Page 1

L-Series

Color Camera

NTSC

HCC334L HCC334LX

HCC484L HCC484LX

PAL

HCC335LX

HCC485LX

User Guide

Document G-113077-001 – 02/07 – Rev 3

Page 2

Revisions

Issue Date Revisions

1.00 06/06 New document

1.01 08/06 Added 230V (HCC335LX, HCC485LX).

3 02/07 Updated document part no.; added

warning to p. iii.

Rev 3 ii G-113077-001

02/07

Page 3

Warnings

Installation and servicing should be performed only by

qualified and experienced personnel to conform to all local

codes and to maintain your warranty.

WARNING! 12 VDC/24 VAC models require the use

of CSA Certified/UL Listed Class 2

power adapters to ensure compliance

with electrical safety standards.

Where the MAINS plug or an appliance coupler is used as

the disconnect device, the disconnect device shall remain

readily operable.

WEEE (Waste Electrical and Electronic Equipment).

Correct disposal of this product (applicable in the

European Union and other European countries with

separate collection systems). This product should be

disposed of, at the end of its useful life, as per applicable

local laws, regulations, and procedures.

Explanation of Graphical

Symbols

CAUTION

RISK OF ELECTRIC

SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC

SHOCK, DO NOT REMOVE THE COVER.

NO USER-SERVICEABLE PARTS INSIDE

REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL

Rev 3 iii G-113077-001

THIS SYMBOL INDICATES THAT

DANGEROUS VOLTAGE

CONSTITUTING A RISK OF

ELECTRIC SHOCK IS PRESENT

WITHIN THE UNIT.

THIS SYMBOL INDICATES THAT

IMPORTANT OPERATING AND

MAINTENANCE INSTRUCTIONS

ACCOMPANY THIS UNIT.

02/07

Page 4

FCC Compliance Statement

Information to the User: This equipment has been tested

and found to comply with the limits for a Class A digital

device. Pursuant to Part 15 of the FCC Rules, these limits

are designed to provide reasonable protection against

harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may

cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Caution Changes or modifications not expressly

approved by the party responsible for

compliance could void the user’s authority to

operate the equipment.

Manufacturer’s Declaration of

Conformance

The manufacturer declares that the equipment supplied

with this guide is compliant with the essential protection

requirements of the EMC directive 89/336/EEC and the Low

Voltage Directive LVD 73/23 EEC, conforming to the

requirements of standards EN 55013 for emissions.

Rev 3 iv G-113077-001

02/07

Page 5

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . .2

Unpack Everything. . . . . . . . . . . . . . . . . . . . . . . . 2

Camera Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Camera Functions . . . . . . . . . . . . . . . . . . . . . . . . 3

Setting Up Your Camera . . . . . . . . . . . . . . . . . . . 4

Selecting the Lens . . . . . . . . . . . . . . . . . . . . . . 4

Manual Lens . . . . . . . . . . . . . . . . . . . . . . . 4

Vari-focal Auto Iris Lens . . . . . . . . . . . . . . . 4

Direct Drive (DC) Lens . . . . . . . . . . . . . . . .4

Video Drive (VSD) Lens. . . . . . . . . . . . . . . 5

Exposure Mode . . . . . . . . . . . . . . . . . . . . . . . . 5

Automatic Exposure Mode . . . . . . . . . . . . . 5

Manual Exposure Mode . . . . . . . . . . . . . . 5

Backlight Compensation (BLC). . . . . . . . . . . . 6

Flickerless Mode (FL) . . . . . . . . . . . . . . . . . . . . 6

Automatic Gain Control (AGC) . . . . . . . . . . . . 6

Auto White Balance (AWB) . . . . . . . . . . . . . . . 6

Auto Trace White Balance (ATW) . . . . . . . 6

Auto White Balance Control (AWC). . . . . . 7

One Push Lock . . . . . . . . . . . . . . . . . . . . . .7

Synchronization Selection (LL/INT) . . . . . . . . . 7

Line Lock Phase Adjustment Potentiometer. . 8

Lens Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Adjusting the Back Focus . . . . . . . . . . . . . . . . . . .9

Completing the Installation . . . . . . . . . . . . . . . . . . 11

Mounting the Camera . . . . . . . . . . . . . . . . . . . . . 11

Connecting the Camera . . . . . . . . . . . . . . . . . . . 12

Warranty and Service . . . . . . . . . . . . . . . . . . . . . . 13

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Rev 3 G-113077-001

02/07

Page 6

Introduction

The Honeywell L-Series Color cameras are ideally suited

for use in day-to-day surveillance applications. The LSeries cameras are designed for exceptional value and

performance for everyday use. Their off-the-shelf feature

set is designed for high picture quality in standard

applications and they require little to no adjustment after

installation.

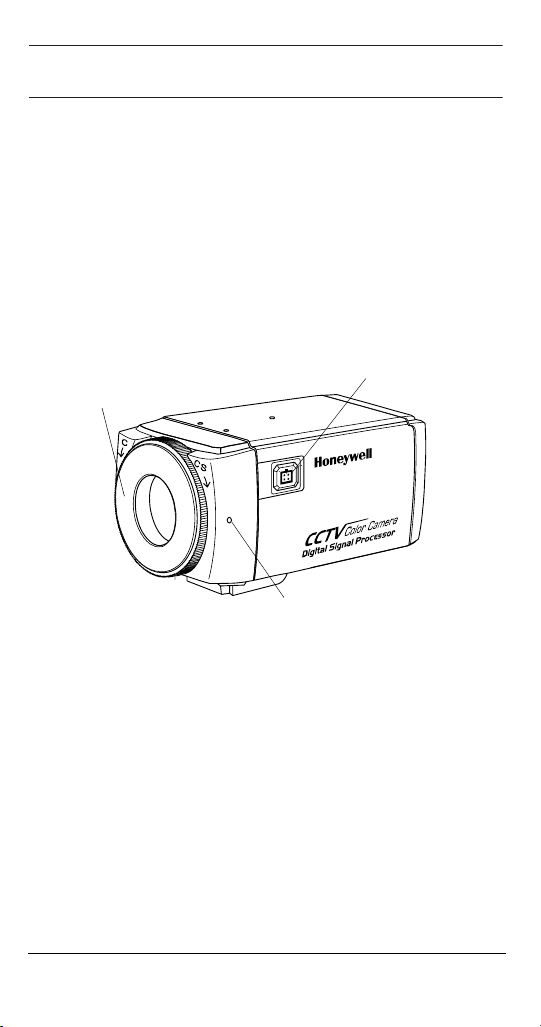

Figure 1 Camera Overview

C/CS mount adapter:

C mount: turn

counterclockwise

CS mount: turn clockwise

Setscrew: loosen locking ring

with a Phillips screwdriver to

adjust mounting ring.

Lens connector for

Auto Iris lens plug

Features

• 1/3” CCD

• C/CS adjustable lens mount adapter

• Excellent signal-to-noise ratio of more than 50 dB

• Minimum illumination:

• High Res — 0.4 lux (F1.2, 50 IRE, AGC ON)

• Standard Res — 0.2 lux (F1.2, 50 IRE, AGC ON)

• 2-way Auto Iris: Video Iris (VSD) or Direct Drive (DC)

Iris lens

Rev 3 1 G-113077-001

02/07

Page 7

Before You Begin

Please read this guide carefully

before you install the L-Series Color

camera.

Keep this guide for future reference.

Unpack Everything

Check that the items received match those listed on the

order form and packing slip. The L-Series packing box

should include, in addition to this User Guide:

• One L-Series Color camera

• One Auto Iris lens plug

If any parts are missing or damaged, contact the dealer you

purchased the camera from or call Honeywell Customer

Service (see Contact Information on the back of this

manual).

Note You will also require a Phillips screwdriver to

complete the installation.

Rev 3 2 G-113077-001

02/07

Page 8

Camera Settings

Camera Functions

Figure 2 Camera Rear View

Low Voltage

(HCC334L/X, HCC484L/X)

Mains 230V — Line Voltage

(HCC335LX, HCC485LX)

9

PUSH

IRIS

LEVEL V-PH

LOCK

6

5

PWR

DC 12V

AC 24V

4

1087

VIDEO

L/L

EE

ME

AES

AI

INT

BLC

FL

VSD

AGC

OFF

WB3

WB2

WB1

GND

DC

1

3

2

10 87

EE

L/L

AES

INT

OFF

VSD

DC

IRIS

LEVEL

ME

AI

BLC

FL

AGC

WB3

WB2

WB1

Legend

#Description

DIP switches for mode settings (see Figure 3)

1

Auto Iris Lens select switch, VSD for Video or DC for Direct

2

Drive

Sync select switch

3

Video output connector

4

Power input connector (24 VAC: 3 terminals)—Low Voltage

5

model only

Power LED indicator

6

DC Iris level adjustment, for use with DC Iris lens

7

V-Phase adjustment, for use with Line lock

8

Push Lock in White Balance (WB) mode

9

EEPROM data setting for factory use only

10

4

9

VIDEO

V-P H

PUSH

LOCK

PWR

~207-253VAC 50HZ

6

Rev 3 3 G-113077-001

02/07

Page 9

Setting Up Your Camera

Figure 3 shows the factory set DIP switch settings.

Automatic Gain Control (AGC) and Auto White Balance

Control (AWC) are set ON.

Figure 3 Factory Set DIP Switch Settings

IRIS

LEVEL

VIDEO

IRIS

PUSH

LEVEL

V-PH

LOCK

PWR

DC 12V

AC 24V

L/L

EE

ME

AES

AI

INT

BLC

FL

VSD

AGC

OFF

WB3

WB2

WB1

-+

GND

DC

EE

AES

OFF

OFF

OFF

OFF

OFF

OFF

ME

AI

BLC

FL

AGC

WB3

WB2

WB1

VSD

DC

= ON

= OFF

Selecting the Lens

Manual Lens

Set the EE/ME DIP switch on the rear of the camera (see

Figure 3) to EE. Set the AES/AI switch to AES. EE and AES

are the typical settings.

Vari-focal Auto Iris Lens

Vari-focal Auto Iris lenses (Direct Drive [DC] or Video Drive

[VSD]) are connected to the camera via a 4-pin square

socket located at the side of the camera. Set the AES/AI

DIP switch to AI. EE and AI are the typical settings.

To set a different exposure, see Exposure Mode on page 5.

Direct Drive (DC) Lens

1. Set the VSD/DC switch on the rear of the camera to

DC. Set the AES/AI DIP switch to AI.

Rev 3 4 G-113077-001

02/07

Page 10

2. Slowly turn the LEVEL potentiometer until the picture

on the monitor is as clear as possible and is not too

bright.

Video Drive (VSD) Lens

Set the VSD/DC switch on the rear of the camera (see

Figure 3) to VSD.

Exposure Mode

Automatic Exposure Mode

The Electronic Exposure feature compensates for

excessive light levels by automatically adjusting the shutter

speed of the camera. Set the EE/ME switch to EE

(recommended setting).

Manual Exposure Mode

Set the EE/ME switch to ME. This setting is typically used

only in machine vision applications. The table below gives

the shutter speeds for the switch settings.

Switch Label

EE

AES

OFF

OFF

OFF

OFF

OFF

OFF

LEGEND

Shutter

speed(s)

1/50 (PAL)

1/60 (NTSC)

ME

1/100 (PAL)

AI

BLC

1/120 (NTSC)

FL

1/250 OFF OFF OFF

AGC

WB3

1/500 ON OFF OFF

WB2

1/1000 OFF ON ON

WB1

= ON

1/2000 ON ON ON

= OFF

1/4000 OFF OFF ON

1/10000 ON OFF ON

FL BLC AES/AI

OFF ON OFF

ON ON OFF

Caution Before you adjust the shutter speed, it is

important that you understand how the settings

can affect the scene detail.

Rev 3 5 G-113077-001

02/07

Page 11

Backlight Compensation (BLC)

If there is excessive light (for example, a window exists in a

scene), the camera tries to compensate by reducing the

overall exposure, resulting in the areas surrounding the

window becoming too dark. Turn the BLC switch ON to

eliminate the silhouette effect.

Flickerless Mode (FL)

Set the FL switch to ON to remove the flicker in a picture.

For PAL models, the shutter speed is 1/100 second; for

NTSC models, the shutter speed is 1/120 second.

Automatic Gain Control (AGC)

This feature can improve picture quality when the level of

scene illumination is low. When set to OFF, the gain is 11

dB. When set to ON, the gain is 30 dB.

Auto White Balance (AWB)

Auto white balance ensures that color integrity is

maintained. To set the white balance, change the WB1,

WB2, or WB3 switches as shown in the following table.

WB1 WB2 WB3 AWB Mode

OFF OFF OFF ATW Mode

EE

AES

OFF

OFF

OFF

OFF

OFF

OFF

LEGEND

ME

OFF ON OFF AWC Mode

AI

OFF ON ON One Push Lock

BLC

ON OFF OFF Indoor Fixed Mode (3200°K)

FL

AGC

ON OFF ON Fluorescent Fixed Mode

WB3

WB2

ON ON OFF User Fixed Mode (4700°K)

WB1

ON ON ON Outdoor Fixed Mode (6300°K)

= ON

= OFF

(4200°K)

Auto Trace White Balance (ATW)

This mode covers a range of 2800°K to 8000°K. This mode

is typically used for indoor applications.

Rev 3 6 G-113077-001

02/07

Page 12

Auto White Balance Control (AWC)

This mode covers a wider range of 2000°K to 10000°K and

performs at a faster operating speed than ATW mode. This

mode is typically used for outdoor applications or where

variable lighting conditions exist.

One Push Lock

Press PUSH LOCK on the rear of the camera to calibrate

the white balance for the current scene. This mode is

typically used for scenes with constant lighting conditions.

Synchronization Selection (LL/INT)

This switch selects the synchronization mode of the

camera. When the camera is connected to an AC supply,

the Line lock (LL) mode is used to lock the camera’s frame

rate to the frequency so that each camera in the system is

triggered at the same point on the supply’s AC cycle. The

default setting is LL.

WARNING! The LL/INT switch must be set to INT

when operating from 12 VDC.

V-PH

IRIS

PUSH

LEVEL V-PH

LOCK

PWR

DC 12V

AC 24V

VIDEO

L/L

EE

ME

AES

AI

INT

BLC

FL

VSD

AGC

OFF

WB3

WB2

WB1

-+

GND

DC

L/L

INT

Rev 3 7 G-113077-001

02/07

Page 13

Line Lock Phase Adjustment Potentiometer

When the camera is in Line lock mode, it is possible to

adjust the point on the AC cycle at which the camera

triggers. This feature allows for synchronization of cameras

that are connected to different phases.

The V-PHASE adjustment potentiometer allows the line

lock phase trigger point to be adjusted by 270°. Rotating

the potentiometer clockwise advances the trigger point and

turning it counterclockwise retards the trigger point. The

factory default setting is the zero crossing point. If all

cameras in a system are on the same phase then no line

lock phase adjustment should be made.

Rev 3 8 G-113077-001

02/07

Page 14

Lens Installation

Adjusting the Back Focus

The back focus adjustment is accessible at the front end of

the camera housing to adjust the back focal length or

picture focus.

The range of adjustment allows both C- and CS-mount

lenses to be used without the need for a spacer ring.

Figure 4 C/CS Mount

CCS

Setscrew

1. Loosen the setscrew with a Phillips screwdriver.

2. Adjust the focus ring to focus the picture.

3. Retighten the setscrew.

Rev 3 9 G-113077-001

02/07

Page 15

Figure 5 DC and VSD Lens Pin Definition

Auto Iris lens connector

21

43

3

1

2

4

Pin DC (Direct Drive) lens Video (VSD) lens

1 CTRL - Power (+12V)

2CTRL + NC

3 DRV + Video Signal

4DRV - GND

Set the select switch to DC Set the select switch to VSD

Rev 3 10 G-113077-001

02/07

Page 16

Completing the Installation

Mounting the Camera

Mounting points are provided on the top of the camera for

mounting the camera on a bracket or tripod. They are

designed to accept standard sized 1/4 x 20 mounting

screws. This bracket can be unscrewed and mounted onto

the opposite side of the camera, depending on your

application. The mounting bracket must be capable of

supporting the weight of the camera and its lens.

Note Some installation codes dictate that the mounting

bracket must be capable of supporting up to four

times the combined weight of the camera and

lens.

Figure 6 Camera Mount

Unscrew 3 bracket

securing screws and

then resecure the

bracket on the other

side of the camera.

Rev 3 11 G-113077-001

02/07

Page 17

Connecting the Camera

1. Connect the VIDEO connector on the rear of the

camera to the video-in connector on your monitor.

2. Connect the camera to a power supply appropriate for

your installation.

HCC334L/X, HCC484L/LX: 12 VDC or 24 VAC power

supply

HCC335LX, HCC485LX: 230V power supply

3. Plug in the power supply. The power (PWR) LED

illuminates to show that the camera is receiving power.

If it does not illuminate, check the connections and the

power source.

Figure 7 Camera Connections

Low voltage model shown

(HCC334L/X, HCC484L/X)

VIDEO

L/L

EE

ME

AES

AI

INT

BLC

FL

VSD

AGC

OFF

WB3

WB2

WB1

GND

DC

Power LED

PUSH

IRIS

LEVEL V-PH

LOCK

PWR

DC 12V

AC 24V

Rev 3 12 G-113077-001

02/07

Monitor

Page 18

Warranty and Service

Subject to the terms and conditions listed on the Product warranty,

during the warranty period Honeywell will repair or replace, at its

sole option, free of charge, any defective product returned prepaid.

In the event you have a problem with any Honeywell product,

please call Customer Service at 1.800.796.CCTV (North America

only) for assistance or to request a Return Merchandise

Authorization (RMA) number. For Europe and the United

Kingdom, please contact your Honeywell dealer.

Be sure to have the model number, serial number, and the nature

of the problem available for the technical service representative.

Prior authorization must be obtained for all returns, exchanges, or

credits. Items shipped to Honeywell without a clearly identified

Return Merchandise Authorization (RMA) number may be

refused.

Specifications

Note These specifications refer to all models, except

where otherwise noted.

HCC334L HCC334LX

Operational

Image Sensor: 1/3” Super HAD CCD

Video

Standard:

Scanning

System:

Number of

Pixels (H x V):

Minimum

Illumination:

Horizontal

Resolution:

NTSC PAL NTSC PAL

525 lines,

2:1 interlace

510 x 492 500 x 582 768 x 494 752 x 582

< 0.2 lux @ F1.2

(50 IRE, AGC ON)

330 TVL 330 TVL 480 TVL 480 TVL

HCC335LX

625 lines,

2:1 interlace

HCC484L HCC484LX

525 lines,

2:1 interlace

< 0.4 lux @ F1.2

(50 IRE, AGC ON)

HCC485LX

625 lines,

2:1 interlace

Rev 3 13 G-113077-001

02/07

Page 19

HCC334L HCC334LX

HCC335LX

Video Output: 1 Vp-p @ 75 Ohms

Sync System: Internal/Line lock

S/N Ratio: > 50 dB

Auto Gain

Control (AGC):

ALC: EE/VSD/DC

Automatic

Electronic

Shutter (AES):

Lens Mount: C/CS mount (adjustable)

White Balance

(AWB):

BLC: On/Off

Gamma: 0.45

1/60 1/100,000

sec

ATW/AWC/One Push Lock/Indoor/Outdoor/

On (30 dB)/Off (11 dB)

1/50 1/100,000

sec

Fluorescent/User

HCC484L HCC484LX

HCC485LX

1/60 1/100,000

sec

1/50 1/100,000

sec

Electrical

Input Voltage: HCC334L/LX, HCC484L/LX: 12 VDC/24 VAC

HCC335LX, HCC485LX: 230 VAC

Input Voltage

Range:

Power

Consumption:

HCC334L/LX, HCC484L/LX: 11 - 16 VDC, 17 - 28 VAC

HCC335LX, HCC485LX: 230 VAC ± 10%

HCC334L/LX, HCC484L/LX: 3.5 W

HCC335LX, HCC485LX: 4.2 W (max)

Mechanical

Dimension:

(W x H x D)

Weight: HCC334L/LX, HCC484L/LX: 0.84 lb (.380 kg)

HCC334L/LX, HCC484L/LX: 2.68 x 2.2 x 4.72 in. (68 x

56 x 120 mm)

HCC335LX, HCC485LX: 2.68 x 2.2 x 5.51 in. (68 x 56 x

140 mm)

HCC335LX, HCC485LX: 0.90 lb (.410 kg)

Environmental

Temperature: Operating: 14°F to 122°F (-10°C to +50°C)

Storage: -4°F to158°F (-20°C to +70°C)

Regulatory

Emissions: FCC, CE (EN55013)

Immunity: CE (EN50130-4)

Safety: EU: 73/23/EEC LVD

Rev 3 14 G-113077-001

02/07

Page 20

Honeywell Video Systems (Head office)

2700 Blankenbaker Pkwy, Suite 150

Louisville, KY 40299, USA

www.honeywellvideo.com

+1.800.796.2288

℡

Honeywell Security Australia Pty Ltd.

Unit 5, Riverside Centre

24-28 River Road West

Parramatta, NSW 2150, Australia

www.ademco.com.au

℡

+61.2.8837.9300

Honeywell Security Asia Pacific

33/F Tower A, City Center, 100 Zun Yi

Road

Shanghai 200051, China

www.security.honeywell.com/cn

℡

+86 21.2527.4568

Honeywell Security Asia

Flat A, 16/F, CDW Building

388 Castle Peak Road

Tsuen Wan, N.T., Hong Kong

www.security.honeywell.com/hk

℡

+852.2405.2323

Honeywell Security France

Parc Gutenberg, 8, Voie La Cardon

91120, Palaiseau, France

www.honeywell.com/security/fr

℡

+33.01.64.53.80.40

Honeywell Security Italia SpA

Via Treviso 2 / 4

31020 San Vendemiano

Treviso, Italy

www.honeywell.com/security/it

℡

+39.04.38.36.51

Honeywell Security España

Mijancas 1. 3

P.Ind. Las Mercedes

28022 Madrid, Spain

www.honeywell.com/security/es

℡

+34.902.667.800

a

Planta

Honeywell Video Systems

Northern Europe

Netwerk 121

1446 WV Purmerend, The Netherlands

www.SecurityHouse.nl

℡

+31.299.410.200

Honeywell Video Systems UK Ltd.

Aston Fields Road, Whitehouse Ind Est

Runcorn, Cheshire, WA7 3DL, UK

www.honeywellvideo.com

℡

+0844 8000 235

Honeywell Security South Africa

Unit 6 Galaxy Park, 17 Galaxy Avenue

Linbro Park, P.O. Box 59904

2100 Kengray, Johannesburg

South Africa

www.honeywell.co.za

℡

+27.11.574.2500

Honeywell Security Deutschland

Johannes-Mauthe-Straße 14

D-72458 Albstadt, Germany

www.honeywell.com/security/de

℡

+49.74 31.8 01.0

Honeywell Security Poland

Chmielewskiego 22a, 70-028

Szczecin, Polska

www.ultrak.pl

℡

+48.91.485.40.60

Honeywell Security Czech Republic

Havránkova 33, Brno

Dolní Heršpice, 619 00

Czech Republic

www.olympo.cz

℡

+420.543.558.111

Honeywell Security Slovakia Republic

Vajnorská 142, 83104 Bratislava

Slovakia

www.olympo.sk

℡

+421.2.444.54.660

www.honeywellvideo.com

+1.800.796.CCTV (North America only)

HVSsupport@honeywell.com

Document

© 2007 Honeywell International Inc. All rights reserved. No part of this publication

may be reproduced by any means without written permission from Honeywell Video

Systems. The information in this publication is believed to be accurate in all respects.

However, Honeywell Video Systems cannot assume responsibility for any

consequences resulting from the use thereof. The information contained herein is

subject to change without notice. Revisions or new editions to this publication may

be issued to incorporate such changes.

G-113077-001 02/07 Rev 3

Loading...

Loading...