Instrumentarium Dental Express Imaging Plate System Service manual

EXPRESS™ Origo ICR6-1

Digital intraoral imaging plate system

Field Service Manual

Document no. 210586 rev.2

(2014-06)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

EXPRESS™ Origo ICR6-1

Digital intraoral imaging plate system

Field Service Manual

Document no. 210586 rev.2 (2014-06)

Copyright © 06/14 by Instrumentarium Dental.

All rights reserved.

EXPRESS™ is a

common law trademark of Instrumentarium Dental,

PaloDEx Group Oy.

Documentation, trademark and the software are copyrighted with all rights

reserved. Under the copyright laws the documentation may not be copied,

photocopied, reproduced, translated, or reduced to any electronic medium or

machine readable form in whole or part, without the prior written permission of

Instrumentarium Dental.

Manufactured by

Instrumentarium Dental, PaloDEx Group Oy

Nahkelantie 160 (P.O. Box 20)

FI-04300 Tuusula

FINLAND

Tel. +358 10 270 2000

Fax. +358 10 270 2230

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 2 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

TABLE OF CONTENTS

INTRODUCTION .................................................................................................................... 5

DISCLAIMER ........................................................................................................................... 5

SCOPE ..................................................................................................................................... 5

INSTRUCTION / COMMAND SYNTAX USED IN THE MANUAL:........................................................ 5

ACRONYMS USED IN THIS MANUAL .......................................................................................... 5

OPERATING WARNINGS AND PRECAUTIONS .............................................................. 6

SERVICING PRECAUTIONS ........................................................................................................ 6

SYSTEM DESCRIPTION ....................................................................................................... 8

BLOCK DIAGRAM .................................................................................................................... 8

ID EXPRESS ORIGO ASSEMBLY ...................................................................................... 9

SCANNER MECHANISM ASSEMBLY ............................................................................. 10

ELECTRONICS ....................................................................................................................... 12

FIRMWARE ............................................................................................................................ 14

USER INTERFACE STATUSES .......................................................................................... 15

SERVICE TERMINAL ......................................................................................................... 17

ACCESSING SERVICE TERMINAL ............................................................................................ 17

NORMAL AND SERVICE MODE OF THE UNIT ........................................................................... 19

SERVICE COMMAND PRINCIPLES ............................................................................................ 19

SERVICE LOG ........................................................................................................................ 20

CONFIGURATION PARAMETERS ................................................................................... 21

SHOWING / SETTING CONFIGURATION PARAMETERS ................................................................ 21

AUTOSTART <AUTOSCAN> .................................................................................................... 21

BEEPER ................................................................................................................................. 21

ENERGY SAVE MODE <IDLE> ................................................................................................. 21

AUTOMATIC SHUTDOWN <OFF> ............................................................................................. 21

RESTORING FACTORY SETTINGS ............................................................................................. 21

TROUBLESHOOTING ......................................................................................................... 22

ERROR MESSAGES ........................................................................................................... 22

ERROR 1, K100 ..................................................................................................................... 22

ERROR 2, PMT ...................................................................................................................... 23

ERROR 3,LASER .................................................................................................................... 24

ERROR 4, RESONATOR ........................................................................................................... 24

ERROR 12, K200 NOT CONNECTED ......................................................................................... 25

ERROR 13, K300 NOT CONNECTED ......................................................................................... 25

ERROR 23, K200 ................................................................................................................... 26

ERROR 24, LINEAR MOVEMENT ............................................................................................. 27

ERROR 34, PLATE SENSOR ...................................................................................................... 28

ERROR 123, DOOR MOVEMENT ERROR .................................................................................. 28

ERROR 124, SAFETY COVER ................................................................................................... 29

ERROR 234, UI ...................................................................................................................... 30

MAINTENANCE ................................................................................................................... 31

ROUTINE CHECKS WITHOUT OPENING THE UNIT ..................................................... 31

ROUTINE CHECKS WHEN UNIT OPENED: ..................................................................... 31

Plate carrier belt (conveyor belt): .................................................................................... 32

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 3 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

Tension check and adjustment .......................................................................................... 32

INSTRUCTIONS FOR CHANGING SPARE PARTS ........................................................ 34

REMOVING AND INSTALLING THE COVERS ............................................................... 34

COLOR ACCENT PANEL ................................................................................................ 34

BACK COVER .................................................................................................................. 35

FRONT COVER ............................................................................................................... 35

CONTROL PANEL ........................................................................................................... 36

LIGHT COVER ................................................................................................................ 37

REPLACING MOVEMENT KIT PARTS (SP00912) ............................................................... 38

REPLACING OUTER COVERS (SP00989) ............................................................................ 43

REPLACING INNER LIGHT PROTECT COVER (SP00914) ................................................. 43

REPLACING CONTROL PANEL ASSEMBLY (SP00991) .................................................... 43

REPLACING K200 HOME-LASER-DETEC IPS-2013 (SP00916).......................................... 44

REPLACING K300 PLATE DETEC REFL.SEN IPS-2013 (SP00917) .................................... 45

REPLACING LASER AND MIRROR ASSEMBLY IPS-2013 (SP00918) .............................. 46

REPLACING PMT (SP00919) ................................................................................................. 47

REPLACING UNIT DOOR (SP00920) .................................................................................... 47

FIRMWARE AND CORE UPGRADE ................................................................................. 48

FIRMWARE ............................................................................................................................ 48

CORE UPGRADE ..................................................................................................................... 48

TROUBLESHOOTING ......................................................................................................... 49

ERRORS WITHOUT ERROR CODE ............................................................................................. 49

IMAGE ERRORS ...................................................................................................................... 50

Improper use of the hygiene accessories .......................................................................... 50

Improper X-ray settings used ............................................................................................ 50

Ghost images, shadows..................................................................................................... 50

Improper aiming of the X-ray ........................................................................................... 50

Unsharp / blurred images ................................................................................................. 51

Geometry distortion .......................................................................................................... 51

Decreased contrast, shadows/shading, ghost images… ..................................................... 51

White or grey dots/spots/stains in images ......................................................................... 51

Wearing of the imaging plates .......................................................................................... 51

Image shows different size than the IP used ...................................................................... 53

Circle on image ................................................................................................................ 53

Vertical stripe(s) ............................................................................................................... 53

White bar before image .................................................................................................... 54

PMT problems .................................................................................................................. 54

Incorrect dimensions ........................................................................................................ 54

Compressed (too narrow) image ....................................................................................... 54

SPARE PARTS ...................................................................................................................... 55

APPENDIX 1: TEST AFTER REPAIR ................................................................................ 59

APPENDIX 2: ELECTRICAL SAFETY TESTING IN ACCORDANCE WITH THE IEC

62353 STANDARD FOR SCANNER .................................................................................... 60

INTRODUCTION ..................................................................................................................... 60

WARNINGS AND PRECAUTIONS .............................................................................................. 60

VISUAL INSPECTION. ............................................................................................................. 61

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 4 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

INTRODUCTION

Disclaimer

Manufacturer endeavors to produce product documentation that is accurate and up to

date. However, our policy of continual product development may result in changes to

products that are not reflected in the product documentation. Therefore, this document

should not be regarded as an infallible guide to current product specifications.

Manufacturer maintains the right to make changes and alterations without prior notice.

Scope

This manual provides the information necessary to perform field servicing and

maintaining of the EXPRESS™ Origo Digital imaging plate system (hereafter referred

as a ” scanner unit”).

NOTE: THIS MANUAL IS NOT A STAND-ALONE MANUAL AND MUST BE READ

TOGETHER WITH THE USER’S MANUAL

Only trained and approved service personnel of authorized distributors are allowed to

service the unit.

Unit can be sent to manufacturer for repair if it cannot be repaired by:

• Performing the calibrations instructed in this manual AND

• Replacing field serviceable parts

Instruction / command syntax used in the manual:

<text> The text inside the brackets is typed in exactly as instructed + followed by

enter

Example <reset> means typing:reset (and pressing enter)

Example <idle> Show the time unit waits before goes to standby

Example <idle XXX> Sets time (XXX seconds) unit waits before goes to standby

Acronyms used in this manual

ADC Analog to Digital Converter

Cmd Command

DSD driver The device driver used together with an imaging application

EMC Electromagnetic compatibility

EMI Electromagnetic interference

FW Firmware control the scanner unit operation

HV High Voltage

I/O Input/Output

IP Imaging Plate

IP address Internet Protocol Address, typically looks like 192.168.0.2

JXXXX Connector number

Msg Message

NIC Network Interface Card

PMT Photo Multiplier Tube (=Photo detector)

PSU External Power Supply Unit

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 5 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

OPERATING WARNINGS AND PRECAUTIONS

CLASS 1 LASER EQUIPMENT

DANGER: Any failure to follow the recommendations and instructions in this manual

may expose the user to laser radiation exceeding the class 1 specifications.

CAUTION:

• Do not move or knock the scanner when it is scanning.

• The use of control or adjustment or performance of procedures other than those

specified herein may result in hazardous laser radiation exposure.

• This scanner must only be used to read image plates and must not be used for

any other purpose. Only use the imaging plates and protective covers that are

supplied by scanner unit manufacturer. NEVER use imaging plates or protective

covers from other manufacturers with the scanner

• This scanner, or its accessories, must not be modified, altered or

remanufactured in any way.

• Only the manufacturer’s authorized service personnel are authorized to carry out

annual maintenance and repair. There are no user serviceable parts inside.

• This device can interfere with other devices due to its EMC characteristics.

• Other devices can interfere with this device due to their EMC characteristics.

• This device complies with IEC 60601-1 standard. Accessory equipment

connected to this device must be in compliance with the related nationally

harmonized IEC standards.

• Equipment not suitable for use in the presence of flammable anesthetic mixture

with air or with oxygen or nitrous oxide.

• Only use the power supply unit that is supplied with the scanner. Do not use any

other power supply units with the scanner.

• Use RJ45 UTP network cable, CAT 6

• Other cables and accessories may negatively affect EMC

Servicing Precautions

WHEN SERVICING EXPRESS™ ORIGO ALWAYS TURN POWER OFF AND

DETACH POWER SUPPLY AND ETHERNET CONNECTORS BEFORE OPENING

THE COVERS.

DO NOT ATTACH POWER SUPPLY AND ETHERNET CONNECTORS BACK UNTIL

COVERS ARE INSTALLED BACK.

ESD

When servicing & unit covers being open, please note that inside the unit all electrical

components are ESD sensitive. Appropriate protective methods (ESD wristbands, ESD

safe working areas & ESD clothes etc…) must be used against ESD problems.

Laser Radiation

There is a class 3B laser inside the scanner. The laser can be activated if the light

beam in the optic safety switch is blocked and the laser is switched on from the service

terminal. Avoid direct exposure to the laser beam or its’ reflections (for instance from

shiny tools etc).

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 6 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

High Voltage

There is a high voltage circuit between the photo multiplier tube and amplifier card. High

voltage can be set on when the light beam of opto safety switch is blocked. See service

commands.

Light Sensitivity of Photo Multiplier Tube

The tube is very sensitive to light when it is active. Tube is activated when the high

voltage is turned on. The tube is used to measure extremely small amounts of light

Normal room light and brighter light sources damage HV-activated tube.

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 7 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

SYSTEM DESCRIPTION

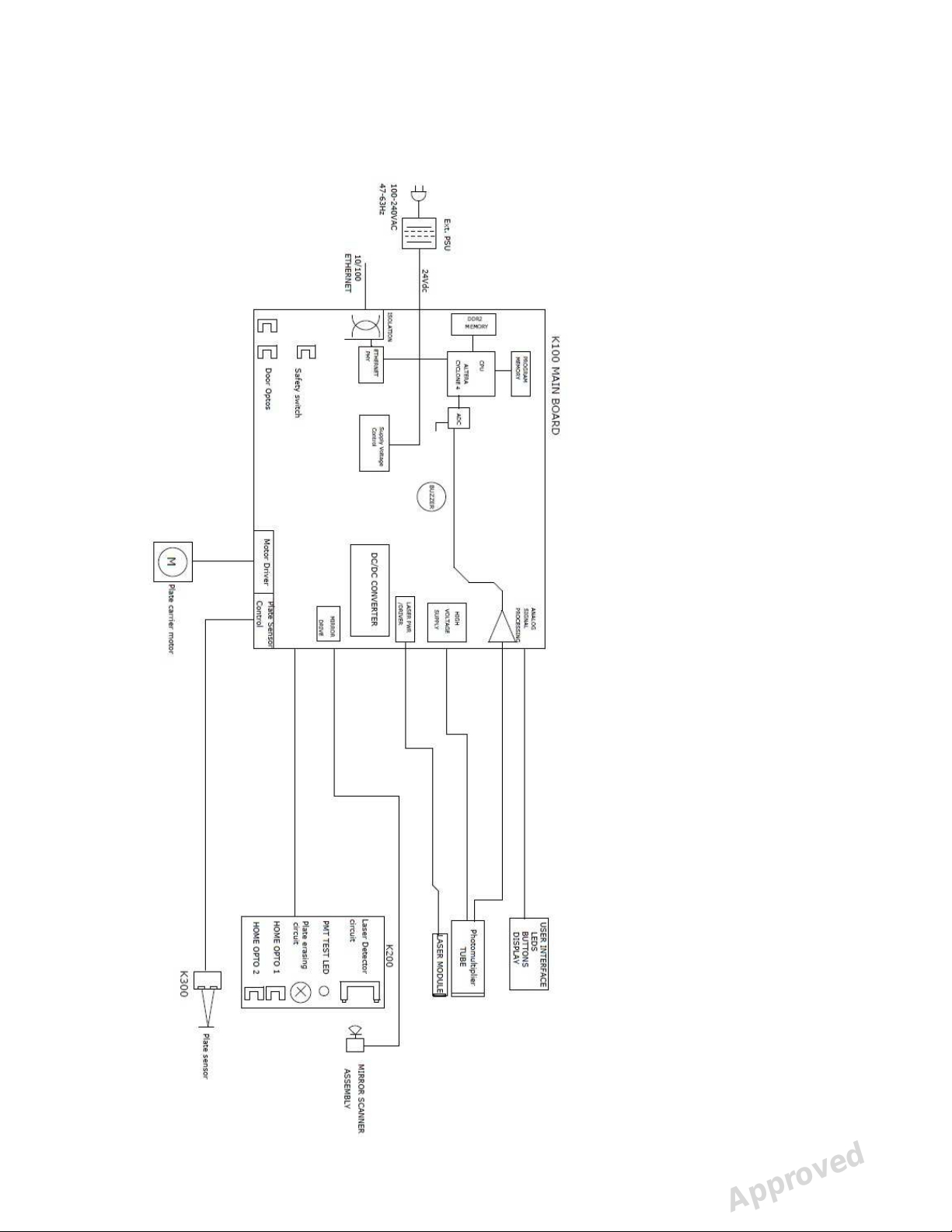

Block diagram

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 8 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

RECYCLING

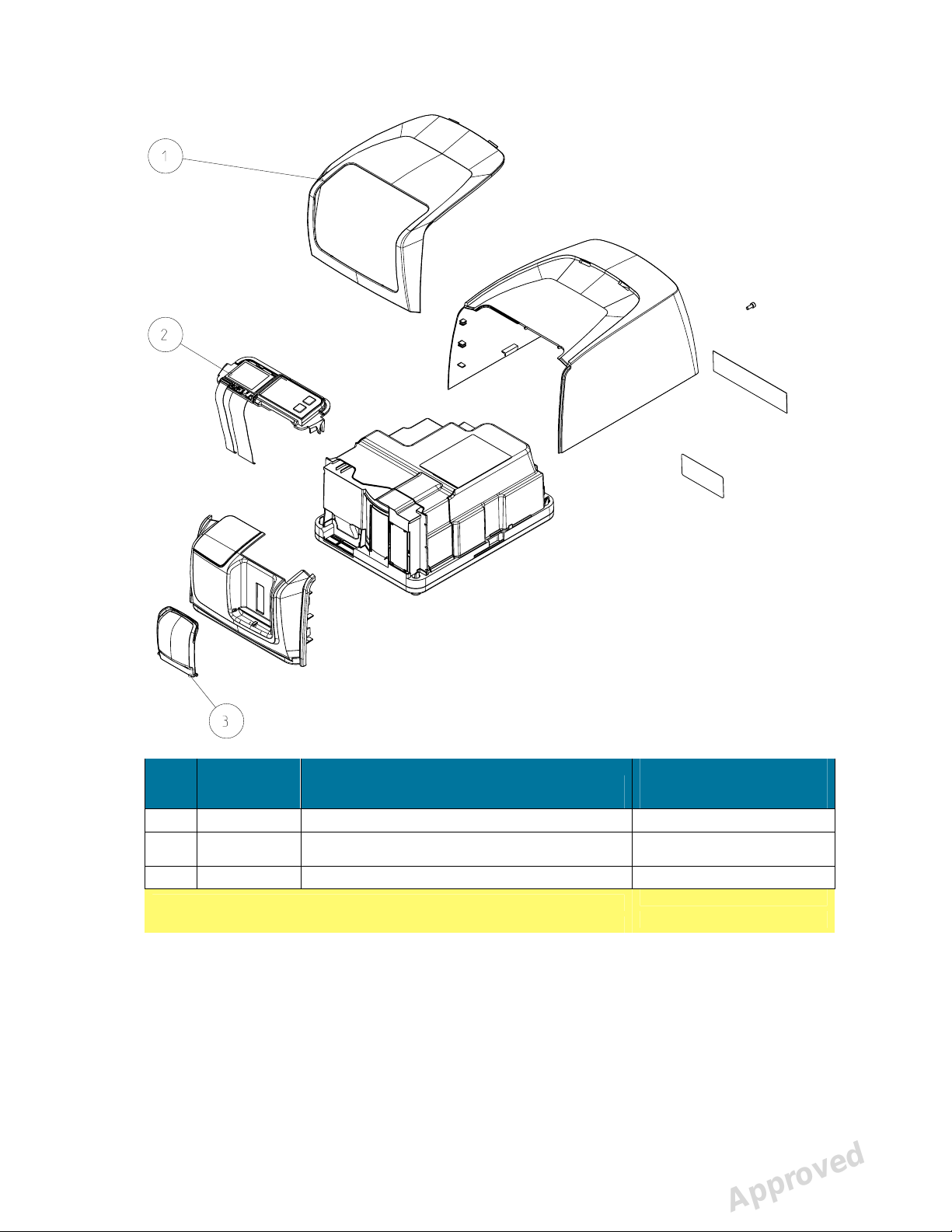

ID EXPRESS ORIGO ASSEMBLY

ITEM CODE

1 SP00989 OUTER COVERS EXPRESS ORIGO

2 SP00991 CONTROL PANEL EXPRESS ORIGO

3 SP00993 IMAGING PLATE COLLECTOR

NOTE!

Products without part numbers are not for sale.

DESCRIPTION

SP00989 OUTER COVERS EXPRESS ORIGO includes:

- 1 pcs SCANNER FRONT COVER

- 1 pcs SCANNER BACK COVER with ICR6 TYPE LABEL and LASER CLASS3B

WARNING LABEL

- 1 pcs ID SCANNER COLOR ACCENT PANEL

- 1 pcs IMAGING PLATE COLLECTOR

- 1 pcs M4X8 DIN85 FEZN

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 9 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

INFORMATION

MATERIAL

PC+ABS

Frame: PC+ABS

Others: E-scrap

PC+ABS

Approved

D511515, 2

E-SCRAP

PBT/Steel

NOTE!

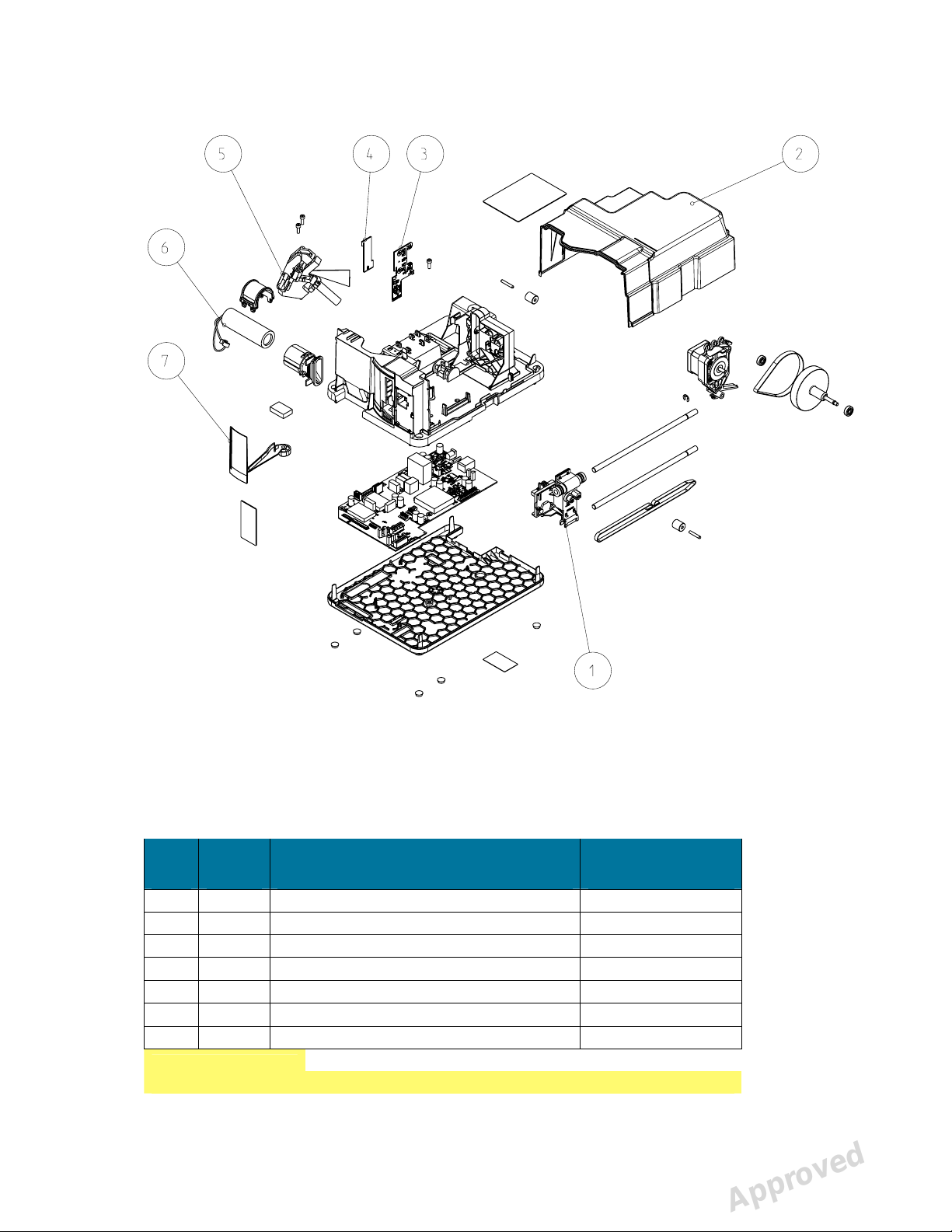

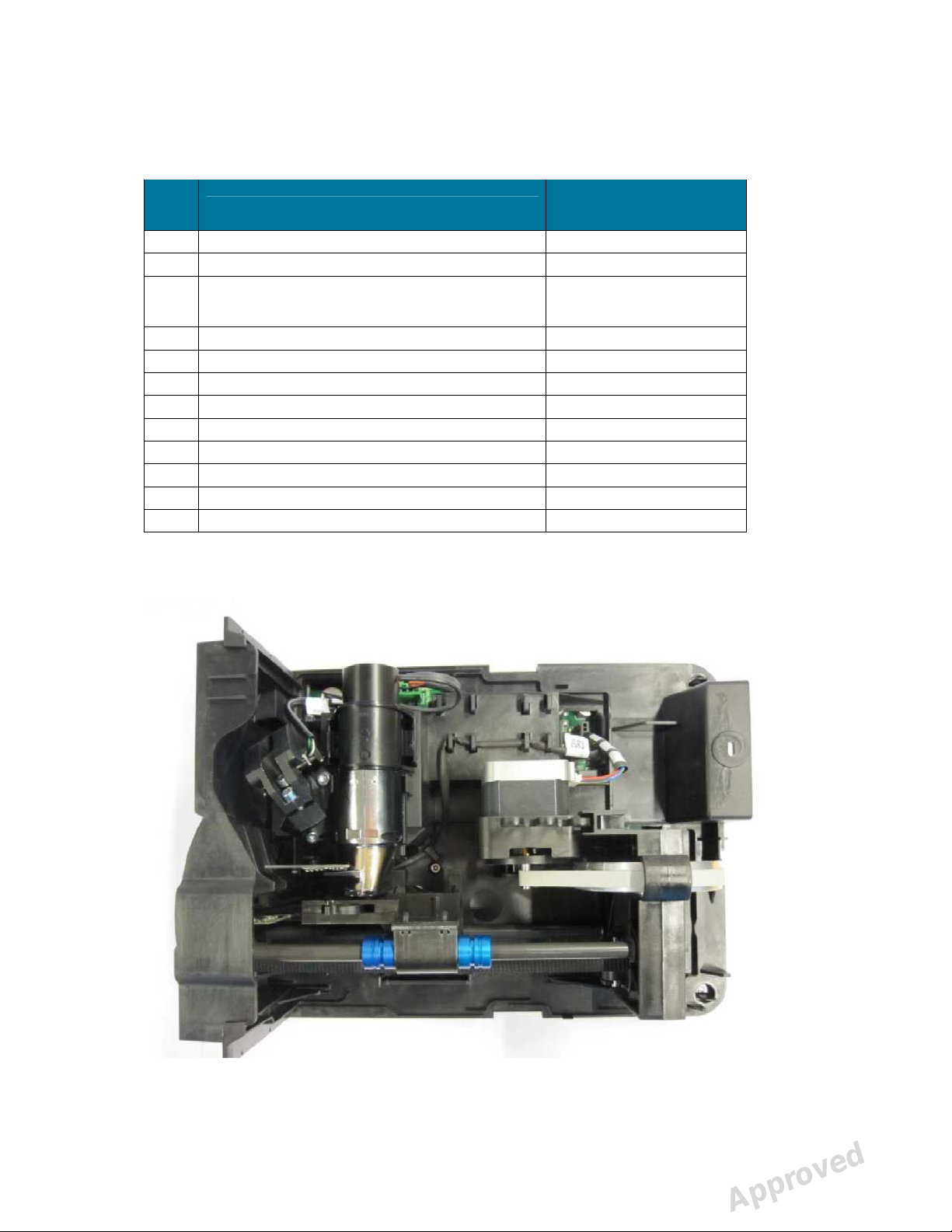

SCANNER MECHANISM ASSEMBLY

ITEM CODE DESCRIPTION

1 SP00912 MOVEMENT KIT IPS-2013

2 SP00914 INNER LIGHT PROTECT COVER IPS-2013

3 SP00916 K200 HOME-ERASE-LASERDETEC IPS-2013

4 SP00917 K300 PLATE DETECT REFL.SEN IPS-2013

5 SP00918 LASER AND MIRROR ASSEMBLY IPS-2013

6 SP00919 PMT, PHOTO MULTIPLIER TUBE IPS-2013

7 SP00920 UNIT DOOR IPS-2013

Products without part numbers are not for sale.

RECYCLING

INFORMATION

MATERIAL

PC+ABS

E-SCRAP

E-SCRAP

E-SCRAP

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 10 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

NdFeB/ Aluminum/

SP00912 MOVEMENT KIT IPS-2013 includes

RECYCLING

INFORMATION

PCS ITEM

2 SHAFT CCM08 CERAMIC COATED Aluminum, ceramic coated

1 BELT PULLEY COVER POM

1 IMAGING PLATE CARRIAGE ASSEMBLY POM/

1 MOTOR HOLDER ASSEMBLY POM/Steel/E-scrap

1 READOUT HEAD BELT MXL025-G Rubber

1 BELT 264X8 CH XL GA152 MANDREL84.1 Rubber

1 BELT PULLEY 73.8 - 5.4 Aluminum

2 BELT PULLEY POM

2 BEARING 625 ZZ Steel

1 DOWEL PIN 4H6X24 DIN6325 Steel

2 LOCKRING 6 DIN6799 Steel

1 NEEDLE ROLLER NRB4X25,8-G2 Steel

MATERIAL

Glass-fiber reinforced

polyarylamide

Covers and control panel assembly removed

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 11 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

Electronics

24VDC from External Power Supply

where supply voltage

Other boards are powered from

all boards must be

External Power Supply Unit

auto switching (100

AC

1.25A / 3

Output connector 2.1mm

No serviceable parts inside.

inside FPGA (incl. Ethernet controller and other logic)

System configuration flash

DDR2

(10M/100M)

(14 bit, AD9245)

START: indicates that input 24V is connected

near DC plug and is connected to back using light pipe

is activity led. D

established link at 100 Mbps. These are connected to the back using light pipe.

Analog signal processing circuitry

ge regulators for all boards & for laser

High voltage power supply for PMT (J106 )

Analog signal from PMT J

Circuitry for checking the high voltage.

to K200, K300 and user interface

ptoswitch D29 p

cover being installed.

ASSEMBLY

Membrane keyboard, which has

See user’s guide for more detailed description of keys and indicator light

K200 ERASE AND LASER DETECTION BOARD

Contains two pin diodes

LEDS for erasing the image plate residual image and control circuit for erasing

Opto switches D14 and D15 for sensing linear movement

is connected to

. This is located

is speed led, it is on when Ethernet PHY has

PMT high voltage

that are used to synchronize laser

Powering of the boards:

• INPUT voltage

Board

•

• For proper operation

• Universal input,

• Most commonly used

• Output 24VDC /

s to internal circuits are made

K100.

attached

-240 VAC / 47-63Hz).

plugs available (EU, US, UK, AU)

0W

K100 Main

•

•

K100 Main Board

• System clock

• CPU

•

• General-purpose

• Ethernet interface

• AD conversion

• Led D27 +12V-

• LED D11

•

• Low volta

•

•

•

• I/O between

• Safety o

without the light

center+ DC plug

Do not open.

-memory

memory

12

113

revents the switching of laser and

CONTROL PANEL

•

leds and control keys on it.

•

• Display and cables.

•

(Q1 and Q2)

movement.

•

•

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

s.

D511515, 2

Approved

• Blue led which can be used to check PMT operation. It’s brightness can be

controlled by CPU

K300 PLATE SENSOR BOARD

• Contains circuits for sensing image plate and that it is correctly inserted. Led

emits light which is reflected from IP to the photodiode receiver.

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 13 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

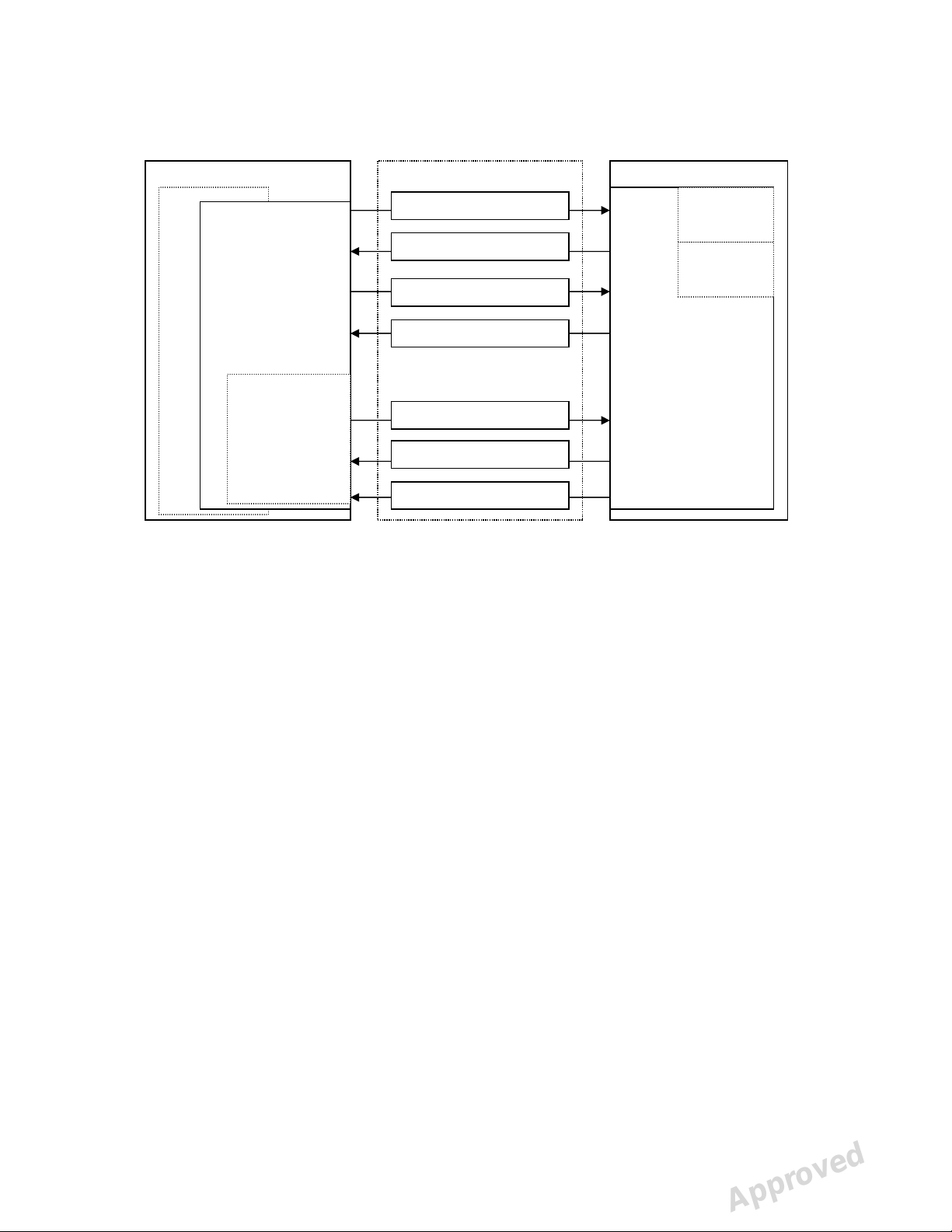

Service Output Msg

Driver Cmd Msg

Image Data Msg

Image Data Request Msg

User Cmd Reply Msg

User Cmd Msg

Driver Cmd Reply Msg

visible to user

Firmware

Architecture

Workstation (PC)

Imaging Application (optional)

Ethernet

Driver

(mandatory)

All messages

invisible to the

user.

Service

Terminal

(optional)

All messages

Imaging Application

• End user’s interface to acquired images.

• Handles image archiving and displaying.

Driver

• Handles the connection/communication to the unit

• Transfers and manipulates images.

• Unit cannot operate without Driver

There are two alternatives to be used as a driver:

1. DSD driver. Run from Application (or other imaging application)

2. s2terminal program. Run from the command prompt of Windows.

Service Terminal

• Optional part of the driver.

• Execute user commands

• View the service output of the unit.

• Run from the command prompt of Windows.

Scanner Firmware and Core

Takes care of the normal unit operations.

• Operates either in normal mode or service mode.

o Normal mode: Unit is fully operational and images can be acquired.

o Service mode: Unit does not react to any other inputs than those given by

the user through service terminal.

The scanner unit

Scanner Firmware and Core

Normal

mode

Service

mode

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 14 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

USER INTERFACE STATUSES

First the user press power button. During boot the system makes initialization and self

test.

1. User presses unit power button

2. Scanner initializes HW

3. Scanner checks that all boards are connected.

4. Scanner IP address configuration is started

5. Scanner drives linear movement to find position where door is closed.

6. Scanner sets linear amplifier offset

7. Check HV

8. Check PMT with blue led

9. Check erase led current and voltage

10. Check mirror resonator operation and stability

11. Check laser

12. Check plate sensor

13. Drive plate carriage out

14. READY for operation (if connection to the application SW is OK)

ERROR CODE is displayed if everything NOT OK during start.

NOTE: if the light protection covers surrounding scanner module is removed

EXPRESS™ Origo goes into error state after erase led test and self test sequence

is halted (recovering from this needs restart of the unit after installing the covers

back)

NOTE! If the opto safety switch light is blocked during start and covers removed –

the PMT may be damaged! Do not turn unit on when the light cover is removed.

Turning off is not possible if image is not transferred to imaging software (for example

Ethernet connection was lost before transfer), unit beeps and blinks PC and connection

leds. The carrier is driven in. The unit will not shutdown automatically. You must start

application and receive image before turning the unit off. You must turn the unit off only

by on/off button.

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 15 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

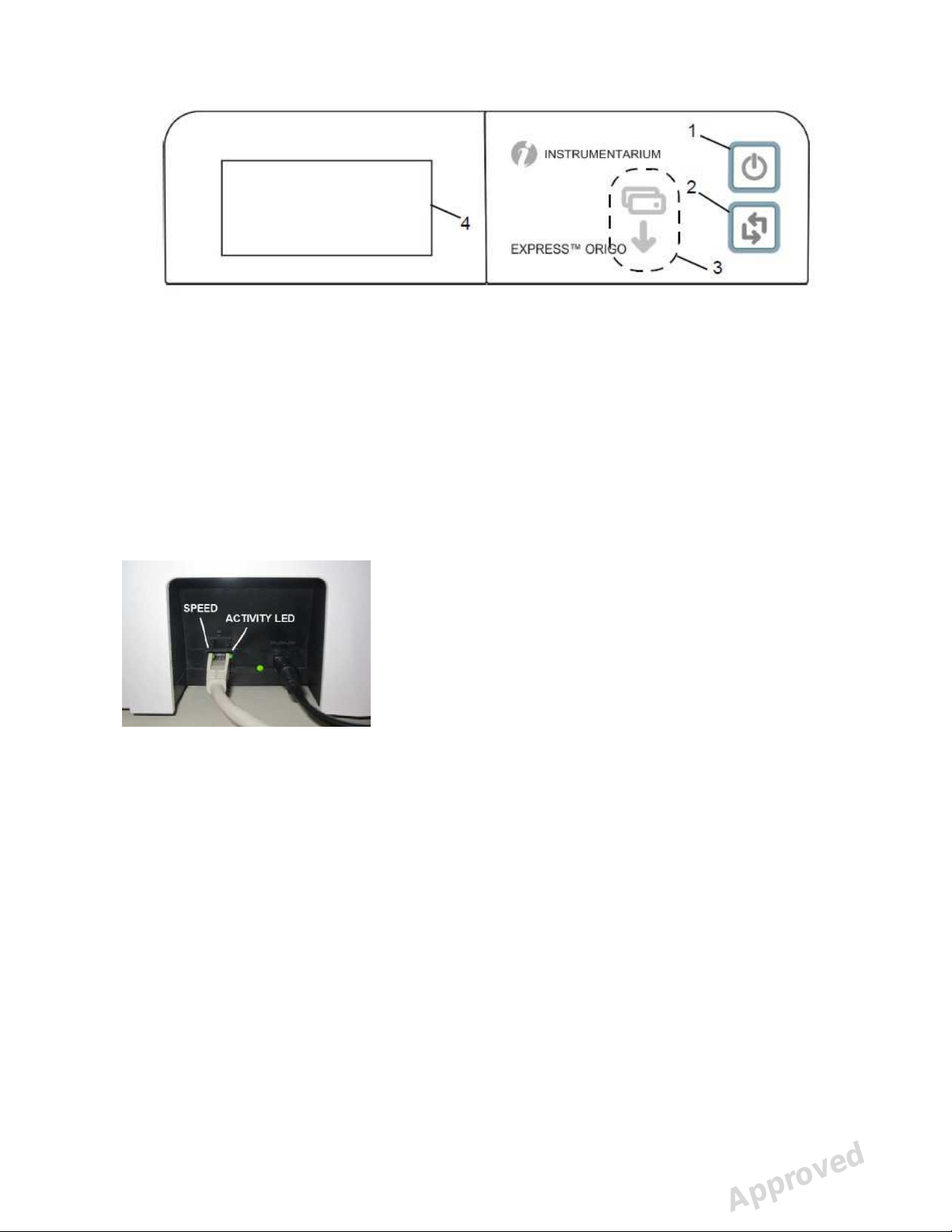

UI PANEL

1. ON/OFF key

2. START key

3. Plate feeding indicator

4. Status display

The use of UI panel display symbols, leds and buttons are described in the user manual.

LEDs backside

The Ethernet speed led is lit when link speed

is established at 100Mhz.

At other speeds the led is off. Activity LED

blinks when the unit sends or receives data

over the Ethernet network.

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 16 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

SERVICE TERMINAL

Service terminal is not an end user interface and training to use it in advance is

mandatory to prevent the changing of unit configuration (=resulting the unit to become

inoperative) accidentally.

Be very careful not to use service commands without the necessary know-how. Gain

knowledge by going through all useful commands and train their usage in practice with

scanner unit.

Service terminal commands and functions are not explained in this manual. They are

instructed in the scanner firmware help (which is accessible through service terminal).

This arrangement is to keep the documentation up to date, since the service terminal

instructions for commands are always up to date in the scanner firmware.

Therefore this manual explains only the principles of the main commands.

More detailed instructions of Service Terminal commands can be found later in this

document and in their help outputs <h [command]>.

Accessing Service Terminal

• Service terminal commands are controlled from s2terminal

NOTE: Only have either imaging application OR s2terminal open at one

time.

• Service commands are executed by scanner unit

• Firmware and core upgrade can only be performed with s2terminal

• s2terminal program is run from the command prompt of Windows.

• Application must be closed when accessing service terminal from s2terminal If

Application is opened at the same time, you will have a “login fail (no

connection)” error message on screen when trying to make the connection.

Note the difference of actual command prompt and the s2terminal program running in it:

• The input and output of the s2terminal and of the command prompt look similar.

• However, the functions and commands available in the command prompt are not

available in the s2terminal and vice versa.

• If you get confused it is good idea to check the title bar of the command prompt

window - it should read “s2terminal” when the s2terminal program is running.

- it reads “cmd.exe” when only Command Prompt is running

• Running the s2terminal program needs the following files:

• s2terminal.exe

• s2.dll

• W32N55.dll

• (s2terminal has to be version 7.7.1188.0 or later)

• S2terminal can be found usually from folder: Program files/Palodex

Group/IAM/

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 17 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

1. Copy all these files to one same and dedicated service folder that you may need

to create (in following example “c:\s2terminal” folder is used to store s2terminal

files)

2. Select from Windows: Start / Programs / Accessories / Command Prompt

Or

Select from Windows: Start / run

3. Type into “Open” -field: <cmd>

4. Choose OK

Command prompt examples:

• <cd\> (Changes to the root directory =C:\)

• <cd s2terminal> (changes to directory “s2terminal”)

5. CHECK THAT Application IS NOT OPENED

6. Type <s2terminal> in the command prompt to see the instructions for the

command syntax. Then execute the program using the unit’s IP -address.

7. Type <s2terminal 192.168.0.2>:

• Starts the Service Terminal for unit having ip 192.168.0.2

Or

Type <s2terminal 192.168.0.2 -c>:

• Starts the service terminal and configures ip –address to scanner unit

192.168.0.2

NOTE: Keep start button pressed when entering <s2terminal 192.168.0.2 –

c>:

8. If the IP-address is correct and the s2terminal program is able to connect to the

unit, it prints out terminal output of the login command, which displays

“s2terminal, the unit’s firmware version(s), serial number and some parameters”.

Otherwise it displays an error message(s).

NOTE: It is normal that you may have few times “login fail (no connection)”

–error also in normal functioning connection

9. Quit s2terminal program by <xq>

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 18 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

Normal and Service Mode of the Unit

Service terminal can be used having scanner unit in Normal mode or Service mode

• Normal mode = Normal operation, use Service terminal to monitor the scanner

unit operation

• Service mode = scanner unit Executes only the commands given from Service

terminal.

Almost all of the service procedures described in this manual are done in the service

mode.

Remember to quit the service mode before trying to use the unit normally.

<s> Activates the service mode – and “service>” prompt is shown in the service

terminal.

NOTE! If scanner unit is in standby mode, the first command only exits the

unit from the standby mode

<quit> Quits the service mode (=resumes scanner into normal operation mode).

<reset> Resets scanner unit. (ONLY SW RESET) Use if you get strange behavior

when trying to use the unit after exiting the service mode. After reset you exit

also the service mode

Service Command principles

General Principles for Command Usage

• About half of the commands activate a function, for instance the movement of

the plate carrier or enabling the laser.

• The other half view or set the configuration parameters of the scanner unit.

• To use commands first see their description by <h [command]>.

>> Then read all of the description before actually using the command.

NOTE: Do not execute the command if you are not sure about it’s function.

Improper use of some commands may result scanner unit to become

inoperative!

• Some commands are used to view and/or set different parameters of the unit.

• When issuing the command without any value (for example <eject>) it will

display the current value of the parameter.

• If the parameter is followed with a value (for example <hv 150>) the parameter

value is changed.

If the unit is in standby mode

• Does not execute the command, exits the energy saving mode when the

command is entered for the first time

>> You have to enter the same command again to perform the required action.

Help Command

EXPRESS™ Origo ICR6-1 Field Service Manual 210586 rev 1 (2014-06) 19 (61)

Reviewed: Klemola Timo 2014-06-19 10:58

Approved: Kyllönen Mika 2014-07-22 11:12

See PDM system to determine the status of this document. Printed out: 2015-04-08 16:23:12

Copyright © 2014 by PaloDEx Group Oy. All rights reserved.

D511515, 2

Approved

Loading...

Loading...