Page 1

Installation, Care, and Use Manual

Standard (Model PRS) Pot/Pan (Model PRP)

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to physical injury.

Please be certain that the person who installs or uses this appliance carefully reads

and understands the Safety Instructions contained in this manual.

Part No. 15392 Rev Bwww.insinkerator.com/foodservice

Page 2

Table of Contents

Product Overview

Introduction ......................................................................................3

System Components ........................................................................ 4

Typical Installation ............................................................................4

Required Tools/Materials ..................................................................4

Table Cutout Dimensions .................................................................5

Installation Instructions

Assembly.........................................................................................6

Plumbing

Water Connections ................................................................7

Adjusting Water Temperature ................................................8

Drain Piping ...........................................................................8

Electrical

Electrical Disconnect Switch .................................................8

Electrical Connections ...........................................................9

Initial Setup and Verification

Prepare the System ...............................................................9

Operating Instructions

Main Operation .............................................................................10

Timed Run Feature .............................................................. 12

To Empty Scrap Basket ............................................................... 13

To Clean Unit ................................................................................13

Troubleshooting .......................................................................................... 14

Wiring Diagrams

Models PRS-1 and PRP-1 (110-120V, 1 Phase) .............................. 16

Models PRS-2 and PRP-2 (208/220-240V, 1 Phase) ..................... 17

Models PRS-3 and PRP-3 (208/220-240V, 3 Phase) ..................... 18

Models PRS-4 and PRP-4 (460-480V, 3 Phase) ............................ 19

SAVE THESE INSTRUCTIONS

2

Page 3

Product Overview

INTRODUCTION

The PowerRinse® Waste Collection System is a food

and food-related waste handling solution that improves

kitchen efciency by increasing scrapping speed and

reducing bulk waste.

A plume of recirculated water aids in the pre-rinse and

scrapping of dishes. Solid waste is collected in a scrap

basket, which can then be emptied into a waste or

compost receptacle, while water soluble waste is sent

down the drain. A at cover ts over the scrap basket,

providing a smooth, level surface that maximizes the

workspace for scrapping and pre-soaking problem

dishes with baked-on or difcult to remove food. The

PowerRinse® Waste Collection System is an alternative to

using a food waste disposer or pulper system.

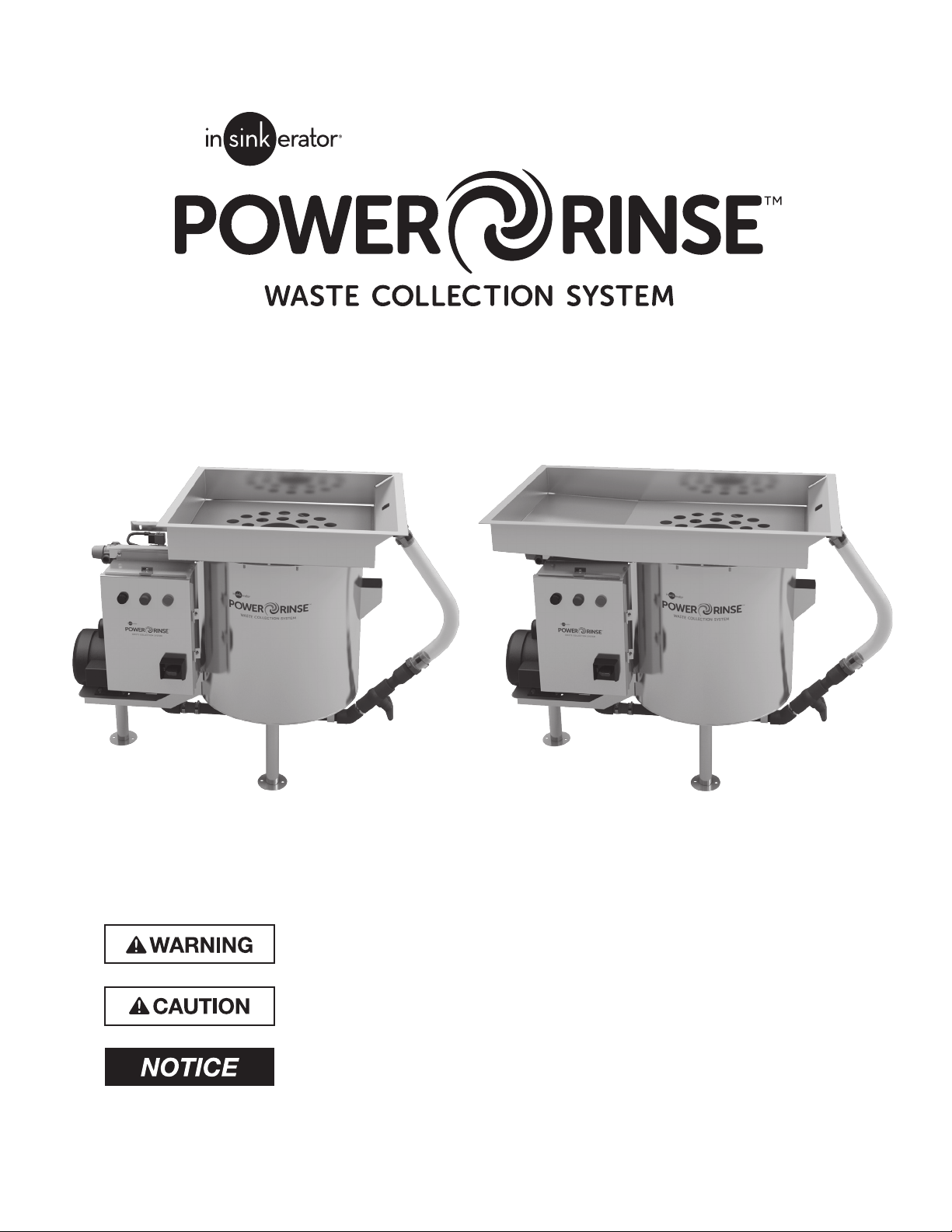

This Installation, Care, and Use Manual covers two (2)

models: Standard (Model PRS) and Pot/Pan (Model PRP)

(see Figures 1 and 2). The Standard Tray is sized for

everyday applications (23.75" x 21.5") and increased

length of the Pot/Pan Tray (35.5" x 21.5") provides

dishwashers additional workspace for oversized

cookware, such as large sheet pans.

The PowerRinse Waste Collection System is CUL® US

Listed when installed in conjunction with InSinkErator

pumps and controls, and per the installation instructions

in this Installation, Care, and Use Manual (see Figure 4 for

typical installation).

This Installation, Care, and Use Manual covers the models

listed in Table 1.

Table 1. Electrical Specifications

PowerRinse® Waste Collection System

Standard (Model PRS)

Model Part No. Voltage Phase

PRS-1 15357 110-120V 1

PRS-2 15357A 208/220-240V 1

PRS-3 15357B 208/220-240V 3

PRS-4 15357C 460-480V 3

PowerRinse® Waste Collection System

Pot/Pan (Model PRP)

Model Part No. Voltage Phase

PRP-1 15357D 110-120V 1

PRP-2 15357E 208/220-240V 1

PRP-3 15357G 208/220-240V 3

PRP-4 15357H 460-480V 3

IMPORTANT NOTE – These installation instructions

are for the benefit of the installing contractor.

InSinkErator and/or InSinkErator Factory Authorized

Service Centers do not make original installations. For

technical information not covered in these instructions,

contact the supplier, an InSinkErator Field Sales

Representative, or InSinkErator Foodservice Sales

and Service at 1-800-845-8345.

Figure 1. Standard (Model PRS) Figure 2. Pot/Pan (Model PRP)

3

Page 4

Product Overview

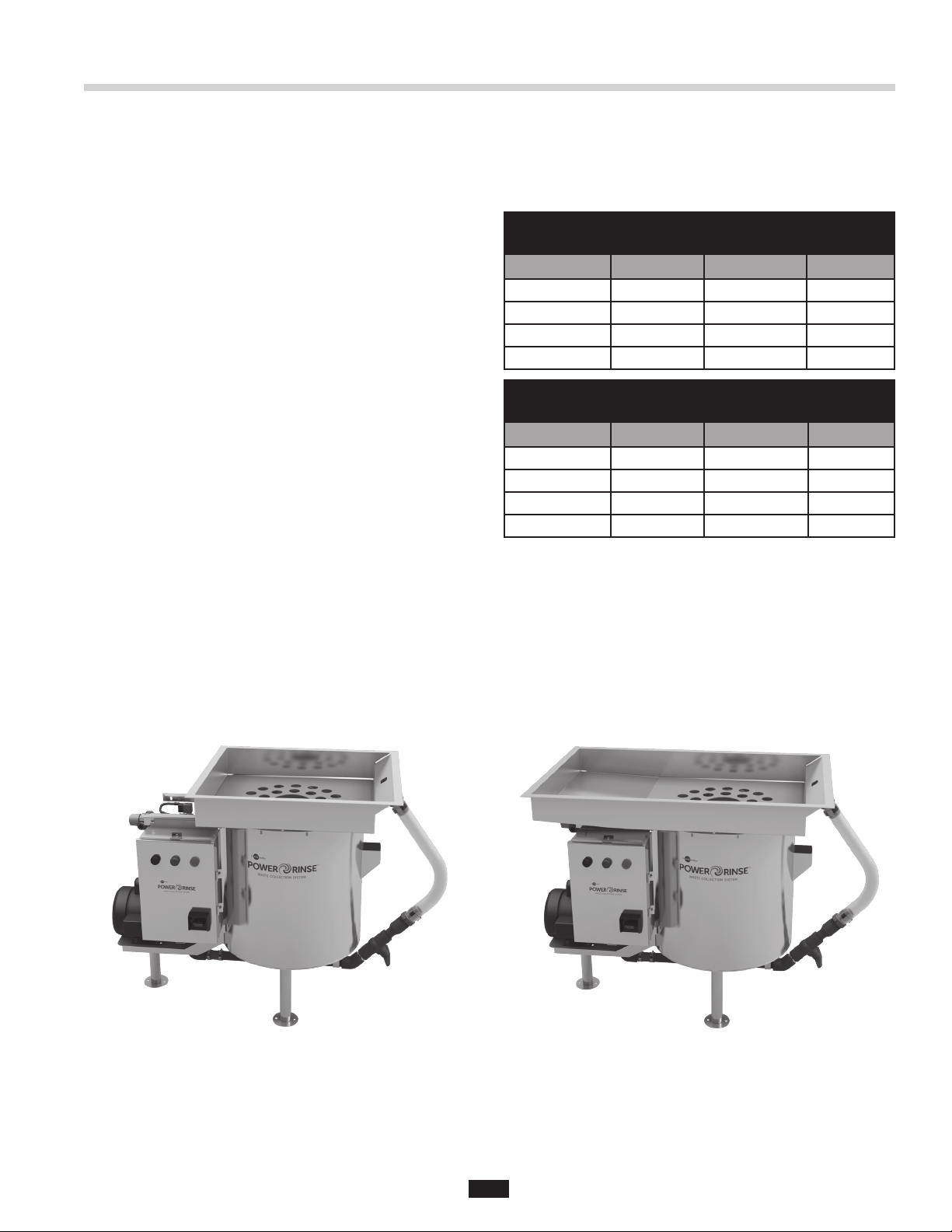

SYSTEM COMPONENTS

The PowerRinse® Waste Collection System includes the

following components (see Figure 3):

a. Tray

• Standard Tray (Only Model PRS)

OR

• Pot/Pan Tray (Only Model PRP)

b. Scrap Basket

c. Cover

d. Plume Hose

e. Waste Collector Base Assembly (see Figure 4)

f. Waste Collector Tank and Mounting Assembly

g. Control (Pre-wired)

h. Solenoid (Pre-wired)

i. Pump (Pre-wired)

j. Air Gap

k. Ball Valve

l. Leveling Flange Feet

m. 2" Drain Discharge

n. 1/2" NPT Water Inlets (Hot and Cold Connections)

o. Installation, Care, and Use Manual

p. Mounting Hardware

• Lock Washers (12)

• 1/4"-20 Nuts (12)

TYPICAL INSTALLATION

Figure 4 illustrates the typical installation of the

PowerRinse® Waste Collection System. For a

complete list of system components refer to the

System Components list located to the left of Figure 4.

See Figure 5 on next page for system dimensions.

Dishwasher

24" min.

(609.6 mm)

Incoming Hot

and Cold Water

Supply Lines

n

g

Min. 1"

i

Clearance

Incoming

Power

(1/2" Conduit)

Figure 4. Typical Installation

h

m

Dish Rack Space

j

f

k

l

a

b

Model PRS Model PRP

e

Figure 3. System Components

OR

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to physical injury.

Please be certain that the person who installs or uses this appliance carefully reads

and understands the Safety Instructions contained in this manual.

a

The PowerRinse® Waste Collection System pump

motor fan must have a minimum of 1" of clearance

from any wall or obstruction in order to operate

co r rectly.

p

REQUIRED TOOLS / MATERIALS

The following items are needed to install the PowerRinse®

o

Part No. 15392 Rev Awww.insinkerator.com/foodservice

c

d

Waste Collection System:

o Screwdriver

o Pipe wrench

o 7/16" wrench or socket

o Tools and materials necessary to install the power line,

drain line, and the hot and cold water

The following items are needed if repositioning the control:

o 1/2" wrench or socket

4

Page 5

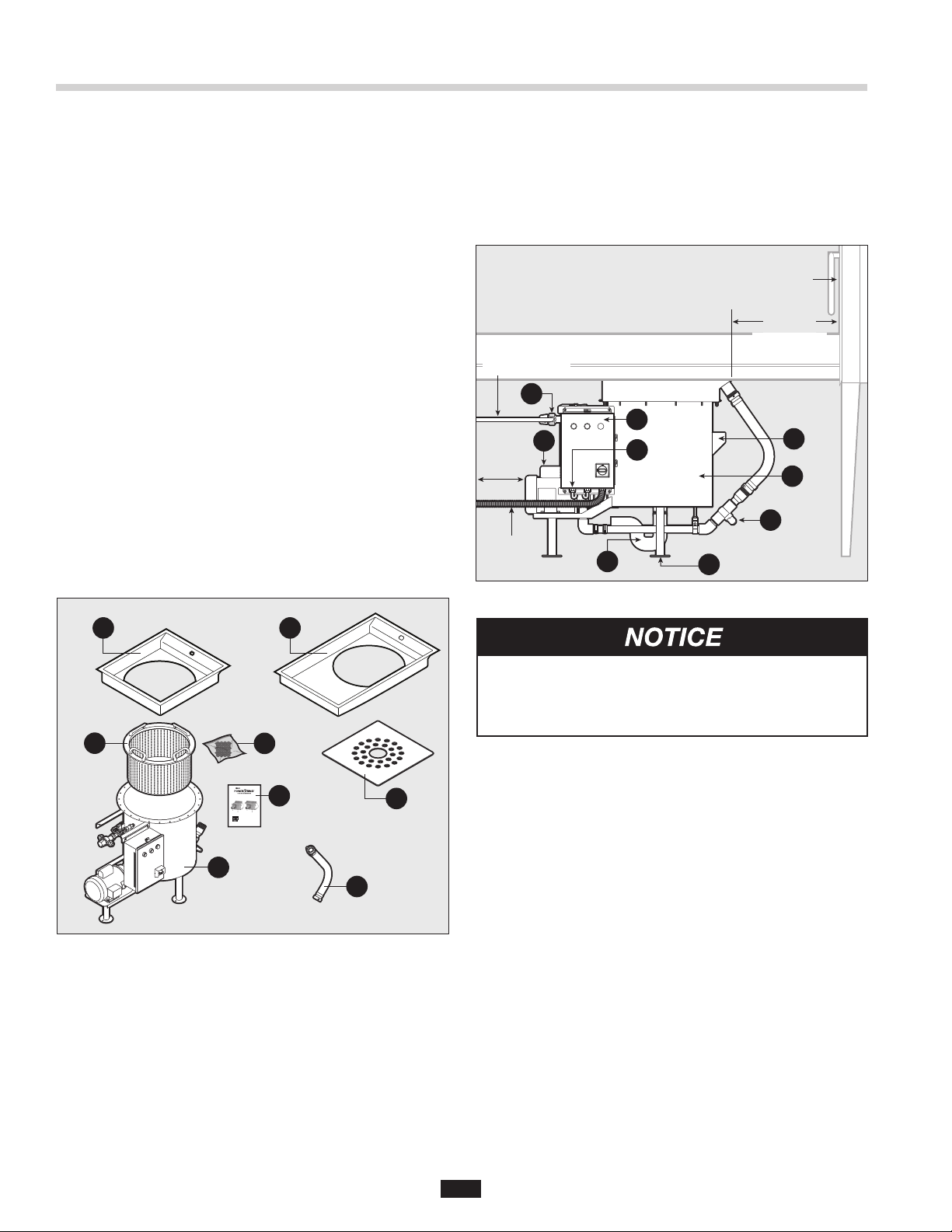

The PowerRinse® Waste Collection

System pump motor fan must have a

minimum of 1" of clearance from any

wall or obstruction in order to operate

co r rectly.

33"-3 6"

(8 38 -914 mm)

28.93"-31.93"

(735-811 mm)

25. 41"-28. 41"

(64 5-722 mm )

Product Overview

7.93"-10.93"

(201-278 mm)

35.5" (902 mm)

Pot/Pa n (Model PR P)

23.75" (603 mm)

Standard (Model PRS)

10.75"

(273 mm)

21.5"

(546 mm)

Figure 5. PowerRinse® Waste Collection System Dimensions

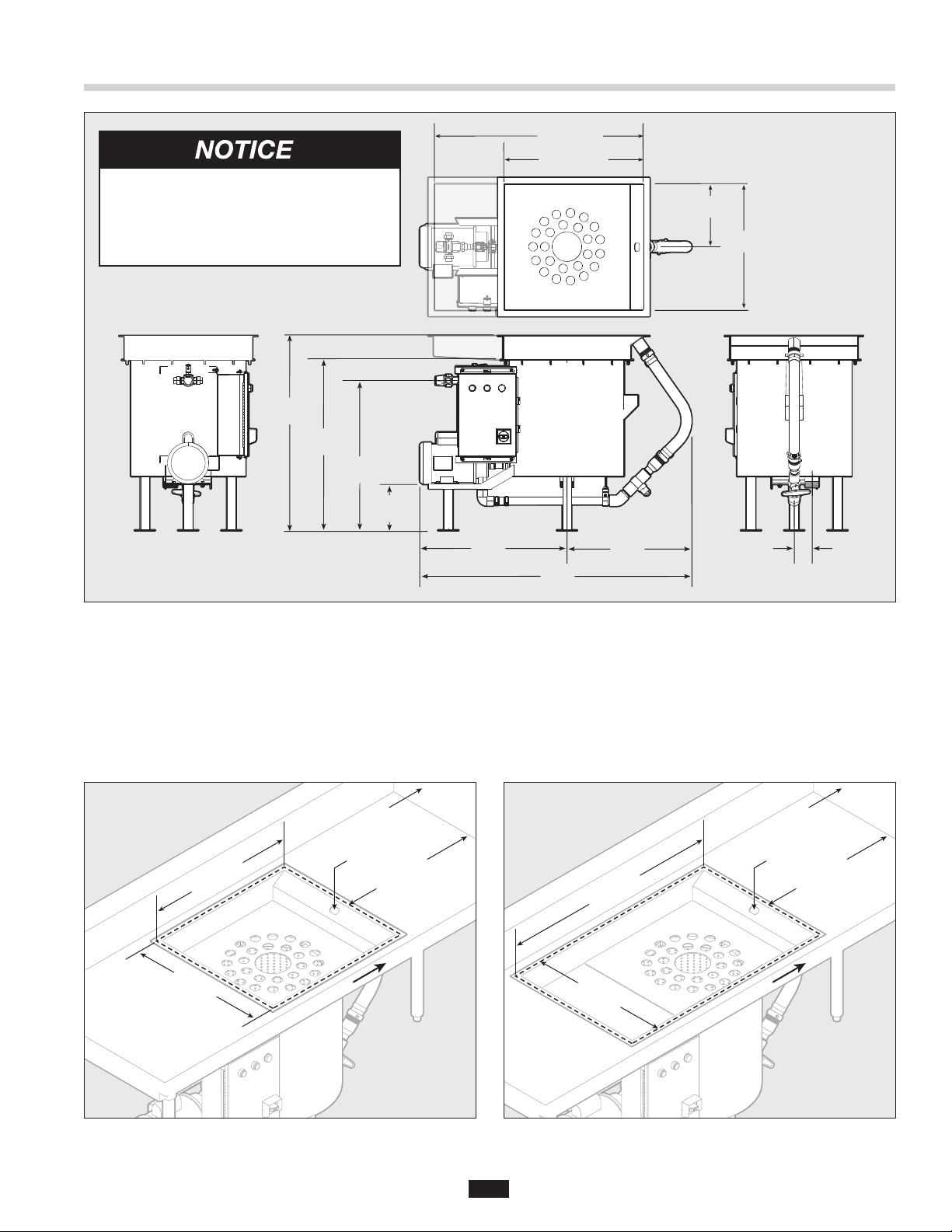

TABLE CUTOUT DIMENSIONS

Use the dimensions from Figure 6 for Standard

(Model PRS) table cutout and Figure 7 for Pot/Pan

(Model PRP) table cutout. Weld the waste collector tray

to the underside of the table so the water nozzle is on

the same side as the dishwasher.

Dishwasher

Water

Dish Flow

Nozzle

24" min.

(609.6 mm)

Dish Rack Space

22-1/4"

(565.2 mm)

24-3/4"

(628.7 mm)

24.9 5"

(634 mm)

44. 95"

(114 2 mm )

20"

(508 mm)

3"

(76 mm)

If using in line with a dishwasher, it is recommended to

mount the waste collector tray a minimum of 24" away

from the loading end of the dishwasher to allow enough

table space for a dish rack.

Dishwasher

Water

Nozzle

36-1/2"

(927.8 mm)

22-1/4"

(565.2 mm)

Dish Flow

24" min.

(609.6 mm)

Dish Rack Space

Figure 6. Standard Table Cutout (Model PRS)

Figure 7. Pot/Pan Table Cutout (Model PRP)

5

Page 6

ASSEMBLY

Installation Instructions

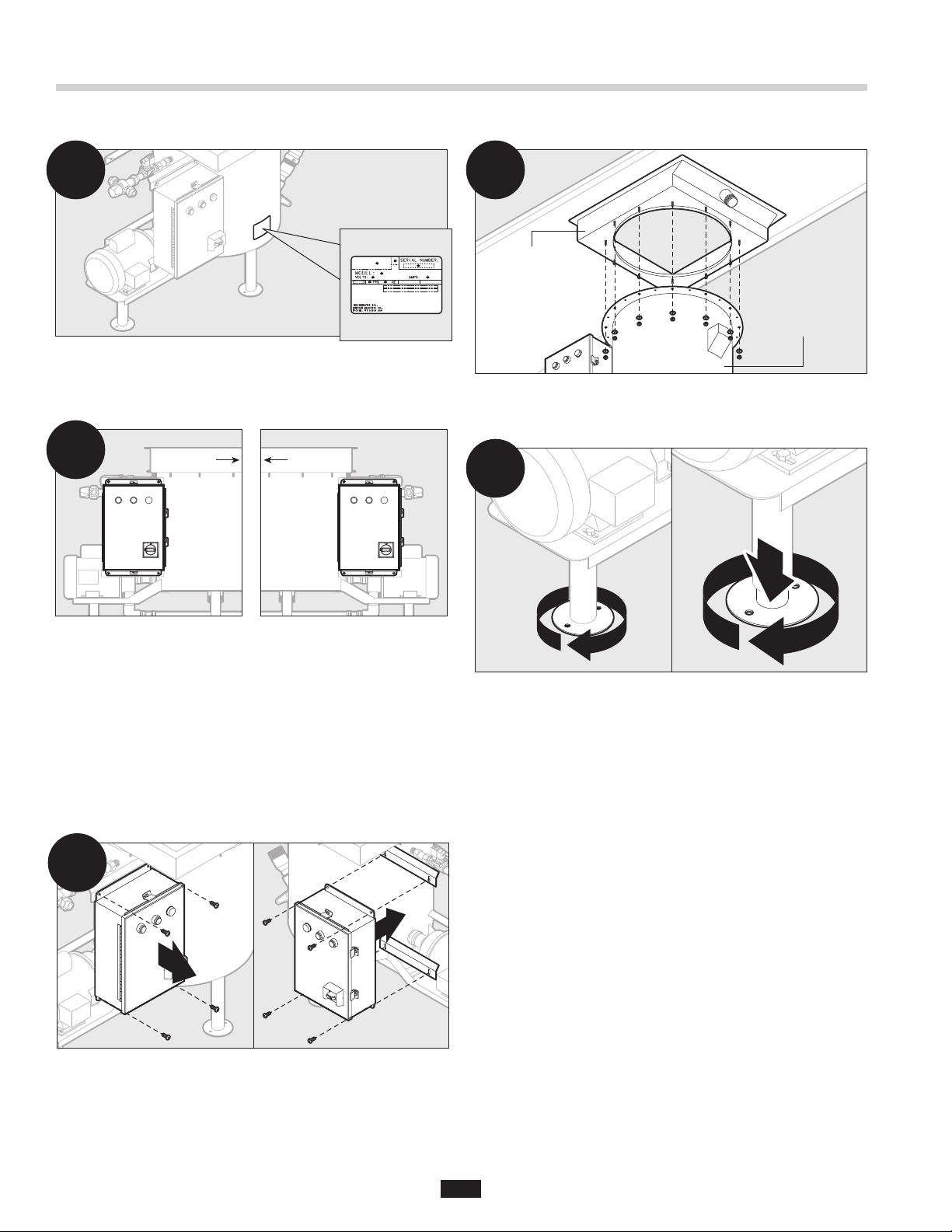

1

Remove unit from package. Ensure that the power

supply is appropriate based on the control conguration

ordered with the unit. Verify using spec plate on tank.

2

Dish FlowDish Flow

3

Waste

Collector

Tra y

Waste Collector

Base Assembly

Secure waste collector base assembly to waste collector

tray using provided lock washers and 1/4"-20 nuts.

4

Verify dish ow and ensure that the control is on the

proper side of the tank. The control should always face

the operator and can be mounted on the opposite side

of the tank if dish ow is reversed.

NOTE: The waste collector base assembly is shipped

with the control factory-installed on the left side of the

tank for left-to-right dish flow.

CHANGING THE CONTROL LOCATION

2a

Optional – to relocate the control, remove and save four

(4) bolts and nuts. Reposition box on other side of tank

and secure with previously removed hardware. It is not

necessary to disconnect factory-installed wiring.

Rotate legs clockwise when viewing from top until they

extend to the oor.

Optional – use the provided holes on the anged foot

to secure unit to oor with anchors (not provided by

InSinkErator).

After relocating control, verify conduit and solenoid

connections are tight.

6

Page 7

Installation Instructions

ASSEMBLY (cont.)

5

Plume

Hose

Waste

Collector

Tan k

Connect plume hose to collector tank. Turn brass

coupling clockwise to secure.

IMPORTANT NOTES:

• DO NOT cross thread brass fitting onto plastic

plumbing.

• For ease of installation, connect plume hose first to

waste collector tank then to waste collector tray.

PLUMBING

PROPERTY DAMAGE

• Installation must comply with all local plumbing

codes.

• If water pressure exceeds the recommended

80 psi, pressure regulators should be used.

WATER CONNECTIONS

Plumb a hot and a cold water supply line to mixer valve

(see Figure 8). Connections are 1/2" NPT.

IMPORTANT NOTES:

• Mixing valve can be relocated.

• Hot and cold water lines must match the markings on

mixer valve. If lines are reversed, mixer valve will not

operate properly after adjustment.

• It is recommended that ball type shutoff valves be

installed in line with the cold and hot water lines.

• A minimum of 30 psi at the mixer valve is needed for

the waste collector to operate correctly.

6

Waste

Collector

Tra y

Plume

Hose

Connect plume hose to waste collector tray.

Cold Water

Supply Line

Mixer

Valve

Figure 8. Water Connections

Hot

Water

Supply

Line

IMPORTANT NOTE: This air gap meets ASME

A112.1.2-2012 standard and eliminates the need for a

vacuum breaker installed with the system (see Figure 9).

Air Gap

Figure 9. Air Gap

7

Page 8

Installation Instructions

PLUMBING (cont.)

ADJUSTING WATER TEMPERATURE

NOTE: It may be necessary to adjust the mixing valve to

set the appropriate water temperature.

To adjust water temperature (see Figure 10):

1. Unscrew button head screw on the valve cap until cap

can be pulled out.

2. Pull cap out.

3. Turn cap to adjust water temperature.

4. When desired temperature is reached, push cap in

and tighten button head screw to secure cap.

2

Cap

1

Figure 10. Adjusting Water Temperature

Button

Head

Screw

3

3

Cap

ELECTRICAL

ELECTRICAL SHOCK

• Turn off all electrical supply to the collector before

attempting any work on it. Use a voltmeter or

circuit tester to ensure that power is off.

• Installation must conform to local electrical codes.

• All control centers and collector components must

be carefully and permanently grounded.

• A properly fused disconnect must be installed at

the electrical supply source for the control center.

ELECTRICAL DISCONNECT SWITCH

The switch on the front panel of the control disconnects

the line voltage (see Figure 12). It interlocks with the

front cover so that the panel cannot be opened unless

the switch is in the OFF position.

ON

Position

OFF

Position

Electrical

Disconnect

Switch

DRAIN PIPING

Plumb a 2" drainline through a “P-trap” from the 2" male

threaded nipple on the bottom of the waste collector

tank (see Figure 11).

2" Drain

Connection

Waste

Collector

Tan k

Figure 11. Drain Piping

Ensure all connections are tight and leak free,

including rubber boots and plumbing connections

supplied by the manufacturer, before moving forward

and engaging the system.

Figure 12. Electrical Disconnect Switch

NOTE: Use of the electrical disconnect switch results

in a 30 second delay before system can be restarted.

You must wait 30 seconds after reactivation of the line

disconnect switch before system will start.

PROPERTY DAMAGE

• Ensure that the control center voltage and phase

match the pump and electrical supply. Reference

the nameplates for voltage and phase.

• The pump motor wiring diagram is shown on the

casing of the pump.

PERSONAL INJURY

Disconnect electricity at line disconnect switch

before servicing system.

8

Page 9

Installation Instructions

1

2

ELECTRICAL (cont.)

ELECTRICAL CONNECTIONS

NOTE: Ensure that the power supply is appropriate

based on the control configuration ordered with the unit.

One electrical connection is required. To connect the

waste collection system to the electricity:

1

2

Remove top cover retainers by loosening screws and

open the front panel.

NOTE: Electrical disconnect switch must be in OFF

position to open control panel (see Figure 12).

Control

2

INITIAL SETUP AND VERIFICATION

PREPARE THE SYSTEM

1

ON

Position

Electrical

Disconnect

Switch

Turn electrical disconnect switch to the ON position.

Open shutoff valves in water lines, if installed.

2

Start Indicator Light

Solenoid

(Pre-wired)

Incoming

Power

(1/2" Conduit)

1/2" Knockout

Run power from main power supply to the 1/2" knockout

on bottom of control and connect as shown.

NOTE: Be sure to use liquid tight conduit and conduit

fittings.

Pump

(Pre-wired)

3

1

Press the START button. Indicator light turns on.

NOTE: If the unit does not turn on, see Troubleshooting.

3

Verify that the pump is functioning correctly.

IMPORTANT NOTE: Wait time until pump

engages is approximately 70 seconds after

starting unit.

Close front panel and tighten screws on top cover

retainers to secure.

9

Page 10

Installation Instructions Operating Instructions

INITIAL SETUP AND VERIFICATION (cont.)

3a

For 3 Phase units only – Ensure pump motor fan is

rotating clockwise (when viewed from the motor end).

If rotation is counter-clockwise, turn off power supply,

open front panel, and switch L1 and L2 connections.

1 ON

0 OFF

L1 L2 L3*

Incoming Power

Supply

*NOTE: Single Phase models

do not have L3 wire.

Panel

Ground

Plug

4

MAIN OPERATION

1

Closed

Plume

Hose

Ball Valve

Slightly

Open

Before operating, slightly open ball valve.

2

Overflow

Tub e

Indicator Light

Stop

Turn off unit by pressing the STOP button. Indicator

light turns off.

NOTE: If the unit does not turn off, see Troubleshooting.

Waste

Collector

Tan k

Place the overow tube into the drain at the bottom of

waste collector tank.

10

Page 11

MAIN OPERATION (cont.)

Operating Instructions

3

Place scrap basket inside waste collector tank. Unit

must always have the scrap basket in place during

operation.

Scrap

Basket

Waste

Collector

Tan k

4

Waste

Collector

Cover

Tra y

6

Ball

Valve

Adjust ball valve until water plume hits desired location

inside tray area (recommended location is the center of

scrap basket and/or cover).

Scrap soiled dishes using the water plume

to help move solid waste from the surface.

Pre-soak problem dishes with baked-on or difcult to

remove food by setting them on the cover under the

plume. Solid waste is collected in the scrap basket.

Water

Plume

Place cover on waste collector tray. Use of cover is

optional but recommended to maximize workspace.

NOTE: When using the Pot/Pan tray (Model PRP), the

cover fits in the square, flat area at the bottom of the tray.

5

Start Indicator Light

To begin, press START button on control and allow the

reservoir tank to ll with water. Indicator light turns on.

Pump turns on and water plume starts once tank has

reached optimal ll level (approximately 70 seconds

after pushing the START button).

DO NOT use corrosive chemicals for scrapping.

8

Indicator Light

Stop

Press STOP on the control panel. Indicator light turns off.

11

Page 12

Operating Instructions

1

1

MAIN OPERATION (cont.)

TIMED RUN FEATURE

The PowerRinse® Waste Collection System has a builtin shut off timer in the control. The timer is preset for 20

minutes from factory. After the set time elapses, the unit

will shut off.

To adjust timer:

1

Timer

Switch

To turn timed run ON or OFF:

1

2

Timer ON and

OFF Switch

Open the control panel. Locate the Timer ON and OFF

switch.

2

Timer ON

Position

Timer OFF

Position

2

Open the control panel. Locate the Timer Switch.

2

Timer

Switch

Time

Range

Switch

Main Dial

Rotate time range switch or main dial to desired

settings (as shown). The time range switch sets the

increments (0.1s, 1s, 10s, etc.) and the main dial is the

“multiplier.” The factory default is 10m on time range

switch and 2 on the main dial, or 20 minutes.

Move switch to desired position.

12

Page 13

Operating Instructions

TO EMPTY SCRAP BASKET

1

Indicator Light

Stop

Ensure unit is turned off by pressing the STOP button

on the control.

2

Waste

Collector

Cover

Tra y

TO CLEAN UNIT

It is recommended that unit be cleaned daily at end of

shift, and as needed throughout the day.

1

Overflow

Tub e

Waste

Collector

Tan k

Turn off unit and empty scrap basket (see above

instructions). Pull overow tube to drain water inside

waste collector tank.

2

Rinse cover, scrap basket, tray, and tank

interior. Scrap basket may be run through

dishwasher.

Remove cover.

3

Remove scrap basket and dump waste into appropriate

trash or compost receptacle.

Scrap

Basket

Waste

Collector

Tan k

DO NOT use corrosive chemicals for cleaning.

13

Page 14

Troubleshooting

ELECTRICAL SHOCK

• Turn off all electrical supply to the collector

before attempting to work on it. Use a voltmeter

or circuit tester to ensure that the power is off.

• DO NOT bypass interlock switch.

Troubleshooting for problems other than what is listed below should be performed by a qualied service person.

Troubleshooting performed by untrained personnel could result in electrical shock or damage to the PowerRinse®

waste collection system.

SYSTEM TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Waste Collector does not turn on. • Electrical supply turned off.

• Fuse blown or circuit breaker turned

off at power supply.

• Control circuit fuse blown.

• Line disconnect switch on control not

in the “ON” position.

• Line disconnect switch on control is

defective.

• Start switch on control center is

defective.

• Stop switch on control center is

defective.

• Turn on the electrical supply.

• Replace fuse or reset circuit breaker.

• Replace fuse.

• Turn to “ON” position, wait 30 seconds

before attempting to start again.

• Call for service.

• Call for service.

• Call for service.

Waste Collector will start when

“START” button is pushed, but

shuts down when “START” button

is released.

Waste Collector stops

unexpectedly.

• Insufcient time allowed after line

disconnect switch on control center

is turned to the “ON” position.

• 24V power from control center

(control circuit) is low or not present.

• Fuse blown or circuit breaker tripped

at power source.

• 24V power from control center

(control circuit) is low or not present.

• STOP button on control has been

pushed.

• Line disconnect switch has been

turned to the “OFF” position.

• Allow 30 seconds before attempting system

startup (at “START” switch).

• Call for service.

• Replace fuse or reset circuit breaker.

• Call for service.

• Push “START” button on control center.

• Turn to “ON” position, wait 30 seconds

before attempting to start system.

NOTE: Line disconnect switch is only

intended for use in the event of control

center servicing.

14

Page 15

PROBLEM POSSIBLE CAUSE SOLUTION

Waste Collector turns on, but pump

does not operate correctly.

Troubleshooting

• Contactor defective.

• Pump clogged.

• Pump inlet screen clogged.

• Call for service.

• Call for service.

• Clean unit.

Water ows continuously before

control is turned on.

Drain is clogged. • Scrap basket not in place when using

Water does not ll in tank. • Overow pipe not in drain. • Place overow pipe in drain.

Water system is too hot or cold. • Mixing valve not adjusted properly. • Adjust mixing valve to achieve proper water

Pump leaks water. • Pump has failed. • Replace pump.

Waste Collector not re-circulating

much water – resulting in small

plume.

Unit does not stop. • Control has failed. • Stop unit by turning the electrical

• Solenoid valve is stuck open.

• Solenoid valve is defective.

Waste Collector.

• Water is too cold.

• Ball valve closed. • Adjust ball valve – open more.

• Call for service.

• Replace solenoid valve.

• Call plumber.

NOTE: Scrap basket should be in place at

all times during operation.

• Adjust mixer valve.

temperature.

disconnect switch to the OFF position.

Call for service.

Drain consistently clogs. • Consultation required to

troubleshoot.

• Call plumber.

15

Page 16

Models PRS-1 and PRP-1 (110-120V, 1 Phase) Wiring Diagram

ELECTRICAL SHOCK

• Turn off all electrical supply to the collector before

attempting any work on it. Use a voltmeter or

circuit tester to ensure that power is off.

• Installation must conform to local electrical codes.

• All control centers and collector components must

be carefully and permanently grounded.

• A properly fused disconnect must be installed at

the electrical supply source for the control center.

120 V

110 -120 V

1-phase

1 Phase

1/2 to 2 HP

PROPERTY DAMAGE

• Ensure that the control center voltage and phase

match the pump and electrical supply. Reference

the nameplates for voltage and phase.

• The pump motor wiring diagram is shown on the

casing of the pump.

Note: Black wires = Line voltage (110 - 120 V).

Call Toll Free 1-800-845-8345

for the nearest InSinkErator

Authorized Service Agency or

to reach Technical Support.

16

Page 17

Models PRS-2 and PRP-2 (208/220-240V, 1 Phase) Wiring Diagram

ELECTRICAL SHOCK

• Turn off all electrical supply to the collector before

attempting any work on it. Use a voltmeter or

circuit tester to ensure that power is off.

• Installation must conform to local electrical codes.

• All control centers and collector components must

be carefully and permanently grounded.

• A properly fused disconnect must be installed at

the electrical supply source for the control center.

120 V

208/220-240V

1-phase

1 Phase

1/2 to 2 HP

PROPERTY DAMAGE

• Ensure that the control center voltage and phase

match the pump and electrical supply. Reference

the nameplates for voltage and phase.

• The pump motor wiring diagram is shown on the

casing of the pump.

Note: Black wires = Line voltage (208/220 - 240 V).

Call Toll Free 1-800-845-8345

for the nearest InSinkErator

Authorized Service Agency or

to reach Technical Support.

17

Page 18

Models PRS-3 and PRP-3 (208/220-240V, 3 Phase) Wiring Diagram

ELECTRICAL SHOCK

• Turn off all electrical supply to the collector before

attempting any work on it. Use a voltmeter or

circuit tester to ensure that power is off.

• Installation must conform to local electrical codes.

• All control centers and collector components must

be carefully and permanently grounded.

• A properly fused disconnect must be installed at

the electrical supply source for the control center.

120 V

208/220-240V

1-phase

3 Phase

1/2 to 2 HP

PROPERTY DAMAGE

• Ensure that the control center voltage and phase

match the pump and electrical supply. Reference

the nameplates for voltage and phase.

• The pump motor wiring diagram is shown on the

casing of the pump.

Note: Black wires = Line voltage (208/220 - 240 V).

Call Toll Free 1-800-845-8345

for the nearest InSinkErator

Authorized Service Agency or

to reach Technical Support.

Overload Settings

Model Current Reset

PRS-3/PRP-3 2.0 Automatic

18

Page 19

Models PRS-4 and PRP-4 (460-480V, 3 Phase) Wiring Diagram

ELECTRICAL SHOCK

• Turn off all electrical supply to the collector before

attempting any work on it. Use a voltmeter or

circuit tester to ensure that power is off.

• Installation must conform to local electrical codes.

• All control centers and collector components must

be carefully and permanently grounded.

• A properly fused disconnect must be installed at

the electrical supply source for the control center.

120 V

460-480V

1-phase

3 Phase

1/2 to 2 HP

PROPERTY DAMAGE

• Ensure that the control center voltage and phase

match the pump and electrical supply. Reference

the nameplates for voltage and phase.

• The pump motor wiring diagram is shown on the

casing of the pump.

Note: • Black wires = Line voltage (460 - 480 V).

Call Toll Free 1-800-845-8345

for the nearest InSinkErator

Authorized Service Agency or

to reach Technical Support.

Overload Settings

Model Current Reset

PRS-4/PRP-4 1.0 Automatic

19

Page 20

Limited Warranty

InSinkErator®, a division of Emerson Electric Co., (“InSinkErator”

or “Manufacturer” or “we” or “our” or “us”) warrants to the original

purchaser only (“Customer” or “you” or “your”), subject to the

exclusions below, that your InSinkErator® PowerRinse® Waste

Collection System (the “InSinkErator Product”) will be free from

defects in material and workmanship for one year from the original

date of purchase (the “Warranty Period”). This limited warranty

terminates if the original purchaser transfers the InSinkErator Product

to any other person or entity.

If a covered claim is made during the Warranty Period, Manufacturer

will, through its authorized service representative, and at

Manufacturer’s or its authorized service representative’s sole

discretion, either repair or replace your InSinkErator Product. If your

InSinkErator Product is replaced, the warranty on the replacement

InSinkErator Product will be limited to the unexpired term remaining

in the original Warranty Period. YOUR SOLE AND EXCLUSIVE

REMEDY UNDER THIS LIMITED WARRANTY SHALL BE LIMITED

TO REPAIR OR REPLACEMENT OF THE INSINKERATOR

PRODU CT.

What is Covered

This limited warranty includes repair or replacement of your

InSinkErator Product, accessories if included in the original

InSinkErator Product package, and all replacement parts and

labor costs if provided by an authorized InSinkErator service

representative.

What is not Covered

This limited warranty does not extend to and expressly excludes:

• Losses or damages or the inability to operate your InSinkErator

Product resulting from conditions beyond the Manufacturer’s

control including, without limitation, accident, alteration, misuse,

abuse, neglect, or negligence (other than Manufacturer’s).

• Wear and tear expected to occur during the normal course of use,

including without limitation, cosmetic rust, scratches, dents or

comparable and reasonably expected losses or damages.

• Failure to install, maintain, assemble, or mount the InSinkErator

Product in accordance with Manufacturer’s instructions or local

electrical and plumbing codes, faulty or improper electrical

installation, faulty or improper plumbing installation, clogged drain

lines, or an improperly sized unit (as specied by InSinkErator).

What we will do to Correct Problems

To le a warranty claim during the Warranty Period, you may call Toll

Free 1-800-845-8345 for the nearest InSinkErator Authorized Service

Agency or to reach Technical Support, or you may visit our website at

www.insinkerator.com.

The following information must be provided as part of your warranty

claim: your name, address, phone number, your InSinkErator Product

model and serial number. You will be required to submit supporting

documentation of the date of purchase.

Manufacturer or its authorized service representative will determine,

in its sole and absolute discretion, if your InSinkErator Product is

covered under this limited warranty. Only an authorized InSinkErator

service representative may provide warranty service. InSinkErator

is not responsible for warranty claims arising from work performed

on your InSinkErator Product by anyone other than an authorized

InSinkErator service representative.

InSinkErator® may make improvements and changes in the specication at any time, in its sole discretion, without notice or obligation and further

reserves the right to change or discontinue models. ©2015 InSinkErator®, a business unit of Emerson Electric Co. All rights reserved.

No Other Express Warranty Applies

THE LIMITED WARRANTIES PROVIDED ABOVE ARE THE SOLE

AND EXCLUSIVE WARRANTIES PROVIDED BY MANUFACTURER

TO THE ORIGINAL PURCHASER, AND ARE IN LIEU OF ALL

OTHER WARRANTIES, WRITTEN OR ORAL, EXPRESS OR

IMPLIED, WHETHER ARISING BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, WITHOUT LIMITATION, WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, WHETHER OR NOT THE PURPOSE HAS BEEN

DISCLOSED AND WHETHER OR NOT THE INSINKERATOR

PRODUCT HAS BEEN SPECIFICALLY DESIGNED OR

MANUFACTURED FOR YOUR USE OR PURPOSE .

Limitation of Liability

TO THE EXTENT PERMITTED BY LAW, IN NO EVENT

SHALL MANUFACTURER OR ITS AUTHORIZED SERVICE

REPRESENTATIVES BE LIABLE FOR ANY INCIDENTAL, SPECIAL,

INDIRECT, OR CONSEQUENTIAL DAMAGES, INCLUDING

ANY ECONOMIC LOSS, WHETHER RESULTING FROM

NONPERFORMANCE, USE, MISUSE OR INABILITY TO USE THE

INSINKERATOR PRODUCT OR THE MANUFACTURER’S OR ITS

AUTHORIZED SERVICE REPRESENTATIVE’S NEGLIGENCE.

MANUFACTURER SHALL NOT BE LIABLE FOR DAMAGES

CAUSED BY DELAY IN PERFORMANCE AND IN NO EVENT,

REGARDLESS OF THE FORM OF THE CL AIM OR CAUSE OF

ACTION (WHETHER BASED IN CONTRACT, INFRINGEMENT,

NEGLIGENCE , STRICT LIABILITY, OTHER TORT OR

OTHERWISE), SHALL MANUFACTURER'S LIABILIT Y TO YOU

EXCEED THE PRICE PAID BY THE ORIGINAL OWNER FOR THE

INSINKERATOR

The term "consequential damages" shall include, but not be limited

to, loss of anticipated prots, business interruption, loss of use or

revenue, cost of capital or loss or damage to property or equipment.

Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation may not apply to you.

This warranty gives you specic legal rights and you may also have

other rights which vary from state to state.

PRODU CT.

Loading...

Loading...