Page 1

PROJECT: ITEM NO.:

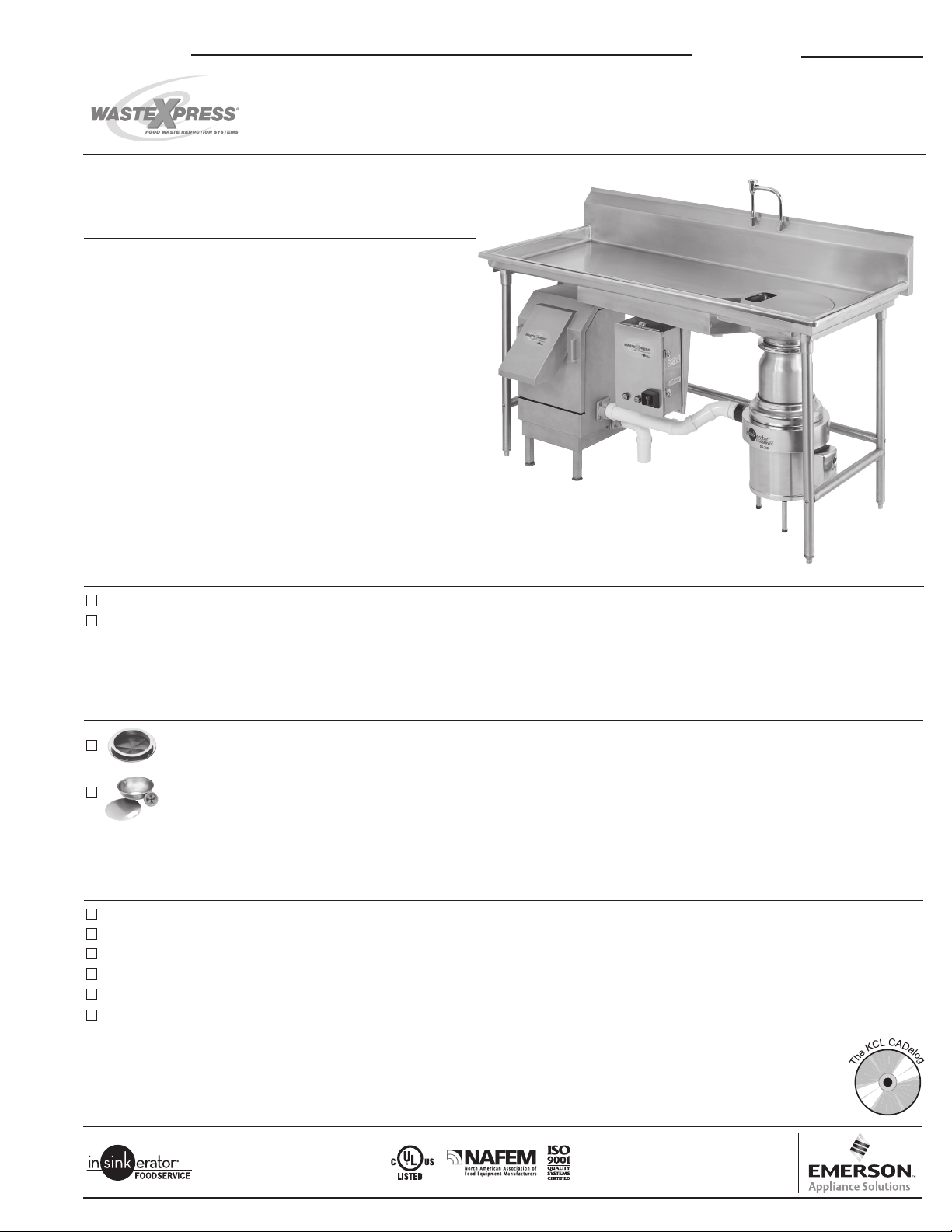

FOOD WASTE REDUCTION SYSTEM

PRODUCT FEATURES & SPECIFICATIONS

• Up to 85% volume reduction

• Capacity 700 lbs ( 317.5 kg) of waste per hour

• Fits under standard table – minimum height 34" (863.6 mm)

• Does not require cardboard

• Stainless steel construction

• Quick and easy to clean – no tools required

• One year full warranty

• Processes 100% food waste or up to 50% disposables

• NEMA 4 stainless steel electrical control panel

• Removeable auger and screen

• Interlock on discharge chute

• Water usage 2-5 GPM (7.6-18.9 LPM) – sink or

bowl configuration

• Trough application – contact factory

ELECTRICAL SPECIFICATIONS

WX-8 – 208-230V, 60 Hz, 3 Ph, 7.7/9.4 amps (Disposer 6.0/7.4 amps, WX 1.7/2 amps)

WX-9 – 460V, 60 Hz, 3 Ph, 4.7 amps (Disposer 3.7 amps, WX 1 amp)

DISPOSER MOUNTING ASSEMBLIES

#6 Collar Adaptor for welding into trough or sink, provides 6-5/8" (168.3 mm) opening, includes splash baffle

18" Type A Sink Bowl Assembly with two water nozzles, includes removable splash baffle and stainless bowl cover

ACCESSORIES

Reel Rinse Spray Unit (Fisher #2980)

Pre-Rinse Spray with wall bracket (Fisher #2010-WB)

Pre-Rinse Spray with wall bracket - Ultra Spray (1.6 GPM) (6.1 LPM) (Fisher #2010-1WB)

Trough Nozzle - 1" (25.4 mm) NPT

WXP Inlet/Outlet Flange - 2" (50.8 mm) NPT (secondary) (Trough or high water flow applications)

Dejamming Wrench

4700 21st STREET

RACINE, WI 53406-5093

TEL: 800-845-8345

FAX: 262-554-3620

www.insinkerator.com

InSinkErator is a division of Emerson Electric Co.

Our products appear on The KCL CADalog

CD-ROM based CAD Foodservice Symbol

Library. More information is available from

Kochman Consultants, Ltd. at www.kclcad.com.

The Emerson logo is a trademark and a

service mark of Emerson Electric Co.

InSinkErator ©2008 Printed in USA Form No. F269-08J-45-02

Page 2

Flow Control Valve

Disposer

Sink Bowl

Syphon Breaker

Cold Water Solenoid Hot Water Solenoid Waste Xpress

Shut Off Valve

(supplied

by others)

WX-101A Controller

10 max

(3.1 m max)

1-1/2" min

(38.1 mm

min)

1" min

(25.4 mm min)

SYSTEM COMPONENTS

45˚ bend shown

(max of 4 can be used)

3"

(76.2 mm)

1-1/2"

(38.1 mm)

This System Includes:

• Waste Xpress Unit

• 3 HP Disposer

• Disposer mount (collar or bowl)

• Syphon Breaker

• Flow Control Valve 5 GPM

(18.9 LPM)

TYPICAL INSTALLATION

Figure 1. Waste Xpress Top View

• Magnetic Silver Saver

• 10 gallon (37.9 liter) Waste Can

• 3" (76.2 mm) to 2" (50.8 mm) disposer waste

outlet reducer fitting

• (2) 24V Water Solenoids

• WX-101A Control Center

Items Supplied by Others:

• Plumbing from cold water supply to bowl or trough

• Plumbing from hot water supply to Waste Xpress

• Plumbing from disposer to Waste Xpress or

Waste Xpress to floor sink or floor drain

• Shut off valves

• Electrical connections

Figure 2. Waste Xpress Typical Installation

GENERAL NOTES

Disposer

• Install the disposer per the Instruction, Care and Use manual.

• When positioning disposer ensure that the overload reset

button is accessible by end user.

• Connect cold water to either the sink bowl or end of trough.

Waste Xpress

• Install the Waste Xpress per the Instruction, Care and

Use manual.

• Position the pulper so that the front surface of the discharge

chute is recessed 3" (76.2 mm) (see Figure 1) from the front

edge of the table and that a minimum clearance of 1" (25.4 mm)

exists between the underside of the table and top of the

discharge chute (see Figure 2) for proper removal of discharge

chute, ease of cleaning and general maintenance.

• Position the pulper so that it is within 10' (3.1 m) of the

disposer outlet flange. (See Figure 2)

• The Waste Xpress should be disassembled and cleaned a

minimum of once daily. Interior of cabinet and discharge chute

should be cleaned with hot soapy water. Auger, screen and

bearing bracket can be cleaned either manually with hot soapy

water or in a dishwasher.

Control Panel

• Install the WX-101A control panel per the Instruction, Care and

Use manual and in accordance to local, state and or national

electric codes.

• Position the control panel so that the front surface is recessed

1-1/2" (38.1 mm) from the front edge of the table and that a

minimum clearance of 2" (50.8 mm) exists between the underside

of the table and the top of the control panel for ease of installation

and serviceability.

• Position the WX-101A control panel so that it is within site of the

disposer and pulper.

Page 3

Trough Flow

Water Nozzle

Recommended

Magnet Location

Optional Magnet Location

Connect Cold Water Supply

1" min

(25.4 mm min)

1" (25.4 mm) min,

3" (76.2 mm) max

to end of Trough

PLUMBING NOTES

Waste Connection

• 2" (50.8 mm) NPT – used between disposer, Waste Xpress

and drain

• When connecting the drain line from the disposer to the

Waste Xpress use a maximum of (4) 90° bends (45° bends

are recommended) with a 1/4" (6.4 mm) drop per foot of run

or as local codes apply.

• Floor sink or drains should be installed per local codes but

kept clear of yet accessible to pulper.

• Trough applications in excess of 10' (3.1 m) and/or systems

plumbed with a cold water supply greater than 7 GPM

(26.5 LPM) must incorporate the second drain outlet from the

pulper and be drained independently to floor sink or drain.

TROUGH APPLICATION NOTES

Construction

• The recommended maximum trough length is 10' (3.1 m).

• A silver saver should be fabricated prior to end of trough to

catch utensils and dishes.

Water Supply

• For trough lengths of 10' (3.1 m) or less place water nozzle at

end of trough.

• For trough lengths greater than 10' (3.1 m) place one

water nozzle at end of trough and one mid stream.

• Do not plumb water to disposer grind chamber.

Fresh Water Connections

• 1/2" (12.7 mm) NPT – used on syphon breaker, solenoid and

flow control valve.

• 1/2" (12.7 mm) NOM compression – used on sink bowl nozzles.

• 1/2" (12.7 mm) Ridged Copper (compression) – used on hot

water connection to pulper.

• If fresh water supply is greater than 50 psi (144.7 kPa), a

pressure regulating valve must be installed in both.

• It is recommend that ball type shutoff valves be installed

in the cold and hot water lines.

• It is recommended that the hot water connected between

solenoid valve and pulper be terminated with a union for

ease of serviceability.

Magnet

• Can be mounted to trough either by tack welding to using weld

studs (see instruction sheet for weld stud pattern).

• Trough magnets should be placed within 12" (304.8 mm) of

end of trough or trough intersection with sink bowl (see Figure 4).

• Additional magnets can be used as necessary.

Figure 3. Trough Typical Installation Top View

Figure 4. Trough Typical Installation

Page 4

21-3/4"

(552.5 mm)

21-1/8"

(536.6 mm)

26-7/8"

(682.6 mm)

33-1/2"

(850.9 mm)

8"

(203.2 mm)

27-3/8"

(695.3 mm)

7-7/8"

(200.0 mm)

Electrical Connection Cover

14-1/2"

(368.3 mm)

8-1/8"

(206.4 mm)

15"

(381 mm)

18-3/4"

(476.3 mm)

1-5/8"

(41.3 mm)

Waste Xpress Top View

15-1/8"

(384.2 mm)

14"

(355.6 mm)

15-3/4"

(400.1 mm)

9-7/8"

(250.8 mm)

8-1/4"

(209.6 mm)

Control Center Front View

Waste Xpress Side View

9-1/8"

(231.8 mm)

1/2"

(12.7 mm)

Electrical Inlet

1/2"

(12.7 mm)

Hot Water Inlet

Waste Xpress Back View

12-1/8"

(308.0 mm)

2"

(50.8 mm)

NPT Outlet

(Either Side)

2"

(50.8 mm)

NPT Inlet

(Either Side)

Leveling Foot

Adjustment Range

2-3/4"

(69.9 mm)

Waste Xpress Front View

8-5/8"

(219.1 mm)

Disposer Front View

External Electrical

Connection Cover

2"

(50.8 mm)

NPT Outlet

Adjustable Legs

Disposer Side View

8-3/4"

(222.3 mm)

8-3/4"

(222.3 mm)

13"

(330.2 mm)

23-3/4"

TO

31-1/8"

(603.3 mm

TO

790.6 mm)

6-1/2"

(165.1 mm)

Control Center Side View

5-1/4"

(133.4 mm)

5-5/16"

(134.9 mm)

6-3/4"

(171.5 mm)

1"

(25.4 mm)

DIMENSIONS

PROJECT INFORMATION

Item Number:

Quantity:

InSinkErator

Manufacturer:

City/State/Zip:

Project:

Address:

Contact:

Phone :

Installer:

Contact:

Phone :

Model Number:

Electrical

Requirements:

Dealer:

City/State/Zip:

Contact:

Phone :

Consultant:

Contact:

Phone :

volts phase

Loading...

Loading...