Ingersoll-Rand IMPACTOOL 2707A1 Operation And Maintenance

03530699

Form P6521

Edition 12

June, 2000

OPERATION AND MAINTENANCE FOR

MODEL 2707A1 HEAVY DUTY IMPACTOOL

Model 2707A1 Impactool is designed for use in heavy duty industrial applications,

automotive repair, body shops, front end service and light truck and farm equipment

applications.

Ingersoll–Rand is not responsible for customer modification of tools for applications on

which Ingersoll–Rand was not consulted.

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING TOOL.

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PLACE THE INFORMATION

IN THIS MANUAL INTO THE HANDS OF THE OPERATOR.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

PLACING TOOL IN SERVICE

• Always operate, inspect and maintain this tool in

accordance with American National Standards

Institute Safety Code for Portable Air Tools

(ANSI B186.1).

• For safety, top performance, and maximum

durability of parts, operate this tool at 90 psig

(6.2 bar/620 kPa) maximum air pressure at the inlet

with 3/8” (10 mm) inside diameter air supply hose.

• Always turn off the air supply and disconnect the

air supply hose before installing, removing or

adjusting any accessory on this tool, or before

performing any maintenance on this tool.

• Do not use damaged, frayed or deteriorated air

hoses and fittings.

• Be sure all hoses and fittings are the correct size

and are tightly secured. See Dwg. TPD905–1 for a

typical piping arrangement.

• Always use clean, dry air at 90 psig maximum air

pressure. Dust, corrosive fumes and/or excessive

moisture can ruin the motor of an air tool.

• Do not lubricate tools with flammable or volatile

liquids such as kerosene, diesel or jet fuel.

• Do not remove any labels. Replace any damaged

label.

USING THE TOOL

• Always wear eye protection when operating or

performing maintenance on this tool.

• Always wear hearing protection when operating

this tool.

• Keep hands, loose clothing and long hair away from

rotating end of tool.

• Note the position of the reversing lever before

operating the tool so as to be aware of the direction

of rotation when operating the throttle.

• Anticipate and be alert for sudden changes in

motion during start up and operation of any power

tool.

• Keep body stance balanced and firm. Do not

overreach when operating this tool. High reaction

torques can occur at or below the recommended air

pressure.

• Tool shaft may continue to rotate briefly after

throttle is released.

• Air powered tools can vibrate in use. Vibration,

repetitive motions or uncomfortable positions may

be harmful to your hands and arms. Stop using any

tool if discomfort, tingling feeling or pain occurs.

Seek medical advice before resuming use.

• Use accessories recommended by Ingersoll–Rand.

• Use only impact sockets and accessories. Do not use

hand (chrome) sockets or accessories.

• Impact wrenches are not torque wrenches.

Connections requiring specific torque must be

checked with a torque meter after fitting with an

impact wrench.

• This tool is not designed for working in explosive

atmospheres.

This tool is not insulated against electric shock.

GB

The use of other than genuine Ingersoll–Rand replacement parts may result in safety hazards, decreased tool

performance, and increased maintenance, and may invalidate all warranties.

Repairs should be made only by authorized trained personnel. Consult your nearest Ingersoll–Rand Authorized

Servicenter.

Refer All Communications to the Nearest

Ingersoll–Rand Office or Distributor.

Ingersoll–Rand Company 2000

Printed in U.S.A.

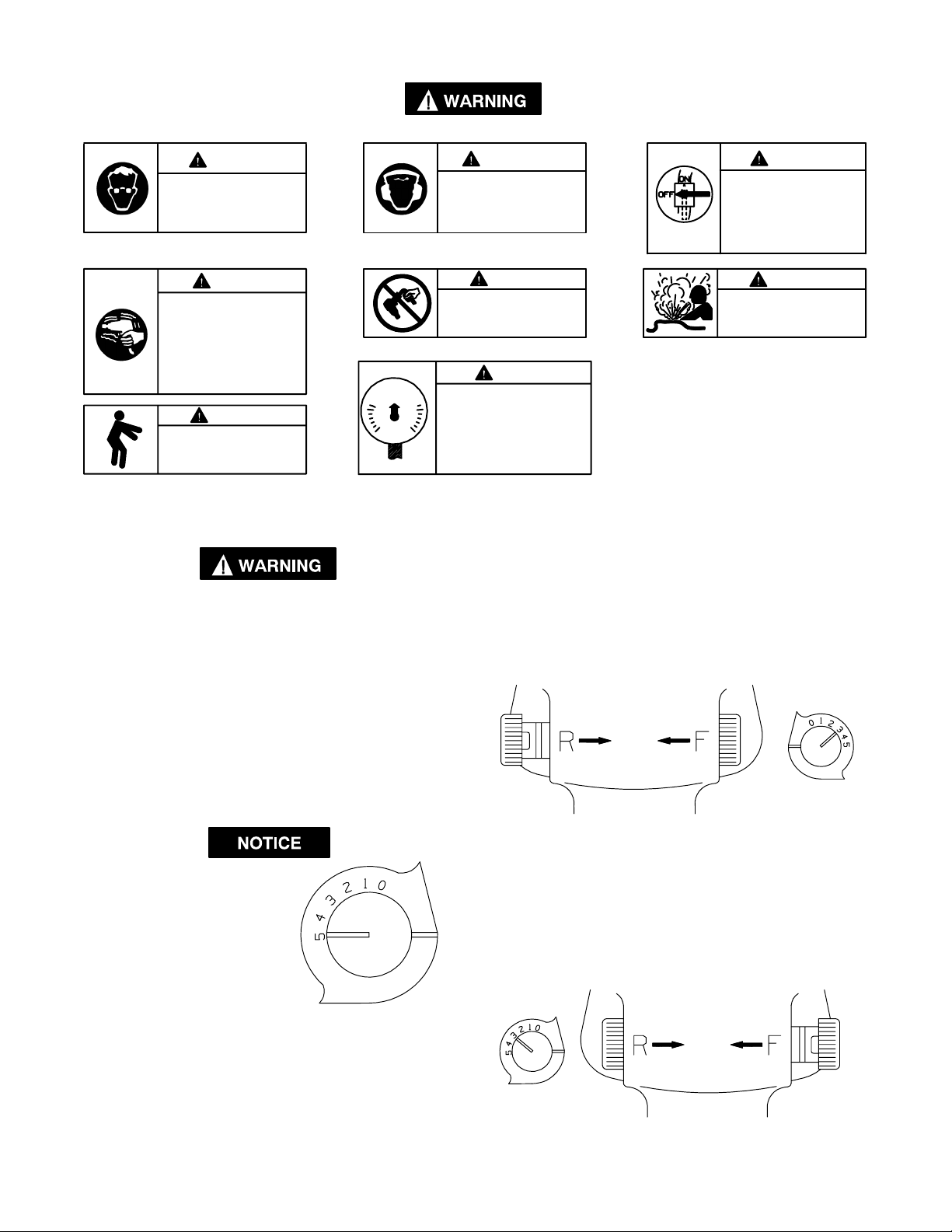

WARNING LABEL IDENTIFICATION

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

WARNING

Always wear eye protection

when operating or performing maintenance on this

tool.

WARNING

Air powered tools can vibrate

in use. Vibration, repetitive

motions or uncomfortable positions may be harmful to your

hands and arms. Stop using

any tool if discomfort, tingling

feeling or pain occurs. Seek

medical advice before resuming use.

90 psig

(6.2bar/620kPa)

WARNING

Keep body stance balanced

and firm. Do not overreach

when operating this tool.

ADJUSTMENTS

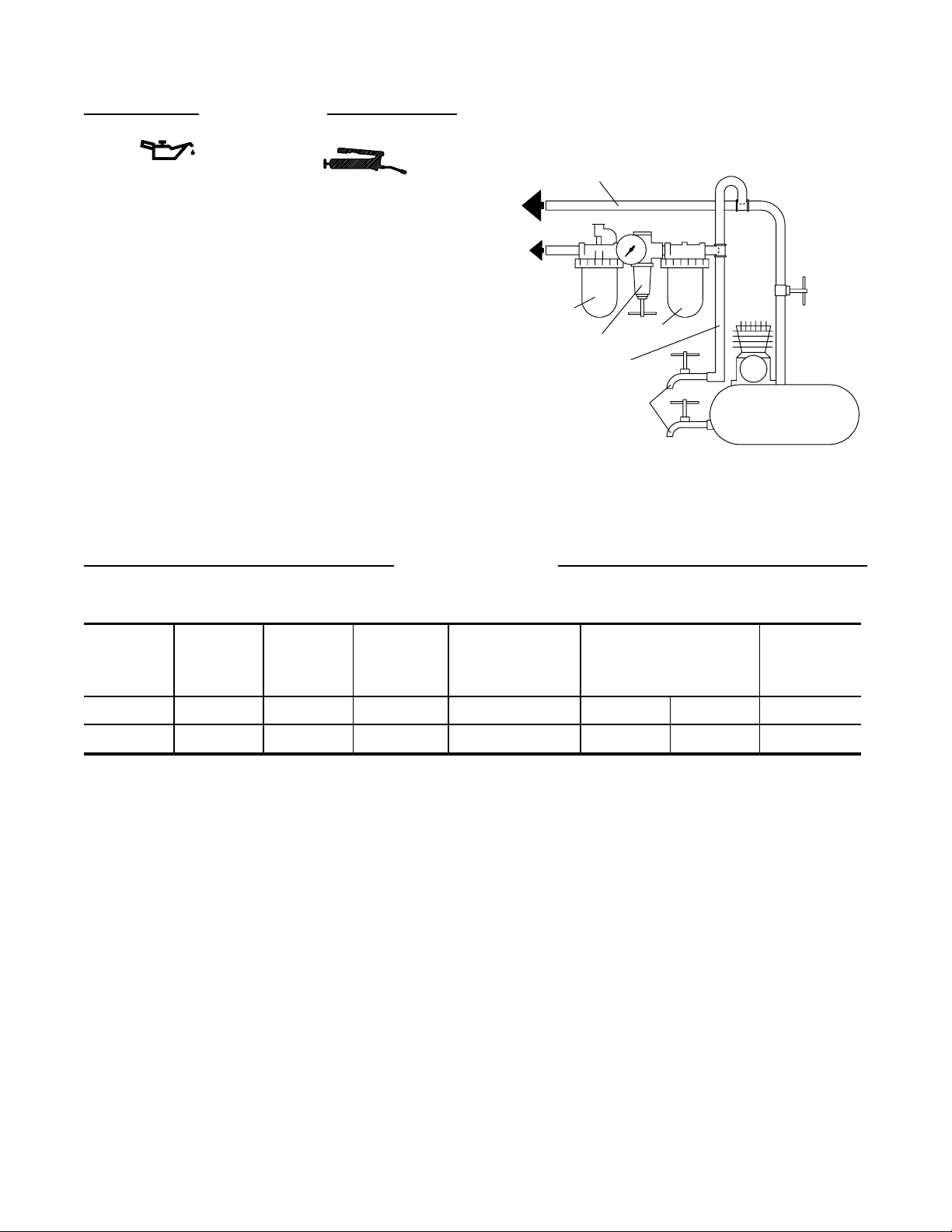

SETTING THE POWER REGULATOR

Impact wrenches are not torque control devices. Fasteners

with specific torque requirements must be checked with

suitable torque measuring devices after installation with

an impact wrench.

Model 2707A1 Impactool incorporates a power regulator into

the reverse mechanism that allows the operator to have either

full power output in one direction and reduced power output in

the other direction or full power output in both directions. To

adjust the power, proceed as follows:

For full power in both directions, rotate the reverse valve

until the notch on each end of the reverse valve aligns with the

number 5 on each side of the housing.

The numbers 0 thru 5 on the

housing are only for reference

and DO NOT denote a specific

power output. Zero (0)

designates the lowest power

output while five (5) denotes the

highest.

(Dwg. TPD1247)

WARNING

Always wear hearing

protection when operating

this tool.

WARNING

Do not carry the tool by

the hose.

WARNING

Operate at 90 psig (6.2 bar/

620 kPa) Maximum air pressure.

For reduced power in the forward direction and full power

in the reverse direction, push the reverse valve inward on the

right side of the tool and rotate the reverse valve until the

notch on the right side aligns with the desired number on the

right side. This provides reduced power in forward but full

power in reverse when the reverse valve is pushed in the

opposite direction.

See Dwg. TPD1248.

.

For reduced power in the reverse direction and full power

in the forward direction, push the reverse valve inward on

the left side of the tool and rotate the reverse valve until the

notch on the left side aligns with the desired number on the

left side. This provides full power in forward but reduced

power in reverse when the reverse valve is pushed the

opposite direction. See Dwg. TPD1249.

WARNING

Always turn off the air supply and disconnect the air

supply hose before installing, removing or adjusting

any accessory on this tool,

or before performing any

maintenance on this tool.

WARNING

Do not use damaged, frayed

or deteriorated air hoses

and fittings.

(Dwg. TPD1248)

(Dwg. TPD1249)

2

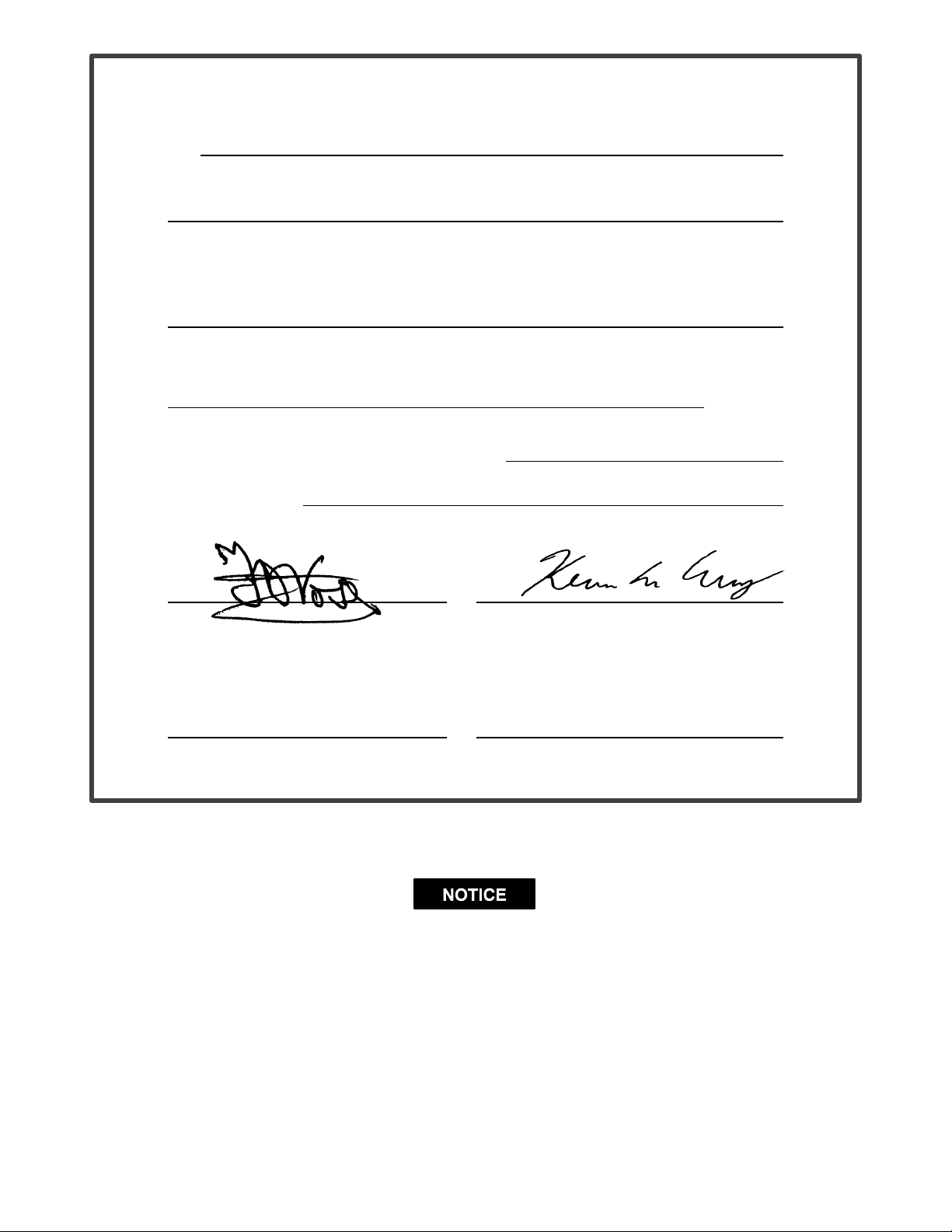

LUBRICATION

PLACING TOOL IN SERVICE

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

Ingersoll–Rand No. 50 Ingersoll–Rand No. 100

Always use an air line lubricator with these tools.

We recommend the following Filter–Lubricator–Regulator

Unit:

For USA – No. C28–04–FKG0–28

After each eight hours of operation, unless an air line

lubricator is used, remove the Oil Chamber Plug and fill the

oil chamber with Ingersoll–Rand No. 50 Oil.

After each forty–eight hours of operation, or as experience

indicates, inject about 4 cc of Ingersoll–Rand No. 100 Grease

into the Grease Fitting .

SPECIFICATIONS

Model Type of

Handle

Drive Impacts per

min.

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

Recommended

Torque Range

FILTER

HSound

Power Level

dB (A)

COMPRESSOR

(Dwg. TPD905–1)

♦Vibrations

Level

in. ft–lbs (Nm) Pressure Power m/s

2707A1 pistol 1/2” sq. 1,300 40–275 (54–373) 95.6 108.6 3.8

H Tested in accordance with PNEUROP PN8NTC1.2

♦ Tested to ISO8662–7

2

3

DECLARATION OF CONFORMITY

We

Ingersoll–Rand, Co.

(supplier’s name)

78192 Trappes Cedex France

(address)

declare under our sole responsibility that the product,

Model 2707A1 Heavy Duty Impactool

to which this declaration relates, is in compliance with the provisions of

98/37/EC

By using the following Principle Standards:

Serial No. Range:

(2000 → ) A00D XXXXX →

ISO8662 PNEUROP PN8NTC1

Directives.

D. Vose Kevin R. Morey

Name and signature of authorised persons Name and signature of authorised persons

June, 2000

Date Date

SAVE THESE INSTRUCTIONS. DO NOT DESTROY.

When the life of the tool has expired, it is recommended that the tool be disassembled,

degreased and parts be separated by material so that they can be recycled.

June, 2000

4

Loading...

Loading...