Page 1

The Danger signal indicates an immediately hazardous situation which,

if not avoided, will result in death or serious injury.

The Warning signal alerts you to potential hazards or unsafe practices which,

if not avoided, could result in severe personal injury or death.

The Caution signal alerts you to hazards of unsafe practices which, if not avoided,

may result in minor personal injury or property damage.

Please be certain that the person who installs or uses this appliance carefully

reads and understands the Safety Instructions contained in this manual.

Part No. 14481 - May 2006www.insinkerator.com

Page 2

Table of Contents

Warranty ......................................................................................................... 4

Introduction/Typical Installation

Introduction ..................................................................................... 4

Typical Installation ........................................................................... 4

Waste Xpress Features ................................................................................. 5

WX-101A Control Features/Mounting Control Center

Introduction ..................................................................................... 6

Typical Installation ........................................................................... 6

Installing Disposer ......................................................................................... 7

InSinkErator Mounting Assemblies

Standard Mounting ......................................................................... 8

Special Mounting ............................................................................ 8

Installing Waste Xpress

Waste Xpress Diagrams .................................................................. 9

Installing Waste Xpress ................................................................. 10

Electrical Connections .................................................................. 10

Plumbing Connections

Waste Inlet Line ............................................................................. 11

Reverse Auger Screen................................................................... 11

Change Waste Inlet ....................................................................... 11

Waste Outlet Line .......................................................................... 12

Plumbing Connections .................................................................. 12

Water Supply Connection ............................................................. 12

Routing Water Flow ....................................................................... 12

Electrical Connections ................................................................................ 13

Operating Instructions

Pre-Operating ................................................................................ 14

Operating Instruction .................................................................... 15

Operating Waste Xpress System .................................................. 16

Operational Tips ............................................................................ 16

Cleaning Instruction .................................................................................... 17

Troubleshooting

System Troubleshooting ................................................................ 18

Disposer Troubleshooting ............................................................. 20

Waste Xpress Troubleshooting ...................................................... 21

Wiring Diagrams

Model No. WX-101A-1 (120V, 1 phase) ......................................... 22

Model No. WX-101A-2 (208/230V, 1 phase) ................................. 24

Model No. WX-101A-3 (208/230V, 3 phase) ................................. 26

Model No. WX-101A-4 (380/460V, 3 phase) ................................. 28

Motor Wiring Diagrams ............................................................................... 30

3

3

Page 3

Warranty

WASTE XPRESS SYSTEM LIMITED WARRANTY

The InSinkErator® Waste Xpress®, disposer and control centers are warranted against defects in material and

workmanship for one year from the date of installation. The warranty includes parts and labor, provided an

InSinkErator Factory Authorized Service Center performs the service. This warranty does not apply if the failure

is due to: faulty or improper electrical installation, faulty or improper plumbing installation, product abuse or

misuse, accidental damage, clogged drain lines, improperly sized unit (as specifi ed by InSinkErator).

Introduction/Typical Installation

INTRODUCTION

The InSinkErator® Waste Xpress® is a Foodservice

kitchen waste reduction system that utilizes a standard

Foodservice disposer in line with the Waste Xpress

dewatering system. The kitchen waste is ground

through the disposer then transferred to the Waste

Xpress where it is compressed. After the waste is

compressed, the liquids are sent down the drain line

and the solid waste exiting the Waste Xpress is 85%

less in volume (see Figure 1 for typical installation).

Important – These installation instructions are for

the benefi t of the installing contractor. InSinkErator

and/or InSinkErator Factory Authorized Service

Centers do not make original installations. For technical

information not covered in these instructions,

contact the supplier, an InSinkErator Field Sales

Representative, or InSinkErator Foodservice Sales

and Service at 1-800-845-8345.

Syphon

Breaker

Sink Bowl

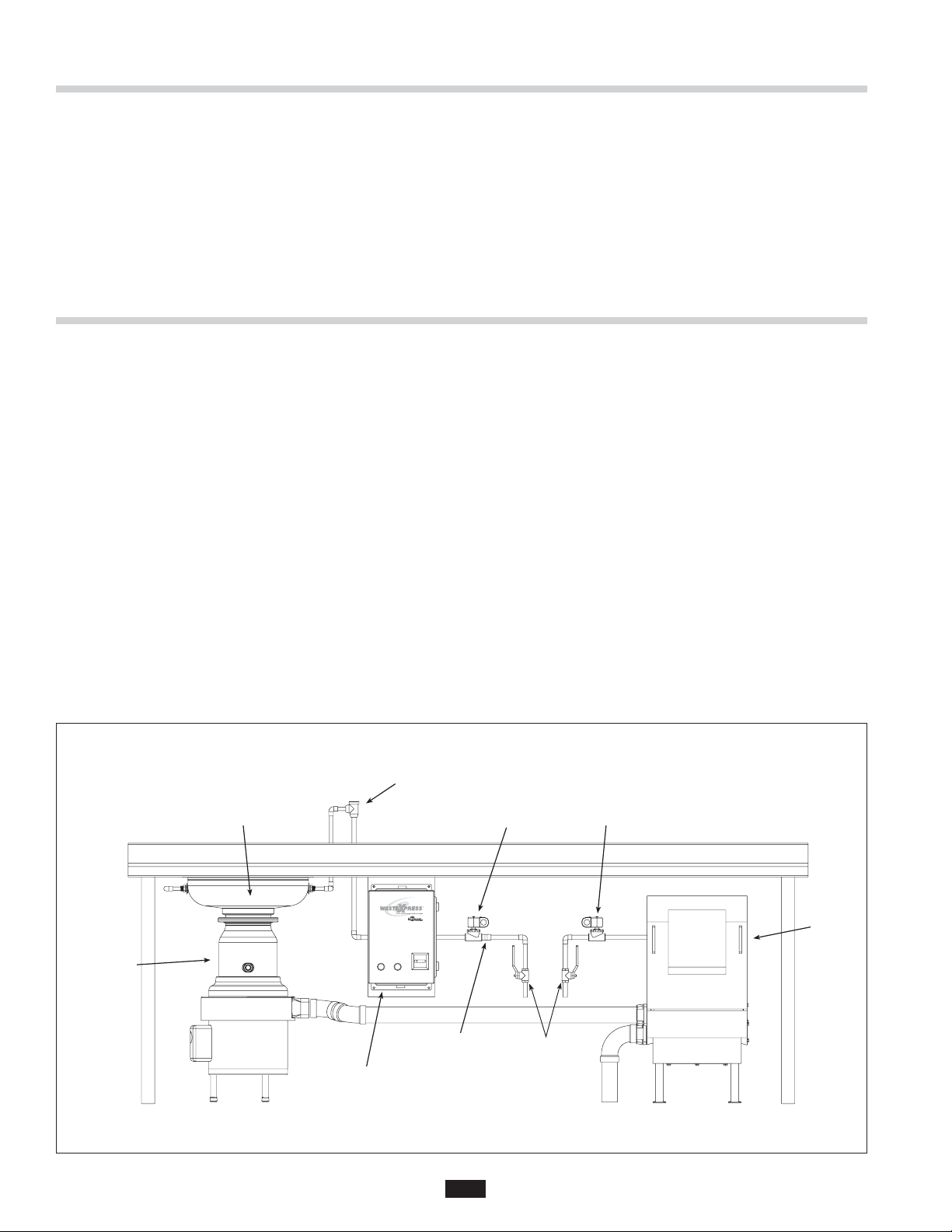

TYPICAL INSTALLATION

A typical Waste Xpress installation incorporates the

following connections (see Figure 1):

• Waste Xpress

• Disposer

• Control Center

• Syphon breaker

• Solenoid valves (2)

• Water shut off valve

• Bowl or trough

• Flow control valve

• Cold water (sink or trough)

• Hot water (Waste Xpress)

Cold Water

Solenoid

Hot Water

Solenoid

Disposer

Figure 1. Typical Installation

WX-101A

Controller

Flow Control

Valve

4

Shut Off

Valve

Waste

Xpress

Page 4

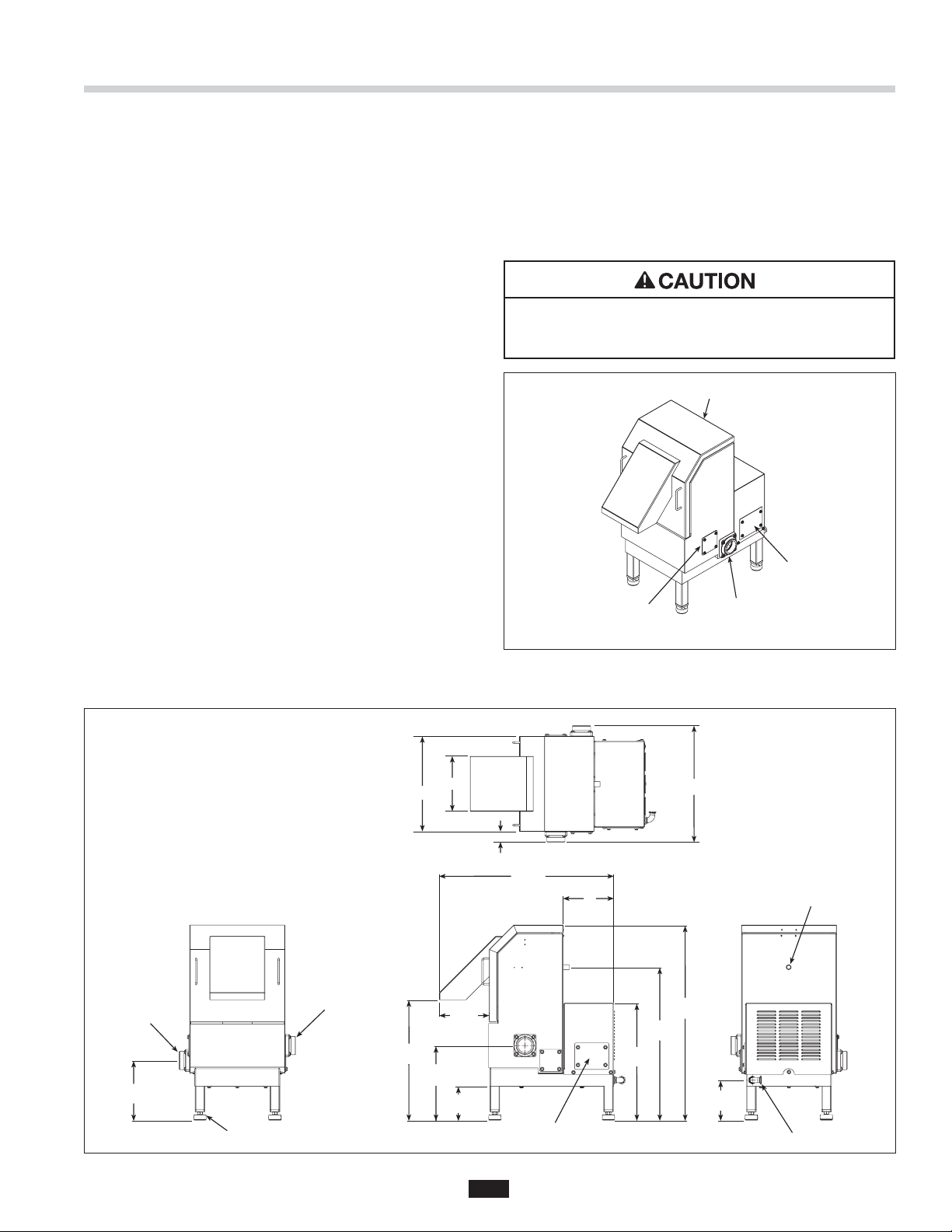

Waste Xpress Features

FEATURES

COMPACT SIZE

The Waste Xpress® is designed to fi t under a 34" high

commercial kitchen table.

WASTE REDUCTION

Reduces volume by 85%.

SAFETY INTERLOCK

The Waste Xpress is equipped with safety interlock

on the discharge chute (see Figure 2). This interlock

prevents the system (disposer & Waste Xpress) from

operating unless the discharge chute is properly seated.

DRAIN CONNECTIONS

• Water outlet should be routed directly to a fl oor drain

(and as close to the Waste Xpress as possible).

• The 2" NPT waste inlet connection can be mounted

on either side.

• The 2" NPT water outlet connection can be mounted

on either side.

• For trough or high water fl ow applications, connect

both Water Outlet connections for optimum

cabinet drainage.

• All drain lines must be a minimum 2" NPT in diameter.

CONSTRUCTION

Stainless steel construction (for physical size see

Figure 3).

WASTE MIX

The Waste Xpress can process non-food waste such

as paper, light and rigid plastic or food wrappings when

mixed with a minimum of 50% food waste.

PROPERTY DAMAGE

Plastic wrap, cans, silverware, rubber, glass and

crockery cannot be processed.

Safety Interlock

Terminal

Connection

Waste Inlet

(either side)

Waste Outlet

(either side)

2" NPT Outlet

(Either Side)

12 1/8"

9 3/8"

2" NPT Inlet

(Either Side)

Leveling Foot

Adjustment Range 2 3/4"

21 3/4"

19"

15"

14 1/2"

11 3/4"

8 5/8"

8 1/8"

5 3/8"

Figure 2.

1 5/8"

7 7/8"

Electrical Connection Cover

27 3/8"

18 1/4"

8"

33 1/2"

30 3/4"

26 7/8"

24 1/8"

21 1/8"

18 3/8"

9 1/8"

6 3/8"

1/2" Hot Water Inlet

1/2" Electrical Inlet

Figure 3. Waste Xpress Dimensions

5

Page 5

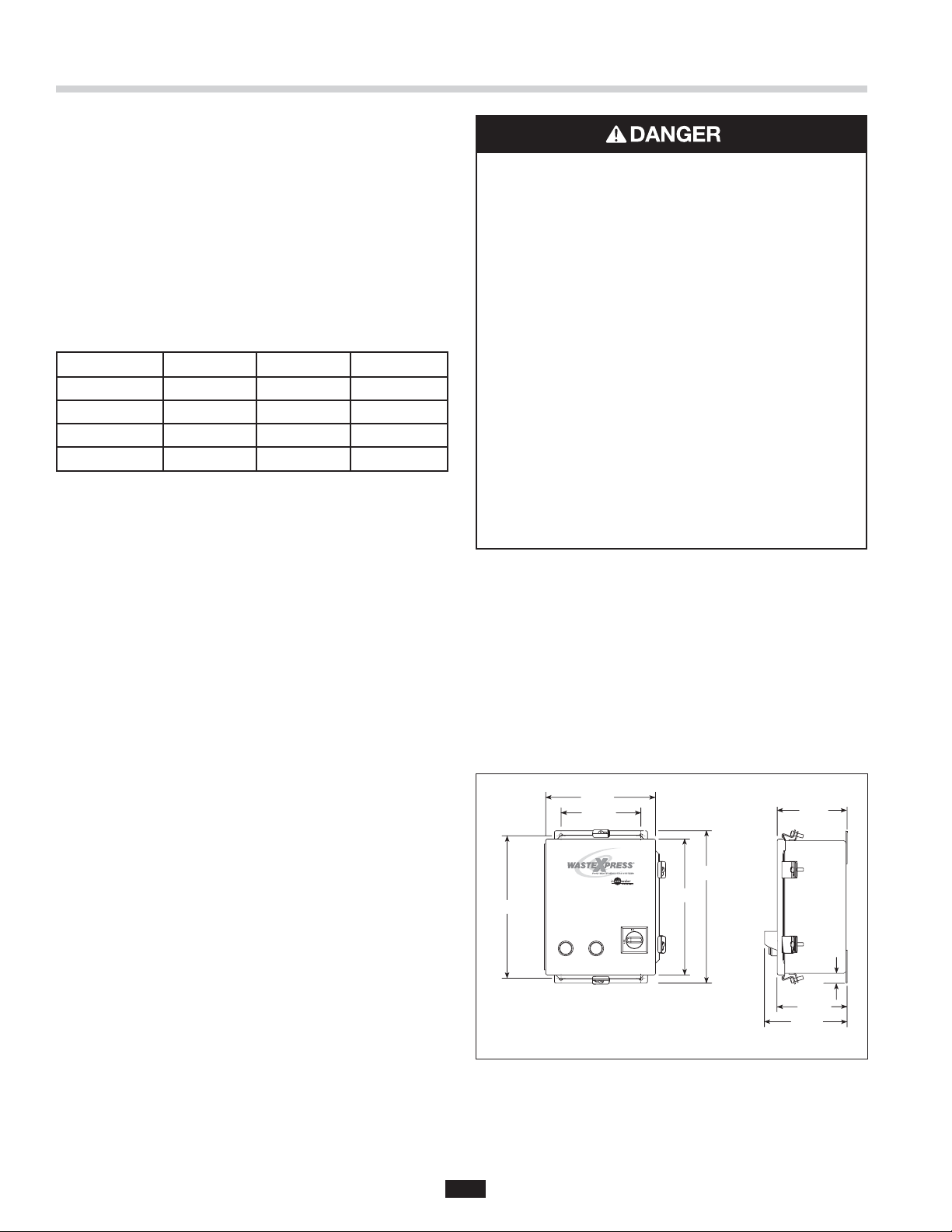

WX-101A Control Features/Mounting Control Center

The WX-101A Control Center is UL® approved for use

with InSinkErator Waste Xpress food waste reduction

systems. The control center operates the disposer and

Waste Xpress. Its main functions are:

• To start and stop the disposer/Waste Xpress system.

• To reverse the direction of the disposer motor

automatically upon restart.

• To start the water fl ow to the disposer.

• To allow water fl ow for several minutes to fl ush the

drain line after the disposer is turned off.

Model Part No. Voltage Phase

WX-101A-1 14479 120V 1

WX-101A-2 14479A 208/230V 1

WX-101A-3 14479B 208/230V 3

WX-101A-4 14479C 380/460V 3

Table 1. Electrical Specifi cations

FEATURES

SINGLE BUTTON OPERATION

Disposer and Waste Xpress are controlled by simple

ON/OFF button operation.

AUTOMATIC REVERSE

The disposer motor will reverse its direction of

rotation automatically upon restart. To avoid motor

damage, a delay feature prevents reversing until

the post fl ush is complete.

ELECTRICAL SHOCK

• Ensure that Waste Xpress voltage and phase match

that of the electrical supply, control center &

disposer. Check nameplate for specifi cation.

• Electrical connections should be made by a

qualifi ed electrician and should comply with all

local codes.

• Turn off electrical supply to Waste Xpress,

control center & disposer before attempting to

work on it. Test with a volt meter or circuit tester

to ensure that power is off.

• Do not operate unit with panels removed.

• All components (disposer, WX, control center

and solenoids) must be carefully and permanently

grounded.

• A properly fused disconnect must be installed at

Waste Xpress, control center & disposer electrical

supply source.

• Use only NEMA 4 watertight electrical connectors

when connecting to junction box.

MOUNTING THE CONTROL CENTER

Use the fl anges at the back of the control center

enclosure and only mount panel in the upright vertical

position (door hinge is on the left). See Figure 4.

Locate control center within sight of disposer per

local codes.

WATER SHUTOFF DELAY (POST FLUSH)

After the motor is turned off, the water continues to

fl ow for up to 10 minutes. The length of this post fl ush

is controlled by the water shutoff delay timer. The post

fl ush helps ensure that ground food waste is fl ushed

out of the drain line.

AUTOMATIC TIMED DISPOSER SHUTOFF

This water saving feature allows the system to run for

10 minutes before it automatically shuts off and must

be manually restarted.

LINE DISCONNECT SWITCH

The switch on the front panel of the control center

disconnects the line voltage. It interlocks with the front

cover so that the cover cannot be opened unless the

switch is in the off position.

LOW VOLTAGE CONTROL

Control operates on a 24 V solid state control circuit.

ENCLOSURE

Stainless steel NEMA 4 construction.

WX TIMER HOT WATER SPRAY ADJUSTABLE

Factory set for 2 minutes off 10 second on controls hot

water spray for cleaning of screen.

If box is mounted to the sink table, recess the box so

that the buttons do not extend beyond the table’s edge

(see Figure 4).

9 7/8"

8 1/4"

15 1/8"

Figure 4. Control Center Dimensions

14"

15 3/4"

5 1/4"

1"

5 5/16"

6 3/4"

6

Page 6

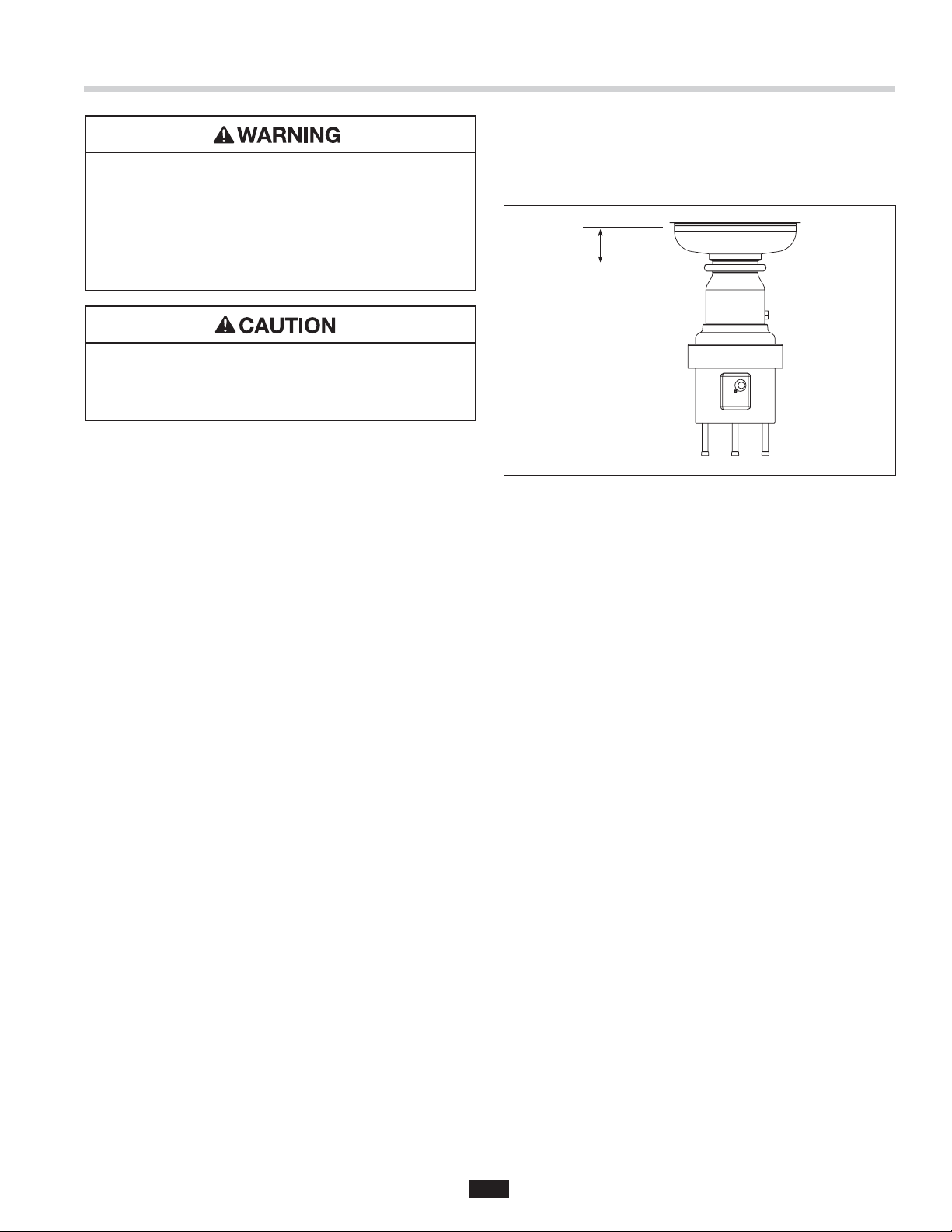

Installing Disposer

PERSONAL INJURY

• For safe operation, The minimum required distance

from the table top or trough to the mounting fl ange

is 6 inches for standard body disposers

(as specifi ed by UL). See Figure 5.

• Moving shredder parts may cause serious injury if

a hopper or cone is not properly installed.

PROPERTY DAMAGE

To avoid excess vibration, InSinkErator

recommends a minimum countertop thickness

of 16 gage stainless steel.

DISPOSER MOUNTING

The disposer can be mounted to the sink or trough

using a standard InSinkErator mount or an

InSinkErator mounting adaptor.

CLEAN THE DRAIN LINE

With a drain line auger, clear away all hardened waste

material in the horizontal drainpipe running from the

drain trap to the main waste line.

6 inch min.

Figure 5.

NOTE: The InSinkErator #5 Sink Flange can not be

used with the Waste Xpress system.

NOTE: InSinkErator must approve attachment to a

non-InSinkErator sink.

7

Page 7

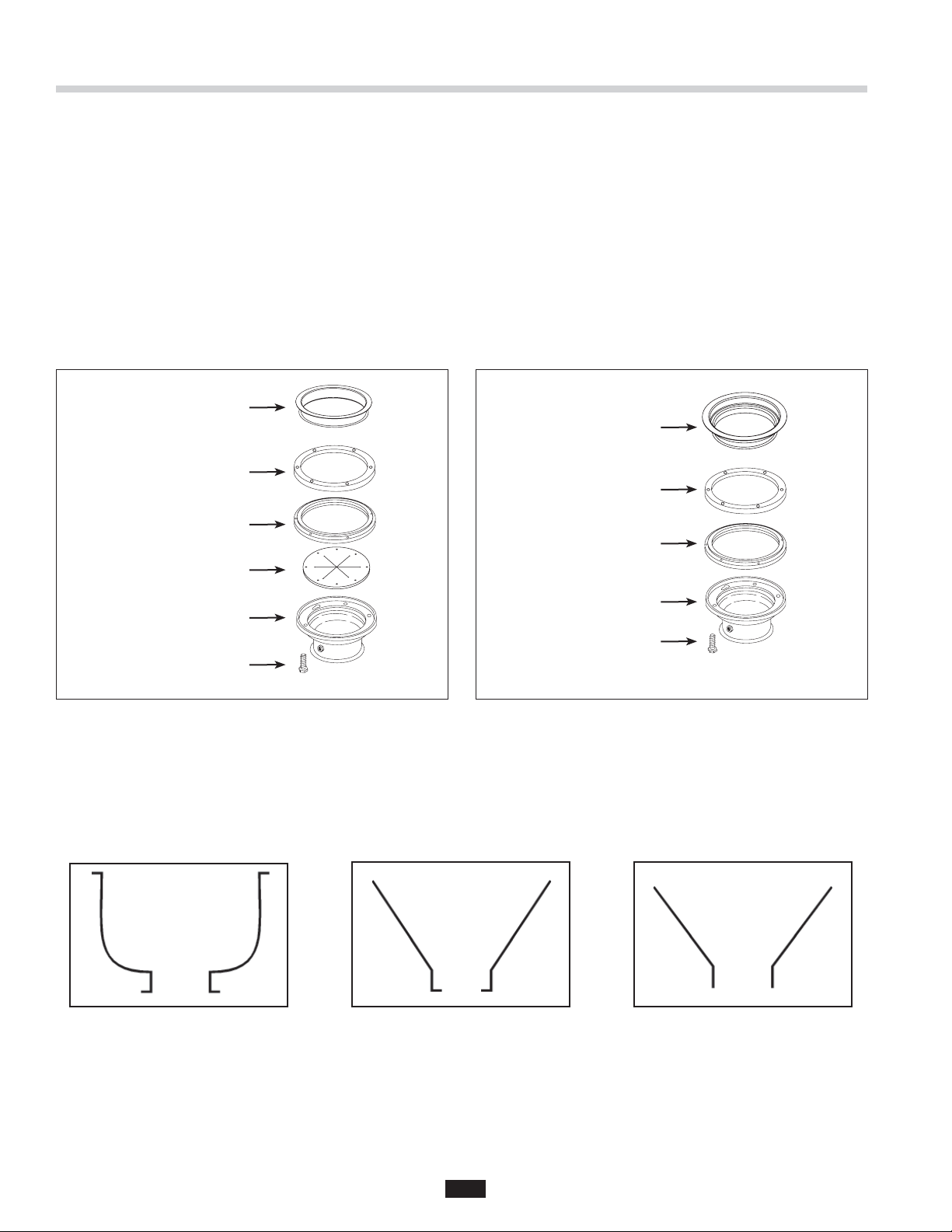

InSinkErator Mounting Assemblies

STANDARD MOUNTING ASSEMBLY

1. Place mounting fl ange (1) over the existing collar

adaptor connection lip or sink bowl fl ange (this may

require some force).

2. Push the mounting fl ange up out of the way and fi t

the groove in the mounting gasket (2) onto the

connection lip. Make sure the gasket is fully seated

on the fl ange.

3. Push the mounting fl ange down over the mounting

gasket, fi tting the threaded mounting fl ange fasteners

into the recesses in the top of the mounting gasket.

#6 Collar Adaptor

(1) Mounting Flange

(2) Mounting Gasket

(3) Flat Gasket

4. From the bottom, insert two screws through opposite

sides of the fl at gasket (3) and mounting fl ange, into

the threaded fasteners in the existing fl ange. The

fl at gasket is used only in the #6 mounting assembly.

The screws should protrude about 1/4 inch below the

mounting gasket.

5. Position the disposer beneath the mounting gasket

and raise it to engage the two protruding screws in

the disposer body fl ange keyhole slots. Secure the

remaining screws and position the disposer correctly

for the plumbing connections. If disposer legs are

included, adjust the legs to support the disposer.

#7 Collar Adaptor

(1) Mounting Flange

(2) Mounting Gasket

Disposer Body Flange

Disposer Body Flange

1/4” Screw

1/4” Screw

Figure 6. #6 Mounting Assembly Figure 7. #7 or Sink Bowl Mounting Assembly

SPECIAL INSINKERATOR MOUNTING ASSEMBLIES

When installing an InSinkErator Foodservice disposer to a non-InSinkErator sink bowl, a special mounting adaptor

kit is required. The special mountings are described in the Mounting Adaptor Selection Guide (for more information,

call 1-800-845-8345 or go to www.insinkerator.com). Figures 8-10 show examples of non-InSinkErator style sinks.

(Mounting instructions are included in each special mounting adaptor kit.)

Figure 8. Outward Flange Figure 9. Inward Flange Figure 10. Straight Flange

8

Page 8

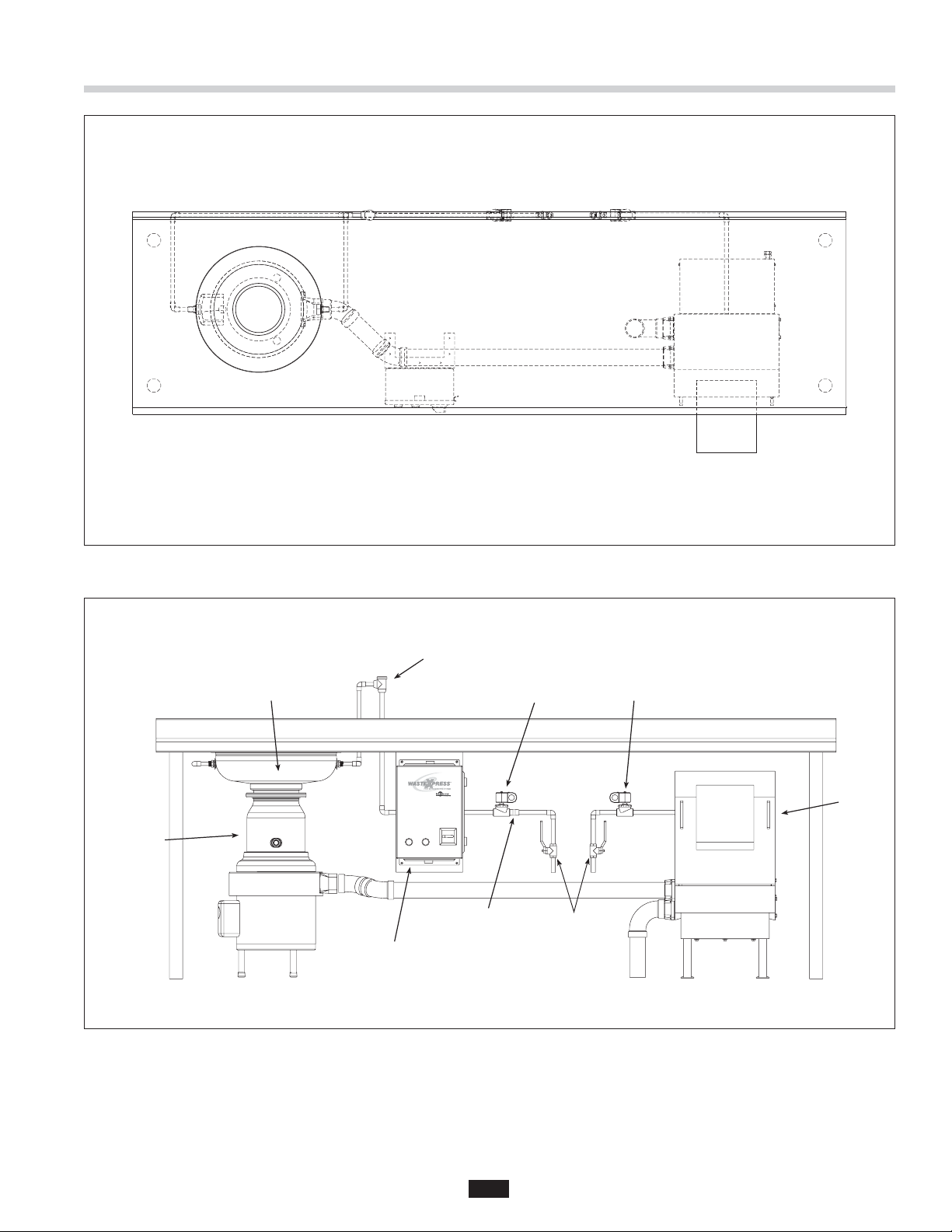

Installing the Waste Xpress

Figure 11. Top View

Disposer

Sink Bowl

WX-101A

Controller

Syphon

Breaker

Flow Control

Valve

Cold Water

Solenoid

Shut Off

Valve

Hot Water

Solenoid

Waste

Xpress

Figure 12. Typical Installation Diagram

9

Page 9

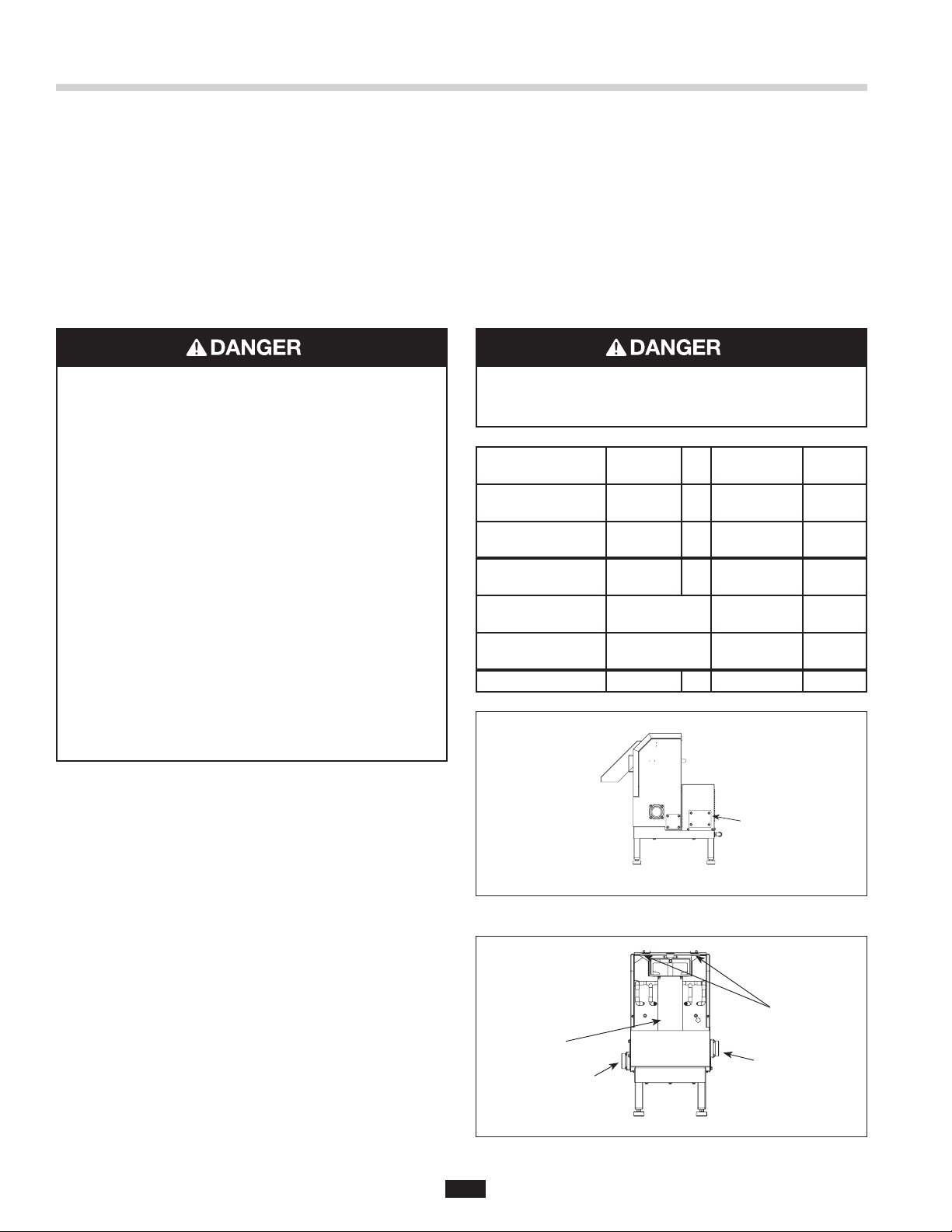

Installing the Waste Xpress

WASTE XPRESS LOCATION

NOTE: Prior to installing the Waste Xpress the

disposer and control center should be installed as

specifi ed within this manual.

• Position Waste Xpress within 10 feet of the disposer

outlet fl ange. A maximum of four (4) 90º elbows can

be used between the disposer and Waste Xpress

(prefer 45º elbow).

• Level Waste Xpress by turning the legs in or out

with a wrench. Place a level on top of the unit.

ELECTRICAL SHOCK

• Ensure that Waste Xpress voltage and phase match

that of the electrical supply, control center &

disposer. Check nameplate for specifi cation.

• Electrical connections should be made by a

qualifi ed electrician and should comply with all

local codes.

• Turn off electrical supply to Waste Xpress,

control center & disposer before attempting to

work on it. Test with a volt meter or circuit tester

to ensure that power is off.

• Do not operate unit with panels removed.

• All components (disposer, WX, control center

and solenoids) must be carefully and permanently

grounded.

• A properly fused disconnect must be installed at

Waste Xpress, control center & disposer electrical

supply source.

• Use only NEMA 4 watertight electrical connectors

when connecting to junction box.

7. Connect wire bundle between WX-101A and

Waste Xpress unit as detailed in wiring diagram.

Door interlock connections are #3 and #95. Replace

terminal cover.

8. Wire per local electrical codes and install

using NEMA 4 watertight electrical connectors

(not supplied).

9. Install disposer terminal box cover and secure with

retaining screw.

10. Secure WX-101A cover with locking clamps.

ELECTRICAL SHOCK

Do not pinch or damage the electrical wires when

installing the terminal box.

WX

Terminal

WX Auger Motor

1 Phase

WX Auger Motor

3 Phase

WX Magnetic

Interlock

Cold Water Solenoid

(Disposer)

Hot Water Solenoid

(WX Spray)

Disposer To See Diagrams Line

T1, T2 To T1, T2 Line

T1, T2, T3 To T1, T2, T3 Line

3, 95 To 3, 95 24V

WX-101A

Terminal

4, 13 24V

7, 18 24V

Voltage

ELECTRICAL CONNECTIONS

The Waste Xpress system requires power only to the

control center. The control center powers the disposer

and Waste Xpress.

1. Remove retaining screw and disposer

electrical cover.

2. Open control center cover by loosening locking

clamps securing it.

3. Remove terminal cover from Waste Xpress

(see Figure 13).

4. Connect incoming power line to electrical door

disconnect switch in WX-101A.

5. Connect disposer motor leads to terminal

block locations.

6. Connect cold water solenoid to appropriate

terminals 4 and 13. Connect hot water solenoid to

terminal 18 and 7.

Figure 13.

Auger

Screen

Waste Outlet

Figure 14. Cover Removed

10

Terminal

Cover

Captive

Fasteners

Waste Inlet

Page 10

Plumbing Connections

PROPERTY DAMAGE

Water connections must comply with all local

plumbing codes.

WASTE INLET LINE

Connect the disposer outlet fl ange as close as

possible and with as few as possible 90° elbows to

the Waste Xpress inlet.

NOTE: The maximum allowable distance between the

disposer outlet fl ange and the Waste Xpress inlet is

10 feet with a maximum of four (4) 90° elbows.

1. Connect the disposer outlet to the Waste Xpress

inlet using 2" NPT plumbing. 3 HP will require 3"

outlet adapter. The run between the disposer and

Waste Xpress should have 1/4" slope per foot and

must comply with all local codes.

NOTE: All horizontal runs should be as short as

possible (not to exceed 10 ft.), with an approximate

fall of 1/4" per foot.

TO REVERSE AUGER SCREEN:

A. Holding both handles remove discharge chute

of the Waste Xpress by tilting it upward

(see Figure 13).

B. Remove auger-bearing bracket by sliding the two

captive fasteners inward and then pull

bracket upward (see Figure 14).

C. Lift auger and screen up and then out

(see Figure 14).

D. Remove auger from screen by lifting up

(see Figure 15).

E. Remove four nuts and washers holding the top

portion of the auger screen to the bottom portion

(see Figure 16).

F. Rotate bottom portion of the auger screen 180°

and secure to top portion with four nuts and

washers (see Figure 17).

Figure 15.

Figure 16.

Figure 17.

Inlet

Nuts &

Washer (4)

Auger

Screen

TO CHANGE WASTE INLET SIDE ON

WASTE XPRESS:

A. Remove four screws holding inlet fi tting and gasket

in position (see Figure 18).

B. Remove four screws holding the cap and gasket in

position (see Figure 18).

C. Install gaskets, cap and inlet fi tting on reverse side

and secure with appropriate screws.

Figure 18.

11

Waste

Outlet

Waste

Inlet

Page 11

Plumbing Connections

WASTE OUTLET LINE

Connect a 2" drain line to the Waste Xpress waste

outlet as specifi ed per local codes (see Figure 18

for water outlet location).

InSinkErator recommends that the water outlet

empties into a fl oor drain.

If the water outlet connection on the Waste Xpress

needs to be switched to the other side, complete

the following:

• Remove the four screws holding the cap and gasket in

position (see Figure 18).

• Install gasket, cap and inlet fi tting on reverse side

and secure with appropriate screws.

NOTE: The Waste Xpress system should not be

plumbed directly into a small inside grease trap.

The unit can be plumbed through a large exterior

grease trap.

PLUMBING CONNECTIONS

The syphon breaker is supplied with all Waste Xpress

systems (packed separately).

Syphon breaker must be installed above the sink fl ood

plane per local plumbing codes. Check direction of

water fl ow arrows.

The solenoid valve is supplied with a 24 V coil.

• The fl ow control valve regulates all cold water fl owing

into the disposer and Waste Xpress. This conserves

water and prevents overloading.

WATER SUPPLY CONNECTIONS

When connecting the incoming water supply to the

disposer, sink bowl and Waste Xpress, use as few

elbows and tees as possible.

All cold water line fi ttings are 1/2" NPT except the

sink bowl nozzles which are 1/2" compression.

Use 1/2" compression fi tting to connect hot water

to Waste Xpress.

Install the fl ow control valve, water solenoid valve,

and syphon breaker according to the direction of the

arrows marked on each valve body.

NOTE: In-line hot and cold shutoff valves are

recommended close to the Waste Xpress system

for ease of service.

ROUTING WATER FLOW

Connect cold water only to disposer, bowl, or trough.

Connect hot water only to Waste Xpress for hot water

spray nozzles.

In a trough system, route all water fl ow to the end of

the trough to fl ush food waste.

PROPERTY DAMAGE

System has hot water spray that must be

connected. Fresh water connection to the

Waste Xpress must be hot water only. Failure

to use hot water may clog system and result

in malfunction.

Sink Bowl

Disposer

Figure 19. Typical Installation Diagram

WX-101A

Controller

Syphon

Breaker

Flow Control

Valve

12

Cold Water

Solenoid

Shut Off

Valve

Hot Water

Solenoid

Waste

Xpress

Page 12

Electrical Connections

ELECTRICAL SHOCK

• Turn off all electrical supply to the disposer before

attempting any work on it. Use a voltmeter or

circuit tester to ensure that power is off.

• All Installation work must conform to local

plumbing and electrical codes.

• All components (disposer, WX, control center

and solenoids) must be carefully and permanently

grounded.

• A properly fused disconnect must be installed at

the electrical supply source for the control center.

• The control center’s door disconnect must be in the

off position before the panel door can be opened.

Power is still present at the disconnect until power

is turned off at the electrical supply source.

LINE VOLTAGE

Connect the incoming line power to the electrical

disconnect switch and connect the disposer motor to

labeled terminal blocks in the control center. Use the

appropriate voltage and phase wiring diagram(s) in

the Wiring Diagram section at the end of this manual.

A wiring diagram is also located on the inside door of

the control center. Wire the disposer motor for correct

voltage using the connection diagram inside the motor

terminal box.

PROPERTY DAMAGE

• Ensure that control center voltage and phase

match the disposer motor and electrical supply.

Check nameplates on disposer and control

center for voltage and phase specifi cations.

• Refer to the control center wiring diagrams in

this manual for correct connection.

• Use NEMA 4 watertight electrical connectors

(not supplied) when making electrical connections

to the control center.

COLD WATER SOLENOID VALVE

One 24 V cold water solenoid valve is supplied with

control centers. Connect solenoid valve to terminals 4

and 13. Supplied fl ow control valve is to be connected

to cold water line.

Wire per local electrical code using NEMA 4 water-tight

electrical connections.

HOT WATER SOLENOID VALVE

One 24 V hot water solenoid valve is supplied with

control centers. Connect solenoid valve to terminals 7

and 18. No fl ow control valve is to be used on hot water

line. Use 1/2" compression fi tting to connect hot water

line to Waste Xpress.

LOW VOLTAGE

The WX-101A control center uses low voltage (24 V)

to operate contactor coils, solid state control circuit,

push buttons, and solenoid valves. Red wires denote

a 24 V circuit.

PERSONAL INJURY

Disconnect electricity at line disconnect switch

before servicing system.

13

Page 13

Operating Instructions

PRE-OPERATION TEST

Before operating the Waste Xpress complete

the following steps to ensure the unit has been

properly installed.

1. Ensure plumbing and electrical connections

are secure.

2. Turn on incoming cold water supply to disposer

and hot water supply to the Waste Xpress.

3. Check to make sure auger and screen are seated on

auger drive hub, positioned correctly, and fasteners

on upper bearing bracket are installed and engaged

correctly prior to starting.

4. Ensure that the discharge chute is fi tted securely

in position.

5. Turn on incoming power to disposer and

Waste Xpress.

NOTE: Use of the electrical door disconnect knob on

the WX-101A control panel will result in a 30 second

delay before the system can be restarted. You must

wait 30 seconds after reactivation of the line disconnect

switch before system will restart.

PERSONAL INJURY

If system does not shut down when front

cover/discharge chute is removed, interlock may

not be wired correctly. See Troubleshooting section

for corrective action.

ELECTRICAL SHOCK

Turn off electrical supply to Waste Xpress, control

center and disposer before attempting to work on

it. Test with a volt meter or circuit tester to insure

that power is off.

6. Push start button on the control center

(see Figure 20). The WX-101A and disposer will run

and cold water will fl ow into the disposer.

7. Observe auger rotation by looking up into discharge

chute; auger should rotate clockwise (when viewed

from above). See Figure 21.

NOTE: If auger rotates counter-clockwise, turn off main

power supply, wait 60 seconds, then restart. If auger

continues to rotate counter-clockwise (when viewed

from above), unit must be re-wired. Turn off main power.

On three phase Waste Xpress interchange leads L1 and

L2. Restart.

8. Make sure cold water is fl owing into disposer.

9. Make sure hot water to Waste Xpress spray nozzles

is cycling. Factory set cycle is 10 seconds on and

2 minutes off.

10. Press stop button to stop disposer and

Waste Xpress. Steam from chute should be evident.

11. Restart system and remove front cover/discharge

chute. Waste Xpress and disposer should turn

off automatically if interlock switch is functioning

properly. Water will continue to fl ow into disposer.

Start Stop

Figure 20.

Rotation of Auger

Figure 21.

12. Replace front cover/discharge chute and

restart system.

14

Page 14

Operating Instructions

TO START

1. Check to ensure disposer is free of foreign objects.

2. Ensure power is on.

3. Push start button. Disposer and Waste Xpress will run

and water will fl ow into disposer

TO STOP

1. Push stop button. System will stop.

2. Water may continue to fl ow into disposer for up to

10 minutes, per the time set on the water shutoff

delay timer. This post-fl ush clears the drain lines

of food waste.

WATER SHUTOFF DELAY ADJUSTMENT

This water shutoff delay is adjustable from 30 seconds

to 10 minutes (see Figure 23). Set water shutoff delay

for at least 2 minutes on trough systems.

PERSONAL INJURY

To adjust the water shutoff delay, disconnect the

electrical power to the control panel and open the

control center door.

Locate the water shutoff delay at the top of the printed

circuit board in the WX-101A (see Figure 22). Set the dip

switches for the desired water shut off delay. Use the

guide printed on the circuit board to set minutes of

delay (also see Figure 23). The dip switches should be

moved to match the fi lled in areas of the guide.

NOTE: Line disconnect should not be turned off

between usage.

AUTOMATIC TIMED DISPOSER SHUTOFF

This water saving feature allows the system to run for

10 minutes before it automatically shuts off and must

be manually restarted.

NOTE: This feature is set in the manual position at

the factory. To activate the automatic timed system

shutoff, disconnect the electric power to the control

center, then open the control center door. Locate the

Dip Switch Module at the top of the circuit board (see

Figure 22). Move the #5 dip switch from MANUAL to

AUTOMATIC. The system now automatically shuts off

10 minutes after it starts.

Figure 22.

30 Second Delay:

Dip Switches 1, 2,

3, pushed down,

Switch 4 pushed

1

up.

234

10 Minute Delay:

Dip Switches 1,

3, 4 pushed up

position, Switch 2

pushed down

Figure 23. Time Delay Setting Examples

1

234

MANUAL

AUTOMATIC

MANUAL

AUTOMATIC

15

Page 15

Operating Instructions

OPERATING WASTE XPRESS SYSTEM

1. Make sure there are no foreign objects in disposer

grind chamber. Do not pre-load disposer with food

waste prior to starting.

2. Place 10 gallon waste bin under discharge chute.

3. Push start button on control center. Waste Xpress

and disposer will run and water will fl ow into disposer.

4. Feed food waste into disposer in a steady,

continuous fl ow. Waste will exit discharge chute

and drop into waste bin.

NOTE: Once all waste has been fed into disposer, allow

approximately 2 minutes for system to clear. This will

allow system to fl ush itself prior to system shutdown.

5. Press Stop button to stop system.

PROPERTY DAMAGE

Do not insert: string, metal, glass, cans, silverware,

dishes, cloth napkins or large quantities of grease

or oil into the disposer.

PERSONAL INJURY

Do not dispose of hot liquids such as grease, oil

and syrup into disposer.

OPERATIONAL TIPS

• Ensure a steady stream of cold water runs into the

disposer while it is operating.

• Do not overload the disposer or turn it off with food

waste inside the grind chamber (run the disposer

and water for three minutes after the fi nal load to

fl ush away all food waste).

• Clean auger and auger screen, bearing bracket, and

discharge chute daily by running through dishwasher.

Start Stop

Figure 24.

16

Page 16

Cleaning Instructions

PERSONAL INJURY

Wait until auger paddles stop before cleaning

Waste Xpress.

1. Press stop button on control center to stop system

(disposer & Waste Xpress).

2. Holding both handles remove discharge chute by

tilting it upward (see Figure 25).

3. Remove auger-bearing bracket by sliding the two

captive fasteners inward and then pull bracket

upward (see Figure 26 and 27).

4. Lift auger and screen up and then out

(see Figure 26).

5. Remove auger from screen by lifting it up and out

(see Figure 28).

6. Rinse auger, screen, auger compartment and

discharge chute. Auger, screen and discharge

chute are dishwasher safe and should be washed

daily. Flush inlet and outlet with a fresh water

supply to keep the drain lines clean.

7. Install auger into screen then place screen

over drive.

8. Ensure that the auger drops into position.

Discharge

Chute

Figure 25.

Auger Screen

Figure 26.

Captive

Fasteners

9. Secure bearing bracket with captive fasteners.

10. Install discharge chute by placing bottom, front

portion in fi rst and then tilting back and downward.

Figure 27. Bearing Bracket

Figure 28.

17

Page 17

Troubleshooting

ELECTRICAL SHOCK

• Disconnect power before servicing.

• Do not bypass interlock switch.

Wait until auger paddles stop before servicing

Waste Xpress.

PERSONAL INJURY

Troubleshooting for problems other than what is listed below should be performed by a qualifi ed service person.

Troubleshooting performed by untrained personnel could result in electrical shock or damage to the Waste Xpress,

disposer and/or Control Center.

SYSTEM TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

The Waste Xpress, disposer and

water do not turn on.

• Electrical supply turned off.

• Fuse blown or circuit breaker

tripped at power supply.

• Discharge chute of Waste Xpress not

seated properly

• Waste blocking safety interlock.

• Control circuit fuse (FNA2) blown.

• 24 volt power from control center

not present.

• Turn on electrical supply.

• Replace fuse or reset circuit breaker.

• Reinstall chute to ensure proper fi t.

• Remove waste from safety interlock.

• Replace fuse.

• Call for service.

The disposer will not start or stops

while grinding, but the Waste Xpress

and water operate properly.

The Waste Xpress, disposer and

water appear to run however

no solid waste is ejected from

the discharge chute of the

Waste Xpress.

Water backs up into

disposer (does not drain).

• The disposer overload

protector tripped.

• The disposer jammed.

• Auger is not suffi ciently primed with

waste after cleaning.

• Insuffi cient waste in waste line.

• Auger turning in wrong direction.

• The auger and screen plugged.

• Auger not turning.

• Plumbing line between disposer and

Waste Xpress clogged.

• Press stop button on control center and

press red reset button on disposer.

Note: you may need to let disposer cool

down before setting.

• Press stop button on control center and

follow direction for dejamming

(supplied with disposer).

• Allow unit to run longer to prime itself.

• Waste will exit when more waste is added.

• Three phase - Switch leads L1 and L2.

• Remove plug.

• Ensure that auger is seated properly and

that auger belt in place. Check motor.

• Remove clog.

18

Page 18

PROBLEM POSSIBLE CAUSE SOLUTION

Waste Xpress stops unexpectedly.

Troubleshooting

SYSTEM TROUBLESHOOTING

• Discharge chute misaligned.

• Reinstall discharge chute to ensure

proper fi t.

Water exits Waste Xpress

at front of cabinet.

Waste Xpress does not run,

but disposer and water run.

No water spraying onto

auger screen.

Water fl ows continuously before

controls are turned on.

• Fuse blown or circuit breaker

tripped at power source.

• Stop button on control center

has been pushed.

• Drain line has clog.

• High water level.

• Contactor defective.

• Auger motor defective.

• Solenoid valve clogged.

• Water turned off.

• Solenoid valve defective.

• Spray nozzles clogged.

• Timer defective.

• Timer not set properly.

• Solenoid valve installed incorrectly.

• Solenoid valve installed incorrectly.

• Replace fuse or reset circuit breaker.

• Push start button on control center.

• Clear drain.

• Add second waste outlet drain connect from

Waste Xpress cabinet to sewer connection

(recommended for trough applications).

• Call service.

• Call service.

• Remove clog.

• Turn on water.

• Call service.

• Replace nozzles.

• Call service.

• Call service.

• Reinstall solenoid valve so arrow is pointing

in correct direction.

• Reinstall the water solenoid valve with the

arrow on the valve pointing in the direction

of the water fl ow.

Overload protector trips frequently.

• Timer is not set properly.

• Solenoid valve is defective.

• Disposer is overloaded with

food waste.

• Call service.

• Replace solenoid valve.

• Do not overload disposer with excessive

amounts of food waste.

19

Page 19

PROBLEM CAUSE SOLUTION

Disposer motor will not start and

water does not fl ow.

Troubleshooting

DISPOSER TROUBLESHOOTING

• No incoming line power

• Line disconnect switch is not ON

• Turn line power on.

• Turn line disconnect to ON position.

Disposer does not reverse direction.

Disposer motor stops while grinding

but water continues to fl ow.

Disposer will not start but

water fl ows.

• Line disconnect switch has been

reactivated and 30-second delay has

not yet expired.

• Control circuit fuse FNA2 is blown.

• Control center has been reactivated

before post-fl ush delay has expired.

• Control center wired for

automatic shut-off.

• Disposer is jammed.

• Disposer motor overload protector

has tripped.

• Overload protector on the disposer

may have tripped.

• Wait 30 seconds and try starting again.

• Replace fuse.

• Wait until post-fl ush is complete and

try again.

• Press start button. If disposer runs for

10 minutes then shuts off, the automatic

shutoff is active. If the manual setting is

desired, change indicated in the

feature section.

• Press stop button and follow directions for

dejamming in disposer installation manual.

• Press stop button. Locate red reset button

on front of disposer electrical cover.

Press to reset. If motor had been running,

wait fi ve minutes for the motor and overload

to cool down.

• Press stop button. Locate red reset button

on front of disposer electrical cover. Press

to reset. If motor had been running, wait

fi ve minutes for the motor and overload to

cool down.

Water fl ows constantly before start

button is pushed.

Overload trips frequently.

• Disposer is jammed

• Water solenoid valve is

installed backward.

• Press stop button and follow directions

for dejamming that were supplied with

the disposer.

• Water fl ow should be in the direction of the

arrow on valve.

• Disposer overloaded. • Do not overload disposer with excess

amounts of garbage and water.

20

Page 20

PROBLEM POSSIBLE CAUSE SOLUTION

Auger runs in Counterclockwise

(CCW) direction.

Troubleshooting

WASTE XPRESS TROUBLESHOOTING

• Power to auger motor reversed. • Reverse motor leads to auger motor or

switch L1 and L2 connections on WX

terminal block. Auger must run in

Clockwise direction.

Unit does not shut off with cover off

of Waste Xpress unit.

• Waste Xpress Interlock not

operating properly.

• Check interlock switch #3 and #95

connections on WX-101A to WX.

• Call service

Hot Water Spray is cold.

Hot Water spray does not work.

Auger reverses direction on

each re-start.

Waste Xpress unit will not start.

Water Shuts off when unit shuts off.

If the Waste Xpress remains inoperative after following this troubleshooting guide, contact InSinkErator’s service department at

1-800-845-8345 for the location of the nearest approved service agency.

• Incorrectly plumbed.

• No hot water.

• Connect solenoid on WX unit to hot

water source.

• Ensure hot water heater/source

is functioning.

• Incorrectly wired. • Check connections on WX-101A #7 to

WX #18.

• Waste Xpress unit auger motor

has been wired into disposer

motor circuit.

• Incorrect wiring.

• Misaligned Interlock switch on chute.

• Improper dipswitch setting

(circuit board).

• Re-wire as shown in instructions.

• Check wiring.

• Check chute for tight fi t.

• Refer to Page 14 to refer to dipswitch

setting instructions.

21

Page 21

Waste Xpress 120V, 1Phase System Wiring Diagram

ELECTRICAL SHOCK

• Turn off the electrical supply to the disposer before

attempting any work on it. Use a voltmeter or

circuit tester to ensure that power is off.

• Installation must conform to local electrical codes.

• All components (disposer, WX, control center

and solenoids) must be carefully and permanently

grounded.

• A properly fused disconnect must be installed at

the electrical supply source for the control center.

120 V

1-phase

PROPERTY DAMAGE

• Ensure that the control center voltage and phase

match the disposer motor and electrical supply.

Check nameplates on disposers and control

centers for voltage and phase specifi cation.

• The disposer motor wiring connection is shown in

the disposer terminal box.

Call Toll Free 1-800-845-8345

for the nearest InSinkErator

Authorized Service Agency or

to reach Technical Support.

22

Page 22

WX101A-1 120V, 1Phase Electrical Connections

23

Page 23

Waste Xpress 208/230V, 1Phase System Wiring Diagram

ELECTRICAL SHOCK

• Turn off the electrical supply to the disposer before

attempting any work on it. Use a voltmeter or

circuit tester to ensure that power is off.

• Installation must conform to local electrical codes.

• All components (disposer, WX, control center

and solenoids) must be carefully and permanently

grounded.

• A properly fused disconnect must be installed at

the electrical supply source for the control center.

208/230 V

1-phase

PROPERTY DAMAGE

• Ensure that the control center voltage and phase

match the disposer motor and electrical supply.

Check nameplates on disposers and control

centers for voltage and phase specifi cation.

• The disposer motor wiring connection is shown in

the disposer terminal box.

Call Toll Free 1-800-845-8345

for the nearest InSinkErator

Authorized Service Agency or

to reach Technical Support.

24

Page 24

WX101A-2 208/230V 1Phase Electrical Connections

25

Page 25

Waste Xpress 208/230V, 3Phase System Wiring Diagram

ELECTRICAL SHOCK

• Turn off the electrical supply to the disposer before

attempting any work on it. Use a voltmeter or

circuit tester to ensure that power is off.

• Installation must conform to local electrical codes.

• All components (disposer, WX, control center

and solenoids) must be carefully and permanently

grounded.

• A properly fused disconnect must be installed at

the electrical supply source for the control center.

120 V

208/230 V

1-phase

3-phase

1/2 to 2 HP

PROPERTY DAMAGE

• Ensure that the control center voltage and phase

match the disposer motor and electrical supply.

Check nameplates on disposers and control

centers for voltage and phase specifi cation.

• The disposer motor wiring connection is shown in

the disposer terminal box.

Call Toll Free 1-800-845-8345

for the nearest InSinkErator

Authorized Service Agency or

to reach Technical Support.

26

Page 26

WX101A-3 208/230V 3Phase Electrical Connections

27

Page 27

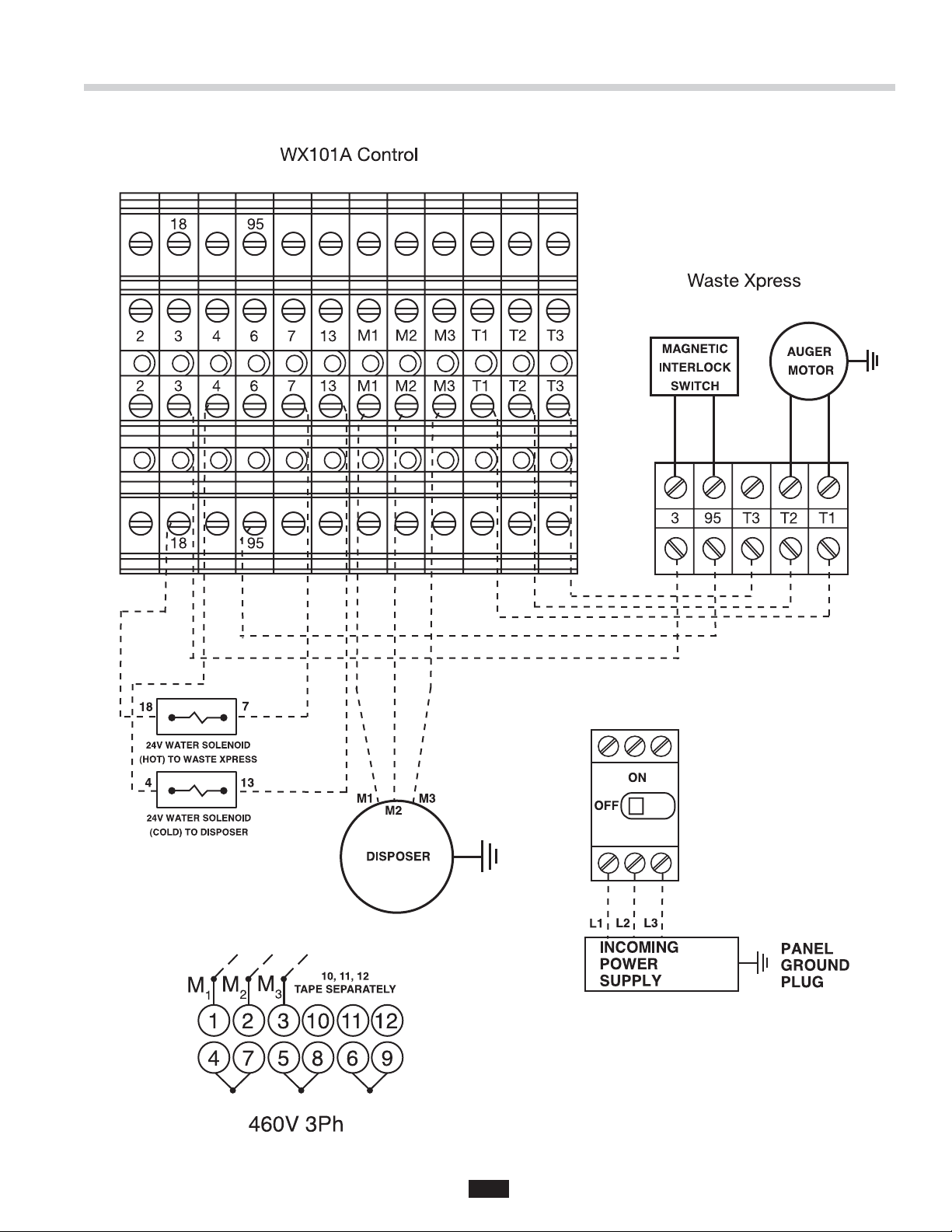

Waste Xpress 380/460V, 3Phase System Wiring Diagram

ELECTRICAL SHOCK

• Turn off the electrical supply to the disposer before

attempting any work on it. Use a voltmeter or

circuit tester to ensure that power is off.

• Installation must conform to local electrical codes.

• All components (disposer, WX, control center

and solenoids) must be carefully and permanently

grounded.

• A properly fused disconnect must be installed at

the electrical supply source for the control center.

120 V

380/460 V

1-phase

3-phase

1/2 to 2 HP

PROPERTY DAMAGE

• Ensure that the control center voltage and phase

match the disposer motor and electrical supply.

Check nameplates on disposers and control

centers for voltage and phase specifi cation.

• The disposer motor wiring connection is shown in

the disposer terminal box.

Call Toll Free 1-800-845-8345

for the nearest InSinkErator

Authorized Service Agency or

to reach Technical Support.

28

Page 28

WX101A-4 380/460V 3Phase Electrical Connections

29

Page 29

Figure 29. 208-230 volt - 3 Phase

460 volt - 3 Phase

Motor Wiring Diagrams

Figure 30. 115 volt - 1 Phase

208-230 volt - 1 Phase

30

Page 30

Loading...

Loading...