Instrumentarium Dental OP-200 Troubleshooting manual

Orthopantomograph

®

Orthoceph

Troubleshooting Manual

OC200 & OC200 D

®

OP200 & OP200 D

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

200214 rev 3

D500211, 3

Approved

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

Copyright Code: 200214 rev 3 Date: 22 May 2008

Document code: D500211 rev 3

Copyright © 05/2008 by PaloDEx Group Oy.

All rights reserved.

Orthopantomograph® and Orthoceph® are registered trademarks

of Instrumentarium Dental. U.S. patents 4,641,336; 5,016,264;

5,425,065, 5,444,754, 6,731,717 and 6,829,326. German patent

4,344,745. Finnish patents 112594 and 114383. Windows

trademark of Microsoft Corporation in the United States of

America and other countries. Pentium

of Intel Corporation. Iomega

®

Jaz® is a registered trademark of

Iomega Corp.

Documentation, trademark and the software are copyrighted

with all rights reserved. Under the copyright laws the

documentation may not be copied, photocopied, reproduced,

translated, or reduced to any electronic medium or machine

readable form in whole or part, without the prior written

permission of Instrumentarium Dental .

®

is a registered trademark

®

is

The original language of this manual is English.

Instrumentarium Dental reserves the right to make changes in

specification and features shown herein, or discontinue the

product described at any time without notice or obligation.

Contact your Instrumentarium Dent al repr esent ativ e fo r the most

current information.

Manufactured by Instrumentarium Dental

Nahkelantie 160 (P.O. Box 20)

FI-04300 Tuusula

FINLAND

Tel. +358 45 7882 2000

Fax. +358 9 851 4048

For service, contact your local distributor.

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

Table of Contents

1 General trouble shooting............................................................................................1

1.1 OP200 Does not operate at all..............................................................................1

1.2 No exposure, no error message, but movements ok............................................1

1.3 Exposure ok, but no movements...........................................................................2

1.4 OP200 Malfunctions, but no error message..........................................................3

1.5 Positioning lights do not operate...........................................................................3

1.6 Cephalostat programs cannot be selected............................................................4

1.7 DAP reading in Control panel is incorrect.............................................................4

1.8 Ceph lateral program can’t be selected................................................................4

1.9 Automatic collimator not detected (digital unit) ....................................................5

1.10 Problem with film image quality.............................................................................5

1.11 Problems with digital image quality.......................................................................7

1.11.1 Image is grainy or noisy.............................................................................7

1.11.2 Image is striped..........................................................................................8

1.11.3 Image is too dark / light..............................................................................9

2 Electric trouble shooting..........................................................................................11

2.1 Microswitches and position indicators.................................................................11

2.2 General, failure messages..................................................................................1 1

2.3 Film unit failure messages ..................................................................................14

2.3.1 Ch 1 CAS.................................................................................................14

2.3.2 Ch 2 CAS (film unit).................................................................................16

2.3.3 Ch 3 COL (film unit) ..............................................................................19

2.3.4 Ch 4 COL..............................................................................................22

2.3.5 Sy 25 AEC..............................................................................................24

2.3.6 Sy 28 PoC..............................................................................................25

2.3.6.1 Cassette movement, principle.................................... .... ...........26

2.3.7 Sy 30 PoH..............................................................................................27

2.3.7.1 Rack movement, principle.........................................................29

2.4 Digital unit failure messages...............................................................................29

2.4.1 Ch 1 PC....................................................................................................29

2.4.1.1 Fiber test....................................................................................32

2.4.2 Ch 2 PAc (digital unit) ..................... .... ..... ..... ............................ .... ..... ......33

2.4.3 Ch 2 CEc (digital unit)..............................................................................33

2.4.4 Ch 3 COL (digi).....................................................................................35

2.4.5 Ch 15 bPL................................................................................................37

2.4.6 Ch 17 HSP...............................................................................................38

2.4.7 Sy 25 AEC (digital unit)..........................................................................38

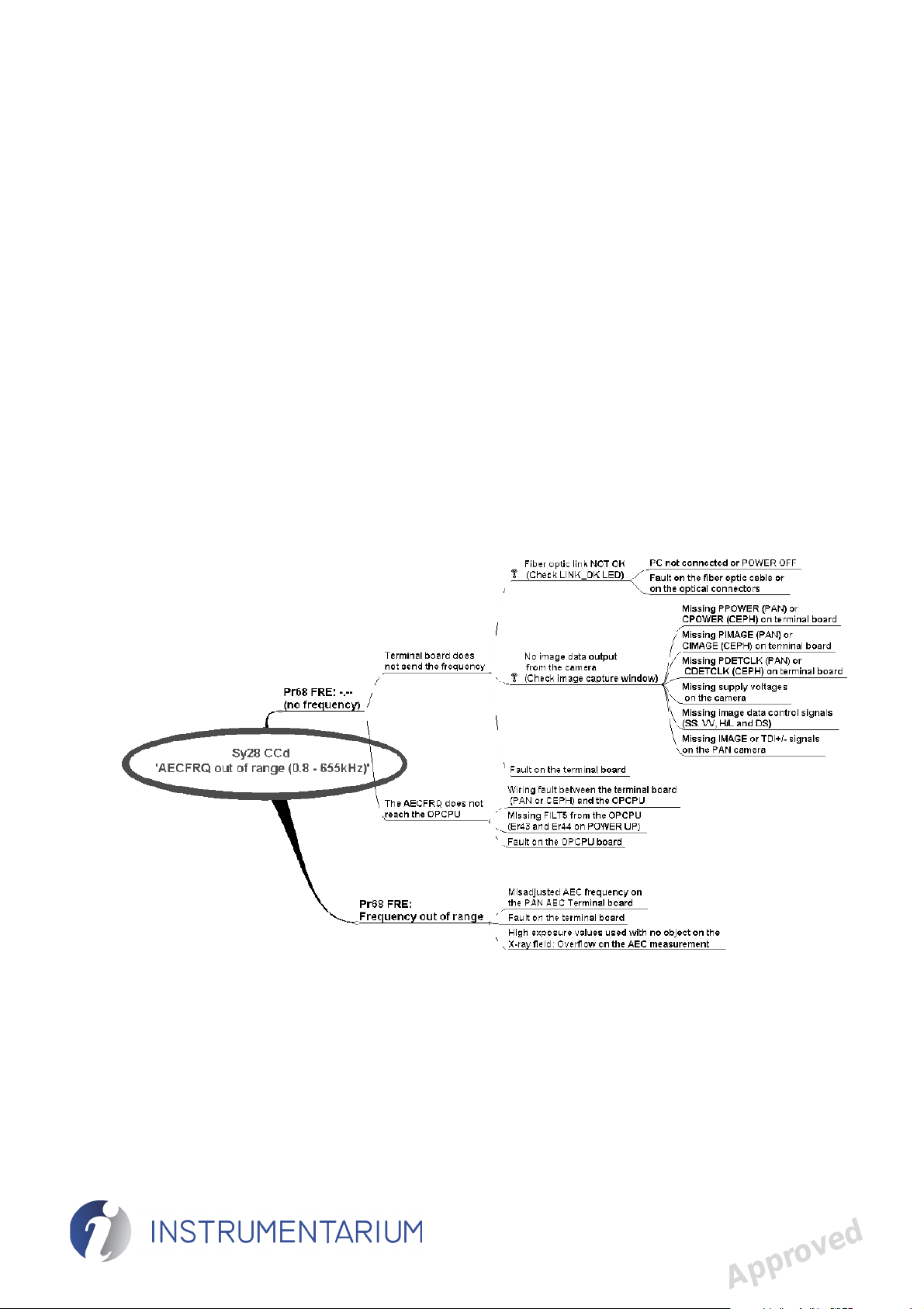

2.4.8 Sy 28 CCd................................................................................................40

2.4.8.1 AEC Frequency generation, block diagram......................... ..... .44

2.4.9 Sy 30 PoC................................................................................................45

2.4.10 Sy 38 COL................................................................................................47

2.4.11 Sy 32 PoA................................................................................................49

2.5 Digital image chain trouble shooting...................................................................52

2.6 Digital image faults ..............................................................................................55

2.6.1 Detector fail..............................................................................................55

2.6.2 Data bits missing.................................................... ..... .... .........................56

2.6.3 PC............................................................................................................58

200214 rev 3 Instrumentarium Dental i

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

2.6.4 Poor beam alignment............................................. ............................ ..... .61

2.7 Common errors...................................................................................................63

2.7.1 Ch 5 *** .................................................................................................63

2.7.2 Ch 6 POS...............................................................................................63

2.7.3 Ch 7 *** .................................................................................................66

2.7.4 Ch 8 PSE ..............................................................................................67

2.7.5 Ch 9 rEo................................................................................................68

2.7.6 Ch 11 PAr.................................................................................................69

2.7.7 Ch 12 dCC ...............................................................................................70

2.7.8 Ch 16 StP.................................................................................................71

2.7.9 Sy 20 ***...................................................................................................71

2.7.10 Sy 21 HHo................................................................................................73

2.7.11 Sy 22 Arc..................................................................................................74

2.7.12 Sy 23 Inu..................................................................................................76

2.7.13 Sy 24 FIL..................................................................................................77

2.7.14 Sy 26 EEP................................................................................................78

2.7.15 Sy 27 Por .................................................................................................78

2.7.15.1 Rotation movement, principle...................................................80

2.7.16 Sy 29 PoL.................................................................................................82

2.7.16.1Linear movement, principle........................................................83

2.7.17 Sy 31 PoU................................................................................................84

2.7.17.1Carriage movement, principle....................................................85

2.7.18 Er 40 Core Module...................................................................................86

2.7.19 Er 41 Core Module...................................................................................87

2.7.20 Er 42 Core Module...................................................................................88

2.7.21 Er 43 *** ...................................................................................................88

2.7.21.1Filament Control Board self check principle..............................89

2.7.22 Er 44 FIL ..................................................................................................90

2.7.23 Er 45 InP..................................................................................................9 1

2.7.24 Er 46 PAy.................................................................................................93

2.8 Indicators and test points....................................................................................93

2.8.1 Led-indicators...........................................................................................93

2.8.2 Test points................................................................................................94

3 Appendix A: Optical Link Test..................................................................................95

3.1 PCI board driver check........................................................................................96

3.2 PCI board, PAN-AEC Term inal bo ard an d Ceph Term inal bo ard l eds status che ck

96

3.2.1 Standard PCI board.................................................................................96

3.2.2 Low profile PCI board

(combined supply voltage led) .................................................................97

3.2.3 PCI board (60187) leds status check.......................................................97

3.2.4 PAN AEC Terminal board (60247) leds status check..............................97

3.2.5 Ceph t erminal board (60191) leds status check

(optional)..................................................................................................98

3.3 PCI Board Fiber Test ..........................................................................................98

3.4 PAN AEC Terminal Board (60247) Fiber Test..................................................100

3.5 Ceph Terminal Board (60191) optical loop test (optional).................................102

ii Instrumentarium Dental 200214 rev 3

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

1 General trouble shooting

Trouble shooting guides listed in this manual are for

solving imaging problems. In case there is no solution

found, contact the technical customer service of the

manufacturer.

Parts are identified in the wiring diagram with letter(s)

followed by number eg. cable or capacitor (C), coil/inductor

(L), fuse (F), lamp (LA), motor (M ), switch (S), coile d cable

(SC), and connector (X).

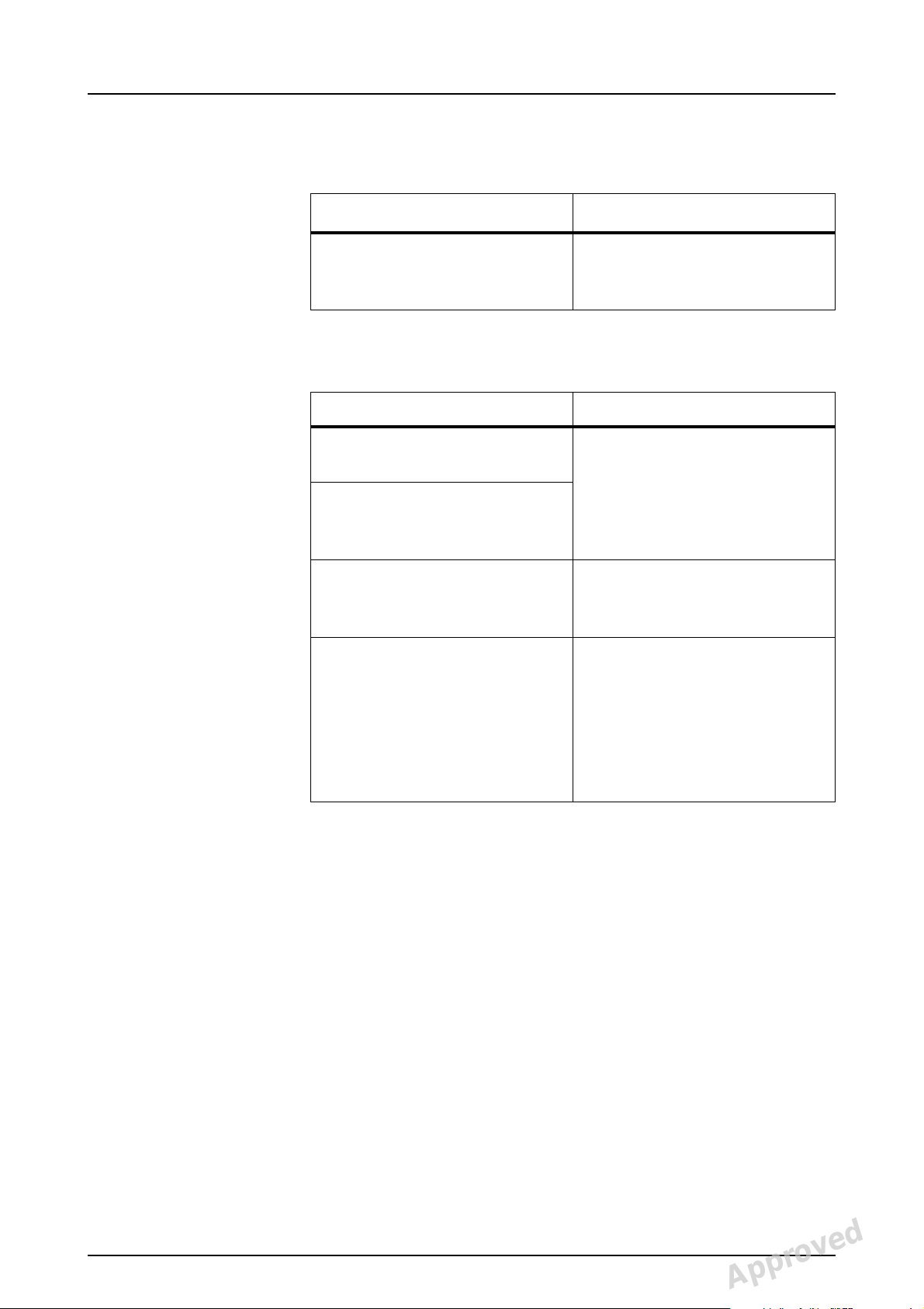

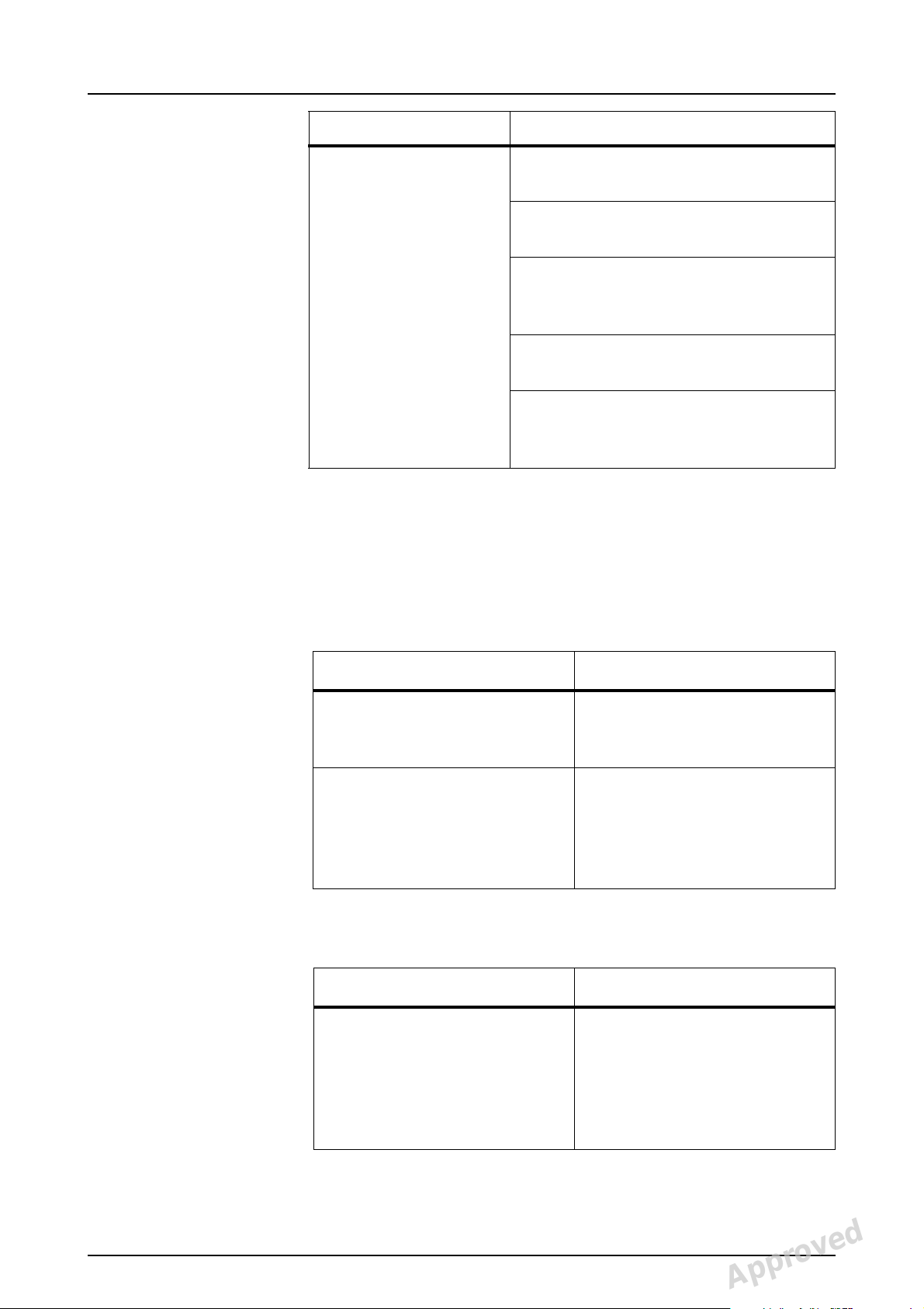

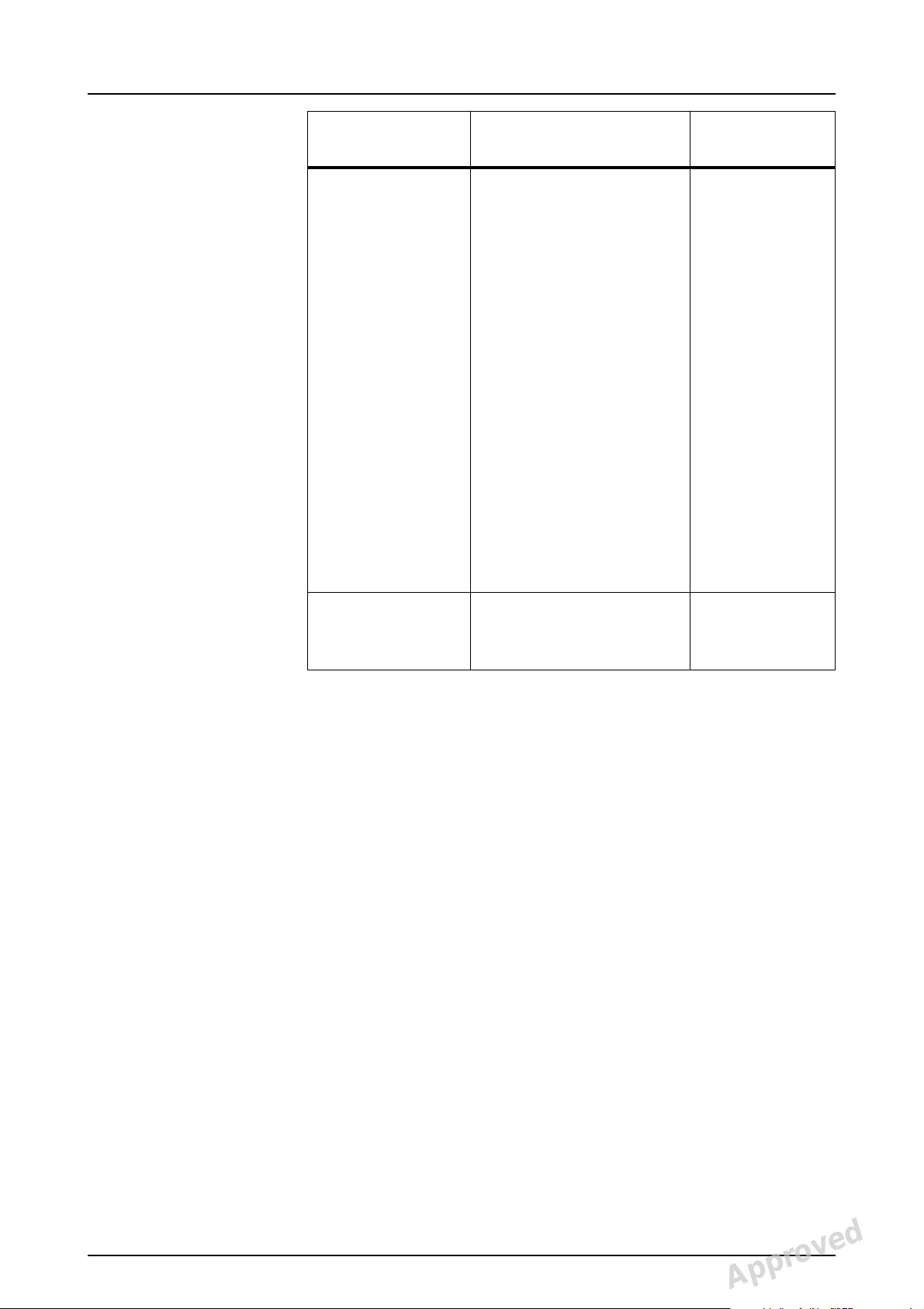

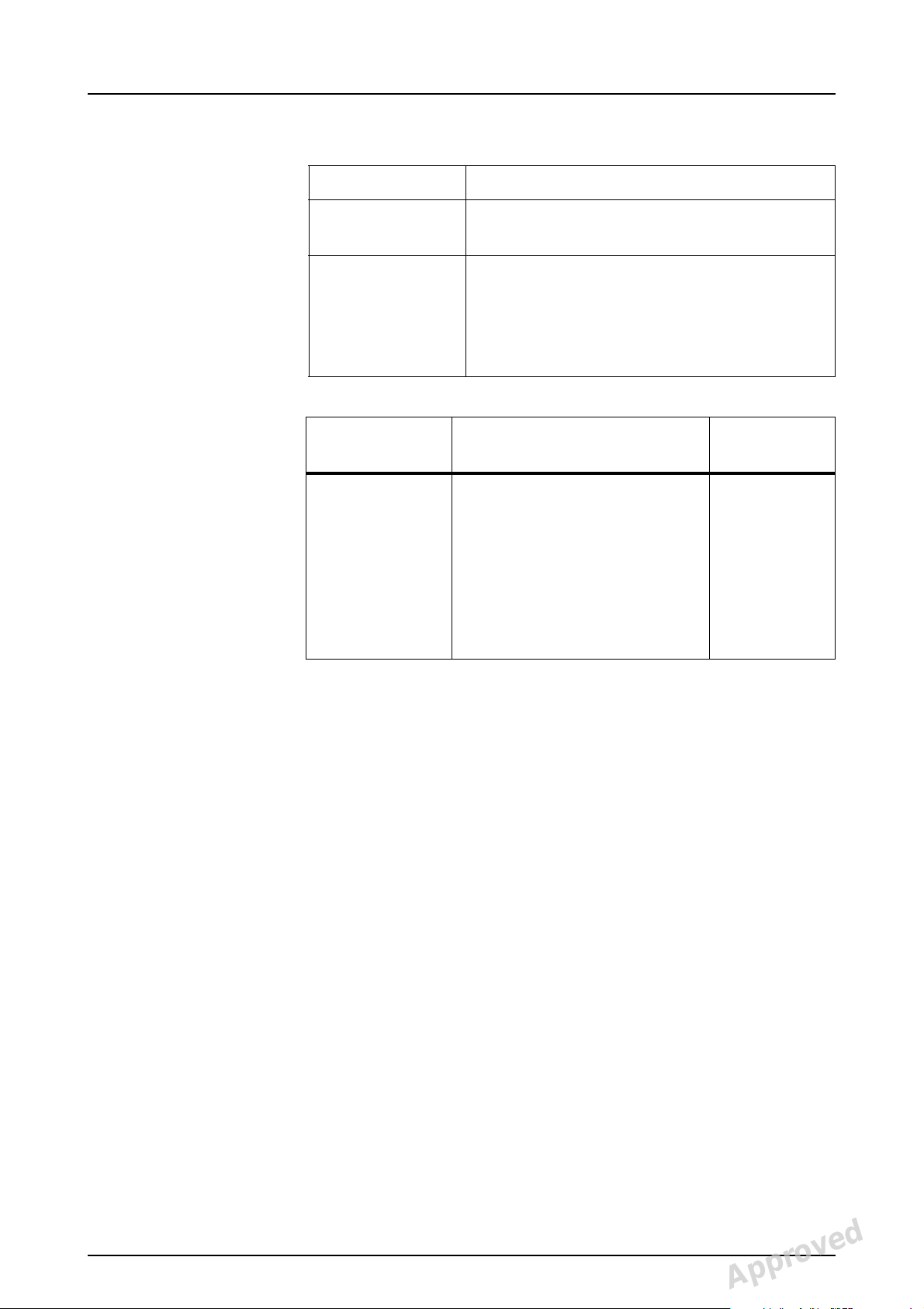

1.1 OP200 Does not operate at all

Possible causes: Check that:

1 General trouble shooting

No power or

OP200 is not

receiving power.

Power switch

turned off.

Wrong mains

voltage setting.

Problem with

secondary

voltages.

Emergency stop

switch is

pressed.

Site’s circuit breakers are ok

Mains cables are connected inside the

OP200 and the unit is properly connected

to the mains voltage.

Mains fuses are ok and have the correct

rating.

The power on/off switch is at I position.

Green indicator under the carriage should

be lit.

OP200 mains voltage setting on the

Power Supply Board matches the power

line.

Fuses of secondary voltages are ok and

that individual circuit boards are receiving

the power (green LED’s).

Make sure the problem, why the switch

was pressed, is solved before relea sing

the switch and turning the unit on.

1.2 No exposure, no error message, but

movements ok

Possible causes: Check

Remote exposure

button does not

operate.

200214 rev 3 Instrumentarium Dental 1

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

Signal EXPSW switch and its

wiring. Use Sr 74 IOC.

Approved

D500211, 3

1 General trouble shooting

Possible causes: Check

Panel exposure button

does not operate.

Unit is used in Test

mode.

Signal PNLEXPSW switch and its

wiring. Use Sr 74 IOC.

The exposure mode selecti on in

the control panel. Select A or M

instead.

Installation. The I/O board jumper X11. Set X11

jumper to OFF or turn S2 to OFF.

Exhibition mode is set when

exposure lights are on but no

buzzer is heard during the

exposure.

Problem with Core

Module signal

The generator and exposure

signals. Replace boards if needed.

PREHREL. Sometimes

this error does not

generate an error

message.

Problem with Inverter

Board signals KVREF

or KVFB. Sometimes

KVREF signal line broken or KVFB

D10 shorted. Replace Inverter

Board.

this error does not

generate an error

message.

1.3 Exposure ok, but no movements

Possible causes: Remedy:

Unit is in the user

programming mode.

Unit is in the service

programming mode.

Film unit is in cephalostat

mode.

Exit from the user

programming mode to the

normal operating mode by

pressing and holding OK

button for three seconds.

Exit from the service

programming mode to the

normal operating mode by

pressing and holding OK

button for three seconds.

Tests. Normal operat ion.

2 Instrumentarium Dental 200214 rev 3

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

1 General trouble shooting

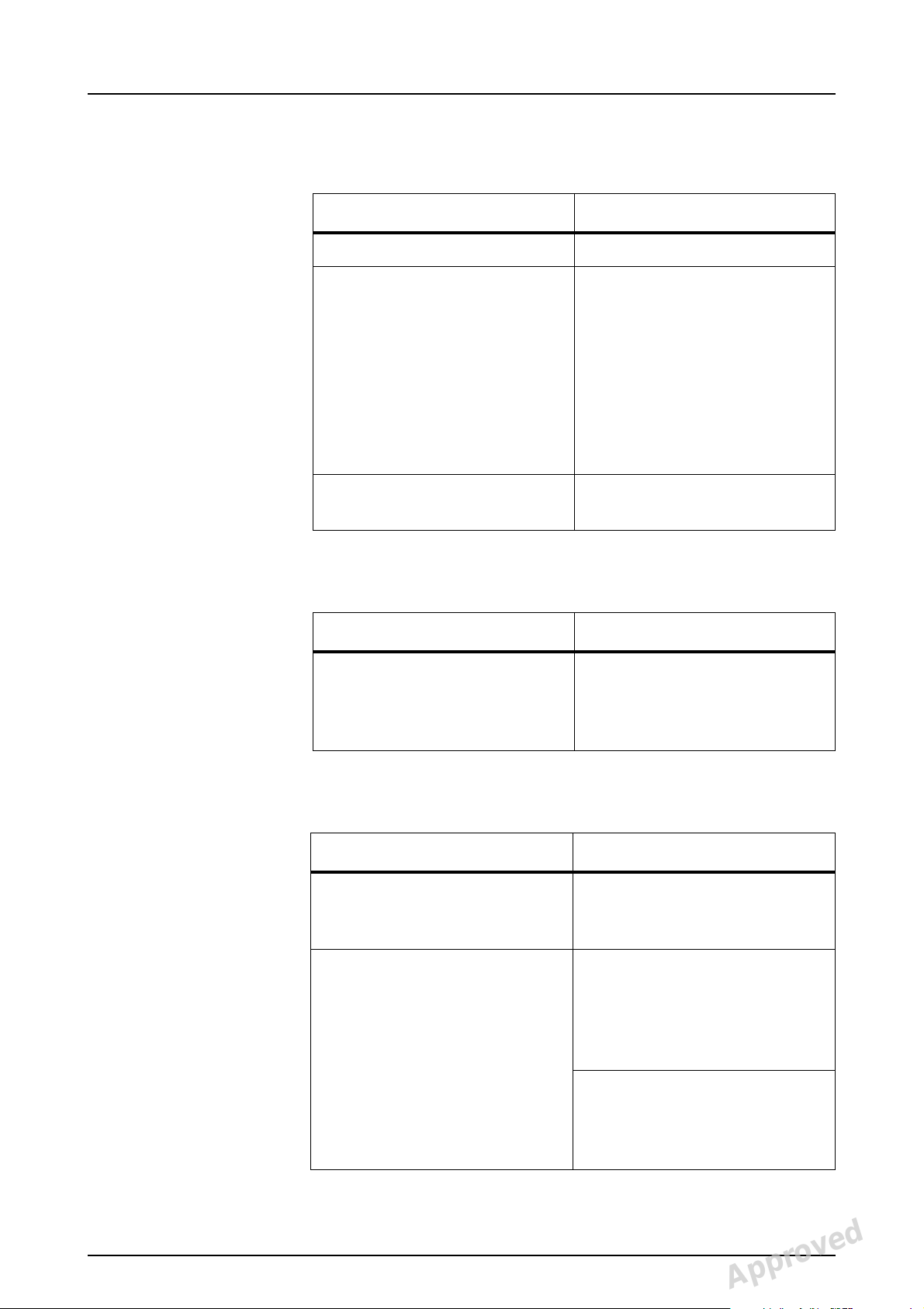

1.4 OP200 Malfunctions, but no error

message

Possible causes: Remedy:

Problem with Core Module

memory contents.

Set Pr 53 nor to on. If this

does not help, replace the

Core Module.

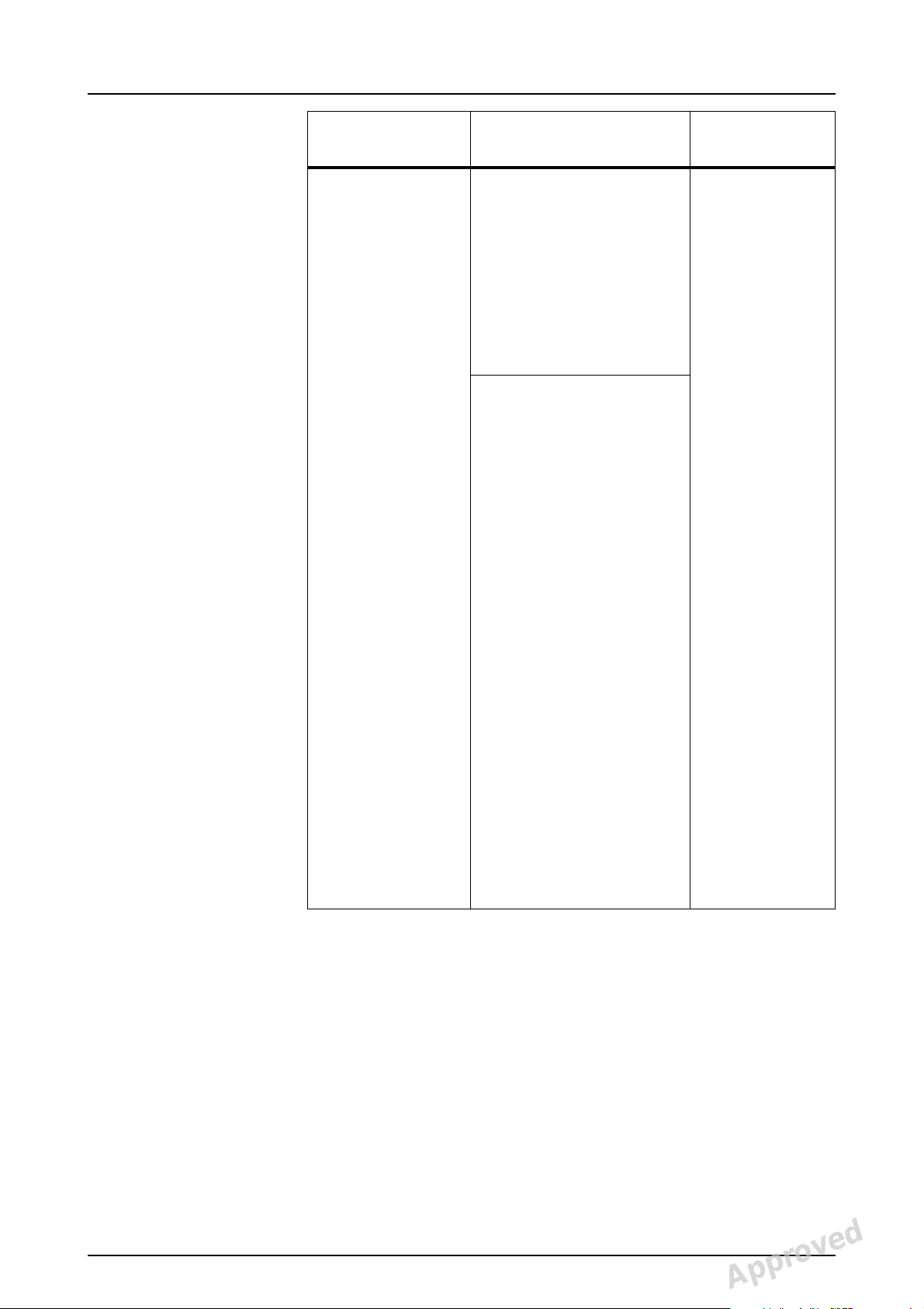

1.5 Positioning lights do not operate

Possible causes: Remedy:

Collimator in CEPH or QA

position. No ligh ts

Collimator in TOMO position.

Only TOMO laser lights

operate.

Problem with lights and their

wiring.

Problem with pos.panel

connectors or lights key(s).

Select the PAN collimator.

Check the 12 VAC power line

wiring, Interface Boar d and

X19 signals.

Check the panel keys and

wiring. Check both side

panels.

In CEPH mode check the

collimator po sition - if CEPH make sure that ear holders

are in lateral position.

NOTE! See patient positioning instructions in OP200 User

Manual.

200214 rev 3 Instrumentarium Dental 3

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

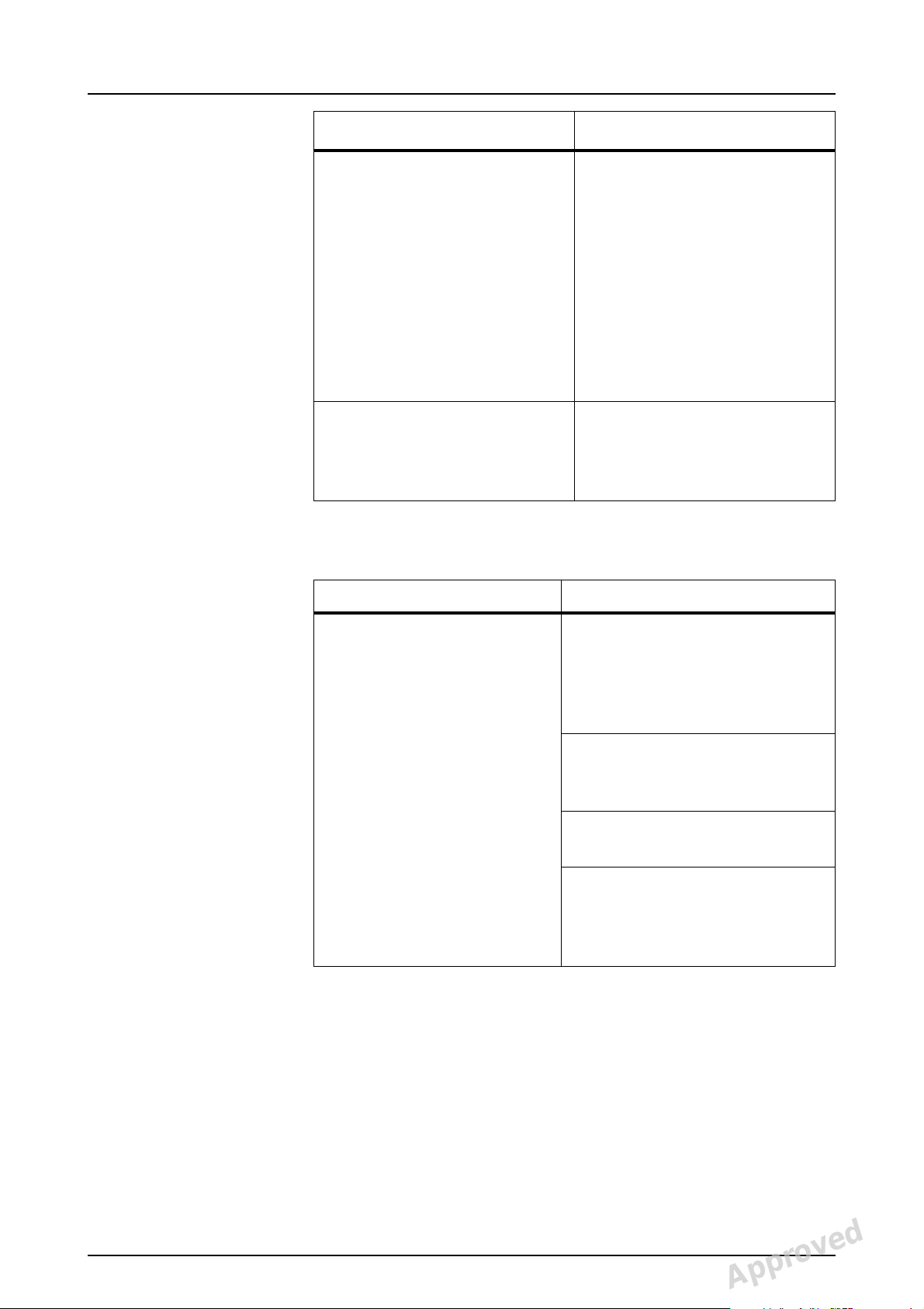

1 General trouble shooting

1.6 Cephalostat programs cannot be

selected

Possible causes: Remedy:

Collimator in wrong position. Check the position.

Cephalostat slot is not

detected.

Check the jumper position on

I/O board.

Note! If ceph side selection

jumper is not installed, the

collimator apertures in Sr 82

COL service progra m are no t

able to be determined (film

unit).

Cephalostat collimator is not

Check collimator position.

ready.

1.7 DAP reading in Control panel is incorrect

Possible causes: Remedy:

Either radiation ra te con sta nt

is not set or collimator

aperture settings undefined.

Check collimator aperture

settings and radiation rate

constant in Sr 82 COL and S r

78 THA service programs.

1.8 Ceph lateral program can’t be selected

Possible causes: Remedy:

Core Module doesn’t sense

LAT/PA switch changes.

Overexposed image at the

end of CEPH LAT program.

Check Ceph LAT-switch

function. Check Ceph main

cable in Digital unit.

Check that Ceph LAT-switch

senses LAT position - if not there isn’t soft-tissue

compensation in Ceph LAT

image.

Check that nasion

potentiometer frequency

(caecfrq) is detected by Core

Module

4 Instrumentarium Dental 200214 rev 3

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

1 General trouble shooting

1.9 Automatic collimator not detected

(digital unit)

Check detected collimator type by entering service

program "Sr 82 COL". If automatic collimator is detected,

text "Auto" along with collimator position information is

displayed. Otherwise, if manu al collimator i s detected, text

"Std" is displayed.

Possible causes: Remedy:

Cable or connector

fault.

Check that pins 5 and 10 are shorted

on connector X114 on C76

(autocollimator cable).

Embedded SW

version too old.

Check that the unit SW revision is

R2.5 or newer. Update if necessary.

1.10 Problem with film image quality

Possible causes: Remedy:

Problem with patient

positioning

Technique fact ors not

correct or not optimal

for film-screen

combination.

See OP200 User Manuals for detail s.

Check that image density is ok for

AEC and manual modes.

Check that constant contrast value

(GCO) is set optimum for film-screen

used. Lower value increases

contrast.

Problem with beam

alignment

200214 rev 3 Instrumentarium Dental 5

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

Check the AEC offset for each

program and density settings.

Check that the preprogrammed

exposure values match to the needs

and preferences of the customer.

Check that a newly taken Quality

Assurance film compares to the

customer’s QA reference film.

Verify that OP200 panoramic beam

alignment is ok.

Verify that OC200 cephalometric

beam alignment is ok.

D500211, 3

Approved

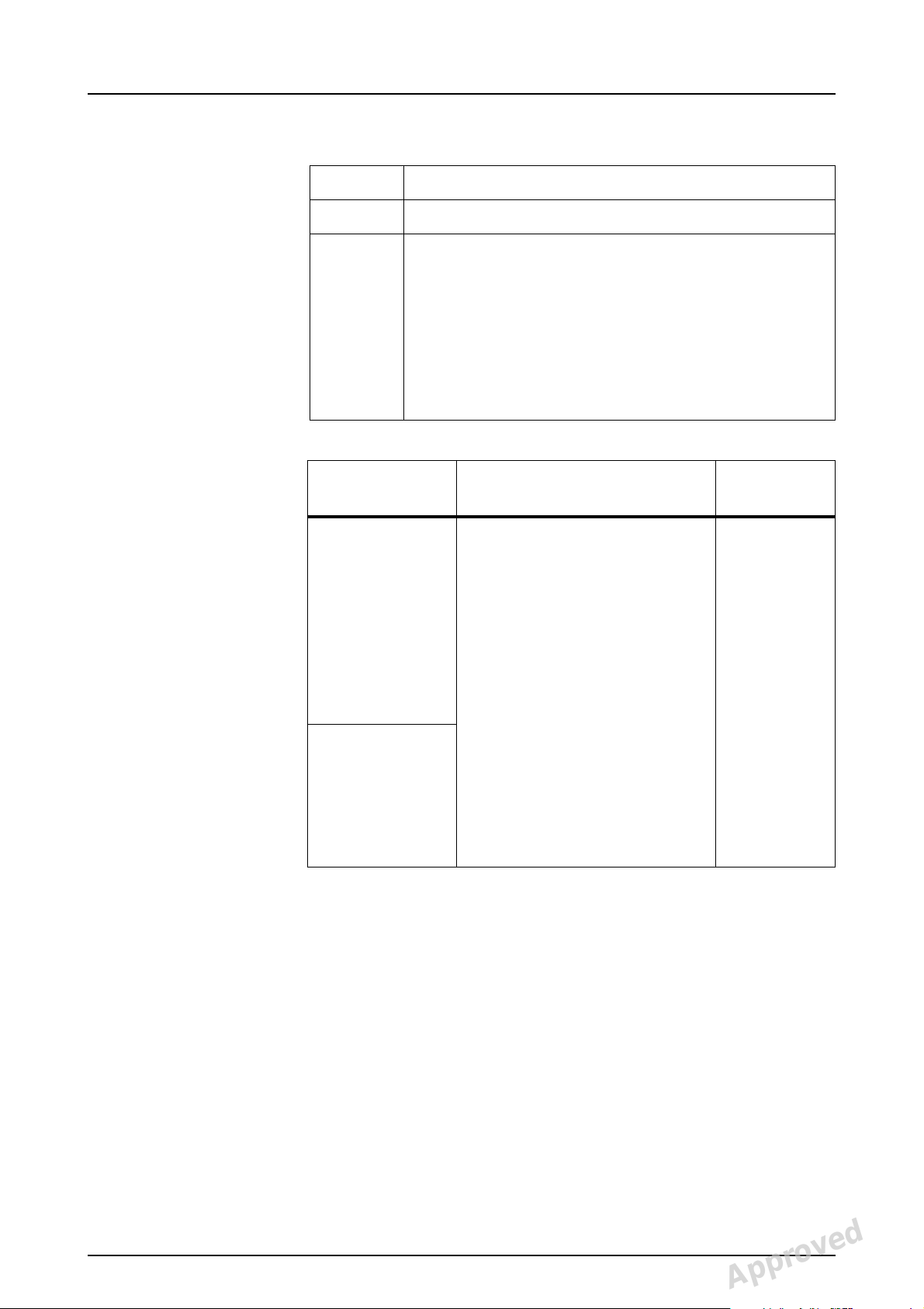

1 General trouble shooting

Possible causes: Remedy:

Problem with

cephalostat

Check that OC200 cephalostat head

assembly is lo c k e d .

Verify that OC200 ear holder

adjustment is ok.

Soft tissue not clear in

ceph image

Check that the nasion support value

mathces with the soft tissue filter

value.

Dark room Check that dark room is light tight.

Check that proper safelight (red

color) and bulb max. 15W are used.

Check that the green lights of OP200

are not fogging the film being loaded,

if OP200 and film processor are in

the same room.

X-ray film Verify that film is processed

immediately after exposure.

Check that films are stored in a cool

dry dark place in vertical position.

Opened film packages are light tight.

Film lot is not expired. Older lot

should be used first.

Film processor Check that processing chemicals

strength and temperature are ok.

Check that processor chemicals are

changed frequently.

Check that processor operation lights

are not fogging the film.

Check that processor is maintained

according to the manufacturer’s

recommendation.

6 Instrumentarium Dental 200214 rev 3

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

1 General trouble shooting

Possible causes: Remedy:

Film Cassettes Check that cassettes are light tight

and do not have dents.

Verify that intensifying screens are

clean and without scratches.

Check that cassette has been

mounted with fl at side to wards the xray tube.

Check that panoramic cassette lid

does not have lead sheet inside it.

Verify that intensifying screens and

film used match to each other.

Please consult the dealer for details.

1.11 Problems with digital image quality

High quality images with sharp contrast and good detail

present optimum diagnostic information. Images with less

quality are usually the result of one or more common

problems, which are described here.

Possible causes: Remedy:

Sharp image layer is not

correct

See OP200 / OC200 User

Manuals for patient

positioning details

Overexposed image at the

end of CEPH LAT program

Check that Ceph LAT-switch

senses LAT posi tion - if not there isn’t soft-tissue

compensation in Ceph LAT

image.

1.11.1 Image is grainy or noisy

Possible causes: Remedy:

Not enough dose to achieve

diagnostic image i.e. x-ray

beam not correctly positione d

compared to the camera

200214 rev 3 Instrumentarium Dental 7

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

Verify that OP200 pan oramic

beam alignment is ok.

Verify that OC200

cephalometric beam

alignment is ok. Check AEC

frequency value.

D500211, 3

Approved

1 General trouble shooting

Possible causes: Remedy:

Too low exposure values Increasing PCo / gCo and

density settings decreases

image noise.

Check the AEC offset and

density settings.

Check that the

preprogrammed exposure

values match to the needs

and preferences of the

customer.

Check AEC frequency value.

Broken main cable, Inverter

Board or Filament Control

Board

Check that darkness of the

columns in a newly taken

Quality Assurance reference

image increases stepwise

1.11.2 Image is striped

Possible causes: Remedy:

Too high exposure values Check that your exposure

settings are reasonable overexposure makes image

striped in the areas where is

little media on the beam.

Decreasing PCo / gCo and

density settings decreases the

amount of stripes in image.

Check the AEC offset and

density settings.

8 Instrumentarium Dental 200214 rev 3

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

Check that the

preprogrammed exposure

values match to the needs and

preferences of the customer.

D500211, 3

Approved

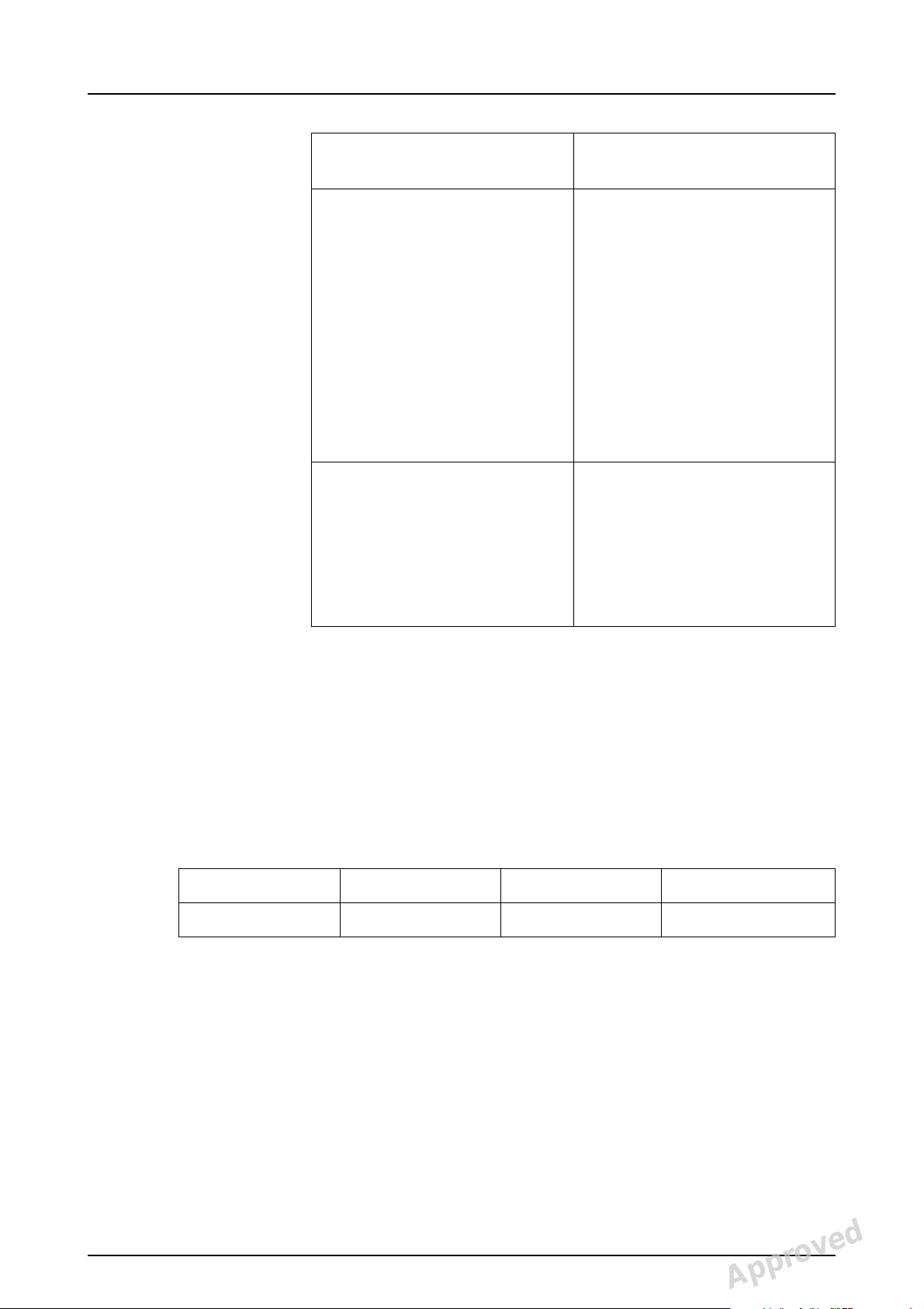

1 General trouble shooting

1.11.3 Image is too dark / light

Possible causes: Remedy:

Monitor settings are wrong See monitor and Cliniview

user manual for preferred

settings

Verify that you are usin g min.

24-bit colour. Less colours

makes gray scale changes

quantized. For detailed

decription see Windows and /

or graphics board installation

manuals.

Cliniview settings are wrong See Cliniview user manual

for preferred and optimized

settings

200214 rev 3 Instrumentarium Dental 9

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

1 General trouble shooting

10 Instrumentarium Dental 200214 rev 3

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

2 Electric trouble shooting

The OP200 has many safety functions and features

assuring the safe operation of the equipment. In the event

of certain user failures or system malfunction the unit does

not produce x-rays and a failure code is displayed on the

control panel.

2.1 Microswitches and position indicators

There are 15 to 18 microswitches a nd

opto sensors in OP200 models to

detect the position of the various

movements of the equipment. All

switches are wired to the I/O Board,

and the microprocessor reads the

status of the switches every 20 ms. The

name of the swit ch is the same as the

name of the signal to the

microprocessor. Open switch is 5 V,

and closed switch is 0 V signal level in I/O Board. Their

operation can be checke d by using Servic e Prog ram Sr 74

IOC.

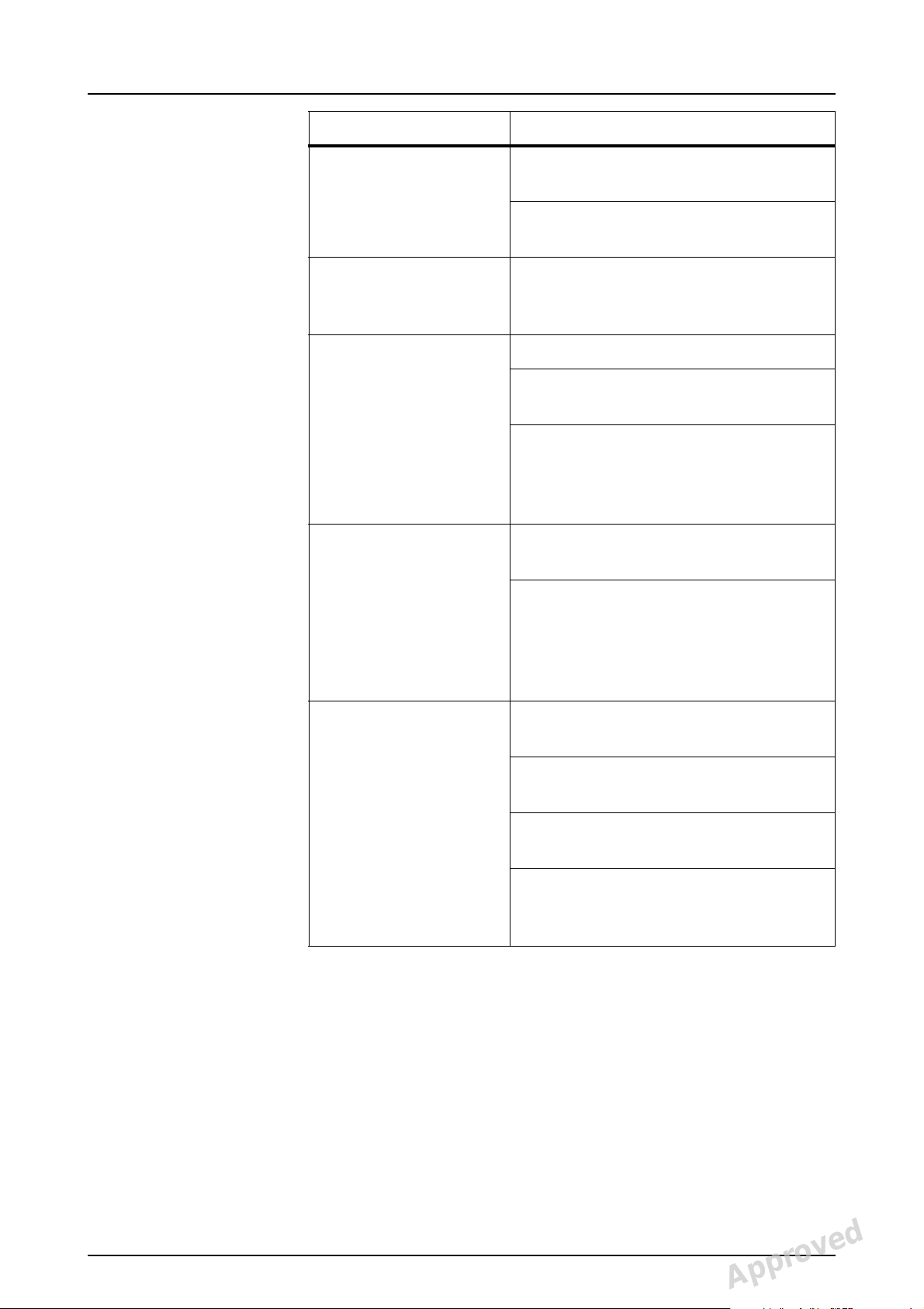

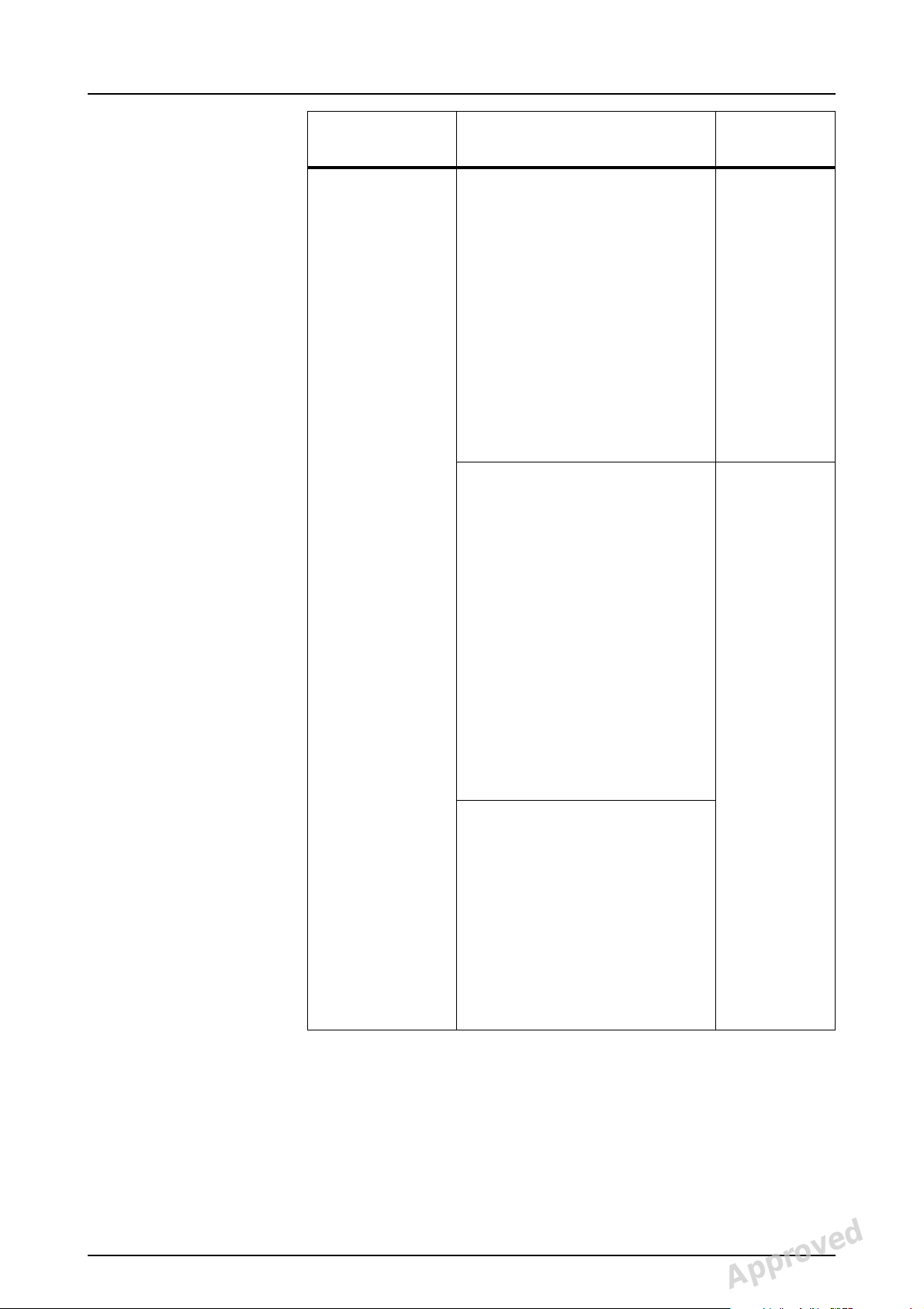

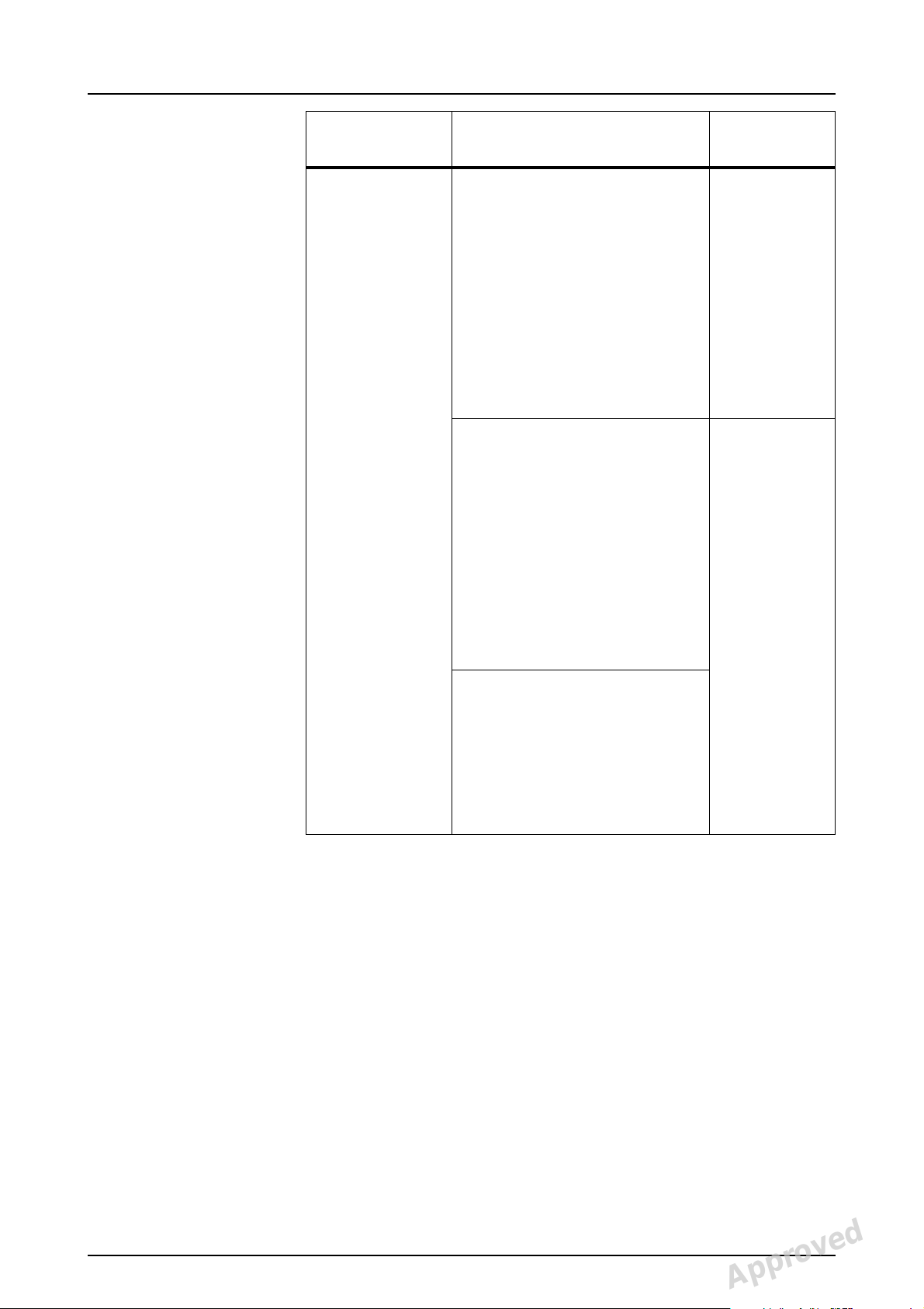

2.2 General, failure messages

In case of malfunction, the unit displays a failure message.

Various letters and numbers are disp la yed in the technique

factors display positions next to kV, mA and s. Failure code

classification is displayed next to kV. A special failure code

number is displayed next to mA with alphanumeric

information in the s-display.

kV display

Letters in the kV-display indicate the nature of the failure,

whether it is caused by user (eg. wrong collimator

selected), environment (eg. low line voltage) or protection

in the unit (eg. tubehead too hot), or whether there is a

serious defect in the unit, which disables the complete

operation (eg. program memory error):

200214 rev 3 Instrumentarium Dental 11

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

2 Electric trouble shooting

Ch Check. A failure caused by

the user.

Sy Safety. Temporary

malfunction or protection in

the unit, caused by the un it or

environment. Operation is

prohibited or te rminated to

protect the operator, patient

and the unit itself. (Eg. the

temperature in th e tu be head

assembly is too high due to

intensive use). After the

corrective action or the wait

time, the unit can be used.

Er Error. There is a serious

defect in the unit, and the

operation is therefore

prohibited to protect the

operator, patient and the unit

itself. (E g. Fa ilu re in the Co re

Module).

WARNING! If the unit is further used, FAIL failure may

cause malfunctio n.

mA display

The mA-display shows the actual numeric failure code.

Each failure code has a unique number, to differ one

malfunction from anoth er :

kV Ch Sy Er

mA 1 to 19 20 to 39 40 to 50

12 Instrumentarium Dental 200214 rev 3

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

2 Electric trouble shooting

s display

The exposure time display indicates the alphanumeric

short form explanation of the malfunction. This reminds the

user or the servicema n of what the actual numeric failure

code means, or sometimes numeric information of the

malfunction, eg. PC for personal computer and COL for

collimator.

kV Time display

Ch-failure PC, PAC, CEC, COL, POS, rEL,

PSE, rEo, EAr,

PAR, LbL, bPL, StP, HSP or

numbers

Sy-failure HHo, ArC, Inu, FIL, AEC, EEP, Por,

CCD, PoL, PoH, PoU, nSY, COL or

numbers

Er-failure CPU, FIL, InP

Failure code resetting

Ch failure codes can be reset by correcting the reason for

the failure code (eg. changing collimator po s ition).

Ch and Sy failures can be reset by pushing any key in the

control panel (up-down-right-left-OK) or in the patient

positioning panel.

Er failures can not be reset. Switch the unit off and on, to

test whether the failure was only temporary.

200214 rev 3 Instrumentarium Dental 13

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

2 Electric trouble shooting

2.3 Film unit failure messages

2.3.1 Ch 1 CAS

Problem: “ Ch 1 CAS “ error message is displayed.

Why? Cassette not ready for the exposure in QA

and panoramic progr ams .

How is it

detected?

At the beginning of the exposure the state

of the PANCASSW signal is read. The

indicator for panoramic film cassette,

optical sensor (D1), is located inside the

cassette holder, behind the cassette

carriage. When the cassette is inserted

the actuator on the cassette carriage

moves the cam away from the optical fork,

thus activating the PANCASSW signal.

Error occurs when the exposure, other

than cephalometric, is initiated and 1) the

signal is not active or 2) the signal has not

been inactive since the previous exp osure.

The exposure is prevented.

To ensure maximal image quality the

panoramic cassette can not be placed in

it’s holder while aqcuiring cephalostatic

image and vice versa.

Possible

causes:

Panoramic or

tomographic

cassette not

properly installed

or not in place.

Panoramic or

tomographic

cassette not

replaced since

the previous

exposure.

Trying to aqcuire

ceph image while

pan cassette

installed.

Check or test: Parts related:

Remove the cassette

Cassette

and reinsert unexposed

one.

- Error should clear.

- If not check the

microswitch operation.

Remove pan cassette.

14 Instrumentarium Dental 200214 rev 3

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

2 Electric trouble shooting

Possible

causes:

Signal

PANCASSW

passive in the

Core Module.

Check or test: Parts related:

Check the microswitch

operation & adjustment:

Press the cassette

Cassette

sensor

assembly

against the cassette

tunnel.

- If the error message

clears then problem with

the cassette sensor

alignment, adjust the

microswitch or opto

coupler.

- If the error stays then

check the wiring.

Check the wiring:

Microswitch

S23

- Check the connectors

and wires for open or

broken wire. Use the

wiring diagram.

or optocoupler,

SC4 or C19,

C18 in CR

units, X114,

C13, X6

- Check the wiring order

on microswitch or

optocoupler

Test the wiring :

- Use Sr 74 IOC. Press

cassette sensor to

check that the signal

status changes. When

signal is active (opto

sensor D1 free or

microswitch S23

closed), cassette is in

the cassette holder.

Signal is indica ted by In

0 LED8, lit LED

indicates the presence

of the cassette. If the

signal does not change

then use wiring diagram

and DVM (digital

voltmeter) to find the

problem.

200214 rev 3 Instrumentarium Dental 15

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

2 Electric trouble shooting

2.3.2 Ch 2 CAS (film unit)

Problem: “ Ch 2 CAS “ error message is display ed.

Why? Cephalostat cassette not ready with the

program P11 and P12.

How is it

detected?

Possible

causes:

Cephalostat

cassette not

properly installed

or not in place.

In OC200 models there is an indicator for

the cephalometric film cassette. This

microswitch (S 34) is located inside the

cassette holder. At the beginning of the

exposure the state of the CEPHCASSW

signal is read. Error occurs when the

cephalometric exposure is initiated and 1)

the signal is not active or 2) the signal has

not been inactive since the previous

exposure. The exposure is prevented.

Error occur also if cephalometric cassette is

installed and panoramic image acquicition

started.

Check or test: Parts related:

Remove the cassette.

Ceph cassette

Reinsert it.

- Error should clear.

- If not check the

microswitch operation.

16 Instrumentarium Dental 200214 rev 3

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

2 Electric trouble shooting

Possible

causes:

Cephalostat

cassette not

replaced since

the previous

exposure.

Check or test: Parts related:

Remove cassette and

replace with unexposed

Cassette

sensor

one.

Check the microswitch

operation & adjustment:

Press the cassette

against the cassette

sensor.

- If the error message

clears then problem is

with the cassette sensor

alignment. Adjust the

microswitch.

- If the error stays then

check the wiring or

adjust the switch.

Ceph cassette

installed while

PAN exposure

Remove ceph cassette Ceph cassette

200214 rev 3 Instrumentarium Dental 17

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

2 Electric trouble shooting

Possible

causes:

Signal

CEPHCASSW

passive in the

Core Module.

Check or test: Parts related:

Check the wiring:

Microswitch

S34, CC4,

- Check the connectors

and wires for open or

broken wire. Use wiring

diagram.

X130, CC2,

X110 or X121,

C13, X8, Core

Module

- Check the wiring order

on microswitch.

Test the wiring :

- Use Sr 74 IOC. Press

the cassette sensor to

check if the signal status

changes.

- If the signal does not

change, then use wiring

diagram and DVM to

find the problem.

- When switch is closed,

cassette is in the

cassette holder. Note

that the switch is

connected normally

closed, i.e. the switch is

closed when the

actuator is released.

Signal is indicated by

In4 LED5, lit LED

indicates the presence

of the cassette.

18 Instrumentarium Dental 200214 rev 3

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

2 Electric trouble shooting

2.3.3 Ch 3 COL (film unit)

Problem: “ Ch 3 COL “ error message is displayed.

Why? Wrong collimator selected.

How is it

detected

?

Error is generated wh en the pano ramic (P1 - P5),

or special (P6 -P10) exposure is initiated while the

panoramic collimator is not in the panoramic

position. Error is also generated when the

tomographic (P13 - P14) exposure is initiated

while the collimator is not in TOMO position.

Signals COL1SW to COL3SW are monitored in

the Core Module.

Possible

causes:

Collimator not

in PAN position

when

panoramic

(Program 1 to

5), TMJ or

sinus (Program

6 to 10)

selected.

Check or test: Parts

related:

Move the collimator to

Collimator.

correct position until it

“clicks”.

- Error should clear.

- If not check the microswitch

operation.

Collimator not

in TOMO

position

when Program

13 or 14

selected.

200214 rev 3 Instrumentarium Dental 19

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

2 Electric trouble shooting

Possible

causes:

Signal

COL1SW

passive and/or

COL2SW

active in the

Core Module.

Check or test: Parts

related:

Test the microswitch

Collimator.

operation: Move the

collimator.

- If the error stays then check

the wiring and microswitch

alignment.

- Remove THA cover.

Visually check that the

switches trigger according to

the code bar and that switch

levers move freely.

Check the wiring:

S31, S32,

S33, CC1,

- Check the connectors and

wires for open or broken

wire. Use wiring diagram.

X113, C13,

X8, Core

Module,

collimator

- Check the wiring order on

code disk

microswitch.

- If error happens at OT

upgrade, check the

collimator code disk, there

are two different models,

OC200 and TOMO. Refer t o

the Table on next page.

Test the wiring : Use Sr 74

IOC and move the coll imator

to check that the signal

status changes. Follow the

Table below.

- If the signals do not change

or are not correct then use

wiring diagram and/or DVM

to find the problem.

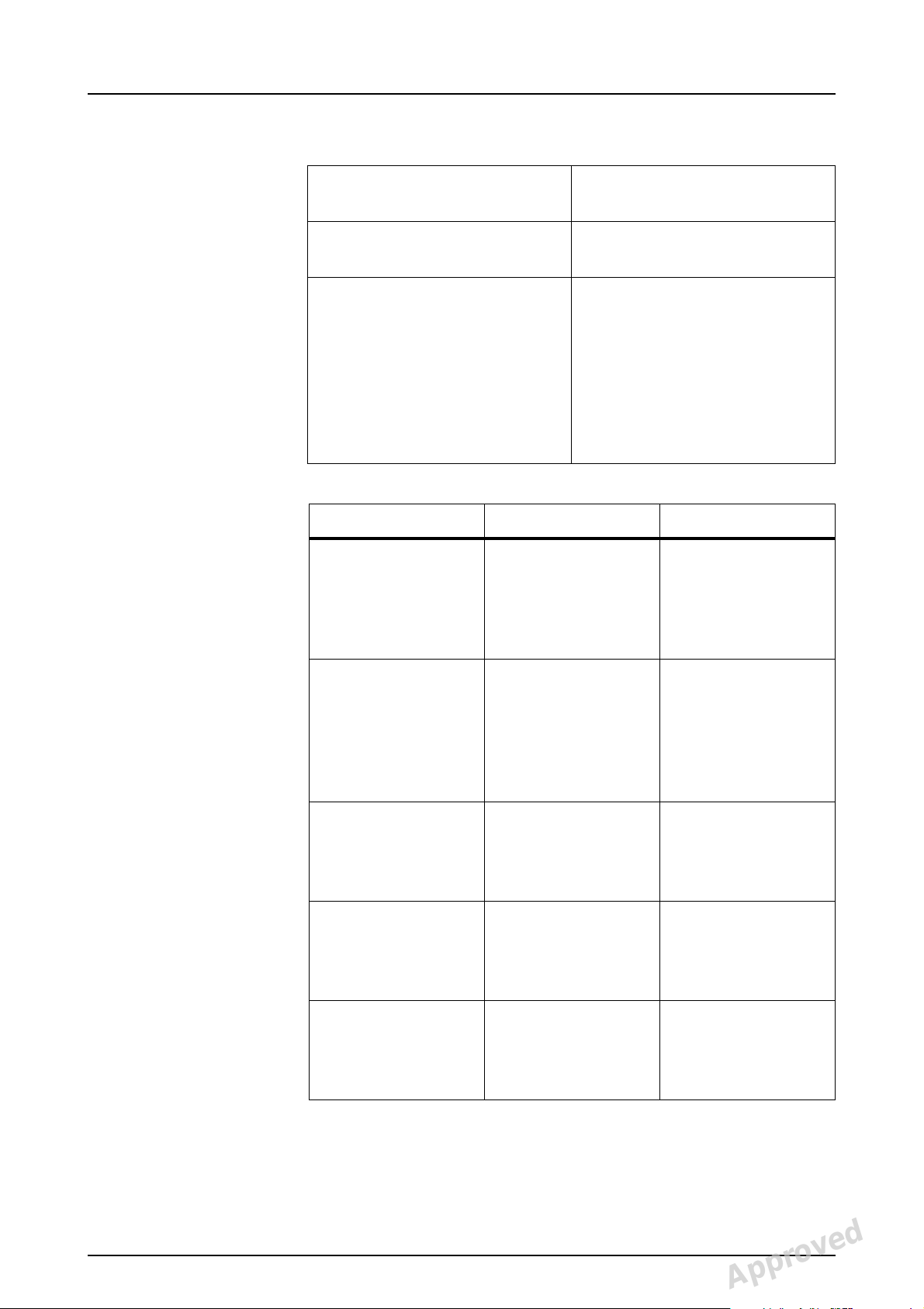

Valid OC200 & OC200 OT collimator switch combinations

(closed switch is active = +5V). There are two different

code bars, one for OC collimators and th e other for Ortho

Trans collimators:

20 Instrumentarium Dental 200214 rev 3

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

2 Electric trouble shooting

S 31

COL1S

W

S 32

COL2S

W

S 33

COL3S

W

COLLIMATOR

POSITION

closed closed open Quality Assurance

collimator

closed open open Panoramic collimator

closed

closed

closed

Cephalostat

collimator:

TOMO

collimator:

24 x 30 cm

AV or

10 x 12 in

AV or

*open

open closed closed 18 x 24 cm

*closed

*open

10 x 8 in AH

or

* TOMO

18 x 24 cm

AV

8 x 10 in AV

or

24 x 30 cm

AV or

8 x 10 in AV

or

10 x12 in AV

or

10 x 8 in AH

open open closed 18 x 24 cm

SV or

8 x 10 in SV

18 x 24 cm

SV or

8 x 10 in SV

open ope n open No valid collimator

200214 rev 3 Instrumentarium Dental 21

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

2 Electric trouble shooting

2.3.4 Ch 4 COL

Problem: “ Ch 4 COL “ error message is displayed.

Why? Wrong collimator selected for ceph

exposure.

How is it

detected?

Possible

causes:

Collimator not

in cephalostat

position when

program P11

or P12

selected

from the

control panel.

Error is generated when the cephalometric

exposure is initiated while the colli mator is

not in one of the cephalostat positions.

Signals COL1SW to COL3SW are

monitored in the Core Module.

Check or test: Parts

related:

Move the collimator to

Collimator.

correct position until it

“clicks”.

- Error should clear.

- If not check the microswitch

operation.

22 Instrumentarium Dental 200214 rev 3

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

2 Electric trouble shooting

Possible

causes:

Signal

COL1SW

active and/or

COL2SW

passive in the

Core Module.

Check or test: Parts

related:

Test the microswitch

Collimator.

operation: move the

collimator.

- If the error stays check the

wiring and micros w it ch

alignment.

- Remove THA cover.

Visually check that the

switches trigger according to

the code bar and that switch

levers move freely.

Check the wiring:

- Check the connectors and

wires for open or broken

wire.

- Check the wiring order on

microswitch.

- If error happens at OT

S31, S32,

S33, CC1,

X113, C13,

X8, Core

Module,

collimator

code bar

upgrade, check the type of

the collimator code disk:

there are two different

models.

Test wiring :

- Use Sr 74 IOC. Move the

collimator to check that the

signal status changes. If the

signal does not change, then

use wiring diagram and/or

DVM to find the problem.

200214 rev 3 Instrumentarium Dental 23

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

D500211, 3

Approved

2 Electric trouble shooting

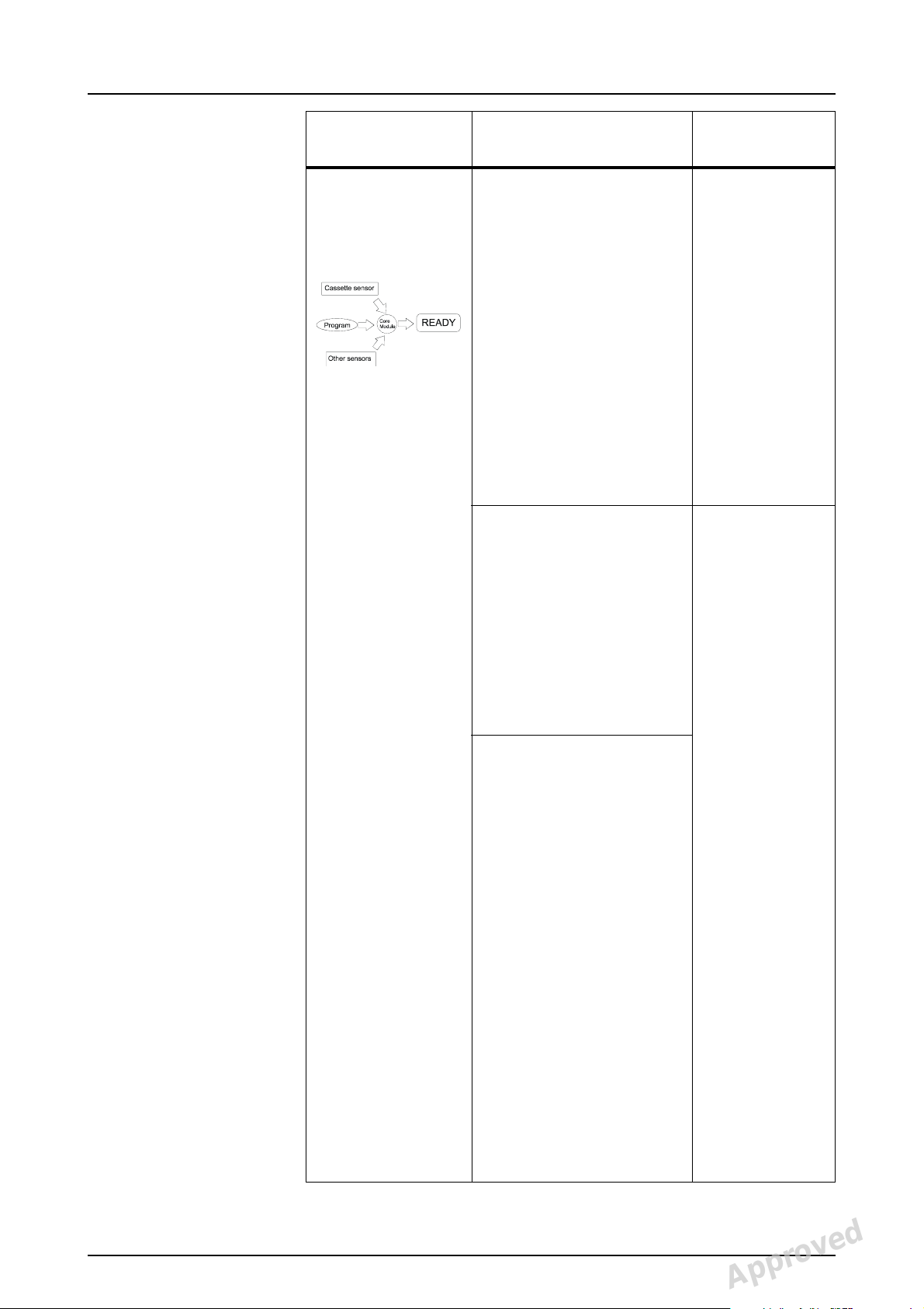

2.3.5 Sy 25 AEC

Problem: “Sy 25 AEC“ error message

is displayed.

Why? AEC base frequency

incorrect.

How is it detected? Occurs in the AEC mode if

the AEC base frequency

(AECFRQ during stand by) is

below 5 kHz. Exposure

sequence is interrupted.

NOTE! The unit can be used

in Manual exposure mode.

Possible cause Check or test Parts rela ted

+25V or -25V

operating voltages

not ok

Wrong AEC base

frequency.

Green LED’s on

AEC board and

Filament board.

Check the power

lines

Check base

frequency with “Sr

AEC board, X39,

Filament board,

X35, C13, X27,

Power Supply

board

AEC board

90 INS” option

“FRE” or “Sr 78

FrE”. Adjust to

5kHz.

AEC base

frequency drifts.

Check with Sr 90

INS

AEC board

Problem with

AEC board.

Open connector Check the wiring.

In CR models

check the 15V

regulator.

Broken Core

Module: signal

Check the signal

and its wiring.

FILT15.

Optocoupler.

24 Instrumentarium Dental 200214 rev 3

Reviewed: Rintamäki Markus 2008-05-26 15:43

Approved: Äärynen Teemu 2008-06-04 17:35

See PDM system to determine the status of this document. Printed out: 2015-04-10 11:48:23

Copyright © 2008 by PaloDEx Group Oy. All rights reserved.

AEC board, X116,

C13, X6, Core

Module

D500211, 3

Approved

Loading...

Loading...