Instrumentarium ORTHOPANTOMOGRAPH Installation Manual

ORTHOPANTOMOGRAPH™ OP 3D Pro

3D Dental X-Ray System

Installation Manual

ENGLISH

216363 rev. 1

0.805.5080

Copyright Copyright © 2017 by PaloDEx Group Oy.

All rights reserved.

ORTHOPANTOMOGRAPH™ and CLINIVIEW™ are either

registered trademarks or trademarks of PaloDEx Group Oy

in the United States and/or other countries.

KaVo™ and EasyScout™ are either registered trademarks

or trademarks of Kaltenbach & Voigt GmbH in the United

States and/or other countries.

All other trademarks are property of their respective

owners.

Documentation, trademark and the software are

copyrighted with all rights reserved. Under the copyright

laws the documentation may not be copied, photocopied,

reproduced, translated, or reduced to any electronic

medium or machine readable form in whole or part, without

the prior written permission of PaloDEx Group Oy.

The original language of this manual is English.

PaloDEx Group Oy reserves the right to make changes in

specification and features shown herein, or discontinue the

product described at any time without notice or obligation.

Contact your PaloDEx Group Oy representative for the

most current information.

Manufacturer Instrumentarium Dental, PaloDEx Group Oy

Nahkelantie 160

FI-04300 Tuusula

FINLAND

Tel. +358 10 270 2000

www.kavokerrgroup.com

For service, contact your local distributor.

Table of Contents

1 Introduction..................................................................................................................1

1.1 ORTHOPANTOMOGRAPH™ OP 3D Pro ............................................................1

1.2 Intended use .........................................................................................................2

1.3 Associated documentation....................................................................................2

1.4 References............................................................................................................2

1.5 Abbreviations used in this manual ........................................................................3

1.6 Warnings and precautions ....................................................................................4

1.6.1 Warnings for cross infection. ......................................................................4

1.6.2 Warnings to be observed during installation and service...........................4

1.6.3 Cautions for Electrostatic discharge...........................................................6

1.6.4 General warnings.......................................................................................6

1.7 Disclaimer .............................................................................................................9

1.8 Disposal ................................................................................................................9

2 Unit description .........................................................................................................11

2.1 Main parts and controls.......................................................................................11

2.2 Patient positioning lights .....................................................................................13

2.3 Patient positioning panel.....................................................................................17

2.3.1 Cephalometric unit positioning panel.......................................................17

2.4 Main control panel...............................................................................................18

2.5 Unit identification labels ......................................................................................19

2.6 Unit movements..................................................................................................20

2.7 Emergency stop switch.......................................................................................21

3 Pre-installation requirements...................................................................................23

3.1 The unit...............................................................................................................23

3.2 Space requirements............................................................................................25

3.3 Fixing hardware and Installation and Setup tools ...............................................26

4 PC requirements........................................................................................................27

4.1 Minimum PC requirements..................................................................................27

4.2 The dental imaging software...............................................................................29

5 Installing the unit.......................................................................................................31

5.1 Content of delivery..............................................................................................31

5.2 The column .........................................................................................................31

5.3 The carriage........................................................................................................37

5.4 Check leveling.....................................................................................................42

5.5 Installing additional set screws and connecting cables.......................................43

5.6 Attaching the touch screen display to the column (new model)..........................45

5.7 Exposure button..................................................................................................47

5.8 External warning light (optional)..........................................................................48

5.9 Installing the cephalometric unit..........................................................................49

5.9.1 Enabling carpus imaging..........................................................................60

rev i

6 Panoramic and 3D calibrations and adjustments...................................................61

6.1 Introduction .........................................................................................................61

6.2 When to calibrate the unit ...................................................................................62

6.3 Reset maintenance counter................................................................................63

6.4 Preparing for calibration......................................................................................63

6.5 The calibration sequence....................................................................................66

6.5.1 Calibration of the preheat of the tube.......................................................66

6.5.2 Calibration of the tube current..................................................................66

6.5.3 3D collimator calibration...........................................................................67

6.5.4 3D Beam size verification (optional).........................................................69

6.5.5 Panoramic collimator calibration..............................................................70

6.5.6 Panoramic geometry calibration...............................................................74

6.5.7 3D geometry calibration...........................................................................75

6.5.8 SFOV (Small panel) 3D lasers alignment ................................................76

6.5.9 MFOV (Medium panel) 3D lasers alignment............................................78

6.5.10 Panoramic laser alignment.......................................................................82

6.5.11 3D pixel calibration...................................................................................84

6.5.12 Panoramic pixel calibration......................................................................84

6.5.13 3D Quality Check ....................................................................................85

6.5.14 Panoramic Quality Check (optional).........................................................90

7 Cephalometric calibration and alignment...............................................................93

7.1 Preparations........................................................................................................93

7.2 Cephalometric calibration sequence...................................................................93

7.2.1 Balancing the cephalostat........................................................................94

7.2.2 Primary collimator calibration...................................................................94

7.2.3 Rotation angle calibration.........................................................................95

7.2.4 Mechanical adjustment program..............................................................97

7.2.5 Secondary collimator horizontal adjustment ..........................................108

7.2.6 Cephalostat laser alignment...................................................................110

7.2.7 Cephalostat pixel calibration..................................................................111

7.2.8 Cephalostat Quality Check (optional).....................................................111

7.2.9 Ear holder alignment..............................................................................113

7.2.10 Horizontal adjustment ............................................................................115

7.2.11 Vertical adjustment.................................................................................116

8 Special procedures..................................................................................................117

8.1 General .............................................................................................................117

8.2 Cephalometric upgrade kit................................................................................117

8.3 Changing the cephalostat arm side...................................................................117

8.4 Changing the cephalostat arm side in service mode ........................................126

8.5 Adjusting and calibrating the cephalostat..........................................................127

8.6 Connecting the unit to the mains.......................................................................128

8.6.1 Preparing the PC....................................................................................131

8.6.2 Configuring the communication link to the PC.......................................131

8.7 Firmware update...............................................................................................133

8.7.1 Preparing for update ..............................................................................133

8.7.2 Software update.....................................................................................134

8.7.2.1 Automatic update.....................................................................134

8.7.2.2 Manual update.........................................................................134

8.8 Volatile installation ............................................................................................138

ii rev

8.8.1 Installation procedure.............................................................................139

8.9 Special cases....................................................................................................142

8.9.1 Programming a R3220 Main CPU board having wrong unit

type configured.......................................................................................142

8.9.2 Programming a non-responsive cephalostat CPU.................................143

8.10 Troubleshooting ................................................................................................147

8.10.1 Problem: No connection to the X-ray unit / R3220 circuit board............147

8.10.2 Problem: Automatic software update fails..............................................148

8.10.3 Problem: Manual update fails.................................................................148

8.10.4 Problem: S2terminal is unable to find binary files..................................148

8.11 Configurable panoramic mAs limit ....................................................................149

9 OP 3D Pro Pre-sales check list...............................................................................151

9.1 Physical Environment Requirements................................................................151

9.2 Radiation Shielding Requirements....................................................................151

9.3 Mechanical Specifications ................................................................................152

9.4 Electrical Specifications ....................................................................................152

9.5 Networking Specifications.................................................................................153

9.6 Computer Specifications...................................................................................154

9.7 Backup Specifications.......................................................................................154

9.8 DICOM Services SCP.......................................................................................154

9.9 Software configuration ......................................................................................155

9.10 Other information ..............................................................................................156

9.11 Notes / comments.............................................................................................157

9.12 Dimensions .......................................................................................................158

9.13 Dimensions with cephalostat.............................................................................159

rev iii

iv rev

1 Introduction

1.1 ORTHOPANTOMOGRAPH™ OP 3D Pro

ORTHOPANTOMOGRAPH™ OP 3D Pro is a dental X-ray

system for producing high quality digital images of

dentition, TM-joints and skull. In order to take images with

OP 3D Pro you need a suitable PC hardware connected to

the OP 3D Pro unit and CLINIVIEW™ imaging software to

capture and manage images. The OP300 performs the

following procedures:

Panoramic

1 Introduction

• Standard panoramic

• Pediatric panoramic

• Wide arch panoramic

• Bitewing

• TMJ, posterior-anterior (PA) projection

• TMJ, lateral projection (axially corrected)

• Ortho TMJ, axial corrected lateral projection

• Maxillary sinus

• Ortho Zone enhanced panoramic

• Orthogonal panoramic

Cephalometric (optional)

• Cephalometric lateral projection

• Cephalometric pediatric lateral projection

• Cephalometric postero-anterior (PA) projection

• Reverse Towne projection

• Waters view

• Carpus program (optional) (Not available in USA

and Canada)

3D Small panel (optional) H x W

• 61 x 41 mm Field of View

• 61 x 78 mm Field of View

1

3D Medium panel, H x W (optional)

• 50 x 50 mm Field of View

• 61 x 78 mm Field of View

• 78 x 78 mm Field of View

• 78 x 150 mm Field of View

• 130 x 150 mm Field of View (optional)

NOTICE! The FOV heights are maximum values measured

at the center of the FOV, the measured heights at the

edges of the FOV are smaller.

1.2 Intended use

The unit is intended for dental radiographic examination of

teeth, jaw and TMJ areas by producing conventional 2D xray images as well as x-ray projection images of an

examined volume for the reconstruction of a 3D view.

The unit is also intended for carpus imaging in assisting

cephalometric analyses (Not in USA).

CAUTION! USA only: Federal law restricts this device to

sale by or on the order of a dentist or other qualified

professional.

1.3 Associated documentation

• OP 3D Pro User manual

• OP 3D Pro Service manual

• CLINIVIEW software user manual

• CLINIVIEW software installation manual

• The user manual supplied with the 3D imaging

software

• The installation manual supplied with the 3D

imaging software

1.4 References

The following instructions are delivered with in the

OP 3D Pro installation manual:

• Firmware update instructions

2

1 Introduction

• Calibration instructions

• Cephalostat upgrade instructions

• Cephalostat side changing instructions

1.5 Abbreviations used in this manual

FOV = Field Of View. The cylindrical 3D volume that is

reconstructed by the system.

ROI = Region Of Interest. The anatomical area or region of

the patient that you are interested to examine.

FH = Frankfort-Horizontal

H = Horizontal

ADC = Automatic Dose Control

LDT = Low Dose Technology™

MAR = Metal Artifact Reduction

3

1 Introduction

1.6 Warnings and precautions

1.6.1 Warnings for cross infection

Always use available disposable protective covers with the

patient positioning accessories:

• Bite fork cover

• Chin support cover

• Head support cover

• Nose support cover

• Ear holder cover

1.6.2 Warnings to be observed during installation and service

In case the transportation package has been damaged,

make sure the actual product is fully intact.

Before attempting to service the device make sure that you

know how to operate it. Read the user’s manual.

Read and familiarize yourself with the warnings and precautions listed in the user’s manual.

Only use original spare parts from the manufacturer when

repairing the device or replacing parts.

Warning - Radiation Safety

Before servicing the unit familiarize yourself with local and

national radiation safety standards and requirements relating to dental x-ray equipment.

Warning - Electrical Safety

Disconnect the unit from the main power supply before removing any covers.

Disconnect the unit from the main power supply before repairing or replacing mechanical parts or installing accessories.

Be careful when operating the unit not to get body parts or

clothing trapped between moving parts.

Disconnect the unit from the mains power connection before servicing the unit, e.g. replacing circuit boards or other

electrical components.

If there are capacitors on a circuit board or electrical device

wait ten (10) minutes, after disconnecting the unit from the

power supply, before handling the board or device.

4

1 Introduction

If you have to leave the unit unattended with covers removed during servicing or maintenance, disconnect the unit

from main power supply so that anyone who inadvertantly

touches the unit does not receive an electric shock.

This unit should only be used in areas that are provided with

a protective earth connection to ensure an equipotential

ground connection.

Warning - Explosion hazard

Some disinfectants and cleaning agents may vaporize to

form an explosive vapour. If such disinfectants and cleaning

agents are used the vapour should be allowed to disperse

before switching the unit on.

Warning - Cleaning the unit

Switch the unit off and disconnect it from the main power

supply before cleaning or disinfecting the unit.

The aperture plate and the tube housing are made of lead

(Pb), which is a toxic material. Do not touch it with your bare

hands.

The installer must ensure that:

- The fixing screws are suitable for the wall material.

- The wall for fixing the unit is strong enough for attaching

the unit. It must withstand loads of 5000N or more.

- Pull out strength of the screws is 5000N or more.

- The wall fixing screws are adequately tightened.

To avoid the unit from tipping over, fix the unit with floor

bolts appropriate to the surface the unit is mounted on. The

bolts and the floor material must endure force of 5000 N.

The installer must ensure that the upper shelf attachment

screws are tightened.

The unit should be installed in a place with enough space

for safe operation. See the unit installation manual for recommended minimum site dimensions. It is the responsibility

of the customer to ensure that the site is large enough for

the patients.

Be aware of hot surfaces when removing covers during installation and maintenance.

When installing a dental X-ray unit always observe local and

national safety, radiation control and electrical regulations.

5

1 Introduction

1.6.3 Cautions for Electrostatic discharge

Electrostatic Discharge (ESD) can damage or destroy electronic components.

When servicing the device take precautions to avoid electrostatic build up and discharge (ESD). Follow the recommendations for the prevention of ESD that are used in the

country in which you are working. If no recommendations

are available follow the guide lines below.

Leave all new or replacement circuit boards and electrical

parts in their protective packaging until the boards are

needed.

Before handling circuit boards and electrical parts make

sure that any static electricity charge that has built up in you

body is discharged.

When handling circuit boards hold them by their edges and

do not touch any connectors or components.

When examining and checking circuit boards use an elasticated wrist wrap which is connected to a ground point

through a 1 Mohm current limiting cable. For a ground point

use water pipes, radiators or other objects that are known

to be connected to the ground. Also use a cable to connect

the x-ray unit to the same ground potential as the wrist

wrap.

If an antistatic mat is used, connect the wrist wrap to the mat

and the mat to the ground potential.

Wash the wrist wrap and check that it is in good condition

frequently.

1.6.4 General warnings

Personnel operating the device must be adequately trained

with respect to the technological principles of operation and

radiation protection when using cone beam computed

tomography (CBCT) imaging.

This unit complies with the EMC (Electromagnetic

Compatibility) according to IEC 60601-1-2. Radio

transmitting equipment, cellular phones etc. shall not be

used in close proximity of the unit as they could influence

the performance of the unit.

6

1 Introduction

Always ensure to fulfill the requirements of the local and national regulations.

The correct software and settings in the workstation are

essential to the performance of the unit. Consult technical

support to ensure correct setup.

Danger - Explosion hazard

Do not use in the presence of flammable anesthetics, gases or

vapors.

The unit is factory set to operate using a 230-240 ±10 VAC

power supply. Never connect the unit to a power supply

different to the voltage marked on the unit.

If the unit needs to be connected to a multiple socket-outlet,

the socket shall not be placed on the floor.

To avoid the risk of electric shock, the unit must only be

connected to a supply mains with protective earth.

The site must fulfill the environmental requirements in the

installation manual chapter technical specifications.

There should be free space around the unit for safe

operation.

The PC / Ethernet switch to which the unit is connected,

should be approved appropriately (e.g. EN 60950, IEC

60950, UL 60950). After installation, check that the IEC

60601-1 leakage current levels are not exceeded.

This product itself complies with IEC 60601-1 medical

safety standard but in order to the system incorporating also

a PC to comply the standard, EITHER the PC has to be a

medical PC OR the PC has to be located over 1,5 meters

apart from the unit. The installer and the user of the system

shall confirm that at least one of the above requirements is

fulfilled. A PC is a medical one if it complies IEC 60601-1

standard and that is indicated in the accompanying

documents of the PC.

The unit shall be connected directly to the acquisition PC

with an Ethernet cable. Connection through the LAN-network of the site is not allowed. Two network ports are

needed in the PC in order to connect also to the site

network.

All service operations must be made by authorized service

personnel only.

The annual service as described in manual is mandatory for

the correct and safe operation of the unit.

7

1 Introduction

When taking exposures, operators and service personnel

must protect themselves from radiation and remain at least

two meters (six feet) away from the unit during exposure.

Protect the patient from scattered radiation by placing a

protective lead apron over the patient.

The unit must be installed and serviced according to the unit

Installation & adjustments manual by a qualified technician.

Only personnel trained and approved by the manufacturer

of the unit are allowed to service the unit.

3D imaging should not be used for routine or screening

examinations in which a radiograph is taken regardless of

the presence or absence of clinical signs and symptoms. 3D

imaging examinations must be justified for each patient to

demonstrate that the benefits outweigh the risks.

Where it is likely that evaluation of soft tissues will be

required as part of the patient’s radiological assessment,

the imaging should be done using conventional medical CT

or MR, rather than 3D imaging using Cone Beam

technology.

Cone beam computed tomography images are not

adequate for the analysis of soft tissue.

Panoramic and 3D exposures should not be used if

conventional intraoral radiographic images (like bitewing

exposures) would be sufficient.

Make sure that patient’s thyroid glands are protected by a

lead apron during the exposure.

The place where the unit is to be installed and the position

from where the user will take exposures must be correctly

shielded from the radiation that is generated when the unit

is operated. Ensure to fulfill or exceed the requirements of

your local regulations.

The unit or its parts must not be changed or modified in any

way without approval and instructions from the

manufacturer.

When servicing use only approved replacement parts

supplied by the manufacturer.

The use of accessories not complying with the equivalent

safety requirements of this equipment may lead to a

reduced level of safety of the resulting system.

8

If this device is used with 3rd party imaging application

software not supplied by the manufacturer, the 3rd party

imaging application software must comply with all local laws

on patient information software. This includes the Medical

Device Directive 93/42/EEC and/or relevant legal

requirements in the USA.

Do not connect any equipment to the unit that has not been

supplied with the unit or that is not recommended by the

manufacturer. The use of accessory equipment not

complying with the equivalent safety requirements of this

equipment may lead to a reduced level of safety of the

resulting system.

All protective covers must be properly installed before

handing unit to the user or when operating the unit.

1.7 Disclaimer

1 Introduction

The manufacturer shall have no liability for consequential

damages, personal injury, loss, damage or expense

directly or indirectly arising from the use of its products. No

agent, distributor or other party is authorized to make any

warranty or other liability on behalf of the manufacturer with

respect to its products.

1.8 Disposal

The device, its spare parts, its replacement parts and its

accessories may include parts that are made of or include

materials that are non-environmentally friendly or

hazardous. These parts must be disposed of in

accordance with all local, national and international

regulations regarding the disposal of non-environmentally

friendly or hazardous materials.

Unit has at least the following parts that should be

regarded as non-environmental friendly waste products:

■ Tubehead (Pb, oil)

■ Collimator (Pb)

■ All electronic circuits, electronic boards inside

■ Sensor covers (EMC painted)

9

1 Introduction

10

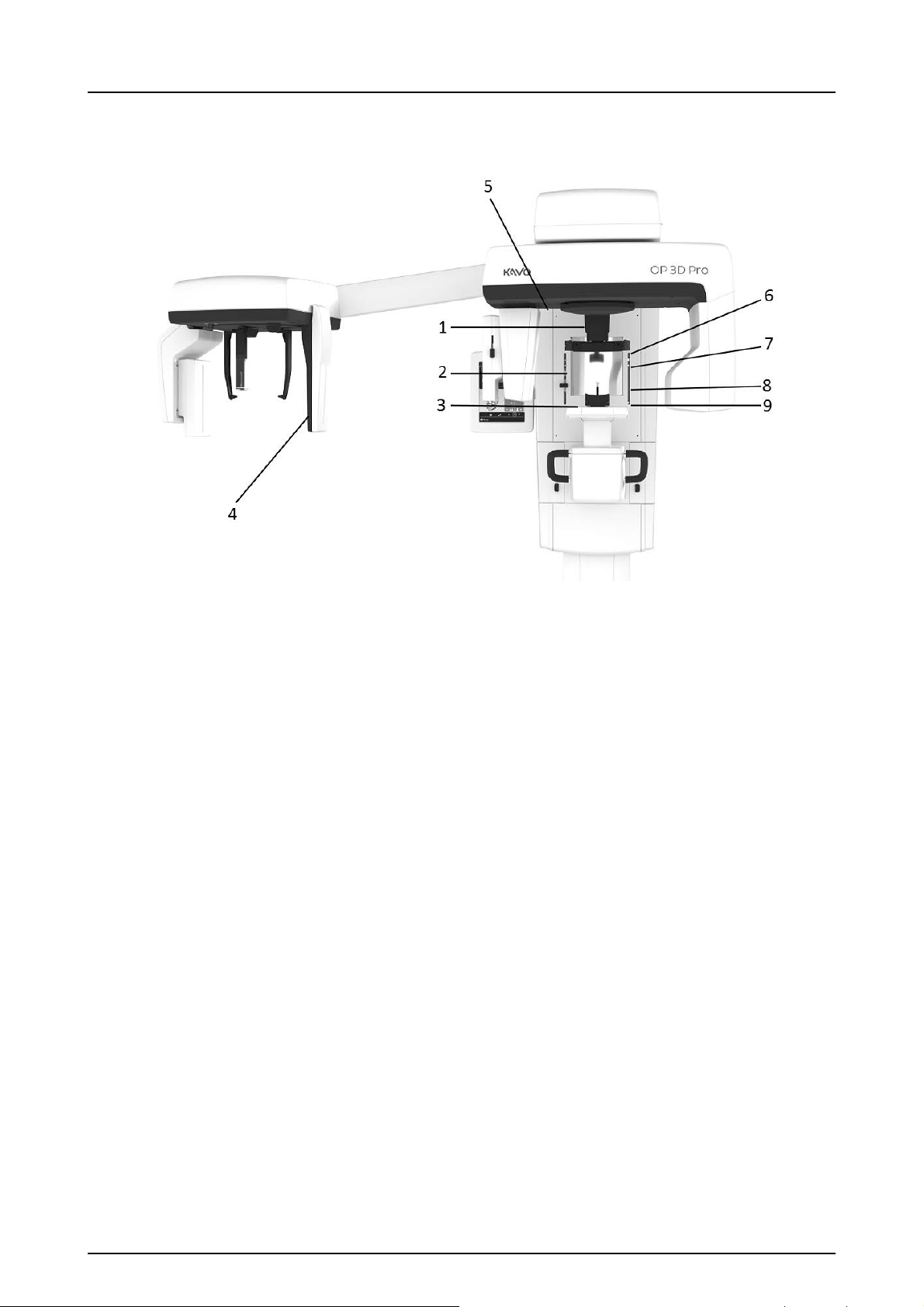

2 Unit description

1. Column

2. Carriage

3. Main support

4. Rotating unit

5. On/off switch (rear of carriage)

and main fuses

6. Tubehead assembly

7. Touch screen display

8. Patient positioning panel

9. Sensor head

10.Head support

11.Chin rest

12.Handles

13.Cephalostat unit

14.Cephalostat sensor

15.Secondary collimator

16.Patient positioning panel

On/off switch (used to power the unit on and off) and

main fuses.

2.1 Main parts and controls

2 Unit description

11

PC with MDD approved dental imaging software and 3D

viewing software (not included).

All software must conform to the MDD and the relevant

legal requirements in the USA.

The PC must conform to all the unit and dental imaging

software requirements.

2 Unit description

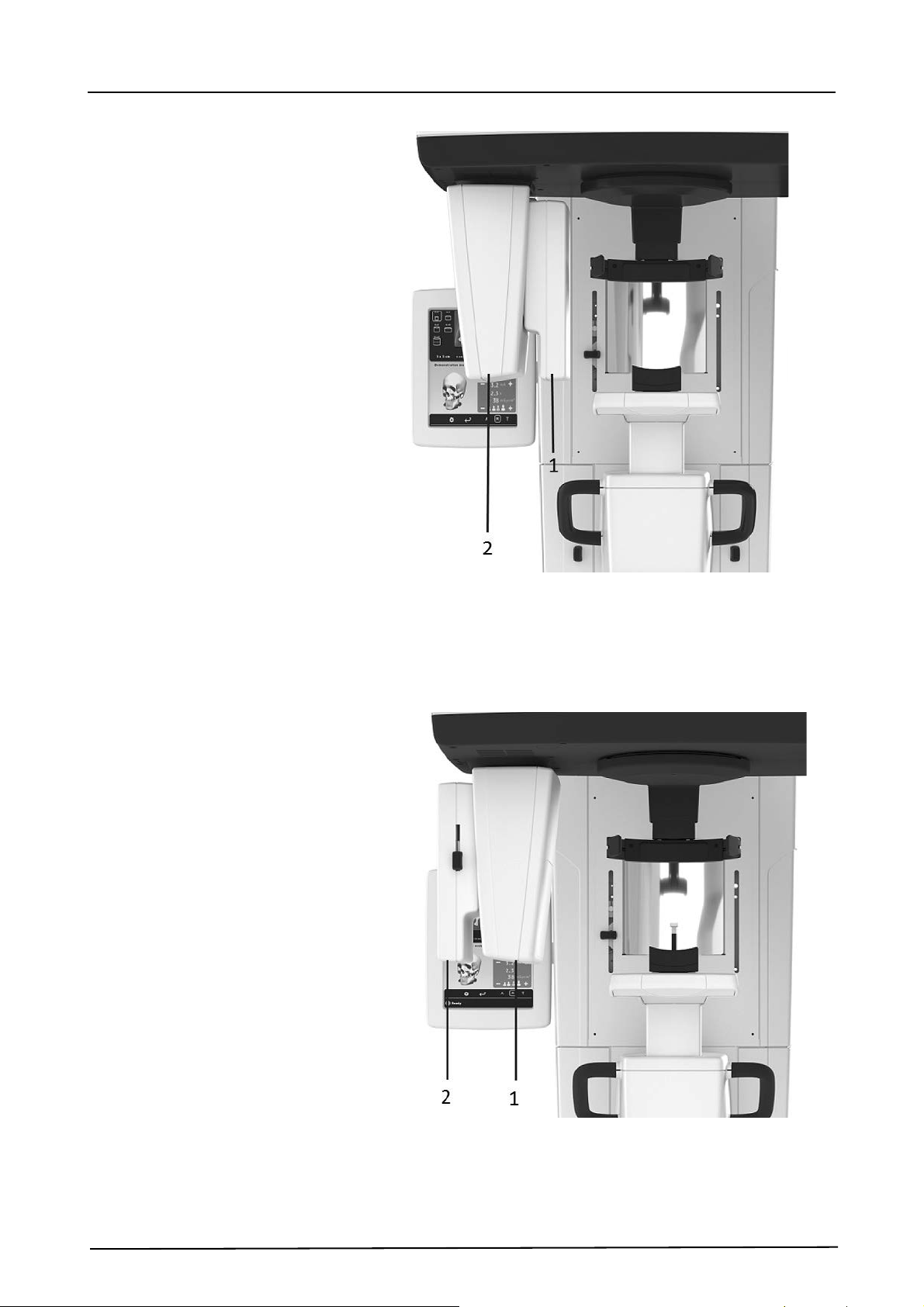

1. Sensor holder (panoramic units without 3D option)

2. Panoramic sensor

12

1. 3D sensor (units with 3D option)

2. Panoramic sensor

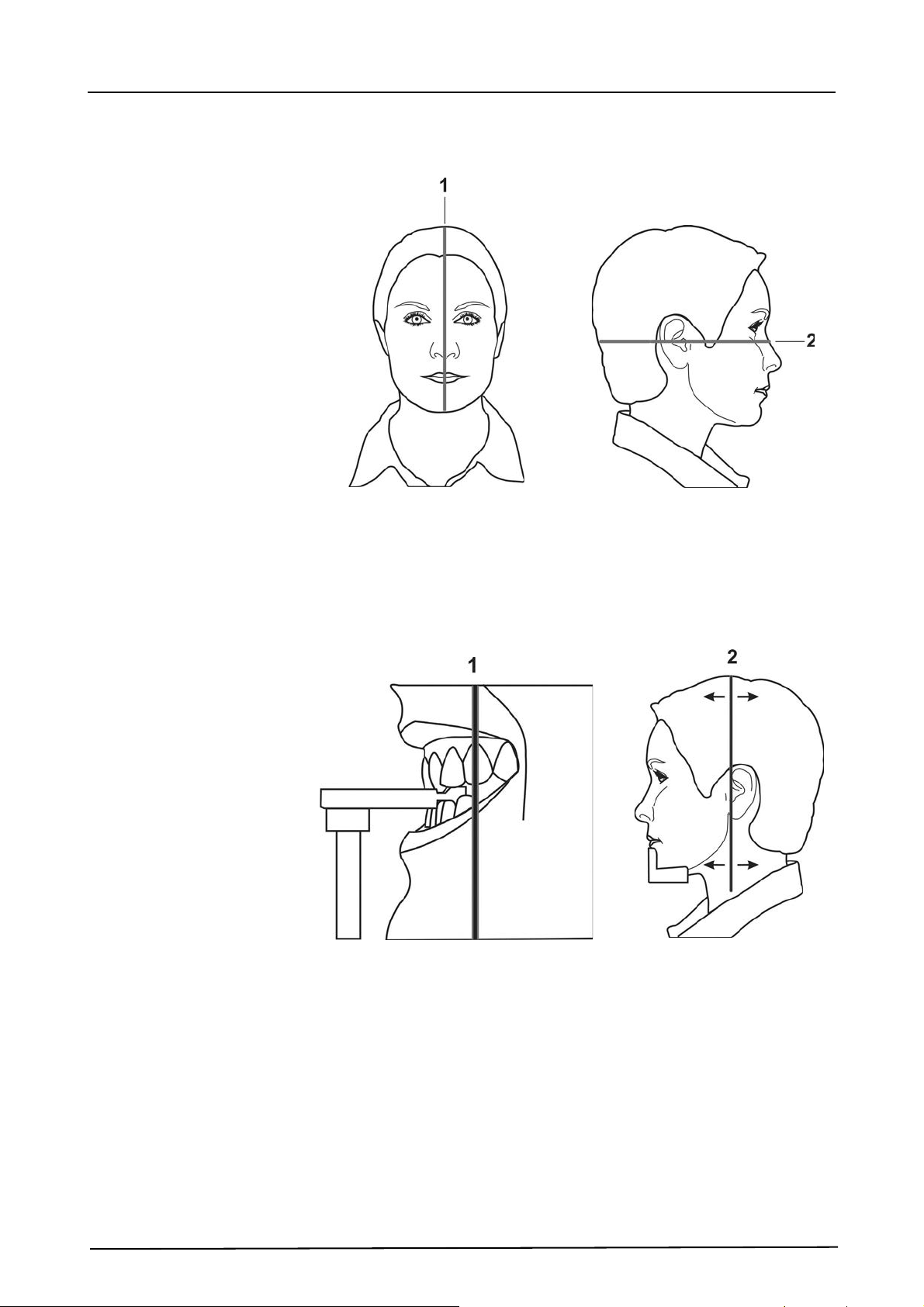

2.2 Patient positioning lights

2 Unit description

1. Midsagittal light

2. Frankfort horizont al (FH) light /

Horizontal light, top of 130 mm high FOV (Medium Panel

3D option only)

3. Image layer light

4. Cephalometric FH light

5. TMJ light

6. Horizontal light, top of 78 mm high FOV

7. Horizontal light, top of 61 mm high FOV

8. Horizontal light, top of 50 mm FOV

9. Horizontal light, bottom of FOV

13

2 Unit description

Panoramic lights

1. Midsagittal light

2. FH light

14

1. Image layer

2. TMJ light

Cephalometric lights (optional)

1. FH light

2 Unit description

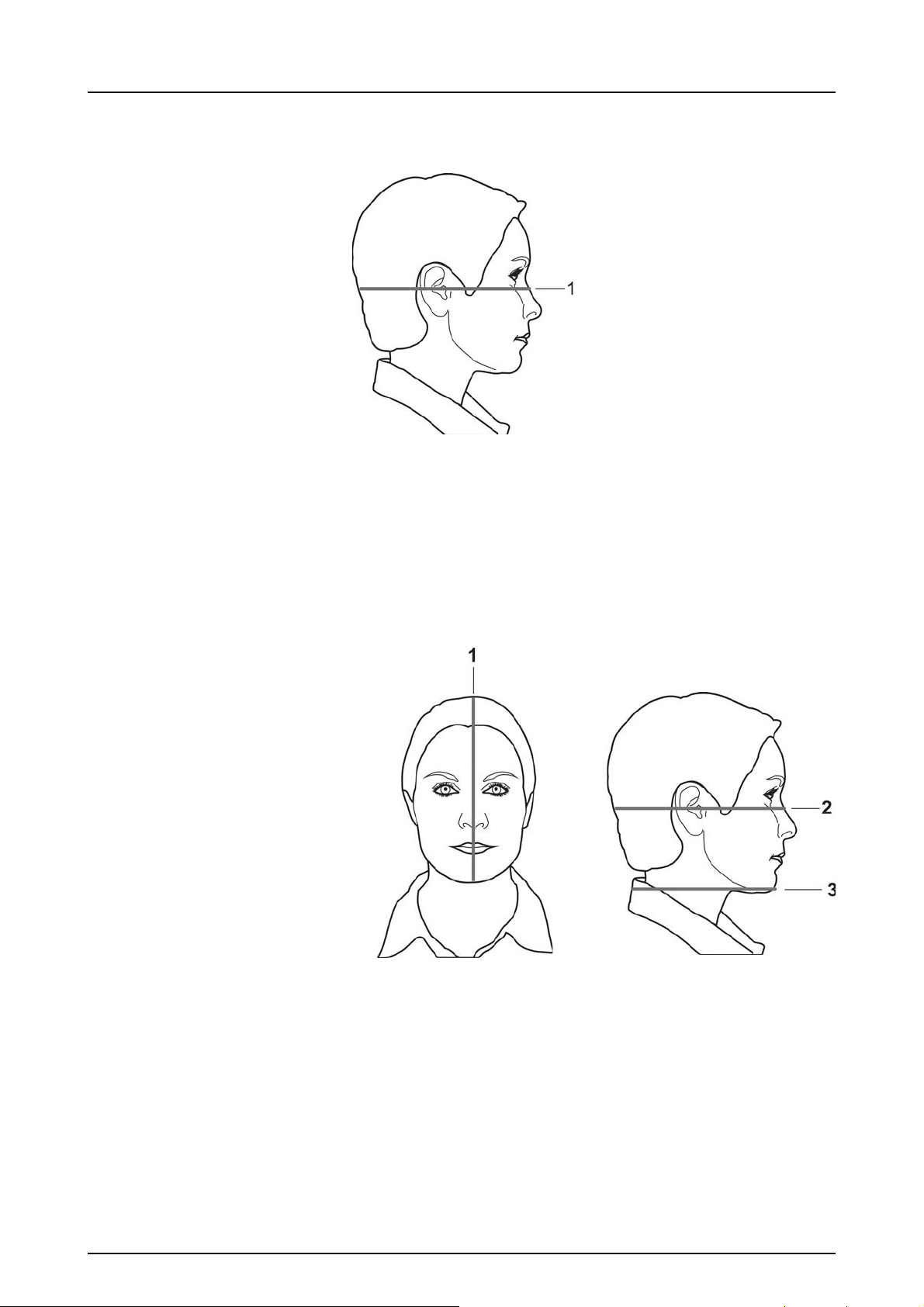

3D lights (optional)

NOTICE! Appropriate lights are turned automatically on

based on selected FOV.

1. Midsagittal light

2. Horizontal light, top of FOV

NOTICE! With Medium Panel 3D option, Optional 130

mm height is indicated with Frankfort horizontal (FH)

light. Move FH light to 130 mm position (locked in upposition).

3. Horizontal light, bottom of FOV

15

2 Unit description

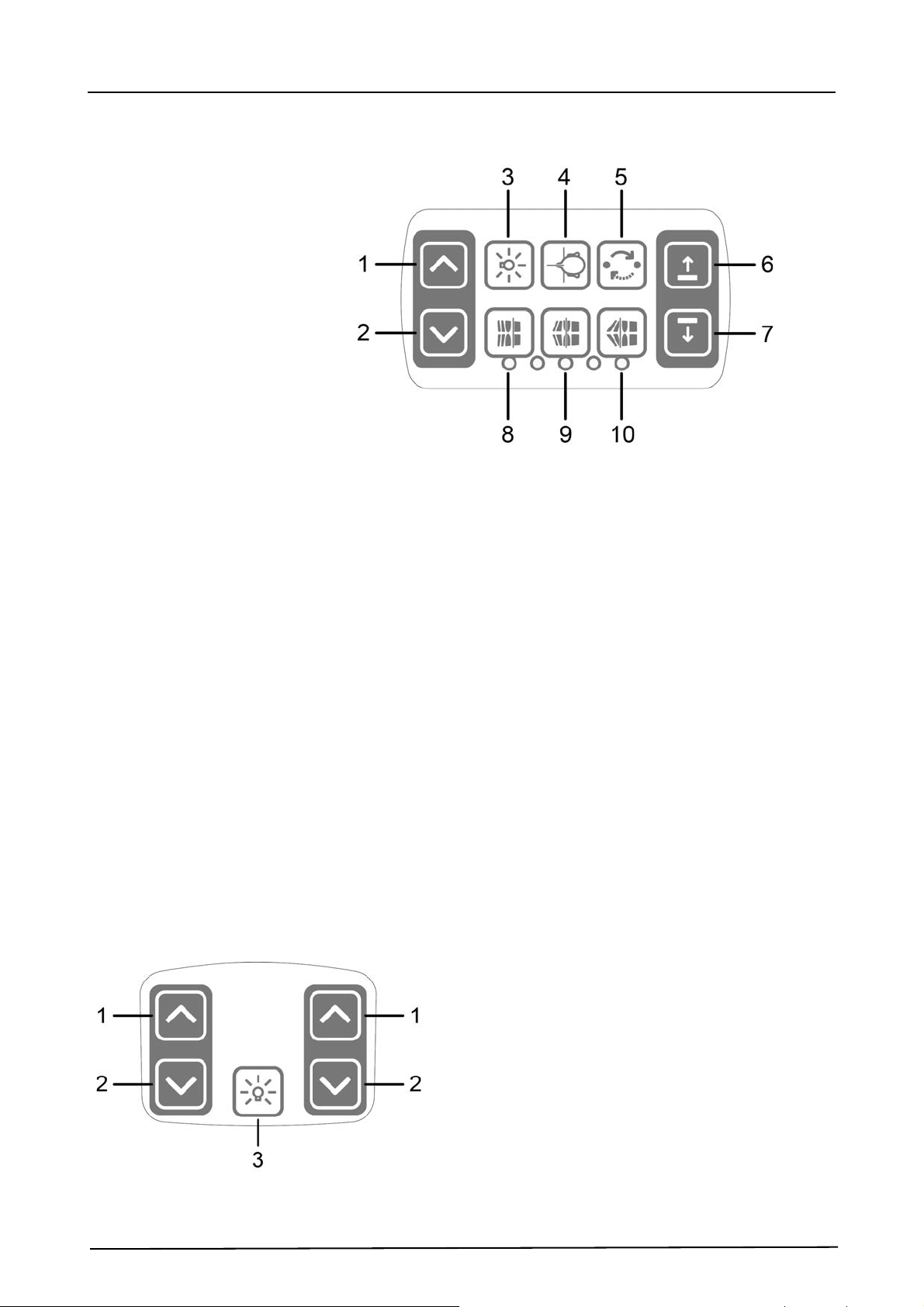

2.3 Patient positioning panel

1. Carriage UP

2. Carriage DOWN

3. Positioning lights ON/OFF

4. Patient positioning

5. Start position

6. Chin support UP

7. Chin support DOWN

8. Move the image layer anterior before exposure 3 mm,

with sinus program 10 mm

9. Normal occlusion/ reset position

10.Move the image layer posterior before exposure 3 mm,

with sinus program 10 mm.

2.3.1 Cephalometric unit positioning panel

1. Carriage UP

2. Carriage DOWN

16

3. Positioning lights ON/OFF

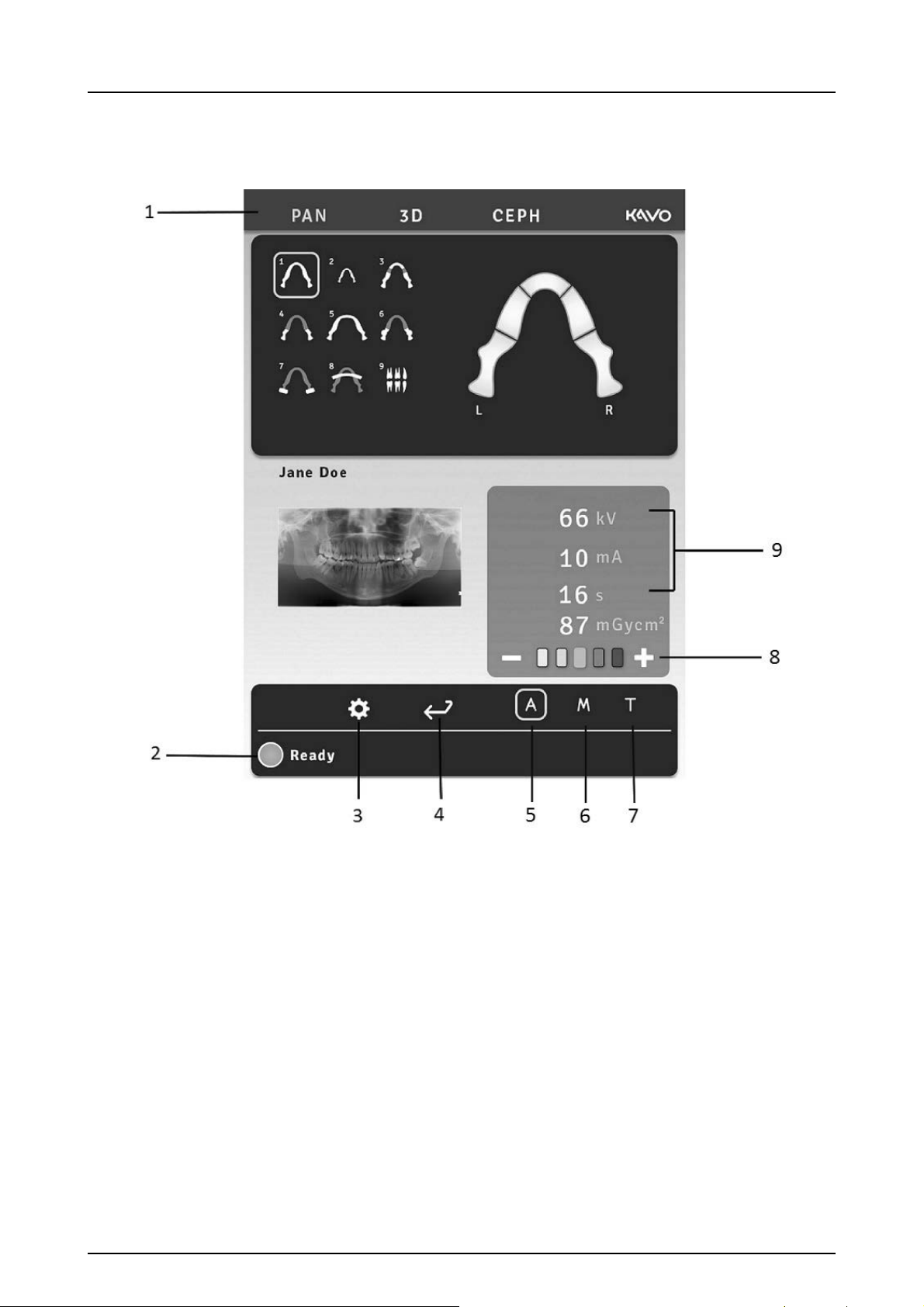

2.4 Main control panel

2 Unit description

1. Modality / imaging program section

2. Status of the unit

3. Settings

4. End examination

5. Automatic Dose Control

6. Manual mode

7. Test mode

8. Patient size selection

9. Exposure settings

17

2 Unit description

2.5 Unit identification labels

1. Main label

2. 10A & 15A Fuse labels (next to the fuse holder)

3. Laser class 1 warning label IEC 60825-1:2007

4. Ethernet label

5. Sensors

6. (Primary) collimator label

7. (Secondary) cephalosta t collimator label

8. Tubehead label

(on the tubehead and on the tubehead cover)

9. Warning label for deadly voltages

(inside the tubehead cover)

10.Cephalostat main label

18

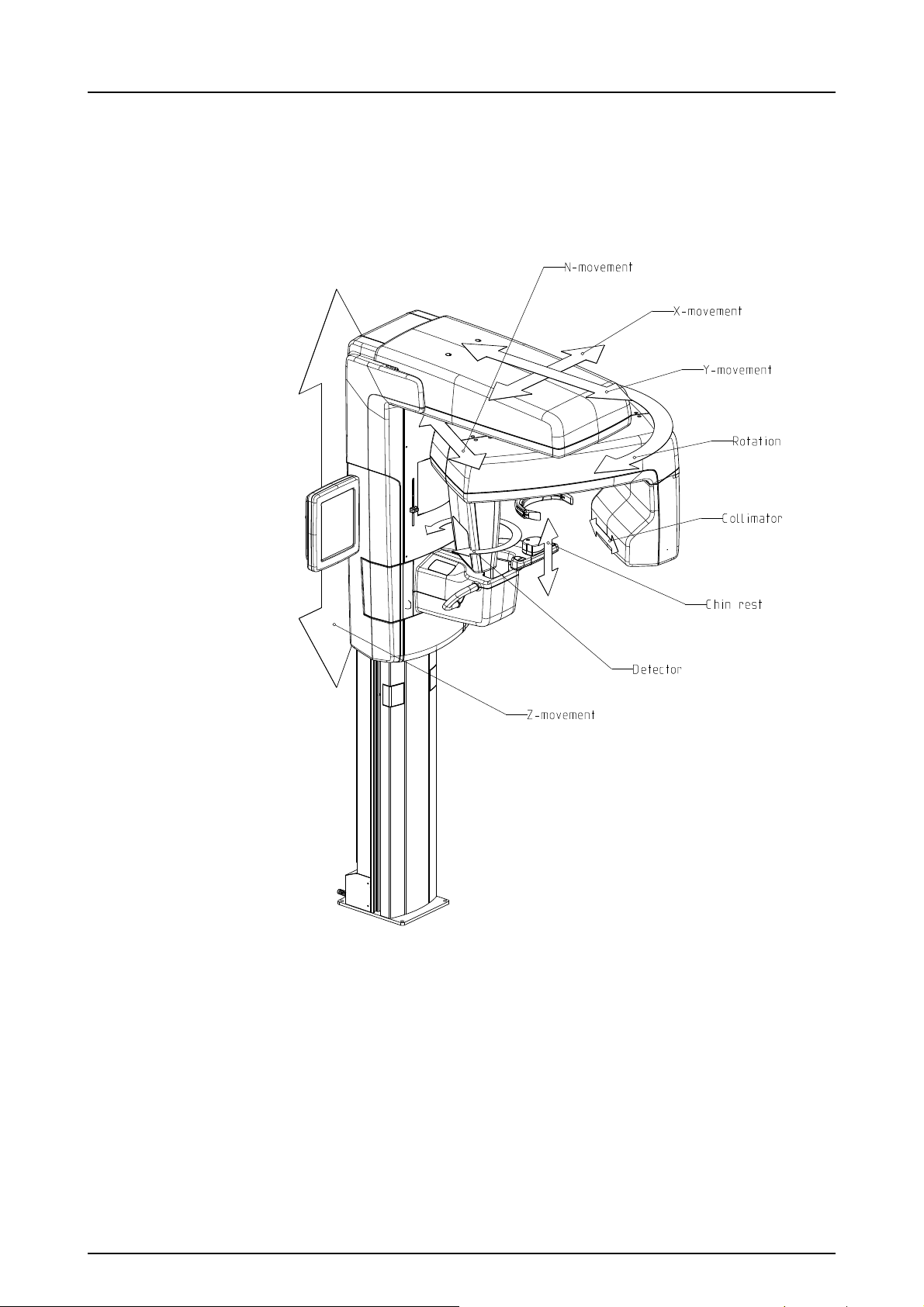

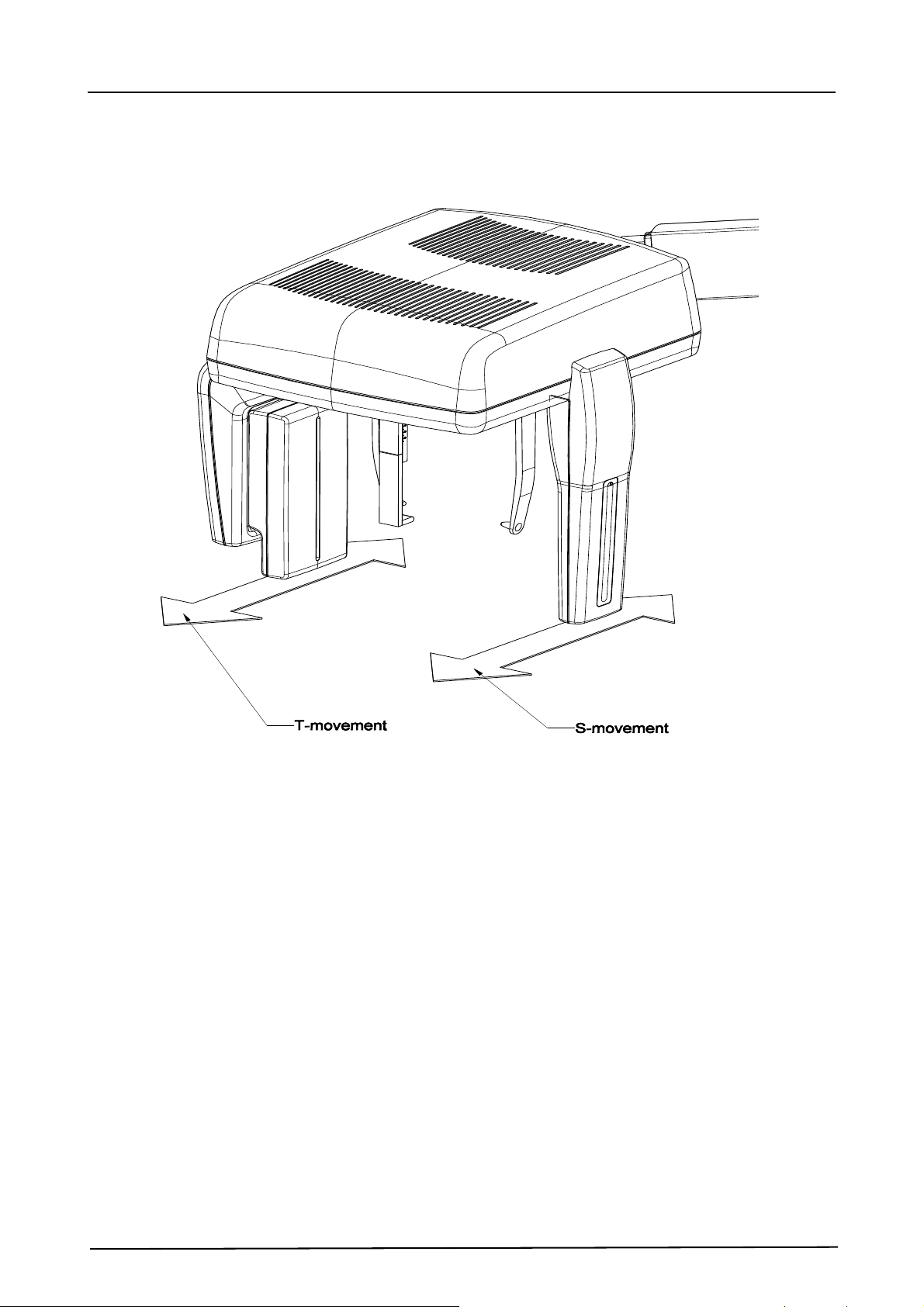

2.6 Unit movements

(R)

(C)

(J)

(D)

Panoramic unit movements

2 Unit description

19

2 Unit description

Cephalometric unit movements

20

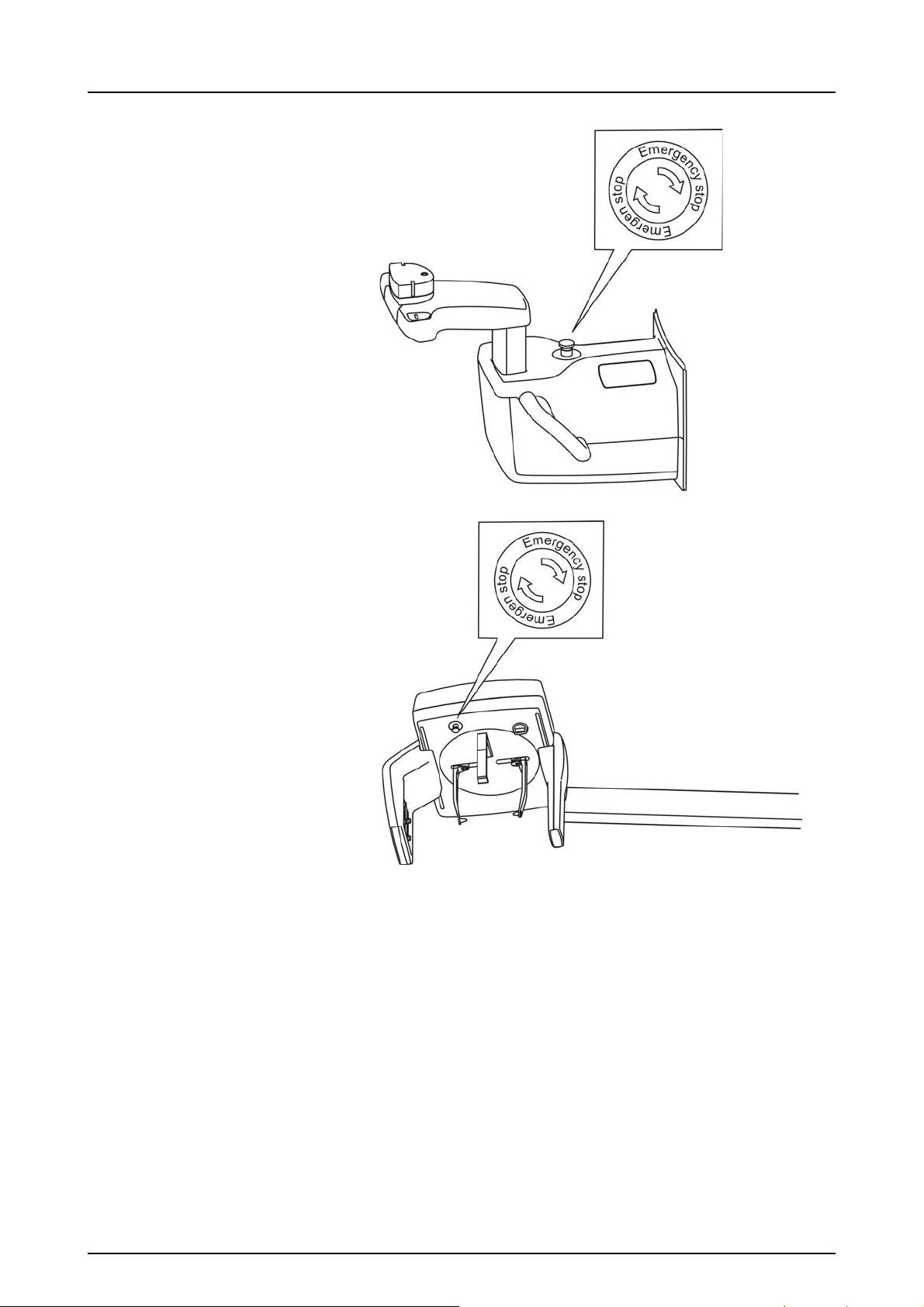

2.7 Emergency stop switch

In case of malfunction of the exposure button or other

protective devices of the unit, an emergency stop switches

are located near the handles and on the cephalostat unit,

so that the patient can easily reach them.

If the emergency stop switch is pressed during an

exposure, the exposure is terminated immediately and the

x-ray unit is completely stopped. An interrupted exposure

cannot be continued later, but has to be retaken from the

beginning after the emergency stop switch is released.

Press to stop the unit, rotate to release.

2 Unit description

21

2 Unit description

22

Loading...

Loading...