Page 1

ISE

IN-SINK-ERATOR

Commercial

Products Group

COMMERCIAL DISPOSER

CONTROL CENTER

Installation Manual

Model CC-202C

WARNING

CAUTION

Please be certain that the person who installs or uses this appliance carefully reads and understands the Safety Instructions

contained in this manual.

The Warning signal alerts you to potential hazards or unsafe practices which, if not avoided, could

result in severe personal injury or death.

The Caution signal alerts you to hazards or unsafe practices which, if not avoided, may result in

minor personal injury or property damage.

Part No. 14125 - February, 1998

Page 2

FEATURES / MOUNTING THE CONTROL CENTER

The contro

l center models and specifications are shown in Table

2

PUSH BUTTON OPERATION

INTRODUCTION

The CC-202C Control Center is UL approved for use with ISE

Commercial Food Waste Disposers. See Table 1 for approved

combinations. The control center operates the disposer. Its main

functions are:

• To start and stop the disposer. Using flanges at the back of the control center enclosure and

• To reverse the direction of the disposer motor automatically

upon restart.

• To start the water flow to the disposer.

TABLE 7. Approved Disposer and Control Center Combinations

Model Waste Disposer Model

Push black button to start disposer.

Push red button to stop disposer.

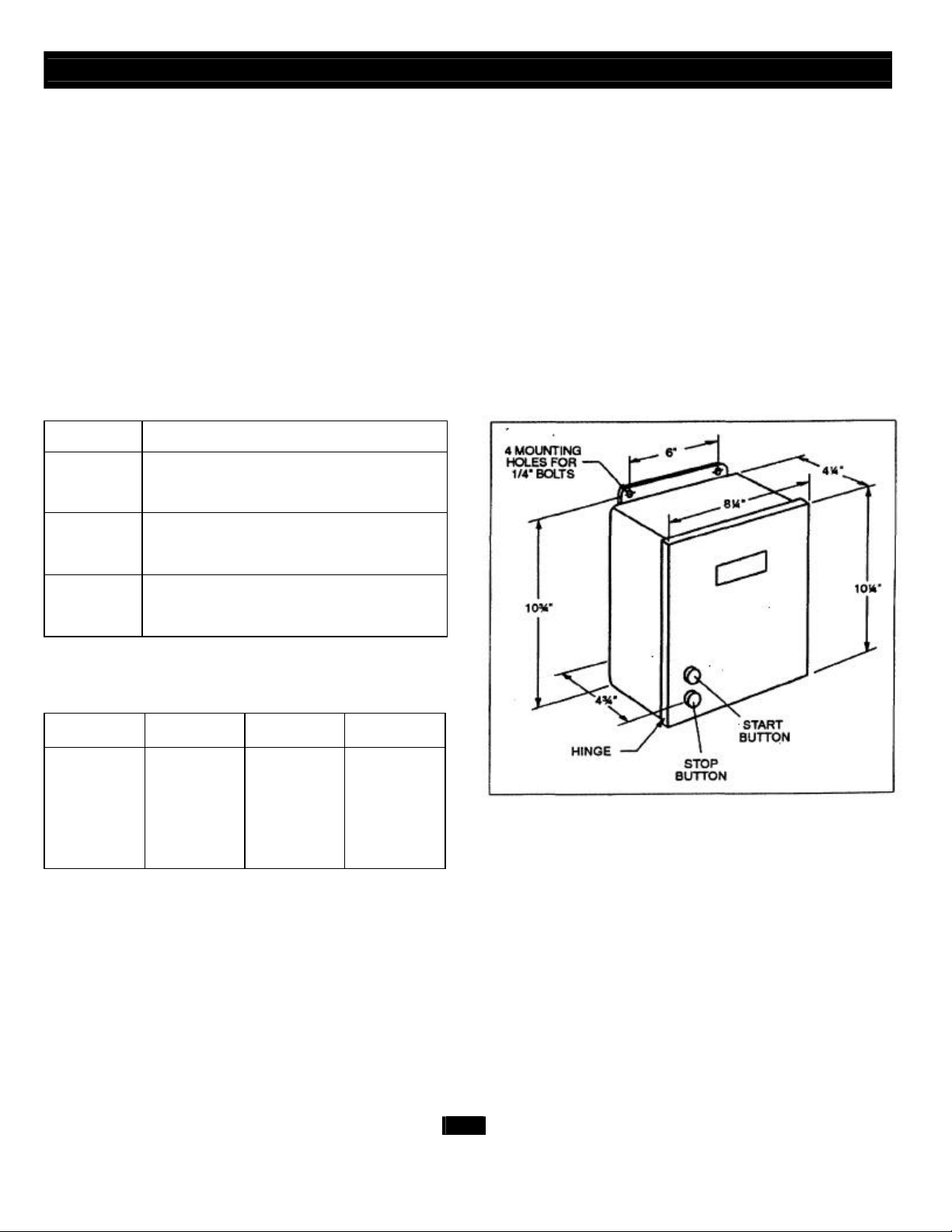

MOUNTING THE CONTROL CENTER

only mount panel in the upright vertical position (door hinge is

on the left). See Figure 1.

Locate control center within sight of disposer per local codes.

If box is mounted to the sink table, recess the box so that the

buttons do not extend beyond the table's edge.

CC-202C-1 CC202C-2

CC-202C-3 CC202C-4

CC-202C-5 CC202C-6

SS50-26, SS75-27. SS100-28, SS125-25, SS150-34,

SS150-38, SS200-27. SS200-31

SS50-27, SS75-28, SS100-29, SS125-26, SS150-36,

SS150-39, SS200-29, SS200-32

SS300-25, SS300-27, SS500-28, SS500-30. SS75013, SS750-15. SS1000-10, SS1000-12

TABLE 2. Electrical Specifications

Model Voltage Phase hp

CC-202C-1 120V 1 1/2-2

CC-202C-2 208/230 V 1 1/2-2

CC-202C-3 208/230 V 3 1/2-5

CC-202C-4 380/460 V 3 1/2-5

CC-202C-5 208/230 V 3 7 ½ -10

CC-202C-6 380/460 V 3 7 ½ - 10

FIGURE 1. Control Center Dimensions

FEATURES

AUTOMATIC REVERSE

The disposer motor will reverse its direction of rotation

automatically upon restart.

ENCLOSURE

Stainless steel NEMA 4 construction.

2

Page 3

ELECTRICAL CONNECTIONS

• Turn off the electrical supply to the disposer before attempting any

work on it. Use a voltmeter or circuit tester to ensure that the

power is off.

• All installation work must conform to local plumbing and electrical

codes.

• All control centers and disposers must be carefully and

permanently grounded.

• A properly fused disconnect must be installed at the electrical

supply source for the control center.

WARNING

ELECTRICAL SHOCK PROPERTY DAMAGE

ELECTRICAL CONNECTIONS

Connect the incoming line power and disposer motor to the labeled

terminal block in the control center. Use appropriate voltage and phase

electrical connection diagrams 5, 6, 7 or 8. Wire the disposer motor. For

correct voltage use the connection diagram inside the motor terminal

box.

• Ensure that control center voltage and phase match the disposer

motor and electrical supply. Check name plates on disposer and

control centers for voltage and phase specifications.

• Refer to the control center wiring diagrams in this manual for

correct connection.

• Use NEMA 4 watertight electrical connectors (not supplied) when

making electrical connections to the control center.

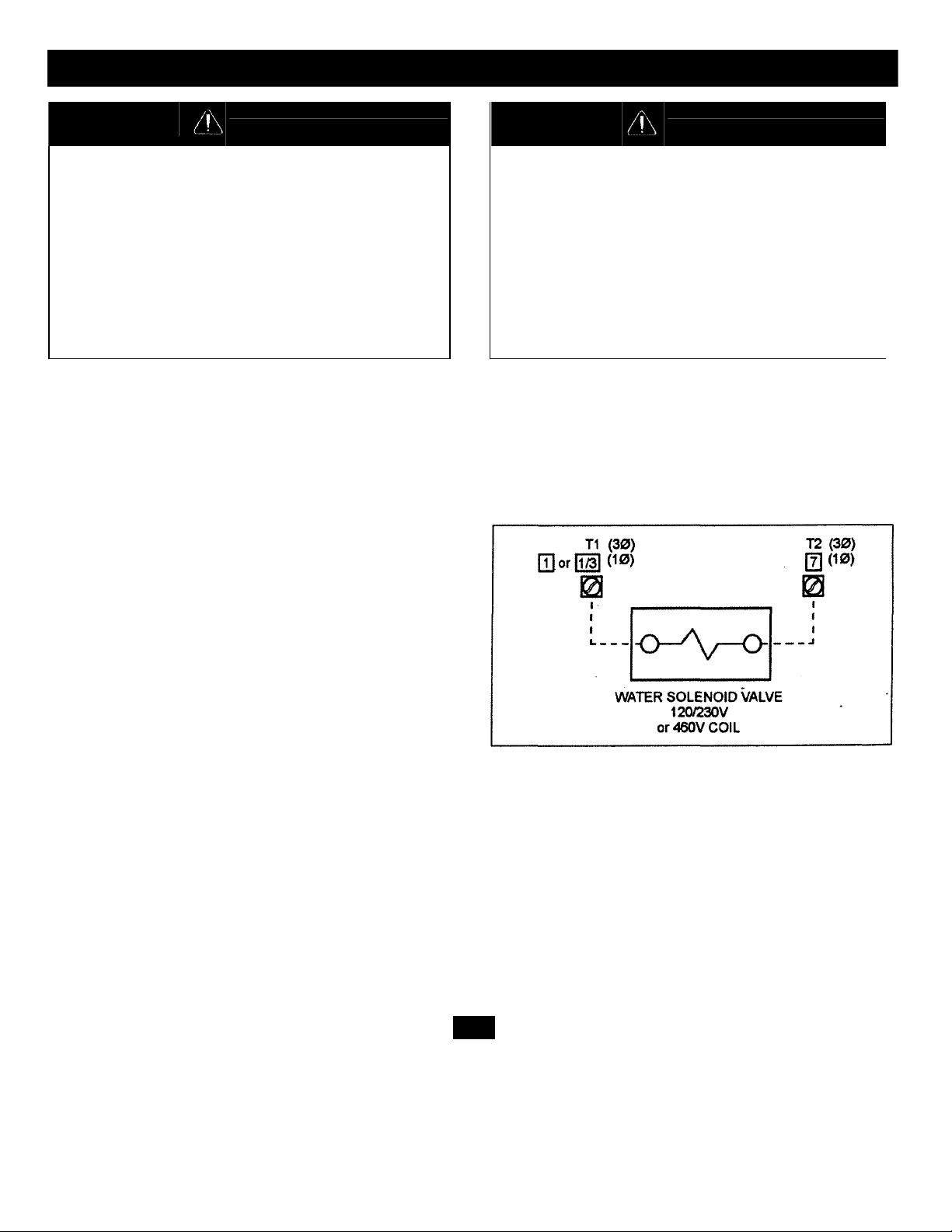

WATER SOLENOID VALVE

Connect solenoid valve to the control terminal numbers as shown

in Figure 3. Make sure the solenoid valve is the same voltage as

the control panel and supply power.

CAUTION

Connect water solenoid valve as shown in Figure 6.

Wire per local electrical code using 1-1/8" diameter holes in bottom of

control center cabinet and install NEMA 4 watertight electrical

connectors. (Not supplied).

After completing the connections, close door and fasten all locking

clamps. Replace disposer motor cover. Turn on power.

FIGURE 3. Solenoid valve connections to control panel terminals

4

Page 4

OPERATING INSTRUCTIONS / TROUBLESHOOTING

6

personnel before operating the disposer. The operating

instructions include:

• Disposer operation:

• How to restart the disposer after a jam condition.

PERSONAL INJURY

• Allow only trained personnel to operate disposer.

• Use baffles and guarding to avoid splashing and ejection of

materials.

• Do not put fingers or hands into the disposer.

• When attempting to remove objects from a disposer, use longhandled tongs or pliers.

• Turn power off before clearing a jam, removing an object from the

disposer or pressing the red reset button. (See Troubleshooting this

page).

• Disconnect electricity before adjusting set points.

ELECTRICAL SHOCK/PROPERTY DAMAGE

• Troubleshooting other than what is recommended in this section

should only be performed by qualified service personnel.

• All electrical checks must be performed by a qualified professional.

C. Disposer will not start but water flows.

1. Overload protector on the disposer may have tripped. Press

stop button. Locate red reset button on front of disposer

electrical cover. Press to reset. If motor had been running, wait

five minutes for the motor and overload to cool down.

2. Disposer is jammed. Press stop button and follow directions for

unjamming supplied with disposer.

WARNING Please read the disposer operating instructions and train your

OPERATING INSTRUCTIONS

TO START

1. Check to ensure disposer is free of foreign objects.

2. Ensure power is on.

3. Push start button. Disposer motor will run and water will flow into the

disposer.

TO STOP

1. Push stop button. Disposer motor and water will stop.

TROUBLESHOOTING

This control center was inspected and tested under operating conditions

before shipment from the factory. In case of trouble, check the items

listed below.

A. Disposer motor will not start and water does not flow.

1. No incoming line power. Turn line power on.

B. Disposer motor stops while grinding but water continues to flow.

D. Water flows constantly before start button is pushed.

1. Water solenoid valve is installed backward. Water flow should

be in the direction of the arrow on valve.

2. Water solenoid valve is wired incorrectly. Recheck wiring

diagram on page 7, 8 or 9.

E. Overload trips frequently.

1. Do not overload disposer with excess amounts of garbage and

water. (See disposer instructions for recommended water

flows.)

If trouble still persists, call your nearest ISE Authorized Service

Agency. For the location of your nearest service agency, call toll-free 1800-558-5700.

1. Disposer is jammed. Press stop button and follow directions for

unjamming supplied with the disposer.

2. Disposer motor overload protector has tripped. Follow instruction

in C1.

Page 5

SCHEMATIC WIRING DIAGRAMS

MODEL N

o. CC202

-

2

WARNING

ELECTRICAL SHOCK PROPERTY DAMAGE

• TURN OFF ALL ELECTRICAL SUPPLY TO THE DISPOSER BEFORE ATTEMPTING

ANY WORK ON IT. USE A VOLTMETER OR CIRCUIT TESTER TO ENSURE THAT

POWER IS OFF.

• INSTALLATION MUST CONFORM TO LOCAL ELECTRICAL CODES.

• ALL CONTROL CENTERS AND DISPOSERS MUST BE CAREFULLY AND

PERMANENTLY GROUNDED.

• A PROPERLY FUSED DISCONNECT MUST BE INSTALLED AT THE ELECTRICAL

CAUTION

• ENSURE THAT THE CONTROL CENTER VOLTAGE AND PHASE MATCH THE

DISPOSER MOTOR AND ELECTRICAL SUPPLY. CHECK NAMEPLATES ON

DISPOSERS AND CONTROL CENTERS FOR VOLTAGE AND PHASE

SPECIFICATION.

• THE DISPOSER MOTOR WIRING CONNECTION IS SHOWN IN THE DISPOSER

TERMINAL BOX.

208/230V, 1 Ø, 1/2 - 2 HP

IN-SINK-ERATOR DIVISION

EMERSON ELECTRIC CO.

4700 21st. STREET

RACINE, WI 53406-5093

8

Page 6

SCHEMATIC WIRING DIAGRAMS

SUPPLY SOURCE FOR THE CONTROL CENTER.

MODEL N

o. CC202

IN-SINK

-

ERATOR DIVISION

WARNING

ELECTRICAL SHOCK PROPERTY DAMAGE

• TURN OFF ALL ELECTRICAL SUPPLY TO THE DISPOSER BEFORE ATTEMPTING

ANY WORK ON IT. USE A VOLTMETER OR CIRCUIT TESTER TO ENSURE THAT

POWER IS OFF.

• INSTALLATION MUST CONFORM TO LOCAL ELECTRICAL CODES.

• ALL CONTROL CENTERS AND DISPOSERS MUST BE CAREFULLY AND

PERMANENTLY GROUNDED.

• A PROPERLY FUSED DISCONNECT MUST BE INSTALLED AT THE ELECTRICAL

CAUTION

• ENSURE THAT THE CONTROL CENTER VOLTAGE AND PHASE MATCH THE

DISPOSER MOTOR AND ELECTRICAL SUPPLY. CHECK NAMEPLATES ON

DISPOSERS AND CONTROL CENTERS FOR VOLTAGE AND PHASE

SPECIFICATION.

• THE DISPOSER MOTOR WIRING CONNECTION IS SHOWN IN THE DISPOSER

TERMINAL BOX.

380/460V, 3 Ø, 1/2 - 5 HP

EMERSON ELECTRIC CO.

4700 21st STREET

RACINE, WI 53406-5093

10

Page 7

SCHEMATIC WIRING DIAGRAM

OL CENTER VOLTAGE AND PHASE MATCH

ELECTRICAL SUPPLY SOURCE FOR THE CONTROL CENTER.

WARNING

ELECTRICAL SHOCK PROPERTY DAMAGE

TURN OFF ALL ELECTRICAL SUPPLY TO THE DISPOSER BEFORE

•

ATTEMPTING ANY WORK ON IT. USE A VOLTMETER OR CIRCUIT

•

INSTALLATION MUST CONFORM TO LOCAL ELECTRICAL CODES.

ALL CONTROL CENTERS AND DISPOSERS MUST BE CAREFULLY AND

•

PERMANENTLY GROUNDED.

A PROPERLY FUSED DISCONNECT MUST BE INSTALLED AT THE

•

CAUTION

ENSURE THAT THE CONTR

•

THE DISPOSER MOTOR AND ELECTRICAL SUPPLY. CHECK

NAMEPLATES ON DISPOSERS AND CONTROL CENTERS FOR

VOLTAGE AND PHASE SPECIFICATION.

• THE DISPOSER MOTOR WIRING CONNECTION IS SHOWN IN THE

DISPOSER TERMINAL BOX.

MODEL No. CC202

380/460V. 3 Ø,7-1/2 - 10 HP

IN-SINK-ERATOR DIVISION

EMERSON ELECTRIC CO.

4700 21st STREET

RACINE. WI 53406-5093

Loading...

Loading...