Power and Reset Push Buttons ............................................................... 56

4.5 Net Detect Button ................................................................................57

4.6 LEDs ..................................................................................................58

4.7 Other Headers ..................................................................................... 59

4.7.1 H8 Programming Headers......................................................... 59

4.7.2 Sideband and Test Headers.......................................................60

Appendix A Add-In Cards..................................................................................................61

A.1 Port 80-83 Add-in Card (Included) .......................................................... 61

A.2 PCI Expansion Card (Thimble Peak 2) (Included) ......................................62

A.3 HDMI and Display Port Video Interface Add-In Card (Eaglemont) (Included) .62

A.3.1 Rework to change Eaglemont Card from HDMI to Display Port........63

A.3.2 AUX Pull Down Rework............................................................. 65

A.4 Intel® High Definition Audio Interposer Card (Mott Canyon 4) (Not Included)66

A.4.1 Mott Canyon 4 Jumper Settings.................................................67

A.5 ExpressCard Module Interposer (Duck Bay 3) (Not Included) ......................69

A.6 PCI Express mini card Interposer (Upham IV) (Not Included)......................70

A.7 Docking Connector Card (Saddlestring II) (Not Included) ...........................71

Appendix B Rework Instructions ........................................................................................74

B.1 Internal HDMI Enabling .........................................................................74

B.2 Enabling the Integrated Trusted Platform Module (iTPM) ............................74

B.3 Enabling External HDMI.........................................................................75

B.4 Support for Upham 4 ............................................................................75

B.5 Low Voltage High-Definition (HD) Audio Rework .......................................75

4 Development Kit User’s Manual

Page 5

Appendix C

Appendix D CPU Thermal Solution (Heatsink) Installation ...................................................... 78

Programming System BIOS Using a Flash Programming Device .............................77

Figures

Figure 1. Fern Hill Block Diagram ...................................................................... 26

Figure 2. Fern Hill Development Board Components ............................................. 49

Figure 3. Back Panel Connectors .......................................................................51

Figure 4. D-Connector to Component Video Cable................................................ 52

Figure 5. D-Connector to Composite Video Cable .................................................52

Figure 6. D-Connector to S-Video Cable ............................................................. 52

Figure 7. Location of the Configuration Jumpers/Switches.....................................53

Figure 8. Power On and Reset Buttons ............................................................... 57

Figure 9. Net Detect Button .............................................................................. 57

Figure 10. Port 80-83 Interposer Card................................................................61

Figure 11. PCI Expansion Card (Thimble Peak 2) ................................................. 62

Figure 12. Eaglemont Add-in Card ..................................................................... 63

Figure 13. Location of Resistors for Rework (before Rework) .................................64

Figure 14. Location of Resistors for Rework (after Rework)....................................64

Figure 15. Location of Resistors for Rework.........................................................65

Figure 16. AUX Pull-Down Rework .....................................................................66

Figure 17. Mott Canyon 4 Interposer Card ..........................................................67

Figure 18. Duck Bay 3 Interposer Card...............................................................69

Figure 19. Upham IV Interposer Card.................................................................70

Figure 20. Saddlestring II Docking Connector......................................................72

Figure 21. iHDMI Rework Instruction 1...............................................................74

Figure 22. iHDMI Rework Instruction 2...............................................................74

Figure 23. Low Voltage HD Audio Rework (Always Rail) ........................................75

Figure 24. Low Voltage HD Audio Rework (Sus Rail)............................................. 76

Figure 25. Step 4 - Backplate Pins..................................................................... 79

Figure 26. Step 6 - Applying the Thermal Grease................................................. 80

Figure 27. Step 7 - Squeezing Activation Arm ..................................................... 81

Figure 28. Step 8 - Installing the Heatsink.......................................................... 82

Figure 29. Step 9 - Plugging in the Fan .............................................................. 83

Figure 30. Step 10 - Completed Assembly ..........................................................84

Development Kit User’s Manual 5

Page 6

Tables

Table 1. Text Conventions..................................................................................9

Table 2. Definitions of Terms ............................................................................10

Table 3. Acronyms .........................................................................................11

Table 4. Related Documents .............................................................................15

Table 5. Intel Literature Centers........................................................................15

Table 6. Fern Hill Feature Set Summary .............................................................27

Table 7. TV–Out Connections............................................................................34

Table 8. PCI Express Ports................................................................................35

Table 9. Selection of I/O Voltage for the High Definition Audio............................... 36

Table 10. SATA Ports....................................................................................... 37

Table 11. USB Ports mapping............................................................................38

Table 12. System Power Management States ......................................................41

Table 13. System Power Management M-States...................................................42

Table 14. Digital Multi-Meter Comparison ........................................................... 43

Table 15. System Voltage Rails .........................................................................43

Table 16. Development Board Components......................................................... 50

Table 17. Configuration Jumpers and Switches Settings........................................ 54

Table 18. BSEL Jumper Settings........................................................................ 56

Table 19. Power-On and Reset Push buttons .......................................................56

Table 20. LEDs ...............................................................................................58

Table 21. H8 Programming Jumpers .................................................................. 60

Table 22. Mott Canyon 4 Configuration Jumper/Switches Settings.......................... 68

Table 23. Upham IV default Jumper/Switches Settings .........................................71

Table 24. Board Rework to Support Display Port on Saddlestring ...........................73

6 Development Kit User’s Manual

Page 7

Revision History

Document

Number

320503 001 Public launch release Sept. 2008

Revision

Number

Description Revision Date

§

Development Kit User’s Manual 7

Page 8

1 About This Manual

About This Manual

This user’s manual describes the use of the Intel® CoreTM 2 Duo Processor (LV and

ULV) and Intel

memory. This manual has been written for OEMs, system evaluators, and embedded

system developers. This document defines all jumpers, headers, LED functions, and

their locations on the development board, along with features of the board’s

subsystems. This manual assumes basic familiarity with installing and configuring

hardware and software in a personal computer system.

The differences between the Fern Hill (GS45, DDR3), Pillar Rock (GM45, DDR2) and

Silver Cascade (GM45, DDR3) User Manuals are in these sections:

• System Memory Section 3.6.8

• D

• Confi

• BS

ll other components and references are the same between boards.

A

For the latest information about the Intel® CoreTM 2 Duo processor and Intel® GS45

Express Chipset Development Kit, visit:

http://developer.intel.com/design/intarch/devkits/index.htm

For design documents related to the Intel® CoreTM 2 Duo processor and Intel® GS45

Express Chipset please visit:

®

GS45 Express Chipset development kit with DDR3 SDRAM system

evelopment Board Feature Set Summary Table (Table 6)

guration Jumpers and Switches Settings Table (Table 17),

EL Jumper Settings Table (Table 18)

Processor

Chipset

: http://developer.intel.com/design/intarch/core2duo/tech_docs.htm

: http://www.intel.com/products/embedded/chipsets.htm

1.1 Content Overview

Chapter 1.0, “About This Manual” — This chapter contains a description of conventions

used in this manual. The last few sections explain how to obtain literature and contact

customer support.

Chapter 2.0, “Getting Started”— Describes the contents of the development kit. This

chapter explains the basics steps necessary to get the board running. This chapter

also includes information on how to update the BIOS.

Chapter 3.0, “Development Board Features” — This chapter provides details on the

hardware features of the development board. It explains the Power Management and

Testability features.

8 Development Kit User’s Manual

Page 9

About This Manual

Chapter 4.0, “Development Board Physical Reference”— This chapter provides a list of

major board components and connectors. It gives a description of jumper settings

and functions. The chapter also explains the use of the programming headers.

Appendix A, “Add-In Cards” – This appendix contains information on add-in cards

available from Intel that can be used with the development board.

Appendix B, “Rework Instructions” – This appendix contains rework instructions for

the development board and for some of the add-in cards to enable additional

supported features and functionality.

Appendix C, “Programming System BIOS Using a Flash Programming Device” — This

appendix provides step by step instructions on programming the flash using a flash

programming device

Appendix D, “CPU Thermal Solution (Heatsink) Installation Instructions” — This

appendix gives detailed installation instructions for the Intel

heatsink.

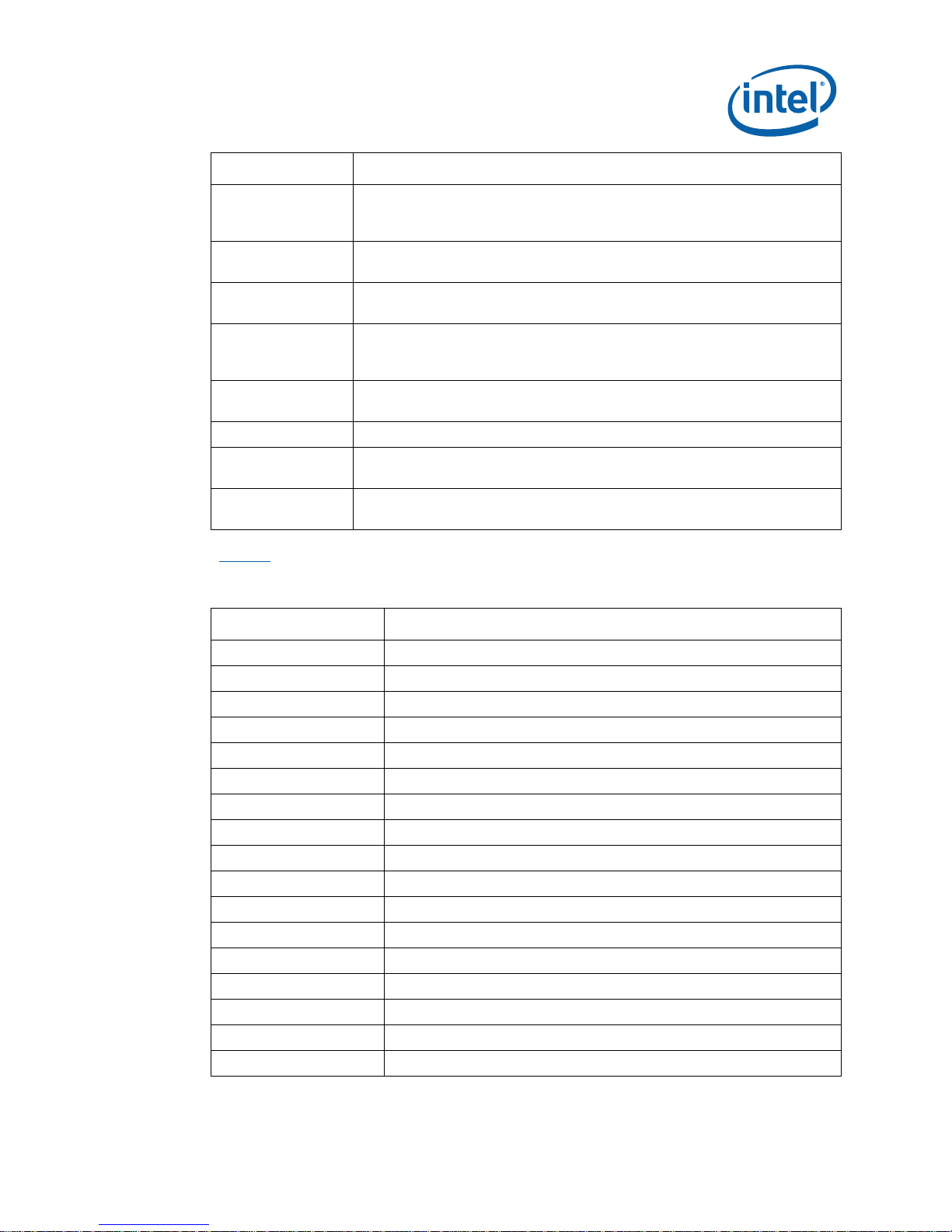

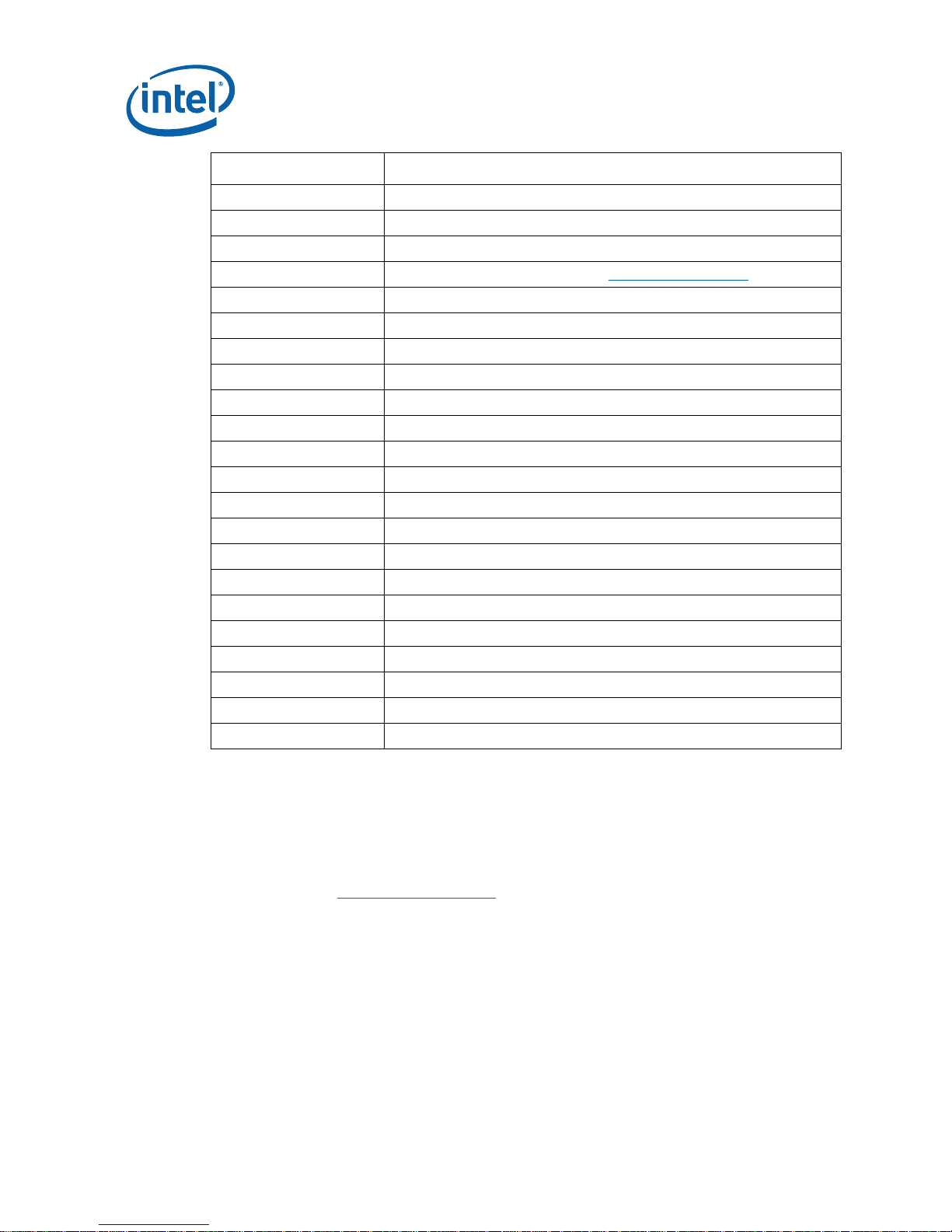

1.2 Text Conventions

The notations listed in Table 1 may be used throughout this manual.

Table 1. Text Conventions

Notation Definition

# The pound symbol (#) appended to a signal name indicates that the signal

is active low. (e.g., PRSNT1#)

Variables Variables are shown in italics. Variables must be replaced with correct

values.

Instructions Instruction mnemonics are shown in uppercase. When you are

programming, instructions are not case-sensitive. You may use either

uppercase or lowercase.

Numbers Hexadecimal numbers are represented by a string of hexadecimal digits

followed by the character H. A zero prefix is added to numbers that begin

with A through F. (For example, FF is shown as 0FFH.) Decimal and binary

numbers are represented by their customary notations. (That is, 255 is a

decimal number and 1111 is a binary number. In some cases, the letter B

is added for clarity.)

Units of Measure

A

GByte

KByte

KΩ

mA

MByte

MHz

ms

mW

ns

pF

W

The following abbreviations are used to represent units of measure:

amps, amperes

gigabytes

kilobytes

kilo-ohms

milliamps, milliamperes

megabytes

megahertz

milliseconds

milliwatts

nanoseconds

picofarads

watts

®

CoreTM 2 Duo processor

Development Kit User’s Manual 9

Page 10

Notation Definition

V

µA

µF

µs

µW

Signal Names Signal names are shown in uppercase. When several signals share a

volts

microamps, microamperes

microfarads

microseconds

microwatts

common name, an individual signal is represented by the signal name

followed by a number, while the group is represented by the signal name

followed by a variable (n). For example, the lower chip-select signals are

named CS0#, CS1#, CS2#, and so on; they are collectively called CSn#.

A pound symbol (#) appended to a signal name identifies an active-low

signal. Port pins are represented by the port abbreviation, a period, and

the pin number (e.g., P1.0).

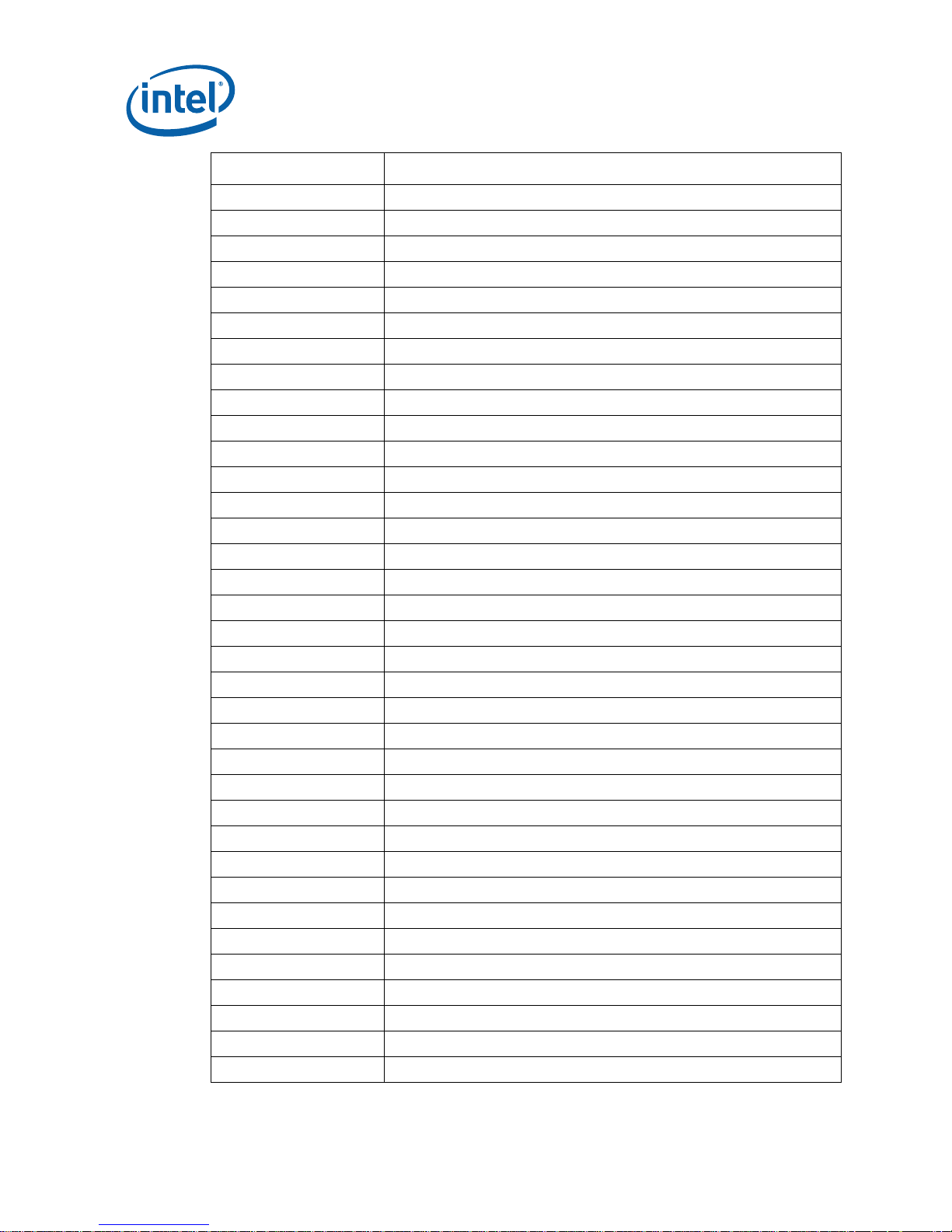

1.3 Glossary of Terms and Acronyms

Table 2 defines terms used in this document.

Table 2. Definitions of Terms

About This Manual

Term/Acronym Definition

Assisted Gunning

Transceiver Logic+

Asynchronous

GTL+

Fern Hill The name of the development board that uses Intel® Core™ 2 Duo

Infrared Data

Assoc.

IMVP6+ The Intel Mobile Voltage Positioning specification for the Intel® Core™ 2

The front-side bus uses a bus technology called AGTL+, or Assisted

Gunning Transceiver Logic. AGTL+ buffers are open-drain, and require

pull-up resistors to provide the high logic level and termination. AGTL+

output buffers differ from GTL+ buffers with the addition of an active

pMOS pull-up transistor to assist the pull-up resistors during the first clock

of a low-to-high voltage transition.

The processor does not utilize CMOS voltage levels on any signals that

connect to the processor. As a result, legacy input signals such as A20M#,

IGNNE#, INIT#, LINT0/INTR, LINT1/NMI, PWRGOOD, SMI#, SLP#, and

STPCLK# utilize GTL+ input buffers. Legacy output signals (FERR# and

IERR#) and non-AGTL+ signals (THERMTRIP# and PROCHOT#) also

utilize GTL+ output buffers. All of these signals follow the same DC

requirements as AGTL+ signals, however the outputs are not actively

driven high (during a logical 0 to 1 transition) by the processor (the major

difference between GTL+ and AGTL+). These signals do not have setup or

hold time specifications in relation to BCLK[1:0], and are therefore

referred to as “Asynchronous GTL+ Signals”. However, all of the

Asynchronous GTL+ signals are required to be asserted for at least two

BCLKs in order for the processor to recognize them.

processor SU9400 or SL9400 with the Mobile Intel GS45 Express Chipset

(Small Form Factor) and DDR3 SDRAM

The Infrared Data Association (IrDA) has outlined a specification for serial

communication between two devices via a bi-directional infrared data

port. The development board has such a port and it is located on the rear

of the board between the two USB connectors.

Duo Processor. It is a DC-DC converter module that supplies the required

voltage and current to a single processor.

10 Development Kit User’s Manual

Page 11

About This Manual

Term/Acronym Definition

Media Expansion

Card

Pad The electrical contact point of a semiconductor die to the package

Pillar Rock The name of the development board that uses Intel® Core™ 2 Duo

Pin The contact point of a component package to the traces on a substrate,

Silver Cascade The name of the development board that uses Intel® Core™ 2 Duo

System Bus The System Bus is the microprocessor bus of the processor.

System

Management Bus

VCC (CPU core) VCC (CPU core) is the core power for the processor. The system bus is

Table 3 defines the acronyms used throughout this document.

Table 3. Acronyms

Acronym Definition

The Media Expansion Card (MEC) provides digital display options through

the SDVO interface. The MEC card also incorporates video-in via a x1 PCI

Express* port.

substrate. A pad is only observable in simulations.

processor with the Mobile Intel GM45 Express Chipset and DDR2 SDRAM

such as the motherboard. Signal quality and timings may be measured at

the pin.

processor with the Mobile Intel GM45 Express Chipset and DDR3 SDRAM

A two-wire interface through which various system components may

communicate.

terminated to VCC (CPU core).

AC Alternating Current

ACPI Advanced Configuration and Power Interface

ADD2 Advanced Digital Display 2

ADD2N Advanced Digital Display 2 Normal

AGTL or AGTL+ Assisted Gunning Transceiver Logic (See also Table 2 above)

AMI American Megatrends Inc. (BIOS developer)

AMPS or iAMPS (Intel) Adaptive Mobile Power System

AMT or iAMT (Intel) Active Management Technology

ATA Advanced Technology Attachment (disk drive interface)

ATX Advance Technology Extended (motherboard form factor)

BGA Ball Grid Array

BIOS Basic Input/Output System

BSEL Bus Select (Front Side Bus frequency control signals)

CL Controller Link

CMOS Complementary Metal-Oxide-Semiconductor

COM Communications

CPU Central Processing Unit (processor)

Development Kit User’s Manual 11

Page 12

About This Manual

Acronym Definition

CRB Customer Reference Board

DC Direct Current

DC Dual-Core

DDR Double Data Rate

DDR2 Double Data Rate SDRAM version 2

DDR3 Double Data Rate SDRAM version 3

DIMM Dual Inline Memory Module

DMI Direct Memory Interface

DOS Disk Operating System

DP Display Port

DPST or iDPST (Intel) Display Power Savings Technology

EBL Extended Battery Life

EC Embedded Controller

ECC Error Correcting Code

EHCI Enhanced Host Controller Interface

EMA Extended Media Access

eSATA External SATA (Serial ATA)

ESD Electrostatic Discharge

FCBGA Flip Chip Ball Grid Array

FCPGA Flip Chip Pin Grid Array

FS Full-speed. Refers to USB

FSB Front Side Bus

FWH Firmware Hub

GbE Gigabit Ethernet

GLCI Gigabit LAN Connect Interface

GS45 Intel® GS45 Express Graphics and Memory Controller Hub

GMCH Graphics and Memory Controller Hub

GND Ground (VSS)

GPIO General Purpose Input/Output

HDA High Definition Audio

HDMI High Definition Media Interface

HS High-speed. Refers to USB

ICH I/O Controller Hub

ICH9M I/O Controller Hub 9M (Mobile)

ICH9M-E SFF ICH9M-Enhanced, Small Form Factor

12 Development Kit User’s Manual

Page 13

About This Manual

IDE Integrated Drive Electronics

IMVP-6 or (Intel MVP-6) Intel Mobile Voltage Positioning – revision 6

I/O Input / Output

IrDA Infrared Data Association

ITP Integrated Test Port

KBC Keyboard Controller

L2 Level-2 (Cache)

LAN Local Area Network

LED Light Emitting Diode

LPC Low Pin Count

LS Low-speed. Refers to USB

LV Low Voltage

LVDS Low Voltage Differential Signaling (Video Standard)

mBGA Mini Ball Grid Array

MEC Media Expansion Card

MHz Mega-Hertz

MT/s Mega Transfers per second

NMI Non-Maskable Interrupt

OEM Original Equipment Manufacturer

PEG PCI Express Graphics

PCI Peripheral Connect Interface

PCIe PCI Express*

PCM Pulse Code Modulation

POST Power On Self Test

PS/2 Personal System/2 (Keyboard and Mouse Connector)

PSI2 Power Status Indicator - 2

PWM Pulse Width Modulation

RAID Redundant Array of Inexpensive Disks

RCA (Type of Audio and Video Connector)

RTC Real Time Clock

SATA Serial ATA

SDVO Serial Digital Video Output

SIO Super Input/Output

SKU (SKU Number) Stock Keeping Unit (Stock Keeping Unit Number)

SMC System Management Controller

Acronym Definition

Development Kit User’s Manual 13

Page 14

About This Manual

Acronym Definition

SODIMM or SO-DIMM Small Outline Dual In-line Memory Module

SOIC-8 or SOIC-16 Small Outline Integrated Circuit (8 or 16 pin package)

SPI Serial Peripheral Interface

SPWG Standard Panels Working Group - http://www.spwg.org/

SRC Source (Clock)

SUT System Under Test

TME Technical Marketing Engineer

TPM Trusted Platform Module

TV or TVO Television (Output)

µBGA Micro Ball Grid Array

UHCI Universal Host Controller Interface

ULV Ultra-Low Voltage

USB Universal Serial Bus

VGA Video Graphics Adapter

VID Voltage Identification

WiMAX (Wireless Communications Standard)

WLAN Wireless Local Area Network

VREG or VR Voltage Regulator

WWAN Wireless Wide Area Network

VCC Power Signal

x1 (x2, etc) By 1 (By 2, etc) (refers to number of PCIe Links)

XDP eXtended Debug Port

1.4 Development Kit Technical Support

1.4.1 Online Support

Intel’s web site (http://www.intel.com/) provides up-to-date technical information and

product support. This information is available 24 hours per day, 7 days per week,

providing technical information whenever you need it.

1.4.2 Additional Technical Support

If you require additional technical support, please contact your Intel Representative or

local distributor.

14 Development Kit User’s Manual

Page 15

About This Manual

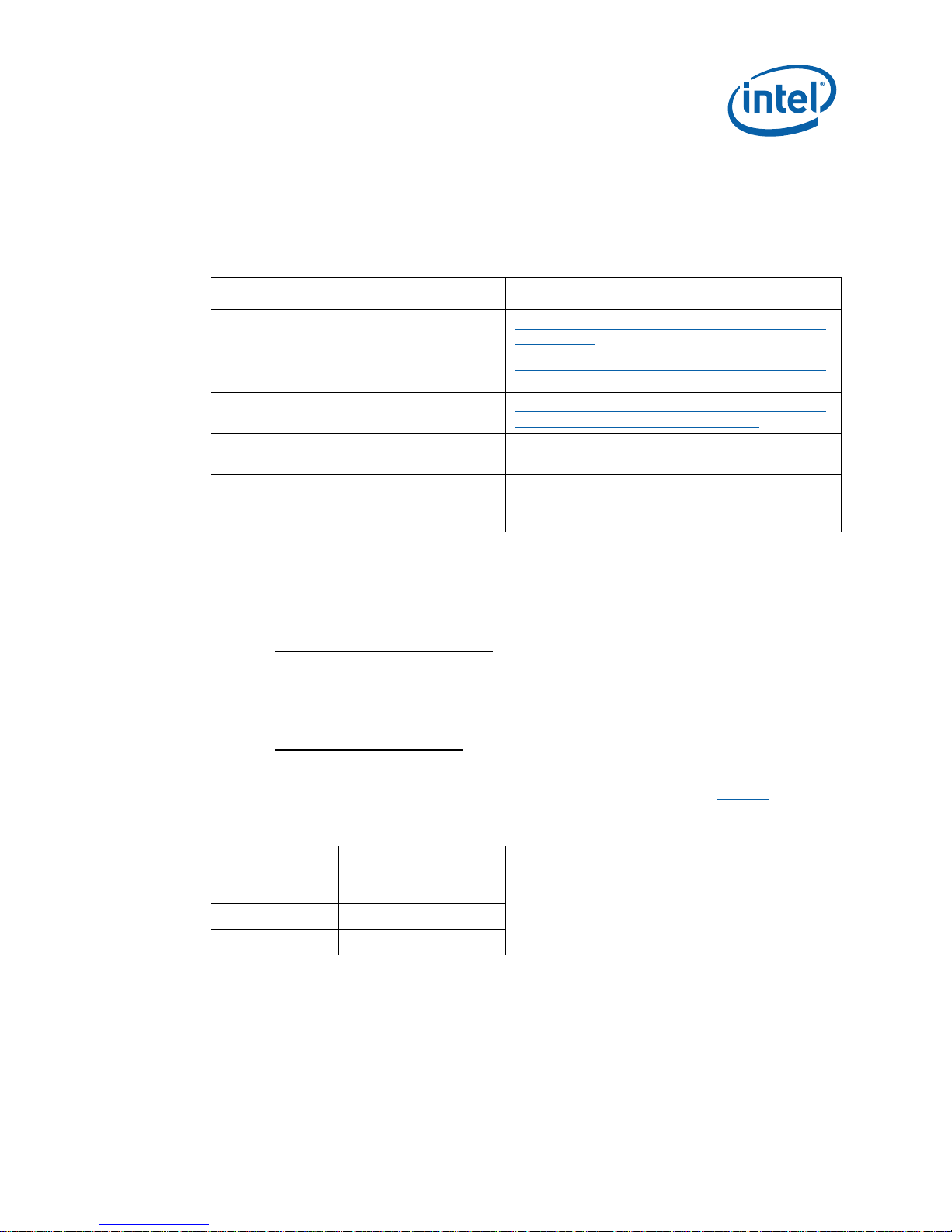

1.5 Related Documents

Table 4 lists publicly available documents related to this development kit. For

additional documentation, please contact your Intel Representative.

Table 4. Related Documents

Document Title Location

Intel® Core™ 2 Duo Processor on 45-nm

process Datasheet

Mobile Intel® 4 Series Express Chipset

Family Datasheet

Intel® I/O Controller Hub 9 (ICH9) Family

Datasheet

[Montevina] Small Form Factor (SFF)

Platform Design Guide

[Montevina] Small Form Factor (SFF)

Platform, Fern Hill (DDR3) – Customer

Reference Board Schematic

http://www.intel.com/design/intarch/core2duo/te

ch_docs.htm

http://www.intel.com/Products/Notebook/Chipset

s/GS45/GS45-technicaldocuments.htm

http://www.intel.com/Products/Notebook/Chipset

s/GS45/GS45-technicaldocuments.htm

Contact your Intel representative for access to

this document. (Doc #358405)

Contact your Intel representative for access to

this document. (Doc #358533)

1.5.1 Ordering Hard Copies of Documents

To order hard copies of product literature, do the following:

1. Determine the SKU Number

The SKU number is listed at the bottom of the download page for that

document. It is also usually the first 6 digits of the name of the PDF file, such

as: 12345612.pdf.

2. Call or E-mail a Request

Call: To place an order for a publication or text in hardcopy or CD form,

please contact the Intel Literature Fulfillment Centers listed in Table 5

Table 5. Intel Literature Centers

Location Telephone Number

U.S. and Canada 1-800-548-4725

International 1-303-675-2148

Fax 1-303-675-2120

Development Kit User’s Manual 15

.

Page 16

About This Manual

Email: To order a publication or text in hardcopy or CD form, send your

request to: intelsupport@hibbertgroup.com

Please make sure to include in your e-mailed request:

SKU #

Company Name

Your Name (first, last)

Full mailing address

Daytime Phone Number in case of questions

Note: Please be aware not all documents are available in all media types. Some may only be

available as a download.

§

16 Development Kit User’s Manual

Page 17

Getting Started

2 Getting Started

This chapter identifies the development kit’s key components, features and

specifications. It also details basic development board setup and operation.

2.1 Overview

The development board consists of a baseboard populated with the Intel® CoreTM 2

Duo SL9400 or SU9400 processor, the Intel

board components and peripheral connectors.

This development kit is available with either a Low-Voltage Intel

Processor SL9400 or an Ultra-Low Voltage Intel

note below). Both the LV and ULV processors are 22 mm x 22 mm, and are

sometimes referred to as “Small Form Factor”, or SFF components. The Intel

Express Chipset included on this development board is also the Small Form Factor

(SFF) version of the Intel

may sometimes be referred to by its code name, Fern Hill. This manual will cover the

features and details of the Fern Hill development board.

Note: The Intel® Core™ 2 Duo SU9400 processor at 1.4 GHz core frequency is not on the

Intel embedded roadmap offering and as such does not have embedded market 7

year availability. The Intel® Core™ 2 Duo SU9300 processor at 1.2 GHz core

frequency is on the Intel embedded roadmap offering and has embedded market 7

year availability.

®

GM45 Express Chipset. The development board in this kit

®

2.2 Development Kit Contents

The following hardware, software and documentation are included in the development

kit. Check for damage that may have occurred during shipment. Contact your sales

representative if any items are missing or damaged.

GS45 Express Chipset, and other system

®

®

CoreTM 2 Duo Processor SU9400 (see

CoreTM 2 Duo

®

GS45

• Letter to the Customer

• Development Kit User’s Manual (this document)

• Software CD-ROM, which includes (see the readme.txt file for a complete list

of CD-ROM contents):

o Embedded system BIOS

o BIOS installation utilities

o Chipset drivers

o Intel Embedded Graphics Drivers

o Intel

®

Active Management Technology (AMT) software installation kit

Document Number: 320249-001

Page 18

• Pre-assembled development system, which includes:

o Fern Hill development board

o Plexiglass stand with Acrylic pad

o Mounting screws and standoffs

®

o Intel

o Processor thermal solution and CPU back plate

o Intel

o GMCH (GS45) heatsink

o I/O Controller Hub 9M-Enhanced Small Form Factor (ICH9M-E SFF)

o Type 2032, 3 V lithium coin cell battery

o 512 MByte DDR3 Memory On-Board (1067 MT/s, 7-7-7, PC3-8500

CoreTM 2 Duo processor SU9400 or SL9400

®

GS45 Express Chipset Graphics and Memory Controller Hub

(GMCH)

compatible)

Getting Started

o Port 80 display card

o Power Supply

o 80 GByte SATA Hard Disk Drive

o DVD-ROM Drive

o Disk Drive Power and SATA Cables

• One HDMI and Display Port add-in card (codename Eaglemont)

• One PCI Extension Card (codename Thimble Peak 2)

• One AC to DC Power Adapter

2.3 Additional Required Hardware (Not Included in

the Development Kit)

The following additional hardware may be necessary to operate the development

board.

VGA Monitor: Any standard VGA or multi-resolution monitor may be used. The setup

instructions in this chapter assume the use of a standard VGA monitor or LCD

monitor.

Keyboard: The development board supports both PS/2 and USB style keyboards.

Mouse: The development board supports both PS/2 and USB style pointing devices.

18 Development Kit User’s Manual

Page 19

Getting Started

Hard Drives and Optical Disc Drives and cables: One SATA hard disk drive and

one SATA optical DVD Drive are included in the development kit. Up to four SATA

drives and two IDE devices (master and slave) may be connected to the development

board. An optical disc drive (included) may be used to load the OS. All these storage

devices may be attached to the board simultaneously.

Video Adapter Card: Integrated video is output from the VGA connector on the back

panel of the development board. Alternately, a standard PCI Express* video adapter

card, ADD2 card or MEC video adapter card may be used for additional display

flexibility. Please contact the respective vendors for drivers and software for adapters

not provided with this development kit. Check the BIOS and the graphics driver,

where appropriate, for the proper video output settings.

Network Adapter and cables: A Gigabit network interface is provided on the

development board. The network interface will not be operational until after all the

necessary drivers are installed. A standard PCI/PCI Express* adapter may be used in

conjunction with, or in place of, the onboard network adapter. Please contact the

respective vendors for drivers and necessary software for adapters not provided with

this development kit.

You must supply appropriate network cables to utilize the LAN connector or any other

installed network cards.

Other Devices and Adapters: The development board functions much like a

standard desktop computer motherboard. Most PC-compatible peripherals can be

attached and configured to work with the development board.

2.4 Additional Required Software (Not included in the

Development Kit)

The following additional software may be necessary to operate the development

board.

Operating System: The user must supply any needed operating system installation

files and licenses.

Application Software: The user must supply any needed application software.

Development Kit User’s Manual 19

Page 20

Getting Started

2.5 Workspace Preparation

Caution: The development kit is shipped as an open system to provide flexibility in changing

hardware configurations and peripherals in a lab environment. Since the board is not in a

protective chassis, the user is required to take the following safety precautions in handling

and operating the board.

1. The power supply cord is the main disconnect device to main power (AC power).

The socket outlet should be installed near the equipment and should be readily

accessible.

2. To avoid shock, ensure that the power cord is connected to a properly wired and

grounded receptacle.

3. Ensure that any equipment to which this product will be attached is also

connected to properly wired and grounded receptacles.

4. Use a flame retardant work surface

5. Ensure a static-free work environment before removing any components from

their anti-static packaging. Wear an ESD wrist strap when handling the

development board or other development kit components. The development

board is susceptible to electrostatic discharge (ESD) damage, and such damage

may cause product failure or unpredictable operation.

20 Development Kit User’s Manual

Page 21

Getting Started

2.6 System Setup and Power-Up

Complete the following steps to operate the reference board.

These steps should already be completed in the kit. Check these items to

ensure that nothing came loose during shipment.

• Place one or more DDR3 SO-DIMMs in the memory sockets, populating J5N1

and/or J5P1. The memory sockets are on the bottom side of the development

board.

• Attach the heatsink for the processor U2E1.

• Install the configuration jumpers as shown in Section 4.3.1 of this document.

acing detached 1-x jumpers is not required for proper board operation.)

(Repl

• Attach hard drive data cable from development board SATA Connector J6J3 to the

drive with the supplied SATA data cable.

• Attach hard drive power from the ATX power supply to the drive.

• Attach optical drive data cable from development board SATA Connector J6J2 to

the drive with the supplied SATA data cable.

• Attach optical drive power from the ATX power supply to the drive.

• Connect the ATX power supply to the board at connector J4J1.

The following steps need to be completed by the user:

1. Attach the included CPU heatsink fan to the top of the CPU heatsink using the four

screws provided. Plug the fan power in at the CPU Fan connector J2B3.

2. Connect a PS/2 keyboard at connector J1A1 (bottom) or connect a USB keyboard

in one of the USB connectors.

3. Connect a PS/2 mouse at connector J1A1 (top) or a connect a USB mouse in one

of the USB connectors.

4. If using the chipset’s integrated graphics, connect a monitor to the VGA Video

output connector J2A2 with a VGA cable.

5. If using an external graphics card, plug a PCIe graphics card in the PCIe x1 slot

J8B3 or a PCI Express Graphics card in the PCIE x16 slot J6B2. Connect a monitor

to the card.

6. For mobile power configuration, unplug the ATX power supply from J4J1. Plug a

mobile Intel

battery pack into J1H1 or J1H2. Do not mix mobile and desktop power

configurations.

7. Plug in the power cord of the ATX power supply or the Intel AMPS AC brick into a

standard 120 V or 240 V AC power outlet.

®

AMPS AC to DC power adapter into J1G9. Optionally plug in a

Development Kit User’s Manual 21

Page 22

Getting Started

Powering up the board:

1. Switch the power supply on (1) at the switch on the rear of the supply.

2. Press the power button located at SW1C1.

3. As the system boots, press F2 to enter the BIOS setup screen.

4. Check time, date, and configuration settings. The default settings should be

sufficient for most users.

5. Insert an operating system installation disk into the optical drive.

6. Press F10 to save and exit the BIOS setup.

7. The system reboots begins to install the operating system from the optical drive.

Note: An operating system disk is not included in this kit and operating system installation

will not be covered in this User Manual.

2.6.1 Using the AC to DC Power Supply (Mobile Power Mode)

There are a few limitations to development board operation when using the AC to DC

power adapter (mobile power mode).

First, do not mix mobile and desktop power configurations. Unplug the ATX power

supply from connector J4J1 before plugging in the AC to DC Power Adapter to

connector J1G9.

Second, desktop peripherals, including add-in cards, will not work when the board is

powered by the AC to DC power adapter or a battery (mobile power mode). If desktop

peripherals are used, the development board must be powered using the included ATX

power supply (desktop power mode).

Warning: Do not mix mobile and desktop power configurations. Unplug the ATX power supply

from connector J4J1 before plugging in the AC to DC Power Adapter to connector J1G9, or a

battery (not included) to connector J1H1-J1H2

Warning: The power supply cord is the main disconnect device from main AC power. The power

outlet shall be installed near the equipment and shall be readily accessible.

22 Development Kit User’s Manual

Page 23

Getting Started

2.7 Power Down

Powering down the board:

There are three options for powering-down the system

1. Power down from the operating system via the Windows Start Menu, or

equivalent.

2. Press the power button on the motherboard at SW1C1 to begin power-down.

3. If the system is hung, it is possible to asynchronously shut the system down by

holding down the power button (SW1C1) continuously for 4 seconds.

Note: We do not recommend powering down the board by shutting off power at the ATX

power supply.

Note: If the power button on the ATX power supply is used to shut down the system, wait at

least five seconds before turning the system on again to avoid damaging the system.

2.8 System BIOS

A version of the AMI* BIOS is pre-loaded on the development board.

Other BIOS vendors also support the Intel Core 2 Duo with Intel GS45 Express

Chipset. For additional BIOS support, please contact your BIOS vendor.

2.8.1 Configuring the BIOS

The default BIOS settings may need to be modified to enable or disable various

features of the development board. The BIOS settings are configured through a menudriven user interface which is accessible during the Power On Self Test (POST). Press

the F2 key or Delete key during POST to enter the BIOS interface. For AMI BIOS POST

codes, visit:

http://www.ami.com

For BIOS Updates, please contact your Intel Sales Representative.

Development Kit User’s Manual 23

Page 24

Getting Started

2.8.2 Programming BIOS Using a Bootable USB Device

The flash chips which store the BIOS and BIOS extensions on the development board

are connected to the SPI bus and are soldered down. One method of programming

these devices is through software utilities as described below. The software files and

utilities needed to program the BIOS are contained on the included CD-ROM. Another

method is described in Appendix C - Programming System BIOS Using a Flash

Programming Device.

low these steps to program the system BIOS using a bootable USB Device.

Fol

1. Prepare the workspace as outlined in Section 2.5 above.

2. Se

3. Warning: Prior to flashing BIOS onto the pl

4. Copy the following files and utilities to the Bootable USB Device

5. Unplug the hard disk drive (HDD) SATA cable from the board at connector

6. Record the 12 digit MAC Address of the board from the sticker near the

7. Insert the Bootable USB Key into one of the USB Ports on the

8. Switch on the power supply (to “1”).

9. Press the Power (PWR) Button on the development board to power on the

10. Wait for the system to boot from the USB Key to a DOS prompt

11. From the DOS prompt (C:>), Run the following:

tup the system as outlined in Section 2.6 above.

atform AMT must be disabled

in BIOS. Failure to do this will render the system inoperable.

a) Boot the system and enter the system BIOS setup by pressing (F2) or

(Del) and navigate to AMT and select (disable)

b) Navigate to ”Save changes and exit”.

c) Power off the system by pressing the power (PWR) button (SW1C1)

d) Turn off the power supply (remove power from the board) for at least

15 seconds

• BIOS Image Files

o spifull.bin

• BIOS Programming Software Utilities

o fpt.exe (DOS SPI Flash Utility)

o fparts.txt (helper file)

• MAC Address Programming Software Utility

o eeupdate.exe

• Other helper files contained on the included CD-ROM

J6J3 so that the board will boot from the bootable USB key.

CPU

Development Board

system

a) fpt –f spifull.bin

b) Make sure there are no warnings or errors

24 Development Kit User’s Manual

Page 25

Getting Started

12. From DOS, Run the following to reprogram the MAC address:

a) eeupdate /nic=1 /mac=xxxxxxxxxxxx (xxxxxxxxxxxx is the MAC

Address from the sticker)

b) Make sure there are no warnings or errors

13. From DOS, Run the following to update the Keyboard and System

Controller flash:

a) kscupdate ksc.bin

b) Make sure there are no warnings or errors

14. Power the system down by pressing the PWR button

15. Clear the CMOS by performing the following:

a) Shunt the CMOS CLR jumper (J5H2 – near the on-board battery)

b) Press the PWR button on the board. The board will not power on, but

a couple of LEDs will flash.

c) Switch the power supply off to power down the board

d) Remove the CMOS CLR jumper (J5H2).

16. Unplug the bootable USB Key

17. Verify Correct BIOS Installation

a) Switch the power supply back on

b) Press the PWR button on the board to power-up the system

c) Boot to BIOS Configuration screen by pressing F2 at the BIOS splash

screen.

d) In the BIOS Main screen, check that the “Project Version” lists the

correct version of the BIOS.

e) Press the PWR key on the board to power the system back down.

18. Re-connect the SATA data cable from the hard drive to the development

board at connector J6J3.

The system is now ready for normal operation.

Development Kit User’s Manual 25

§

Page 26

Development Board Features

3 Development Board Features

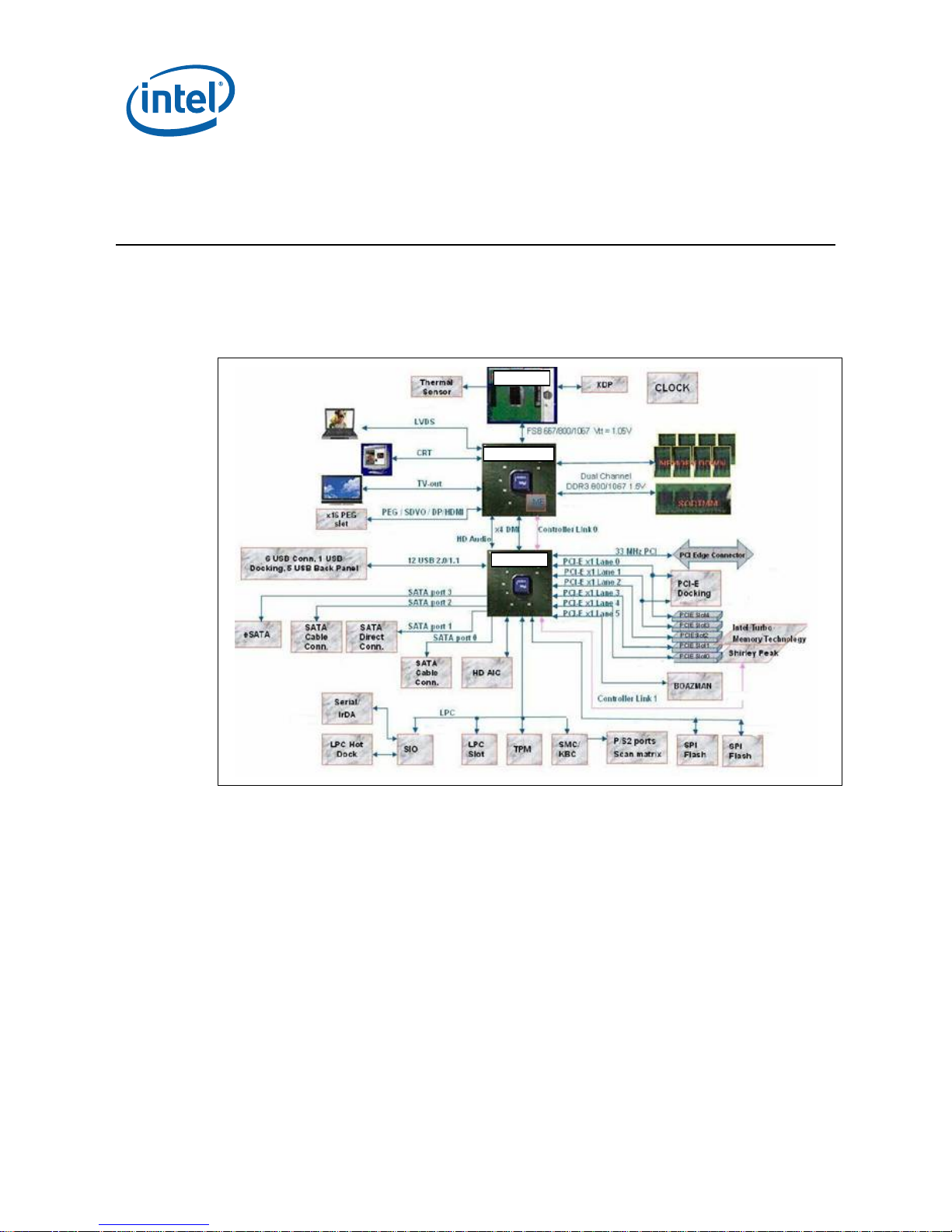

3.1 Block Diagram

Figure 1. Fern Hill Block Diagram

CPU

GS45 GMCH

ICH9M-E SFF

3.2 Mechanical Form Factor

The development board conforms to the ATX form factor. The development board will

fit in most standard ATX chassis. A list of add-in card connector and slot locations is

provided in Section 4.1 Internal and rear panel system I/O connectors are described

Section 4.2.

in

3.3 Development Board Key Features

Features of the development board are summarized in the following table.

26 Development Kit User’s Manual

Page 27

Development Board Features

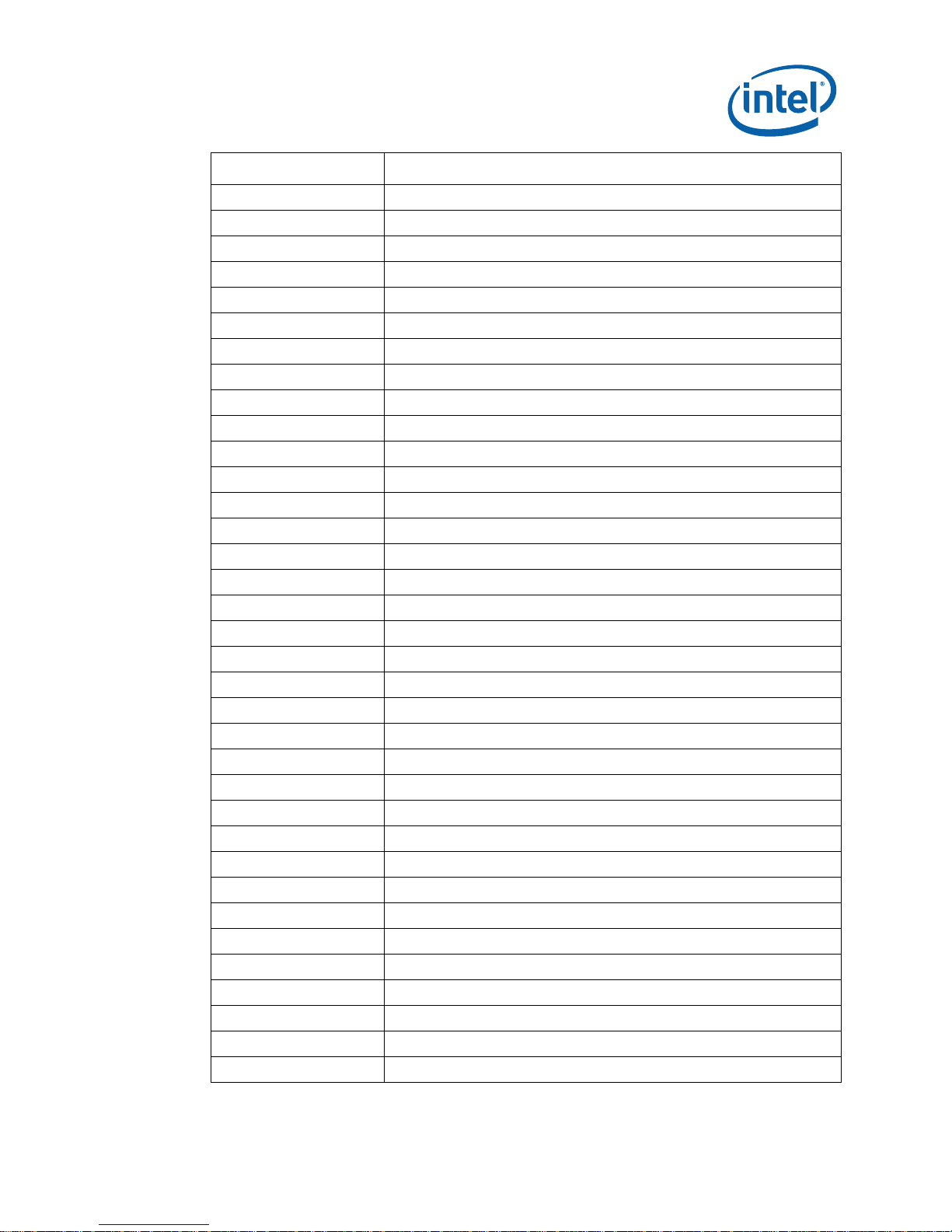

Table 6. Fern Hill Feature Set Summary

Component Fern Hill Board Implementation Comments

Processor

Chipset

Memory

Video

PCI

Intel® Core™ 2 Duo processor SL9400

or

Intel® Core™ 2 Duo processor SU9400

Intel® GS45 Express Graphics and

Memory Controller Hub (GS45 GMCH)

ICH9M-Enhanced SFF 569-pin BGA package

512 MB DDR3 memory down

One DDR3 SO-DIMM slot

One PCI Express* Graphics Slot

One dual channel LVDS Connector

One VGA Connector

One TV D-Connector supporting S-Video,

Composite video and Component video

Spread spectrum clocking

PCI revision 2.3 compliant

(33 MHz)

Three 5-V PCI slots are supported

through PCI Extension card

SL9400 has 1066 MT/s FSB; 1.86 GHz core;

6 MB L2 cache; 17 W TDP; 2 Cores; 956-ball

µFCBGA package.

SU9400 has 800 MT/s FSB; 1.40 GHz core; 3

MB L2 cache; 10 W TDP; 2 Cores; 956-ball

µFCBGA package.

1363-pin Micro-FCBGA package

1 channel used for memory down and the

second used for SO-DIMM slot

Channel A: Memory down with 512-MB DDR3

1067 MT/s (x16 devices, four device on top

and four device on bottom)

Channel B: DDR3 800/1067 MT/s SO-DIMM

slot

Maximum 4.5 GB using 2-Gb technology and

stacked SO-DIMMs.

Maximum 2.5 GB using 2-Gb technology and

non-stacked SO-DIMMs.

No ECC support

Intel GS45 Express Chipset supports quad

monitors, but only has two video pipes which

support two different screens.

Support for SPWG3.5. 24 bit color panel

support (based on planned SPWG 4.0)

Support for two SDVO channels via x16 PCIe*

connector (through add-in cards)

Support for DisplayPort and native HDMI*

(via a x16 PCIe* connector, usage through

Eaglemont and native HDMI through add-in

card)

No PCI slots on motherboard

Only one PCI gold finger on board

Six x1 PCIe lanes

PCI Express

On-Board LAN

Five x1 connectors

One x16 connector

The Intel® 82567 Gigabit Ethernet LAN The Intel 82567 is connected to ICH9M SFF

Development Kit User’s Manual 27

Revision 1.0a compliant

Two sets of 2 in-line x1 PCIe slots

Intel® 82567 GbE controller LAN on

motherboard (muxed with one PCIe lane)

x2 PCIe lanes to docking via resistor stuffing

option

via LCI interface and GLCI interface

Page 28

Development Board Features

Component Fern Hill Board Implementation Comments

Wireless

Communication

BIOS (SPI)

BIOS (FWH)

Soft Audio/Soft

Modem

ATA/Storage

USB

LPC One LPC slot Includes sideband headers

SMC/KBC

Clocks

RTC Battery-backed real time clock

Thermal

Monitoring

Processor

Voltage

Regulator

Power Supply

Debug

Interfaces

Wireless LAN and Bluetooth* support via

UPHAM-IV interposer

Supports two compatible flash device

Support for 8-Mb Intel FWH using Port80 card

Intel® High Definition Audio (Intel® HD

Audio) MDC Header

4 SATA Ports

12 USB 2.0/1.1 Ports

Hitachi H8S/2117* micro-controller

Two PS/2 ports

One scan matrix keyboard connector

CK-505D system clock and DB800M

Processor temperature sensor

Intel® Mobile Voltage Positioning Intel®

MVP-6 for processor core

Desktop mode

Mobile mode

Port-80 display Through add-in card. Four seven-segment

6 ports to back-panel I/O connector, 5 ports

WLAN/WiMAX combo card Echo Peak support

via UPHAM-IV

Support for multi-vendor SPI

Support multi-package (SOIC-8 & SOIC-16)

device

No FWH connector on motherboard

Support only through Port-80 add-in card

(through the TPM header)

Support via interposer

Use Mott Canyon-4 daughter card (support

via sideband cable)

Intel HD Audio routed to docking connector

Two cable connector and one direct connect

connector, one eSATA connector

Both port 0 & port 1 have interlock switch.

to front-panel I/O connector and port to

eSATA+USB combo connector with resistor

stuffing option for docking

ACPI compliant

Three 133/166/200/233/400 MHz CPU

differential clock pair

Twelve 100-MHz PCIe differential pair SRC

clocks

Twelve 33-MHz PCI clocks

48-MHz USB clock, 14-MHz ref clock,

96-MHz Dot clock, Spread spectrum clocks

ATX power supply

Battery pack (smart battery support)

Mobile Intel AMPS AC Brick

displays

28 Development Kit User’s Manual

Page 29

Development Board Features

Component Fern Hill Board Implementation Comments

IAMT® support

Intel® Turbo

Memory

Power

Management

Form Factor

Miscellaneous

Extended Debug Port (XDP)

Intel® Active Management Technology

(Intel® AMT) is supported on the CRBs

with M0 M1, and M-off management

states

Intel® Turbo Memory (formerly Robson

technology) of hardware cache is

supported using Intel Turbo Memory

add-in card

ACPI Compliant

ATX 2.2 like form factor 10 layer board(8 layer with 2 additional

EBL support

Intel® Display Power Saving Technology

(Intel® DPST) 4.0 support

SPWG 3.5 complaint LVDS panel support

Mobile Digital Office initiatives

TPM 1.2 and support for Trusted Platform

Enabling

Intel® Active Management Technology

(Intel® AMT) support

Lead free design

XDP connector (for processor run control) RJ11 for Intel® Management Engine JTAG

LAI support

Controller Link to GMCH and to wireless LAN

Intel® Management Engine power plane

C0, C1, C1E, C2, C2E, C3, C3E, C4E, slow C4

exit, Intel® Enhanced Deeper Sleep (with

Level5 read) and Intel Deep Power Down

Technology processor power states for

mobility processors

S0 (Power On), S3 (Suspend to RAM), S4

(Suspend to Disk), S5 (Soft Off) system

power states.

M0 (All Wells powered), M1 (Main Well down,

Only Intel® Management Engine power on),

M-off (Intel Management Engine powered off)

manageability power states

validation hooks layer) – 12” x 10.2”

EBL support includes:

• PSI2 support

• Backlight optimization

• Device Power State (DPS)

• DVD power control

• Ambient Light Sensor

• Narrow VDC

• Ambient Light Sense with UPD through IR

sensor

• Intel DPST 4.0

• 72 WHr Battery

• LED Backlight

• Intel® Adaptive Mobile Power System

(Intel® AMPS)

• Dynamic Display Power Optimization

Note: Review the document provided with the Development Kit titled “Important Safety and

Regulatory Information”. This document contains safety warnings and cautions that

must be observed when using this development kit.

Development Kit User’s Manual 29

Page 30

3.4 Software Key Features

The driver CD included in the kit contains all software drivers necessary for basic

system functionality under the following operating systems: Windows* XP/XP

Embedded, Vista and Linux.

While every care was taken to ensure the latest versions of drivers were provided on

the enclosed CD at time of publication, newer revisions may be available. Updated

drivers for Intel components can be found at: http://downloadcenter.intel.com

For all third-party components, please contact the appropriate vendor for updated

drivers.

Note: Software in the kit is provided free by the vendor and is only licensed for evaluation

purposes. Refer to the documentation in your evaluation kit for further details on any

terms and conditions that may be applicable to the granted licenses. Customers using

the tools that work with Microsoft* products must license those products. Any targets

created by those tools should also have appropriate licenses. Software included in the

kit is subject to change.

Development Board Features

3.4.1 AMI BIOS

This development kit ships with AMI* BIOS pre-boot firmware from AMI* preinstalled. AMI* BIOS provides an industry-standard BIOS on which to run most

standard operating systems, including Windows* XP/XP Embedded, Linux*, and

others.

The AMI* BIOS Application Kit (available through AMI*) includes complete source

code, a reference manual, and a Windows-based expert system, BIOStart*, to enable

easy and rapid configuration of customized firmware for your system.

30 Development Kit User’s Manual

Page 31

Development Board Features

The following features of AMI* BIOS are enabled in the development board:

• DDR2 or DDR3 SDRAM detection, configuration, and initialization

®

• Intel

• POST codes displayed to port 80h

• PCI/PCI Express* device enumeration and configuration

• Integrated video configuration and initialization

• Super I/O configuration

• Active Management Technology

• RAID 0/1 Support

GS45 Express Chipset configuration

3.5 Thermal Management

The objective of thermal management is to ensure that the temperature of each

component is maintained within specified functional limits. The functional temperature

limit is the range within which the electrical circuits can be expected to meet their

specified performance requirements. Operation outside the functional limit can

degrade system performance and cause reliability problems.

The development kit is shipped with a heatsink thermal solution for installation on the

processor. This thermal solution has been tested in an open-air environment at room

temperature and is sufficient for development purposes. The designer must ensure

that adequate thermal management is provided for if the system is used in other

environments or enclosures.

3.6 System Features and Operation

The following sections provide a detailed view of the system features and operation of

the development board.

3.6.1 Processor Support

The Fern Hill board includes either an Intel® Core™ 2 Duo processor SL9400 at 1.86

GHz core frequency and 6 MB L2 cache, or an Intel® Core™ 2 Duo processor SU9400

at 1.4 GHz core frequency and 3 MB L2 cache. The processor is in a 956-ball MicroFCBGA (Flip Chip Ball Grid Array) package at board location U2E1.

Note: The Intel® Core™ 2 Duo SU9400 processor at 1.4 GHz core frequency is not on the

Intel embedded roadmap offering and as such does not have embedded market 7

year availability. The Intel® Core™ 2 Duo SU9300 processor at 1.2 GHz core

frequency is on the Intel embedded roadmap offering and has embedded market 7

year availability.

Development Kit User’s Manual 31

Page 32

3.6.2 Processor Voltage Regulators

The reference board implements an onboard Intel® Mobile Voltage Positioning (Intel®

MVP) -6 regulator for the processor core supply. The core VR solution supports PSI2.

The VR will support up to 56 amps. Slow C4 exit is supported to reduce perceptible

audio noise caused by periodically exiting the C4 state.

3.6.3 Front-Side Bus (FSB)

The Front Side Bus (FSB) on the development board supports data rates of 800 MT/s

(200-MHz quad pumped, FSB-800) & 1067 MT/s (266-MHz quad pumped, FSB-1067).

The FSB is AGTL+ and will be running at 1.05 V.

3.6.4 Processor Power Management

Intel® Core™ 2 Duo processor SL9400 and SU9400 supports C0-C6 power states. This

processor also supports C2E and C4E. Additionally, the processor supports a new

processor state, Intel Deep Power Down Technology, that brings the CPU leakage

power down to the lowest possible. DPWR# protocol is also supported on the

development board through signal H_DPWR#.

Development Board Features

3.6.5 Processor Active Cooling

The system supports PWM based FAN speed control. Fan circuitry is controlled by the

signal CPU_PWM_FAN signal from the EC (PWM signal from the H8 is driven high to

3.3 V and low to 0 V at about 40 kHz carrier frequency).

A 3-pin header J2B3 is provided to support FAN Tacho output measurement for the

CPU.

3.6.6 Manual Processor Voltage ID (VID) Support

The development board supports manual VID operation for processor VR. A jumper

J2B2 is provided to incorporate “VID override” to allow the overriding of CPU VID

outputs to the CPU VCC Core VR. The intent of this “VID override’ circuit is for ease of

debug and testing.

32 Development Kit User’s Manual

Page 33

Development Board Features

3.6.7 Chipset

The Intel® GS45 Express Chipset (GS45 Chipset) is included on the development

board. The chipset consists of the GS45 Graphics and Memory Controller Hub (GS45

GMCH) and the ICH9M-Enhanced Small Form Factor I/O Controller Hub (ICH9M-E

SFF).

The GS45 GMCH provides a processor interface at 800 or 1067 MT/s and two DDR3

memory interfaces running at 800 or 1067 MT/s. It also supports memory down on

one channel and SO-DIMM on the other channel. The GS45 GMCH supports internal

graphics (integrated LVDS, 2 SDVO channels, VGA, TVO, DisplayPort) as well as

external graphics (through add-in card on a X16 PCI Express Graphics slot). It also

supports a manageability engine (manageability JTAG signals brought to test point/8pin header) and is connected to the ICH device via a DMI bus.

The ICH9M-E SFF features twelve USB 2.0/1.1 compatible ports (Six back panel, five

front panel USB ports and one port to docking), 4 Serial ATA channels (Two cable

connects, one direct connect, one eSATA port) , an Intel HD Audio digital link, PCI 2.3

compliant interface (no slots on board, slots provided on thimble peak card), LPC bus,

six general purpose PCI Express 1.1a compliant lanes in which sixth PCI Express lane

is used for Gigabit LAN interface. The ICH9M-E SFF also provides manageability

support through a controller link interface to the GS45 GMCH and optionally to

wireless LAN.

3.6.8 System Memory

The development board supports a dual channel DRR3 interface with one channel as

memory down (Channel A) and the second as an SO-DIMM socket (Channel B).

Channel A has 512 MB of PC3-8500 compatible DDR3 memory down. The DDR3 SODIMM socket on the development board is at J5P1 and the memory down devices are

at U5C2, U5C1,U4C1,U4C2,U5P2,U5P1,U4P2 and U4P1.

The GS45 GMCH supports four ranks of memory at 800 or 1067MT/s. The maximum

amount of memory supported this development board is 4.5 GB of DDR3 memory by

utilizing 2-Gb technology in stacked SO-DIMMs and 2.5 GB of DDR3 memory by

utilizing 2-Gb technology in non-stacked SO-DIMMs. There is no ECC support on this

development board.

Warning: SO-DIMM Memory that is not PC3-8500 DDR3 compatible may not work with the

memory that is already down on the board. In this case the board may not boot.

Development Kit User’s Manual 33

Page 34

3.6.9 Video Display

The reference board has six options for displaying video: VGA, LVDS, TVOUT, SDVO,

Display port (through Add in card) or PCI Express Graphics (PEG). Display port, SDVO

and PCI Express Graphics (PEG) are multiplexed on the same pins within the chipset.

The development board contains one DP/SDVO/PCI Express Graphics Slot (J6B2) for a

PCI Express compatible graphics card or an SDVO compatible graphics card (ADD2N &

ADD2R), one LVDS connector (J6F1), one TV-OUT D-connector (J2A1), and one 15-pin

VGA connector (J2A2). To support ADD2R (with PCI graphic lanes reversed), resistor

R1U4 should be made “NO STUFF”.

By default the voltage supplied to the SDVO/PCI Express Graphics slot is switched off

in suspend mode, and the reset signal is not gated. A stuffing option allows the

voltage to be supplied from voltage rails that stay on in suspend mode. A different

stuffing option allows the reset signal to be gated as well. Details of these stuffing

options can be referred on page 19 of the Fern Hill schematics.

The TV is output through a D-connector. There are two cables in order to access TV: a

black D-connector to S-video (IPN: C87694-001) and a black D-connector to 3 pin

component (IPN: C87695-001). The blue coax pin can be used for composite TV

interface. To use a non-high definition external display with the board, change the

resolution to 480 lines interlaced (480i) in the Internal Graphics Device properties.

Development Board Features

Table 7. TV–Out Connections

Note: Composite video and component video both use the same cable.

3.6.10 PCIe Slots

The ICH9M-Enhanced Small Form Factor I/O Controller Hub (ICH9M-E SFF) provides 6

PCIE ports (x1). Port 6 is multiplexed with Gigabit LAN Controller Interface. The

reference board has five x1 PCIe slots (J6B1, J6D1, J8B3, J8D1 & J7B1). Three of the

five slots, Slot 1, Slot 3, and Slot 5, are located at standard expansion slot locations.

The fourth and fifth slots, Slot 2 and Slot 4, are located in-line with Slot 1 and Slot 3

respectively.

D-connector Cable

Composite Video

Component Video

S–Video

Blue

Cable TV

Red Red

Green Green

Blue Blue

D-connector to S-video

34 Development Kit User’s Manual

Page 35

Development Board Features

Support for x2 on lane 1 and lane 2 (Port 1 can be configured as a x1 port or a x2 port

shared with port 2) and on Lane 3 and lane 4 (port 3 can be configured as a x1 port or

a x2 port shared with port 4) can be configured via the ICH9M-E SFF “RPC – Root Port

Configuration” register.

Table 8. PCI Express Ports

ICH9M

PCIe Port

1 PCIe Slot 1 (J6B1) PCIe Docking (1st lane)

2 PCIe Slot 2 (J6D1) (in-line with Slot

3 PCIe Slot 3 (J8B3)

4 PCIe Slot 4 (J8D1) (in-line with Slot

5 PCIe Slot 5 (J7B1)

6 (GLCI) Intel 82567 LAN Muxed with PCIe slot5 (only for testing)

Default Destination Optional Destination

1)

3)

Slot 4 also supports controller link. Upon a net detect event, Slot 4 gets a switched

Auxiliary 3.3 V supply.

3.6.11 PCI Slots

The reference board does not have any PCI slots on the motherboard. Three 5V PCI

slots are supported via the Thimble Peak 2 PCI Extension Card.

3.6.11.1 PCI Gold-Fingers

A gold-finger connector (S9B1) is also supplied on the development board, which

allows an external PCI expansion board, Thimble Peak 2, to connect to it. Thimble

Peak 2 has three additional PCI slots allowing the user greater expansion. See

Appendix A

for more information on the Thimble Peak 2 add-in card.

PCIe Docking (2nd lane)

C-link south routed to this slot. WLAN card

support through Upham3 Add-in card

3.6.12 On-Board LAN

The development board provides 10/100/1000 LAN through EU8A1. Intel ® 82567 is

used on the reference board. The 82567 component is connected to the ICH9M-E SFF

I/O Controller Hub through the LAN Connect Interface (LCI) and supports 10/100Mbps

link. The same device is connected through GLCI interface and supports 1000Mbps

link. The Intel 82567 connects to an RJ45 connector at J5A1 with built in magnetic

decoupling.

Development Kit User’s Manual 35

Page 36

3.6.13 Serial Peripheral Interface (SPI)

The Serial Peripheral Interface on ICH9M-E SFF can be used to support two compatible

flash devices (U8C1 (or U8B2), U8C4 (or U8C3)). Both the SPI devices supports for

multi-package (SOIC-8 and SOIC-16) device. The SOIC-8 package (U8C1 & U8C4)

would support 16 Mb SPI flashes, while the SOIC-16 package (U8B2 & U8C3) will

support 32Mb or higher SPI flash. Unified BIOS code (BIOS+ IAMT+ LAN) resides in

these two SPI devices.

Note: Out of the SOIC-8 and SOIC-16 footprints supported on the board only one of these

can be used at a time and on the board the Footprint is arranged one over the other.

By default, U8C1 (16Mb on CS#0) and U8C4 (16Mb on CS#1) will be stuffed.

Note: SPI programming details are given in Section 2.8.2

3.6.14 Soft Audio/Soft Modem

Intel® High Definition Audio functionality is enabled through the Mott Canyon 4

Daughter Card. ICH9M-E SFF supports 4 Intel® High Definition Audio codecs. All the

four are routed to MDC header through resistor stuffing option. By default Codec 0 & 1

will be connected to MDC Card. An on-board header is provided at J9E2 and J9E4 for

this purpose. No direct connection is provided for the Intel® High Definition Audio

Card on the development board; the Mott Canyon 4 card is required to enable the

Intel® High Definition Audio functionality. See Appendix A

the Mott Canyon 4 card.

Development Board Features

for more information on

The development board supports low voltage (LV) High definition codecs I/O. R8E7,

R8E8 & R7H2, R7H3 resistors are used to select between 3.3V I/O and 1.5VI/O.

Table 9. Selection of I/O Voltage for the High Definition Audio

I/O Voltage for the High

Definition Audio

3.3V (Default) R8E7, R7H3 R8E8, R7H2

1.5V R8E8, R7H2 R8E7, R7H3

STUFF NO STUFF

3.6.15 SATA Storage

The development board provides four serial ATA (SATA) connectors. One of the four

serial ATA (SATA) connectors is a “direct connect” connector located at J8J1 (port 0

from the ICH9M). The other two serial ATA connectors are “cable connect” connectors

located at J6J3 (port 1 from ICH9M) & J6J2 (port 4 from ICH9M). Also, the

development board supports an eSATA connector located at J7J1 (port 5 of ICH9M).

The eSATA connector is available on the front edge of the board.

Additionally SATA port 4 can be made available at docking connector by stuffing

(C7W2, C7W3, C7V13 and C7V14) and making C7H1, C7H2, C7G9 and C7G8 to “NO

STUFF”.

36 Development Kit User’s Manual

Page 37

Development Board Features

Table 10. SATA Ports

SATA Port Connection Type Connector

Port 0 Direct Connect J8J1

Port 1 & Port 4 Cable Connect J6J3 & J6J2

Port 5 eSATA J7J1

These connectors mentioned in Table 10 are for the serial data signals. The board has

a power connector J5J1 to power the serial ATA hard disk drive. A green LED at

CR7H1 indicates activity on the ATA channel.

The development board shares the power connector for both SATA ports. Due to this

only one of the serial ATA channel (Port1 by default) supports hot swapping capability.

Hot swap on Port 1 can be used only when the Port 4 is not used. Y-Power cable needs

to be connected first to the device on Port 1 before connecting the signal cable. When

hot swap is not desired, both Port 1 and Port 2 can be used. A jumper J7H1 is

provided to enable hot plug/removal on port-1. For jumper setting details refer to

Section 4.3.1, Table 17.

Note: The eS

ATA drives should be externally powered. Hence, there is no power supply

support for them on the motherboard

3.6.16 USB Connectors

ICH9M-E SFF provides a total of twelve USB 2.0/1.1 ports. 6 USB ports (0, 2, 4, 6, 8,

10) are connected to the back-panel I/O connector, 6 ports (1, 3, 5, 7, 9, 11) to the

front-panel I/O connector (of these ports, port 9 is also routed to Docking).

Four ports (0, 2, 4, and 6) are routed to a 4 stacked USB connector (J3A1) at the back

panel. The other 2 ports (8 and 10) are routed to the RJ45+Dual USB stacked

connector (J5A1) at the back panel.

Six USB ports are routed to USB 2X5 front panel headers: Port (1, 3) at J6H4, Port (5,

7) at J6H2 and Port (9, 11) at J6J1. The remaining one USB port is routed to docking

connector J9C2.

Note: The USB Port 9 is routed to the docking station interface by default. By changing the

straps near ICH9M-E SFF Port 9 can be routed to the front panel header also. The

advantage of this scheme is that Port 9 can be tested on the Motherboard without

using the docking card.

Development Kit User’s Manual 37

Page 38

Table 11. USB Ports mapping

USB Port Panel Connector

Development Board Features

Port 0, Port2, Port4,

Port 6

Port 1 & Port 3 Front Panel I/O Header J6H4

Port 5 & Port 7 Front Panel I/O Header J6H2

Port 8 & Port 10 Back Panel I/O Connector J3A1 (RJ45 with Dual USB Connector)