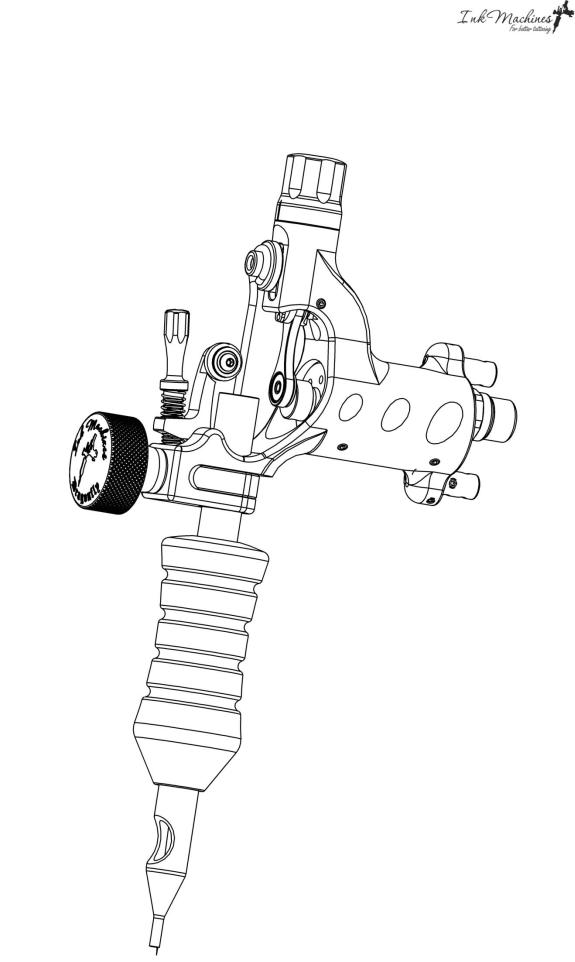

Ink Machines Dragonfly User Manual

Manual for the Dragonfly tattoo machine

1

Introduction

We are proud to present the Dragonfly tattoo machine. Designed with the tattoo artist in focus and manufactured with the highest quality materials and components available.

The Dragonfly is a state of the art rotary based tattoo machine with features that gives it several advantages compared to other tattoo machines. The adjustable suspension system allows the needles hitting force to be adjusted, the low noise, the light weight, the needlebar retainer and the ability to accept most standard grips, tubes, needles and power supplies with RCA or clipcord are some of the features and improvements incorporated in to the design without compromising the function or ergonomics. All of these things and more put together in one package makes the Dragonfly the most complete tattoo machine ever made.

The Dragonfly have been tested and developed for over three years by engineers and several professional tattoo artists which means that you can look forward to the reliable and satisfactory performance of the Dragonfly for years to come.

You should expect a return on your investment in the form of you and your customers well being, enabling you to perform better and ultimately improving your business.

To ensure safety and obtain maximum service life from the machine it is essential that users read and understand this manual. Check out www.Inkmachines.com for more info and news.

Safety

The Dragonfly is designed and developed solely for tattooing of humans by professional tattoo artists. Do not under any circumstances use for other purposes.

Inkmachines only provide products for professional tattoo artists and may only be used by professionals with knowledge about diseases and how to maintain a clean working environment and sterile equipment. Work safe!

Always use sterile tubes, grips, tips and needles.

Always use rubber gloves.

Use plastic bags and wraps for tattoo equipment around the machine and the power cord.

Always keep your machines clean! Before and after every use you should: remove any oil or dirt and wipe the machine clean with alcohol or equivalent disinfectant.

The manufacturer does not have responsibility for any kind of material damage, person damage or infection caused by negligence or misuse of the machine or the components attached to the machine.

The manufacturer does not have responsibility for contamination or infection of humans or animals.

2

Maintenance instructions

Moving parts exposed to friction needs lubrication!

Use the oil that were supplied with the machine and follow these steps to lubricate every 100 hours of use. Only use the oil provided with the machine, other oils may reduce lifetime of the machine and / or clog.

1.Remove grip and needle.

2.Remove the cap and push the piston assembly down to the bottom of its stroke by pushing on the needlebar pin and lube with a small amount of oil in the corners between the piston and the housing. Put the cap back in place.

3.Apply oil just above the needlebar pin in the oval hole.

4.Apply oil on the bearings of the needlebar retainer and roll the bearings a few times back and forward to let the oil run into the bearings.

5.Run the machine between 9-12 volts for about a minute and clean it when done.

Service

Tools and spare parts are available on www.inkmachines.com in the spare parts section if you want to do service work yourself. You can also send machines to our service technicians for a full service. For more information go to www.inkmachines.com

Warranty

This product includes a 12 month warranty from the date of purchase. The warranty applies to factory faults and not to wear of any components caused by normal or abnormal use.

The warranty is void if:

1.Input voltage above 14 volts have been applied to the machine.

2.Machine or any of its components have been autoclaved or cleaned in a ultrasonic cleaner.

3.Components have been damaged by misuse or carelessness.

4.Components have been manipulated.

3

Getting started

1.Disconnect the machine from the power supply.

2.Attach a new quality rubber nipple or grommet to the needlebar pin . The nipple or grommet should have a tight fit with the needlebar loop.

3.Open the retainer to make clearance for the needlebar and tube by adjusting the retainer screw .

4.Bend the needlebar to a slight arc shape to compensate the pressure from the needlebar retainer. This enables the needles to work straighter, prevent it from wobbling and making it more stable in the tip.

5.Insert the needle carefully into the tube without damaging the needle tips.

6.Insert the tube / needle assembly trough the tube vice clamp and tighten the vice lightly. Attach the needlebar loop to the nipple.

7.Move the needlebar pin and the attached needlebar down to the bottom of its stroke by pressing the needlebar pin downwards, if the needlebar pin won’t move down push the excentric bearing to the side at the same time.

8.Inspect and adjust the protrusion and alignment of the needle and tip by moving the grip and tube to the desired location. Tighten the tube vice firmly when done .

9.Adjust the needlebar retainer by turning the retainer screw until the retainer o-rings makes contact with the needlebar. Don’t tighten more than necessary to keep the needle stable in the tip. If the needlebar don’t align properly with the retainer o-rings, adjust / bend the needlebar so that it aligns.

10.Connect the machine to a power supply ( max 14 volts DC ) either with a RCA cable to the RCA contact or a clipcord to the clipcord binding posts , if you choose to use a clipcord make sure to connect positive to + and negative to – marked on the machine next to the bindingposts.

11.Run the machine between 9-12 volts depending on needle size and friction, fine adjust the needlebar retainer until the needle feels stable in the tip and make sure that everything runs smoothly without excessive friction or noise.

12.Run the machine and adjust the needle suspension by feeling the needlebar pin and nipple with your finger and by turning the cap to get the desired hitting, clockwise = harder, counter clockwise = softer. When the cap is turned clockwise to the bottom the needlebar pin will be locked with the piston . This position will give the hardest hitting and shortest stroke. When the cap is turned counter clockwise the stroke will be increasingly softer / longer until the limit is reached. When the limit is reached the adjustment screw will make contact with the cap from the inside and produce noise, turn the cap clockwise until the adjustment screw clears the cap and the noise stops. If you turn the cap too far and the cap should come off during this operation, screw down the adjustment screw two turns and reattach the cap by pushing it until it clicks into place.

13.Encapsulate the machine and cord with plastic bags and wrappings for tattoo equipment.

4

Loading...

Loading...