In-Situ TROLL 300, TROLL 500, TROLL 700 Operators Manual

Operator's Manual

Level TROLL®300, 500, 700, 700H Instruments

Informationsubject to changewithout notice. In-Situ, In-Situ logo, Baro Merge, BaroTROLL, HERMIT, iSitu, Pocket-Situ, RDO,

RuggedCable, RuggedReader, TROLL, and Win-Situ are trademarks or registeredt rademarks of In-Situ Inc.©2013. All rights reserved.

0052210 | Rev. 008 | 06/2013

Copyright © by In-Situ Inc. All rights reserved.

This document contains proprietary information which is protected by copyright. No part

of this document may be photocopied, reproduced, or translated to another language

without the prior written consent of In-Situ Inc.

Mailing and Shipping

Address:

In-Situ Inc.

221 East Lincoln Avenue

Fort Collins, CO 80524

U.S.A.

Phone: 970-498-1500 (international & domestic)

Fax: 970-498-1598

Internet: www.in-situ.com

Support: 800-446-7488 (U.S.A. & Canada)

In-Situ Inc. makes no warranty of any kind with regard to this material, including, but not

limited to, its fitness for a particular application. In-Situ will not be liable for errors

contained herein or for incidental or consequential damages in connection with the

furnishing, performance, or use of this material.

In no event shall In-Situ Inc. be liable for any claim for direct, incidental, or

consequential damages arising out of, or in connection with, the sale, manufacture,

delivery, or use of any product.

In-Situ and the In-Situ logo, Win-Situ, TROLL, Baro Merge, BaroTROLL, HERMIT, iSitu,

Pocket-Situ, RDO, RuggedCable, RuggedReader, TROLL, and Win-Situ are

trademarks or registered trademarks of In-Situ Inc. Microsoft and Windows are

registered trademarks of Microsoft Corporation. Pentium is a registered trademark of

Intel. Tefzel and Delrin are registered trademarks of E. I. DuPont de Nemours and

Company. Viton is a registered trademark of DuPont Dow Elastomers. Kellems is a

registered trademark of Hubbell Inc. Alconox is a registered trademark of Alconox

Company. Lime-A-Way is a registered trademark of Reckitt Benckiser. iPod and iPhone

are trademarks of of Apple Inc., registered in the U.S. and other countries. The

Bluetooth word mark and logos are registered trademarks owned by the Bluetooth SIG,

Inc. and any use of such marks by In-Situ Inc. is under license. NIST is a registered

trademark of the National Institute of Standards and Technology, U.S.A. Other brand

names and trademarks are property of their respective owners.

The presence of the Waste Electrical and Electronic Equipment (WEEE) marking on the product

indicates that the device is not to be disposed via the municipal waste collection system of any

member state of the European Union.

For products under the requirement of WEEE directive, please contact your distributor or local InSitu Inc. office for the proper decontamination information and take back program, which will

facilitate the proper collection, treatment, recovery, recycling, and safe disposal of the device.

0052210 | Rev. 008

1-800-446-7488 2 www.in-situ.com

Table of Contents

1 Introduction

Scope

Serial Number Location 7

Certification 7

Unpacking and Inspection 7

Warranty 7

Contact Information 8

2 Product Specifications

Level TROLL 300 Instrument

Level TROLL 500 Instrument 10

Level TROLL 700 Instrument 11

Level TROLL 700H Instrument 12

BaroTROLL Instrument 13

RuggedCable System 14

Suspension Wire 14

3 About the Pressure/Level Sensor

7

7

9

9

15

Absolute Pressure Sensor 15

Gauged Pressure Sensor 15

BaroTROLL Atmospheric Pressure Sensor 16

Configuring Depth and Level for PLC or Data Logger 17

4 System Components

Instrument 18

RuggedCable System 18

Vented or Non-Vented Cable 18

Jacket Options 18

Customizable Cable Lengths

Cable Termination 18

Suspension Wire 20

Communication Cables 21

Cable-Connect TROLL Com Communication Device 21

Direct-Connect TROLL Com Communication Device 22

Power Options 23

Internal Power—Batteries 23

18

18

AC Adapter 23

External Power—External Battery Packs 23

TROLL Battery Pack 23

1-800-446-7488 3 www.in-situ.com

TROLL Replaceable Battery Pack

Estimated Battery Lifetime 24

Installation Accessories 25

NPT Adapter 25

Cable Extender 25

Twist-Lock Hanger 25

Bulkhead Connector 26

Locking Well Cap 26

Well Dock Installation Ring 27

RuggedReader Handheld PC 28

Control Software 29

Win-Situ 5 Software 29

Win-Situ Mobile Software 29

24

5 Getting Started

Select a TROLL Com Communication Device 30

Connecting RuggedCable Systems 32

Connect the Instrument to the RuggedCable 32

Connect TROLL Com Communication Device to the RuggedCable System 32

Install the Software 34

Win-Situ 5 Software 34

Win-Situ Mobile Software 34

To update or reinstall Win-Situ Mobile use the following procedure. 34

Win-Situ Sync Software 34

6 Field Deployment

Program the Instrument 35

Position the Instrument 35

Verify Instrument Depth 36

Secure the Cable

Install the Desiccant 37

Desiccant 37

30

35

36

Installation Guidelines 38

Stabilization Time 39

BaroTROLL Instrument Installation 40

Programming the Baro TROLL Instrument 40

Installation 40

7 Software Overview

First Screen (Data Tab) 42

Home Tab 44

1-800-446-7488 4 www.in-situ.com

42

Logging Tab

Sensors Tab 49

Device Setup Tab 50

47

8 Using Win-Situ 5 Software

Connecting an Instrument to the Software

Selecting the Correct COM Port 51

Setting the Instrument Time 52

Adding a New Site 52

Log Setup 52

Logging Method Descriptions 53

Logging Methods for Long-Term Monitoring 53

Linear 53

Linear Average 53

Event 53

Logging Methods for Aquifer Testing 53

True Logarithmic 53

Fast Linear 54

Step Linear 54

About the Level Reference 54

Starting a Log 55

51

51

Starting a Pending Log 55

Starting a Manual Log 55

Suspending (Pausing) a Log 55

Resuming a Suspended Log 56

Stopping a Log 56

Downloading Data to a PC 56

Viewing Logged Data 57

Using BaroMerge Software

BaroMerge Input—BaroTROLL File 58

BaroMerge Output 59

Disconnecting an Instrument From the Software 60

9 Connect to a Data Logger or PLC Controller

Wiring 62

Analog (4-20 mA) 2 Wire 63

SDI-12 3 Wire 64

Modbus Master 65

Modbus Master with RS232 (Converter Required) 66

58

60

Power Connections 67

1-800-446-7488 5 www.in-situ.com

Communication Protocols

Redundant Logging 68

67

10 Cleaning and Maintenance

Overview

Operating Considerations 69

Temperature 69

Pressure Range 69

Batteries 69

Desiccant Pack Options 70

Small Desiccant 70

Large Desiccant 70

Outboard Desiccant 70

Extra Large Desiccant 71

Desiccant Refill Kit 71

Installing Desiccant with Twist-Lock Connectors 71

Installing Outboard Desiccant 72

Using the Desiccant Refill Kit 72

Antifouling 73

TROLL Shield Nose Cone 73

69

69

O-ring Inspection and Replacement 73

Cleaning and Storage 74

Cleaning the Instrument 74

Twist-Lock Connectors 74

Storage 74

Factory Calibration and Service 75

In-House Factory Calibration 75

Return Materials Authorization (RMA) Form 75

Obtaining Repair Service

Guidelines for Cleaning Returned Equipment 76

11 Decontamination and Cleaning Form

12 Troubleshooting

13 Declaration of Conformity

75

77

78

80

1-800-446-7488 6 www.in-situ.com

Introduction

The Level TROLL Instrument is a compact, modular system for measuring level and

temperature in natural groundwater, surface water, industrial waters, and other

installations.

Scope

This document is intended to describe the characteristics, operation, calibration, and

maintenance of the instrument. Communication registers and SDI-12 programming

information can be found in the Modbus and SDI-12 Reference Guides on the In-Situ

Inc. website.

Serial Number Location

The serial number is engraved on the instrument housing. It is also programmed into

the instrument and is displayed when the instrument is connected to a computer

running Win-Situ Software.

Certification

The Level TROLL Instrument complies with all applicable directives required by CE

and the FCC, and is found to comply with EN 61326, ICES-003, and FCC Part 15

specifications. Declarations of conformity can be found at end of this manual.

Unpacking and Inspection

Your instrument was carefully inspected before shipping. Check for any physical

damage sustained during shipment. Notify In-Situ and file a claim with the carriers

involved if there is any shipping damage. Accessories may be shipped separately and

should also be inspected for physical damage and the fulfillment of your order.

Please save packing materials for future storage and shipping.

The shipping boxes have been performance-tested and provide

protection for the instrument and its accessories.

Warranty

In-Situ Inc. warrants that all new instruments manufactured by it shall be free from

defects in materials and workmanship for a period of:

l One (1) year: Level TROLL 300

l Two (2) years: Level TROLL 500, Level TROLL 700, and BaroTROLL

when properly installed and operated in accordance with the instruction manuals

provided by, or available through In-Situ Inc., and when used within the design

specifications for the product. Products and accessory products including batteries,

which are manufactured by others, carry the warranty of that manufacturer, or 30 days,

1-800-446-7488 7 www.in-situ.com

whichever is greater. The warranty period for all products begins on the day the product

is shipped to the customer or distributor.

The complete Warranty Policy is available on the In-Situ website.

Contact Information

Mailing and Shipping

Address:

In-Situ Inc.

221 East Lincoln Avenue

Fort Collins, CO 80524

U.S.A.

In-Situ offers calibration and repair service. See page 75.

Phone: 970-498-1500 (international & domestic)

Fax: 970-498-1598

Internet: www.in-situ.com

Support: 800-446-7488 (U.S.A. & Canada)

1-800-446-7488 8 www.in-situ.com

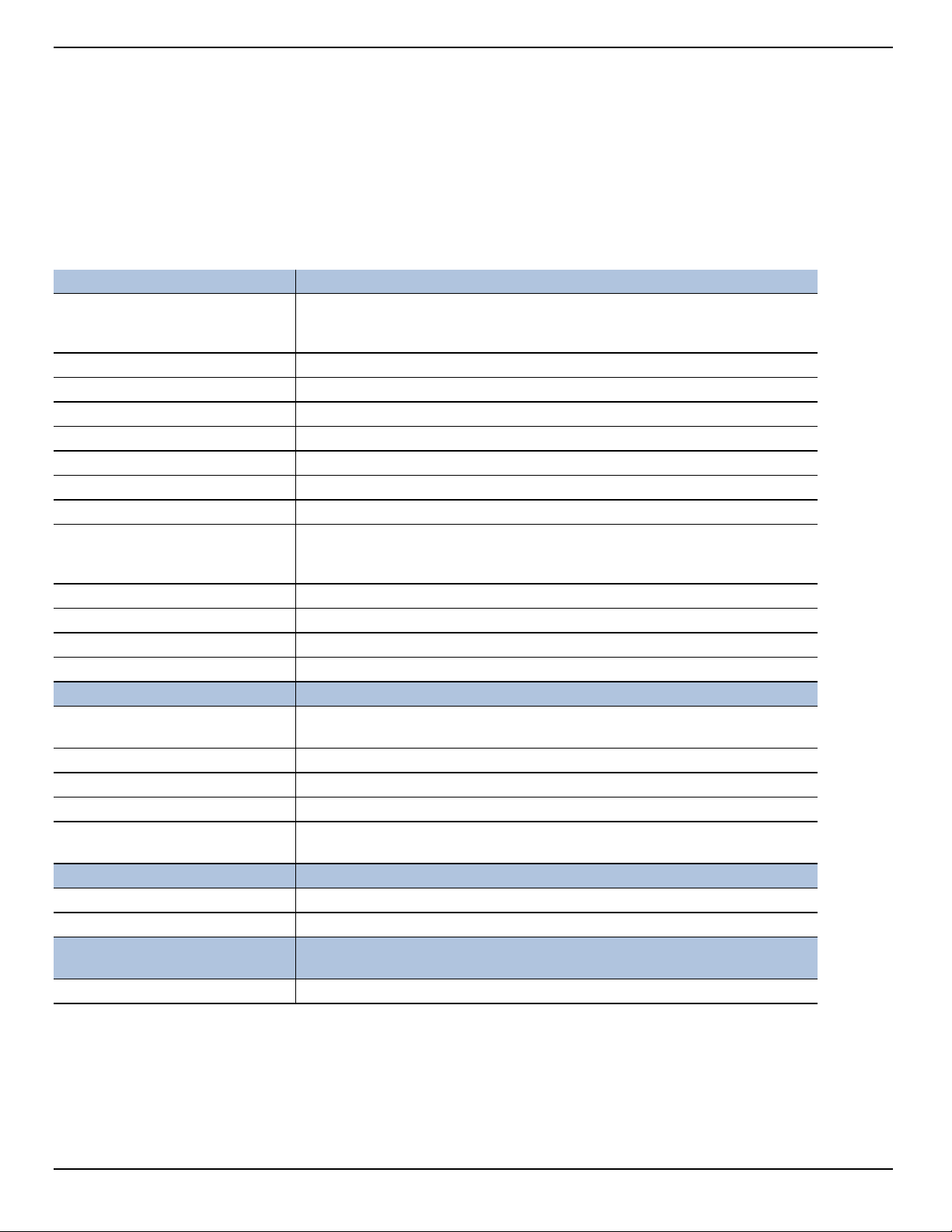

Product Specifications

Level TROLL 300 Instrument

General Level TROLL 300

Temperature ranges

1

Diameter 2.08 cm (0.82 in.)

Length 22.9 cm (9.0 in.)

Weight 245 g (0.54 lb)

Materials Stainless steel body; Delrin nose cone

Output options Modbus/RS485, SDI-12, 4-20 mA

Battery type & life

2

External power 8-36 VDC

Memory

Data records

3

Data logs

Log types Linear, Fast Linear, and Event

Fastest logging rate &

Modbus rate

Fastest SDI-12 & 4-20 mA

output rate

Real-time clock Accurate to 1 second/24-hr period

Sensor Type/Material Piezoresistive; stainless steel

Range

Burst pressure Max. 2x range; burst > 3x range

Accuracy @ 15° C

Accuracy (FS)

4

5

Resolution ±0.01% FS or better

Units of measure

Temperature Sensor

Accuracy & resolution ±0.1° C; 0.01° C or better

Units of measure Celsius or Fahrenheit

Warranty

Footnotes

Operational: -20-80° C (-4-176° F)

Storage: -40-80° C (-40-176° F)

Calibrated: -5-50° C (23-122° F)

3.6V lithium; 10 years or 2M readings

1.0 MB

65,000

2

2 per second

1 per second

Absolute (non-vented)

30 psia: 10.9 m (35.8 ft)

100 psia: 60.1 m (197.3 ft)

300 psia: 200.7 m (658.7 ft)

±0.1% full scale (FS)

±0.2% FS

Pressure: psi, kPa, bar, mbar, mmHg, inHg, cmH2O, inH2O

Level: in, ft, mm, cm, m

1 year

Up to 5-year extended warranties are available for all instruments—call for details

1

Temperature range for non-freezing liquids

2

Typical battery life when used within the factory-calibrated temperature range.

3

1 data record = date/time plus 2 parameters logged (no wrapping) from device within the factory-

calibrated temperature range

4

Across factory-calibrated pressure range

5

Across factory-calibrated pressure and temperature ranges

Specifications are subject to change without notice.

Delrin is a registered trademark of E.I. du Pont de Nemours and Company.

1-800-446-7488 9 www.in-situ.com

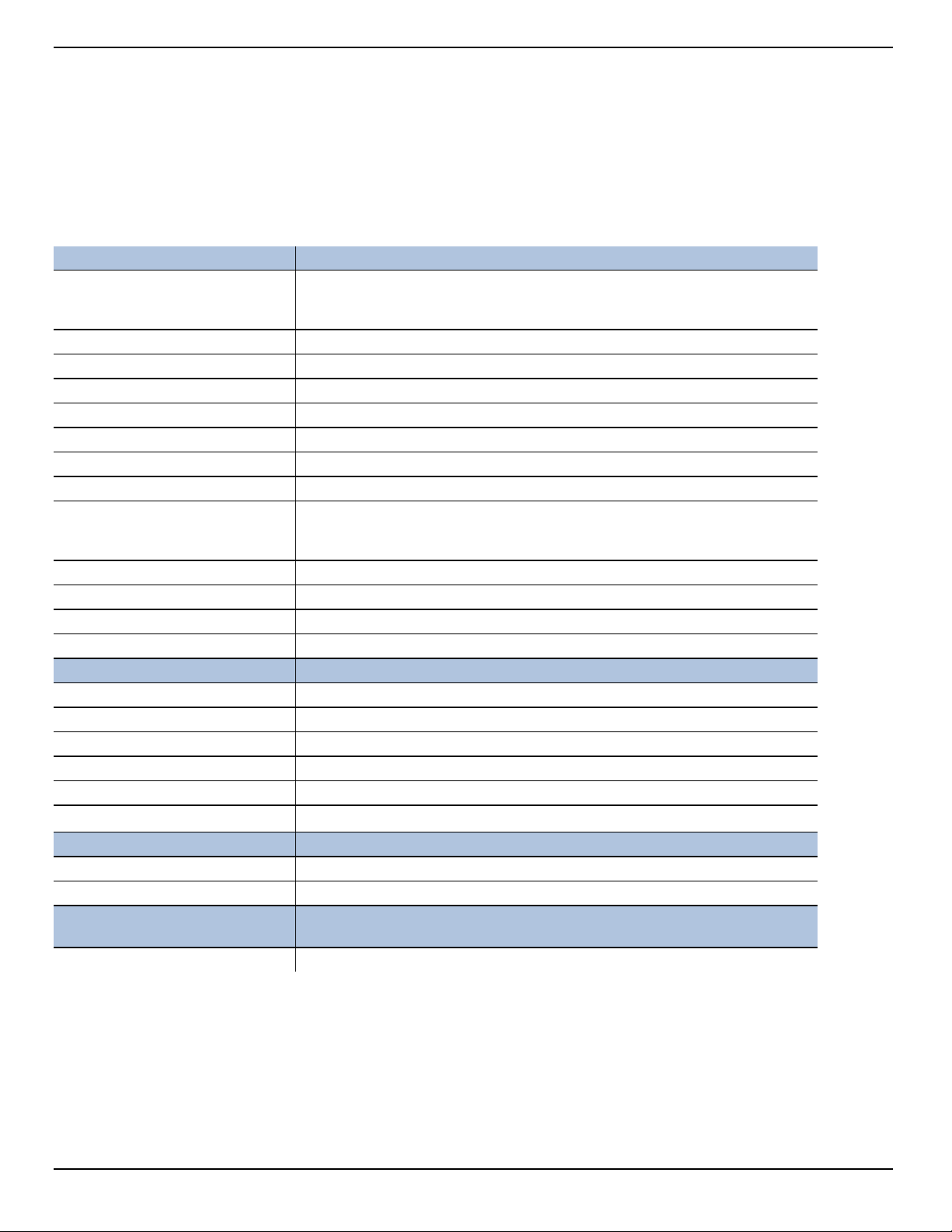

Level TROLL 500 Instrument

General Level TROLL 500

Temperature ranges

Diameter 1.83 cm (0.72 in.)

Length 21.6 cm (8.5 in.)

Weight 197 g (0.43 lb)

Materials Titanium body; Delrin nose cone

Output options Modbus/RS485, SDI-12, 4-20 mA

Battery type & life

External power 8-36 VDC

Memory

Data records

Data logs

Log types Linear, Fast Linear, and Event

Fastest logging rate & Modbus rate 2 per second

Fastest SDI-12 & 4-20 mA output rate 1 per second

Real-time clock Accurate to 1 second/24-hr period

Sensor Type/Material Piezoresistive; titanium

3

1

2

Operational: -20-80° C (-4-176° F)

Storage: -40-80° C (-40-176° F)

Calibrated: -5-50° C (23-122° F)

3.6V lithium; 10 years or 2M readings

2.0 MB

130,000

50

Absolute (non-vented)

30 psia: 10.9 m (35.8 ft)

100 psia: 60.1 m (197.3 ft)

300 psia: 200.7 m (658.7 ft)

500 psia: 341.3 m (1120 ft)

Range

Burst pressure Max. 2x range; burst > 3x range

Accuracy @ 15° C

Accuracy (FS)

Resolution ±0.005% FS or better

Units of measure

Temperature Sensor

Accuracy & resolution ±0.1° C; 0.01° C or better

Units of measure Celsius or Fahrenheit

Warranty

Footnotes See See page 9.

4

5

Gauged (vented)

5 psig: 3.5 m (11.5 ft)

15 psig: 11 m (35 ft)

30 psig: 21 m (69 ft)

100 psig: 70 m (231 ft)

300 psig: 210 m (692 ft)

500 psig: 351 m (1153 ft)

±0.05% FS

±0.1% FS

Pressure: psi, kPa, bar, mbar, mmHg, inHg, cmH2O, inH2O

Level: in, ft, mm, cm, m

2 years

Up to 5-year extended warranties are available for all instruments—call for details

1-800-446-7488 10 www.in-situ.com

Level TROLL 700 Instrument

General Level TROLL 700

Temperature ranges

Diameter 1.83 cm (0.72 in.)

Length 21.6 cm (8.5 in.)

Weight 197 g (0.43 lb)

Materials Titanium body; Delrin nose cone

Output options Modbus/RS485, SDI-12, 4-20 mA

Battery type & life

External power 8-36 VDC

Memory

Data records

Data logs

Log types Linear, Fast Linear, Linear Average, Event, Step Linear, True Logarithmic

Fastest logging rate & Modbus rate 4 per second

Fastest SDI-12 & 4-20 mA output rate 1 per second

Real-time clock Accurate to 1 second/24-hr period

Sensor Type/Material Piezoresistive; titanium

Range

Burst pressure Max. 2x range; burst > 3x range

Accuracy @ 15° C

Accuracy (FS)

Resolution ±0.005% FS or better

Units of measure

Temperature Sensor

Accuracy & resolution ±0.1° C; 0.01° C or better

Units of measure Celsius or Fahrenheit

Warranty

Footnotes See See page 9.

3

1

2

4

5

Operational: -20-80° C (-4-176° F)

Storage: -40-80° C (-40-176° F)

Calibrated: -5-50° C (23-122° F)

3.6V lithium; 10 years or 2M readings

4.0 MB

260,000

50

Absolute (non-vented)

30 psia: 10.9 m (35.8 ft)

100 psia: 60.1 m (197.3 ft)

300 psia: 200.7 m (658.7 ft)

500 psia: 341.3 m (1120 ft)

1000 psia: 692.9 m (2273 ft)

Gauged (vented)

5 psig: 3.5 m (11.5 ft)

15 psig: 11 m (35 ft)

30 psig: 21 m (69 ft)

100 psig: 70 m (231 ft)

300 psig: 210 m (692 ft)

500 psig: 351 m (1153 ft)

±0.05% FS

±0.1% FS

Pressure: psi, kPa, bar, mbar, mmHg, inHg, cmH2O, inH2O

Level: in, ft, mm, cm, m

2 years

Up to 5-year extended warranties are available for all instruments—call for details

1-800-446-7488 11 www.in-situ.com

Level TROLL 700H Instrument

Comply with the Office of Surface Water by using the most accurate pressure

transducer available. The Level TROLL 700H meets the surface-water specification of

±0.01 foot.

For accuracy under all operating conditions, instruments are calibrated over the full

pressure and temperature range. Each instrument includes a serialized, NIST-traceable

calibration report.

General Level TROLL 700H

Temperature ranges

Diameter 1.83 cm (0.72 in.)

Length 21.6 cm (8.5 in.)

Weight 197 g (0.43 lb)

Materials Titanium body; Delrin nose cone

Output options Modbus/RS485, SDI-12, 4-20 mA

Battery type & life

External power 8-36 VDC

Memory

Data records

Data logs

Log types Linear, Fast Linear, Linear Average, Event, Step Linear, True Logarithmic

Fastest logging rate & Modbus rate 4 per second

Fastest SDI-12 & 4-20 mA output rate 1 per second

Real-time clock Accurate to 1 second/24-hr period

Pressure Sensor Type/Material Piezoresistive; titanium

Range

Burst pressure Max. 2x range; burst > 3x range

Accuracy

Resolution ±0.005% FS or better

Units of measure

Temperature Sensor

Accuracy & resolution ±0.1° C; 0.01° C or better

Units of measure Celsius or Fahrenheit

Warranty

Footnotes See See page 9.

3

4

1

2

Operational: -20-80° C (-4-176° F)

Storage: -40-80° C (-40-176° F)

Calibrated: 0-40° C (32-104° F)

3.6V lithium; 5 years or 2M readings

4.0 MB

260,000

50

Gauged (vented)

15 psig: 11 m (35 ft)

±0.01 foot up to 10 ft and ±0.1% of reading > 10 ft

Pressure: psi, kPa, bar, mbar, mmHg, inHg, cmH2O, inH2O

Level: mm, cm, m, in, ft,

2 years

Up to 5-year extended warranties are available for all instruments—call for details

1-800-446-7488 12 www.in-situ.com

BaroTROLL Instrument

The titanium BaroTROLL measures and logs barometric pressure and temperature.

Use the BaroTROLL in conjunction with non-vented In-Situ Instruments.

Win-Situ BaroMerge Software simplifies post-correction of water level data by

automatically subtracting barometric readings from data collected by a non-vented

instrument to compensate for changes in pressure due to barometric fluctuations.

General BaroTROLL

Temperature ranges

Diameter 1.83 cm (0.72 in.)

Length 21.6 cm (8.5 in.)

Weight 197 g (0.43 lb)

Materials Titanium body; Delrin nose cone

Output options Modbus/RS485, SDI-12, 4-20 mA

Battery type & life

External power 8-36 VDC

Memory

Data records

Data logs

Log types Linear

Fastest logging rate & Modbus rate 1 per minute

Fastest SDI-12 & 4-20 mA output rate 1 per second

Real-time clock Accurate to 1 second/24-hr period

Sensor Type/Material Piezoresistive; titanium

Range 0 to 16.5 psi; 0 to 1.14 bar

Burst pressure Vaccum/over-pressure above 16.5 psi damages sensor

Accuracy @ 15° C

Accuracy (FS)

Resolution ±0.005% FS or better

Units of measure Pressure: psi, kPa, bar, mbar, mmHg, inHg, cmH2O, inH2O

Temperature Sensor

Accuracy & resolution ±0.1° C; 0.01° C or better

Units of measure Celsius or Fahrenheit

Warranty

Footnotes See See page 9.

3

1

2

4

5

Operational: -20-80° C (-4-176° F)

Storage: -40-80° C (-40-176° F)

Calibrated: -5-50° C (23-122° F)

3.6V lithium; 10 years or 2M readings

1.0 MB

65,000

2

±0.1% FS

±0.2% FS

2 years

Up to 5-year extended warranties are available for all instruments—call for details

1-800-446-7488 13 www.in-situ.com

RuggedCable System

General RuggedCable System

Operating temp. range -25° to 80° C (-13° to 176° F)

Jacket options

Vent options

Conductors 6 conductors, 24 AWG, polypropylene insulation

Cable diameter

Connector diameter 18. 5 mm (0.73 in.)

Weight

Minimum bend radius 2X cable diameter (13.5 mm; 0.54 in.)

Break strength 127 kg (280 lbs)

Maximum cable length 1,219 m (4,000 ft) for RS485

Desiccant pack

(required for vented

systems)

Warranty 2 years

TPU (thermoplastic polyurethane)

Tefzel (ETFE fluoropolymer; generic equivalent to Teflon)

Non-vented (absolute)

Vented (gauged) with desiccant (used to mitigate moisture/humidity)

TPU: 6.7 mm (0.265 in.)

Tefzel: 6.35 mm (0.25 in.)

Non-vented, TPU: 16 kg/300 m (35.6 lbs/1,000 ft)

Non-vented, Tefzel: 14 kg/300 m (32 lbs/1,000 ft)

Vented, TPU: 14 kg/300 m (32 lbs/1,000 ft)

Vented, Tefzel: 14 kg/300 m (32 lbs/1,000 ft)

Large and extra large desiccant packs available with titanium, ABS, or stripped-and-tinned

termination.

Specifications are subject to change without notice.

Suspension Wire

General Suspension Wire

Material 304 stainless steel, 7 x 7 strand

Coating 15 mil polyester elastomer insulation

Weight 0.28 kg / 30 m (0.60 lb / 100 ft)

Break strength 122 kg (270 lb) with proper clip tightening

Specifications are subject to change without notice.

1-800-446-7488 14 www.in-situ.com

About the Pressure/Level Sensor

A pressure transducer senses changes in pressure, measured in force per square unit

of surface area, exerted by water or other fluid on an internal media-isolated strain

gauge. In-Situ Inc. offers instruments with either absolute (non-vented) or gauged

(vented) pressure sensors.

The "Absolute vs. Gauged: Comparing Absolute and Gauged

Pressure Sensors" technical note describes the difference

between absolute and gauged pressure sensors and explains the

proper use of each type of sensor in different applications. See

www.in-situ.com/technical_notes.

Absolute Pressure Sensor

An absolute or non-vented pressure sensor measures all pressure forces detected by

the strain gauge, including atmospheric pressure (P

(pounds per square inch absolute), measured with respect to zero pressure. The back

of an absolute pressure sensor is sealed from the atmosphere. Therefore, the front of

the absolute pressure sensor responds to both atmospheric pressure and the pressure

head of water above the sensor.

). The unit of measure is PSIA

ATM

Absolute Sensor

1 Sensor back

2 Sensor front

3 Water pressure, PW(e.g., 20 PSI)

4 Atmospheric pressure P

5 Vacuum

(e.g., 14.5 PSI)

ATM

Gauged Pressure Sensor

A gauged or vented pressure sensor eliminates the effects of atmospheric pressure

because the vent tube in the cable allows atmospheric pressure to be applied to the

1-800-446-7488 15 www.in-situ.com

back of the sensor. The unit of measure is PSIG (pounds per square inch gauge),

measured with respect to atmospheric pressure.

Gauged Pressure Sensor

1 Sensor back

2 Sensor front

3 Water pressure, PW(e.g., 20 PSI)

4 Atmospheric pressure P

5 Atmospheric pressure P

(e.g., 14.5 PSI)

ATM

(e.g., 14.5 PSI)

ATM

BaroTROLL Atmospheric Pressure Sensor

Barometric pressure applies a direct stress upon open wells and surface water. Locally,

barometric effects can change significantly from location to location as a result of

topographical and micro-meteorological changes. Therefore, it is important to

compensate for the barometric pressure changes when monitoring water elevation.

BaroTROLL Sensor

1 Sensor back

2 Sensor front

3 Atmospheric pressure P

(e.g., 14.5 PSI)

ATM

4 Vacuum

1-800-446-7488 16 www.in-situ.com

Configuring Depth and Level for PLC or Data Logger

When you configure level using the Sensors tab, the settings are stored in the

instrument and are available for use in Modbus, SDI-12, or 4-20 mA analog

communication. A different configuration can be selected when you set up a log.

1. Connect the instrument to the software.

2.

Click the Sensors tab

.

3.

Select the level/pressure sensor and click the Configure

Sensor Setup window appears.

4. In the Sensor Setup window, select the Level parameter, then click Configure The

Level Setup Wizard opens.

button. The

5. In the Level Setup Wizard, select the options you want. For more information, view

the Help in the Win-Situ 5 Software.

1-800-446-7488 17 www.in-situ.com

System Components

Instrument

The Level TROLL Instrument is completely sealed and contains no user-serviceable

parts. The instrument includes pressure and temperature sensors, a real-time clock,

microprocessor, sealed lithium battery, data logger, and memory. Options include a

vented or non-vented pressure sensor in a variety of ranges.

RuggedCable System

RuggedCable Systems are custom-built, durable, direct-read cables that include the

following items.

l Titanium twist-lock connectors for quick, reliable connections to the instrument,

desiccant, and communication cable

l Metal shield beneath the cable jacket to prevent electrical interferences

l Kellems grip for secure instrument deployment

l Small desiccant for vented systems (for storage only)

Non-vented cables are marked with VF, which means vent free.

Vented or Non-Vented Cable

Vented cable is used with vented pressure sensors to produce gauged measurements.

The cable vent tube ensures that atmospheric pressure is applied to the back of the

sensor diaphragm.

Non-vented cable is used with non-vented instruments for absolute measurements.

Compensate absolute measurements by using a BaroTROLL Instrument and Win-Situ

Baro Merge Software.

Vented cable is shipped with a small desiccant to protect against

condensation. Larger desiccants are necessary for deployment.

Jacket Options

Tefzel (vented) or thermoplastic polyurethane (TPU, vented or non-vented)

Customizable Cable Lengths

Cables can be ordered up to 1,219 m (4,000 ft).

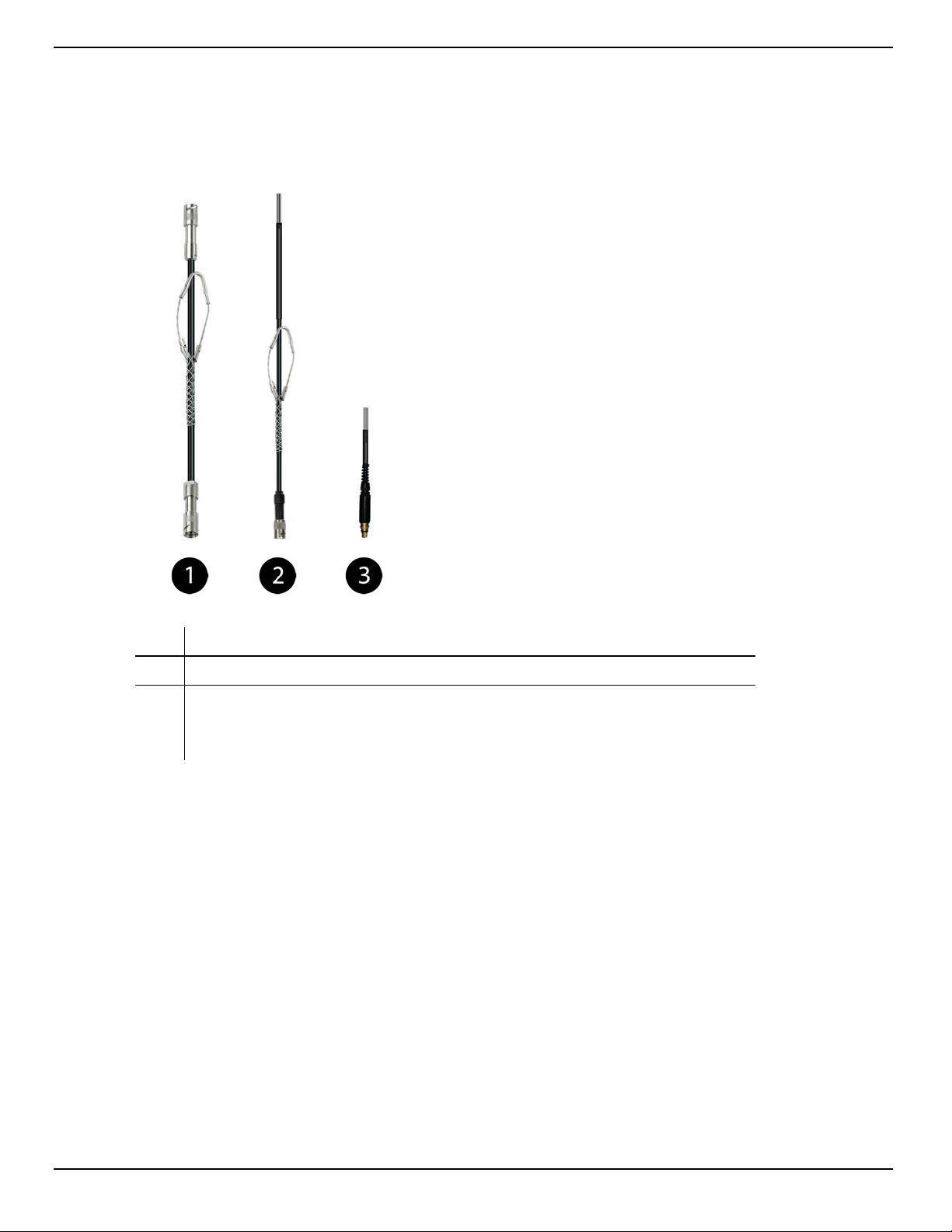

Cable Termination

Cables can be ordered with a twist-lock termination (female connector) on both ends

that connect to the instrument, the TROLL Com Communication Device, desiccant, and

1-800-446-7488 18 www.in-situ.com

other accessories.

Cables can also be ordered with stripped-and-tinned termination for wiring to a data

logger or controller using SDI-12, analog (4-20 mA), or Modbus communication

protocol.

1 RuggedCable System with female to female connectors

2 Stripped-and-tinned RuggedCable System with female connector

Stripped-and-tinned RuggedCable System with male connector

3

(short length that converts a cable with a twist-lock connector to a

stripped-and-tinned cable)

1-800-446-7488 19 www.in-situ.com

Suspension Wire

Polyurethane-coated stainless steel suspension cable can be used to deploy

instruments with non-vented pressure sensors such as the Level TROLL 300

Instrument, the non-vented Level TROLL 500 or 700 Instrument, and the BaroTROLL

Instrument. Suspension wire is appropriate to use when direct communication with the

instrument is not necessary during deployment.

Description Part Number

Suspension Wire - 300 feet 0066450

Suspension Wire - 150 feet 0066460

Suspension Wire - 50 feet 0066470

1-800-446-7488 20 www.in-situ.com

Communication Cables

The TROLL Com Communication Device provides an interface between the instrument

and a desktop/laptop PC or the RuggedReader Handheld PC for calibrating and

programming the instrument and for profiling and downloading data. The TROLL Com

Communication Device is offered in either a cable-connect or direct-connect

configuration including a 0.9 m (3 ft) vented polyurethane cable, external power input

jack, and vent with replaceable membrane.

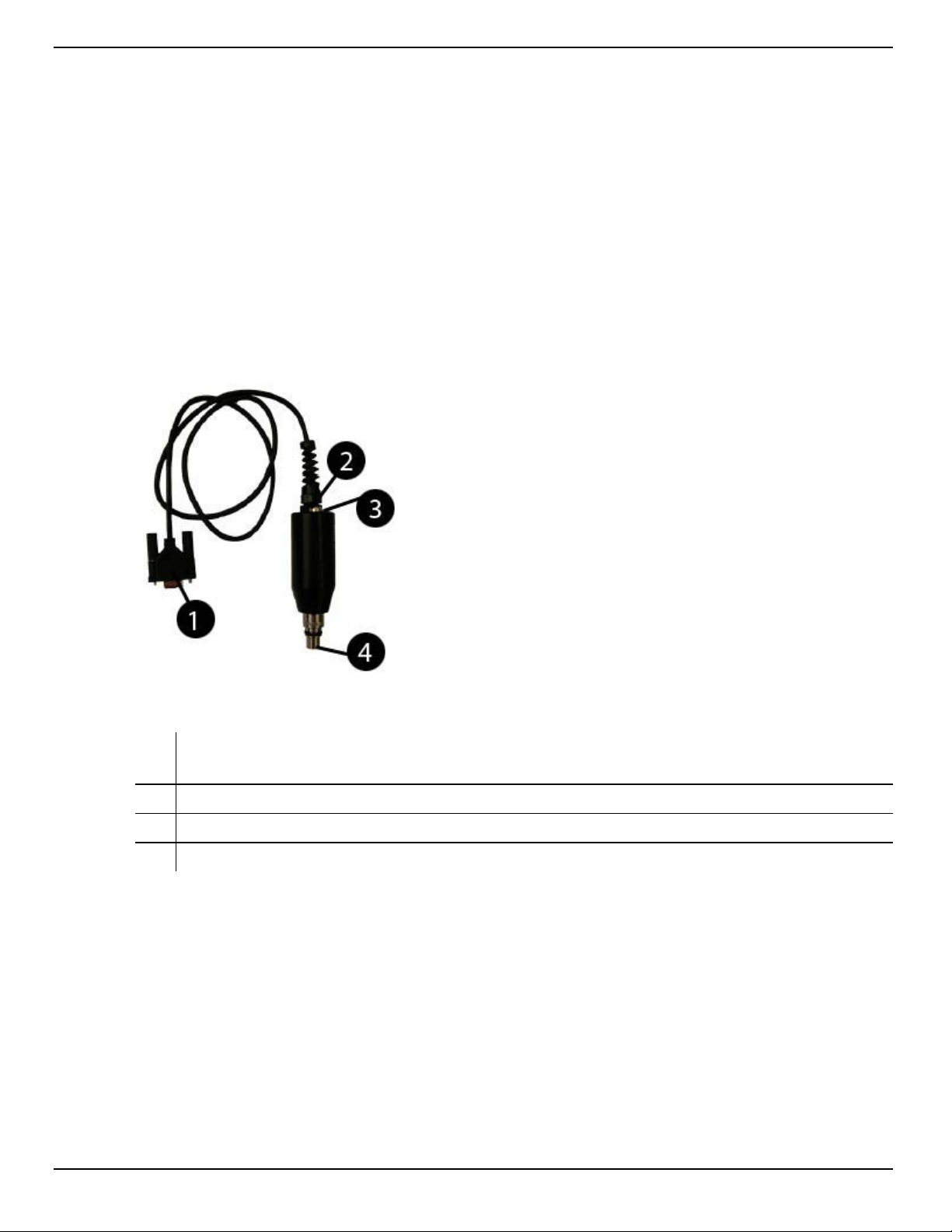

Cable-Connect TROLL Com Communication Device

The Cable-Connect TROLL Com Communication Device connects to an instrument's

RuggedCable System and to a serial or USB port. This communication cable is

weatherproof and withstands temporary immersion in water (IP67 compliant).

RS232 TROLL Com, Cable-Connect, part number 0056140 (pictured) or USB

1

TROLL Com, Cable-Connect, part number 0052500

2 External power input

3 Vent

4 Twist-lock connector

1-800-446-7488 21 www.in-situ.com

Direct-Connect TROLL Com Communication Device

The Direct-Connect TROLL Com Communication Device connects directly to an

instrument and to a serial or USB port. This option is intended for programming a nonvented instrument that will be deployed without a RuggedCable System.

RS232 TROLL Com, Direct-Connect, part number 0056150, or USB TROLL Com,

1

Direct-Connect, part number 0052510 (pictured)

2 External power input

3 Vent

4 Snap-on connection to instrument

1-800-446-7488 22 www.in-situ.com

Power Options

Internal Power—Batteries

Internal batteries are not user-replaceable. The approximate percentage of the power

remaining in an internal battery is displayed on the Home Screen when an instrument is

connected to Win-SituSoftware.

The instrument is powered by 3.6 VDC, supplied by a sealed, non-replaceable AA

lithium battery. Battery life depends on sampling speed. The battery typically lasts for

10 years or 2,000,000 readings, whichever occurs first.

When an instrument is wired to a data logger or PLC controller, power to the instrument

is supplied by the data logger or controller.

AC Adapter

The AC adapter provides 24 VDC, 0.75 A, AC input 100-250 V and includes a North

American power cord. The TROLL Com Communication Device includes an external

power input port for connection to the AC adapter.

Description Part Number

AC Adapter 24 VDC 0052440

Use only In-Situ Inc.'s AC adapter. Damage to the instrument

caused by the use of third-party converters is not covered by the

warranty.

External Power—External Battery Packs

External battery packs can significantly increase the life of an instrument, either for

long-term deployments or to preserve an aging instrument.

TROLL Battery Pack

The sealed, submersible TROLL Battery Pack supplements internal battery power

when an instrument is used for fast, frequent sampling or during long-term deployments.

When this power source is connected, the instrument will use the external battery

source first and switch to the internal batteries when external battery power is depleted.

Total battery life depends on the sampling speed.

Description Part Number

TROLL Battery Pack 0051450

1-800-446-7488 23 www.in-situ.com

The sealed, submersible TROLL Battery Pack supplies 14.4 V. When this power

source is connected, the Level TROLL will use the external battery source first and

switch to the internal batteries when external battery power is depleted.

0.5 second sampling interval 1.2 months

1 second sampling interval 2.3 months

1 minute (or longer) sampling interval 1 year

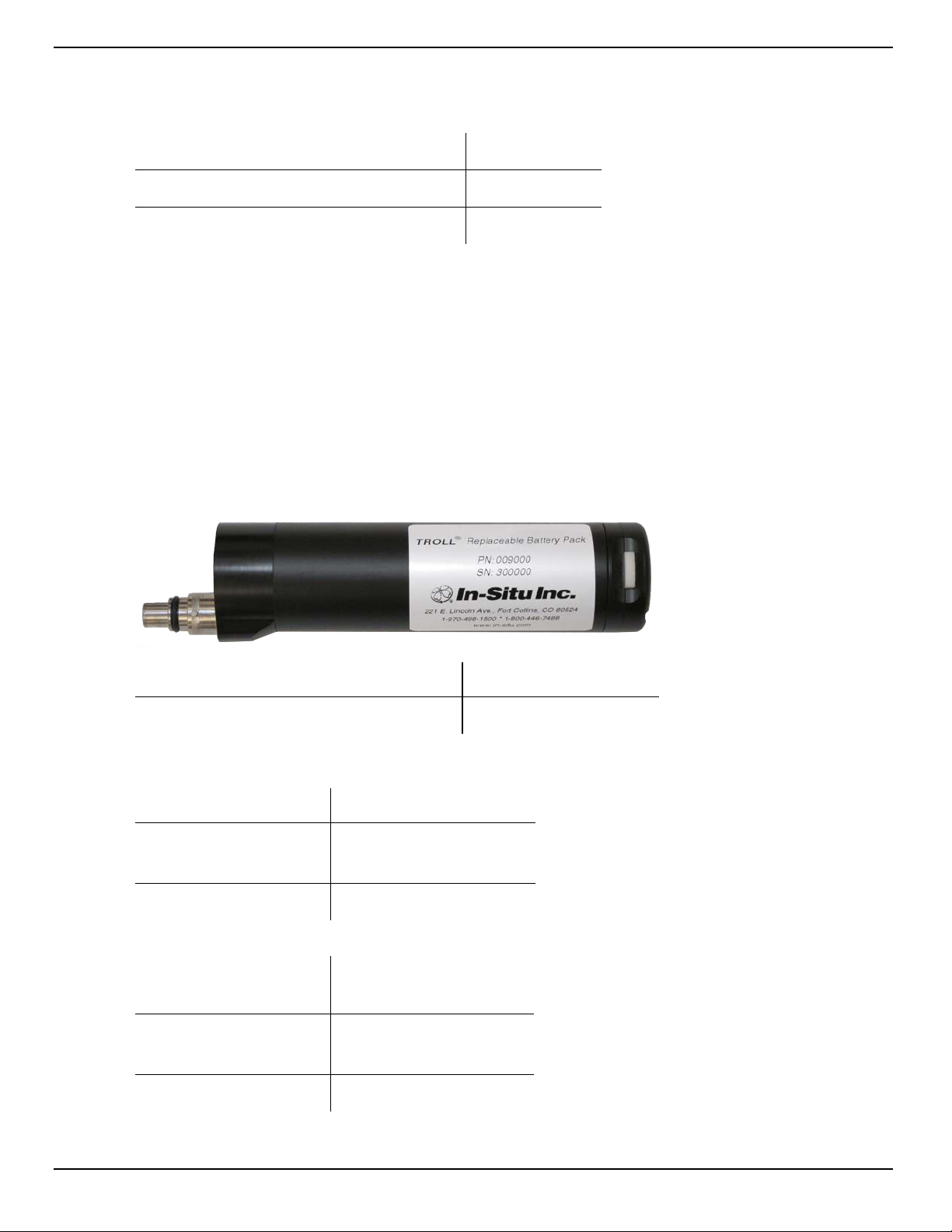

TROLL Replaceable Battery Pack

The TROLL Replaceable Battery Pack supplements internal battery power when a

Level TROLL or Aqua TROLL 100 or 200 Instrument is used for frequent, fast sampling

or during long-term deployments. When this power source is connected, the TROLL

instrument will use the external battery source first and switch to the internal batteries

when external battery power is depleted. Battery life depends on sampling rate. This

battery pack allows for 1.5 V UM-3 or size AA batteries (8) that are replaced by the user.

Description Part Number

TROLL Replaceable Battery Pack 0090000

Estimated Battery Lifetime

TROLL Battery Pack Level TROLL Family

15 minute logging

rate*

1.1 years

1 hour logging rate* 1.1 years

*Logging with all sensors. Actual battery lifetime varies based on site conditions.

TROLL Replaceable

Battery Pack

15 minute logging

rate*

Level TROLL Family

1.6 years

1 hour logging rate* 1.7 years

*Logging with all sensors. Actual battery lifetime varies based on site conditions.

1-800-446-7488 24 www.in-situ.com

Installation Accessories

NPT Adapter

The 0.25 in. NPT adapter allows instrument installation in piping.

Part Number Image Description

0051470

Cable Extender

The cable extender connects two lengths of RuggedCable System to meet varying

installation needs.

Description Image Part Number

Cable Extender 0051490

Twist-Lock Hanger

The Twist-Lock Hanger is used with a suspension wire to install a non-vented

instrument when the user does not require direct communication.

Part Number Image Description

0051480

NPT Adapter

Twist-Lock Hanger, titanium

for Level TROLL 500, 700,

700H, BaroTROLL

0055050

1-800-446-7488 25 www.in-situ.com

Twist-Lock Hanger, stainless

steel for Level TROLL 300

Bulkhead Connector

The panel-mounted bulkhead connector provides connection between RuggedCable

System and a controller panel.

Part Number Image Description

0053240

Locking Well Cap

Description Part Number

Locking Well Cap, 2" 0020360

Locking Well Cap, 2" vented 0020370

Locking Well Cap, 4" 0020380

Locking Well Cap, 4" vented 0020390

Bulkhead Connector

1-800-446-7488 26 www.in-situ.com

Loading...

Loading...