Instrumentarium Dental OP-100 Service manual

Orthopantomograph® OP100 & OP100 D

Orthoceph® OC100 & OC100 D

Electrical Operation & Wiring Manual

Reviewed: Vartia Jussi 2006-10-03 08:31

Approved: Ukkonen Juha-Pekka 2006-10-11 09:53

See PDM system to determine the status of this document. Printed out: 2015-04-09 17:21:03

Copyright © 2006 by PaloDEx Group Oy. All rights reserved.

5139519-100 rev 3

Approved

5139519-100TPH-1, 3

Reviewed: Vartia Jussi 2006-10-03 08:31

Approved: Ukkonen Juha-Pekka 2006-10-11 09:53

See PDM system to determine the status of this document. Printed out: 2015-04-09 17:21:03

Copyright © 2006 by PaloDEx Group Oy. All rights reserved.

5139519-100TPH-1, 3

Approved

Copyright Code: 5139519-100 rev 3 Date: 22 September 2006

Copyright © 09/2006 by PaloDEx Group Oy. All rights reserved.

Orthopantomograph

®

and Orthoceph® are registered trademarks of

Instrumentarium Dental. U.S. patents 4,641,336; 5,016,264; 5,425,065,

5,444,754, 6,731,717 and 6,829,326. German patent 4,344,745. Finnish

patents 112594 and 114383.

®

Orthopantomograph

and Orthoceph® are registered trademarks of

Instrumentarium Dental. U.S. patents 4,641,336; 5,016,264; 5,425,065,

5,444,754, 6,731,717 and 6,829,326. German patent 4,344,745. Finnish

®

patents 112594 and 114383. Windows

is trademark of Microsoft

Corporation in the United States of America and other countries. Pentium

is a registered trademark of Intel Corporation. Iomega® Jaz® is a

registered trademark of Iomega Corp.

Documentation, trademark and the software are copyrighted with all

rights reserved. Under the copyright laws the documentation may not be

copied, photocopied, reproduced, translated, or reduced to any electronic

medium or machine readable form in whole or part, without the prior

written permission of Instrumentarium Dental.

The original language of this manual is English.

Instrumentarium Dental reserves the right to make changes in

specification and features shown herein, or discontinue the product

described at any time without notice or obligation. Contact your

Instrumentarium Dental representative for the most current information.

®

Manufactured by Instrumentarium Dental

P.O. Box 20

FI-04301 Tuusula

FINLAND

Tel. +358 45 7882 2000

Fax. +358 45 7882 2506

For service, contact your local distributor.

Reviewed: Vartia Jussi 2006-10-03 08:31

Approved: Ukkonen Juha-Pekka 2006-10-11 09:53

See PDM system to determine the status of this document. Printed out: 2015-04-09 17:21:03

Copyright © 2006 by PaloDEx Group Oy. All rights reserved.

5139519-100TPH-1, 3

Approved

Reviewed: Vartia Jussi 2006-10-03 08:31

Approved: Ukkonen Juha-Pekka 2006-10-11 09:53

See PDM system to determine the status of this document. Printed out: 2015-04-09 17:21:03

Copyright © 2006 by PaloDEx Group Oy. All rights reserved.

5139519-100TPH-1, 3

Approved

Table of Contents

1 Electrical operation, schematics and layouts .................................................... 1

1.1 Electrical block diagrams.............................................................................................................................1

1.2 Wiring diagram.................................................................................................................................................2

1.3 Primary electronics .........................................................................................................................................2

1.4 Power supply board (CODE 60113)..........................................................................................................2

1.4.1 Line voltage jumper...................................................................................................................................... 3

1.4.2 High voltage section...................................................................................................................................... 3

1.4.3 Low voltage section....................................................................................................................................... 3

1.5 C167 CORE MODULE (CODE 60244)........................................................................................................4

1.6 Digital I/O Board (60229) ..............................................................................................................................5

1.7 Interface Board (CODE 60166)...................................................................................................................8

1.8 X-ray generator ................................................................................................................................................9

1.9 Filament Control Board (CODE 60114)................................................................................................10

1.10 Inverter board (CODE 60115)..................................................................................................................13

1.11 Tube head assembly (CODE 66360) .....................................................................................................15

1.12 Automatic Exposure Control (AEC) Board

(CODE 60122) ..................................................................................................................................................15

1.13 PAN AEC terminal Board (CODE 60247)..............................................................................................16

1.13.1 PAN Automatic Exposure Control (AEC)..............................................................................................17

1.14 Panorama & cephalometric camera

(digi only) ...........................................................................................................................................................18

1.15 Camera power supply Board (CODE 60197)

(DIGI ONLY) .......................................................................................................................................................19

1.16 Ceph terminal Board (Code 60191)

(DIGI ONLY) .......................................................................................................................................................20

1.16.1 Nasio -frequency adjustment.................................................................................................................21

1.17 Ceph head Board (CODE 60243)

(DIGI ONLY) .......................................................................................................................................................22

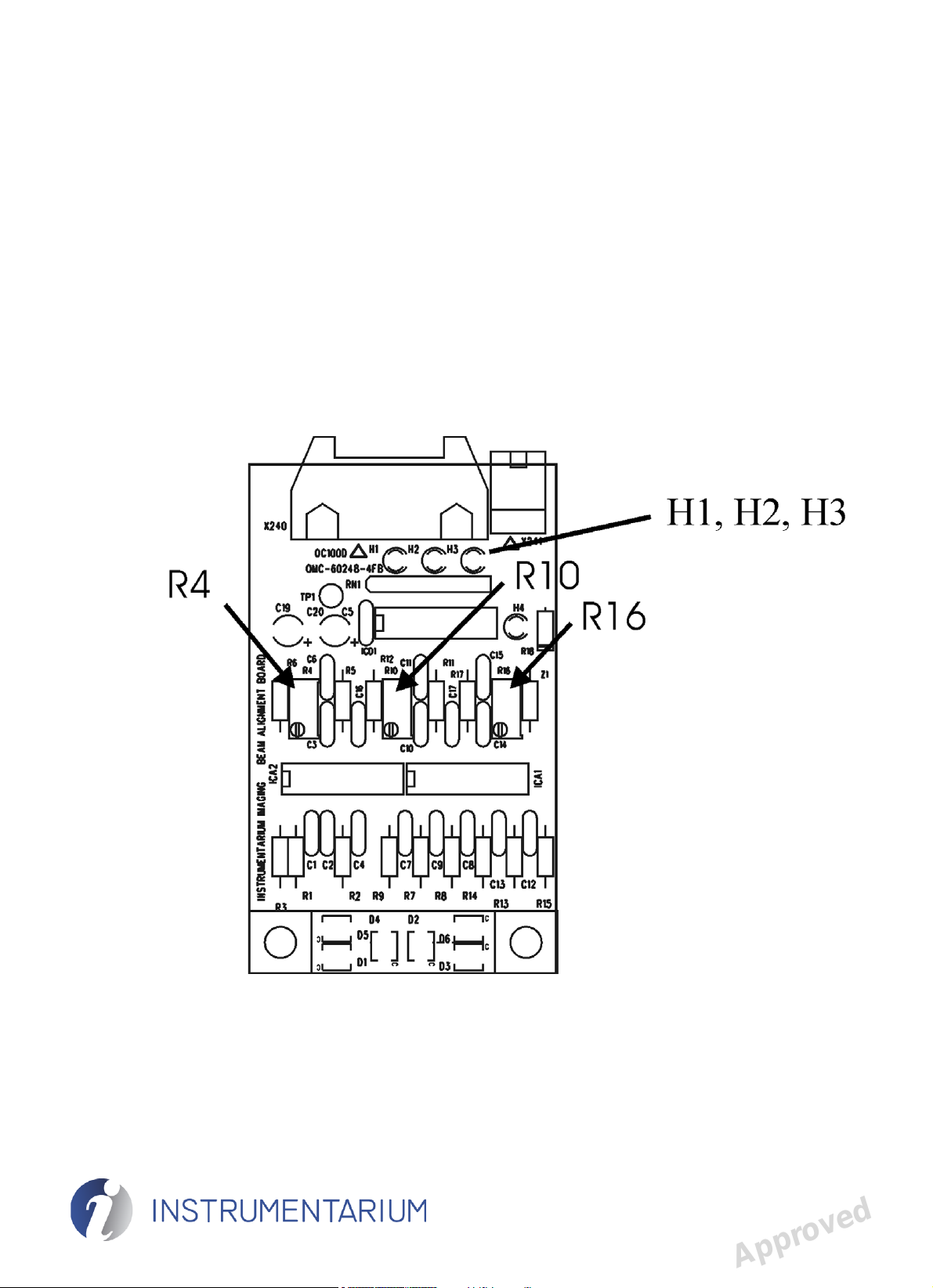

1.18 Beam alignment Board (CODE 60249)

(DIGI ONLY) .......................................................................................................................................................22

1.19 PCI Board (CODE 60187) AND fibre cable (CODE 69061)

(DIGI ONLY) .......................................................................................................................................................24

2 Other components .................................................................................................27

2.1 CONTROL PANELS

(CODE 64105 FOR FILM AND

64104 FOR DIGITAL).....................................................................................................................................27

2.2 Patient positioning panel (CODE 60218).............................................................................................28

2.3 Head support lock ........................................................................................................................................29

2.4 Halogen positioning lights........................................................................................................................29

2.5 Ortho Trans positioning lights.................................................................................................................30

2.6 FH laser light (digi only) ..............................................................................................................................30

2.7 Remote exposure control..........................................................................................................................30

2.8 Ceph soft tissue display (film only)........................................................................................................31

2.9 Ceph soft tissue automatic adjustment

(digi only) ...........................................................................................................................................................31

2.10 Ceph nose support.......................................................................................................................................31

5139519-100 rev 3 Instrumentarium Dental i

Reviewed: Vartia Jussi 2006-10-03 08:31

Approved: Ukkonen Juha-Pekka 2006-10-11 09:53

See PDM system to determine the status of this document. Printed out: 2015-04-09 17:21:03

Copyright © 2006 by PaloDEx Group Oy. All rights reserved.

5139519-100TPH-1, 3

Approved

2.11 Up/down panel (CODE 60193) +

UP/DOWN SWITCH (CODE 60143)

(DIGI ONLY) .......................................................................................................................................................31

2.12 Cephalostat L/R coding..............................................................................................................................32

3 Overview of Digital Image Capture ....................................................................33

3.1 Operation Overview.....................................................................................................................................33

3.2 Digital parts overview.................................................................................................................................39

4 List of documents...................................................................................................41

4.1 Common film and digital unit documents ........................................................................................41

4.2 Film unit documents....................................................................................................................................41

4.3 Digital unit documents...............................................................................................................................41

ii Instrumentarium Dental 5139519-100 rev 3

Reviewed: Vartia Jussi 2006-10-03 08:31

Approved: Ukkonen Juha-Pekka 2006-10-11 09:53

See PDM system to determine the status of this document. Printed out: 2015-04-09 17:21:03

Copyright © 2006 by PaloDEx Group Oy. All rights reserved.

5139519-100TPH-1, 3

Approved

1 Electrical operation, schematics and layouts

1 Electrical operation, schematics and

layouts

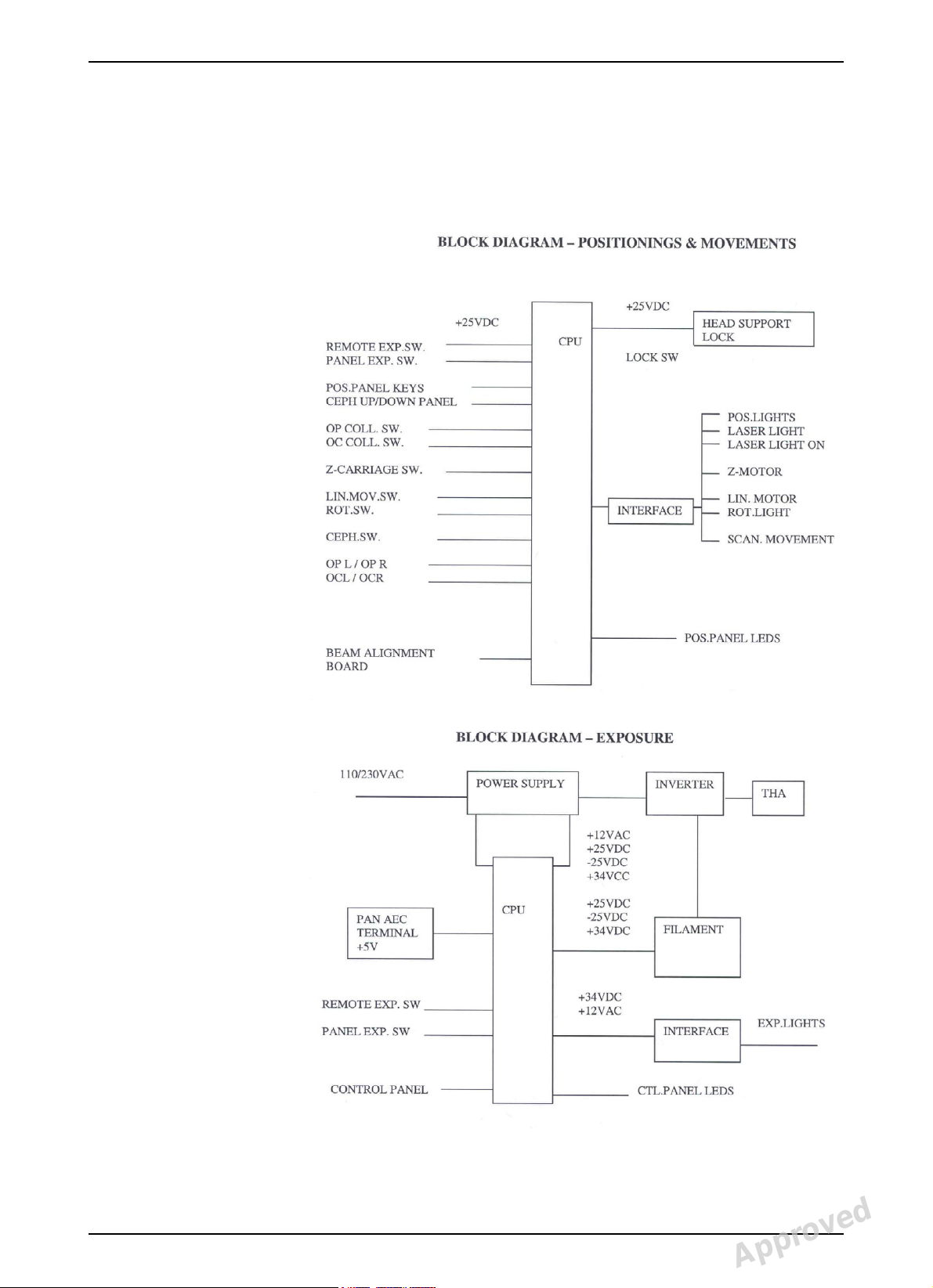

1.1 ELECTRICAL BLOCK DIAGRAMS

5139519-100 rev 3 Instrumentarium Dental 1

Reviewed: Vartia Jussi 2006-10-03 08:31

Approved: Ukkonen Juha-Pekka 2006-10-11 09:53

See PDM system to determine the status of this document. Printed out: 2015-04-09 17:21:03

Copyright © 2006 by PaloDEx Group Oy. All rights reserved.

5139519-100TPH-1, 3

Approved

1 Electrical operation, schematics and layouts

WARNING!

NOTE!

1.2 WIRING DIAGRAM

Copies of OP100 Wiring diagrams, see section “List of Documents”.

1.3 PRIMARY ELECTRONICS

1-phase electric power is fed through a 3-pole cable to the column where

the cable goes inside the right side groove to the vertical carriage

(connectors X101 and X122). Line filter is located under the lower shelf.

Line filter ground is connected to the incoming 3-pole cable ground. Flat

connectors or fixed screws are used. The line filter type with CE-marking:

type S-124-10 or NM-240-10 (code 69025).

Always make sure OP100 D has a good protective ground.

Main switch with power on indicator light is located under the vertical

carriage. Main fuses are located below the vertical carriage. Both F1 and

F2 are slow blow type for incoming main voltage 230 VAC:

In USA/Canada 15AT fuses are used also with 230 VAC rating.

1.4 POWER SUPPLY BOARD (CODE 60113)

Power Supply Board rectifies AC voltages and filters the unregulated DC

voltages. Power Supply Board consists of two main parts: low voltage and

high voltage parts.

2 Instrumentarium Dental 5139519-100 rev 3

Reviewed: Vartia Jussi 2006-10-03 08:31

Approved: Ukkonen Juha-Pekka 2006-10-11 09:53

See PDM system to determine the status of this document. Printed out: 2015-04-09 17:21:03

Copyright © 2006 by PaloDEx Group Oy. All rights reserved.

5139519-100TPH-1, 3

Approved

1 Electrical operation, schematics and layouts

WARNING!

WARNING!

Voltages in high voltage part of the power supply board can be deadly.

The peak-to-peak voltage level normally exceeds 600 V.

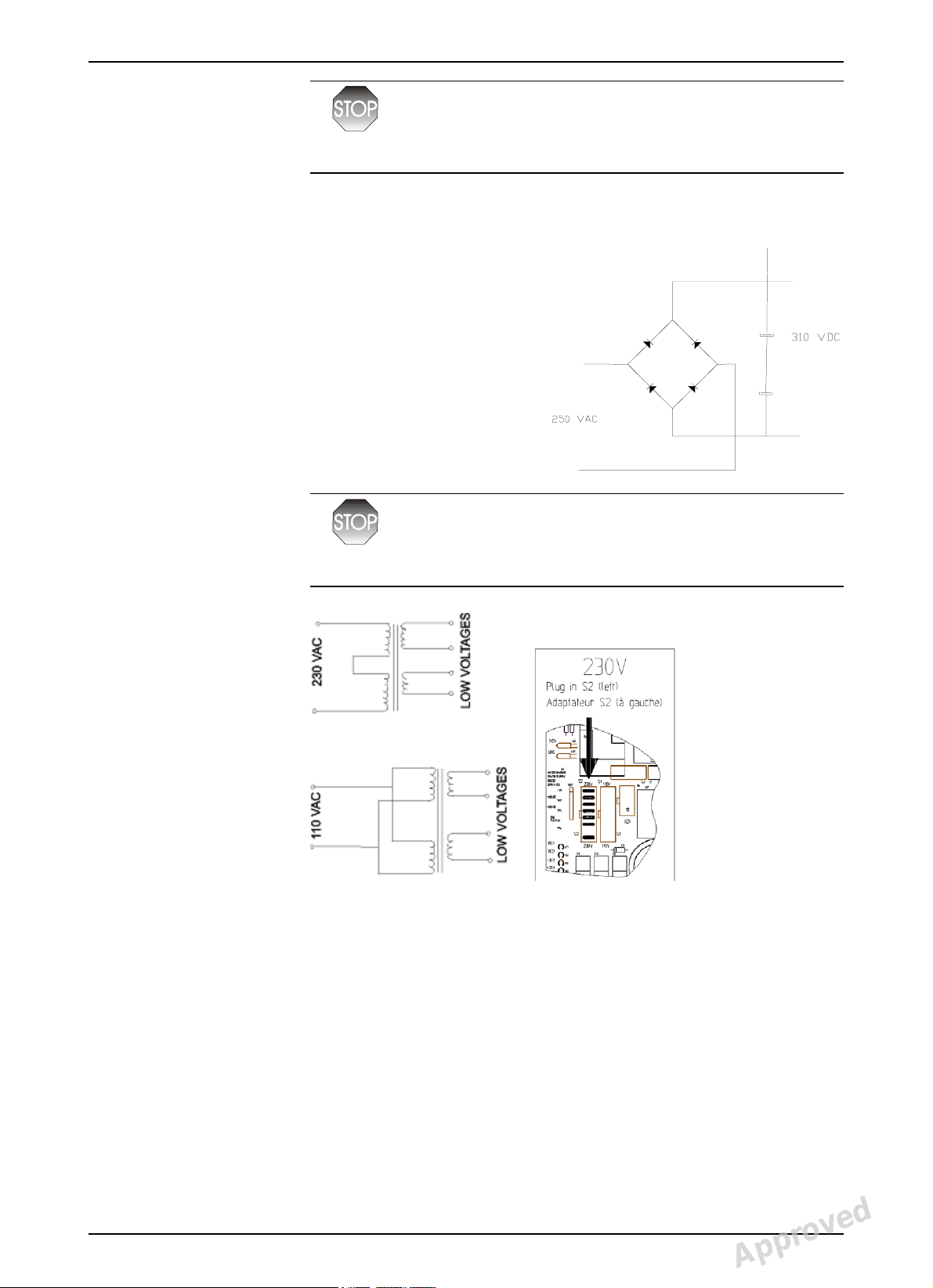

1.4.1 Line voltage jumper

Jumper S2 is for setting the

unit to local line voltage:

S1 switches the rectifier V4 to

the 1500uF capacitors C1 and

C2, located above the Power

Supply Board, to be full-wave

rectified (230 VAC).

It also connects the primary

coils of the line transformer

TF1 & TF2 parallel (230 VAC).

The line voltage selection jumper must always be at the correct position;

left for 230 VAC.

1.4.2 High voltage section

In high voltage section (upper half of the PC board) there is a rectifier D 4

for line voltage and loading circuitry K1-K2-R6 for two capacitors C1 and

C2, which are connected to the PC board through connector X22.

1.4.3 Low voltage section

In low voltage section (= lower half of the PC board) there are fuses,

rectifiers and filter capacitors for low operating voltages:

• 24 VAC (from transformer TF1) is fused by F2, rectified by D5 (to +34

V) and filtered by C3-C4-C5.

• 18 VAC (from transformer TF2) is fused by F3, rectified by D6 (to +25

V) and by D7 (to -25 V) and filtered by C7-C8.

• 12 VAC (from transformer TF2) is fused by F1.

5139519-100 rev 3 Instrumentarium Dental 3

Reviewed: Vartia Jussi 2006-10-03 08:31

Approved: Ukkonen Juha-Pekka 2006-10-11 09:53

See PDM system to determine the status of this document. Printed out: 2015-04-09 17:21:03

Copyright © 2006 by PaloDEx Group Oy. All rights reserved.

5139519-100TPH-1, 3

Approved

1 Electrical operation, schematics and layouts

NOTE!

POWER SUPPLY BOARD FUSES

FUSE RATING FUNCTION SIZE

F1 6.3 AT or

+12 VAC 6.3 x 32 mm

10 AT

F2 6.3 AT +34 VAC 6.3 x 32 mm

F3 2 AT +25 V,

6.3 x 32 mm

-25 V

F1 with 10 AT rating is needed, if the OP100 has with 5 projectors for

double side patient positioning.

List of indicators and test points, see Service Manual: Trouble Shooting.

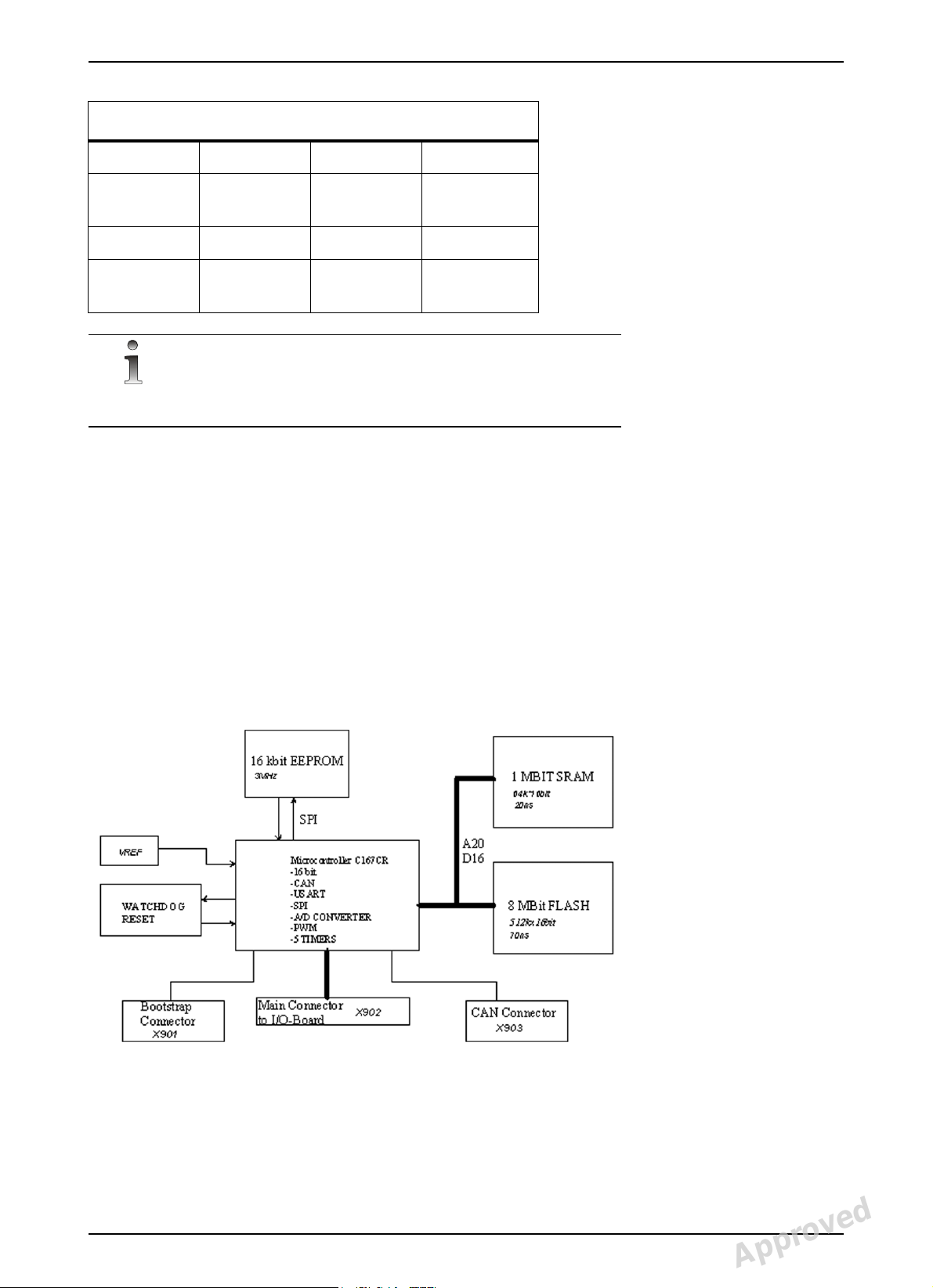

1.5 C167 CORE MODULE (CODE 60244)

OP100/OP100 D is a microprocessor controlled equipment. Core Module

monitors control it’s all movements and other operations, except the head

support lock operation and ceph soft tissue display (in OP100). All key

inputs, microswitches and optocouplers are read by the Core Module.

Accordingly the Core Module controls all operations by supplying control

signals through it's input/output. Core Module is connected to other

boards through Digital I/O Board (60229). X902 connects module to Digital

I/O Board.

Fig 1.1. C167 Core Module Block Diagram.

SAB-C167CR-LM (ICD6) is 16-bit microcontroller. Program is stored in

8 Mbit flash ICD1. 5 MHz clock frequency is multiplied internally by four to

get operating frequency 20 MHz.

4 Instrumentarium Dental 5139519-100 rev 3

Reviewed: Vartia Jussi 2006-10-03 08:31

Approved: Ukkonen Juha-Pekka 2006-10-11 09:53

See PDM system to determine the status of this document. Printed out: 2015-04-09 17:21:03

Copyright © 2006 by PaloDEx Group Oy. All rights reserved.

5139519-100TPH-1, 3

Approved

1 Electrical operation, schematics and layouts

Core Module has different digital and analog ground. They are connected

to each other by R30.

During voltage startup or at reset configuration is loaded to ICD6. ICD7-8,

RN1, RN6, R23, R1, R5, R6, R9 and S2-E are used for configuring. When

/RST from ICD3 goes low it enables ICD7 and 8 which load configuration

to bus. ICD6 reads the configuration values at the end of the internal reset

sequence. The rising edge of /ALE sets ICD7 and 8 to high impedance

state after configuration. Default values are: clock multiply by four, 16 bit

demultiplexed data bus, no bootstrap, /WR and /BHE control, two chip

select lines (/CS0 and /CS1), 1 Mbyte directly accessible address space.

For details of configuration see C167CR Derivatives User's manual.

X901 can be used to load program to Core Module. X903 is a CAN

connector. Core Module includes CAN driver.

DIL switch S2 settings are the same in all OP units.

1-4 must be ON and 5-8 OFF. Their functions are presented in schematics.

Push button switch S1 can be used to RESET the microcontroller.

RESET CIRCUIT

ICD3 (MAX823) is a watchdog RESET generator. During startup ICD resets

the microcontroller. ICD3 has also a "watchdog" feature. If the software

does not frequently generate pulses in /WD signal, ICD3 activates the

RESET signal. Switch S1 can also be used to generate RESET.

RS232

Driver that converts C167 serial data to RS232 voltage levels is located in

Digital I/O Board.

+5V VOLTAGE REGULATOR

6V is fed from Digital I/O Board. Linear regulator ICA1 regulates it to 5V.

Reference Voltage

Reference voltage is made by ICA2. It is 4.096V.

LEDS

H2 Green lit when supply voltage 5V is on.

H1 Red lit when ICD6 is in reset.

1.6 DIGITAL I/O BOARD (60229)

Digital I/O Board forms interface between Core Module and other boards.

Supply Voltages

Switcher ICA1 (L4971) is used to convert 25V input to 5V required by the

board and 6V to Core Module.

5139519-100 rev 3 Instrumentarium Dental 5

Reviewed: Vartia Jussi 2006-10-03 08:31

Approved: Ukkonen Juha-Pekka 2006-10-11 09:53

See PDM system to determine the status of this document. Printed out: 2015-04-09 17:21:03

Copyright © 2006 by PaloDEx Group Oy. All rights reserved.

5139519-100TPH-1, 3

Approved

1 Electrical operation, schematics and layouts

Grounding

There are three separate ground levels in the I/O Board. The actual I/O

board ground level (GND for +5V). The generator ground-level from

Filament Control Board and Inverter Board (from connector X 4, pins 22,

23, 25 and 26). Connected to several optoisolators. Signals from Control

Panel are filtered to the ground level which is connected to chassis at the

left hand lower corner of the IO-board to reduce common mode

interference at control panel cable.

Signals with different GND levels are isolated by optoisolators to eliminate

noise and RF interference problems, but connected inside the Tube Head

Assembly and in the Power Supply Board.

PARALLEL INPUTS/OUTPUTS

I/O from I/O drivers to connectors is buffered and protected according to

use:

• Relay drives and control panel signals are buffered by ICD34 (2803,

Darlington driver).

• Signals to x-ray generator (Filament Drive Board, Inverter Board and

Tube Head Assembly) and signal AECFRQ are optoisolated by quadoptoisolators.

• Rest of the output signals are driven by line driver HCT245 and

protected by serial resistors.

SWITCHES:

SERVICE JUMPER X90 pins 3 and 4

Service switch is connected to pins 3 and 4 at connector X90. If pushed

and keep pressed during reset or voltage startup it brings service

programs available.

OPTION JUMPER X11

Jumper X11 is an option switch, normally in "off" position. When switched

"on", the OP100 can be demonstrated normally, but the exposure is

prevented. This feature can be used eg. in exhibitions.

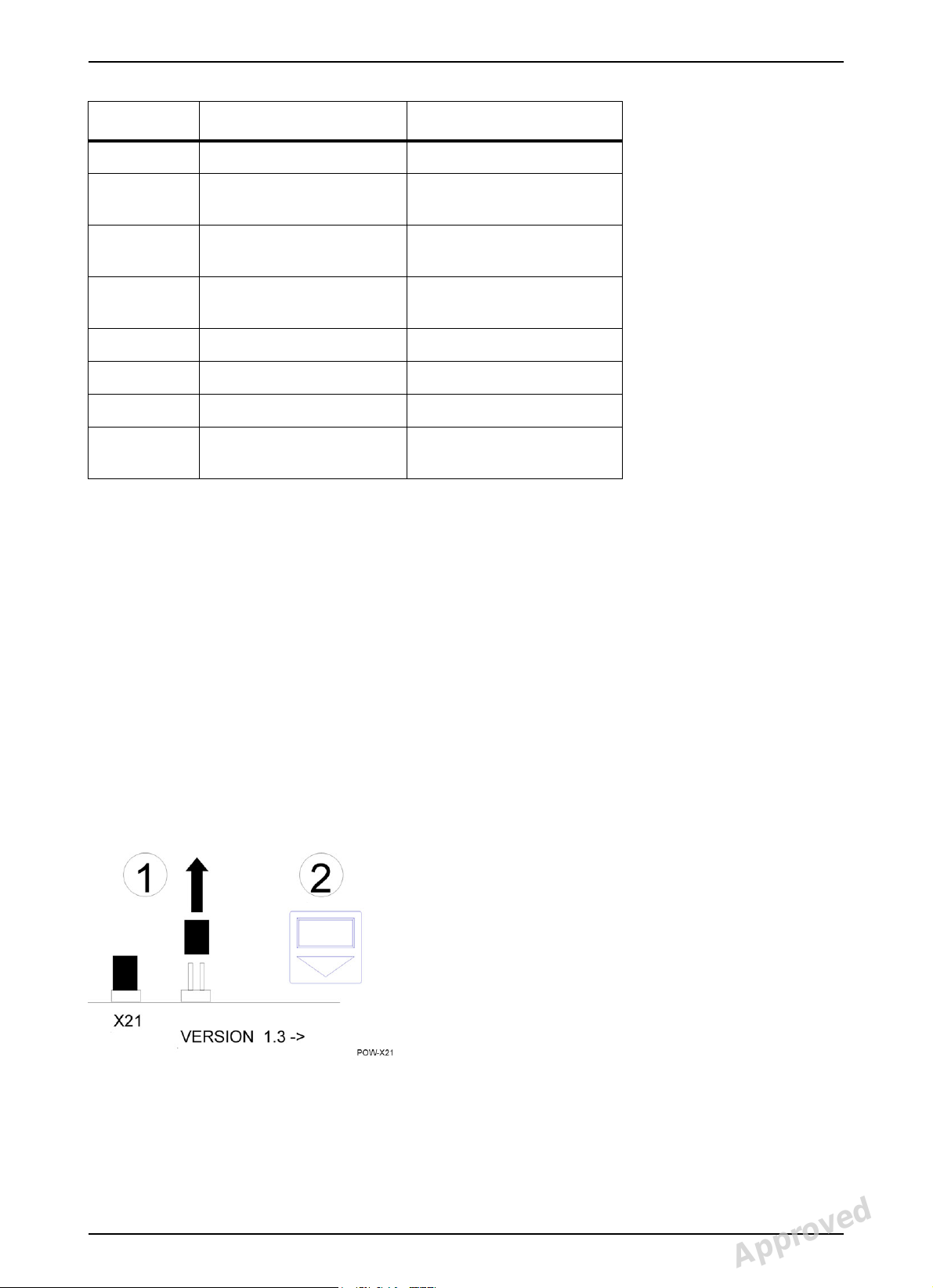

Figure: X11 in ON position, XRAYS prevented.

X14

Program options in Core Module.

X15

L position, cephalo on left side.

R position, cephalo on right side.

JP1-3

These are used to select RS232 routing. In OP100/OP100 D they must be in

A position.

6 Instrumentarium Dental 5139519-100 rev 3

Reviewed: Vartia Jussi 2006-10-03 08:31

Approved: Ukkonen Juha-Pekka 2006-10-11 09:53

See PDM system to determine the status of this document. Printed out: 2015-04-09 17:21:03

Copyright © 2006 by PaloDEx Group Oy. All rights reserved.

5139519-100TPH-1, 3

Approved

1 Electrical operation, schematics and layouts

Signals at A position

INPUT OUTPUT

TXD0 X10-52 X12-5, X3-4 Select=1

TXD0 X10-52 X3-1 Select=0

RXD2 X12-6 X10-53 Select=1

rXD1 X3-2 X10-53 Select=0

rXD2 X3-5 X10-53 Select=1

In B position RXD and TXD from X12 and X10 go to X3.

SPI

SPI interface is used between Core Module and Digital I/O board to reduce

the number of connections. Serial data from Core Module is loaded to

ICD28 and outputs are then buffered by HCT245 line drivers. Respectively

a part of signals (for example microswitch states) are fed as serial data to

Core Module.

SPI_SELECT is used to select data source. When 0 data to Core is from

ICD17 and from Core to ICD28. When 1 data is read and written to control

panel.

S1 settings

Fig 1.2. Service switch

5139519-100 rev 3 Instrumentarium Dental 7

Reviewed: Vartia Jussi 2006-10-03 08:31

Approved: Ukkonen Juha-Pekka 2006-10-11 09:53

See PDM system to determine the status of this document. Printed out: 2015-04-09 17:21:03

Copyright © 2006 by PaloDEx Group Oy. All rights reserved.

5139519-100TPH-1, 3

Approved

1 Electrical operation, schematics and layouts

Switch Function Setting

1 (A) Film/Digital OP selection OFF=FILM, ON=DIGITAL

2 (B) COL3SW OFF, not used with 69088

cable

3 (C) COL2SW OFF, not used with 69088

cable

4 (D) COL1SW OFF, not used with 69088

cable

5 (E) NOT CONNECTED

6 (F) NOT CONNECTED

7 (G) NOT CONNECTED

8 (H) CAEFRQ ON in digital OP, off in film

OP

1.7 INTERFACE BOARD (CODE 60166)

Interface Board contains driver circuits for stepper motors, DC motors,

driver projector and warning lights, under the control of C167 core

module.

STEPPER MOTOR DRIVERS

Stepper motor drivers ICA’s 2, 7 & 11 (PMB 3690) convert incoming

frequencies to stepper motor control sequences, and the half-bridge

drivers ICA’s 1, 3 & 5 (L298) drive the stepper motor windings.

FILM UNIT CASSETTE RACK

It is possible to increase power to the cassette holder down drive. This is

done by removing X 21 jumper. Full power is available for down

movement. This can be used if the cassette holder movement is jammed.

DC MOTOR DRIVERS

The Vertical carriage motor (Z-motor) and the Cassette lift motor (rack

motor) are driven accordingly by circuits around pulse width modulators

ICA9 and ICA10 (TL494).

8 Instrumentarium Dental 5139519-100 rev 3

Reviewed: Vartia Jussi 2006-10-03 08:31

Approved: Ukkonen Juha-Pekka 2006-10-11 09:53

See PDM system to determine the status of this document. Printed out: 2015-04-09 17:21:03

Copyright © 2006 by PaloDEx Group Oy. All rights reserved.

5139519-100TPH-1, 3

Approved

1 Electrical operation, schematics and layouts

PROJECTORS, WARNING LIGHTS

Positioning projectors are controlled by relay K1. The x-ray warning lights

LA1 and LA2 are controlled by relay K4.

Interface board OT: Laser lights are used in Ortho Trans units. Lasers are

controlled by transistor T7.

+15V VOLTAGE REGULATOR

+15V operating voltages for PWM circuits ICA9 and ICA10 are regulated

from unregulated +25V by ICA1 (LM317).

List of indicators and test points, see Troubleshooting Manual.

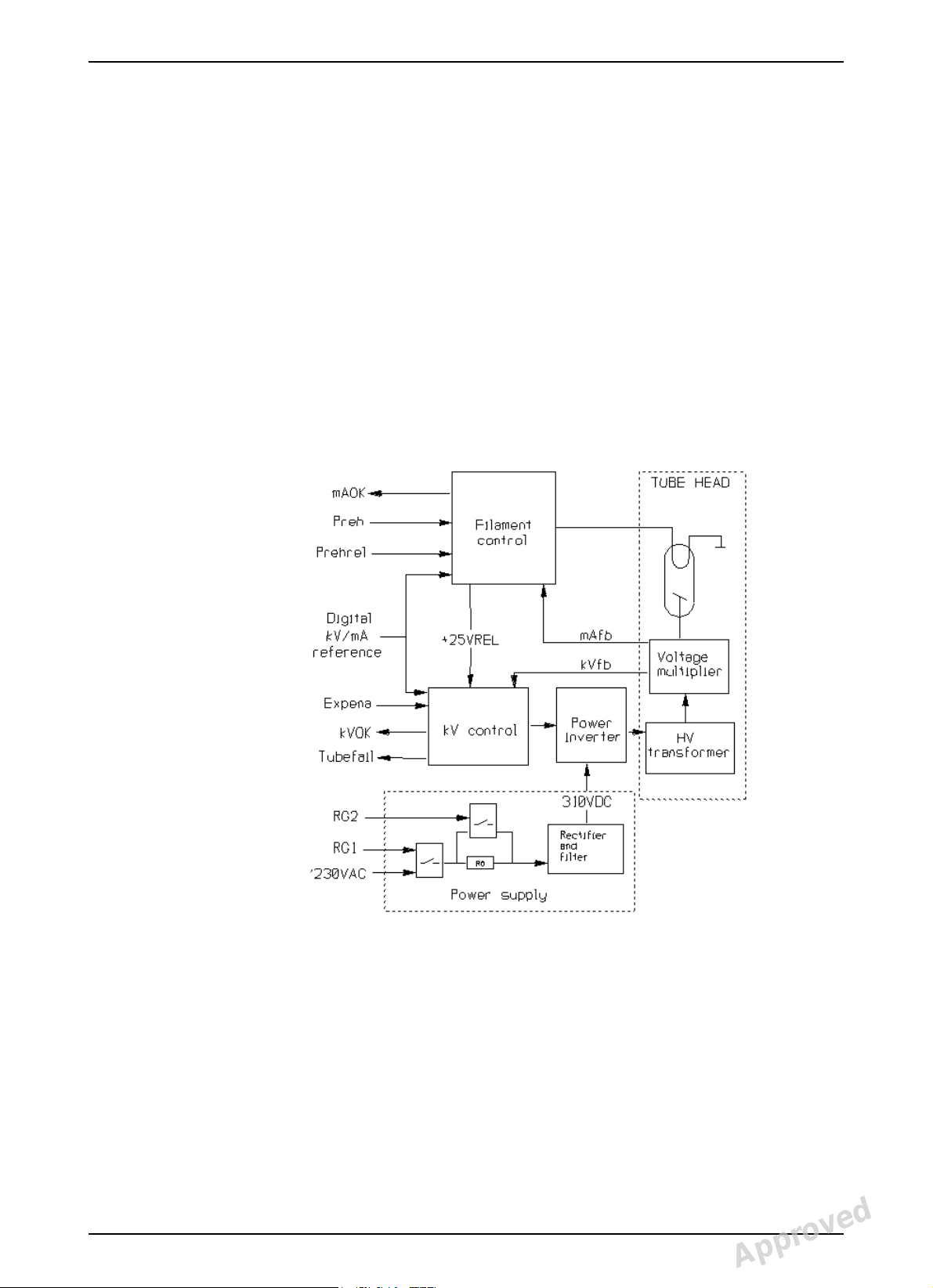

1.8 X-RAY GENERATOR

The X-ray generator consist of Tube Head assembly, Filament control

Board and Inverter Board.

Generator exposure sequence

Time 0: Exposure button pressed, exposure sequence starts

• RG1 on:

– Connects high voltage (+310V) to the Inverter Board (via soft start

resistor R6 on Power supply Board).

– Red LED H1 (RG1) on Power supply Board is lit.

– Green led H1 (+310V) on inverter Board is lit.

• PREH on:

– Sets the Filament control Board into preheat mode.

– Red LED H7 (PREH) on Filament control Board is lit.

• PREHREL on:

– Enables filament power circuit.

5139519-100 rev 3 Instrumentarium Dental 9

Reviewed: Vartia Jussi 2006-10-03 08:31

Approved: Ukkonen Juha-Pekka 2006-10-11 09:53

See PDM system to determine the status of this document. Printed out: 2015-04-09 17:21:03

Copyright © 2006 by PaloDEx Group Oy. All rights reserved.

5139519-100TPH-1, 3

Approved

Loading...

Loading...