Page 1

SERVICE MANUAL

DANGER indicates an imminently hazardous situation which, if not avoided, will

(WX-1, WX-2, WX-3, WX-4)

DANGER

WARNING

result in death or serious injury.

WARNING indicates a potential hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may

CAUTION

result in minor or moderate injury.

Ensure that the person servicing the Mini Waste Xpress carefully reads and understands the

safety instructions in this manual.

Part No. 14272 April 2000

Page 2

MINI WASTE REDUCTION SYSTEM LIMITED WARRANTY

The In-Sink-Erator Mini Waste Xpress, disposer and control centers are warranted against detects in material and workmanship for one year

from the date of installation. The warranty includes parts and labor, provided an In-Sink-Erator Factory Authorized Service Center performs

the service. This warranty does not apply if the failure is due to: faulty or improper electrical installation, faulty or improper plumbing

installation, product abuse or misuse, accidental damage, clogged drain lines, improperly sized unit (as specified by In-Sink-Erator).

Page 3

Table of Contents

Introduction 1

Defining Problems 2

Testing & Replacing

Discharge Interlock Assembly 3, 4

Replacing auger Paddles 5

Replacing Tension Adjustment Dial 6

Replacing Tension Spring 7

Replacing Auger Weight 8

Replacing Auger 9

Replacing Screen 10

Replacing Spray Nozzle 11

Replacing Inlet/Outlet Fitting 12

Replacing Captive Fasteners 13

Replacing Retaining Spring 14

Replacing Auger Belt 15

Replacing Pulley 16

Replacing Auger Drive Assembly 17, 18

Replacing Auger Motor 19, 20

Replacing Motor Bracket 21

Replacing Solenoid Valve 22

Replacing Plumbing 23

Replacing Leveling Foot 24

Replacing Control Panel Components 25

Wiring Diagrams 26-33

Internal Motor Connections 34

Trouble shooting 35, 36

Page 4

Table of Contents

Introduction 1

Defining Problems 2

Testing & Replacing

Discharge Interlock Assembly 3, 4

Replacing auger Paddles 5

Replacing Tension Adjustment Dial 6

Replacing Tension Spring 7

Replacing Auger Weight 8

Replacing Auger 9

Replacing Screen 10

Replacing Spray Nozzle 11

Replacing Inlet/Outlet Fitting 12

Replacing Captive Fasteners 13

Replacing Retaining Spring 14

Replacing Auger Belt 15

Replacing Pulley 16

Replacing Auger Drive Assembly 17, 18

Replacing Auger Motor 19, 20

Replacing Motor Bracket 21

Replacing Solenoid Valve 22

Replacing Plumbing 23

Replacing Leveling Foot 24

Replacing Control Panel Components 25

Wiring Diagrams 26-33

Internal Motor Connections 34

Trouble shooting 35, 36

Page 5

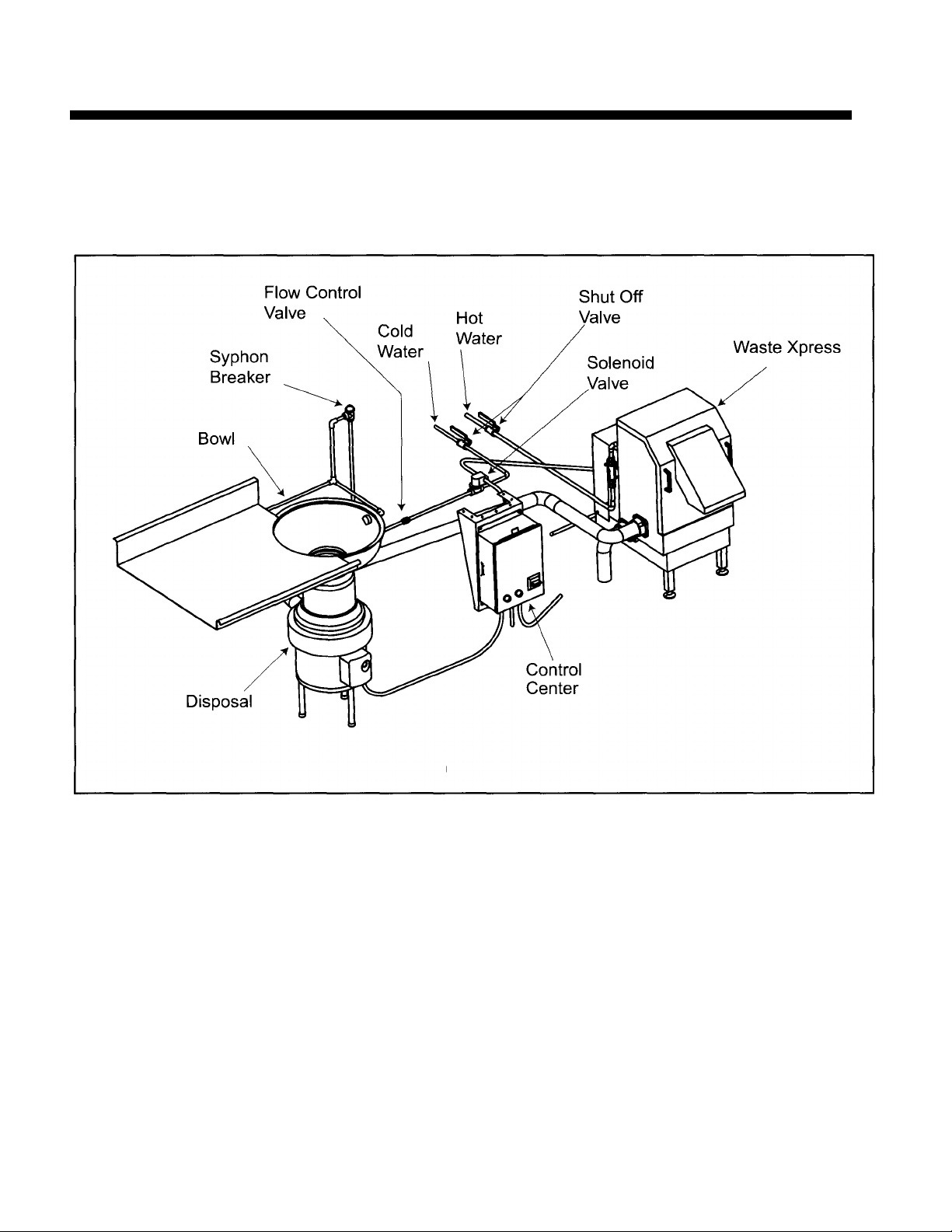

Introduction

Figure

1-1

The In-Sink-Erator Mini Waste Xpress is a commercial kitchen waste reduction system that utilizes a standard commercial food waste disposer

inline with the Mini Waste Xpress dewatering system. The kitchen waste is ground through the disposer then transferred to the Mini Waste

Xpress where it is compressed. After the waste is compressed, the liquids are sent down the drain line and the solid waste exiting the Mini

Waste Xpress is 85% less in volume. (See figure 1 -1 for typical installation.)

PRIOR TO SERVICE CALL

• Obtain the model number, serial number, voltage and phase from the customer to prepare for the service

call.

• Check the service history of the Mini Waste Xpress.

• Make sure the customer has checked for foreign objects jammed in auger area (see troubleshooting).

1

Page 6

Defining Problems

DEFINING PROBLEMS

Before troubleshooting for mechanical problems, determine if the problem is electrical.

• Do the Mini Waste Xpress electrical specifications match those of the electrical power supply, control center and

disposer?

• Are the motor lead connections correct for the corresponding power supply?

• If the problem is electrical, determine if there are electrical problems with other kitchen appliances (this may indicate

a problem in the electrical circuitry of the building).

Are the water connections installed correctly?

A hot water supply should be connected to 1/2" copper tube water inlet as specified per local codes.

(In-Sink-Erator recommends installing a shut off valve close to unit).

AFTER COMPLETING SERVICE

Test the Mini Waste Xpress for proper operation and ensure that the fittings are secure and do not leak.

NOTE: Please references the Mini Waste Xpress Parts List (14273) for additional part identification when

servicing the Mini Waste Xpress.

2

Page 7

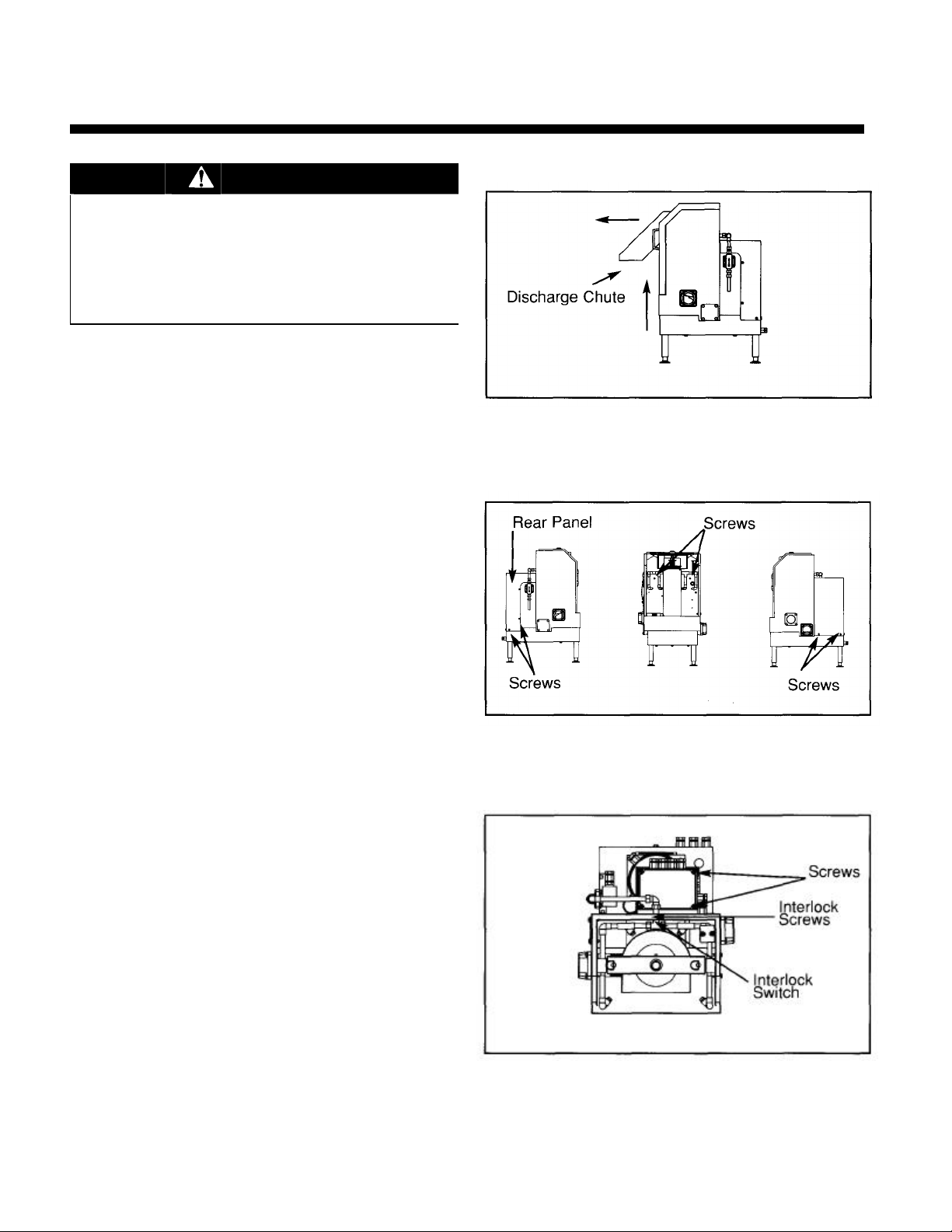

Testing & Replacing Discharge Chute Interlock Assembly

Figure

1-1

Figure

1-2 Figure

1 -3

DANGER

Electrical Shock

Failure to turn off the water and electrical

supply before servicing may result in product

damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Holding both handles remove discharge chute by

tilting it upward (see figure 1-1).

3. Remove rear panel by removing the screws securing it

in place (see figure 1-2).

4. Remove control box cover by removing the

screws securing it in place (see figure 1-3).

5. Install discharge chute by placing bottom front portion

in first and then tilting back and downward.

6. With interlock assembly closed, test wires 6 & 7 for

continuity (see pages 26-33).

• If continuity reads closed, skip to step 18.

• If continuity reads open, replace interlock switch

assembly.

To replace interlock assembly:

7. Remove discharge chute.

8. Loosen strain relief on cord going from switch to

control box (see figure 1-3).

9. Remove wires 6 & 7 from control box.

10. Remove two screws securing interlock switch to

cabinet (see figure 1 -3).

11. Remove interlock switch.

12. Install new interlock switch, securing with two screws.

13. Insert wires 6 & 7 (from interlock switch) through strain

relief and into control box. Connect wires 6 & 7 to

terminal block (see pages 26-33) and tighten strain

reliefs.

3

Page 8

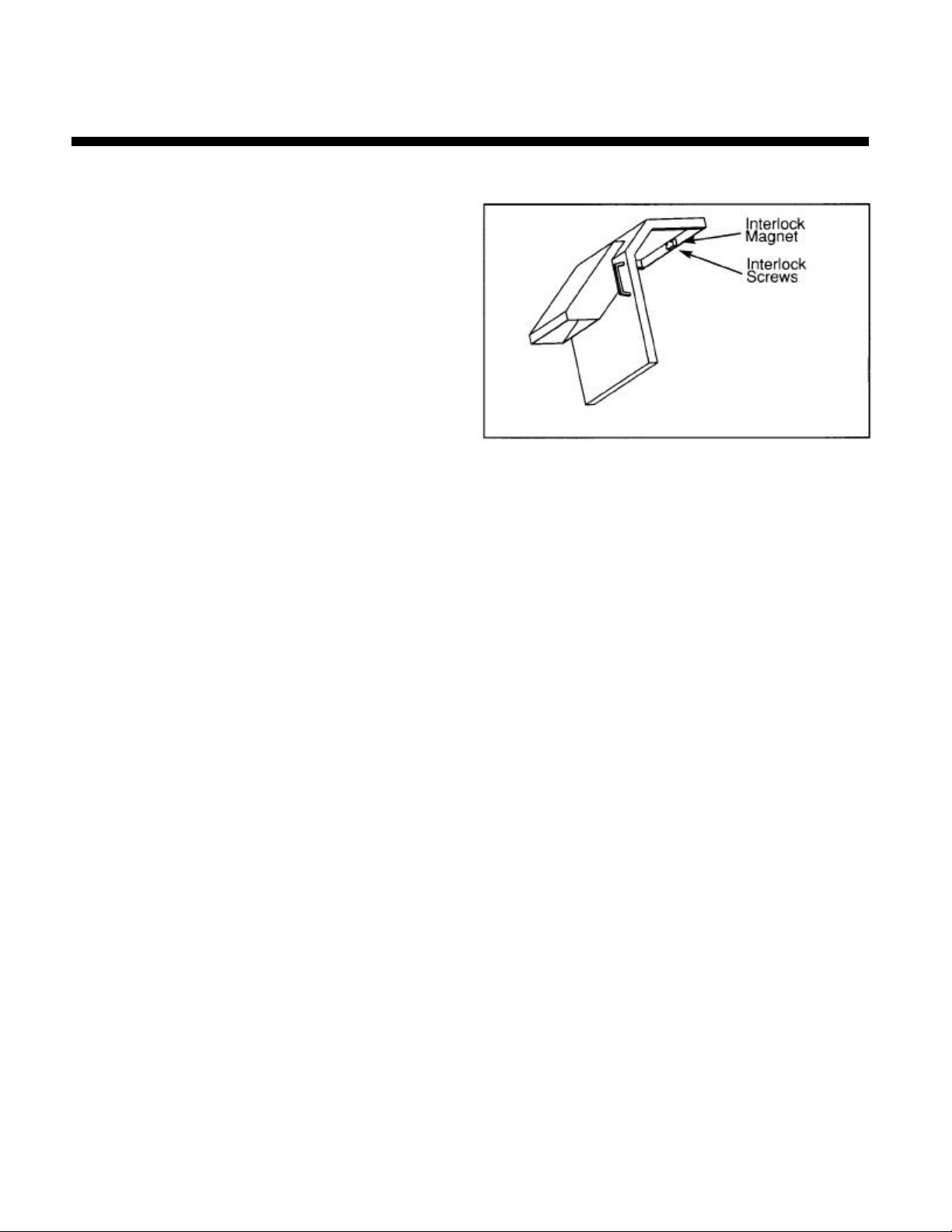

Figure

1-4

Testing & Replacing Discharge Chute Interlock Assembly (Cont.)

14. Unscrew two screws securing interlock magnet on

discharge chute and remove interlock magnet (see

figure 1 -4).

15. Install new interlock magnet and secure with two

screws.

16. Install discharge chute.

17. With interlock switch closed, test wires 6 & 7 for

continuity.

• If continuity reads closed, skip to step 18.

• If continuity reads open, rotate interlock magnet

180° on discharge chute and test for continuity

again.

18. Replace rear panel, control box cover and secure

with screws.

19. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

4

Page 9

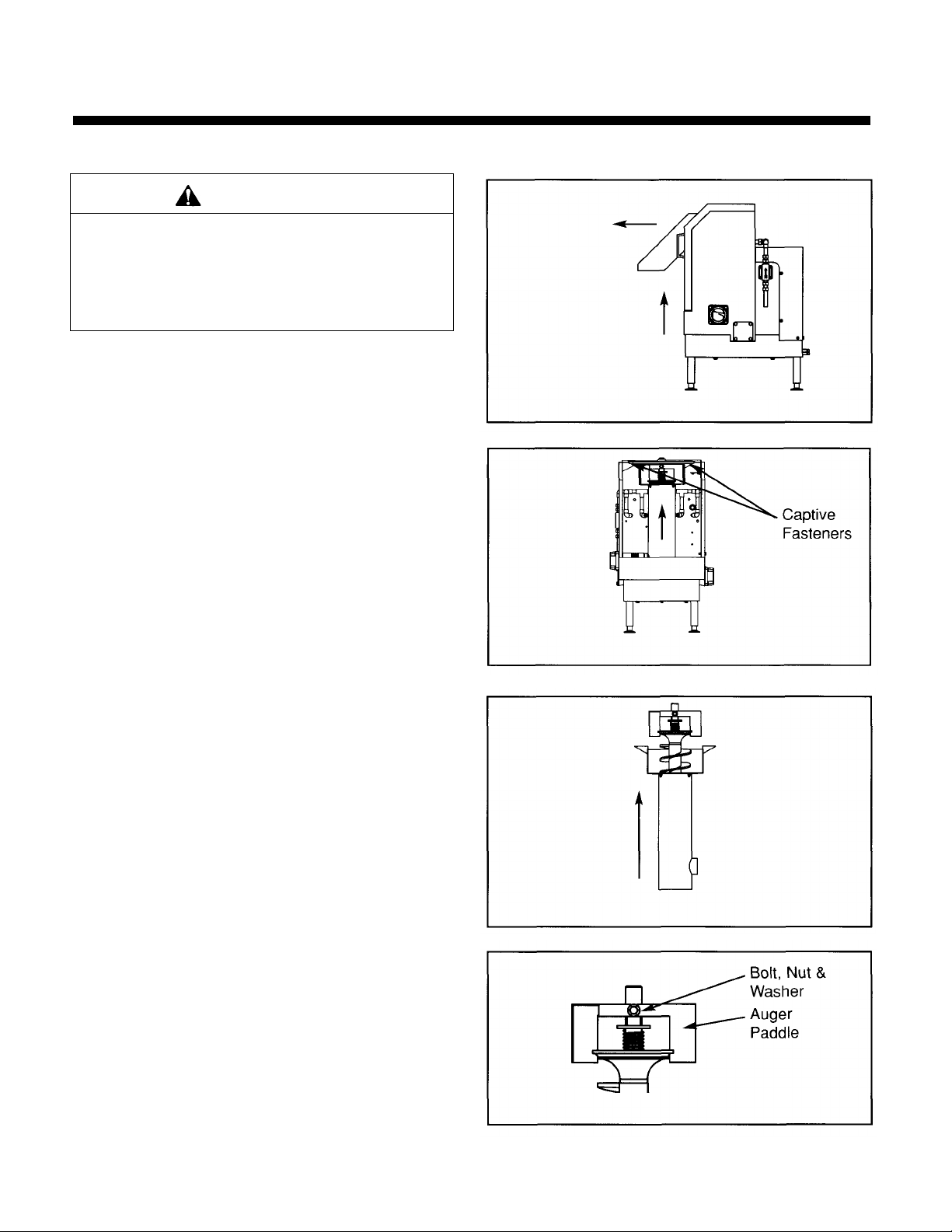

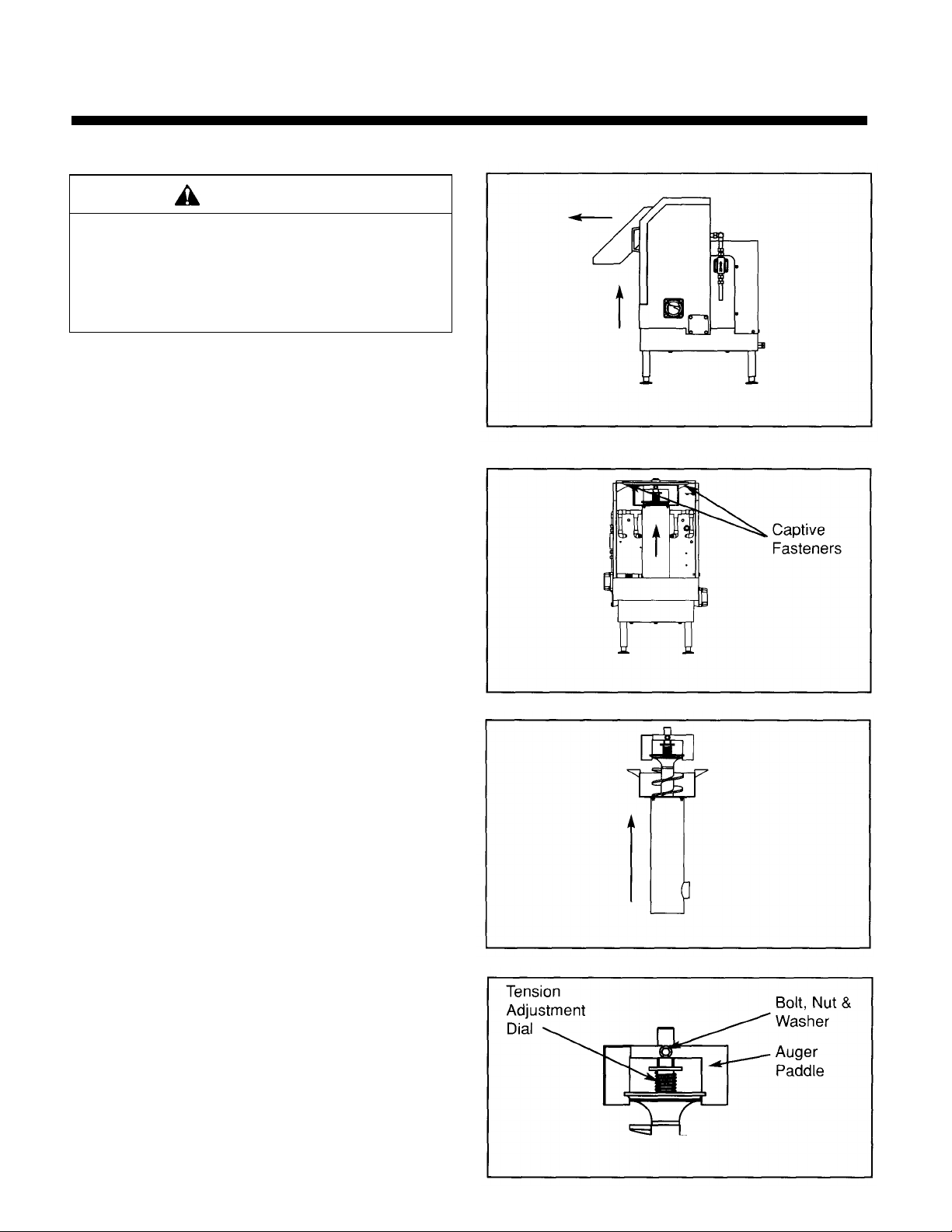

Replacing Auger Paddles

Figure

2-4 Figure

2-2

Failure to turn off the water and electrical

WARNING

Personal Injury

supply before servicing may result in product

damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Holding both handles remove discharge chute by tilting

it upward (see figure 2-1).

3. Remove auger-bearing bracket by turning the two

captive fasteners counter clockwise and then pull

bracket upward (see figure 2-2), replace if necessary.

4. Lift auger and screen up and then out.

5. Remove auger from screen by lifting up (see figure 2-

3).

6. Remove bolt, nut and washers securing auger paddle

to auger shaft (see figure 2-4).

7. Remove auger paddle from shaft.

8. Install new auger paddle and secure with bolt, nut and

washers.

9. Ensure auger weight travels freely up and down after

assembly.

10. Install auger into screen then place screen over drive.

11. Ensure that the auger drops into position.

12. Secure bearing bracket with captive fastener.

13. Install discharge chute by placing bottom front portion

in first and then tilting back and down ward.

14. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

Figure 2-1

Figure 2-3

5

Page 10

Replacing Tension Adjustment Dial

Figure

3-1

Figure

3-2 Figure

3-3

Figure

3-4

WARNING

Personal Injury

Failure to turn off the water and electrical

supply before servicing may result in product

damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Holding both handles, remove discharge chute by tilting

it upward (see figure 3-1).

3. Remove auger-bearing bracket by turning the two

captive fasteners counter clockwise and then pull

bracket upward (see figure 3-2), replace if necessary.

4. Lift auger and screen up and then out.

5. Remove auger from screen by lifting it up (see figure 3-

3).

6. Remove bolt, nut and washers securing auger paddle

to auger shaft (see figure 3-4).

7. Remove auger paddle (replace if necessary) and

tension adjustment dial from shaft.

8. Install new tension adjustment dial and auger paddle.

Secure auger paddle to shaft with bolt, nut and

washers.

9. Ensure auger weight travels freely up and down after

assembly.

10. Install auger into screen then place screen over drive.

11. Ensure that the auger drops into position.

12. Secure bearing bracket with captive fastener.

13. Install discharge chute by placing bottom front portion

in first and then tilting back and down ward.

14. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

6

Page 11

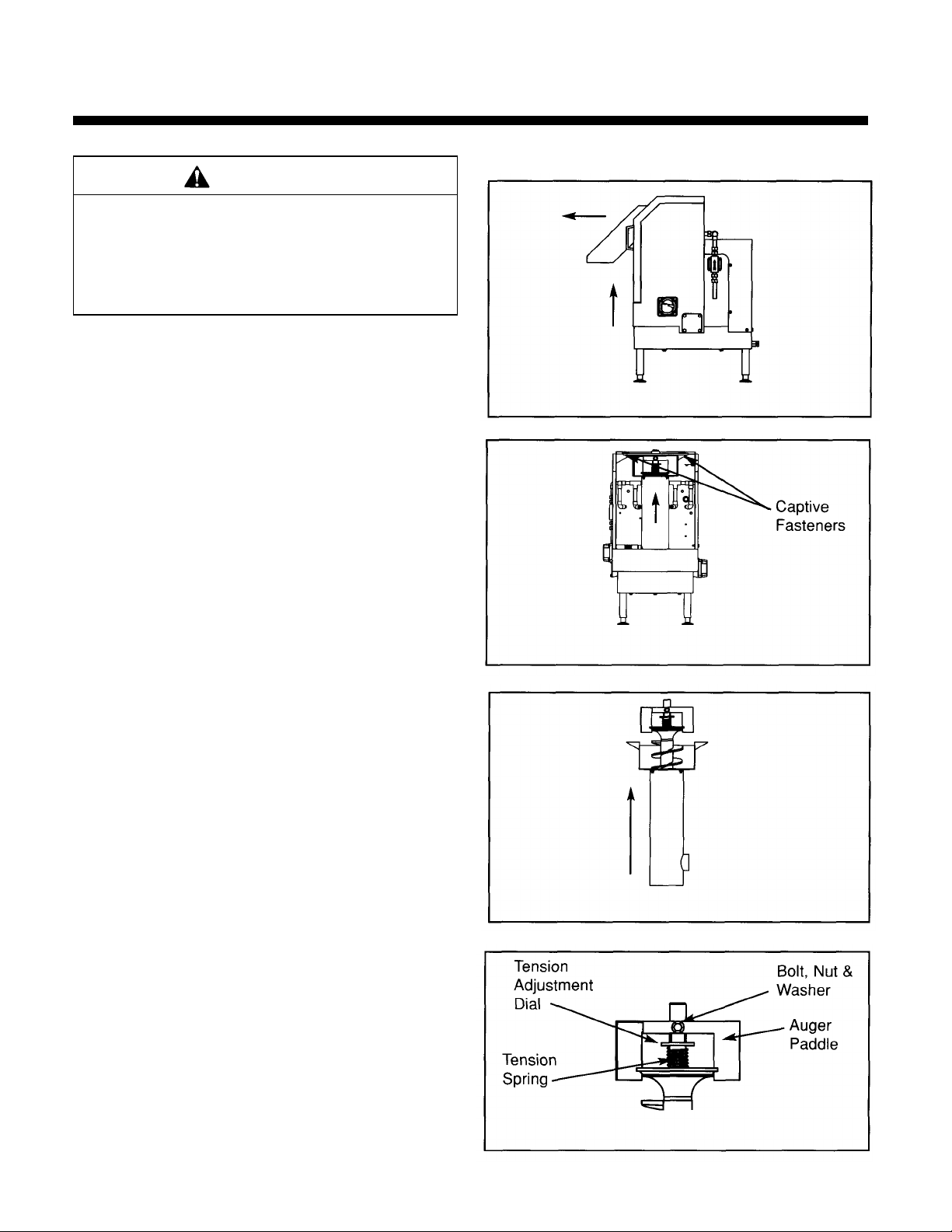

Replacing Tension Spring

damage or injury.

Figure

4-1 Figure

4-2 Figure

4-3 Figure

4-4

WARNING

Personal Injury

Failure to turn off the water and electrical

supply before servicing may result in product

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Holding both handles, remove discharge chute by tilting

it upward (see figure 4-1).

3. Remove auger-bearing bracket by turning the two

captive fasteners counter clockwise and then pull

bracket upward (see figure 4-2), replace if necessary.

4. Lift auger and screen up and then out.

5. Remove auger from screen by lifting it up (see figure 4-

3).

6. Remove bolt, nut and washers securing auger paddle

to auger shaft (see figure 4-4).

7. Remove auger paddle (replace if necessary), tension

adjustment dial (replace if necessary) and tension

spring from shaft.

8. Install new tension spring, tension adjustment dial and

auger paddle. Secure auger paddle to shaft with bolt,

nut and washers.

9. Ensure auger weight travels freely up and down after

assembly.

10. Install auger into screen then place screen over drive.

11. Ensure that the auger drops into position.

12. Secure bearing bracket with captive fastener.

13. Install discharge chute by placing bottom front portion in

first and then tilting back and downward

14. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

7

Page 12

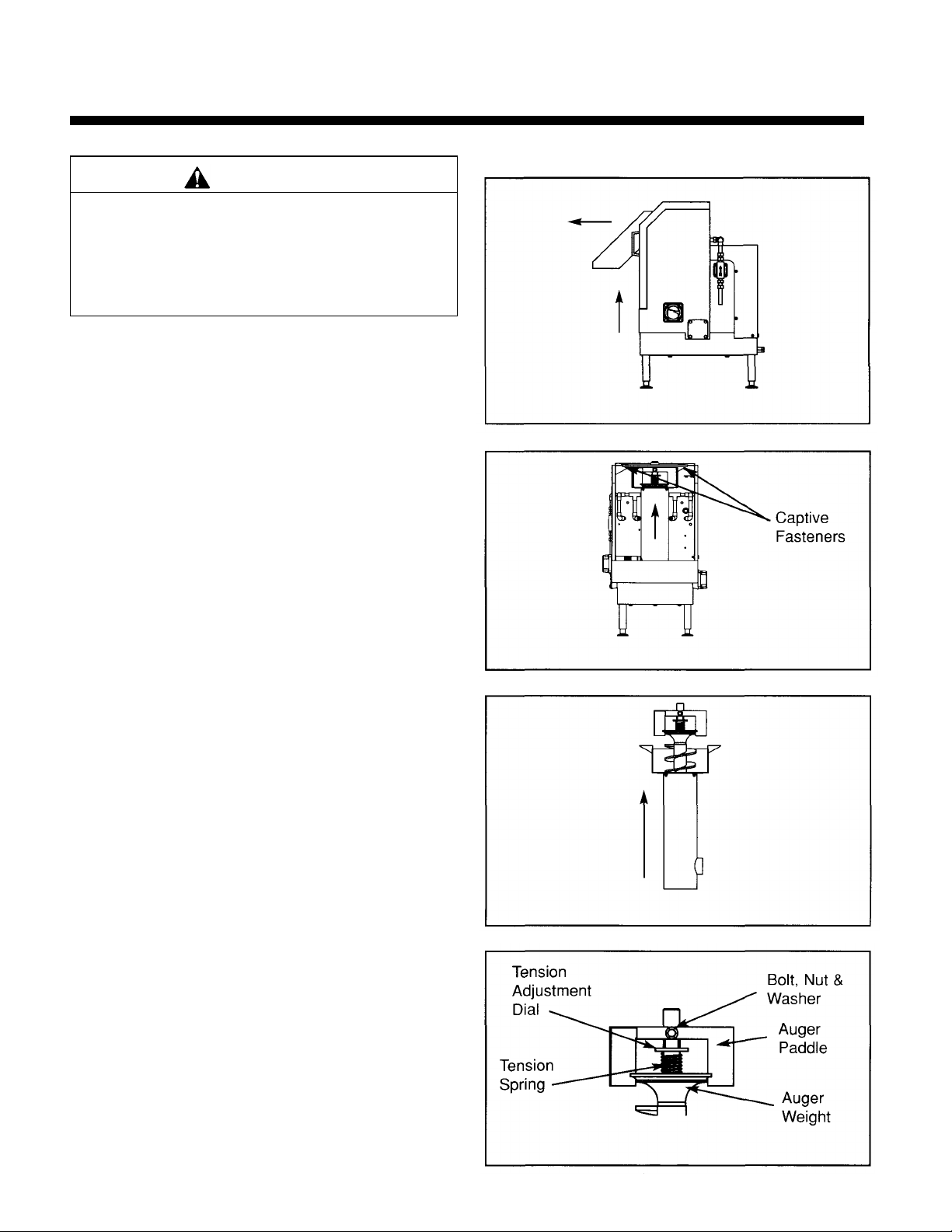

Replacing Auger Weight

Figure

5-2

Figure

5-3 Figure

5-4

WARNING

Personal Injury

Failure to turn off the water and electrical

supply before servicing may result in product

damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Min Waste

Xpress.

2. Holding both handles, remove discharge chute by

tilting it upward (see figure 5-1).

3. Remove auger-bearing bracket by turning the two

captive fasteners counter clockwise and then pull

bracket upward (see figure 5-2), replace if necessary.

4. Lift auger and screen up and then out.

5. Remove auger from screen by lifting it up (see figure

5-3).

6. Remove bolt, nut and washers securing auger paddle

to auger shaft (see figure 5-4).

7. Remove auger paddle (replace if necessary), tension

adjustment dial (replace if necessary), tension spring

(replace if necessary) and auger weight from shaft.

8. Install new auger weight, tension spring, tension

adjustment dial and auger paddle. Secure auger

paddle to shaft with bolt, nut and washers.

9. Ensure auger weight travels freely up and down after

assembly.

10. Install auger into screen then place screen over drive.

11. Ensure that the auger drops into position.

12. Secure bearing bracket with captive fastener.

13. Install discharge chute by placing bottom front portion

in first and then tilting back and downward.

14. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

Figure 5-1

8

Page 13

Replacing Auger

Figure

6-1

Figure

6-2

Figure

6-3

Figure

6-4

WARNING

Personal Injury

Failure to turn off the water and electrical

supply before servicing may result in product

damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Holding both handles, remove discharge chute by

tilting it upward (see figure 6-1).

3. Remove auger-bearing bracket by turning the two

captive fasteners counter clockwise and then pull

bracket upward (see figure 6-2), replace if

necessary.

4. Lift auger and screen up and then out.

5. Remove auger from screen by lifting it up (see figure

6-3).

6. Remove bolt, nut and washers securing auger

paddle to auger shaft (see figure 6-4).

7. Remove auger paddle (replace if necessary), tension

adjustment dial (replace if necessary), tension

spring (replace if necessary) and auger weight

(replace if necessary) from shaft.

8. Install auger weight, tension spring, tension

adjustment dial and auger paddle onto new auger

shaft. Secure auger paddle to shaft with bolt, nut

and washers.

9. Ensure auger weight travels freely up and down after

assembly.

10. Install auger into screen then place screen over

drive.

11. Ensure that the auger drops into position.

12. Secure bearing bracket with captive fastener.

13. Install discharge chute by placing bottom front

portion in first and then tilting back and downward.

14. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

Page 14

Replacing Spray Nozzles

Figure

8-1 Figure

8-2 Figure

8-3

WARNING

Personal Injury

Failure to turn off the water and electrical

supply before servicing may result in product

damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Holding both handles, remove discharge chute by tilting

it upward (see figure 8-1).

3. Remove auger-bearing bracket by turning the two

captive fasteners counter clockwise and then pull

bracket upward (see figure 8-2), replace if necessary.

4. Lift auger and screen up and then out.

5. Remove damaged spray nozzle with socket wrench

(remove plastic nozzle only not metal nut) see figure 8-

3.

6. Install new spray nozzles secure,

NOTE: DO NOT OVER-TIGHTEN.

7. Install auger and screen over drive.

8. Ensure that the auger drops into position.

9. Secure bearing bracket with captive fastener.

10. Install discharge chute by placing bottom front portion

in first and then tilting back and downward.

11. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

11

Page 15

Replacing Inlet / Outlet fitting

Figure

9-1 Figure

9-2

WARNING

Personal Injury

Failure to turn off the water and electrical

supply before servicing may result in product

damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Holding both handles, remove discharge chute by tilting

it upward (see figure 9-1).

3. Remove auger-bearing bracket by turning the two

captive fasteners counter clockwise and then pull

bracket upward (see figure 9-2), replace if necessary.

4. Lift auger and screen up and then out.

5. Remove the four screws holding the fitting in place

(see figure 9-1).

6. Remove any gasket material from panel.

• If fitting location is correct skip to step 10.

• If fitting location needs to be moved to opposite side

skip to step 7.

7. Remove four screws holding the cap and gasket in

position.

8. Install gasket and cap on opposite side.

9. Install new gasket and fitting and secure with four

screws.

10. Install auger and screen over drive.

11. Ensure that the auger drops into position.

12. Secure bearing bracket with captive fastener.

13. Install discharge chute by placing bottom front portion in

first and then tilting back and downward.

14. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

12

Page 16

Replacing Captive Fasteners

Figure

10-2

Figure

10-3

WARNING

Personal Injury

Failure to turn off the water and electrical

supply before servicing may result in product

damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Holding both handles, remove discharge chute by

tilting it upward (see figure 10-1).

3. Remove auger-bearing bracket by turning the captive

fasteners counter clockwise and then pull bracket

upward (see figure 10-2), replace if necessary).

4. Install new captive fastener by inserting the fastener

through the hole in the bearing bracket and secure it

by pushing the "c" clip onto the grove of the captive

fastener (see figure 10-3).

5. Secure bearing bracket with captive fastener.

6. Install discharge chute by placing bottom front portion

in first and then tilting back and downward.

7. Turn on power to Mini Waste Xpress at use box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

Figure 10-1

13

Page 17

Replacing Retaining Spring

Figure

11-1

Figure

11-3

Failure to turn off the water and electrical

supply before servicing may result in

product damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Holding both handles, remove discharge chute by

tilting it upward (see figure 11-1).

3. Remove auger-bearing bracket by turning the two

captive fasteners counter clockwise and then pull

bracket upward (see figure 11 -2), replace if

necessary).

4. Lift auger and screen up and then out.

5. If required remove "pop rivet" securing the dam aged

retaining spring in place by drilling it out with a dia drill

bit (see figure 11 -3).

6. Install new retaining spring with coil side up and secure

with pop rivets (see figure 11 -3).

7. Install auger and screen over drive.

8. Ensure that the auger drops into position.

9. Secure bearing bracket with captive fastener.

10. Install discharge chute by placing bottom front portion

in first and then tilting back and downward.

11. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

WARNING

Personal Injury

Figure 11-2

14

Page 18

Replacing Auger Belt

Figure

12-1

Figure

12-2

WARNING

Personal Injury

Failure to turn off the water and electrical

supply before servicing may result in

product damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Remove screws holding the bottom cover in place

(see figure 12-1).

3. Loosen the bolts securing the auger motor bracket in

place (see figure 12-2).

4. Loosen the tension bolt located at the back of the unit,

until there is enough slack to remove the belt (see

figure 12-2).

5. Remove the belt (see figure 12-2).

6. Install new belt and remove the slack by tightening the

tension bolt located at the back of the unit. NOTE: DO

NOT OVERTIGHTEN.

7. Secure the auger motor bracket to the frame.

8. Install bottom cover and secure with screws.

9. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

(Bottom View)

15

Page 19

Replacing Pulley

Figure

13-1

Figure

13-2

WARNING

Personal Injury

Failure to turn off the water and electrical

supply before servicing may result in

product damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Remove screws holding the bottom cover in place

(see figure 13-1).

3. Loosen the bolts securing the auger motor bracket in

place (see figure 13-2).

4. Loosen the tension bolt located at the back of the unit,

until there is enough slack to remove the belt (see

figure 13-2).

5. Remove the belt (see figure 13-2).

6. Remove the nut and washer securing the pulley in

position and pull the pulley off (see figure 13-2).

7. Remove woodruff key.

8. Install the new pulley, woodruff key and secure with

nut and washer.

9. Install belt and remove the slack by tightening the

tension bolt located at the back of the unit. NOTE: DO

NOT OVER-TIGHTEN

10. Secure the auger motor bracket to the frame.

11. Install bottom cover and secure with screws.

12. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

(Bottom View)

16

Page 20

Replacing Auger Drive Assembly

Figure

14-1

Figure

14-2

Figure

14-3

Figure

14-4

Failure to turn off the water and electrical

supply before servicing may result in

product damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Holding both handles, remove discharge chute by

tilting it upward (see figure 14-1).

3. Remove auger-bearing bracket by turning the two

captive fasteners counter clockwise and then pull

bracket upward (see figure 14-2), replace if

necessary).

4. Lift auger and screen up and then out.

5. Remove screws holding the bottom cover in place (see

figure 14-1).

6. Loosen the bolts securing the auger motor bracket in

place (see figure 14-3).

7. Loosen the tension bolt located at the back of the unit,

until there is enough slack to remove the belt (see

figure 14-2).

8. Remove the belt (see figure 14-3)

9. Remove the nut and washer securing the pulley in

position and pull the pulley off (see figure 14-3).

10. Remove woodruff key.

11. Remove the nuts and washers holding the auger drive

assembly in place.

NOTE: If silicon was used you may need to tap the

assembly down with a rawhide mallet (see figure 14-

4).

12. Run a bead of silicon between the bottom of the

cabinet and the auger drive.

13. Install new auger drive assembly and secure with four

nuts and washers.

WARNING

Personal Injury

(Bottom View)

17

(Bottom View)

Page 21

Replacing Auger Drive Assembly (Cont.)

14. Install the pulley, woodruff key and secure with nut

and washer.

15. Install new belt and remove the slack by

tightening the tension bolt located at the back of

the unit.

NOTE: DO NOT OVER TIGHTEN.

16. Secure the auger motor bracket to the frame.

17. Install bottom cover and secure with screws.

18. Install screen over drive.

19. Ensure that the auger drops into position.

20. Secure bearing bracket with captive fastener.

21. Install discharge chute by placing bottom front portion

in first and then tilting back and downward.

22. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

18

Page 22

Replacing Auger Motor

Figure

15-2

Figure

15-3

Figure

15-4

DANGER

Electrical Shock

Failure to turn off the water and electrical

supply before servicing may result in

product damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Holding both handles, remove discharge by tilting

upward (see figure 15-1)

3. Remove screws holding the bottom cover in place (see

figure 15-1).

4. Loosen the bolts securing the auger motor bracket in

place (see figure 15-2)

5. Loosen the tension bolt located at the back of the unit,

until there is enough slack to remove the belt (see

figure 15-2).

6. Remove the belt (see figure 15-2).

7. Remove rear panel by removing the screws securing it

in place (see figure 15-3).

8. Remove cover to control box by loosening the screws

securing it in place (see figure 15-4).

9. Loosen strain relief on cord going from auger motor to

control box.

10. Remove wires from terminal block position and ground

terminal (see pages 26-33).

11. Remove four bolts and washers securing auger motor

to bracket (see figure 15-5).

12. Remove auger motor.

13. Install new auger motor, securing with four bolts and

washers.

14. Insert wires from auger motor through strain relief and

into control box. Connect wires to terminal block (see

pages 26-33), secure ground wire to grounding

terminal then tighten strain relief.

Figure 15-1

(Bottom View)

19

Page 23

Figure

15-5

Replacing Auger Motor (Cont.)

15. Replace rear panel, control box cover and secure

with screws.

16. Install belt and remove the slack by tightening the

tension bolt located at the back of the unit. NOTE:

DO NOT OVER TIGHTEN.

17. Secure the auger motor bracket to the frame.

18. Install bottom cover and secure with screws.

19. Install discharge chute by placing bottom front

portion in first and then tilting back and downward.

20. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

20

Page 24

Replacing Motor Bracket

Figure

16-1

Figure

16-2

Figure

16-3

Figure

16-4

DANGER

Electrical Shock

Failure to turn off the water and electrical

supply before servicing may result in

product damage or injury.

1. Turn off pow er to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Holding both handles, remove discharge by tilting

upward (see figure 16-1)

3. Remove screws holding the bottom cover in place (see

figure 16-1).

4. Rem ove the bolts securing the auger motor bracket in

place (see figure 16-2).

5. Loosen the tension bolt located at the back of the unit,

until there is enough slack to remove the belt (see

figure 16-2).

6. Remove the belt (see figure 16-2).

7. Remove rear panel by removing the screws securing it

in place (see figure 16-3).

8. Remove four bolts and washers securing auger motor

to bracket (see figure 16-4).

9. Remove auger motor.

10. Install auger motor to the new motor bracket, securing

with four bolts and washers.

11. Position motor bracket over holes in cabinet.

12. Replace rear panel and secure with screws.

13. Install belt and remove the slack by tightening the

tension bolt located at the back of the unit. NOTE:

DO NOT OVER TIGHTEN.

14. Secure the auger motor bracket to the frame.

15. Install bottom cover and secure with screws.

16. Install discharge chute by placing bottom front portion

in first and then tilting back and downward.

17. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

(Bottom View)

21

Page 25

Replacing Solenoid Valve

Figure

17-1

Figure

17-3 Figure

17-4

Failure to turn off the water and electrical

supply before servicing may result in

product damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Holding both handles, remove discharge chute by

tilting it upward (see figure 17-1).

3. Remove rear panel by removing the screws securing

it in place (see figure 17-2).

4. Remove cover to control box by loosening the

screws securing it in place (see figure 17-3).

5. Loosen strain relief on cord going from solenoid

valve to control panel.

6. Remove wires from terminal block and ground

terminal (see pages 26-33).

7. Loosen compression fittings on solenoid valve.

8. Remove clip securing solenoid valve to body (see

figure 17-4).

9. Align new solenoid valve with water flow arrow

pointing in correct direction, and secure solenoid

valve with clip.

10. Tighten compression fittings on solenoid valve.

11. Insert wires (from solenoid valve) through strain

relief and into control box. Connect wires to terminal

block, secure ground to wire to grounding terminal

(see pages 26-33) then tighten strain relief.

12. Replace rear panel, control box cover and secure

with screws.

13. Install discharge chute by placing bottom front

portion in first and then tilting back and downward.

14. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

DANGER

Electrical Shock

Figure 17-2

22

Page 26

Replacing Plumbing

Figure

18-2

Figure

18-3

WARNING

Personal Injury

Failure to turn off the water and electrical

supply before servicing may result in

product damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Holding both handles, remove discharge chute by

tilting it upward (see figure 18-1).

3. Remove auger-bearing bracket by turning the two

captive fasteners counter clockwise and then pull

bracket upward (see figure 18-2), replace if necessary.

4. Lift auger and screen up and then out.

5. Loosen appropriate compression fittings and remove

plumbing (see figure 18-3).

6. Install new plumbing and secure by tightening

compression fittings.

Figure 18-1

7. Install auger and screen over drive.

8. Ensure that the auger drops into position

9. Secure bearing bracket with captive fastener.

10. Install discharge chute by placing bottom front portion

in first and then tilting back and downward.

11. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

23

Page 27

Replacing Leveling Foot

WARNING

Personal Injury

Failure to turn off the water and electrical

supply before servicing may result in

product damage or injury.

1. Turn off power to Mini Waste X-Press at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Disconnect the plumbing to the unit.

3. Prop the Mini Waste Xpress up and remove the

damaged leveling foot by unscrewing it (see figure 19-

1).

4. If the threaded insert is ok skip to step 8.

5. If the threaded insert is damaged skip to step 6.

6. Using a screwdriver and hammer remove the threaded

insert by taping the edge of it (see figure 19-1).

7. Insert the new threaded insert

NOTE: A rawhide mallet may be required to position it

correctly.

8. Install the new leveling foot by threading it into the

insert.

9. Remove block used to prop the unit up and then level

the unit off by adjusting the leveling foot.

10. Reconnect the plumbing to the unit.

11. Turn on power to Mini Waste Xpress at fuse box or

circuit breaker. Turn on water supply to Mini Waste

Xpress.

Figure 19-1

24

Page 28

Replacing Control Panel Components

Figure

20-1

Figure

20-2

Figure

20-3

Figure

20-4

DANGER

Electrical Shock

Failure to turn off the water and electrical

supply before servicing may result in

product damage or injury.

1. Turn off power to Mini Waste Xpress at fuse box or

circuit breaker. Turn off water supply to Mini Waste

Xpress.

2. Holding both handles, remove discharge chute by

tilting it upward (see figure 20-1).

3. Remove rear panel by removing the screws securing it

in place (see figure 20-2).

4. Remove cover to control box by loosening the screws

securing it in place (see figure 20-3).

5. Remove the wires to the failed component (timer,

overload or contactor) then remove the component

from the din rail (see figure 20-4).

6. Install new component (timer or contactor) by

snapping it onto the din rail.

7. Wire component as for the specific voltage and phase

as shown on pages 26 through 33.

8. Replace rear panel, control box cover and secure with

screws.

9. Install discharge chute by placing bottom front portion

in first and then tilting back and downward.

10. Turn on power to Mini Waste Xpress at

fuse box or circuit breaker. Turn on water supply to

Mini Waste Xpress.

25

Page 29

ELECTRICAL SHOCK

Use a voltmeter or circuit tester to ensure power is off.

•

Installation must conform to all local electrical codes.

All control centers a

nd disposers must be carefully and permanently

for the control center.

PROPERTY DAMAGE

Turn off all electrical supply to the disposer before attempting any work on it.

•

DANGER

CAUTION

• Ensure that the control center voltage and phase match the

disposer motor and electrical supply. Check nameplates on

A properly fused disconnect must be installed at the electrical supply source

•

• The disposer motor wiring connection is shown in the

disposer terminal box.

26

Page 30

Use a voltmeter or circuit tester to ensure power is off.

Installation must conform to all local electrical codes.

•

All control centers a

nd disposers must be carefully and permanently

for the control center.

PROPERTY DAMAGE

DANGER

ELECTRICAL SHOCK

Turn off all electrical supply to the disposer before attempting any work on it.

•

A properly fused disconnect must be installed at the electrical supply source

•

CAUTION

• Ensure that the control center voltage and phase match the

disposer motor and electrical supply. Check nameplates on

• The disposer motor wiring connection is shown in the

disposer terminal box.

27

Page 31

ELECTRICAL SHOCK

Use a voltmeter or circuit tester to ensure power is off.

• Installation must conform to all local electrical codes.

• All control centers a

nd disposers must be carefully and permanently

PROPERTY DAMAGE

• Turn off all electrical supply to the disposer before attempting any work on it.

• A properly fused disconnect must be installed at the electrical supply source

for the control center.

DANGER

CAUTION

• Ensure that the control center voltage and phase match the

disposer motor and electrical supply. Check nameplates on

• The disposer motor wiring connection is shown in the

disposer terminal box.

28

Page 32

•

Installation must conform to all local electrical codes.

•

for the control center.

PROPERTY DAMAGE

DANGER

ELECTRICAL SHOCK

Turn off all electrical supply to the disposer before attempting any work on it.

•

Use a voltmeter or circuit tester to ensure power is off.

All control centers and disposers must be carefully and permanently

A properly fused disconnect must be installed at the electrical supply source

•

CAUTION

• Ensure that the control center voltage and phase match the

disposer motor and electrical supply. Check nameplates on

• The disposer motor wiring connection is shown in the

disposer terminal box.

29

Page 33

ELECTRICAL SHOCK

•

All control centers a

nd disposers must be carefully and permanently

PROPERTY DAMAGE

Turn off all electrical supply to the disposer before attempting any work on it.

•

Use a voltmeter or circuit tester to ensure power is off.

Installation must conform to all local electrical codes.

DANGER

CAUTION

• Ensure that the control center voltage and phase match the

disposer motor and electrical supply. Check nameplates on

A properly fused disconnect must be installed at the electrical supply source

•

for the control center.

• The disposer motor wiring connection is shown in the

disposer terminal box.

30

Page 34

ELECTRICAL SHOCK

PROPERTY DAMAGE

supply source for the control center.

DANGER

CAUTION

• Turn off all electrical supply to the disposer before attempting

any work on it. Use a voltmeter or circuit tester to ensure

• Installation must conform to all local electrical codes.

• All control centers and disposers must be carefully and

• A properly fused disconnect must be installed at the electrical

• Ensure that the control center voltage and phase match the disposer

motor and electrical supply. Check nameplates on disposers and

control centers for voltage and phase specification.

• The disposer motor wiring connection is shown in the disposer

terminal box.

31

Page 35

ELECTRICAL SHOCK

• All control centers and disposers must be carefully

and permanently

• Turn off all electrical supply to the disposer before attempting any work on it.

Use a voltmeter or circuit tester to ensure power is off.

• Installation must conform to all local electrical codes.

• A properly fused disconnect must be installed at the electrical supply source

for the control center.

DANGER

PROPERTY DAMAGE

• Ensure that the control center voltage and phase match the

disposer motor and electrical supply. Check nameplates on

disposers and control centers for voltage and phase specification.

• The disposer motor wiring connection is shown in the disposer

terminal box.

CAUTION

32

Page 36

ELECTRICAL SHOCK

•

Turn off all electrical supply to the disposer before attempting any work on it.

•

Use a voltmeter or circuit tester to ensure power is off.

Installation must conform to all local electrical codes.

All control centers and disposers must be carefully and permanently

•

A properly fused disconnect must be installed at the electrical supply source

•

for the control center.

DANGER

CAUTION

PROPERTY DAMAGE

Ensure that the control center voltage and phase match the

•

disposer motor and electrical supply. Check nameplates on

disposers and control centers for voltage and phase specification.

The disposer motor wiring connection is shown in the disposer

•

terminal box.

33

Page 37

Internal Motor Connections

Figure 21-1 Figure 21-2

34

Page 38

Troubleshooting for problems other

than what is listed below should be

performed by a qualified service

person. Troubleshooting performed by

untrained personnel could result in

electrical shock or damage to the Mini

Waste Xpress, disposer and/or Control

Center

PROBLEM POSSIBLE CAUSE SOLUTION

Troubleshooting

Disconnect power before servicing. Do

not bypass interlock switch.

DANGER

Electrical Shock

WARNING

Personal Injury

Wait until auger paddles stop before

servicing Mini Waste Xpress.

The Mini Waste Xpress, disposer and water

do not turn on.

The disposer will not start or stops while

grinding, but the Waste Xpress and water

operate properly.

Electrical supply is turned off. Turn on electrical supply.

Fuse is blown or circuit breaker is tripped at

power supply.

Discharge chute of Mini Waste Xpress is not

seated properly.

Waste is blocking safety interlock. Remove waste from safety interlock.

Control circuit fuse (FNA2) is blown. Replace fuse.

24 volt power from control center not present. Troubleshoot control center (see individual

The disposer overload protector is tripped. Press stop button on control center and press the

The disposer is jammed. Press stop button on control center and follow

Replace fuse or reset circuit breaker.

Reinstall chute to ensure proper fit.

troubleshooting guide).

red reset button on the disposer. Note you may need

to let disposer cool down before setting.

direction for un-jamming (supplied with the

disposer).

The Waste Xpress, disposer and water

appear to run however no solid waste is

ejected from the discharge chute of the

Waste Xpress.

Water backs up into disposer (does not

drain).

cleaning.

Insufficient waste in waste line.

Auger turning in wrong direction On single phase unit interchange leads to start

The auger and screen are plugged. Remove plug.

Auger is not turning.

Plumbing line between disposer and Mini Waste

Xpress is clogged.

Allow unit to run longer to prime its self. Auger is not sufficiently primed with waste after

Waste will exit when more waste is added.

winding (see figure 22-1). On three phase unit

interchange leads L1 and L2.

Ensure that auger is seated properly and that the

auger belt is in place.

Check motor.

Remove clog.

35

Page 39

Troubleshooting for problems other

than what is listed below should be

performed by a qualified service

person. Troubleshooting performed

by untrained personnel could result

in electrical shock or damage to the

Mini Waste Xpress, disposer and/or

Control Center

PROBLEM POSSIBLE CAUSE SOLUTION

Waste Xpress stops unexpectedly.

Troubleshooting continued

Disconnect power before

Discharge chute misalign. Reinstall discharge chute to ensure proper fit.

DANGER

Electrical Shock

WARNING

Personal Injury

Wait until auger paddles stop before

servicing Mini Waste Xpress.

Fuse is blown or circuit breaker is tripped at

power source.

Stop button on control center has been pushed. Push start button on control center.

Water exit Waste Xpress at front of cabinet. Drain line has clog. Clear drain.

Mini Waste Xpress does not run, but the

disposer and water does.

No water spraying onto auger screen.

Contactor is defective. Replace contactor (see replacing control panel

Auger motor is defective. Replace contactor (see replacing control panel

Solenoid valve is clogged. Remove clog.

Water is turned off. Turn on water.

Solenoid valve is defective. Replace solenoid valve (see replacing solenoid

Spray nozzles are clogged. See replacing spray nozzles.

Timer is defective. Replace timer (see replacing control panel

Timer is not set properly. Adjust setting for timer (setting should be 10 sec on 2

Replace fuse or reset circuit breaker.

component).

component).

valve).

component).

min off).

Solenoid valve is installed incorrectly. Reinstall solenoid valve so arrow is pointing in

correct direction.

Water flows continuously before the

controls are turned on.

Overload protector trips frequently. Disposer is overloaded with food waste. Do not overload disposer with excessive amounts of

Solenoid valve installed incorrectly. Reinstall the water solenoid valve with the arrow on

the valve pointing in the direction of the water flow.

Timer is not set properly. Adjust setting for timer (setting should be 10 sec on 2

min off)

Solenoid valve is defective. Replace solenoid valve (see replacing solenoid

valve)

food waste.

If the Waste Xpress remains inoperative after following this troubleshooting guide, contact In-Sink-Erator's

service department at 1-800-558-5700. 36

Loading...

Loading...