Page 1

DISPOSER CONTROL CENTERS

SERVICE MANUAL

CC-101 SERIES

COMMERCIAL DISPOSER

CONTROL CENTERS

(INCLUDES WIRING DIAGRAMS)

SEE PREFACE FOR MODEL REFERENCE

IN-SINK-ERATOR DIVISION

EMERSON ELECTRIC CO.

4700 21st STREET, RACINE, WI 53406

Page 2

TABLE OF CONTENTS

2 Preface

2-1

CC-101 B

15-2

SECTION PAGE NO.

1 Safety Precautions 1-1

3 General Information 3-1

4 Wiring Diagrams 4-1

5 Plumbing, Motor and Line Voltage Connections 5-1

6 Subpanel Removal and Replacement 6-1

7 Component Description 7-1

8 Component Location 8-1

9 Operating Sequence 9-1

10 Component Testing and Replacement 10-1

11 Troubleshooting 11-1

12 Information Tips 12-1

13 Special Equipment 13-1

14 Glossary of Terms 14-1

15 Technical Data Sheets (How the Control Center Works)

CC-101 C & CC-101D 15-10

CC-101 E 15-18

CC-101 G & CC-101H 15-26

Page 3

PREFACE SECTION 2

A Control center is a device used to start and stop a commercial

disposer by the use of two push-button switches. It is commonly

referred to as a control panel and contains various electrical

component parts. The main functions of the control panel are to

reverse the direction of the disposer motor each time it is started,

start the water flow to the disposer, and allow it to flow for several

minutes after the disposer is turned off.

This manual includes CC-101 series control centers manufactured

since 1976 (i.e., CC-101 A through CC-101 G). Basic functions

remained the same throughout the CC-101 series, but component

parts changed, and eventually additional features were added.

NOTE

Once the function and purpose of each component is learned, control

centers manufactured before 1976 can also be diagnosed. If one

studies the B and C models, the remaining models become easier to

understand.

The model number of a control center can be found on the

specifications decal located on the inside or outside of the enclosure

door. All information on the decal (i.e., voltage, horsepower and

phase) must be noted prior to diagnosing. Variations of a control

center do not necessarily change the model number. Visual

inspection will determine which wiring diagram in this manual applies

to a given control center.

Factory assistance is available by calling 1-800-558-5700 (in

Wisconsin call 1-800-922-2331).

2-1

Page 4

GENERAL INFORMATION SECTION 3

GENERAL

This section is not intended as a complete installation guide.

Basic notes and guidelines for installation are provided here

for the purpose of checking or troubleshooting an existing

installation. Detailed installation instructions were provided

with the disposer; to obtain technical information not covered

in those instructions, contact the Factory.

NOTE

Neither the IN-SINK-ERATOR Company nor any of its Authorized

Service Centers performs original installations,

All installations are to be in accordance with local plumbing

and electrical codes.

NOTE

The disposer control center must be mounted within direct sight of

the disposer per local codes. Any remote control stations must also

be located within direct sight of the disposer per local codes.

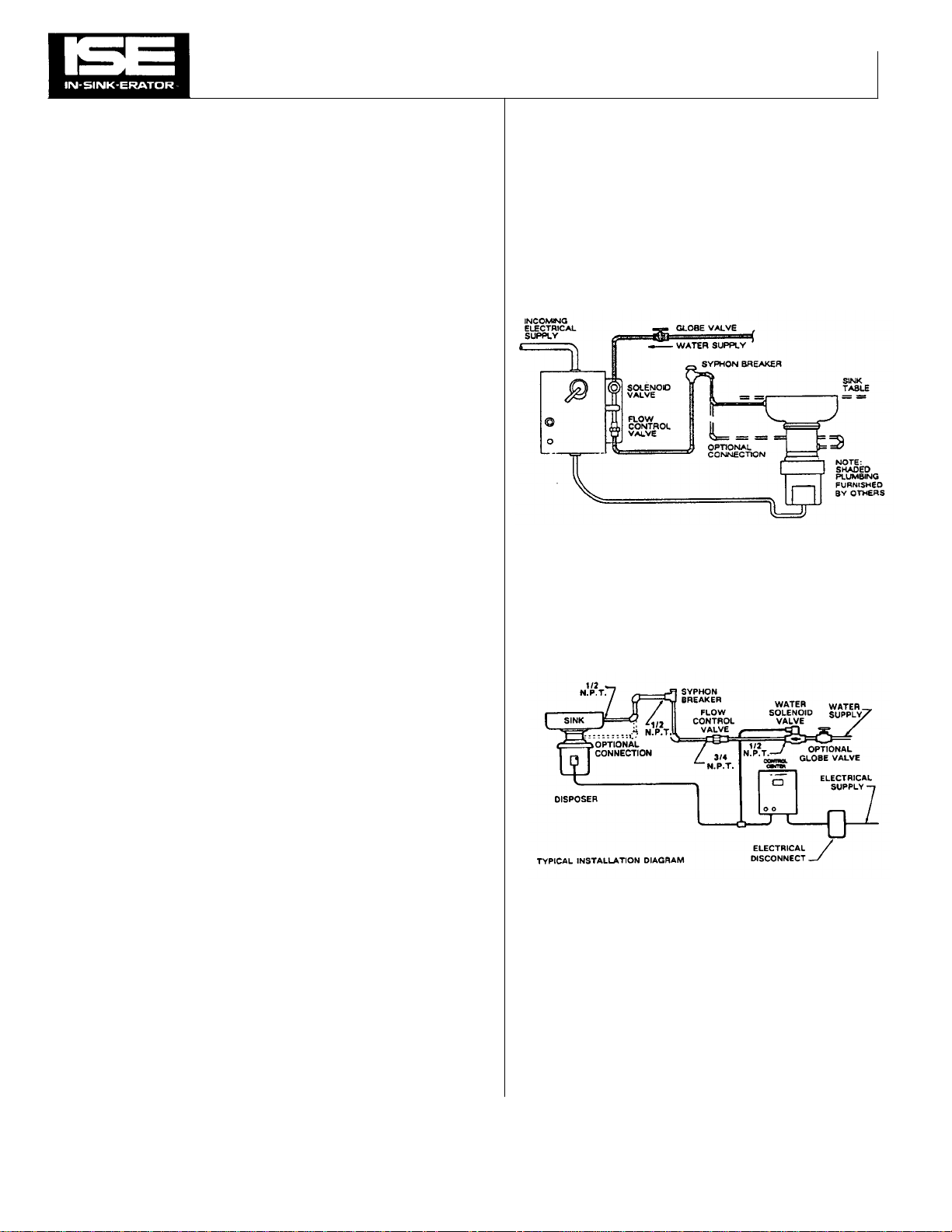

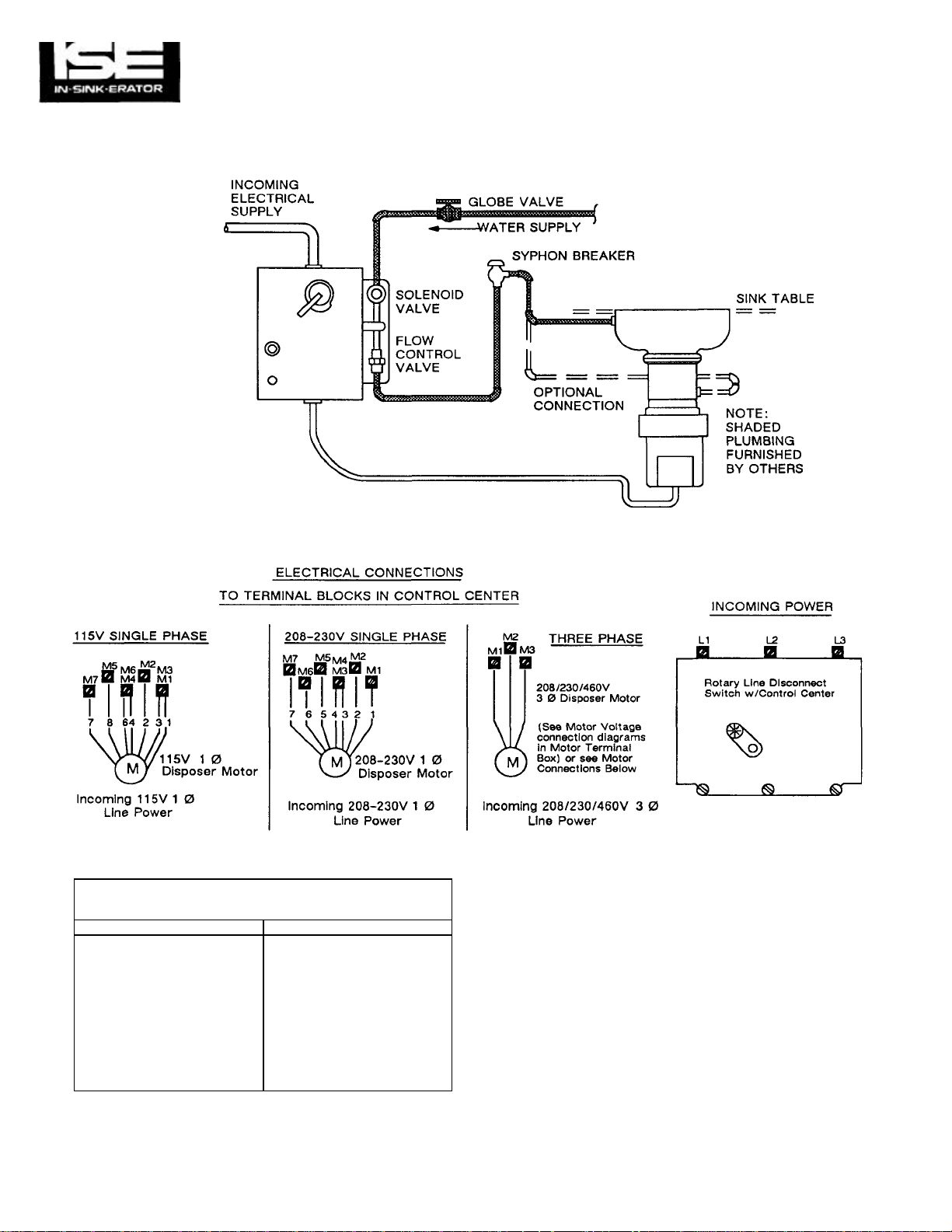

PLUMBING INSTALLATION

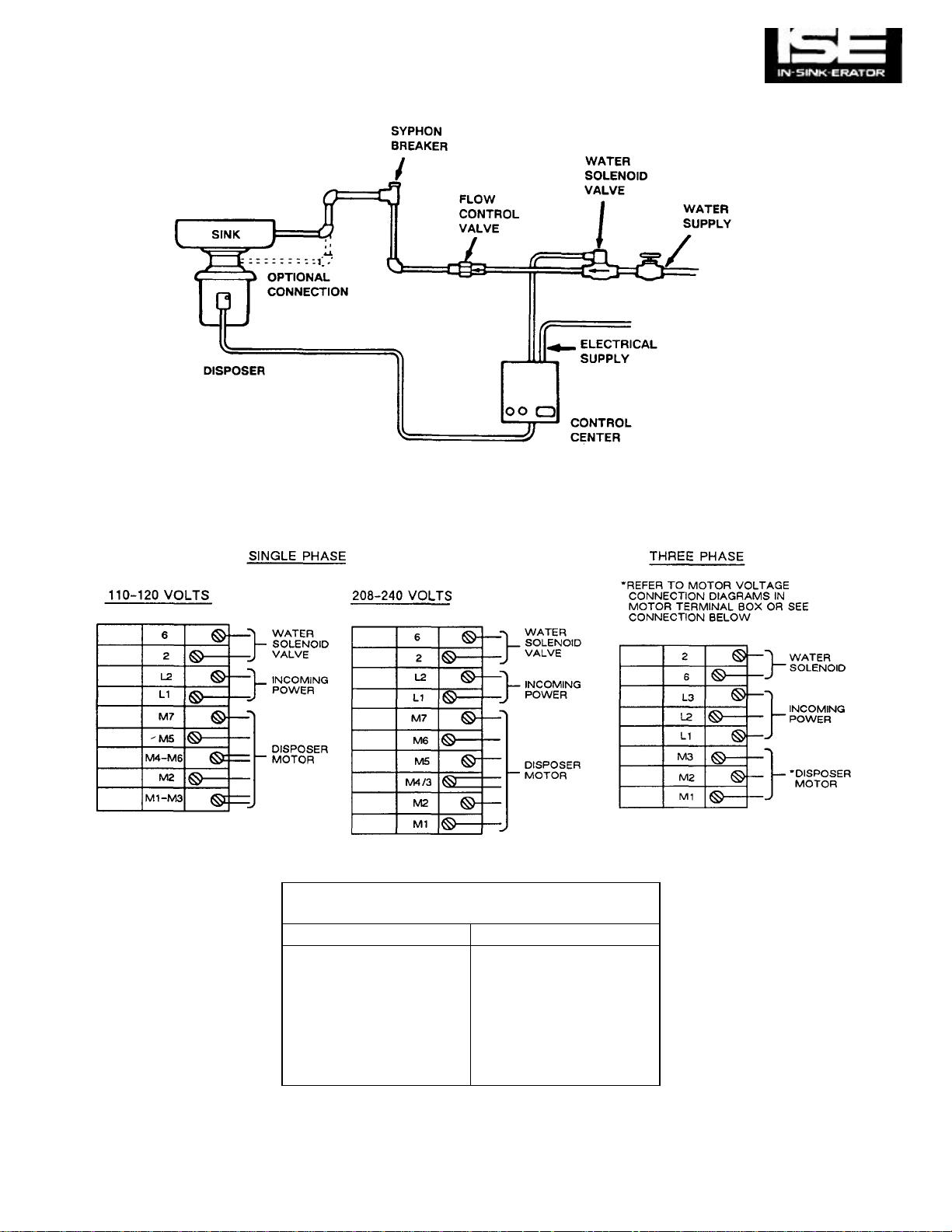

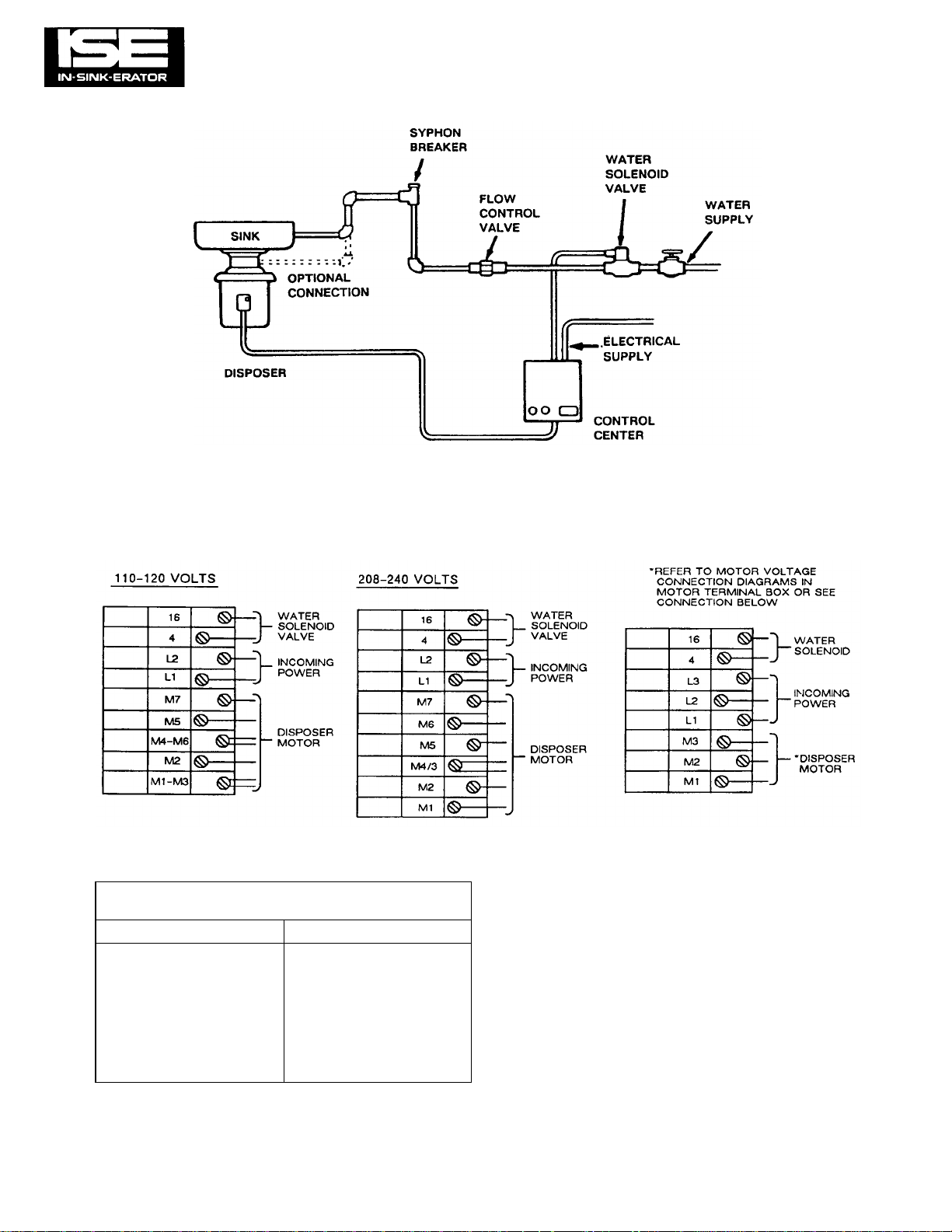

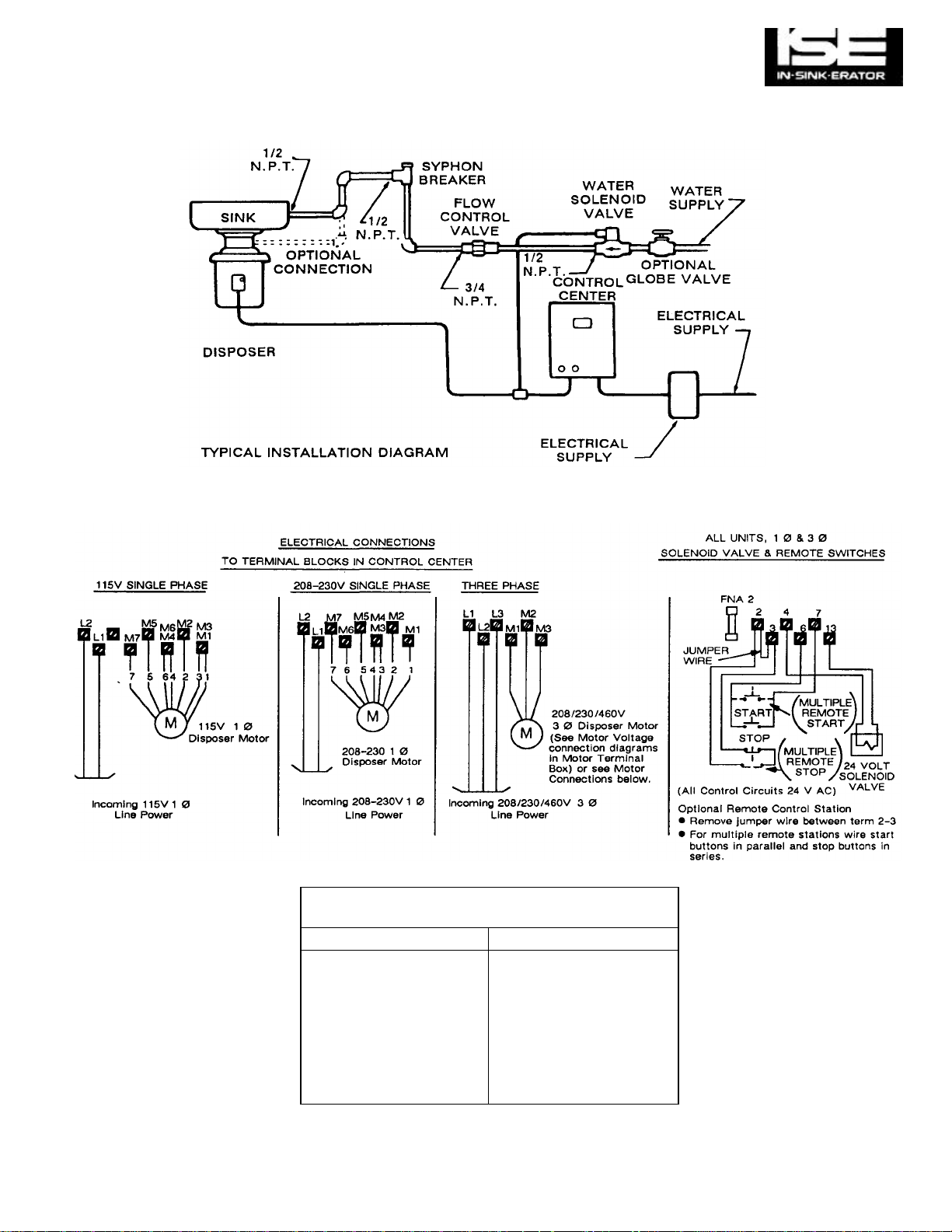

The following plumbing installation diagrams are included to

illustrate the plumbing connections of a typical installation.

Figure 5-1 shows an installation for a control center with an

enclosure-mounted solenoid valve (models CC-101A and

CC-101B). Figure 5-2 shows an installation with a remote-

mount solenoid valve (all other models).

The solenoid valve and flow control valve are each marked

with arrows showing the proper water flow direction. Both

valves must be installed so that the water flows through them

in the correct direction or the valves will not work properly.

Note that in all installations a syphon breaker (vacuum

breaker) must be installed above the sink flood plane per local

plumbing code.

Figure 5-1. Plumbing Connection Diagram, Typical

Installation (Enclosure-Mount Solenoid

Valve).

GENERAL ELECTRICAL INFORMATION

IN-SINK-ERATOR Commercial Disposer Control Centers are

shipped from the factory wired for a specific voltage and

phase. Please refer to the Control Center wiring diagrams in

this manual for the correct connections. (Disposer motor

connections will depend upon the operating voltage and

phase of the disposer.)

Figure 5-2. Plumbing Connection Diagram, Typical

Installation (Remote-Mount Solenoid

Valve).

3-1

Page 5

Figure

4-1.

CC-101B

Figure

4-2.

CC-101E

SECTION 3 GENERAL INFORMATION (Cont'd)

FEATURES

All CC-101 series Commercial Disposer Control Centers have

the following features:

Automatic Reversing Action — Automatically reverses the

disposer motor each time it is started to double the life of the

disposer grinding shredders.

Built-in Magnetic Starter — Automatically disengages electric

power to disposer if power loss occurs. Disposer must be

restarted.

Post Water Flush — Adjustable time delay relay automatically

permits water to flush sewer lines clear after disposer has

been turned off, eliminating sewer clogging.

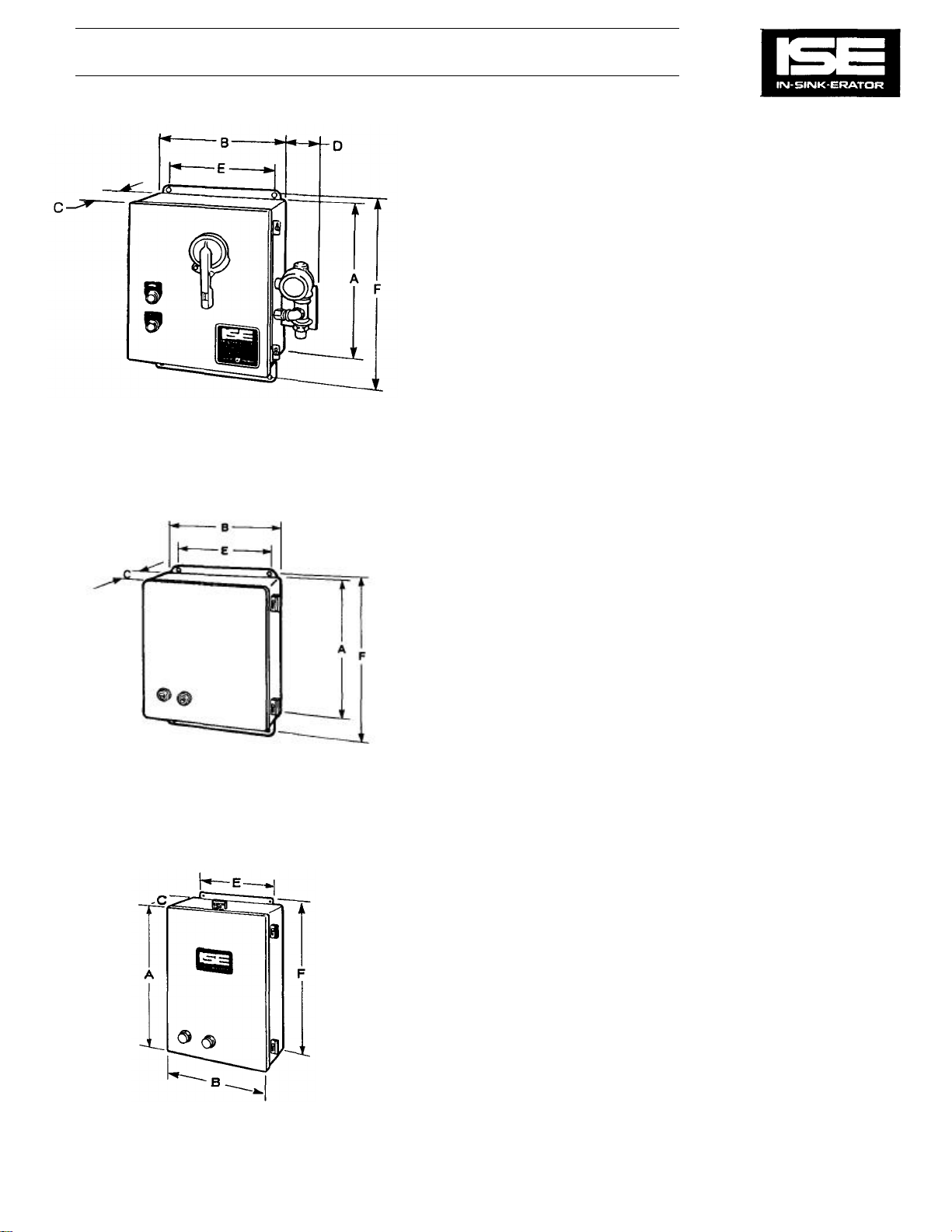

DIMENSIONS

Models CC-101 A and CC-101B

Length (A) 14"

Width (B) 12"

Depth (C) 6"

Width (D) 3-1/2"

5/16" Bolt Holes, Center to Center (E) 10"

5/16" Bolt Holes, Center to Center (F) 14-11/16"

Models CC-101C. CC-101D, and CC-101E

Length (A) 14"

Width (B) 12"

Depth (C) 6"

5/16" Bolt Holes, Center to Center (E) 10"

5/16" Bolt Holes, Center to Center (F) 14-11/16"

Other Features:

—Main flow control valve and solenoid valve mounted elsewhere in water line

Model CC-101G

Length (A) 15"

Width (B) 10"

Depth (C) 6"

5/16" Bolt Holes, Center to Center (E) 8"

5/16" Bolt Holes, Center to Center (F) 15-5/8"

Figure 4-3. CC-101G

3-2

Page 6

WIRING DIAGRAMS SECTION 4

The standard disposer motor voltages are 115/208/230 volts for

single phase electrical power and 208/230/460 volts for three phase

electrical power.

NOTE

Three phase contactors require three sets of contacts to carry line

voltage to the disposer, while single phase contactors require four

Circuitry and parts function on all control centers are identified

within their respective models. This applies to all component parts

controlled by or on the secondary voltage side of the transformer,

whether it is a 1 phase or 3 phase control center.

The wiring (circuitry) to the line voltage connections on the Reversing

contactors are identical on all 3 phase (only) contactors. The wiring

(circuitry) to the line voltage connections on the Reversing contactors

are identical on all 1 phase (only) contactors.

sets. Two identical contactors are utilized in every control center to

perform the function of reversing the disposer motor rotation.

Therefore, the wiring diagrams in this section (Figs. 4-12 through 4-

19) show 3 phase contactors but can be used to diagnose or trace

circuitry for 1 phase or 3 phase control centers, keeping in mind that

only the contactors are different from 1 phase to 3 phase. Refer to

Figs. 4-10 and 4-11 for 1 phase contactor connections.

All electrical connections must conform to local codes. Be

certain that all IN-SINK-ERATOR disposers and control centers

are carefully and permanently grounded.

CAUTION

ELECTRICAL INSTALLATION

BEFORE ANY ELECTRICAL WORK IS PERFORMED, REMOVE LINE

POWER FROM THE DISPOSER CONTROL CENTER BY TURNING OFF

THE CIRCUIT BREAKER. USE A VOLTMETER OR CIRCUIT TESTER TO

ENSURE THAT POWER IS OFF BEFORE PROCEEDING.

disposer motor voltage and phase must be the same as the

electrical supply. Check name-plates on both units for ratings.

All connections must conform to local codes. Ground the

disposer control center, the disposer, and all control boxes.

The following wiring diagrams are included to illustrate the electrical

connections for each standard model of disposer control center and

disposer motor. For each standard model of disposer control center,

wiring diagrams are shown to illustrate the most typical configurations. The wiring diagrams include motor connections. Since various

options can be custom ordered for a control enter, the wiring

diagrams for a particular model of control center do not reflect every

possible option. Additional wiring diagrams illustrating various special

(nonstandard) configurations of each model are provided in section

10 of this manual.

WARNING

CAUTION The control center and

4-1

Page 7

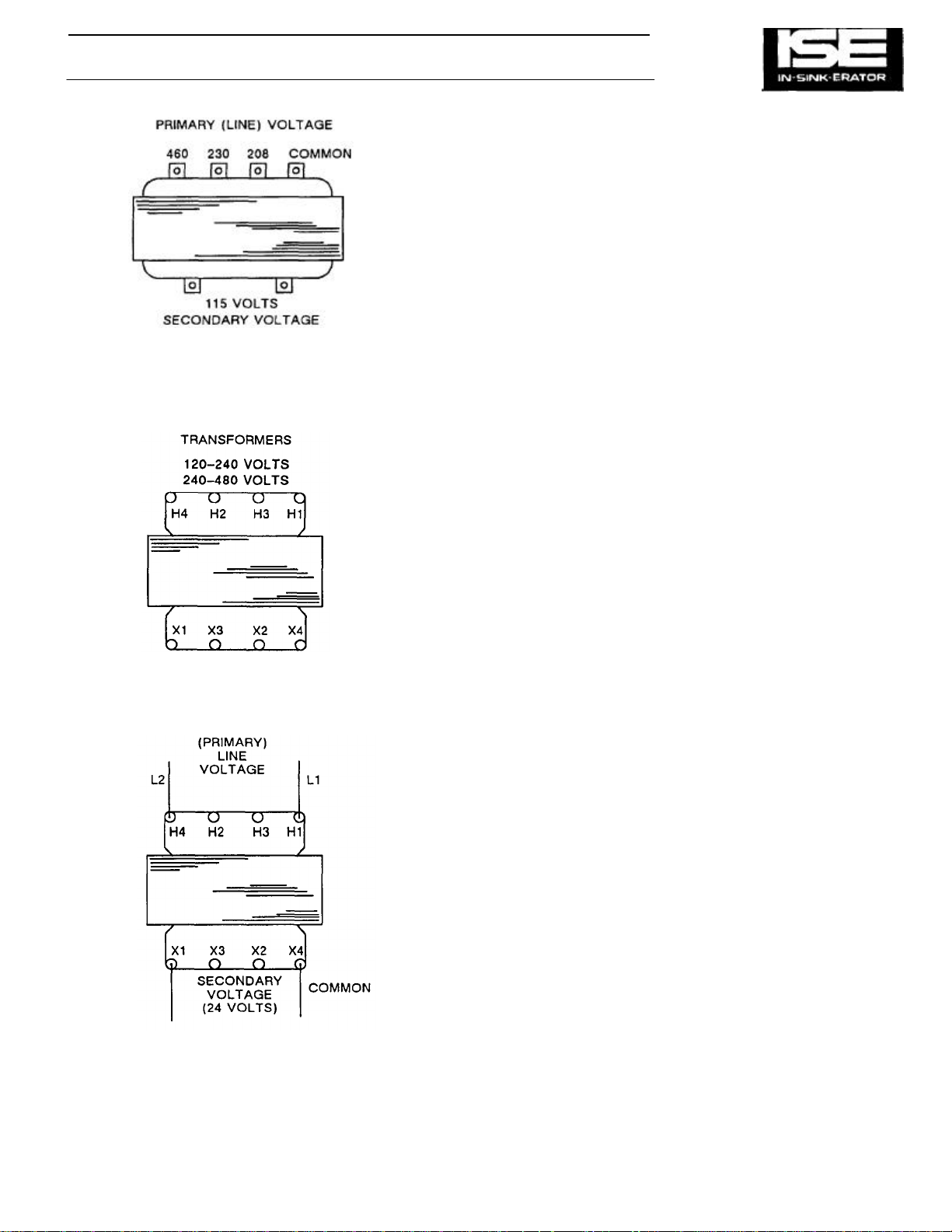

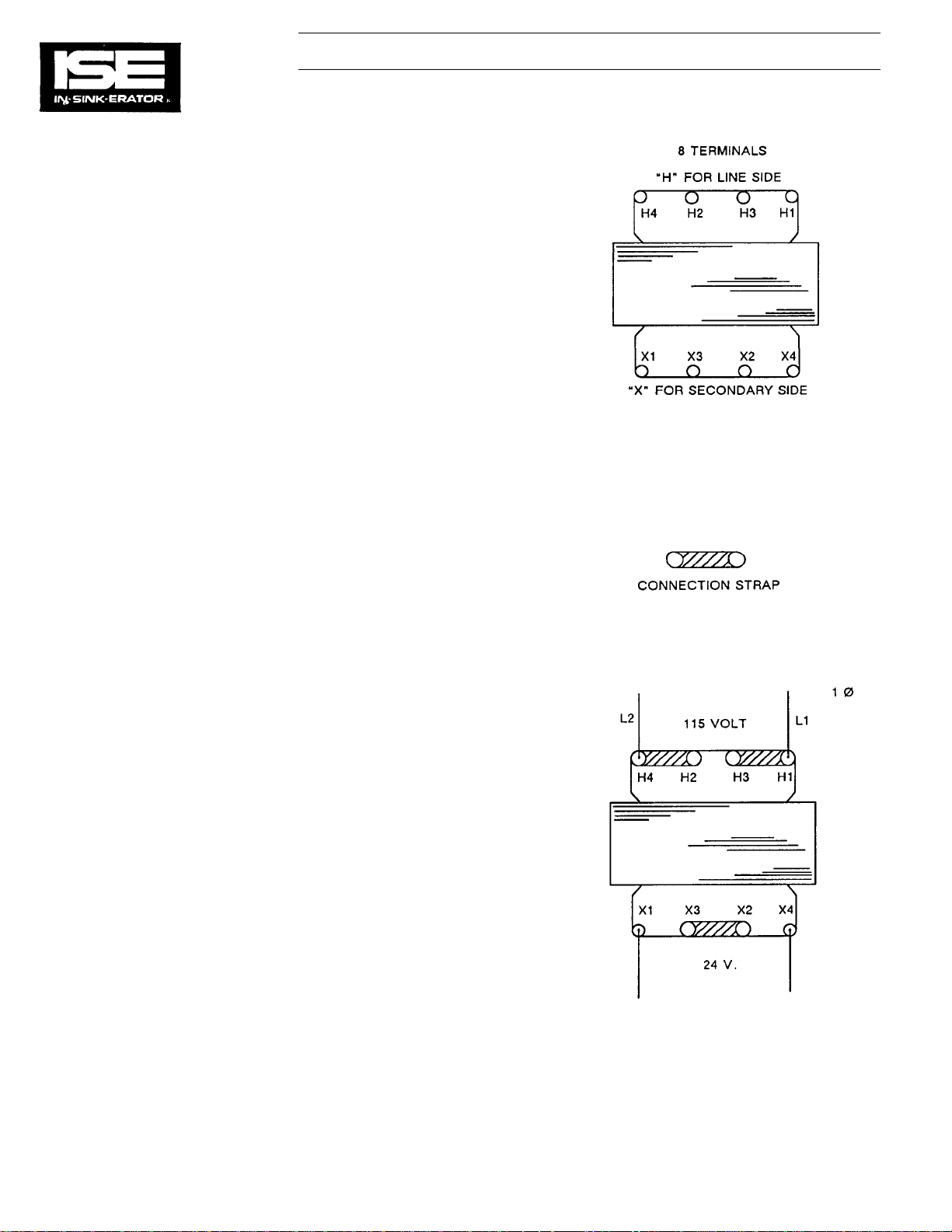

TRANSFORMER CONNECTIONS FOR

SECTION 4 WIRING DIAGRAMS (Cont'd)

Figure 4-3. 115 V Transformer Taps.

CONTROL CENTERS WITH 115 V CONTROL

CIRCUIT

Power lines carry line voltage to the primary terminals (also

called "taps") of the transformer. Line L2 is connected to the

common (ground) tap with Line L1 connected to the tap

coinciding with the line voltage.

The secondary taps on these transformers will always

supply 115 V ac to the load. This secondary voltage

operates the component parts in the control circuit. These

transformers are rated at 100 VA (Volt/Amperes), and can

be used for any 208 V/230 V/460 V incoming line. See

Figure 4-3.

TRANSFORMER CONNECTIONS FOR

CONTROL CENTERS WITH 24 V CONTROL

CIRCUITS

All control centers with 24 V secondary voltage require one

of two transformers. They appear identical. The specification

decal on the transformers will show 120 - 240 V or 240 -480

V (connections for line voltage). There is no reference to 208

V, but it is to be understood that 208 V connections will be

the same as 240 V. Whenever the recommended

transformer is used wiring diagrams furnished with the Control Center or in this manual apply.

Both 24 V secondary tap transformers can be used with 240

or 208 V inputs, but the terminal connections will change

and Control Center wiring diagrams may not necessarily apply. Whenever in doubt, refer to and use the connections

shown on the transformer specification decal. Connections

for input (primary) and output (secondary) voltages are the

same in all cases. See Figure 4-4 for connections.

RATED AT 100 VA

Figure 4-4. 24 V Transformer Taps.

4-2

Page 8

WIRING DIAGRAMS (Cont'd) SECTION 4

Terminal Connections

Transformer tap connections vary and are made in accordance with the applied line voltage. A conductive connection strap is normally used but 12 ga. wire can be

substituted (see Fig. 4-5).

Connections

Shown are the standard connections when the recommended

transformer is used. Refer to the illustrated parts list for specific

Control Centers. The voltage and phase of the Control Center

must be known. Secondary voltage for Figs. 4-5 through 4-8 is

24 V.

Figure 4-5. 115 V, 1 Phase.

4-3

Page 9

*SEE WIRING DIAGRAM IN DISPOSER

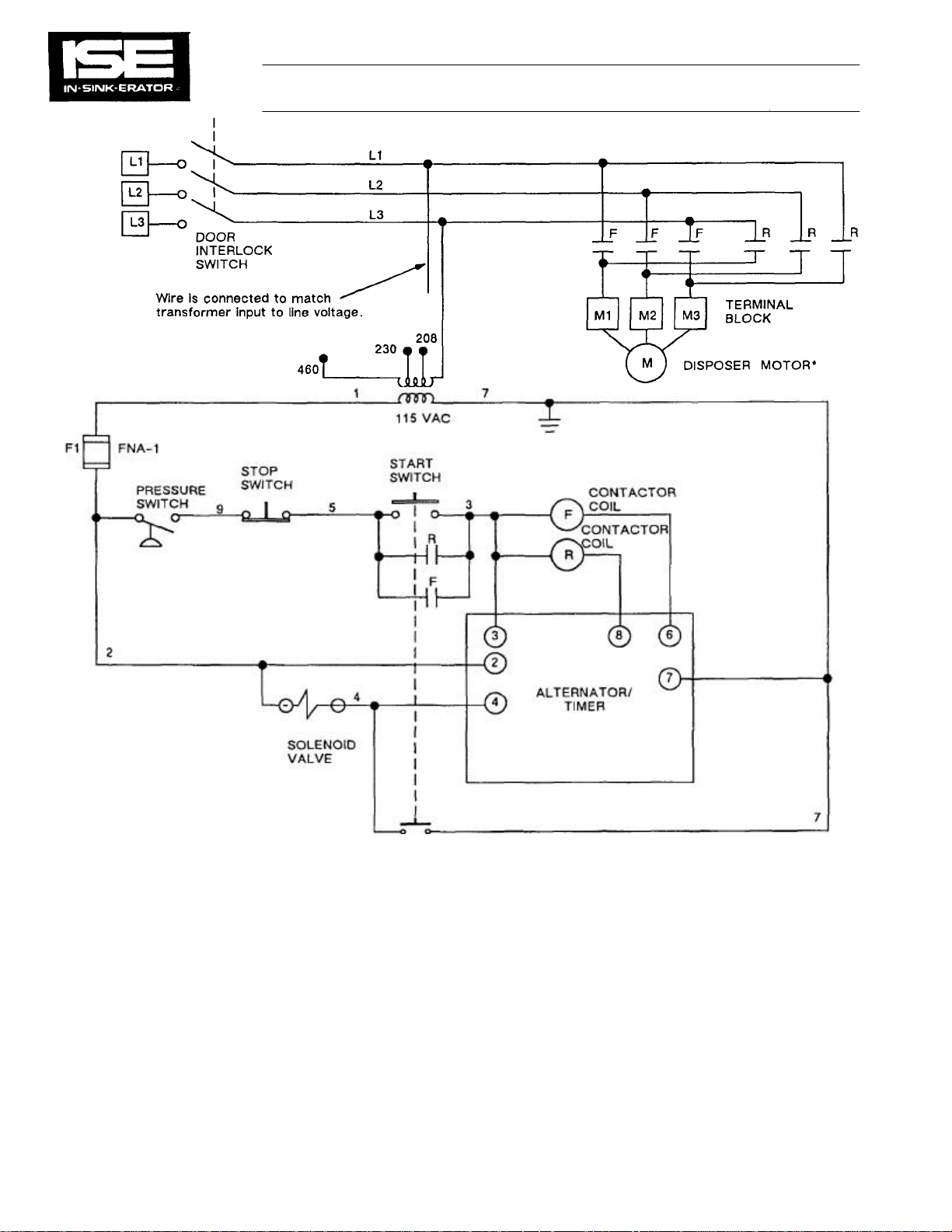

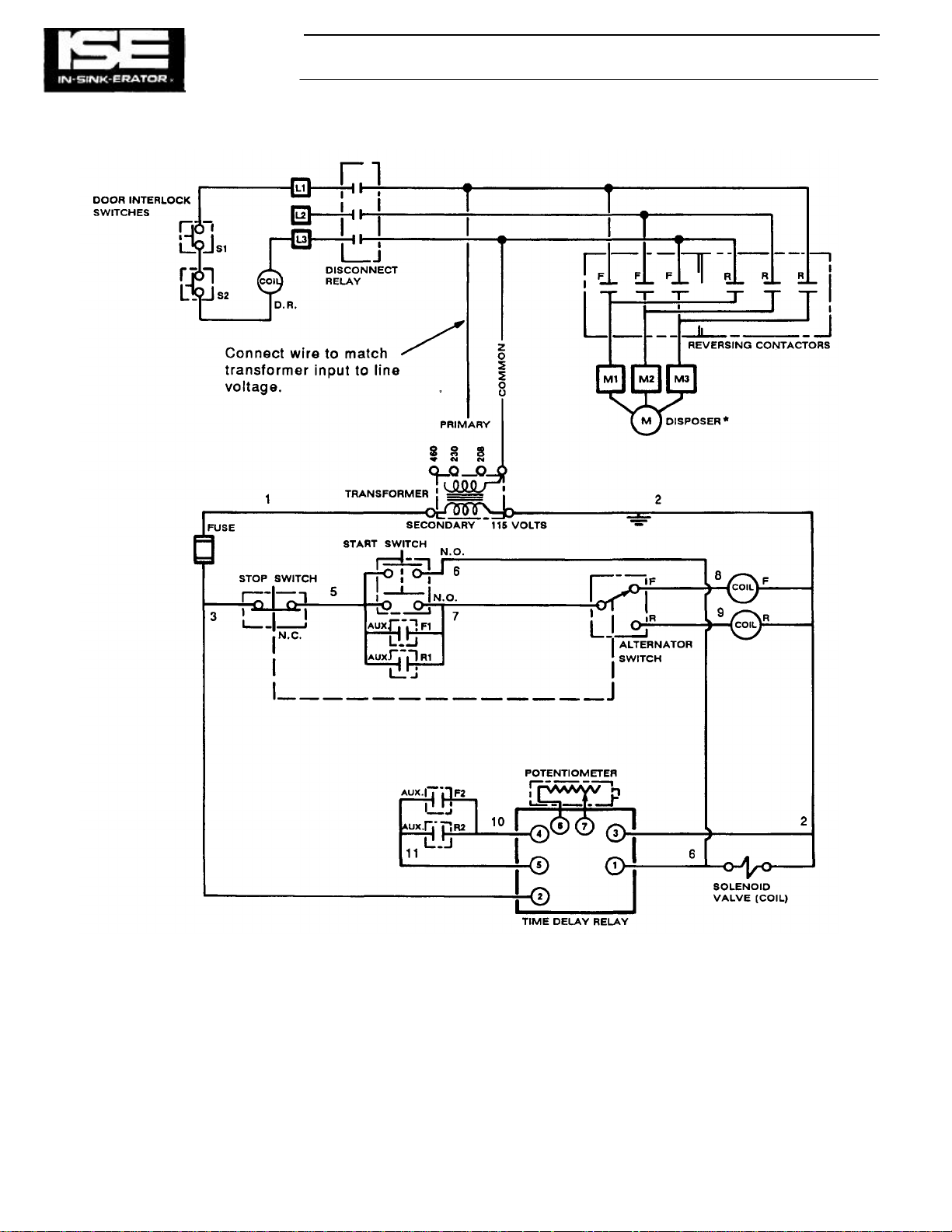

Figure

4-12.

Model CC

-

101A Wiring Diagram.

WIRING DIAGRAMS (Cont'd) SECTION 4

TERMINAL BOX FOR PROPER

CONNECTIONS OR FIG. 5-2.

4-7

Page 10

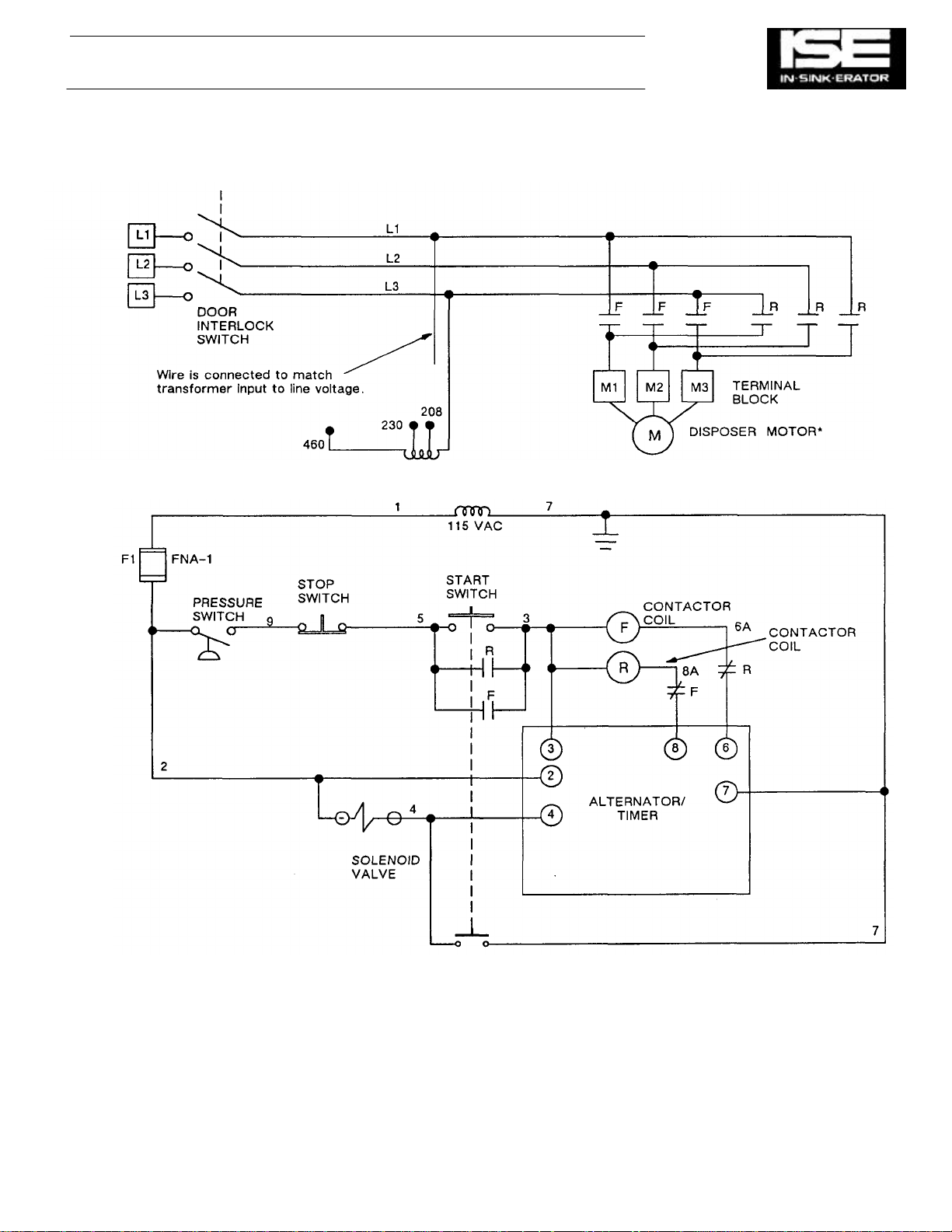

*SEE WIRING DIAGRAM IN DISPOSER

SECTION 4 WIRING DIAGRAMS (Cont'd)

TERMINAL BOX FOR PROPER

CONNECTIONS OR FIG. 5-2.

4-8

Figure 4-13. Model CC-101A Wiring Diagram (with Contactor Interlocks).

Page 11

*SEE WIRING DIAGRAM IN

Figure

4-14.

Model CC

-

101B Wiring Diagram.

WIRING DIAGRAMS (Cont'd) SECTION 4

DISPOSER TERMINAL BOX FOR

PROPER CONNECTIONS OR FIG.

5-2.

4-9

Page 12

SECTION 4 WIRING DIAGRAMS (Cont'd)

4-10

*SEE WIRING DIAGRAM IN DISPOSER

TERMINAL BOX FOR PROPER

CONNECTIONS OR FIG. 5-2.

Figure 4-15. Model CC-101B Wiring Diagram (with Auto-Shutoff Timer).

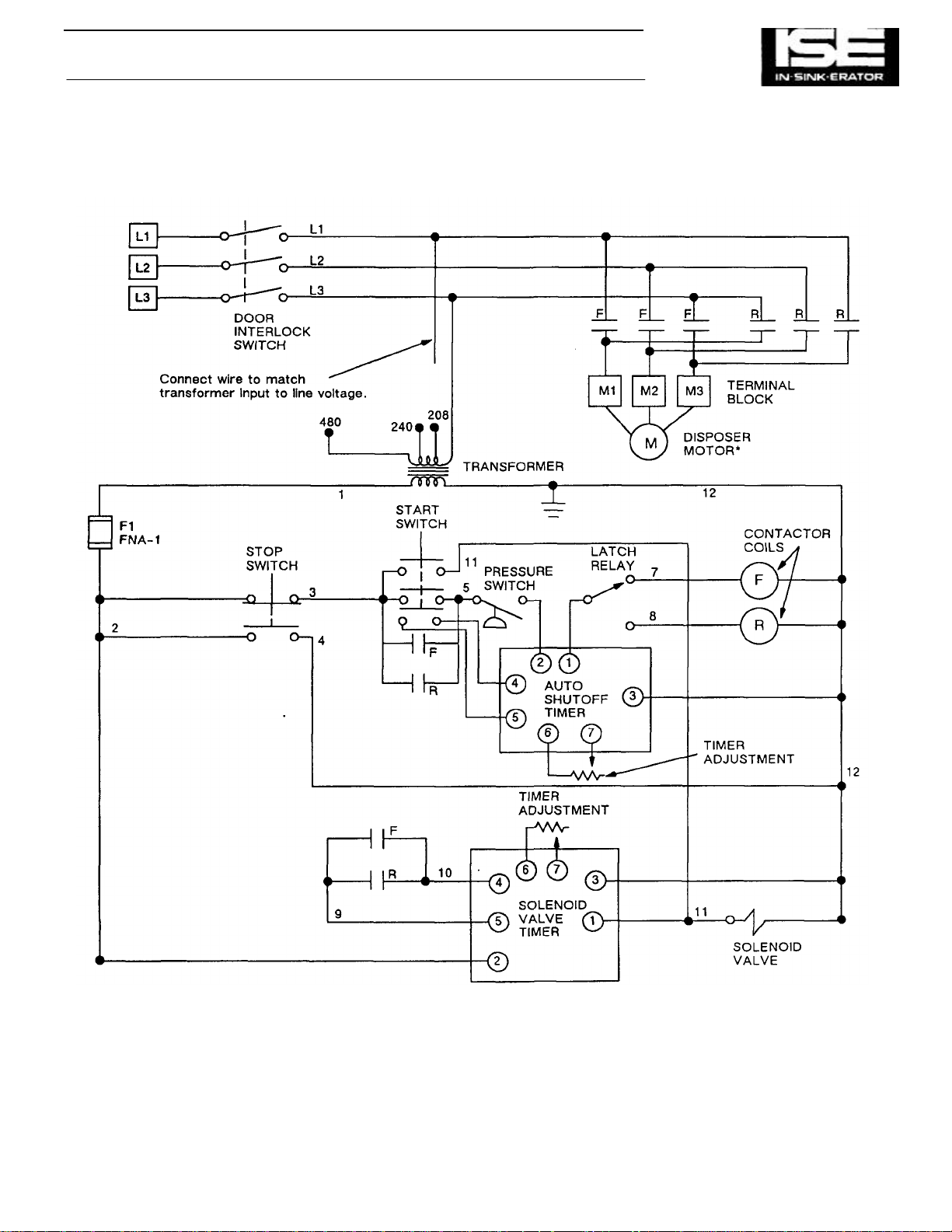

Page 13

WIRING DIAGRAMS (Cont'd) SECTION 4

*SEE WIRING DIAGRAM IN DISPOSER

TERMINAL BOX FOR PROPER

CONNECTIONS OR FIG. 5-5.

Figure 4-16. Modal CC-101C and CC-101D Wiring Diagram.

4-11

Page 14

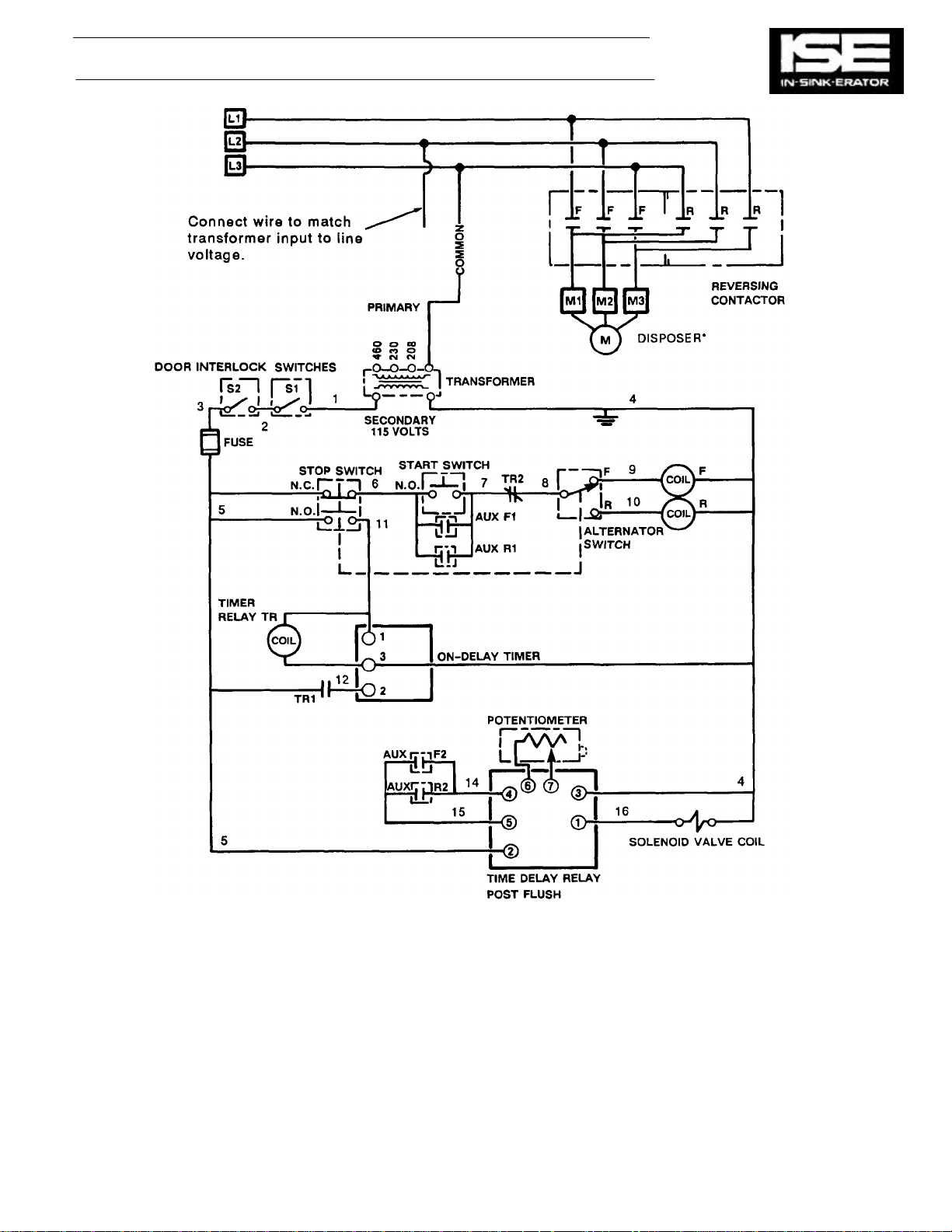

*SEE WIRING DIAGRAM IN

Figure

4-17.

Model CC

-

101E Wiring Diagram.

4-

12

SECTION 4 WIRING DIAGRAMS (Cont'd)

DISPOSER TERMINAL BOX FOR

PROPER CONNECTIONS OR FIG.

5-7.

Page 15

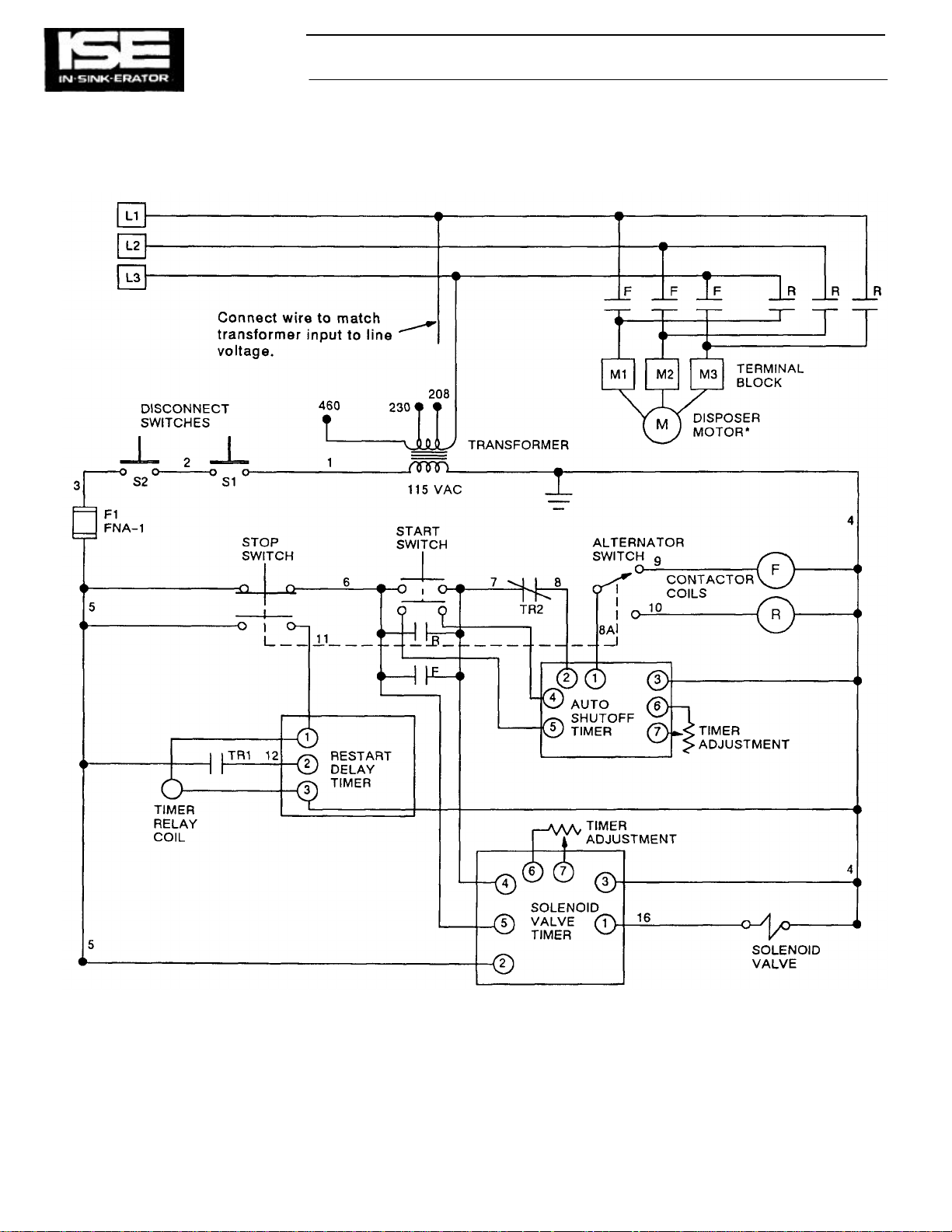

WIRING DIAGRAMS (Cont'd) SECTION 4

•SEE WIRING DIAGRAM IN DISPOSER

TERMINAL BOX FOR PROPER

CONNECTIONS OR FIG. 5-7.

Figure 4-18. Model CC-101E Wiring Diagram (with Auto-Shutoff Timer).

4-13

Page 16

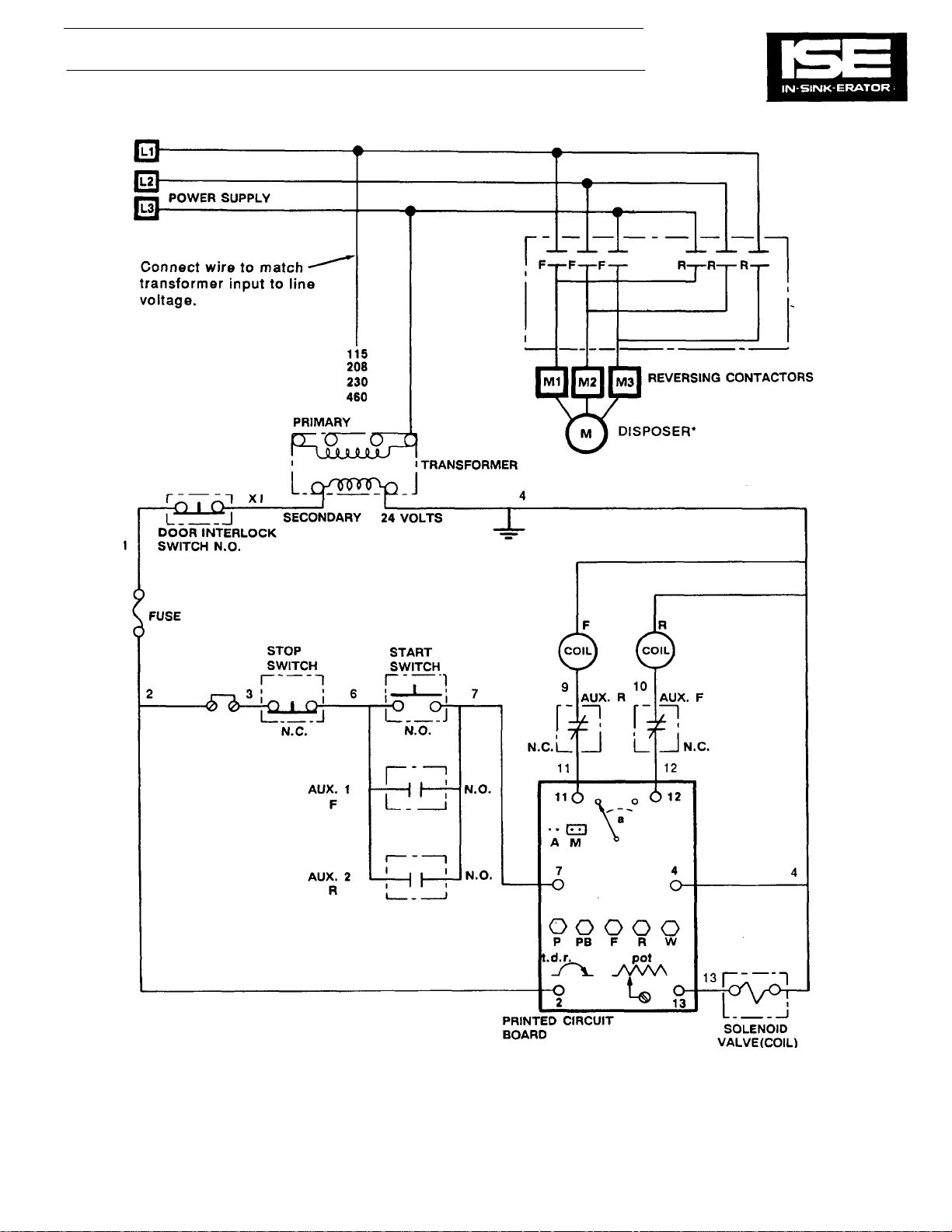

SECTION 4 WIRING DIAGRAMS (Cont'd)

•SEE WIRING DIAGRAM IN DISPOSER

TERMINAL BOX FOR PROPER

CONNECTIONS OR FIG. 5-9.

Figure 4-19. Model CC-101G Wiring Diagram.

4-14

Page 17

PLUMBING, MOTOR AND LINE VOLTAGE

208/230

VOLT

-3 0 460

VOLT

-3 0

Figure

5-2.

Electrical Connections

Figure

5-3.

Rotary Disconnect

CONNECTIONS

SECTION 5

Figure 5-1. CC-101A & B General Layout.

For CC-101A & CC-101B.

MOTOR CONNECTIONS FOR

For CC-101A & CC-101B.

7 & 1 ———— M1 1 —————— M1

8 & 2 ———— M2 2 —————— M2

3 & 9 ———— M3 3 —————— M3

10 & 4 ———— TT 4 & 7 ———— TT

5 & 1 ———— TT 5 & 8 ———— TT

12 & 6 ———— TT 3 & 9 ———— TT

TS = TAPE SEPARATELY 11 - TS

TT = TIE TOGETHER

NOTE: OLD 208 VOLT 3 0 MOTORS HAD ONLY 3 LEAD WIRES

ATTACHED TO TERMINAL BLOCK M1, M2 & M3.

10 - TS

12 - TS

These control centers have rotary line disconnect switches directly

connected to the incoming line.

The terminal blocks accommodate the motor connections.

5-1

Page 18

PLUMBING, MOTOR AND LINE VOLTAGE

7 & 1

————

M1

1

——————

M1

SECTION 5

CONNECTIONS (Cont'd)

Figure 5-4. CC-101C & D General Layout.

ELECTRICAL CONNECTIONS TO TERMINAL

BLOCK IN CONTROL CENTER

MOTOR CONNECTIONS FOR

20B/230 VOLT-3 0 460 VOLT-3 0

8 & 2 ———— M2

3 & 9 ———— M3

10 & 4 ———— TT

5 & 1 ———— TT

12 & 6 ———— TT

TS = TAPE SEPARATELY

TT = TIE TOGETHER

Figure 5-5. Electrical Connections For CC-101C & CC-101D.

5-2

2 —————— M2

3 —————— M3

4 & 7 ———— TT

5 & 8 ———— TT

3 & 9 ———— TT

10 - TS

11 - TS

12 - TS

Page 19

PLUMBING, MOTOR AND LINE VOLTAGE

3 & 9

————

M3 3 ——————

M3

10 & 4

————

TT

4 & 7

————

TT

5 & 1

————

TT

5 & 8

————

TT

12 & 6

————

TT

3 & 9

————

TT

10 - TS

TS = TAPE SEPARATELY

11 - TS

CONNECTIONS (Cont'd)

Figure 5-6. CC-101E General Layout.

SECTION 5

SINGLE PHASE THREE PHASE

MOTOR CONNECTIONS FOR

208/230 VOLT-3 0 460 VOLT-3 0

7 & 1 ——— M1

8 & 2 ———— M2

ELECTRICAL CONNECTIONS TO TERMINAL

BLOCK IN CONTROL CENTER

1 —————— M1

2 —————— M2

TT = TIE TOGETHER

12 - TS

Figure 5-7. Electrical Connections For CC-101E.

5-3

Page 20

PLUMBING, MOTOR AND LINE VOLTAGE

SECTION 5

CONNECTIONS (Cont'd)

Figure 5-8. CC-101G General Layout.

MOTOR CONNECTIONS FOR

208/230 VOLT-3 0 460 VOLT-3 0

7 & 1 ———— M1

8 & 2 ———— M2

3 & 9 ———— M3

10 & 4 ———— TT

5 & 1 ——— TT

12 & 6 ———— TT

TS = TAPE SEPARATELY

TT = TIE TOGETHER

5-4

Figure 5-9. Electrical Connections For CC-101G.

1 —————— M1

2 —————— M2

3 —————— M3

4 &7 ———— TT

5 & 8 ———— TT

3 & 9 ———— TT

10 - TS

11 - TS

12 - TS

Page 21

SUBPANEL REMOVAL AND REPLACEMENT SECTION 6

GENERAL

This section provides the information required for the removal and replacement of the subpanel in the disposer

control center enclosure. The subpanel is the flat piece

of sheet metal inside the enclosure that most of the

components are mounted on. Most components are

secured with screws and can be changed without

removing the subpanel. However, a few components

are secured with screws to a nut on the back of the

subpanel and require that the panel be removed to

remove the component. Also, it is sometimes necessary

to remove the subpanel to retrieve lost fasteners.

Differences between control center models sometimes

require slight differences in the procedures. The

changes are described when necessary.

REMOVAL PROCEDURE

WARNING

BEFORE PERFORMING ANY REPAIRS ON THE

DISPOSER OR THE DISPOSER CONTROL CENTER, BE

SURE TO TURN OFF THE MAIN POWER AT THE

DISCONNECT, CIRCUIT BREAKER OR FUSE BOX. LABEL

AND LOCK THE CIRCUIT OPEN. USE A METER OR

ELECTRICAL TESTER TO ENSURE THAT POWER IS OFF

BEFORE PERFORMING ANY REPAIRS.

1. Turn off power line to disposer control center. Label

and lock the circuit open.

2. For units equipped with door interlock switch, turn

door interlock switch to OFF position.

3. Loosen screws securing enclosure door clamps and

open door.

NOTE

Before disconnecting any wire, write down its location. You

will need to refer to It when reassembling the disposer control

center.

NOTE

Some units have plastic safety shields covering the terminals

of some components. On units so equipped, remove the shield

(s) before disconnecting wires from those components.

4. Disconnect power line wires from contactor or

disconnect relay.

5. Disconnect and separately insulate disposer motor

wires from terminal block.

6. Disconnect wires from start switch terminals.

7. Disconnect wires from stop switch terminals.

8. On units so equipped, cut cable tie securing stop

switch/start switch wire harness to enclosure.

9. Disconnect solenoid valve wires from terminal block.

10. On units equipped with pressure switch, disconnect

pressure switch wires.

11. On units equipped with disconnect switch (es),

disconnect wires from disconnect switch terminals.

6-1

Page 22

SECTION 6

SUBPANEL REMOVAL AND

REPLACEMENT (Cont'd)

12. Remove screws securing panel to enclosure.

13. Carefully remove panel from enclosure. It may be

necessary to tilt the panel somewhat to remove it

from the enclosure.

NOTE

Some units have a plastic safety shield over the terminals of

the door interlock switch or disconnect contactor. On units so

equipped, the safety shield must be removed before the

power line wires can be disconnected.

REASSEMBLY PROCEDURE

WARNING

BEFORE PERFORMING ANY REPAIRS ON THE

DISPOSER OR THE DISPOSER CONTROL CENTER. BE

SURE TO TURN OFF THE MAIN POWER AT THE

DISCONNECT, CIRCUIT BREAKER OR FUSE BOX.

LABEL AND LOCK THE CIRCUIT OPEN. USE A METER

OR ELECTRICAL TESTER TO ENSURE THAT POWER IS

OFF BEFORE PERFORMING ANY REPAIRS.

1. Make sure power line to disposer control center is

still turned off.

2. Insert panel in enclosure and position panel so that

mounting holes in panel are aligned with standoffs

(mounting posts) in enclosure.

3. Secure panel to enclosure with 4 screws.

4. Connect solenoid valve wires.

5. On units equipped with a pressure switch, connect

pressure switch wires.

6. On units equipped with disconnect switch (es),

connect wires to disconnect switch terminals.

7. If cable tie was cut during disassembly procedure,

replace cable tie.

8. Connect wires to start switch terminals.

9. Connect wires to stop switch terminals.

10. Connect disposer motor wires.

11. Connect power line wires.

12. On units equipped with plastic safety shields,

replace the safety shield over the terminals.

13. Close and secure enclosure door.

6-2

Page 23

COMPONENT DESCRIPTION SECTION 7

GENERAL

This section provides information on the function of the

component parts of the control center. Photographs of the

individual components are provided, with a description accompanying each one. For some components, more than one

photograph is provided in order to illustrate minor component

changes from one model to the next. This section also calls out

the location of each component on the schematic diagram.

Note that no one model of disposer control center contains all

the components listed in this section. The components used in

a particular control center can be determined by looking at the

wiring diagram on the inside of the control center enclosure

door.

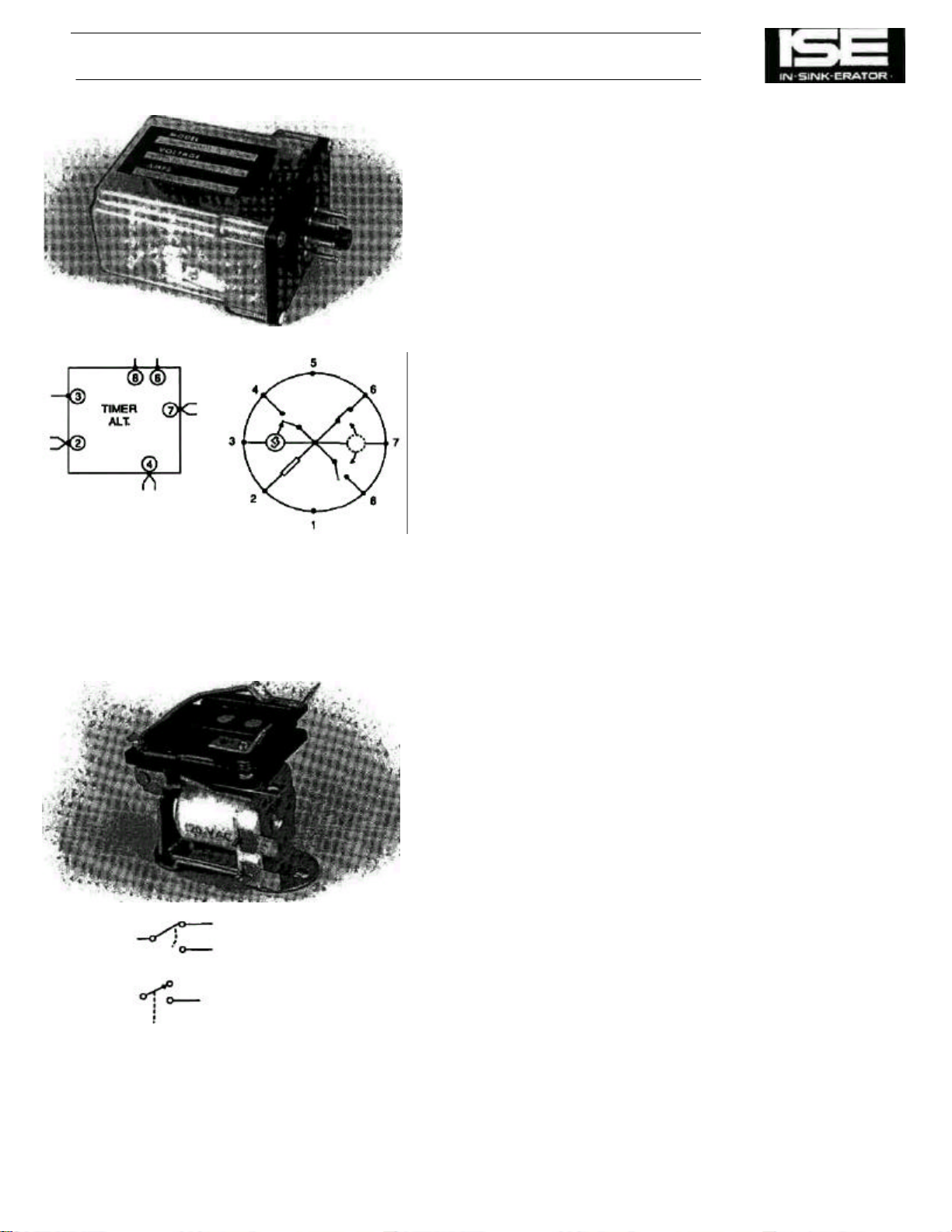

Transformer

The transformer steps down the higher voltage from the power

line to a relatively low 115 volts (24 volts for some models).

This lower voltage is used for control purposes to power the

controlling components, which may include a reverser/timer, a

latch relay coil, a contactor coil, a solenoid valve, a solenoid

valve timer, a restart delay timer, a timer relay coil, a control

circuit board, and an auto shutoff timer.

Line voltage is applied to the primary winding (the top winding

of the transformer as shown on the wiring diagram), and the

control voltage (115 or 24 volts) is taken from the secondary

winding (the bottom winding). The transformer has several

different input connections so that it can be used with different

line voltages.

Figure 7-1. Transformer.

7-1

Page 24

Figure

7-2

. Fuse.

SECTION 7 COMPONENT DESCRIPTION (Cont'd)

Fuse

The fuse, designated F1 on the wiring diagrams in this

manual, provides circuit protection in the event of a

short circuit or other electrical problem in the control

center. If too much current is used by the any

component in the control center, the fuse will blow,

opening the circuit. This fuse does not protect the

disposer motor from excessive current; the disposer

motor is protected by the circuit breaker or fuse in the

line that supplies power to it or by the overload

protector or the disposer motor.

On the wiring diagrams Inside the enclosure door,

some models designate the fuse by Its F1 reference

designation;

other models designate It only by its fuse type, e.g.

FNA 1 or FHA 2.

Door Interlock Switch (Line Disconnect)

NOTE

The door interlock switch is a safety device that

combines a disconnect switch with a mechanical door

latch. They are connected together by an "operating

rod" that is fastened to the interlock switch. The door

interlock switch must be turned off to open the control

center door. Turning the switch off disconnects the

power line from the disposer motor and from the

transformer that supplies power to the control circuits

in the control center. This is done as a safety

precaution. However, line voltage is still present on the

line terminals of the door interlock switch.

Figure 7-3. Door Interlock Switch.

7-2

Page 25

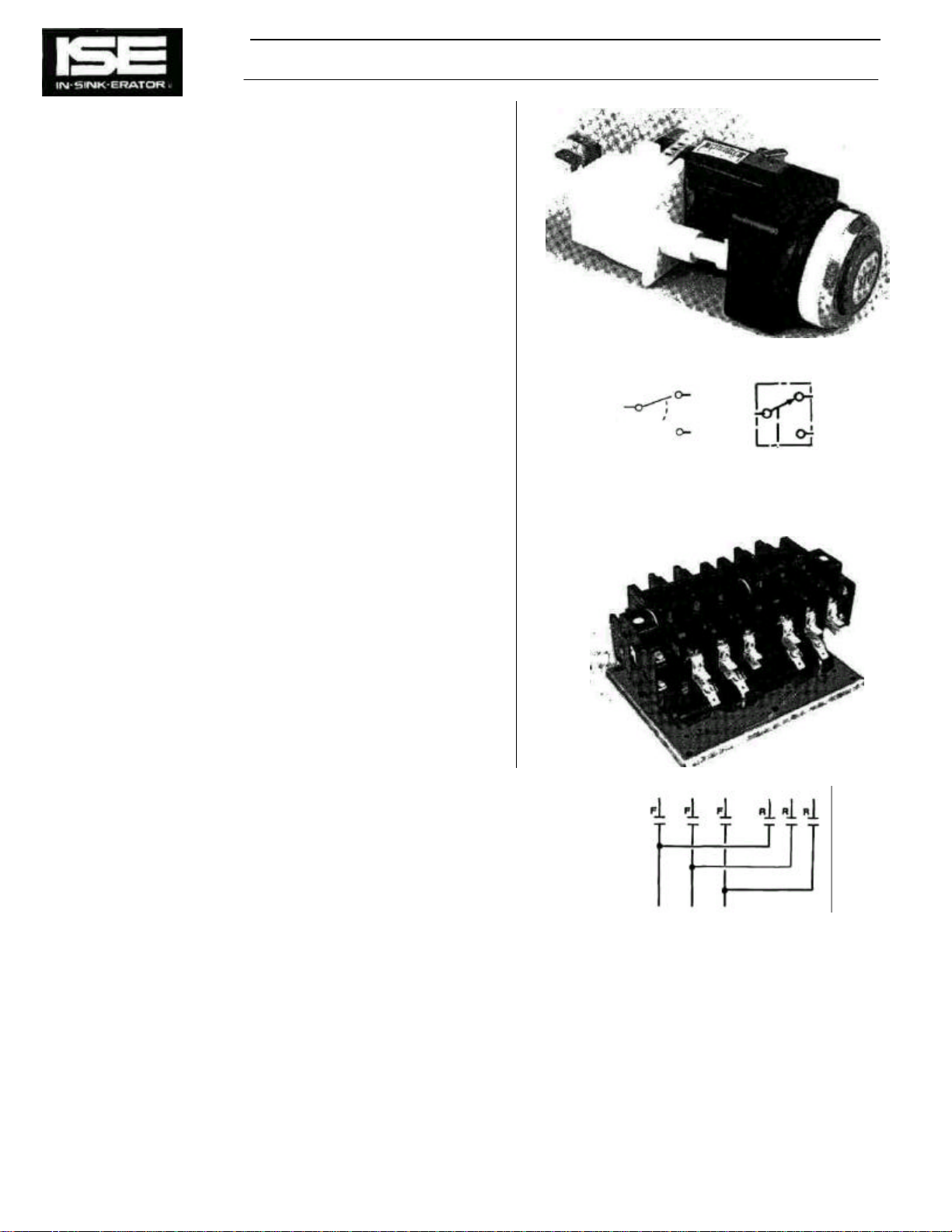

Disconnect Switch

COMPONENT DESCRIPTION (Cont'd) SECTION 7

Control centers that do not have a door interlock switch have

one or two disconnect switches mounted at the top of the

control center enclosure. The switch (es) are positioned so that

when the control center door is closed, the switch plunger(s)

are pushed in, closing the switch contacts. Disconnect switch

contacts are wired in series. When the control center door is

opened, the switch contacts open and the control voltage is

turned off, either directly by the disconnect switch or indirectly

by a disconnect relay on units so equipped. This turns off line

voltage to the disposer control center (for units with two

disconnect switches, only one disconnect switch has to be

open to disconnect the control voltage). However, line voltage

is still present at the power line terminals of some components

(refer to the appropriate wiring diagram to determine which

terminals remain live for any particular model).

Disconnect Relay (Line Disconnect)

Some models of disposer control center have a disconnect

relay that works in conjunction with disconnect switches. The

disconnect relay supplies line power to the disposer control

center. The disconnect relay coil is powered directly from the

power lines (line voltage). Power to the disconnect relay coil is

controlled by the disconnect switches. If either switch opens

(the control center door is opened), the disconnect relay coil is

turned off. This opens the relay, disconnecting line power to the

disposer control center. However, line voltage is still present on

the power line terminals of the disconnect relay even when the

contactor is open.

Figure 7-4. Disconnect Switch.

Figure 7-5. Disconnect Relay.

7-3

Page 26

Figure

7-6.

START Switch.

SECTION 7 COMPONENT DESCRIPTION (Cont'd)

START Switch

The START switch has one or more sets of contacts, depending upon

the model. When the START switch is pressed, all the contacts close.

Depending upon the model, the contacts send power to different

devices such as the contactor coil, the solenoid valve, the control

circuit board, and the auto shutoff timer. All functions required to start

the disposer are switched by the START switch contacts.

For all models, the START and STOP switches are each composed of a mechanical pushbutton connected to one or two

detachable sets of electrical contacts that open and close as

the pushbutton moves In and out. However, for the operational

description, the STOP and START switches are treated as

single components rather than as assemblies.

STOP Switch

The STOP switch has one or more sets of contacts, depending

upon the model. When the STOP switch is pressed the

contacts open or close, depending upon whether they are

normally open. or normally closed. One set of contacts opens

to interrupt power to the contactor coil (either directly or via the

control circuit board). Other contacts close to activate the

alternator/timer, latch relay, or the restart delay timer.

NOTE

NOTE

The start and stop switches are momentary contact pushbutton switches. Once pressed in, they will return to their original

position when released.

Figure 7-7. STOP Switch.

7-4

Page 27

Remote Control Station

Figure

7-8.

Remote Control Station.

COMPONENT DESCRIPTION (Cont'd) SECTION 7

This is a START switch and a STOP switch that can be mounted at a

distance from the control center, and are the same type and design of

those on the control center. The remote START switch contacts are

connected in parallel with the control center START switch contacts.

The remote STOP switch contacts are connected in series or parallel

with the control center STOP switch contacts, depending upon the

model. (Refer to the appropriate wiring diagram.)

Pressure Switch

The pressure switch prevents the disposer motor from operating if the

water pressure falls below approximately 15 p.s.i. If pressure drops

below this point, the pressure switch opens, interrupting power to the

component parts and shuts down the disposer. The START switch

must be pressed to restart the disposer. The pressure switch acts in

the same manner as a STOP switch.

Figure 7-9. Pressure Switch.

7-5

Page 28

Reverser/Timer

SECTION 7 COMPONENT DESCRIPTION (Cont'd)

The reverser/timer performs two different functions for the

disposer control center. It switches between the F and the R

contactor coils with every START/STOP cycle. This provides

the automatic reversing action for the disposer motor. It also

controls the water flow timing cycle. When the STOP switch is

pressed the reverser/timer begins the 5-minute water flow

timing cycle; it maintains power to the solenoid valve until the

cycle ends. Terminal 2 is the power input, terminal 7 is ground

(common), terminal 4 is the output that drives the solenoid

valve, and terminal 3 senses when each START/ STOP cycle

begins and ends. Terminals 6 and 8 connect to the F (forward)

and R (reverse) contactor coils respectively. Note that when the

START switch is pressed, the reverser/ timer connects the F or

R contactor coil internally to pin 7 to turn the contactor coil on.

Latch Relay (Reversing Relay)

The latch relay performs the automatic reversing of the disposer motor. This relay toggles ("flip-flops") or switches

between its two sets of contacts once per START/STOP cycle.

In one position, the latch relay directs voltage to the F (forward)

contactor coil, causing the disposer motor to run in the forward

direction. In the other position, the latch relay directs voltage to

the R (reverse) contactor coil, causing the motor to run in the

Figure 7-10. Reverser/Timer and Socket.

reverse direction. The latch relay changes position every time

the STOP switch is pressed.

Figure 7-11. Latch Relay.

7-6

Page 29

COMPONENT DESCRIPTION (Cont'd) SECTION 7

Alternator Switch (Reversing)

The alternator switch provides auto-reversing action for the

disposer motor by alternately selecting between its two outputs every START/STOP cycle. The alternator switch is mechanically linked with the STOP switch so that every time the

STOP switch is pressed, the alternator switch changes from

one output to the other. One output is connected to the F

contactor coil; the other is connected to the R contactor coil.

Contactors (Reversing Contactors)

Two contactors, F (forward) and R (reverse), direct line

voltage to the disposer motor. They are either mounted separately or on a mutual mounting plate. One connects the

disposer motor windings to run the disposer in the forward

direction. The other connects them to run in the reverse direction. Depending upon the model of disposer control center,

selection of the contactors is controlled by the reverser/ timer,

reversing switch, latch relay, or control circuit board. This

description does not include the auxiliary contacts or auxiliary

contact microswitches mounted to the reversing contactor.

When power is applied to one of the contactor coils, all of the

contacts associated with that coil close. They open again

when power is removed from the coil. Note that only one

contactor, F or R, can be energized at a time. All the F

contacts shown on the wiring diagram close when the F contactor coil is energized. All the R contacts close when the R

coil is energized. When the contactor pulls down engaging the

contacts carrying power to the motor, it also activates the

auxiliary contacts or auxiliary contact microswitches.

Since the application of the contacts differs from one model of

disposer control center to the next, it is necessary to refer to

the wiring diagram for each model to determine their

functions.

Figure 7-12. Alternator Switch (Is fastened to the

STOP switch).

Figure 7-13. Contactors.

7-7

Page 30

Figure

7-14.

Auxiliary Contacts.

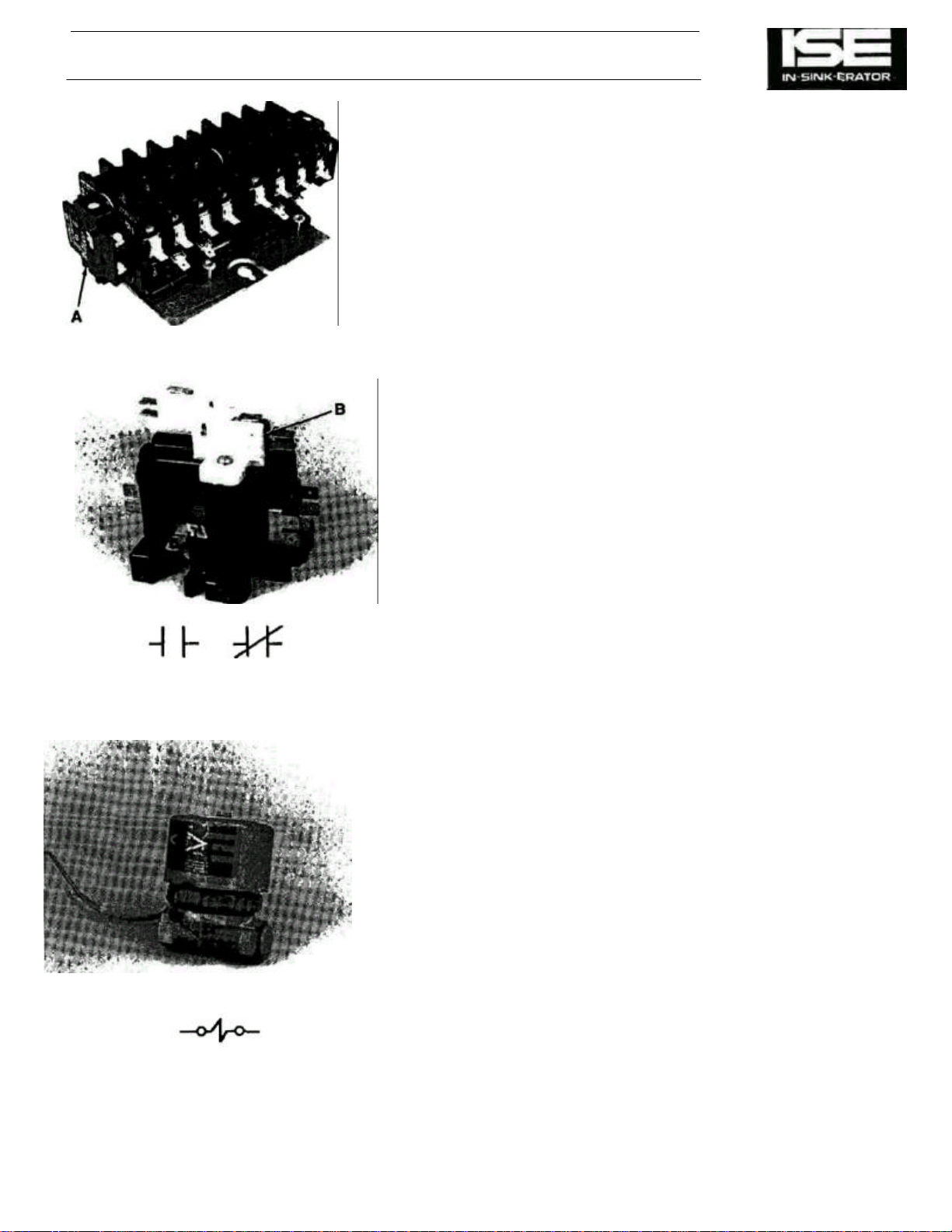

Auxiliary Contacts

SECTION 7 COMPONENT DESCRIPTION (Cont'd)

Auxiliary contacts are additional sets of contacts (block or

microswitches) mounted to and are activated in unison with the

mechanical action of the reversing contactors.

Auxiliary contact blocks are mounted to the end of the reversing

contactor. See Fig. 7-14 (A).

Auxiliary contact microswitches are mounted to the top of the

reversing contactor. See Fig. 7-14 (B).

Auxiliary contacts may contain one or two sets of contacts which may

have any combination of N.O. and/or N.C.

They are used in the control circuit to:

• Bypass the start button (switch) after the unit is started and the start

button is released, maintaining power to the control circuit.

• Activate power to the "F" or "R" coil in the reversing contactor.

• Engage the time delay relay controlling the solenoid

valve.

• "Lockout" the reversing contactor coil not engaged preventing it

from being activated.

• Maintain power to the time delay relay holding the solenoid valve

engaged after the stop button is pressed and the disposer motor

stops.

The model of the control center determines the type, the number of

and the function of the auxiliary contacts. Review the respective wiring

diagram.

Solenoid Valve

The solenoid valve is an electrically-controlled water valve. The

valve opens when power is applied to the solenoid valve coil,

allowing water to flow to the disposer. When power to the coil is

removed, the valve shuts off the water flow. The solenoid valve

is powered by the transformer in the disposer control center,

and is controlled by the reverser/timer, the time delay relay, or

a printed circuit board.

The solenoid valve must be installed with its arrow pointing

downstream or erratic water flow will occur.

Figure 7-15. Solenoid Valve.

7-8

Page 31

COMPONENT DESCRIPTION (Cont'd) SECTION 7

Solenoid Valve Timer (Time Delay Relay)

The solenoid valve timer is a solid state electronic device.

After the STOP switch is pressed the disposer motor stops

but, the solenoid valve timer supplies power to the solenoid

valve for a defined time (which can be adjusted by a potentiometer) to provide water to the disposer which helps reduce

drain clogging. When the water flow timing cycle ends, the

solenoid valve timer removes power from the solenoid valve,

shutting off the flow of water.

Potentiometer

The potentiometer is a device with an adjustable screw or

stem used to control the time-out of the time delay relay. It is

connected directly to the time delay relay and is adjustable

from 0 to 5 or 10 minutes depending on the model. Using a

small flat blade screwdriver and turning the screw fully

clockwise, will set the time-out to maximum.

Restart Delay Timer

The disposer motor should not be subjected to rapid reversals

in direction which could occur if the unit were turned on and

off rapidly a number of times, which causes' motor burnout. To

prevent this, the restart delay timer stops the disposer from

restarting within 5 seconds after it is turned off. The restart

delay timer is a non-adjustable electronic timer. When the

STOP switch is pressed, one pair of STOP switch contacts

(as shown on the wiring diagram) signals the restart delay

timer to begin the restart timeout period. When this happens,

the restart delay timer applies power to the timer relay coil.

The timer relay contacts open, preventing power from

reaching either contactor; this prevents the unit from being

started. When the restart timeout period ends, the restart

delay timer allows normal operation again.

Figure 7-16. Solenoid Valve Timer and Potentiometer.

Figure 7-17. Restart Delay Timer.

7-9

Page 32

Figure

7-18.

Timer Relay.

SECTION 7 COMPONENT DESCRIPTION (Cont'd)

Timer Relay

This time relay has several sets of contacts which can N.O., N.C., or

both. The contacts open or close when the coil in the relay is

activated.

This relay works in conjunction with the restart delay timer to

provide restart delay protection control for the disposer motor.

When the STOP switch is pressed, the bottom STOP switch

contacts close, supplying power to the restart delay timer and

the timer relay coil (TR). The energized coil closes the TR1

contacts, supplying power to terminal 2 of the restart delay

timer. This signals the restart delay timer to maintain power to

the timer relay coil (via terminal 1) until the restart timeout

period expires. During the restart timeout period, the TR2

contacts open to prevent current from flowing through the

reversing contactor coils, thus preventing operation of the

disposer motor. When the restart timeout period expires, the

restart delay timer removes the power from terminal 1. The TR

relay then returns to normal, opening the TR1 contacts and

closing the TR2 contacts. When this happens, the disposer

can be started again.

7-10

Page 33

Control Circuit Board

Figure

7-19.

Control Circuit Board.

COMPONENT DESCRIPTION (Cont'd) SECTION 7

NOTE

This electronic circuit board contains the larger and bulkier time

delay relays, relays potentiometer and alternator found is earlier

model control centers. It is a totally self-contained unit and is

non-repairable.

This device controls the reversing contactor coils, the water flow

tinning cycle, the restart timeout period, and the auto shutoff

function for the control center. It also controls the auto reversing

for the disposer motor with every START/ STOP cycle.

Power from the transformer is supplied to the circuit board via

terminals 2 and 4. Terminal 4 is the common, or chassis

ground. Terminal 7 of the control circuit board is the START/

STOP switching input. When the input goes high (on), the

control circuit board starts the disposer motor and turns on the

solenoid valve to allow water to flow to the disposer. When the

input goes low (off), the control board stops the disposer,

begins the water flow timing cycle and begins the restart

timeout period.

Terminal 11 is the output line to the F (forward) contactor coil.

(Power is supplied to the F contactor coil via terminal 11 and

chassis ground, terminal 4.) This line is used to close the F

contactor, which runs the disposer motor in the forward

direction.

Terminal 12 is the output line to the R (reverse) contactor coil.

(Power is supplied to the R contactor coil via terminal 12 and

chassis ground, terminal 4.) This line is used to close the R

contactor, which runs the disposer motor in the reverse

direction.

Terminal 13 is the output line to the solenoid valve. (Power is

supplied to the solenoid valve via terminal 13 and chassis

ground, terminal 4.) This line is used to turn on the solenoid

valve, which allows water to flow to the disposer.

Flow Control Valve

The flow control valve is installed in the water supply line

between the solenoid valve and the disposer. When the solenoid valve is open, the flow control valve regulates the flow of

water to the disposer. By providing optimum water flow, it

prevents excessive water consumption while allowing adequate

water for proper disposer operation. The flow control valve

requires no electric power.

Disposer application requires a properly sized valve (3,5 or 10

G.P.M.) 3/4" N.P.T. It must be installed with the arrow on the

valve pointing downstream or the diaphragm in the valve will not

control proper water flow.

Figure 7-20. Flow Control Valve.

7-11

Page 34

SECTION 7 COMPONENT DESCRIPTION (Cont'd)

Auto Shutoff Timer

The auto shutoff timer is an adjustable electronic device that is

electrically the same as the solenoid valve timer. The auto

shutoff timer is connected so that once the disposer motor is

started, it will shut off automatically after a defined period of

time (the period may or may not be adjusted by a potentiometer). However, the motor will also stop at any time if the

STOP switch is pressed.

Figure 7-21. Auto Shutoff Timer.

7-12

Page 35

COMPONENT DESCRIPTION (Cont'd) SECTION 7

Pressure Switch

A pressure switch is an electrical switch whose contacts are activated

by water pressure.

A water line connected to the water fitting allows water pressure to

press against a diaphragm. This action overcomes the spring

tensioned disk behind the diaphragm, allowing the disk to make and

activate the switch contacts.

The pressure switch assures water flow to the disposer when it is

running. Whenever the water pressure diminishes, it is sensed by the

pressure switch and its contacts open shutting down the operation.

Pressure switches in control centers are preadjusted to close its

contacts at a water pressure of 15 P.S.I, or more.

A momentary pressure drop can cause the switch to drop out,

opening the circuit.

Figure 7-22. Pressure Switch.

7-13

Page 36

COMPONENT LOCATION SECTION 8

GENERAL

This section shows the location of each component for each standard

model of disposer control center. A separate photograph is provided

for each model.

CC-101 A

Figure 8-1. Model CC-101 A Disposer Control Center, Component Location Diagram. PARTS

LEGEND

Item No. Description

1 START Switch

2 STOP Switch

3 Disconnect Handle

4 Transformer

5 Fuse

6 Contactor, Reversing

7 Alternator-Timer

8 Water Solenoid Valve

9 Pressure Switch

10 Flow Control Valve

11 Operating Rod

12 Auxiliary Contacts

13 Line Disconnect Switch

8-1

Page 37

SECTION 8 COMPONENT LOCATION (Cont'd)

C-101 B

Figure 8-2. Model CC-101B Disposer Control Center, Component Location Diagram.

PARTS LEGEND

Item No. Description

1 START Switch

2 STOP Switch

3 Disconnect Handle

4 Transformer

5 Fuse

6 Contactor, Reversing

7 Latch Relay (Alternator)

8 Potentiometer

9 Line Disconnect Switch

10 Solenoid Valve

11 Pressure Switch

12 Flow Control Valve

13 Operating Rod

14 Auxiliary Contacts

15 Time Delay Relay

8-2

Page 38

COMPONENT LOCATION (Cont'd) SECTION 8

CC-101 C

Figure 8-3. Model CC-101C Disposer Control Center, Component Location Diagram.

PARTS LEGEND

Item No. Description

1 STOP Switch (w/Reverser Switch attached)

2 START Switch

3 Disconnect Switch

4 Transformer

5 Fuse

6 Contactor, Disconnect

7 Time Delay Relay

8 Potentiometer

9 Reversing Contactor

10 Auxiliary Contacts

8-3

Page 39

PARTS LEGEND

SECTION 8 COMPONENT LOCATION (Cont'd)

CC-101 D

Figure 8-4. Model CC-101D Disposer Control Center, Component Location Diagram.

Item No. Description

1 START Switch

2 STOP Switch (w/Reverser Switch attached)

3 Disconnect Switch

4 Transformer

5 Fuse

6 Auxiliary Contact Block

7 Time Delay Relay

8 Potentiometer

9 Disconnect Contactor

10 Contactor, Reversing

8-4

Page 40

COMPONENT LOCATION (Cont'd) SECTION 8

CC-101 E

Figure 8-5. Model CC-101 E Disposer Control Center, Component Location Diagram.

PARTS LEGEND

Item No. Description

1 START Switch

2 STOP Switch (w/Reverser Switch attached)

3 Disconnect Switch

4 Transformer

5 Fuse

6 Contactor, Reversing

7 Timer-On Delay

8 Time Delay Relay

9 Potentiometer

10 Relay

11 Auxiliary Contacts

12 Water Solenoid Valve (Not Shown)

Page 41

SECTION

8 COMPONENT LOCATION (Cont'd)

CC-101 G

8-6

Figure 8-6. Model CC-101G Disposer Control Center, Component Location Diagram.

PARTS LEGEND

Item No. Description

1 START Switch

2 STOP Switch

3 Disconnect Switch

4 Transformer

5 Fuse

6 Auxiliary Contact Block

7 Circuit Board

8 Terminal Block

9 Contactor, Reversing

10 Water Solenoid Valve (Not Shown)

Page 42

OPERATING SEQUENCE SECTION 9

GENERAL

This section describes the operating sequence of the IN-SINKERATOR Commercial Disposer Control Center and illustrates

the electrical operation with diagrams. The description is

written to apply to all control centers, with differences between

models noted as necessary. Differences between models are

best noted by referring to the schematic wiring diagrams that

are mounted on the inside of the door in each control center

enclosure.

NOTE

All models have some type of interlock or disconnect switch

that prevents operation of the disposer when the control center door is open.

1. The operator presses the START switch. The START

switch contacts close, supplying power to the F (forward) or R

(reverse) contactor coil. On some models, the power does not

go directly to the contactor coils from the switch, but instead

goes to a control circuit board that determines which contactor

coil will be energized.

Some models have a second set of contacts on the START

switch that supply power to the solenoid valve while the start

switch is pressed. When the START switch is released, power

to the solenoid valve is supplied by the reverser/ timer, the

solenoid valve timer, or the control circuit board, depending

upon the model.

Models equipped with an auto shutoff timer have an additional

pair of contacts on the START switch that signal the auto

shutoff timer to begin timing the auto shutoff cycle. (On all

models the disposer motor stops immediately when the STOP

switch is pressed, regardless of whether the unit has an auto

shutoff timer.)

NOTE

For models that have a pressure switch, the water pressure

must be at least 15 p.s.i. to keep the pressure switch closed or

the disposer motor will not run. If the water pressure Is less

than 15 p.s.i. the pressure switch contacts will open, preventing power from reaching the contactor coil.

NOTE

For the purpose of this description, operation is described with

the F contactor coil selected. However, operation Is the same

when the R coil is selected; the only thing that changes is the

disposer motor's direction of rotation. (The direction reverses

with every START/STOP cycle.) Energizing the F contactor

coil closes all the F contacts shown on the wiring diagram.

Energizing the R contactor coil closes all the R contacts. Only

one contactor can be closed at a time.

2. The energized contactor coil closes the contactor, causing

two things to happen:

a. Power is applied to the disposer motor through the F

contacts.

b. The F contact across the START switch closes, sup-

plying continuous power to the contactor coil. This

keeps the contactor closed after the START switch is

released. (This has the same effect as holding the

START switch in continuously.)

9-1

Page 43

SECTION 9 OPERATING SEQUENCE (Cont'd)

3. Solenoid valve power is maintained by the reverser/ timer,

the solenoid valve timer, or the control circuit board,

depending on the control center model.

This condition continues until the operator presses the STOP

switch.

4. The operator presses the STOP switch. The STOP switch

contacts open, interrupting power to the F contactor coil.

Some models have a second set of contacts on the STOP

switch that are used to supply power to the latch relay coil to

make it change from one state to another, or to signal a restart

delay timer to begin the restart timeout period.

On some models a reverser switch is mechanically linked to

the STOP switch. The reverser switch is used to alternately

select the F (forward) or R (reverse) contactor coil, which

determines the disposer motor's direction of rotation. The two

output terminals of the reverser switch are connected to the F

and R contactor coils. Every time the STOP switch is pressed,

the reverser switch changes from one output terminal to the

other.

Models with a restart delay timer have an additional set of

contacts on the stop switch that signal the restart delay timer to

begin the restart timeout period.

5. The F contactor coil releases (opens) the F contacts,

turning off power to the disposer motor.

6. The water flow timing cycle begins. During the water flow

timing cycle, solenoid valve power is maintained by the

reverser/timer, the solenoid valve timer, or the control

circuit board, depending on the control center model.

7. When the water flow timing cycle ends, the reverser/ timer,

the solenoid valve timer, or the control circuit board

removes power from the solenoid valve, shutting off the

flow of water to the disposer.

8. Operation is the same for the next START/STOP cycle,

except that the R contactor is energized instead of the F

contactor.

REVERSING

All CC-101 Series Commercial Disposer Control Centers

perform automatic reversing of the disposer motor with each

START/STOP cycle. The disposer operates effectively in either

direction, and the reversing action doubles the life of the

shredders in the disposer. The reversing can be accomplished

with a reverser/timer, a latch relay, an reverser switch, or a

control circuit board, depending on the control center model.

Although the components are different, they all perform

disposer motor reversing by changing state every

START/STOP cycle. Descriptions of these components are

provided in the Component Function section of this manual.

9-2

Page 44

COMPONENT TESTING AND REPLACEMENT SECTION 10

GENERAL

This section provides information on testing and replacement of all

the disposer control center components, including the solenoid valve

and the pressure switch. Component variations among the different

disposer control center models are noted in the procedures when

applicable. To simplify testing, these procedures test the components

in the circuit whenever possible. This eliminates having to remove

each component for testing.

Many of the test procedures require a voltmeter. Either a volt-ohm

meter (VOM), a digital multimeter (DMM), or a vacuum-tube

voltmeter (VTVM) may be used. All measurements are in AC volts

unless otherwise noted. Continuity testing (with ohm meter) can be

used - with line voltage off - to test components. Care must be taken

to set the meter to the correct setting (voltage or ohms) and range

BEFORE each measurement is taken. Failure to do so may destroy

the meter. (The expected voltage or resistance reading is listed in

each step where a voltage measurement is taken.) Also, be sure to

plug the meter test leads into their correct sockets on the meter; on

many meters, the lead sockets used for resistance measurements

are separate from the sockets used for voltage measurements.

WARNING

TESTING OF COMPONENTS IN THE CIRCUIT WITH POWER APPLIED

EXPOSES THE REPAIR TECHNICIAN TO DANGEROUS VOLTAGES. BE

VERY CAREFUL NOT TO TOUCH ANY WIRES OR TERMINALS THAT

MAY BE CARRYING HIGH VOLTAGE.

Each wire in the disposer control center is identified by a numbered

tag on the wire. (Red wires carry control voltage, black wires carry

line voltage.) The same numbers are shown on the wiring diagram.

Component terminal numbers provided in this section, unless

otherwise noted, refer to the identification number of the wire

connecting to a component terminal.

Many tests require that the door interlock switch or disconnect switch

(es) be defeated. Appropriate defeat procedures are provided at the

beginning of this section.

DOOR INTERLOCK SWITCH DEFEAT PROCEDURE,

MODELS CC-101A AND CC-101B

Perform this procedure when it is necessary to test any component

with the enclosure door open.

WARNING

THIS PROCEDURE DEFEATS THE DOOR INTERLOCK SWITCH

AND PLACES LINE VOLTAGES AND CONTROL VOLTAGES ON

NUMEROUS TERMINALS INSIDE THE DISPOSER CONTROL

CENTER. BE VERY CAREFUL NOT TO TOUCH ANY WIRES OR

TERMINALS INSIDE THE DISPOSER CONTROL CENTER

ENCLOSURE.

Figure 10-1. Defeating Door Interlock Switch.

10-1

Page 45

SECTION 10

COMPONENT TESTING AND

REPLACEMENT (Cont'd)

1. Turn off power line to disposer control center. Check

power inside control center to ensure that it is off.

2. Grasp shaft of door interlock switch with large pliers and

turn shaft counterclockwise until switch snaps into ON

position (See Figure 10-1).

3. When testing is complete, switch must be returned to

OFF position before enclosure door can be closed.

DISCONNECT SWITCH DEFEAT PROCEDURE,

MODELS CC-101C THROUGH CC-101G

Perform this procedure when it is necessary to test any

component with the enclosure door open.

THIS PROCEDURE DEFEATS THE DISCONNECT SWITCH (ES)

AND PLACES LINE VOLTAGES AND CONTROL VOLTAGES ON

NUMEROUS TERMINALS INSIDE THE DISPOSER CONTROL

CENTER. BE VERY CAREFUL NOT TO TOUCH ANY WIRES OR

TERMINALS INSIDE THE DISPOSER CONTROL CENTER

ENCLOSURE.

1. Turn off power line to disposer control center.

2. Place a small piece of plywood over plunger(s) of disconnect switch (es). Clamp wood to lip of enclosure,

holding the switch plunger(s) in (closed) position. (See

Figure 10-2). Ensure that clamp does not touch any wires

or connectors inside the enclosure.

Model CC-101G Control Centers have normally closed

switches that can be bypassed by moving switch leads from

the normally closed (N.C.) to the normally open (N.O.) terminal.

3. When testing is complete, be sure to remove wood and

clamp, or restore switch to the correct configuration.

WARNING

NOTE

Figure 10-2. Defeating Disconnect Switch.

10-2

Page 46

COMPONENT TESTING AND

SECTION

10

Figure

10-4.

Measuring Fuse Voltage.

REPLACEMENT (Cont'd)

TRANSFORMER TEST PROCEDURE. ALL

MODELS

1. Turn off power line to disposer control center. Check inside

enclosure to ensure that power is off.

2. Perform door interlock switch defeat procedure or disconnect switch defeat procedure as appropriate.

3. Turn on power line to disposer control center.

4. Measure voltage between two power line (black) wires

connected to primary winding terminals of transformer.

(See Figure 10-3.) Voltage should be same as power line

voltage. If voltage is 0, either power line is off or door

interlock/disconnect switch was not defeated properly.

Correct these conditions before proceeding to next step.

5. Measure voltage between two red wires on secondary

winding terminals of transformer. Voltage should be 115

volts (CC-101G 24 volts).

TRANSFORMER REPLACEMENT PROCEDURE, ALL

MODELS

1. Turn off power line to disposer control center.

2. Note location of all wires connected to transformer.

Disconnect wires.

3. Remove screws securing transformer to panel and remove

transformer.

4. Align replacement transformer with mounting holes and

secure to panel with screws.

5. Connect wires to proper transformer terminals. FUSE

Figure 10-3. Measuring Transformer Input

Voltage.

TEST PROCEDURE, ALL MODELS

1. Turn off power line to disposer control center.

2. Perform door interlock switch defeat procedure or disconnect switch defeat procedure as appropriate.

3. Turn on power line to disposer control center.

4. Measure voltage between chassis ground (any un-painted

metal surface on the disposer control center housing) and

one end of fuse, then between ground and other end of

fuse. (See Figure 10-4). Voltage should be 115 volts (24

volts for CC-101G) on either end of fuse. If one end is 0

volts, fuse is blown and should be replaced.

10-3

Page 47

SECTION 10

(Model CC-101A) (Model CC-101 B)

Figure 10-5. Measuring Voltage Across Door

Interlock Switch.

COMPONENT TESTING AND

REPLACEMENT (Cont'd)

FUSE REPLACEMENT PROCEDURE,

ALL MODELS

1. Turn off power line to disposer control center. Check for power

inside enclosure to ensure that power is off.

2. Remove fuse from spring-loaded holder using a cartridge

fuse puller (or equivalent).

3. Push replacement fuse into holder. DOOR INTERLOCK

SWITCH TEST PROCEDURE

1. Turn on power to disposer control center.

2. Measure voltage across one pair of disconnect switch

terminals. (See Figure 10-5). Voltage should be same as

line voltage.

3. Use pliers to carefully rotate door interlock switch to ON

position. Voltage should go to 0 volts.

4. Repeat steps 2 and 3 for other sets of contacts on door

interlock switch.

DOOR INTERLOCK SWITCH REPLACEMENT

PROCEDURE

1. Turn off power line to disposer control center. Check to

ensure that power is off in the enclosure.

2. Note location of wires connected to door interlock switch.

Disconnect wires.

3. Remove screws securing door interlock switch to panel.

Remove door interlock switch.

4. Put replacement switch in position on panel and secure

with screws.

5. Connect wires to proper terminals on replacement switch.

10-4

DISCONNECT SWITCH TEST PROCEDURE,

MODEL CC-101A AND CC-101B

1. Turn on power line to disposer control center.

2. Measure voltage between disconnect switch terminals. Voltage

should be 115, 208, 230, or 460 volts, depending on model.

Page 48

COMPONENT TESTING AND

REPLACEMENT (Cont'd)

DISCONNECT SWITCH TEST PROCEDURE, MODEL

CC-101C, MODEL CC-101D AND CC-101E

1. Turn on power line to disposer control center.

2. Measure voltage between terminals of disconnect switch on

right-side of enclosure while holding down plunger of leftside switch. (See Figure 10-6.) Voltage should be 24 or 115

volts, depending on model.

3. Measure voltage between terminals of left-side disconnect

switch while holding down plunger of right-side disconnect

switch. Voltage reading should be 24 or 115 volts,

depending on model.

DISCONNECT SWITCH TEST PROCEDURE,

MODEL CC-101G

1. Turn on power line to disposer control center.

2. Measure voltage between terminals of disconnect switch.

With door open (disconnect switch plunger should be out),

voltage should be 24 volts.

3. Push switch plunger in. Voltage should go to 0 volts.

DISCONNECT SWITCH REPLACEMENT

PROCEDURE, SNAP-MOUNT SWITCH

SECTION 10

Figure 10-6. Measuring Voltage Across

Disconnect Switch.

1. Turn OFF power to disposer control center.

2. Note location of wires connected to disconnect switch.

Disconnect wires.

3. Use a razor blade or hobby knife to carefully cut away any

adhesive securing disconnect switch to mounting hole.

4. Squeeze together the retaining clips on each side of switch

to allow switch to be pulled out through mounting hole.

Remove switch from mounting hole.

5. Put replacement switch in mounting hole and push switch

into hole until it snaps into place. Secure switch with clear

silicone-type adhesive such as R.T.V. or G.E. Silicone

adhesive.

6. Connect wires to proper terminals on disconnect switch.

DISCONNECT SWITCH REPLACEMENT

PROCEDURE, THREAD-MOUNT SWITCH

1. Make sure power is off to disposer control center.

2. Note location of wires connected to disconnect switch.

Disconnect wires.

3. Remove nut and lock washer securing switch to enclosure.

Remove switch from enclosure.

4. Position replacement switch in mounting hole and secure

with nut and lock washer.

10-5

Page 49

SECTION 10

COMPONENT TESTING AND

REPLACEMENT (Cont'd)

Figure 10-7. Measuring Voltage At Disconnect

Relay.

5. Connect wires to proper terminals on disconnect switch.

DISCONNECT RELAY TEST PROCEDURE

1. Turn on power to disposer control center.

2. Perform disconnect switch defeat procedure. Disconnect

relay should close when both disconnect switch plungers

are pushed down.

3. Measure voltage between 1L1 (line) and L1 (load) terminals of disconnect relay. (See Figure 10-7). Voltage

reading should be 0 volts.

• Measure voltage between any 2 line terminals. Voltage

reading should be line voltage.

• Repeat step 3 for terminals 1L2 and L2, and for terminals

1L3 and L3.

DISCONNECT RELAY REPLACEMENT

PROCEDURE, MODELS CC-101C AND CC-101D

1. Turn off power to disposer control center.

2. Note location of wires connected to disconnect relay.

Disconnect wires.

3. Remove screws securing disconnect relay to panel.

Remove disconnect relay.

4. Put replacement disconnect relay in position on panel and

secure with screws.

5. Connect wires to proper terminals on disconnect relay.

Figure 10-8. Measuring Voltage Across START

Switch.

10-6

START SWITCH TEST PROCEDURE,

MODEL CC-101A

WARNING

WHEN PERFORMING THIS TEST, THE DISPOSER MOTOR WILL

RUN. MAKE SURE NO PERSON IS WORKING NEAR THE

DISPOSER WHEN THIS TEST IS PERFORMED.

1. Turn off power line to disposer control center.

2. Perform door interlock defeat procedure.

3. Turn on power line to disposer control center.

4. Measure voltage between switch terminals 4 and 7. (See

Figure 10-8.) Voltage should be 120 volts.

5. Press START switch. Measure voltage between switch

terminals 4 and 7. Voltage should be 0 volts.

6. Press STOP switch and repeat steps 4 and 5 for terminals

3 and 5.

7. Press STOP switch when finished with test procedure.

Page 50

COMPONENT TESTING AND

REPLACEMENT (Cont'd)

START SWITCH TEST PROCEDURE, MODEL

CC-101B

WARNING

WHEN PERFORMING THIS TEST, THE DISPOSER MOTOR

WILL RUN. MAKE SURE NO PERSON IS WORKING NEAR

THE DISPOSER WHEN THIS TEST IS PERFORMED.

1. Turn off power line to disposer control center.

2. Perform door interlock defeat procedure.

3. Turn on power line to disposer control center.

4. Measure voltage between switch terminals 3 and 11.

Voltage should be 120 volts.

5. Press START switch. Measure voltage between switch

terminals 3 and 11. Voltage should be 0 volts.

6. Press STOP switch and repeat steps 4 and 5 for terminals

3 and 5.

7. Press STOP switch when finished with test procedure.

START SWITCH TEST PROCEDURE,

MODELS CC-101C AND CC-101D

SECTION 10

WARNING

WHEN PERFORMING THIS TEST, THE DISPOSER MOTOR WILL

RUN. MAKE SURE NO PERSON IS WORKING NEAR THE

DISPOSER WHEN THIS TEST IS PERFORMED.

1. Turn off power line to disposer control center.

2. Perform disconnect switch defeat procedure.

3. Turn on power line to disposer control center.

4. Measure voltage between switch terminals 5 and 6. (See

Figure 10-9.) Voltage should be 120 volts.

5. Press START switch. Measure voltage between switch

terminals 5 and 6. Voltage should be 0 volts.

6. Press STOP switch and repeat steps 4 and 5 for terminals

5 and 7.

7. Press STOP switch when finished with test procedure.

START SWITCH TEST PROCEDURE, MODEL

CC-101E

WARNING

WHEN PERFORMING THIS TEST, THE DISPOSER MOTOR WILL

RUN. MAKE SURE NO PERSON IS WORKING NEAR THE

DISPOSER WHEN THIS TEST IS PERFORMED.

1. Turn off power line to disposer control center.

2. Perform disconnect switch defeat procedure.

3. Turn on power line to disposer control center.

Figure 10-9. Measuring Voltage Across START

Switch.

10-7

Page 51

10-8

SECTION 10

COMPONENT TESTING AND

REPLACEMENT (Cont'd)

4. Measure voltage between switch terminals 6 and 7. Voltage

should be 120 volts.

5. Press START switch. Measure voltage between switch terminals

6 and 7. Voltage should go to 0 volts.

6. Press STOP switch when finished with test procedure.

START SWITCH TEST PROCEDURE.

MODEL CC-101G

WARNING

WHEN PERFORMING THIS TEST, THE DISPOSER MOTOR WILL

RUN. MAKE SURE NO PERSON IS WORKING NEAR THE

DISPOSER WHEN THIS TEST IS PERFORMED.

1. Turn off power line to disposer control center.

2. Perform disconnect switch defeat procedure.

3. Turn on power line to disposer control center.

4. Measure voltage between switch terminals 6 and 7. Voltage

should be 24 volts.

5. Press START switch. Voltage should go to 0 volts.

6. Press STOP switch when finished with test procedure.

START SWITCH REPLACEMENT PROCEDURE,

THREADED-COLLAR MOUNT

1. Turn off power line to disposer control center.

2. Note location of wires on switch. Disconnect wires.

3. Unscrew threaded collar securing switch to control center

door. Remove switch.

4. Insert replacement switch in mounting hole in door. Secure switch to door with threaded collar. Be sure letter ing

on switch button is right-side up.

5. Connect wires to proper switch terminals.

START SWITCH REPLACEMENT PROCEDURE,

TWO-SCREW MOUNT

1. Turn off power line to disposer control center.

2. Note location of wires on switch. Disconnect wires.

3. Loosen two screws at rear top and bottom of switch so that rear

section of switch is flush with door.

4. Push front section of switch in (toward rear section), turn it

counterclockwise until it stops (about 1/8 turn). Front and rear

switch sections can now be separated by pulling front section

away from rear section.

5. Remove switch from mounting hole.

6. Position rear section of replacement switch behind mounting

hole. Loosen two screws at rear top and bottom of switch so that

rear section of switch is flush with door.

Page 52

SECTION

10

COMPONENT TESTING AND

REPLACEMENT (Cont'd)

7. Position front section of switch so that lettering on pushbutton is

upright, then turn front section counter-clockwise about 1/8 turn.

Insert front section into rear section as far as it will go, then turn

front section clockwise until it stops (about 1/8 turn).

8. Tighten two screws on rear of switch until switch is secured

tightly in mounting hole. Be sure lettering on pushbutton is still

upright.

9. Connect wires to proper switch terminals.

STOP SWITCH TEST PROCEDURE,

MODEL CC-101A

1. Turn off power line to disposer control center.

2. Open disposer control center door.

3. Perform door interlock switch defeat procedure.

4. Turn on power line to disposer control center.

5. Measure voltage between switch terminals 5 and 9. (See

Figure 10-10.) Voltage should be 0 volts.

6. Press STOP switch. Voltage should go to 120 volts.

7. Measure voltage between switch terminals 2 and 4.

Voltage should be 120 volts.

8. Press STOP switch. Voltage should go to 0 volts.

STOP SWITCH TEST PROCEDURE,

MODEL CC-101B

1. Turn off power line to disposer control center.

2. Open disposer control center door.

3. Perform door interlock switch defeat procedure.

4. Turn on power line to disposer control center.

5. Measure voltage between switch terminals 2 and 3.

Voltage should be 0 volts.

6. Press STOP switch. Voltage should go to 120 volts.

7. Measure voltage between switch terminals 2 and 4.

Voltage should be 120 volts.

8. Press STOP switch. Voltage should go to 0 volts.

Figure 10-10. Measuring STOP Switch Voltage.

STOP SWITCH TEST PROCEDURE,

MODELS CC-101C AND CC-101D

1. Turn off power line to disposer control center.

2. Open control center door.

3. Perform door interlock defeat procedure.

4. Turn on power line to disposer control center.

5. Measure voltage between switch terminals 5 and 3. (See Figure

10-11.) Voltage should be 0 volts.

6. Press STOP switch. Voltage should go to 120 volts.

Figure 10-11. Measuring Voltage Across STOP

Switch.

10-9

Page 53

SECTION 10

COMPONENT TESTING AND

REPLACEMENT (Cont'd)

STOP SWITCH TEST PROCEDURE,

MODEL CC-101E

1. Turn off power line to disposer control center.

2. Perform door interlock defeat procedure.

3. Turn on power line to disposer control center.

4. Measure voltage between switch terminals 5 and 6.

Voltage should be 0 volts.

5. Press STOP switch. Voltage should go to 120 volts.

6. Measure voltage between switch terminals 5 and 11.

Voltage should be 120 volts.

STOP SWITCH TEST PROCEDURE, MODEL

CC-101G

1. Turn off power line to disposer control center.

2. Perform door interlock defeat procedure.

3. Turn on power line to disposer control center.

4. Measure voltage between switch terminals 3 and 6.

Voltage should be 24 volts.

5. Press STOP switch. Voltage should go to 0 volts.

STOP SWITCH REPLACEMENT PROCEDURE,

THREADED-COLLAR MOUNT WITHOUT ATTACHED

REVERSER SWITCH

1. Turn off power line to disposer control center.

2. Note location of wires on switch. Disconnect wires.

3. Unscrew threaded collar securing switch to control center

door. Remove switch.

4. Insert replacement switch in mounting hole in door. Secure switch to door with threaded collar. Be sure lettering

on switch button is right-side up.

5. Connect wires to proper switch terminals.

STOP SWITCH REPLACEMENT PROCEDURE.

THREADED-COLLAR MOUNT WITH ATTACHED

REVERSER SWITCH

1. Turn off power line to disposer control center.

2. Note location of wires on switch. Disconnect wires.

3. Note location of wires connected to reverser switch.

Disconnect wires (reverser switch is mechanically

attached to STOP switch and are replaced as one unit).

4. Unscrew threaded collar securing switch to control center

door. Remove switch.

5. Insert replacement switch in mounting hole in door. Secure switch to door with threaded collar. Be sure letter ing

on switch button is right-side up.

6. Connect wires to proper switch terminals.

10-10

Page 54

COMPONENT TESTING AND

SECTION

10

REPLACEMENT (Cont'd)

STOP SWITCH REPLACEMENT PROCEDURE.

TWO-SCREW MOUNT

1. Turn off power line to disposer control center.

2. Note location of wires on switch. Disconnect wires.

3. Unscrew threaded collar securing switch to control center

door. Remove switch.

4. Insert replacement switch in mounting hole in door.

Secure switch to door with threaded collar. Be sure

lettering on switch button is right-side up.

5. Connect wires to proper switch terminals.

PRESSURE SWITCH TEST PROCEDURE

WARNING

WHEN PERFORMING THIS TEST, THE DISPOSER MOTOR WILL

RUN. MAKE SURE NO PERSON IS WORKING NEAR THE

DISPOSER WHEN THIS TEST IS PERFORMED.

1. Turn off power line to disposer control center.

2. Perform door interlock switch or disconnect switch defeat

procedure as appropriate.

3. Turn on power line to disposer control center.

4. Press START switch.

5. Measure voltage across pressure switch wires. (See

Figure 10-12.) Voltage should be 0 volts. If voltage is 120

volts, check water pressure. Pressure must be at least 15

p.s.i. to close the pressure switch contacts. If pressure is

over 15 p.s.i. and voltage is 120 volts, switch is defective

and must be replaced.

CAUTION

When performing the next step, do not allow the disposer

to run for more than 10 seconds without water. If the

pressure switch is working properly, the disposer will

turn itself off.

6. With disposer running, shut off water supply. Disposer

should stop within 10 seconds. If it does not stop within

10 seconds, pressure switch is defective. Press STOP

switch to stop disposer.

Figure 10-12. Measuring Voltage Across Pressure

Switch.

PRESSURE SWITCH REPLACEMENT

PROCEDURE

1. Turn off power line to disposer control center.

2. Turn off water supply to pressure switch.

• Remove reverser/timer.

• Note location of pressure switch wires. Disconnect wires.

• Remove screws securing pressure switch to control

center enclosure.

• Put replacement pressure switch in correct position and

secure with screws.

10-11

Page 55

SECTION 10

COMPONENT TESTING AND

REPLACEMENT (Cont'd)

• Connect pressure switch wires to proper terminals.

• Replace reverser/timer.

• Turn on water supply.

REVERSER/TIMER TEST PROCEDURE

WARNING

WHEN PERFORMING THIS TEST, THE DISPOSER MOTOR WILL

RUN. MAKE SURE NO PERSON IS WORKING NEAR THE

DISPOSER WHEN THIS TEST IS PERFORMED.

1. Turn off power line to disposer control center.

2. Perform door interlock switch defeat procedure.

3. Turn on power line to disposer control center.

4. Make sure water supply to disposer is turned on.

5. Press START switch.

6. Disposer motor should run and water should flow to disposer.

7. Press STOP switch.

8. Disposer motor should stop. Water should continue flowing for

several minutes, then stop.

REVERSER/TIMER REPLACEMENT PROCEDURE

1. Turn off power to disposer control center.

2. Turn door interlock switch to off position and open en-

closure door.

3. Grasp reverser/timer firmly and pull it straight out of its

socket.

4. Put replacement reverser/timer in position on socket and

press firmly into socket until it is completely seated.

NOTE

The reverser/timer connector is keyed so that it can only be inserted

Into Its socket when the pins are correctly lined up.

LATCH RELAY (REVERSER) TEST PROCEDURE

1. Turn off power line to disposer control center.

2. Perform door interlock defeat procedure.

3. Turn on power line to disposer control center.

4. Measure voltage between latch relay terminal 7 and any

chassis ground.

5. Press STOP switch a number of times. Voltage should

alternate between 0 and 120 volts each time STOP switch

is pressed.

6. Repeat steps 4 and 5 for latch relay terminal 8 and any

chassis ground.

10-12

Page 56

LATCH RELAY (REVERSER) REPLACEMENT

SECTION

10

PROCEDURE

COMPONENT TESTING AND

REPLACEMENT (Cont'd)

1. Turn off power line to disposer control center.

2. Note location of wires connected to latch relay. Disconnect wires.

3. Remove screws securing latch relay to panel. Remove

latch relay.

4. Place replacement latch relay in position on panel and

secure with screws.

5. Connect wires to proper terminals on latch relay.

REVERSER SWITCH TEST PROCEDURE,

MODELS CC-101C AND CC-101D

1. Turn off power line to disposer control center.

2. Perform door interlock defeat procedure.

3. Turn on power line to disposer control center.

4. Measure voltage between reverser switch terminal 8 and

any chassis ground. (See Figure 10-13.)

5. Press STOP switch several times. Voltage should alternate between 120 volts and 0 volts each time STOP

switch is pressed.

6. Repeat steps 4 and 5 for alternator switch terminal 9 and

chassis ground.

REVERSER SWITCH TEST PROCEDURE, MODEL CC101E

1. Turn off power line to disposer control center.

2. Perform disconnect switch defeat procedure.

3. Turn on power line to disposer control center.

4. Measure voltage between alternator switch terminal 9 and

any chassis ground.

5. Press STOP switch several times. Voltage should alternate between 120 volts and 0 volts each time STOP

switch is pressed.

6. Repeat steps 4 and 5 for reverser switch terminal 10 and