Intedge GP620B Service Manual

INTEDGE INDUSTRIES.INC.

1875 CHUMLEY ROAD

GP Series MIXERS

1-26 At EXIT 38

P.O. BOX 969

WOODRUFF, S.C. 29388

Tel. (864) 969-9601

Fax (864) 969-9604

MODELS 620 & 630

Bench & Floor

- TABLE OF CONTENTS -

SECTION 1

DESCRIPTION

SECTION 2

INSTALLATION

SECTION 3

OPERATION

SECTION 4

MAINTENANCE & TROUBLESHOOTING 21

SECTION 5

ATTACHMENTS & ACCESSORIES

SECTION 6

PARTS LIST

SECTION 7

ELECTRICAL SCHEMATICS

A Manual Usage 1

B Mixer Usage 1

C Mixer Models 1

D Specifications 2

E Detail and Dimension Drawings 3-4

F Component Function 5

I Unpacking 7

II Installation 7

III Pre-Operation Checks 8

I Mixer Set-Up 9-11

II Mixer Operation 12

A Before Starting Mixer 12

B Timer 12

C Speed Selector 13

D Overload 13

E Bowl Accessories 14

F Attachment Hub 15

III Agitator Uses 16

IV Operation 18

V Cleaning & Helpful Hints 19

VI Absorption Ratio 19

VII Production Capacity Chart 20

I Lubrication 21

II Cleaning 21

III Troubleshooting 21

Attachments 23

Accessories 24

Overall Exploded View and Parts List 26-27

Transmission Exploded View 28-29

Electrical Components 30

100V/240V, 1 Ph 32

208V/240V, 3 Ph 32

440V/480V 3 Ph 33

380V,3Ph, Scandinavian Only 33

CONTENTS PAGE

section 1

description

A. Manual Usage

This Owners Manual is to be used with the

GP Series Model 620 and Model 630

Mixers which are manufactured by

Middleby Marshall Inc.

B. Mixer Usage

Model 620 and 630 Mixing Machines are

intended for use in bakeries and kitchens.

The mixers are used to mix:

• Bread Dough

• Roll Dough

• Pizza Dough

• Cake Batter

• Cookie Dough

• Pastry Dough

The mixers are also used for lighter mixing

and whipping such as:

• Whipped Potatoes

• Egg Whites and Whole Eggs

• Whipped Cream

The mixing machines can be equipped with

optional accessories for preparing meats,

vegetables and cheeses.

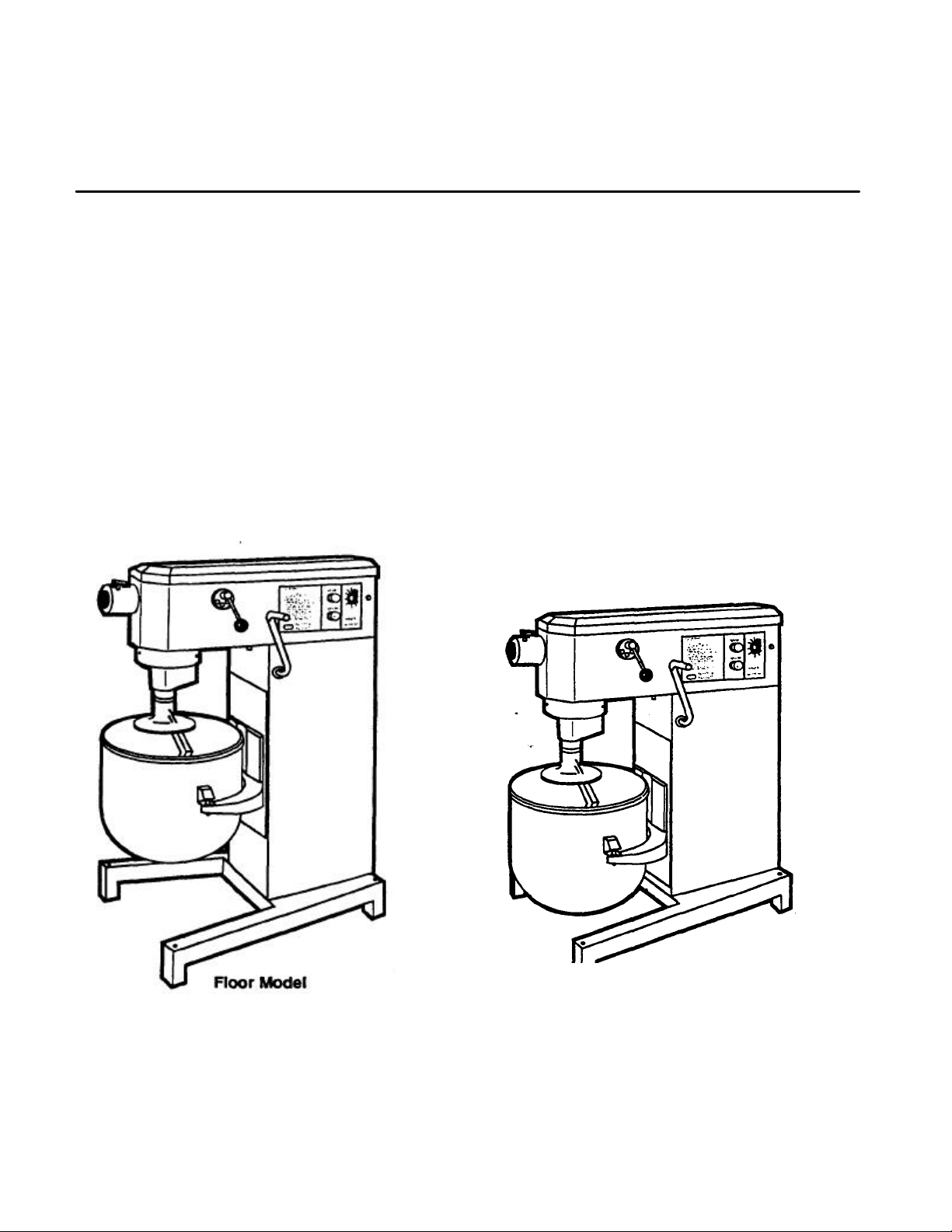

C. Mixer Models

GP Series Model 620 and Model 630 Mixers

are both available in either Floor Models or

Bench Models. The mixers are also available

as domestic or export units.

Figure 1-1

1

section 1

description

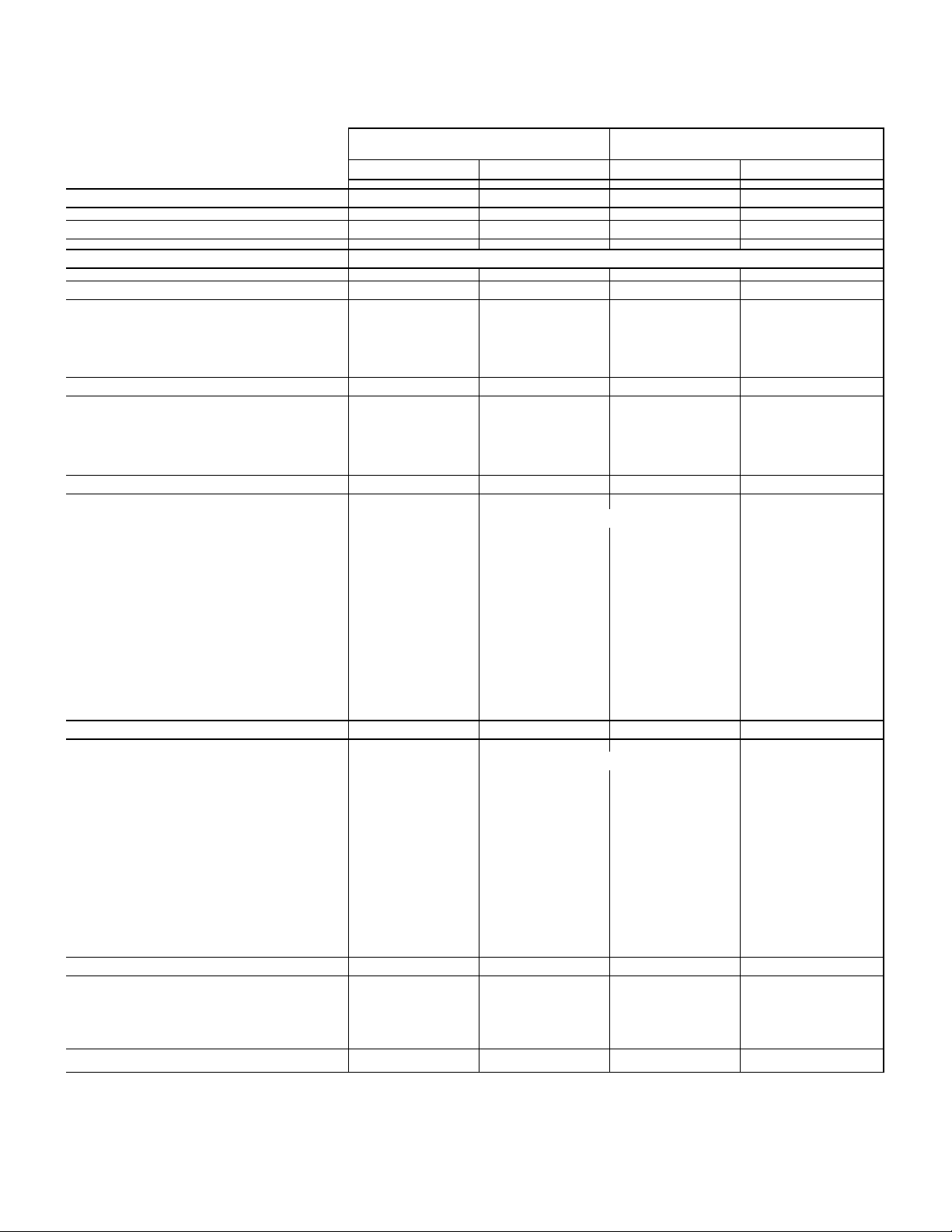

D. Specifications

12qt. 20 qt. 20qt. 30 qt.

620

Capacity 12qt.(11.25ltr.) 20qt.(19ltr.) 20qt.(19ltr.) 30 qt. (28 hr.)

Horsepower 1/2 H.P. 1/2 H.P. 3/4 H.P. 3/4 H.P.

Transmission Three Speed Gear with Neutral between each speed setting.

Agitator Speeds:

1st (low) 89 rpm 89 rpm 89 rpm 89 rpm

2nd (medium) 161 rpm 161 rpm 161 rpm 161 rpm

3rd (high) 310 rpm 310 rpm 310 rpm 310 rpm

Accessory Drive Speeds

1st (tow) 178 rpm 178 rpm 178 rpm 178 rpm

2nd (medium) 322 rpm 322 rpm 322 rpm 322 rpm

3rd (high) 620 rpm 620 rpm 620 rpm 620 rpm

Floor Model:

Model

Model

630

Machine Dimensions

Refer to Detail Drawings on next page

Machine Only Weight 255 IDS. (111 kg) 255lbs.(111kg) 265 lbs.016kg) 265 lbs.(116kg)

Shipping Weight - Domestic 294 lbs.(135kg) 294lbs.(135kg) 305 lbs.(159kg) 305 lbs.(159kg.)

Shipping Cube - Domestic 31.7 ft

3

(0.9m

) 31.7 ft

3

3

(0.9m

) 31.7ft

3

3

(0.9m

) 31.7ft

3

(0.9m

3

)

3

Shipping Weight - Export 294 lbs.(135kg) 294 lbs.(135kg) 305 lbs.(159kg) 305 lbs.(159kg.)

Shipping Cube - Export 31.7 ft

3

(0.9m

) 31.7 ff (0.9m3) 31.7 ft

3

3

(0.9m

) 31.7ft

3

(0.9m•

>

)

3

Shipping Carton Dimensions - Domestic 54-3/8"H(1381mm) 54-3/8"H(1381mm) 54-3/8"H(1381mm) 54-3/8"H(1381mm)

and Export x x x x

35-1/4"D(895mm) 35-V4"D(895mm) 35-1/4"D(895mm) 35-1/4"D(895mm)

x x x x

32-7/8-W(835mm) 32-7/8'W(835mm) 32-7/8"W(835mm) 32-7/8-W(835mm)

Bench Model

Machine Dimensions

Refer to Detail Drawings on next page

Machine Only Weight 240 lbs.(93kg) 240 lbs.(93kg.) 250 lbs.(98kg.) 250 lbs.(98kg.)

Shipping Weight - Domestic 280 lbs.( 109kg.) 280 lbs.(109kg.) 290 lbs.(122kg.) 290 lbs.(122kg.)

Shipping Cube - Domestic 25.8ft

3

(0.73m

) 25.8ft

3

(0.73m

3

) 25.8ft

3

(0.73m

3

) 25.8ft

3

(0.73m

3

)

3

Shipping Weight - Export 280Ibs.(109kg.)' 280 lbs.(109kg.) 290 lbs.(122kg.) 290 lbs.(122kg.)

Shipping Cube - Export 25.8ft

3

(0.73m

) 25.3ft

3

(0.73m-

1

) 25.8ft

3

(0.73m

3

) 25.8ft

3

(0.73m

3

)

3

Shipping Carton Dimensions - Domestic 54-3/8"H(1381mm) 54-3/8"H(1381mm) 54-3/8'H(1381mm) 54-3/8"H(1381mm)

and Export x x x x

35-1/4"D(895mm) 35-1/4"D(895mm) 35-1/4"D(895mm) 35-1/4"D(895mm)

x x x x

32-7/8'W(835mm) 32-7/8"W(835mm) 32-7/8"W(835mm) 32-7/8"W(835mm)

Electrical Cord and Plug

for 115V/60Hz/1ph 7 ft. (2.1 m) 7 ft. (2.1 m) 7 ft. (2.1 m) 7 ft. (2.1 m)

3 Wire Cord 3 Wire Cord 3 Wire Cord 3 Wire Cord

Grounding Plug Grounding Plug Grounding Plug Grounding Plug

Timer 15 minutes 15 minutes 15 minutes 15 minutes

section 1

description

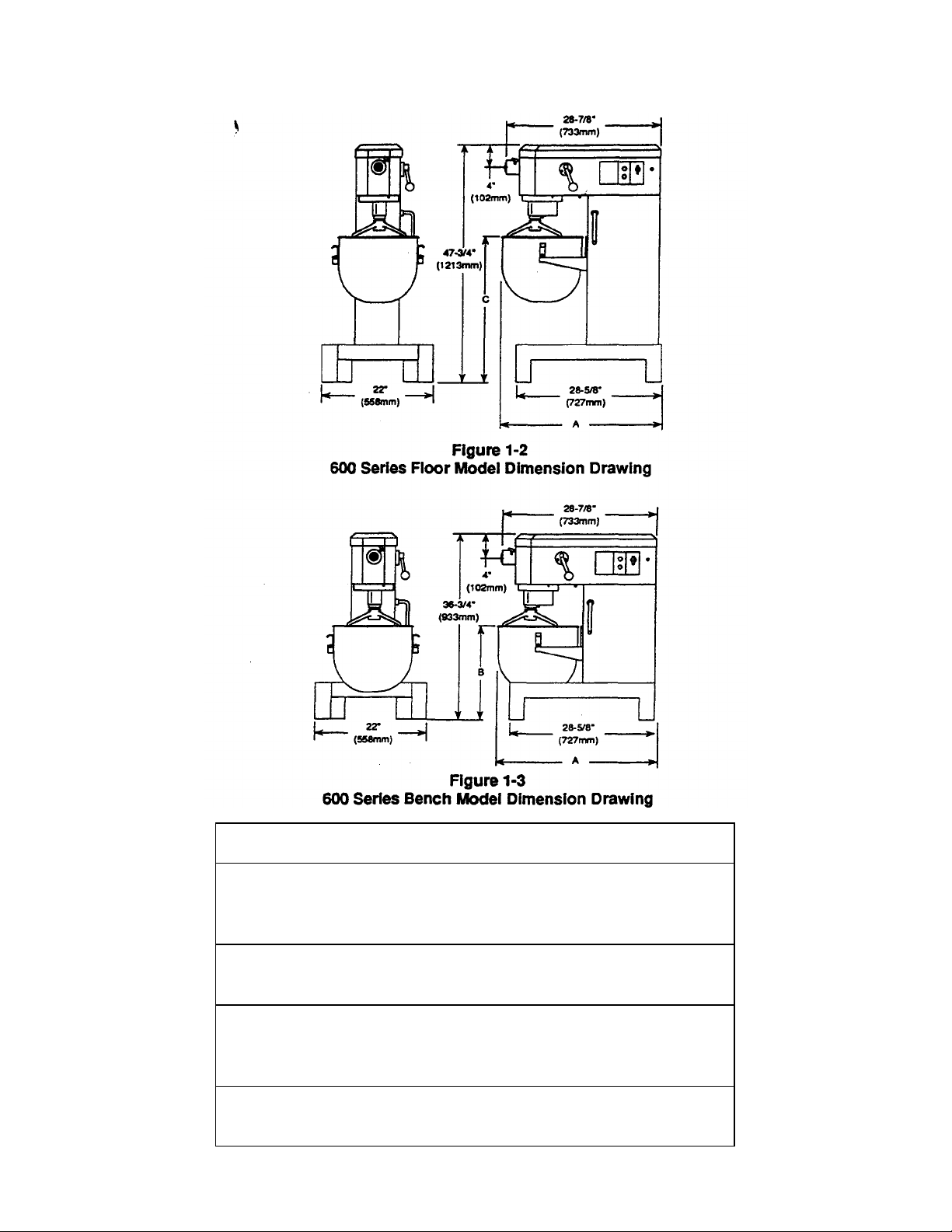

E.. Detail and Dimension Drawlngs

Dimension

Model 620 -

Floor

12 qt.

20 qt.

Bench

12qt.

20 qt.

Modal 630 -

Floor

20 qt.

30 qt.

Bench

20 qt.

30 qt.

A B C

28-3/4" n/a 29"

30-1/4" n/a 30"

28-3/4" 18" n/a

30-1/4" 19" n/a

30-1/4" n/a 29"

30-3/4" n/a 30"

30-1/4" 18" n/a

30-3/4" 19" n/a

(Refer to above drawings)

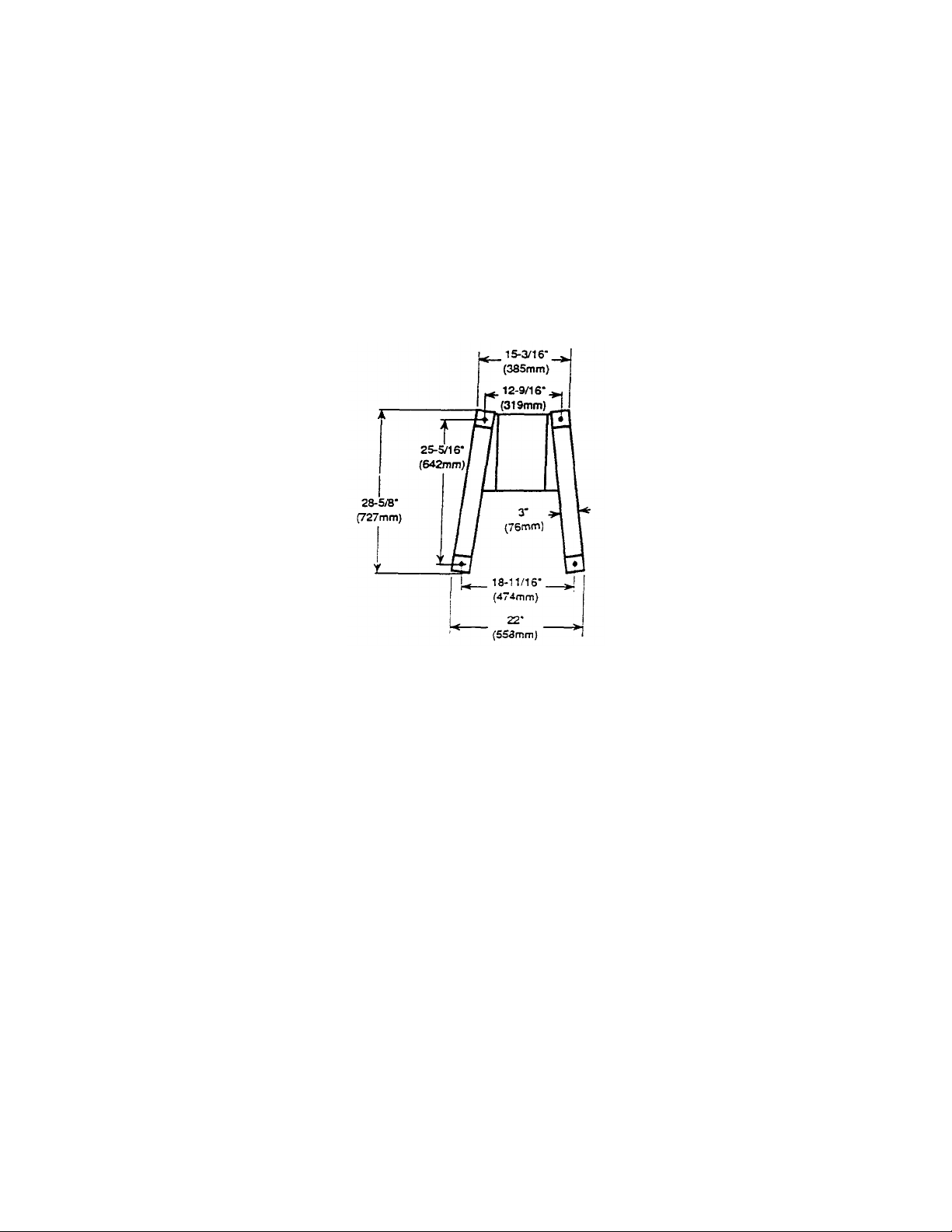

Figure 1-4

Floor Model & Bench Model Base Dimension Drawing

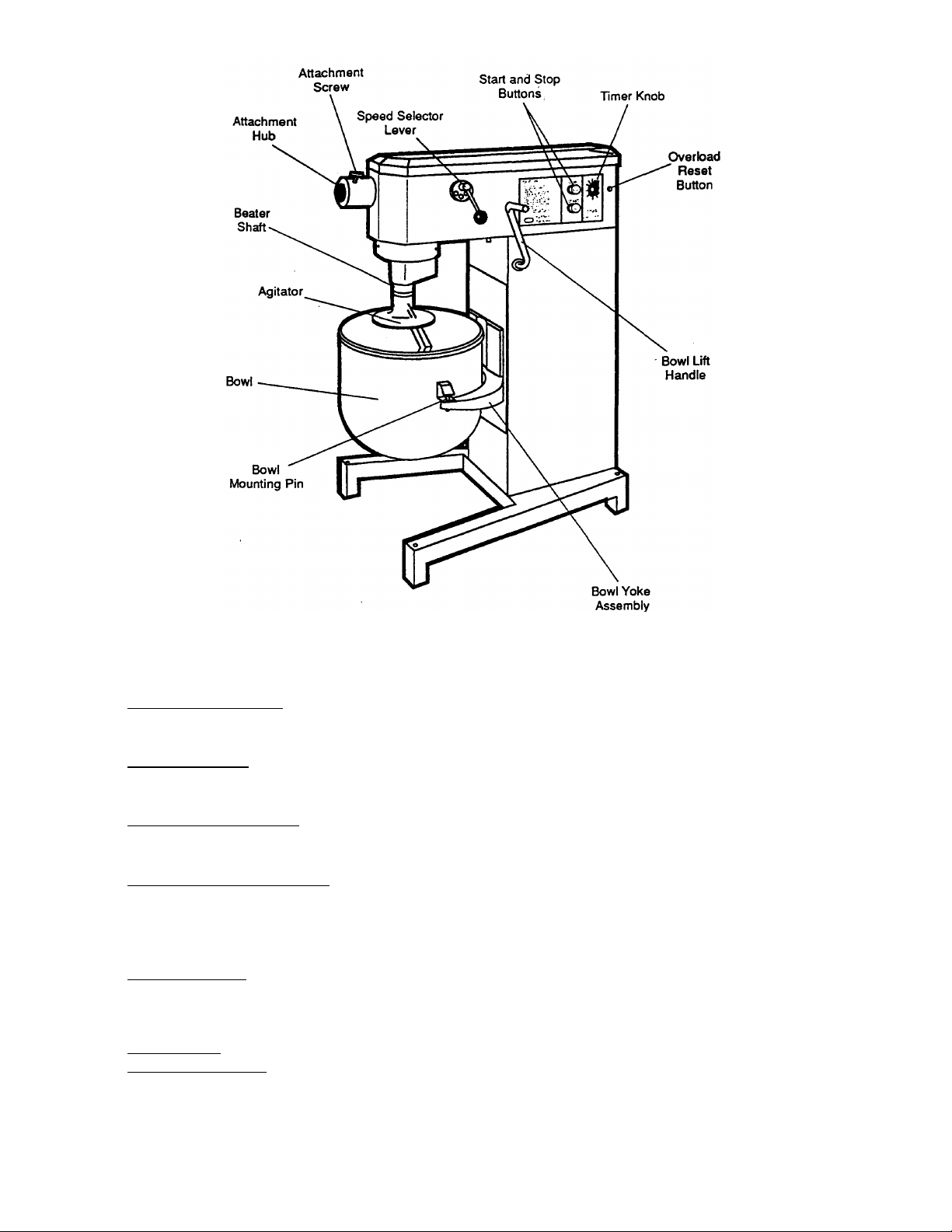

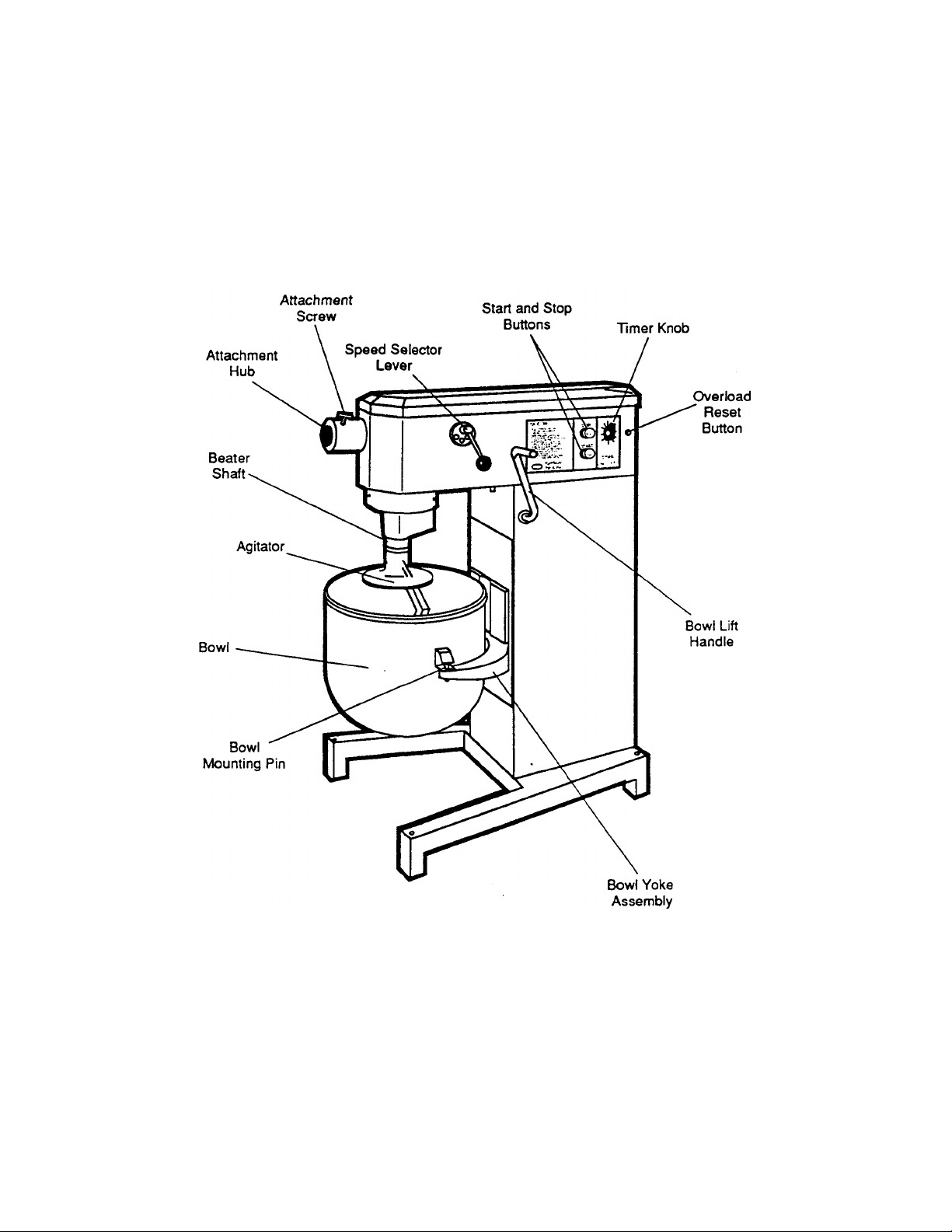

F. Component Function • Refer to Figure 1-5

Bowl Yoke Assembly - The bowl yoke assembly is used to hold the bowl in place. The Model 620

bowl yoke has a pin on each side and two at the rear to hold the bowl in place. The Model 630

bowl yoke has a pin on each side and no rear pins.

Bowl Lift Handle - The bowl lift handle is used to lift the bowl into place by lifting the bowl and yoke

assembly.

When the bowl is lifted into place it is at the correct height for mixing operations.

Speed Selector Lever - The speed selector lever is used to select one of the three speeds of the

transmission.

There is a neutral position between each speed setting.

START and STOP Buttons - The START and STOP Buttons are used to start and instantly stop

the mixer. TimerKnob-The timer knob is used to set the amount of time the mixerwill run and then

shut off automatically. Overload Reset Button -The overload reset button is used to reset the

motor after being stalled by an overload.

Also refer to the Operation Section of this manual.

Attachment Hub - The attachment hub is used for driving a vegetable slicer or chopper/grinder.

Agitator- There are six types of agitators used for various purposes, refer to Operation Section of

this manual

for agitator usage.

Beater Shaft - The beater shaft is used to hold agitators.

Bowl Mounting Pin - There are bowl mounting pins located on both sides of the bowl yoke

assembly. The

mounting brackets on the sides of the bowl are placed on the bowl mounting pins and are used to

support the bowl and keep it in a stationary position.

Figure 1-5

Component Location

section 2

Figure

2-1

installation

I. UNPACKING

A. Your Middleby Marshall GP Series Mixer will

arrive in a carton 54-3/8"H(1381 mm) x 351/4-D (895mm) x 32-7/8"W(835mm). Cut and

remove bands from around the carton.

Remove nails at bottom of carton to expose

the mixer and accessories. Before removing

mixer from the skid check packing list against

your order and inspect all Hems for damage

during transit. If any damage is found save all

packing materials and parts and arrangement

should be made to file a claim against the

carrier.

B. Loosen and remove the 4 lag bolts holding

the mixer onto the skid.

C. To process a valid claim the driver or other

representative of the delivering freight

company should immediately be notified and

requested to witness and certify in writing the

damage found. Interstate Commerce

Regulations require that the claim must be

initiated by the consignee.

D. After the damage has been certfied a

Middleby Marshall, Inc., Authorized

Service and Parts Distributor, should

immediately be contacted for assistance

in the repair or replacement of damaged

parts. Failure to do so could lead to added

costs.

lated room with proper storage facilities for

agitators and accessories.

C. Be sure to allow working space on the

controls side of the mixer.

D. It is recommended that the accessories all

be thoroughly washed and rinsed in very

hot, soapy water. The mixer should be

washed with mild soapy water and then

rinsed clean.

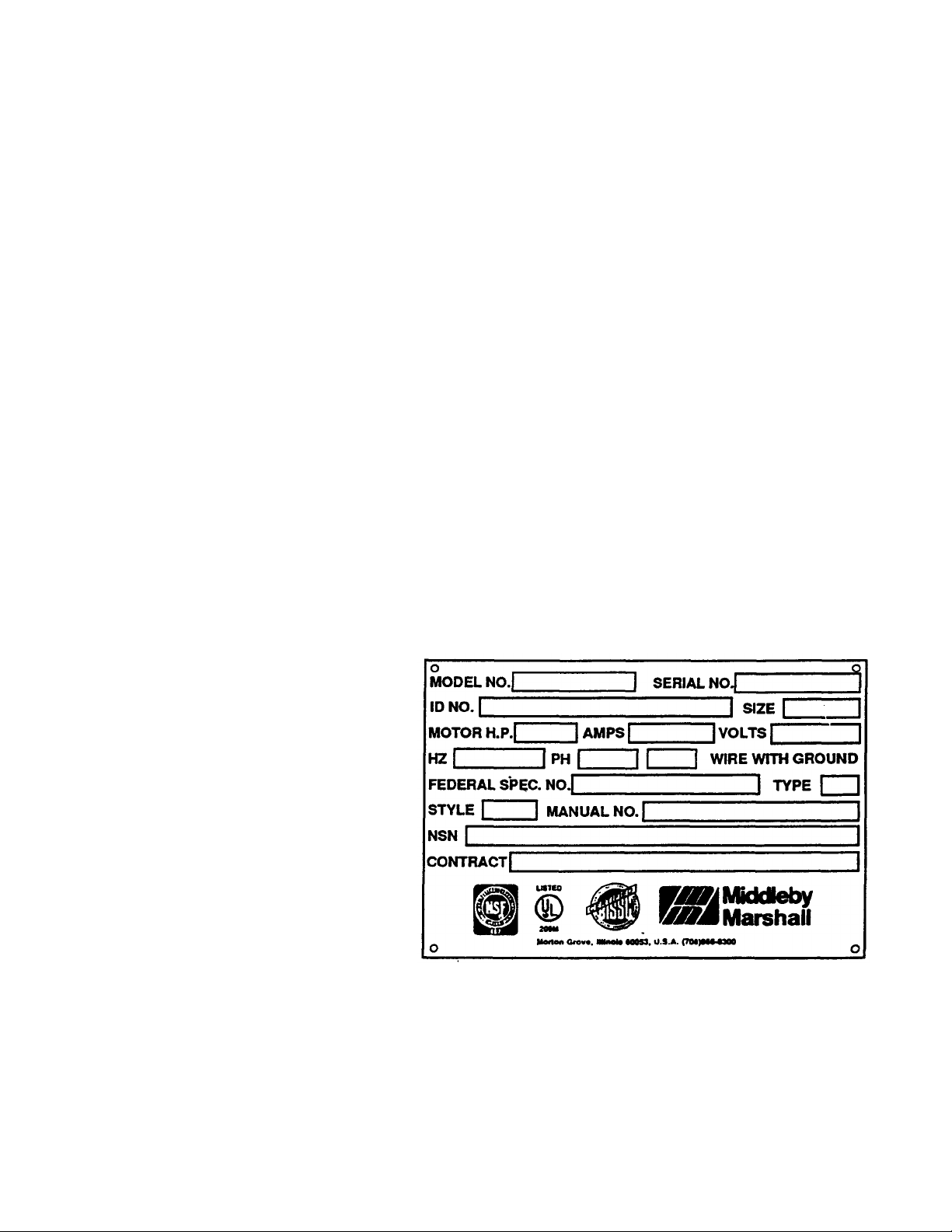

E. Electrical Connections - The Specification

Data Plate shown in Rgure 2-1 and located

on the outside of mixer must be noted for

proper electrical requirements before

connecting the mixer to the electrical

supply.

II. INSTALLATION

A. Bench and floor model mixers are both

designed to be placed on rigid level

surfaces. Since the operating weight of

this machine is approximately 250 tos

(112 kg), the bench or floor mounting

surface must be strong enough to support

this weight. The base of the mixer is

provided with mounting holes(refer to

base dimension drawing on Page 4) for

bolting to a bench, counter or floor, if

necessary.

B. Sanitary standards for food processing areas

require a clean, adequately lighted and venti

Specification Data Plate

section 2

III. PRE

-

OPERATION CHECKS

installation

• Machines with cord:

A 7 ft. (2.1 m) cord and grounding plug comes

standard with all 115V/60Hz/1ph mixers. On

mixers with other voltages local codes govern

type of cord and wiring to the mixer. Consult your

local electrician

• Machines without cord:

IMPORTANT:

All electrical connections must be made by a

certified electrician.

1. Amps - Check amp rating on

mixer Specification Data Plate to

properly size your electrical wiring

and circuit breaker.

2. Voltage (115V, 220V, etc.) and

phase (1 or 3 phase) on mixer

Specification Data Plate must

correspond with voltage and

phase of your power supply.

Figure 2-2 Correct Planetary

Rotation

NOTE: If your machine is equipped with a 15 minute

timer turn the knob clockwise to the "Hold'position. The

mixer motor can then be operated manually for the preopera-tion checks by pushing the start and stop switch.

A. Before attaching any accessories to the mixer

make certain that the direction of rotation of the

planetary corresponds to the arrow located on the

head of the mixer as shown in Figure 2-2. Refer to

Section 3 for operating instructions to oerform the

above check.

3. Type of power supplied (60Hz

or 50Hz) must correspond with

rating on Specification Data Plate.

IMPORTANT:

The mixer must be wired and

grounded in accordance with

local codes, or in the absence of

local codes, with ANSl/NFPA latest edition.

4. This mixer has been completely

internally wired at the factory. To put into operation,

connect the power supply to mixer. This is the only

connection required.

If the planetary is not rotating in the proper

direction you must change wiring. On single

phase motors change wire connection as per

instructions inside motor cover. On three phase

motors reverse any two of the three line leads.

B. It is recommended that each of the mixer bowls,

agitators and accessories be assembled onto

the mixer to become familiar with their installation. Refer to Operation Section 3 of this manual

for bowl, agitator and accessory installation.

C. Operate the machine with an empty mixing bowl

and agitator installed in place to verify that there

is clearance between the rotating agitator and

inside of bowl. The agitator and bowl clearance

has been set at the factory and should be approximately 1/4".

section 3

operation

I. MIXER SET-UP

Figure 3-1

Controls and Components

Loading...

Loading...