Page 1

HD16

CCTV Camera

User Guide

Document 900.0345 – Rev 1.02 – 03/07

Page 2

Revisions

Issue Date Revisions

1.00 03/06 New document based on 900.0184 rev 4.00.

1.01 05/06 Amended Figure 11 to show 4 DIP switches.

1.02 03/07 Removed monochrome models, updated specs.

2

Page 3

Warnings

Installation and servicing should be performed only by qualified and experienced

technicians to conform to all local codes and to maintain your warranty.

WARNING! The use of CSA Certified/UL Listed Class 2

power adapters is required to ensure

compliance with electrical safety standards.

Explanation of Graphical Symbols

CAUTION

RISK OF ELECTRIC

SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC

SHOCK, DO NOT REMOVE THE COVER.

NO USER-SERVICEABLE PARTS INSIDE

REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL

THIS SYMBOL INDICATES THAT

DANGEROUS VOLTAGE

CONSTITUTING A RISK OF

ELECTRIC SHOCK IS PRESENT

WITHIN THE UNIT.

THIS SYMBOL INDICATES THAT

IMPORTANT OPERATING AND

MAINTENANCE INSTRUCTIONS

ACCOMPANY THIS UNIT.

Document 900.0345 Rev 1.02 3

03/07

Page 4

FCC Compliance Statement

Information to the User: This equipment has been tested and found to

comply with the limits for a Class A digital device. Pursuant to Part 15 of the

FCC Rules, these limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct

the interference at his own expense.

Caution Changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to

operate the equipment.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la Classe A est conforme à norme NMB-003 du

Canada.

4

Page 5

Contents

Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Unpack Everything . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Overview of Assembly Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Mount the HD16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Connect the Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Install the Camera Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Adjust the Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

DIP Switch Functions (Color and TDN Cameras) . . . . . . . . . . . . . . .13

Adjustment Method (Color and TDN Cameras) . . . . . . . . . . . . . . . .13

White Balance Adjustment Method (Color and TDN Cameras) . . . .14

Manually Setting Shutter Speed (Color and TDN Cameras) . . . . . .14

DIP Switch Functions (WDR Cameras) . . . . . . . . . . . . . . . . . . . . . . .15

Adjustment Method (WDR Cameras) . . . . . . . . . . . . . . . . . . . . . . . .15

Adjust the Line Lock (Vertical Phase) For External Sync Reference 16

Adjust the Backlight Compensation . . . . . . . . . . . . . . . . . . . . . . . . .16

Secure the Camera and Dome Enclosure . . . . . . . . . . . . . . . . . . . . . . .16

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Dome Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Solving Common Technical Issues . . . . . . . . . . . . . . . . . . . . . . . . . 18

Service19

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cable Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

HD16 Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Document 900.0345 Rev 1.02 5

03/07

Page 6

Overview

The HD16 CCTV Camera can be flush or surface mounted to a wall or ceiling. The

HD16 features a high-impact plastic enclosure and polycarbonate dome that has

an adjustable dome insert to conceal camera components without compromising

light sensitivity or picture quality. The HD16 accommodates a 5-50 mm varifocal

auto-iris lens.

Before You Begin

Please read this guide carefully before you

install this HD16 CCTV Camera.

Keep this guide for future reference.

Unpack Everything

Check that the items received match those listed on the order form and packing

slip. The HD16 packing box should include, in addition to this User Guide:

• One fully assembled HD16 Camera

• One HD16 hardware kit

• One Product Warranty card

If any parts are missing or damaged, please contact the dealer you purchased

the camera from, or call Honeywell Customer Service. See “Service” on page 19.

Equipment Required

You will require the following tools to complete the installation:

• Phillips screwdriver.

•Side-cutters.

• Mounting screws. Use mounting screws appropriate to your installation.

6

Page 7

Installation

The HD16 Camera is designed to be flush or surface mounted on a wall or

ceiling. It is weather sealed for indoor or outdoor locations.

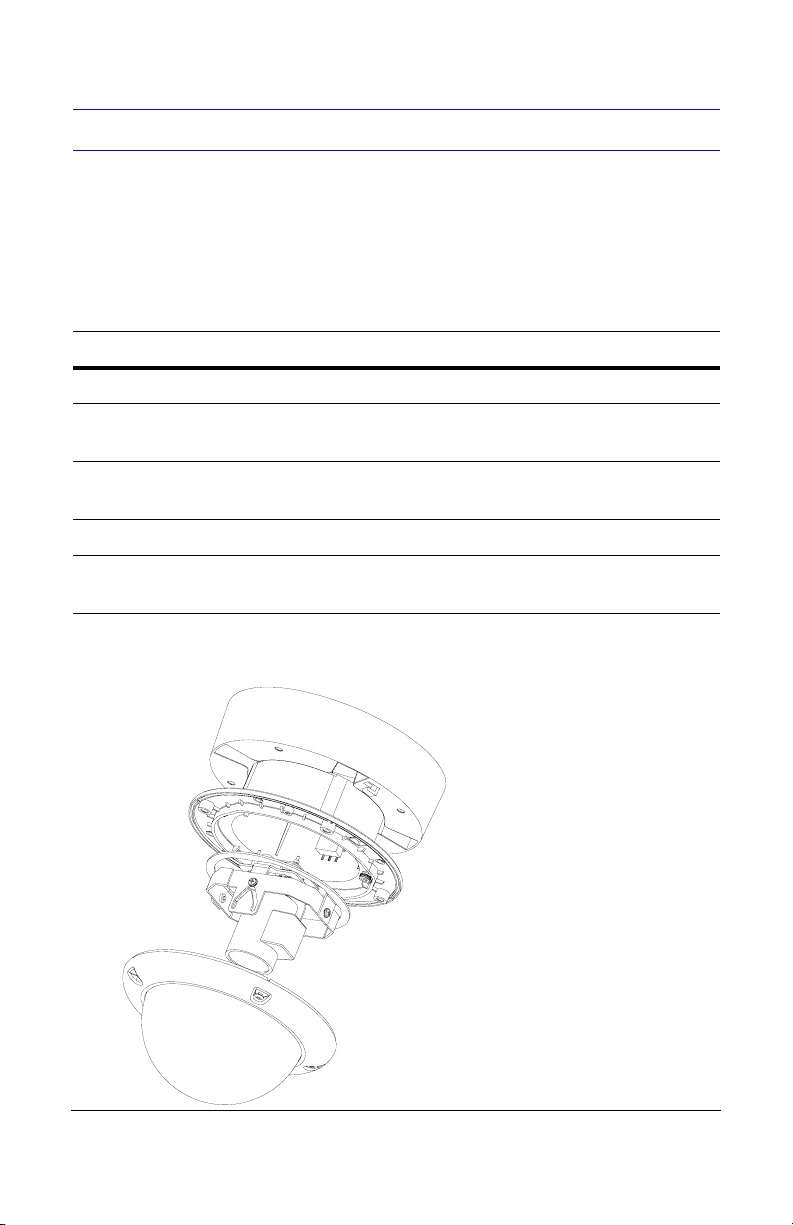

Overview of Assembly Procedure

Task See section

1. Mount the HD16 to a ceiling or wall. See “Mount the HD16” on page 8.

2. Connect the cable to the camera

board.

3. Secure the gimbal into the HD16

base.

4. Adjust the camera settings. See “Adjust the Camera” on page 10.

5. Secure the cover. See “Secure the Camera and Dome

Figure 1 Installation Components

Gimbal

See “Connect the Power Cable” on

page 9.

See “Install the Camera Assembly”

on page 10.

Enclosure” on page 16.

Skirt (optional)

HD16 base

HD16 dome cover

Document 900.0345 Rev 1.02 7

03/07

Page 8

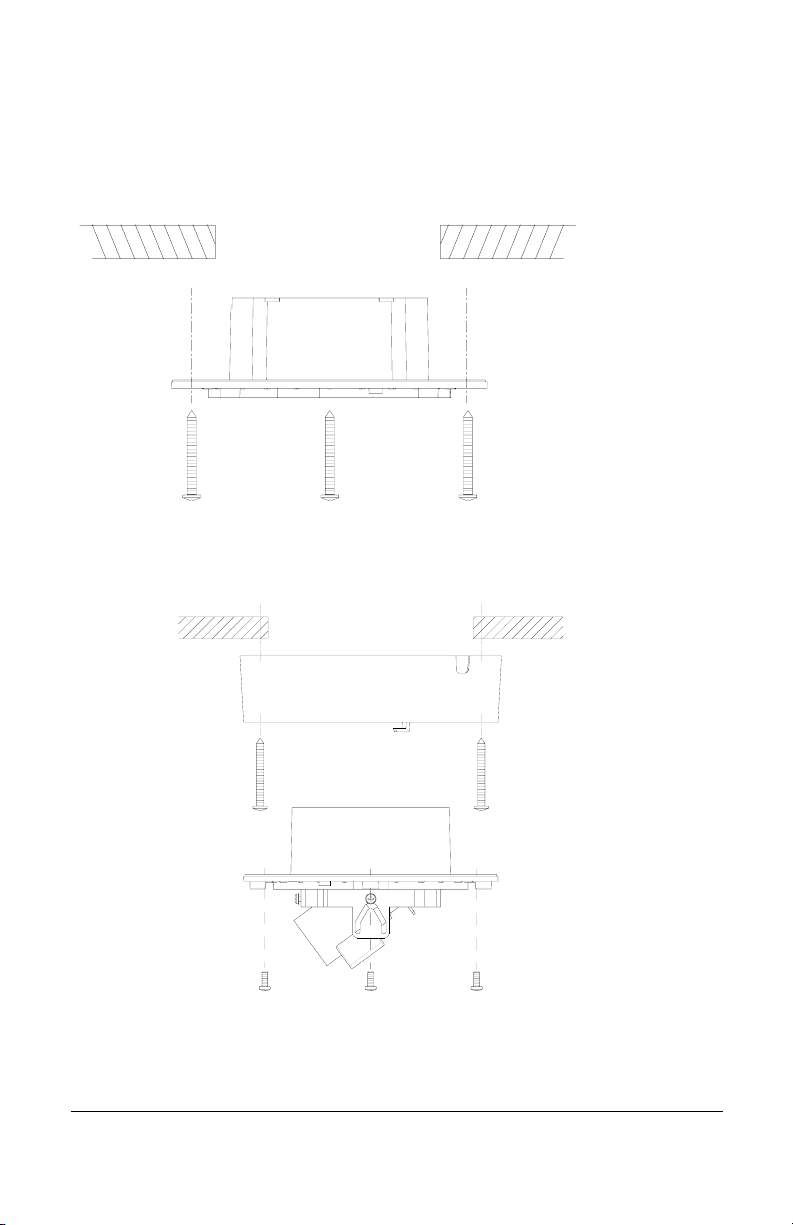

Mount the HD16

Follow Figure 2 to mount the HD16 flush to a ceiling or wall.

Figure 2 Flush Mount Installation

HD16 base

Mounting screws (not

supplied)

Follow Figure 3 to surface mount the HD16 to a wall or ceiling.

Figure 3 Surface Mount Installation

Skirt

Mounting screws (not

supplied)

#8-32 x 3/8 inch machine

screws (x4)

8

Page 9

Connect the Power Cable

1. Follow Figure 4 for the wiring connection.

Figure 4 Wiring

Coaxial Cables UTP Cables

Video: Unshielded

Twisted Pair wire

Video: female BNC

Power

red +

connect to red +

black connect to ground

Power: 2.1 mm

male jack center pin

2. Connect the power/video cable from the gimbal assembly to the camera

board (see Figure 5).

Note For secure installations, surface-mounted cables should be

protected by plastic or metal cable covers.

Figure 5 Power Cable Connection

Gimbal assembly

Power/video cable

Camera board

Document 900.0345 Rev 1.02 9

03/07

Page 10

Install the Camera Assembly

To install the camera assembly into the HD16 base:

1. Remove one of the three thumb nuts from the camera chassis (see Figure 6).

Loosen the other two thumb nuts.

2. Slide the gimbal ring under the two loosened thumb nuts.

3. Adjust the camera position. See “Adjust the Camera” on page 10.

4. Replace the thumb nut you previously removed in step 1.

5. Tighten all three thumb nuts to secure the camera assembly.

Make sure that the camera DIP switches are on the top of the lens mount

when the HD16 is mounted on the wall or ceiling.

Figure 6 Camera Assembly

Loosen thumb

nuts (x2)

Gimbal chassis

Remove thumb nut

Gimbal ring

Adjust the Camera

To adjust the HD16 Camera:

1. Apply 11-16 VDC or 24 VAC power to the camera and monitor the video

signal.

2. Loosen as many screws and thumb nuts that lock the gimbal assembly in

place as necessary to adjust the camera position (see Figure 6).

3. Adjust the camera carrier to the desired view by moving the gimbal in the V

groove (see Figure 7).

10

Page 11

Figure 7 Recommended Camera Positions

Recommended

camera positions

Use these alternate

positions when your

desired field of view

(FOV) is a steep angle

or parallel to a wall or

ceiling.

FOV

Figure 8 shows how to use the thumb nuts and screws to adjust the gimbal.

Figure 8 Gimbal Adjustment

Tilt rotation

C

A

Pan rotation

V groove

B

C

A

Legend

A = Pan rotation

B = Horizontal rotation

C = Tilt rotation

Document 900.0345 Rev 1.02 11

03/07

B

B

Horizontal rotation

Page 12

4. Tighten the screws and thumb nuts to lock the gimbal assembly in place.

5. Focus the lens:

a. Place the dome as shown in Figure 9.

b. Adjust the focal length using the top locking screw. See Figure 10 for

color cameras or Figure 11 for monochrome cameras.

c. Adjust the focus using the bottom locking screw (closest to the camera

board). See Figure 10 for color cameras or Figure 11 for monochrome

cameras.

6. To adjust the camera direction, view angle and focus, connect the service

monitor cable (supplied) to the video monitor output (see Figure 10 for color

cameras and Figure 11 for monochrome cameras).

7. Rotate the dome and place it over the base so that the security screws are

lined up with the screw holes on the base.

8. Check the picture. If the focus is clear, go to step 9. If the focus is not clear,

repeat step 5 and step 6 until you are satisfied with the picture clarity.

Figure 9 Lens Focus and Field of View Adjustment

Vari-focal Auto Iris Configuration (Color Cameras)

To adjust the focal length and focus of the lens, see Figure 10. Color

cameras have a potentiometer on top of the board to regulate the Auto Iris

lens.

9. Set the DIP switches. See the following sections for the DIP switch functions

and adjustment methods.

12

Page 13

DIP Switch Functions (Color and TDN Cameras)

o

Figure 10 Color Camera Switch Settings (Vari-focal Auto Iris Lens

Shown)

* N/U = Not used.

Leave in Off position.

Note You may find it helpful t

use the Allen key (supplied) to

access the DIP switches.

AWB2

AWB3

Push lock

Video

monitor

output

Top locking

screw adjusts

focal length.

Bottom locking

screw adjusts

focus.

Factory (default) settings

Vari-focal Auto Iris

10 9 8 7 6 5 4 3 2 1

= ON (up)

= OFF (down)

DC Iris

adjust

GAMMAAEFLON

BLC

IRIS

NU*

AGC MAX

AWB1

10 9 8 7 6 5 4 3 2 1

Line-lock phase

adjustment pot

Adjustment Method (Color and TDN Cameras)

Switch

no.

10 GAMMA Off (0.45) On (1.0)

9 AE (Automatic

8 FLON (Flicker Less) Off On

7BLC (Backlight

6 IRIS Control Electronic IRIS Auto IRIS

5 Not used Not used Not used

4 AGC 4 dB 26 dB

Function Off On

Off On (see Manually Setting Shutter

Exposure)

Speed (Color and TDN Cameras))

Off On (Center window)

Compensation)

Document 900.0345 Rev 1.02 13

03/07

Page 14

White Balance Adjustment Method (Color and TDN Cameras)

Symbol SW3/AWB1 SW2AWB2 SW1AWB3

AWB Off Off Off

ATW Off On Off

Push lock Off On On *

Indoor (3200° K) On Off On

Outdoor (6500° K) On On On

* To manually set Push lock feature: place a white background in front of camera

and press “Push lock” switch.

Manually Setting Shutter Speed (Color and TDN Cameras)

To manually set the shutter speed, turn switch #9 to the ON position; then set

switch #6, #7, and #8 for the desired shutter speed (see Figure 10).

Shutter

speed(s)

1/50 (PAL)

1/60 (NTSC)

1/100 (PAL)

1/120 (NTSC)

1/250 Off Off Off On

1/500 Off Off On On

1/1000 On On Off On

1/2000 On On On On

1/4000 On Off Off On

1/10000 On Off On On

Note FLON, BLC, and IRIS can be set when switch #9 is set to the OFF

position.

Caution Before you adjust the shutter speed, it is important that you

SW6

IRIS

Off On Off On

OffOnOnOn

understand how the settings can affect the scene detail.

SW7

BLC

SW8

FLON

SW9

AE

14

Page 15

DIP Switch Functions (WDR Cameras)

Figure 11 WDR Camera Switch Settings

* Not used.

Leave in ON

position.

Auto Iris level

adjustment. If

necessary, turn

clockwise to

increase brightness

level.

Line-lock

adjustment

AGC

N/U*

WDR

AWB/ATW

Video monitor

output

Note The Wide Dynamic Range camera has been designed for the best

wide dynamic performance and can only be used with Vari-focal

Auto Iris lens.

Note You may find it helpful

to use the Allen key (supplied)

to access the DIP switches.

Factory (default) settings

= ON (up)

= OFF (down)

Adjustment Method (WDR Cameras)

Switch

no.

1AGC Off On

2 Not used Off On*

3 WDR (Wide Dynamic Range) Off On

4 AWB/ATW ATW AWB

* Leave switch #2 in ON position to ensure the camera functions

properly.

Document 900.0345 Rev 1.02 15

03/07

Function Off On

Page 16

Adjust the Line Lock (Vertical Phase) For External Sync Reference

Phase adjustment may be necessary in multiple camera installations to prevent

picture roll when switching between cameras. To adjust the vertical phase while

switching between two cameras, turn the line lock adjustment pot on one camera

until there is no vertical roll. See Figure 10 for color cameras and Figure 11 for

monochrome cameras. The wide dynamic range (WDR) cameras use line lock

adjustment buttons to adjust the vertical phase (see Figure 11).

Note If the phase cannot be adjusted to prevent picture roll, reverse the

line-lock input polarity.

Adjust the Backlight Compensation

The backlight compensation (BLC) adjusts the electronic shutter speed of the

camera based on the light levels in specific areas of the scene. This adjustment

provides better image quality for scenes that are unevenly lit.

To adjust the BLC, set the BLC switch to ON (see Figure 10 for color cameras and

Figure 11 for monochrome cameras). Center window weighted.

Secure the Camera and Dome Enclosure

To secure the camera and dome enclosure:

1. Ensure that the gimbal is locked in place (see Figure 6).

2. Rotate the dome enclosure until the #8-32 security screws line up with the

base, then secure it to the base (see Figure 12).

Thumb nuts

(x3)

Figure 12 Enclosure Cover Installation

HD16 base

#8-32 security screws

(x4)

Dome enclosure

16

Page 17

Routine Maintenance

Use regular liquid cleaners to remove most dirt and grime from the HD16

enclosure.

Caution Do not use harsh or abrasive cleaners which can scratch the

polycarbonate dome and reduce visibility from the camera.

Dome Replacement

If the polycarbonate dome is damaged or scratched beyond use, contact your

distributor or salesperson to order a dome replacement. To replace the HD16

dome:

1. Use the security hex key (supplied) to loosen the #8-32 security screws

securing the HD16 lid to the base.

2. Use a Phillips screwdriver to remove the #6 x 1/4 inch Hi-lo tapping screws

that attach the dome retainer plate to the front cover.

3. Remove the damaged dome and replace it with the new dome.

4. Use a Phillips screwdriver to attach the dome retainer plate to the HD16 front

plate with the screws you removed in step 2.

5. Use the security hex key to tighten the security screws that secure the HD16

lid to the base.

Figure 13 Dome replacement

#8-32 security screws (x4)

Front cover

Polycarbonate dome

Dome turret

Gasket

Retainer plate

#6 x 1/4 inch Hi-lo tapping screws (x4)

Document 900.0345 Rev 1.02 17

03/07

Page 18

Solving Common Technical Issues

No video

❐ Check that the power supply voltage is within the operating

specifications for your camera model (see Specifications) for

details).

❐ Connect a video monitor directly to the HD16 video output cable to

eliminate video problems that could be caused by other

equipment such as video switches.

❐ Check the video connections to the monitor or CCTV system.

❐ Check for a loose connection at the video camera.

Fuzzy video

❐ Check the video ground connections.

❐ Check for ground loops.

Call Honeywell Customer Service for additional assistance (see Service for

contact numbers).

18

Page 19

Service

Subject to the terms and conditions listed on the Product Warranty Card, during

the warranty period Honeywell will repair or replace, at its sole option, free of

charge, any defective products returned prepaid.

In the event you have a problem with any Honeywell product, please call

Customer Service for assistance or to request a Return Merchandise

Authorization (RMA) number.

In the U.S.A. and Canada, call 1.800.796.2288.

Be sure to have the model number, serial number, and the nature of the problem

available for the technical service representative.

Prior authorization must be obtained for all returns, exchanges, or credits. Items

shipped to Honeywell without a clearly identified Return Merchandise

Authorization (RMA) number may be refused.

Document 900.0345 Rev 1.02 19

03/07

Page 20

Specifications

Video specifications High RES Standard RES

Pickup device: 1/3 in. CCD

Electronic iris: 1/60 to 1/100,000 second

Surge protection: 1.5 kW transient

Video output impedance: 1 Vp-p @ 75 Ohms

Video signal:

Color Standard NTSC

Resolution: High RES Standard RES

Color, True Day/Night 480 TV lines 350 TV lines

Wide Dynamic, Wide

Dynamic True Day/Night

Signal to noise ratio

(monochrome and color):

Dynamic range (Wide

Dynamic camera only):

Light sensitivity:

Color 0.7 lux @ F1.7 0.6 lux @ F1.7

True Day/Night 0.3 lux @ F1.7 0.2 lux @ F1.7

Wide Dynamic 1.0 lux @ F1.7

Wide Dynamic True Day/Night

White Balance:

Color, True Day/Night AWB/ATW/Indoor (3200°K), Outdoor (6500°K), Push Lock

BLC Center window weighted on/off, switchable

Lens Type 5 to 50 mm (F1.7) Vari-focal Auto Iris CS Mount

Angle of View Tele: 6.9°(D), 5.5°(H), 4.1°(V)

480 TV lines n/a

Better than 51 dB

Better than 52 dB

0.4 lux @ F1.7

Wide: 63°(D), 48°(H), 35°(V)

Power requirements

Input voltage: 24 VAC/12 VDC

Input range: 17 to 28 VAC, 11 to 16 VDC

Power consumption:

Color 3.5 W (max)

True Day/Night 3.5 W (max)

Wide Dynamic, Wide

Dynamic True Day/Night

4.5 W (max)

20

Page 21

Operating environment

Temperature:

Operating -13°F to 122°F (-25°C to 50°C)

Storage -31°F to 140°F (-35°C to 50°C)

Humidity: 0 to 95% RH non-condensing

Size and weight

Dimensions 7.5 in. x 5.3 in. (191 mm x 134.5 mm

Size 2.0 lb (0.9 kg)

Regulatory

Emissions FCC, CE (EN55013)

Immunity CE (EN50130-4)

Safety EU: 73/23/EEC LVD, UL2044

Note Specifications apply to all camera models, unless noted otherwise.

Document 900.0345 Rev 1.02 21

03/07

Page 22

Cable Guidelines

Power supply cable maximum length (feet/meters)

Wire gauge

Total

load

Cameras with AC/DC power supplies

3.5 W 15 VDC 180/55 290/88 730/220 1170/352

3.5 W 24 VAC 470/143 760/232 1926/587 3065/934

Note Calculations are based on an unregulated linear power supply which would

be the worst case. Using a regulated or switching power supply can increase

the cable distance. We recommend using a CSA Certified/UL listed Class 2

power adapter to ensure compliance with electrical safety standards.

Video cable maximum length (feet/meters)

Maximum length (feet/meters) 750/229 1500/457 2000/610

* Copper clad steel core, 95% braided shield

We recommend these NVT video transceivers (sold separately by NVT Inc.):

• NV-212A (500 ft/152 m—26 Ω)**

• NV-213A/A-M (1000 ft/305 m—52 Ω)**

• NV-652R, NV-862R or NV-1662R (3000 ft/914 m—163 Ω)**

** Distances have been calculated using 24 AWG Twisted Pair wire.

Note We recommend that you measure the wire distance to ensure the capability

of the twisted pair product is not exceeded. Use an ohmmeter to measure wire

resistance by shorting the two conductors together at the far end, then

measure the loop resistance out and back. Compare to the table below.

AWG 250/76 500/152 1000/305 1500/457 2000/610

18 3 Ω 6 Ω 13 Ω 19 Ω 26 Ω

20 5 Ω 10 Ω 20 Ω 30 Ω 40 Ω

22 8 Ω 17 Ω 33 Ω 48 Ω 66 Ω

24 13 Ω 26 Ω 52 Ω 78 Ω 108 Ω

Note Use point-to-point Unshielded Twisted Pair wire only.

Power

supply 24 AWG 22 AWG 18 AWG 16 AWG

Cable type RG-59RG-6RG-11

Wire gauge 23 AWG* 18 AWG* 14 AWG*

Maximum length (feet/meters)

22

Page 23

HD16 Model Numbers

HD16T-DW-480

Typical HD16 model number

Camera Resolution

350 Standard Resolution, 350 TVL

480 High Resolution, 480 TVL

Camera Options

C Color

D True Day/Night

W Wide Dynamic

DW Wide Dynamic True Day/Night

Interface

C Coaxial

T UTP (Twisted Pair)

Document 900.0345 Rev 1.02 23

03/07

Page 24

Honeywell Video Systems (Head Office)

2700 Blankenbaker Pkwy, Suite 150

Louisville, KY 40299, USA

www.honeywellvideo.com

℡ +1.800.796.2288

Honeywell Video Systems Northern Europe

Netwerk 121

1446 WV Purmerend, The Netherlands

www.SecurityHouse.nl

℡ +31.299.410.200

Honeywell Security Australia Pty Ltd.

Unit 5, Riverside Centre, 24-28 River Road West

Parramatta, NSW 2150, Australia

www.ademco.com.au

℡ +61.2.8837.9300

Honeywell Security Asia Pacific

33/F Tower A, City Center, 100 Zun Yi Road

Shanghai 200051, China

www.security.honeywell.com/cn

℡ +86 21.2527.4568

Honeywell Security Asia

Flat A, 16/F, CDW Building, 388 Castle Peak Road

Tsuen Wan, N.T., Hong Kong

www.security.honeywell.com/hk

℡ +852.2405.2323

Honeywell Security France

Parc Gutenberg, 8, Voie La Cardon

91120, Palaiseau, France

www.honeywell.com/security/fr

℡ +33.01.64.53.80.40

Honeywell Security Italia SpA

Via Treviso 2 / 4

31020 San Vendemiano

Treviso, Italy

www.honeywell.com/security/it

℡ +39.04.38.36.51

Honeywell Security España

Mijancas 1. 3a Planta

P. Ind. Las Mercedes

28022 Madrid, Spain

www.security.honeywell.com/es

℡ +34.902.667.800

Honeywell Video Systems UK Ltd.

Aston Fields Road, Whitehouse Ind Est

Runcorn, Cheshire, WA7 3DL, UK

www.honeywellvideo.com

℡ +0844 8000 235

Honeywell Security South Africa

Unit 6 Galaxy Park, 17 Galaxy Avenue

Linbro Park, P.O. Box 59904

2100 Kengray, Johannesburg, South Africa

www.honeywell.co.za

℡ +27.11.574.2500

Honeywell Security Deutschland

Johannes-Mauthe-Straße 14

D-72458 Albstadt, Germany

www.honeywell.com/security/de

℡ +49.74 31.8 01.0

Honeywell Security Poland

Chmielewskiego 22a, 70-028

Szczecin, Polska

www.ultrak.pl

℡ +48.91.485.40.60

Honeywell Security Czech Republic

Havránkova 33, Brno

Dolní Heršpice, 619 00, Czech Republic

www.olympo.cz

℡ +420.543.558.111

Honeywell Security Slovakia Republic

Vajnorská 142, 83104 Bratislava

Slovakia

www.olympo.sk

℡ +421.2.444.54.660

www.honeywellvideo.com

+1.800.796.CCTV (North America only)

HVSsupport@honeywell.com

Document 900.0345 – Rev 1.02 – 03/07

© 2007 Honeywell International Inc. All rights reserved. No part of this publication may be

reproduced by any means without written permission from Honeywell Video Systems. The

information in this publication is believed to be accurate in all respects. However, Honeywell Video

Systems cannot assume responsibility for any consequences resulting from the use thereof. The

information contained herein is subject to change without notice. Revisions or new editions to this

publication may be issued to incorporate such changes.

Loading...

Loading...