Page 1

DIS POS ER CONTROL CENTER

Installation Manual

Model CC-101K

www.insinkerator.com

The Danger signal indicates an immediately hazardous situation which, if not

avoided, will result in death or serious injury.

The Warning signal alerts you to potential hazards or unsafe practices which,

if not avoided, could result in severe personal injury or death.

The Caution signal alerts you to hazards of unsafe practices which, if not avoided,

may result in minor personal injury or property damage.

Please be certain that the person who installs or uses this appliance carefully reads

and understands the Safety Instructions contained in this manual.

Part No. 14175 - January 2007

Page 2

Table of Contents

Introduction/Features

Introduction ..................................................................................... 3

Features .......................................................................................... 3

Mounting The Control Center/Plumbing Connections

Mounting the Control Center........................................................... 4

Plumbing Connections .................................................................... 4

Electrical Connections Diagrams ................................................................ 5

Electrical Connections .................................................................................. 6

Operating Instructions .................................................................................. 7

Troubleshooting ............................................................................................. 8

Wiring Diagrams

Model No. CC-101K-1 (120V, 1 phase, 1/2-2 HP) .......................... 9

Model No. CC-101K-2 (208-240V, 1 phase, 1/2-2 HP) ................. 10

Model No. CC-101K-3 (208-240V, 3 phase, 1/2-10 HP) ............... 11

Model No. CC-101K-4 (380-460V, 3 phase, 1/2-10 HP) ............... 12

Warranty

FOODSERVICE DISPOSER CONTROL CENTER LIMITED WARRANTY

InSinkErator Foodservice Disposer Control Centers are warranted against defects in material and workmanship for

one year from the date of installation. The warranty includes parts and labor, provided the service is performed by an

InSinkErator Factory Authorized Service Center. This warranty does not apply if failure is due to: faulty or improper

electrical installation, faulty or improper plumbing installation, product abuse or misuse, or accidental damage.

2

Page 3

Introduction/Features

INTRODUCTION

The CC-101K Control Center is UL® approved for use

with InSinkErator Foodservice Disposers. See Table 1

for approved disposer and control center

combinations. The control center operates the

disposer. Its main functions are:

• To start and stop the disposer.

• To reverse the direction of the disposer motor

automatically upon restart.

• To start the water fl ow to the disposer.

• To allow water fl ow for several minutes to fl ush the

drain line after the disposer is turned off.

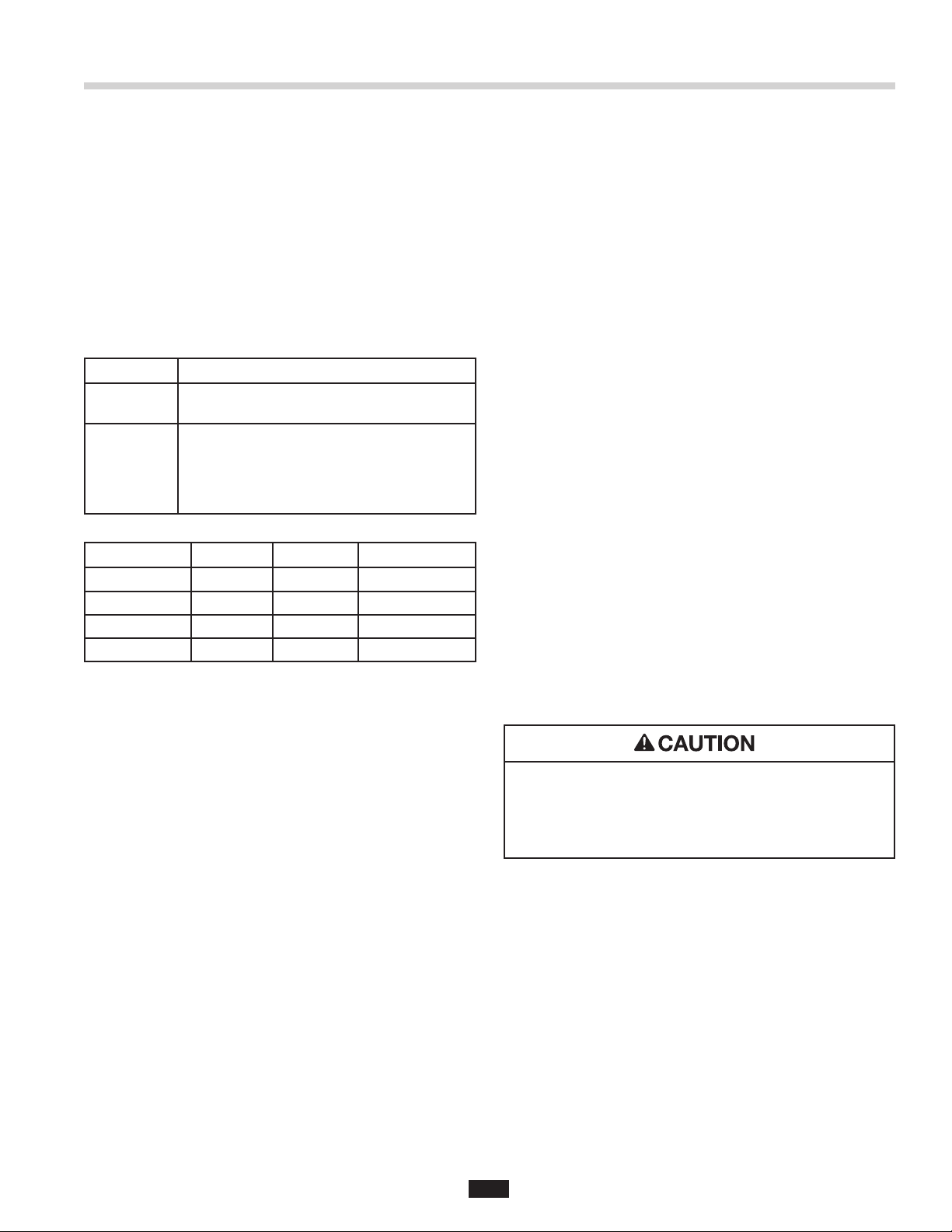

Model Waste Disposer Model

CC-101K-1

CC-101K-2

CC-101K-3

CC-101K-4

Tabel 1. Approved Disposer and Control Center Combinations

SS50-26, SS75-27, SS100-28, SS125-25,

SS150-34, SS150-38, SS200-27, SS200-31

SS50-27, SS75-28, SS100-29, SS125-26,

SS150-36, SS150-39, SS200-29,

SS200-32, SS300-25, SS300-27,

SS500-28, SS500-30, SS750-13,

SS750-15, SS1000-10, SS1000-12

Model Voltage Phase HP

CC-101K-1 120V

CC-101K-2 208-240V 1

CC-101K-3 208-240V 3 1/2-10

CC-101K-4 380-460V 3 1/2-10

Table 2. Electrical Specifi cations

1 1/2-2

1/2-2

FEATURES

AUTOMATIC REVERSE

The disposer motor will reverse its direction of rotation

automatically upon restart. To avoid motor damage, a

fi ve second delay feature prevents reversing while the

motor is coasting.

WATER SHUTOFF DELAY (POST FLUSH)

After the motor is turned off, the water continues to

fl ow for up to 10 minutes. The length of this post fl ush

is controlled by the water shutoff delay timer. The post

fl ush helps ensure that ground food waste is fl ushed out

of the drain line. Adjust water shutoff delay as described

in the operating instructions on page 7.

NOTE: This feature is set in the manual position at the

factory. To activate the automatic timed disposer shutoff,

disconnect the electric power to the control center, then

open the control center door. Locate the shutoff plug

at the top of the printed circuit board in the CC-101K

(see Figure 8). Move the plug from manual (MAN) pins to

automatic (AUTO) pins. The disposer now automatically

shuts off 10 minutes after it starts.

EXTERNAL REMOTE CONTROL

One or more remote controls may be connected to

the control center. These enable the operator to

start or stop the disposer from any control station.

A 24 V control circuit provides low voltage push

button operation.

ELECTRIC DISCONNECT SWITCH

The lever switch on the front panel of the control center

disconnects the line voltage. It interlocks with the front

cover so that the cover cannot be opened unless the

switch is in the off position.

NOTE: Use of the electrical disconnect switch results

in a 30-second delay before system can be restarted.

You must wait 30 seconds after reactivation of the line

disconnect switch before system will start.

LOW VOLTAGE CONTROL

Controls operate on a 24 V solid state control circuit.

ENCLOSURE

NEMA 4 construction.

PUSH BUTTON OPERATION

Push Black button to start disposer.

PROPERTY DAMAGE

Use of more than two solenoid valves will affect the

overall function of the CC-101K control center. Extra

solenoid valves will cause a reduction in voltage and

solenoid actuation will not occur.

AUTOMATIC TIMED DISPOSER SHUTOFF

This water saving feature allows the disposer to run for

up to 10 minutes before it automatically shuts off and

must be manually restarted.

3

Page 4

Mounting the Control Center/Plumbing Connections

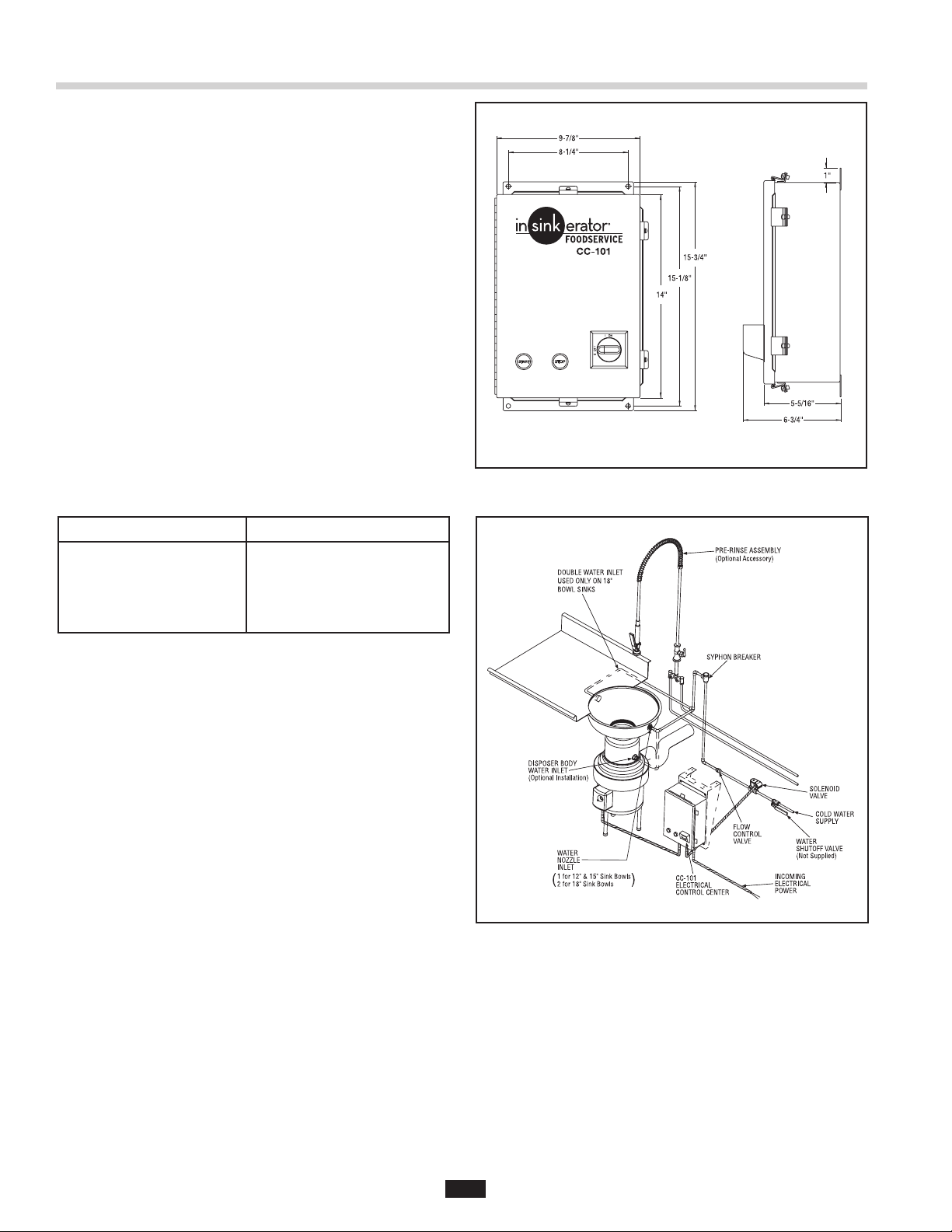

MOUNTING THE CONTROL CENTER

Use the fl anges at the back of the control center

enclosure and only mount panel in the upright vertical

position (door hinge is on the left). See Figure 1.

Locate control center within sight of disposer per local

codes. Locate any remote control station within sight of

disposer per local codes.

If box is mounted to the sink table, recess the box so

that the buttons do not extend beyond the table’s edge.

PLUMBING CONNECTIONS

The syphon breaker is supplied with all complete

disposer packages (packed separately).

The solenoid valve is supplied with a 24 V coil. Make

certain that the valve is plumbed according to the water

fl ow direction arrows marked on the valve or the valves

will not function properly.

The fl ow control valve regulates all water fl owing into

the disposer. This conserves water and prevents

overloading. Check direction of water fl ow arrows.

Figure 1. Control Center Dimensions

Disposer Model (X) GPM

SS-50 - SS-75

SS-100 - SS-125

SS-150 - SS-200

SS-300 - SS-500

SS-750 - SS-1000

Table 3. Sizing Flow Control Valve

3

5

7

8

10

Syphon breaker must be installed above the sink fl ood

plane per local plumbing codes. Check direction of

water fl ow arrows.

Figure 2. Typical Installation Diagram

4

Page 5

Electrical Connection Diagrams

Figure 3. Incoming 120 V Single Phase Line Power

Figure 4. Incoming 208-240 V Single Phase Line Power

Figure 5. Incoming 208-240 V Three Phase Line Power

Figure 6. Incoming 380-460 V Three Phase Power

5

Page 6

Electrical Connections

ELECTRIC SHOCK

• Turn off the electrical supply to the disposer before

attempting any work on it. Use a voltmeter or

circuit tester to ensure that power is off.

• All installation work must conform to local

plumbing and electrical codes.

• All control centers and disposers must be carefully

and permanently grounded.

• A properly fused disconnect must be installed at

the electrical supply source for the control center.

• The control center’s door disconnect must be in the

off position before the panel door can be opened.

Power is still present at the disconnect until power

is turned off at the electrical supply source.

Figure 7. Remote Control Station Wiring

LINE VOLTAGE

Connect the incoming line power to the electrical

disconnect switch and connect the disposer motor to

labeled terminal blocks in the control center. Use the

appropriate voltage and phase electrical connection

diagram, Figure 3, 4, 5, or 6.

LOW VOLTAGE

The CC-101K control center uses low voltage (24 V)

to operate contactor coils, solid state control circuit,

push buttons, and solenoid valves. Red wires denote

a 24 V circuit.

REMOTE CONTROL STATION

Any number of remote control stations can be used.

Mount remote controls within sight of the disposer

per local codes. Refer to Figure 7. Remove jumper

wire when using remote control stations.

PROPERTY DAMAGE

• Ensure that control center voltage and phase

match the disposer motor and electrical supply.

Check name plates on disposer and control

centers for voltage and phase specifi cations.

• Refer to the control center wiring diagrams in this

manual for correct connection.

• Use NEMA 4 watertight electrical connectors

(not supplied) when making electrical connections

to the control center.

WATER SOLENOID VALVE

One 24 V solenoid valve is supplied with all control

centers. Connect solenoid valve in line with the X GPM

fl ow control to terminal 4 and 13. See Figures 3 to 7.

Wire per local electrical code using 7/8" diameter holes

in bottom of control center cabinet and install NEMA 4

water-tight electrical connectors.

After completing the connections, replace all terminal

block shields, close door, and fasten all locking clamps.

Replace disposer motor cover. Turn on power.

Please read the disposer operating instructions and

train your personnel before operating the disposer.

The operating instructions include:

• Disposer operation

• How to restart the disposer after a jam condition

PERSONAL INJURY

• Allow only trained personnel to operate disposer.

• Use baffl es and guarding to avoid splashing and

ejection of materials.

• Do not put fi ngers or hands into the disposer.

• When attempting to remove objects from a

disposer, use long-handled tongs or pliers.

• Turn power off before clearing a jam, removing an

object from the disposer or pressing the red reset

button. (See Troubleshooting).

• Disconnect electricity before adjusting set points.

6

Page 7

Operating Instructions

OPERATING INSTRUCTIONS

TO START

1. Check to ensure disposer is free of foreign objects.

2. Ensure power is on.

3. Push start button. Disposer motor will run and water

will fl ow into the disposer.

TO STOP

1. Push stop button. Disposer motor and water will stop.

2. Water may continue to fl ow into disposer for up to

10 minutes, per the time set on the water shutoff

delay timer.

NOTE: This post-fl ush clears the drain lines of

food waste.

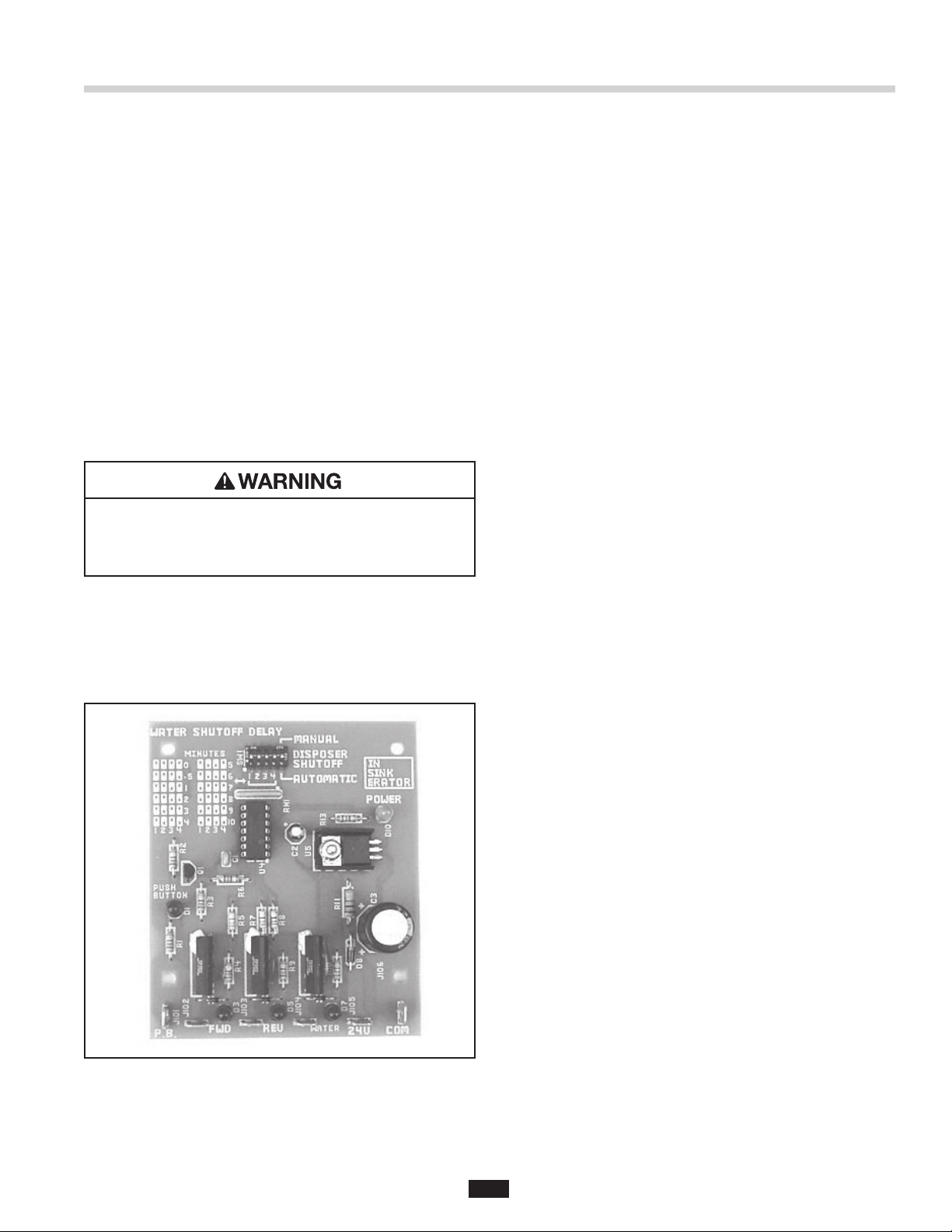

WATER SHUTOFF DELAY ADJUSTMENT

The water shutoff delay is adjustable from 30 seconds

to 10 minutes.

PERSONAL INJURY

To adjust the water shutoff delay, disconnect the

electrical power to the control panel and open the

control center door.

Example 1: Dip switches 1, 2, 3, 4 pushed to the down

position will give a 0 minute delay.

Example 2: Dip switches 1, 3, 4 pushed to the up

position; and dip switch 2 pushed to the

down position will give a 10 minute delay.

AUTOMATIC TIMED DISPOSER SHUTOFF

This water saving feature allows the disposer to run for

up to 10 minutes before it automatically shuts-off and

must be manually restarted.

NOTE: This feature is set in the manual position at the

factory. To activate the automatic timed disposer

shut-off, disconnect the electric power to the control

center, then open the control center door. Locate the

Dip Switch Module at the top of the printed circuit board

(see Figure 8). Move the #5 dip switch from MANUAL to

AUTOMATIC. The disposer now automatically shuts off

10 minutes after it starts.

Locate the water shutoff delay at the top of the printed

circuit board in the CC-101K (See Figure 8). Set the

dip switches for the desired water shut off delay. Use

the guide printed on the circuit board to set minutes of

delay. The dip switches should be moved to match the

fi lled in areas of the guide.

Figure 8.

7

Page 8

Troubleshooting

PERSONAL INJURY

• Allow only trained personnel to operate disposer.

• Use baffl es and guarding to avoid splashing and

ejection of materials.

• Do not put fi ngers or hands into the disposer.

• When attempting to remove objects from a

disposer, use long-handled tongs or pliers.

• Turn power off before clearing a jam, removing

an object from the disposer or pressing the red

reset button.

This control center was inspected and tested under

operating conditions before shipment from the factory.

In case of trouble, check the items listed below.

A. Disposer motor will not start and water

does not fl ow.

1. No incoming line power, turn line power on.

2. Electric disconnect switch is not ON. Turn electric

disconnect to ON position.

3. Electrical disconnect switch has been reactivated

and 30-second delay has not yet expired. Wait

30 seconds and try starting again.

4. Control circuit fuse FNA2 is blown. Replace fuse.

ELECTRICAL SHOCK/PROPERTY DAMAGE

• Troubleshooting other than what is recommended

in this section should only be performed by

qualifi ed service personnel.

• Further troubleshooting performed by untrained

personnel could result in electric shock or damage

to the control center.

• All electrical checks must be performed by a

qualifi ed professional.

D. Water fl ows constantly before start button

is pushed

1. Water solenoid valve is installed backward.

Water fl ow should be in the direction of the

arrow on valve.

E. Overload trips frequently.

1. Do not overload disposer with excess amounts of

garbage and water. (See disposer instructions for

recommended water fl ows.)

PROPERTY DAMAGE

Use only an FNA2 replacement fuse. Using another

replacement fuse will result in product damage.

B. Disposer motor stops while grinding but water

continues to fl ow.

1. Control center wired for automatic shut-off.

Repress start button. If disposer runs for

10 minutes then shuts off, the automatic shutoff

is active. If the manual setting is desired, change

as indicated in the feature section.

2. Disposer is jammed. Press the stop button and

follow directions for unjamming that were

supplied with the disposer.

3. Disposer motor overload protector has tripped.

Follow instruction in C1.

C. Disposer will not start but water fl ows.

1. Overload protector on the disposer may have

tripped. Press stop button. Locate red reset

button on front of disposer electrical cover. Press

to reset. If motor had been running, wait fi ve

minutes for the motor and overload to cool down

before starting.

2. Disposer is jammed. Press the stop button and

follow directions for unjamming that were

supplied with the disposer.

8

Page 9

CC-101K-1 Wiring Diagram

ELECTRICAL SHOCK

• Turn off the electrical supply to the disposer before

attempting any work on it. Use a voltmeter or

circuit tester to ensure that power is off.

• Installation must conform to local electrical codes.

• All control centers and disposers must be carefully

and permanently grounded.

• A properly fused disconnect must be installed at

the electrical supply source for the control center.

120 V

1-phase

1/2 to 2 HP

PROPERTY DAMAGE

• Ensure that the control center voltage and phase

match the disposer motor and electrical supply.

Check nameplates on disposers and control

centers for voltage and phase specifi cation.

• The disposer motor wiring connection is shown in

the disposer terminal box.

Call Toll Free 1-800-845-8345

for the nearest InSinkErator

Authorized Service Agency or

to reach Technical Support.

9

Page 10

CC-101K-2 Wiring Diagram

ELECTRICAL SHOCK

• Turn off the electrical supply to the disposer before

attempting any work on it. Use a voltmeter or

circuit tester to ensure that power is off.

• Installation must conform to local electrical codes.

• All control centers and disposers must be carefully

and permanently grounded.

• A properly fused disconnect must be installed at

the electrical supply source for the control center.

PROPERTY DAMAGE

• Ensure that the control center voltage and phase

match the disposer motor and electrical supply.

Check nameplates on disposers and control

centers for voltage and phase specifi cation.

• The disposer motor wiring connection is shown in

the disposer terminal box.

208/240 V

1-phase

1/2 to 2 HP

Call Toll Free 1-800-845-8345

for the nearest InSinkErator

Authorized Service Agency or

to reach Technical Support.

10

Page 11

CC-101K-3 Wiring Diagram

ELECTRICAL SHOCK

• Turn off the electrical supply to the disposer before

attempting any work on it. Use a voltmeter or

circuit tester to ensure that power is off.

• Installation must conform to local electrical codes.

• All control centers and disposers must be carefully

and permanently grounded.

• A properly fused disconnect must be installed at

the electrical supply source for the control center.

208/240 V

3-phase

1/2 to 10 HP

PROPERTY DAMAGE

• Ensure that the control center voltage and phase

match the disposer motor and electrical supply.

Check nameplates on disposers and control

centers for voltage and phase specifi cation.

• The disposer motor wiring connection is shown in

the disposer terminal box.

Call Toll Free 1-800-845-8345

for the nearest InSinkErator

Authorized Service Agency or

to reach Technical Support.

11

Page 12

CC-101K-4 Wiring Diagram

ELECTRICAL SHOCK

• Turn off the electrical supply to the disposer before

attempting any work on it. Use a voltmeter or

circuit tester to ensure that power is off.

• Installation must conform to local electrical codes.

• All control centers and disposers must be carefully

and permanently grounded.

• A properly fused disconnect must be installed at

the electrical supply source for the control center.

PROPERTY DAMAGE

• Ensure that the control center voltage and phase

match the disposer motor and electrical supply.

Check nameplates on disposers and control

centers for voltage and phase specifi cation.

• The disposer motor wiring connection is shown in

the disposer terminal box.

380/460 V

3-phase

1/2 to 10 HP

Call Toll Free 1-800-845-8345

for the nearest InSinkErator

Authorized Service Agency or

to reach Technical Support.

12

Loading...

Loading...