Ingersoll-Rand EP50-PE, SSR UP6 50PEI HF50-PE, SSR UP6 40, HP50-PE, HXP50-PE User Manual

...

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI

HF50–PE, EP50–PE, HP50–PE, HXP50–PE

60Hz

This manual contains

important safety information

and must be made available

to personnel who operate and

maintain this machine.

OPERATION AND MAINTENANCE MANUAL

C.C.N. :

REV. : A

DATE : OCTOBER 2008

80445190

AIR COMPRESSOR GROUP

BONDED WARRANTY & REGISTERED START UP

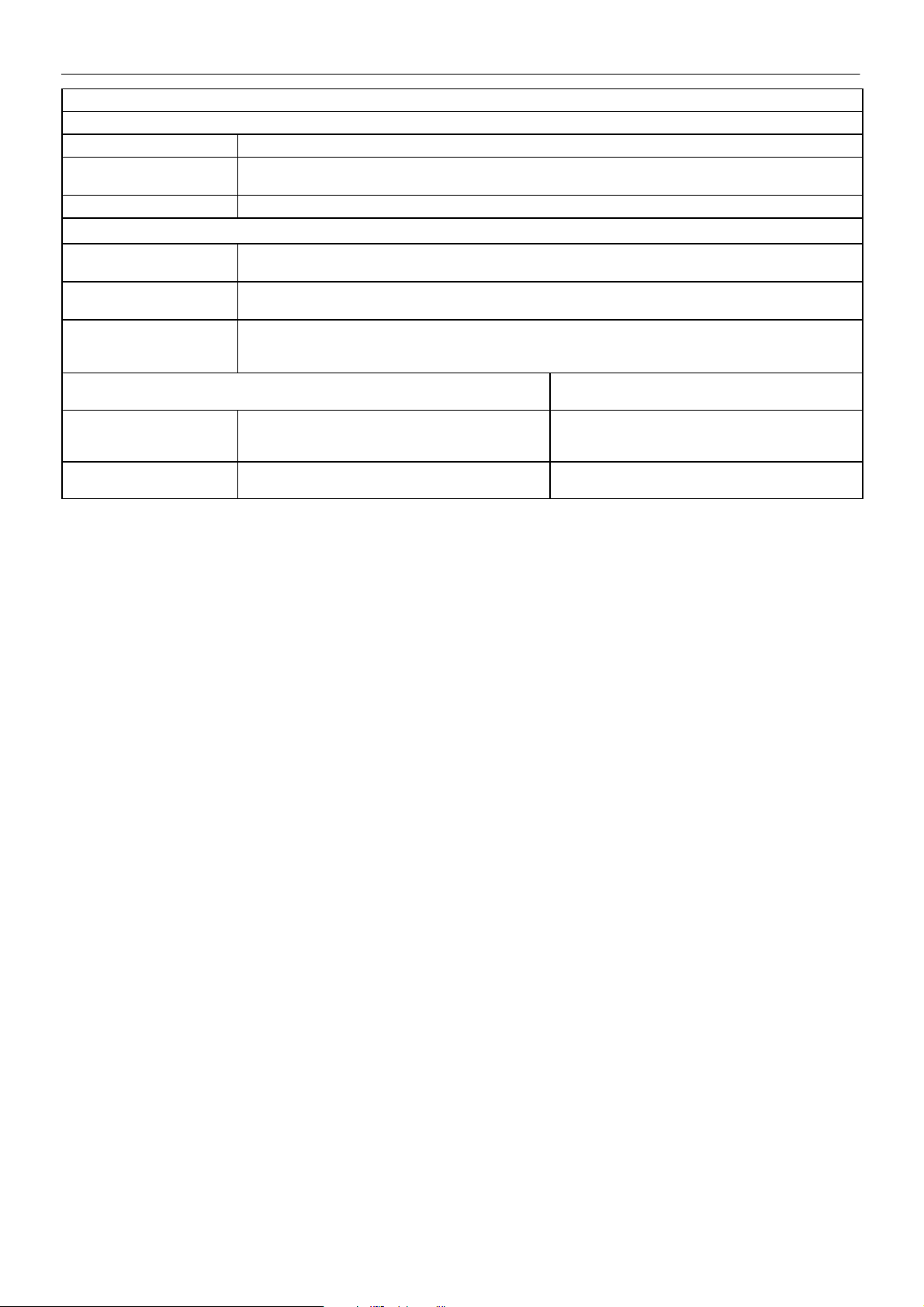

Warranty

The Company warrants that the equipment manufactured by it and delivered hereunder will be free of defects in

material and workmanship for a period of twelve months from the date of placing the Equipment in operation or eighteen

months from the date of shipment from the factory, whichever shall first occur. The Purchaser shall be obligated to

promptly report any failure to conform to this warranty, in writing to the Company in said period, whereupon the

Company shall, at its option, correct such nonconformity, by suitable repair to such equipment or, furnish a replacement

part F.O.B. point of shipment, provided the Purchaser has stored, installed, maintained and operated such Equipment

in accordance with good industry practices and has complied with specific recommendations of the Company.

Accessories or equipment furnished by the Company, but manufactured by others, shall carry whatever warranty the

manufacturers have conveyed to the Company and which can be passed on to the Purchaser. The Company shall

not be liable for any repairs, replacements, or adjustments to the Equipment or any costs of labor performed by the

Purchaser or others without Company‘s prior written approval.

The effects of corrosion, erosion and normal wear and tear are specifically excluded. Performance warranties are

limited to those specifically stated within the Company‘s proposal. Unless responsibility for meeting such performance

warranties are limited to specified tests, the Company‘s obligation shall be to correct in the manner and for the period

of time provided above.

THE COMPANY MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND WHATSOEVER,

EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY DISCLAIMED.

Correction by the Company of nonconformities whether patent or latent, in the manner and for the period of time

provided above, shall constitute fulfillment of all liabilities of the Company for such nonconformities whether based on

contract, warranty negligence, indemnity, strict liability or otherwise with respect to or arising out of such Equipment.

The purchaser shall not operate Equipment which is considered to be defective, without first notifying the Company

in writing of its intention to do so. Any such use of Equipment will be at Purchaser‘s sole risk and liability.

Note that this is Ingersoll Rand standard warranty. Any warranty in force at the time of purchase of the compressor

or negotiated as part of the purchase order may take precedence over this warranty.

Register on–line at http://air.ingersollrand.com

Ingersoll Rand Air Solutions Group

Global Aftermarket Division

800–B Beaty Street

Davidson, NC 28036

1–800–526–3615

CONTENTS & ABBREVIATIONS

1

CONTENTS

1 CONTENTS

2 FOREWORD

3 DECALS

8 SAFETY

10 GENERAL INFORMATION

12 INSTALLATION / HANDLING

OPERATING INSTRUCTIONS

21 – GENERAL

22 – ELECTRO–PNEUMATIC

29 – INTELLISYS

40 MAINTENANCE

47 TROUBLE SHOOTING

ABBREVIATIONS & SYMBOLS

#### Contact Ingersoll Rand for serial number

–>#### Up to Serial No.

####–> From Serial No.

* Not illustrated

{ Option

NR Not required

AR As required

SM Sitemaster/Sitepack

HA High ambient machine

WC Watercooled machine

AC Aircooled machine

ERS Energy recovery system

T.E.F.C. Totally enclosed fan cooled motor (IP55)

O.D.P. Open drip proof (motor)

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE, HP50–PE, HXP50–PEhttp://air.ingersollrand.com

2

FOREWORD

The contents of this manual are considered to be proprietary and

confidential to Ingersoll Rand and should not be reproduced without

the prior written permission of Ingersoll Rand.

Nothing contained in this document is intended to extend any

promise, warranty or representation, expressed or implied, regarding

the Ingersoll Rand products described herein. Any such warranties or

other terms and conditions of sale of products shall be in accordance

with the standard terms and conditions of sale for such products, which

are available upon request.

This manual contains instructions and technical data to cover

routine operation and scheduled maintenance tasks by operation and

maintenance staff. Major overhauls are outside the scope of this

manual and should be referred to an authorised Ingersoll Rand service

department.

The design specification of this machine has been certified as

complying with E.C. directives. Any modification to any part is

absolutely prohibited and would result in the CE certification and

marking being rendered invalid.

All components, accessories, pipes and connectors added to the

compressed air system should be:

. of good quality, procured from a reputable manufacturer and,

wherever possible, be of a type approved by Ingersoll Rand.

. clearly rated for a pressure at least equal to the machine maximum

allowable working pressure.

. compatible with the compressor lubricant/coolant.

. accompanied with instructions for safe installation, operation and

maintenance.

Details of approved equipment are available from Ingersoll Rand

Service departments.

The use of non–genuine spare repair parts other than those

included within the Ingersoll Rand approved parts list may create

hazardous conditions over which Ingersoll Rand has no control.

Therefore Ingersoll Rand does not accept any liabilitity for losses

caused by equipment in which non–approved repair parts are installed.

Standard warranty conditions may be affected.

The intended uses of this machine are outlined below and examples

of unapproved usage are also given, however Ingersoll Rand cannot

anticipate every application or work situation that may arise.

IF IN DOUBT CONSULT SUPERVISION.

This machine has been designed and supplied for use only in the

following specified conditions and applications:

. Compression of normal ambient air containing no known or

detectable additional gases, vapours. or particles

. Operation within the ambient temperature range specified in the

GENERAL INFORMATION section of this manual.

The use of the machine in any of the situation types listed in

table 1:–

a) Is not approved by Ingersoll Rand,

b) May impair the safety of users and other persons, and

c) May prejudice any claims made against Ingersoll Rand.

TABLE 1

Use of the machine to produce compressed air for:

a) direct human consumption

b) indirect human consumption, without suitable filtration and purity

checks.

Use of the machine outside the ambient temperature range

specified in the GENERAL INFORMATION SECTION of this manual.

Use of the machine where there is any actual or foreseeable risk of

hazardous levels of flammable gases or vapours.

THIS MACHINE IS NOT INTENDED AND MUST NOT BE

USED IN POTENTIALLY EXPLOSIVE ATMOSPHERES,

INCLUDING SITUATIONS WHERE FLAMMABLE GASES OR

VAPOURS MAY BE PRESENT.

Use of the machine fitted with non Ingersoll Rand approved

components.

Use of the machine with safety or control components missing or

disabled.

Ingersoll Rand reserves the right to make changes and

improvements to products without notice and without incurring any

obligation to make such changes or add such improvements to

products sold previously.

The company accepts no responsibility for errors in translation of

this manual from the original English version.

© COPYRIGHT 2008

INGERSOLL RAND COMPANY

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE, HP50–PE, HXP50–PE http://air.ingersollrand.com

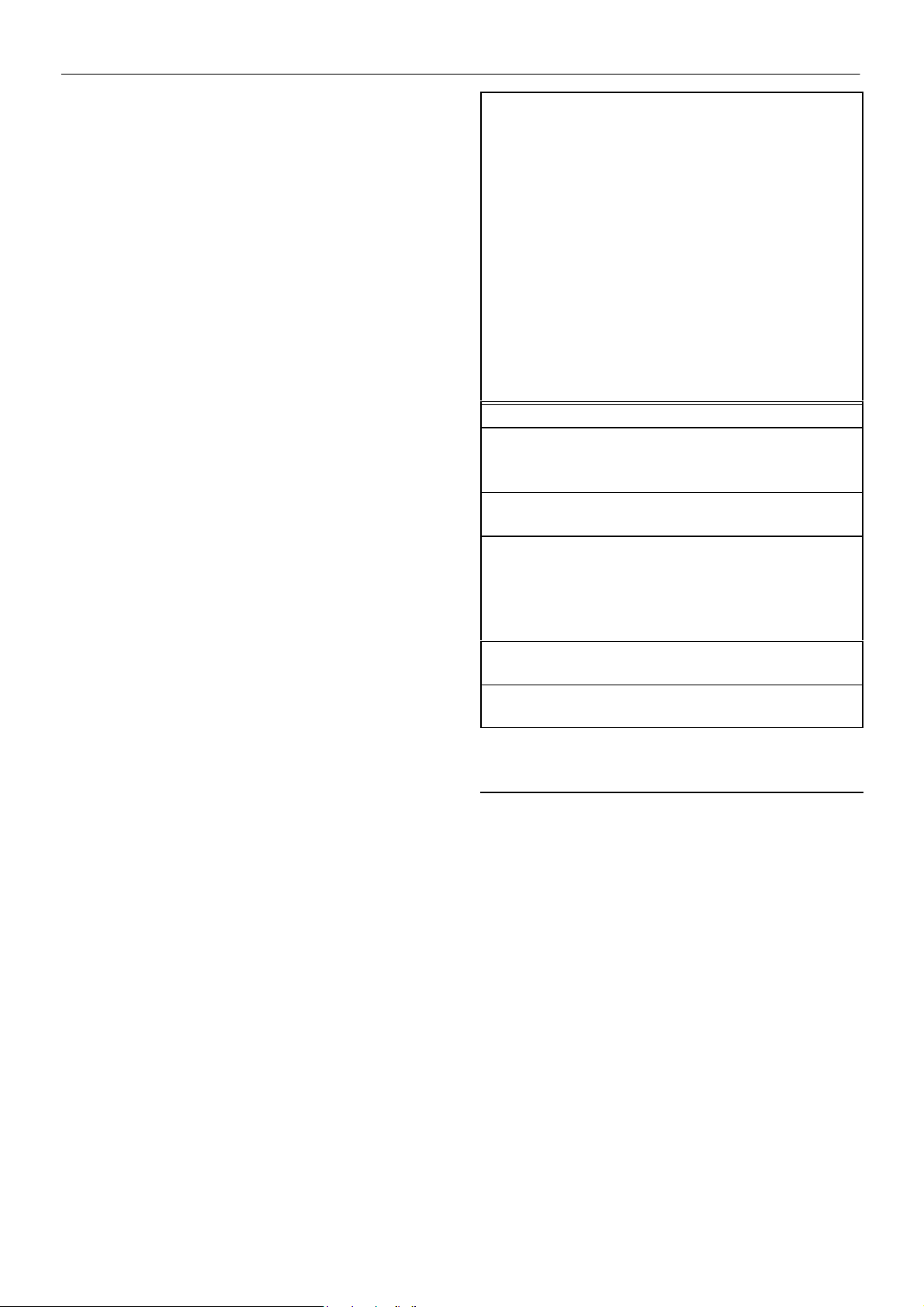

DECALS 3

ISO SYMBOLS

GRAPHIC FORM AND MEANING OF ISO SYMBOLS

Prohibition / Mandatory Information / Instructions Warning

Use fork lift truck from this side only. RESET Do not use fork lift truck from this side.

Emergency stop. On (power). Off (power).

AUTOMATIC RESTART MAINTENANCE MAINTENANCE PROHIBITED

FRAGILE KEEP DRY THIS WAY UP

USE NO HOOKS NO SIDE CLAMPS HOURS

http://air.ingersollrand.com

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

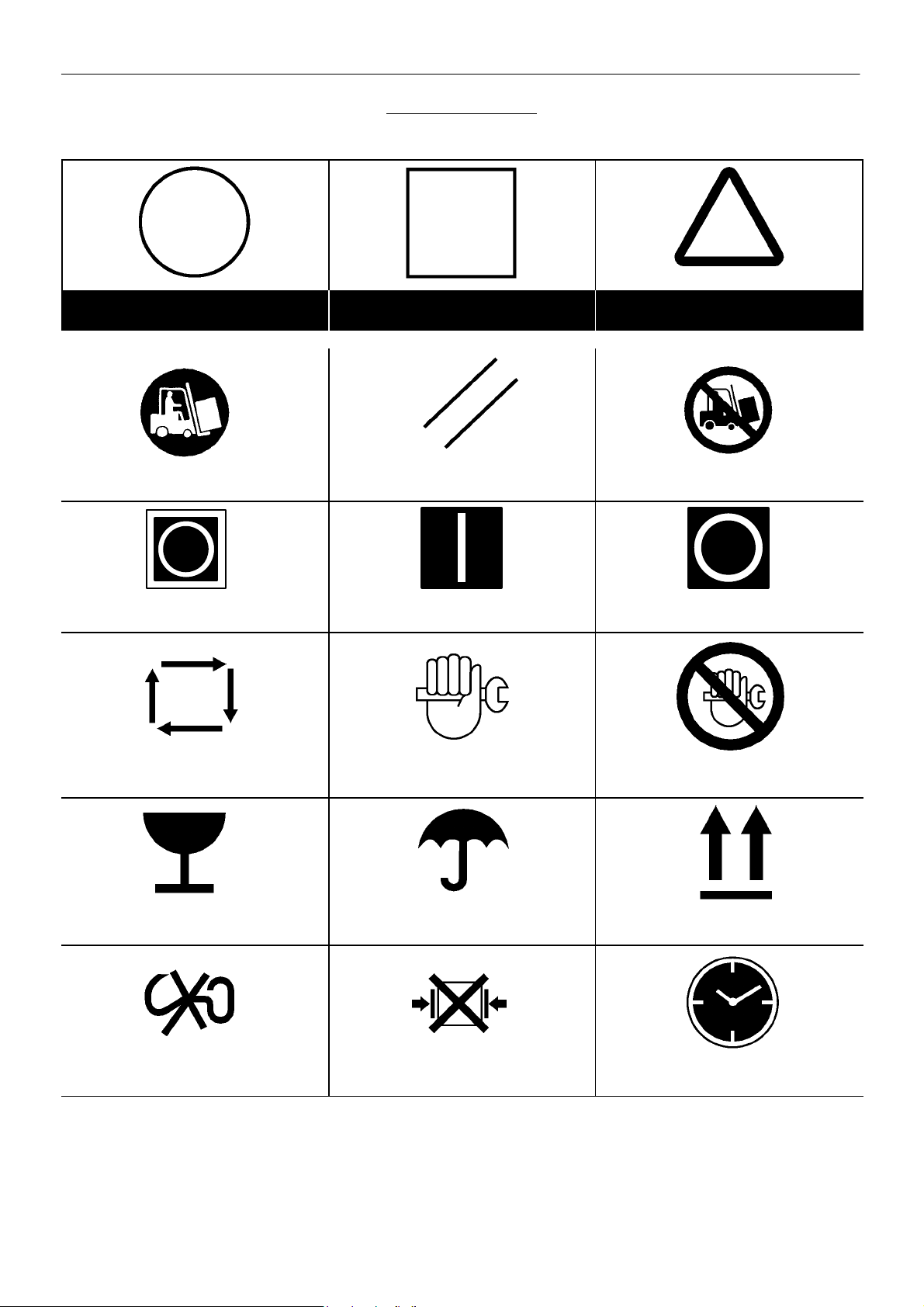

DECALS4

POWER INSPECT

Every X months, if sooner than required by

operating hours

CLEAN

CHANGE / REPLACE

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE, HP50–PE, HXP50–PE http://air.ingersollrand.com

DECALS 5

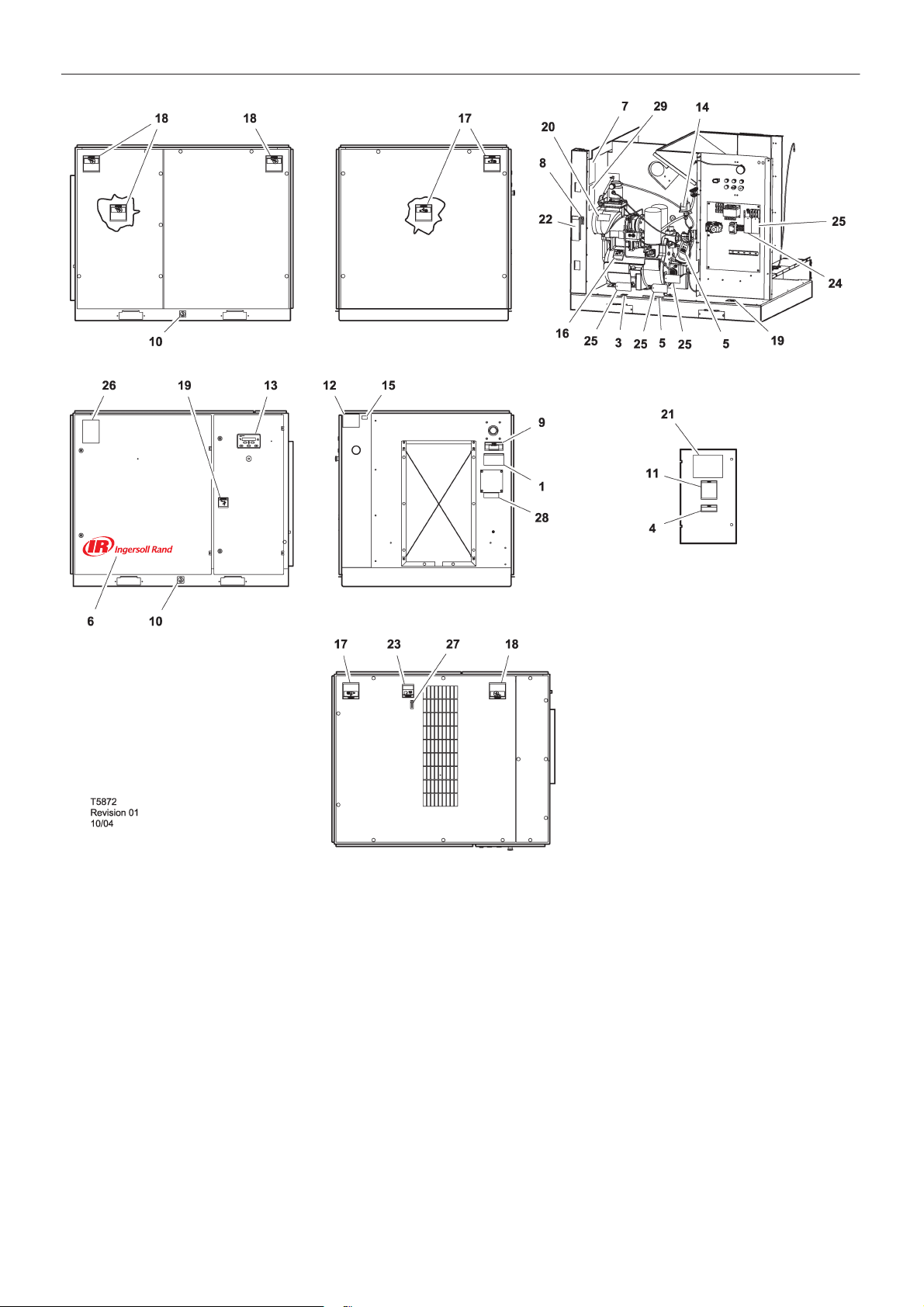

ANSI SYMBOLS

GRAPHIC FORM AND MEANING OF ANSI SYMBOLS

DANGER

INTAKE AIR. Can contain carbon monoxide or other contaminants. Will cause serious injury or death. Ingersoll Rand

air compressors are not designed, intended or approved for breathing air. Compressed air should not be used for

breathing air applications unless treated in accordance with all applicable codes and regulations.

WARNING

HAZARDOUS VOLTAGE. Can cause serious injury or death. Disconnect power and bleed pressure from tank before

servicing. Lockout/Tagout machine. Compressor must be connected to properly grounded circuit. See Grounding

Instructions in manual. Do not operate compressor in wet conditions. Store indoors.

RISK OF FIRE OR EXPLOSION. Electrical arcing from compressor components can ignite flammable liquids and

vapors which can result in serious injury. Never operate the compressor near flammable liquids or vapors. If used to

spray flammable materials, keep compressor at least 20ft away from the spray area.

HIGH PRESSURE AIR. Rusted tanks can cause explosion and severe injury or death. Receiver under perssure.

Operator should relieve tank pressure before performing maintenance. In addition to automatic drain, operate manual

drain valve weekly. Manual drain valve located at bottom of the tank.

MOVING PARTS. Can cause serious injury. Do not operate with guards removed. Machine may start automatically.

Disconnect power before servicing. Lockout/Tagout machine.

HOT SURFACES. Can cause serious injury. Do not touch. Allow to cool before servicing. Do not touch hot

compressor or tubing.

EXPOSED MOVING BELTS AND SHEAVES.

Can cause severe injury or death.

Do not operate without guard in place. Disconnect power before servicing.

Lockout/Tagout machine.

http://air.ingersollrand.com

Air flow exhaust may contain flying debris.

Safety protection should be worn at all times.

Pinch point hazard.

Keep hands clear.

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

6

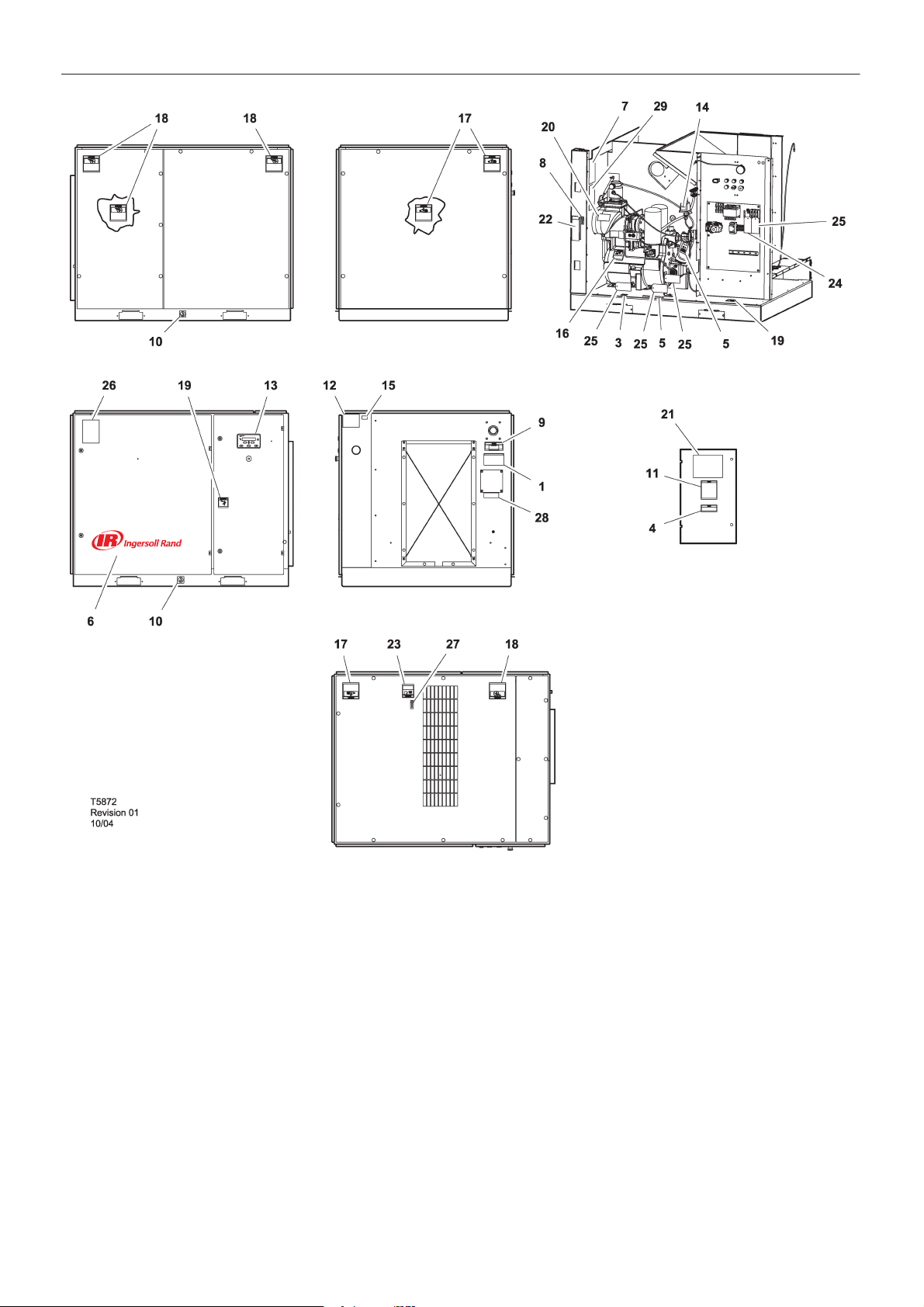

60 Hz Units

DECALS – ANSI

VIEW BACK

VIEW FRONT

VIEW LEFT

VIEW RIGHT

INSIDE PACKAGE

INSIDE STARTER DOOR

VIEW TOP

Item ccn Qty. Description Item ccn Qty. Description

1 32343519 1 Decal, warning contaminated air

2 93166502 1 Decal, replacement filter element

3 93166460 1 Decal, coolant drain

4 32343501 1

5 22248538 2 Decal, pinch hazard

6 23038474 1 Decal, Ingersoll Rand signature

7

23353170 1 Decal, maintenance parts

8 30286686 1 Decal, notice rotation

9 32343543 1 Decal, notice air discharge

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE, HP50–PE, HXP50–PE http://air.ingersollrand.com

Decal, dual voltage (if needed)

horizontal 27.5“

10 93171262 2 Decal, notice lift here

11 32343493 1 Decal, overload setting IEC starter

12 SPEC 1 Specifications, compressor package

13 81295883 1 Decal, facia – Electro–Pneumatic

81295891 1 Decal, facia – Intellisys

14 32017469 1 Decal, voltage 120/1/60

15 32017436 1 Decal, voltage 230/3/60

32018475 1 Decal, voltage 200/3/60

32236481 1 Decal, voltage 380/3/60

60 Hz Units

DECALS – ANSI

7

VIEW BACK

VIEW FRONT

VIEW LEFT

VIEW RIGHT

INSIDE PACKAGE

INSIDE STARTER DOOR

VIEW TOP

Item ccn Qty. Description Item ccn Qty. Description

32017444 1 Decal, voltage 460/3/60

32177305 1 Decal, voltage 575/3/60

16 32343527 1 Decal, warning high pressure

17 32343535 3 Decal, warning moving belts

18 32343550 4 Decal, warning exposed fan

19 32343568 2 Decal, warning hazardous voltage

20 32343584 1 Decal, warning hot surface

21 22182372 1 Decal, wiring schematic

Full Voltage 60Hz

22182349 1 Decal, wiring schematic

Star Delta 60Hz

22182364 1 Decal, wiring schematic

Full Voltage Intellisys 60Hz

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE, HP50–PE, HXP50–PEhttp://air.ingersollrand.com

22182356 1 Decal, wiring schematic

Star Delta Intellisys 60Hz

22 32343907 1 Decal, lock and tag out

23 32343899 1 Decal, warning flying debris

24 22115703 1 Tag, rotation 60Hz

25 22436760 4 Tag, shipping bracket

26 22064562 1 Decal, aircare

27 30286686 1 Decal, rotation arrow

28 22181663 1 Decal, condensate drain

29 81296196 1 Decal, maintenance schedule

8

SAFETY

DANGER!

Hazard that WILL cause DEATH, SEVERE INJURY or substantial

property damage if ignored. Instructions must be followed precisely to

avoid injury or death.

WARNING!

Hazard that CAN cause DEATH, SEVERE INJURY or substantial

property damage if ignored. Instructions which must be followed

precisely to avoid injury or death.

CAUTIONS!

Cautions call attention to instructions which must be followed

precisely to avoid damaging the product, process or its surroundings.

NOTES

Notes are used for supplementary information.

BREATHING AIR PRECAUTION

Ingersoll Rand air compressors are not designed, intended or

approved for breathing air. Compressed air should not be used for

breathing air applications unless treated in accordance with all

applicable codes and regulations.

General Information

Ensure that the operator reads and understands the decals and

consults the manuals before maintenance or operation.

Ensure that the Operation and Maintenance manual is not removed

permanently from the machine.

Ensure that maintenance personnel are adequately trained,

competent and have read the Maintenance Manuals.

Do not point air nozzles or sprayers toward anyone.

Compressed air and electricity can be dangerous. Before

undertaking any work on the compressor, ensure that the electrical

supply has been isolated and the compressor has been relieved of all

pressure.

Wear eye protection when operating or servicing compressor.

All persons positioned near to operating machinery should be

equipped with hearing protection and given instructions on its use in

accordance with workplace safety legislation.

Make sure that all protective covers are in place and that the

canopy/doors are closed during operation.

The specification of this machine is such that the machine is not

suitable for use in flammable gas risk areas.

Installation of this compressor must be in accordance with

recognised electrical codes and any local Health and Safety Codes.

The use of plastic bowls on line filters can be hazardous. Their

safety can be affected by either synthetic lubricants, or the additives

used in mineral oils. Ingersoll –Rand recommends that only filters with

metal bowls should be used on a pressurised system.

If more than one compressor is connected to one common

downstream plant, effective isolation valves must be fitted and

controlled by work procedures, so that one machine cannot accidently

be pressurised / over pressurised by another.

Compressed air must not be used for a direct feed to any form of

breathing apparatus or mask.

The discharged air contains a very small percentage of compressor

lubricant and care should be taken to ensure that downstream

equipment is compatible.

If the discharged air is to be ultimately released into a confined

space, adequate ventilation must be provided.

When using compressed air always use appropriate personal

protective equipment.

All pressure containing parts, especially flexible hoses and their

couplings, must be regularly inspected, be free from defects and be

replaced according to the Manual instructions.

Compressed air can be dangerous if incorrectly handled. Before

doing any work on the unit, ensure that all pressure is vented from the

system and that the machine cannot be started accidentally.

Avoid bodily contact with compressed air.

All safety valves located in the separator tank must be checked

periodically for correct operation.

Do not over–pressurize the receiver tank or similar vessels beyond

design limits.

Do not use a receiver tank or similar vessels that fail to meet the

design requirements of the compressor. Contact your distributor for

assistance.

Do not drill into, weld or otherwise alter the receiver tank or similar

vessels.

Materials

The following substances are used in the manufacture of this

machine and may be hazardous to health if used incorrectly:

. preservative grease

. rust preventative

. compressor coolant

AVOID INGESTION, SKIN CONTACT AND INHALATION OF

FUMES

Transport

When loading or transporting machines ensure that the specified

lifting and tie down points are used.

Lifting equipment must be properly rated for the weight of the

compressor.

Do not work on or walk under the compressor while it is suspended.

Compressed air

Compressed air can be dangerous if incorrectly handled. Before

doing any work on the unit, ensure that all pressure is vented from the

system and that the machine cannot be started accidentally.

WARNING

Imposing a normal or emergency stop on the compressor will

only relieve presure upstream of the minimum pressure valve on

top of the separator tank.

If maintenance work is required downstream of this valve, ensure

that all pressure is relieved at the process vent point external to

the compressor

Ensure that the machine is operating at the rated pressure and that

the rated pressure is known to all relevant personnel.

All air pressure equipment installed in or connected to the machine

must have safe working pressure ratings of at least the machine rated

pressure.

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE, HP50–PE, HXP50–PE http://air.ingersollrand.com

Electrical

Keep all parts of the body and any hand–held tools or other

conductive objects, away from exposed live parts of the compressor

electrical system. Maintain dry footing, stand on insulating surfaces

and do not contact any other portion of the compressor when making

adjustments or repairs to exposed live parts of the compressor

electrical system.

WARNING

Any electrical connections or adjustments should only be

made by a suitably qualified electrician

Close and lock all access doors when the compressor is left

unattended.

Do not use extinguishers intended for Class A or Class B fires on

electrical fires. Use only extinguishers suitable for class BC or class

ABC fires.

Attempt repairs only in clean, dry, well lighted and ventilated areas.

Connect the compressor only to electrical systems that are

compatible with its electrical characteristics and that are within it’s rated

capacity.

Condensate disposal

As waste water regulations vary by country and region it is the

responsibility of the user to establish the limitations and regulations in

their particular area. Ingersoll Rand and its associated distributors are

happy to advise and assist in these matters.

For further information, consult Material Data Sheets

for ULTRA Coolant.

SAFETY

9

http://air.ingersollrand.com

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE, HP50–PE,

HXP50–PE

10

http://air.ingersollrand.com

GENERAL INFORMATION

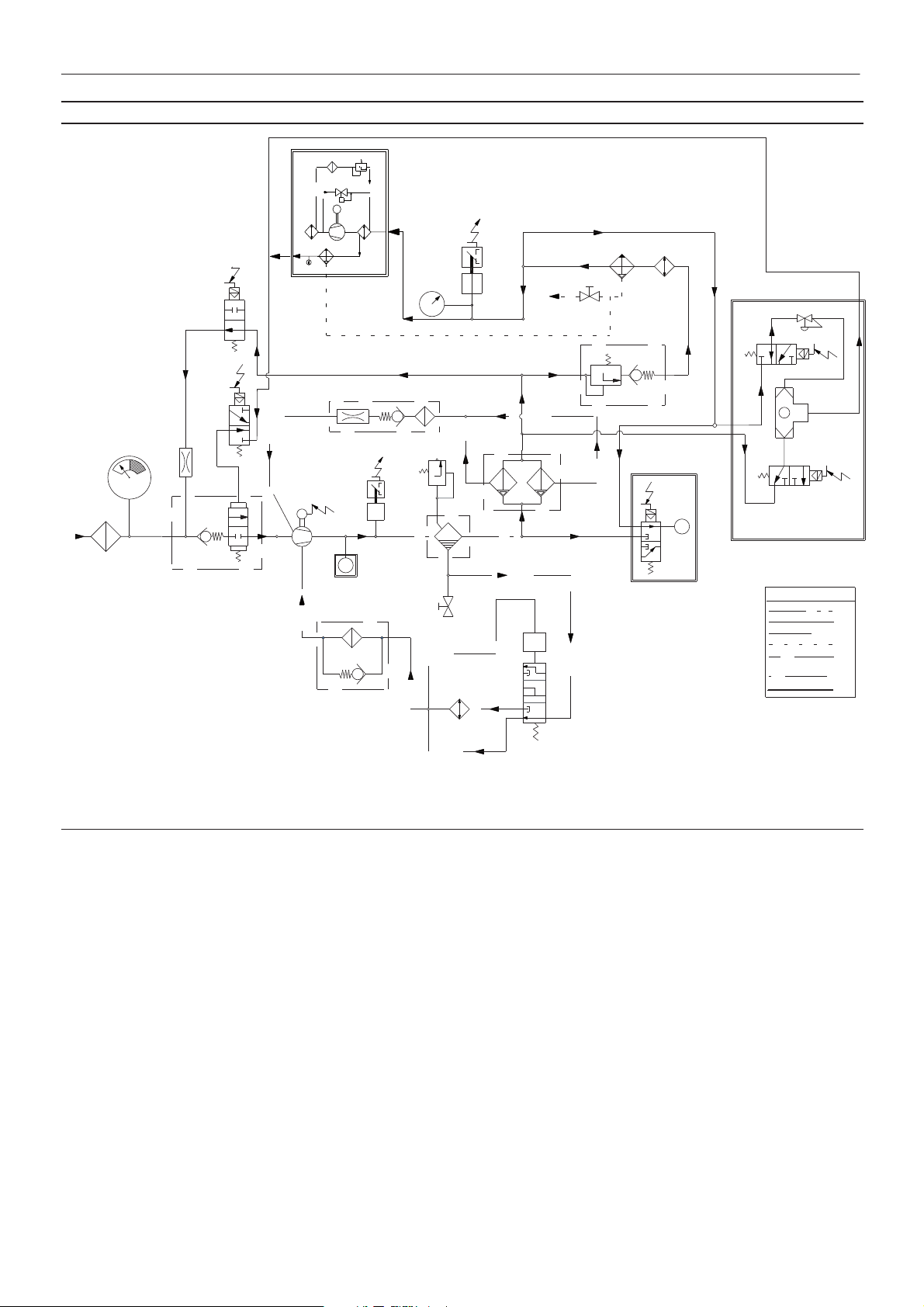

PIPING AND INSTRUMENTATION – Electro–pneumatic and Intellisys Units

36

37

41

M

38

40

39

28

20

DRYER

OPTION

27

35

11

10

P

27

29

23

9

34

31

8

30

KEY

22

1

22292783

Rev F

3

21

2

5

M

4

12

16

26

INTELLISYS (OPTION)

REPLACES ITEM 12

13

19

33

17

T

6

18

15

7

24

25

INTELLISYS (OPTION)

REPLACES ITEMS 10 & 11

14

T

32

MODULATION (OPTION)

PIPING LEGEND

A

B

C

D

E

F

G

1. Filter, air

2. Valve, inlet

3. Valve, solenoid (load)

4. Airend assembly

5. Motor

6. Tank, separator

7. Separator elements

8. Valve, minimum pressure

9. Aftercooler

10.Gauge, pressure

11.Switch, discharge pressure

12.Switch, temperature

13.Filter, coolant

14.Thermostat

15.Cooler

16 Relay, overload, Motor

17.Valve, safety

18.Valve, drain

19.Screen, scavenge

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

20 Valve, solenoid (blowdown)

21.Orifice

22 Indicator, air restriction

23.Electric drain valve (EDV – condensate)

24.Valve solenoid (line/sump), Intellisys Option

25.Transducer pressure, Intellisys Option, replaces 10 and 11

26.Sensor temperature, Intellisys Option, replaces 12

27.Moisture separator

28.Compressor air discharge

29.Condensate discharge

30.Compressor air inlet

31.Valve, solenoid, (modulation option)

32.Valve, solenoid, (modulation option)

33.Valve, shuttle, (modulation option)

34.Valve, modulation (modulation option)

35.Sensor, temperature, dryer (option) thermometer or

thermistor–Intellisys

36.Valve, expansion, dryer (option)

37.Filter, refrigerant, dryer (option)

GENERAL INFORMATION

11

38.Condenser, dryer (option)

39.Evaporator, dryer (option)

40.Refrigerant compressor, dryer (option)

41.Hot gas bypass valve, dryer (option)

A Air/Coolant

B Air

C Coolant

D Condensate

E Component boundary

F Refrigerant

G Option

http://air.ingersollrand.com

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE,

EP50–PE, HP50–PE, HXP50–PE

12

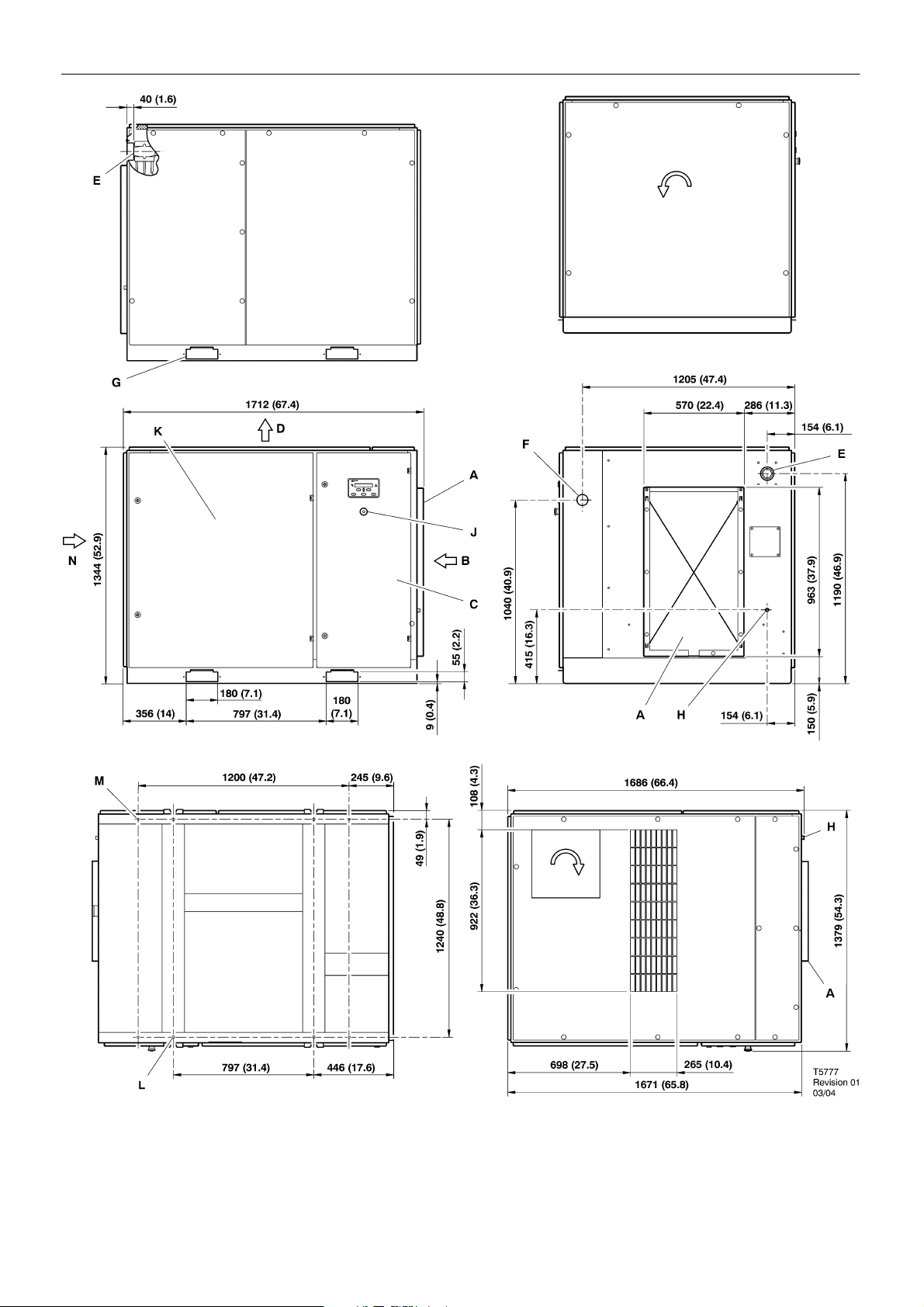

INSTALLATION / HANDLING

ROTATION

VIEW LEFT

VIEW REAR

VIEW FRONT VIEW RIGHT

DRYER

ROTATION

VIEW TOPVIEW BOTTOM

Note: Dimensions are mm (inches)

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

http://air.ingersollrand.com

KEY

INSTALLATION / HANDLING

13

A Pre filter

B Compressor and cooling air intake

C Starter box

D Cooling air exhaust

E 1.5” NPT air discharge

F Customer power inlet

G Fork lift openings

(Fork lift hole covers must be installed after unit is in place to

reduce noise and ensure proper cooling of package)

NOTES

1. Coolant (lubricant) fill quantity (approximate) 5.5 US gallons

(21 litres).

2. Recommended clearance in front of control panel door 42 inches

(1067 mm) or minimum as required by the latest national electrical

codes (NEC) or applicable local codes.

3. Recommended clearances on left and right sides 36 inches

(914mm).

4. Minimum recommended clearance for the rear of the compressor

is to be 6 inches (152mm).

5. External piping shall not exert any unresolved moments or forces

on the unit. Use pipe size as large or larger at discharge connection.

6. There should be no plastic or pvc piping attached to this unit or used

for any lines downstream.

7. Any field installed ducting to and from the compressor cannot add

more than 1/2 inch (12.5mm) water gauge total air resistance.

Ducting is not recommended for the dryer cooling air inlet and outlet

openings.

8. Do not pipe into a common header with a reciprocating compressor,

unless the reciprocating compressor utilizes a discharge pulsation

damper.

9. Sizing of electrical components not supplied by Ingersoll Rand is

the responsibility of the customer and should be done in accordance

with the information on the compressor data plate and national and

local electrical codes.

H .25 Inch female NPT moisture separator drain.

J Emergency stop button

K Primary compressor service door

L 4 holes, 0.67 Inch (17mm) diameter

M 4 holes, 0.47 Inch (12mm) diameter

N Dryer cooling air intake

NOTE

All dimensions are in millimetres (inches) unless otherwise stated.

Ensure that the correct fork lift truck slots or marked lifting points are

used whenever the machine is lifted or transported.

UNPACKING

The compressor will normally be delivered with a polythene cover.

If a knife has to be used to remove this cover ensure that the exterior

paintwork of the compressor is not damaged.

Ensure that all transport and packing materials are discarded in a

manner prescribed by local codes.

NOTE

Units are shipped with transit locking bolt in place. Prior to

running the unit the shipping bolt must be removed and the belt

tension checked. Loosen, remove and discard 10mm shipping

bolt. For belt tensioning procedure refer to Maintenance section.

http://air.ingersollrand.com

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

14

INSTALLATION / HANDLING

1

4

2

T5750

Revision 02

07/04

KEY

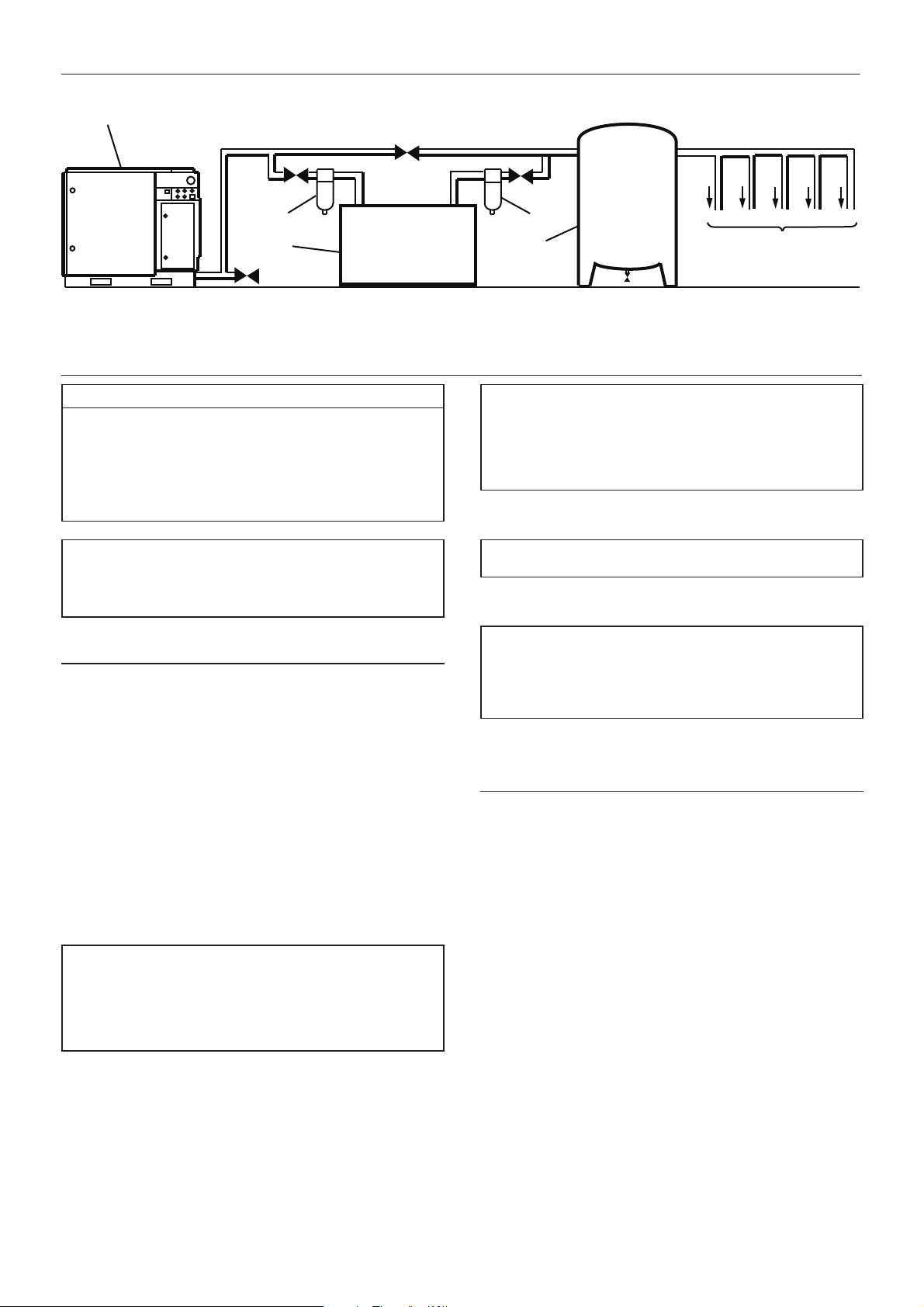

1. Compressor

2. Air Dryer

3. Air Receiver

4. Compressed air filters

5. System demand points

NOTE

Items [2] to [5] are optional or may be existing items of plant. Refer

to your Ingersoll Rand distributor / representative for specific

recommendations.

LOCATION IN THE PLANT

Note:

Ensure that the unit is wired for proper voltage before installation.

4

3

CAUTION

The use of plastic bowls on line filters and other plastic air line

components can be hazardous. Their safety can be affected by

either synthetic coolants or the additives used in mineral oils.

Ingersoll Rand recommends that only filters with metal bowls

should be used on any pressurised system.

CAUTION

Before starting machine remove shipping bolt and discard

CAUTION

The standard compressor unit is not suitable for operation in

temperatures liable to cause freezing as Condensate water is

liable to be produced in the after cooler and receiver where fitted.

Refer to your Ingersoll Rand distributor for further information.

5

The compressor can be installed on any level floor capable of

supporting it. A dry, well ventilated area where the atmosphere is clean

is recommended. A minimum of 6 inches (150mm) should be left at the

rear and 3ft (1m) at the sides of the machine for adequate service

access and ventilation.

Adequate clearance needs to be allowed around and above the

machine to permit safe access for specified maintenance tasks.

Ensure that the machine is positioned securely and on a stable

foundation. Any risk of movement should be removed by suitable

means, especially to avoid strain on any rigid discharge piping.

CAUTION

Screw type compressors [1] should not be installed in air

systems with reciprocating compressors without means of

isolation such as a common receiver tank. It is recommended that

both types of compressor be piped to a common receiver using

individual air lines.

DISCHARGE PIPING

Discharge piping should be at least as large as the discharge

connection of the compressor. All piping and fittings should be suitably

rated for the discharge pressure.

It is essential when installing a new compressor [1], to review the

total air system. This is to ensure a safe and effective total system. One

item which should be considered is liquid carryover. Installation of air

dryers [3] is always good practice since properly selected and installed

they can reduce any liquid carryover to zero.

It is good practice to locate an isolation valve close to the

compressor and to install line filters [4].

It is a requirement for air dryers covered under Aircare that correctly

sized Ingersoll Rand pre and afterfilters are installed.

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

http://air.ingersollrand.com

INSTALLATION / HANDLING

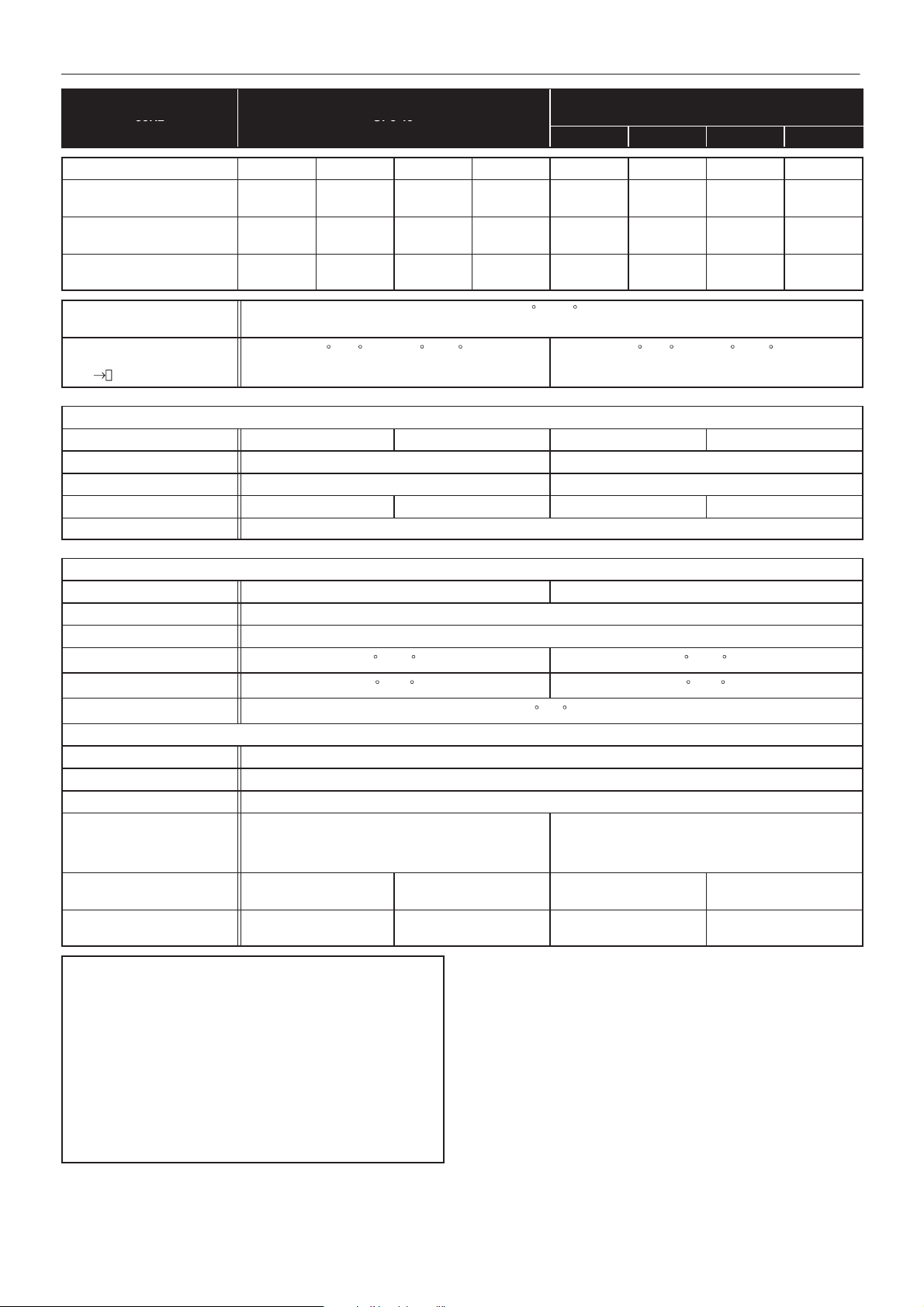

60Hz

UP6 40

UP6 50PE

125

(8.5)

115

(7.9)

208

(5.89)

UP6 50PEI

150

(10.3)

140

(9.6)

201

(5.70)

200

(13.8)

190

(13.1)

167

(4.73)

60Hz UP6 40

HF50–PE EP50–PE HP50–PE HXP50–PE

COMPRESSOR 115 125 150 200 115 125 150 200

Maximum operating pressure

psig (barg)

Factory set reload pressure

psig (barg)

Flow rate

cfm (m3/min)

115

(8.0)

105

(7.2)

188

(5.32)

125

(8.5)

115

(7.9)

185

(5.24)

150

(10.3)

140

(9.6)

170

(4.81)

200

(13.8)

190

(13.1)

143

(4.05)

115

(8.0)

105

(7.2)

212

(6.02)

15

Maximum airend discharge

temperature

Ambient operating

temperature

min. max.

MOTOR

Motor enclosure ODP TEFC ODP TEFC

Nominal power 40HP 50HP

Speed 1775 RPM 1775 RPM

Frame 324T 324T 326T 326T

Insulation class F

COOLING SYSTEM – Air cooled

Cooling air flow 3100 ft3/min (87.8m3/min) 3900 ft3/min (110m3/min)

Dryer cooling air flow 1200 ft3/min (34m3/min)

Maximum ∆ P in air ducts 0.5 inWg (12.7mmH2O) (not recommended for dryer openings)

Compressed air outlet ∆T

Cooling air outlet ∆T

Dryer cooling air outlet ∆T

GENERAL DATA

Residual coolant content 3ppm (3 mg/m3)

Separator vessel capacity 3.7 US gallons (14 liters)

Coolant capacity 5.5 US gallons (21 liters)

Sound pressure level to

CAGI–PNEUROP

(Non–dryer unit)

Weight – base mount unit 2326 lbs

Weight – dryer option unit 2576 lbs

36 F(+2 C ) ? 105 F(+40 C) 36 F(+2 C ) ? 115 F(+46 C)

15 F (8.3 C) 15 F (8.3 C)

40 F (22 C) 42 F (23 C)

69 dB(A) 69 dB(A)

(1055 kg)

(1168 kg)

2436 lbs

(1105 kg)

2686 lbs

(1218 kg)

216 F (102 C)

11 F (6 C)

2384 lbs

(1081 kg)

2634 lbs

(1194 kg)

2476 lbs

(1123 kg)

2726 lbs

(1236 kg)

CAUTION

230/460 Dual voltage machines are fitted with a decal to advise

the correct supply voltage as connected from the factory.

Factory units wired for 230V supply can be re–wired to 460V

supply voltage by re–wiring the main drive motor and the fan

motor as shown on the electrical schematic AND by replacing

the fan motor starter CCN 22395800 - 50HP with CCN 22395792

- 50 HP (shipped loose). The main motor overload and the fan

motor starter overload settings should be adjusted accordingly –

reference the IEC decal mounted inside the starter door. Also,

the transformer primary voltage connections will need to be

re–wired for the new supply voltage.

Re–wiring should only be effected by a competent Electrician.

http://air.ingersollrand.com

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

16

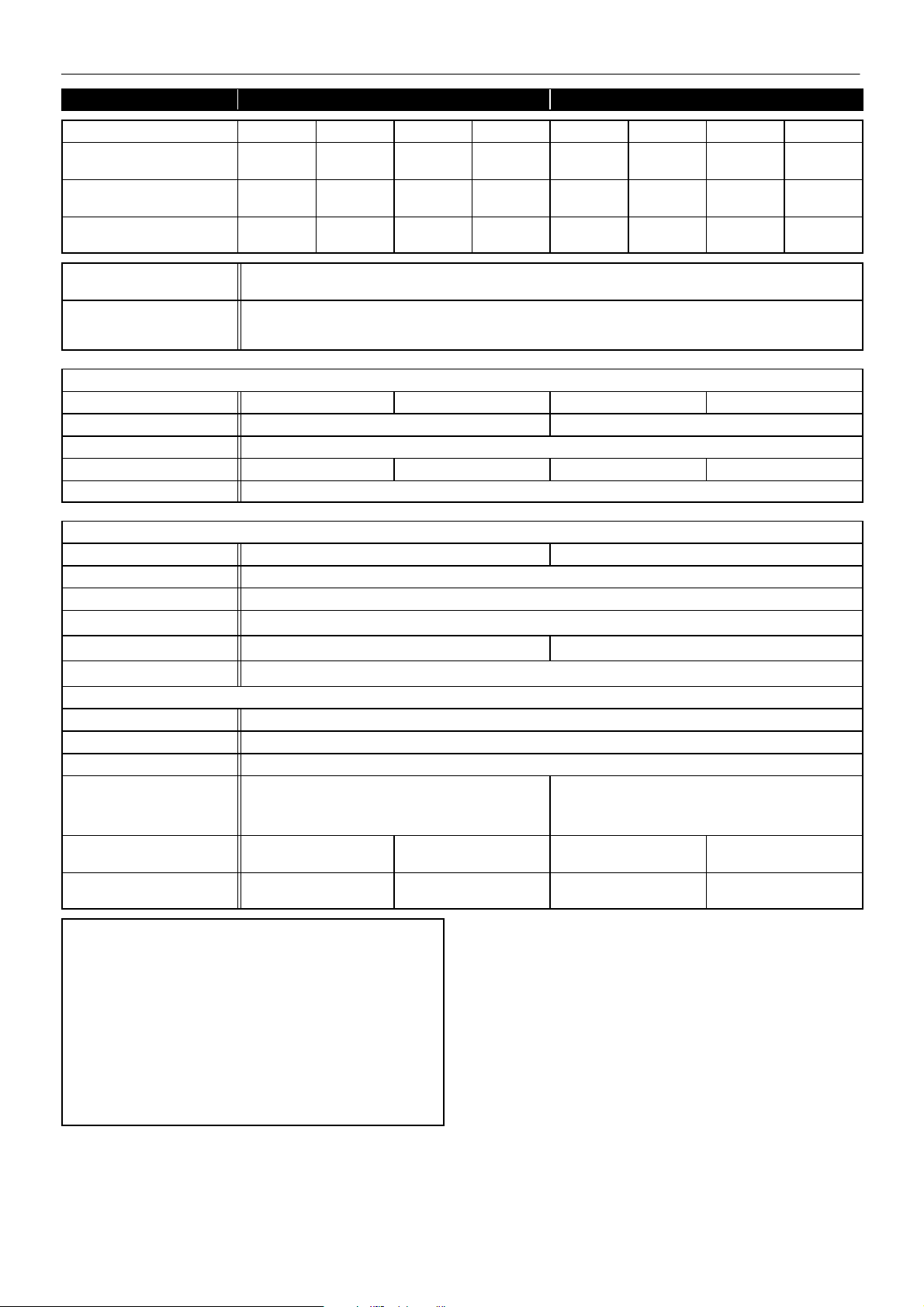

COMPRESSOR 115 125 150 200 115 125 150 200

Maximum operating pressure

psig (barg)

Factory set reload pressure

psig (barg)

Flow rate

cfm (m3/min)

INSTALLATION / HANDLING

60Hz UP6 30E–HA UP6 40–HA

125

(8.5)

115

(7.9)

125

(3.54)

150

(10.3)

140

(9.6)

112

(3.17)

200

(13.8)

190

(13.1)

92

(2.61)

115

(8.0)

105

(7.2)

188

(5.32)

125

(8.5)

115

(7.9)

185

(5.24)

150

(10.3)

140

(9.6)

170

(4.81)

(13.8)

(13.1)

(4.05)

200

190

143

Maximum airend discharge

temperature

Ambient operating

temperature

min. →max.

MOTOR

Motor enclosure ODP TEFC ODP TEFC

Nominal power 30HP 40HP

Speed 1775 RPM

Frame 324T 324T 326T 326T

Insulation class F

COOLING SYSTEM – Air cooled

Cooling air flow 3100 ft3/min (87.8m3/min) 3900 ft3/min (110m3/min)

Dryer cooling air flow 1200 ft3/min (34m3/min)

Maximum ∆P in air ducts 0.5 inWg (12.7mmH2O) (not recommended for dryer openings)

Compressed air outlet ∆T

Cooling air outlet ∆T

Dryer cooling air outlet ∆T

GENERAL DATA

Residual coolant content 3ppm (3 mg/m3)

Separator vessel capacity 3.7 US gallons (14 liters)

Coolant capacity 5.5 US gallons (21 liters)

Sound pressure level to

CAGI–PNEUROP

(Non–dryer unit)

Weight – base mount unit 2326 lbs

(1055 kg)

Weight – dryer option unit 2576 lbs

(1167 kg)

40_F (22_C) 42_F (23_C)

69 dB(A) 69 dB(A)

2436 lbs

(1105 kg)

2686 lbs

(1218 kg)

216_F (102_C)

36_F(+2_C ) → 122_F(+50_C)

15_F (8.3_C)

11_F (6_C)

2384 lbs

(1081 kg)

2634 lbs

(1194 kg)

2476 lbs

(1123 kg)

2726 lbs

(1236 kg)

CAUTION

230/460 Dual voltage machines are fitted with a decal to advise

the correct supply voltage as connected from the factory.

Factory units wired for 230V supply can be re–wired to 460V

supply voltage by re–wiring the main drive motor and the fan

motor as shown on the electrical schematic AND by replacing

the fan motor starter CCN 22395800 - 50 HP with CCN 22395792 -

50 HP (shipped loose). The main motor overload and the fan

motor starter overload settings should be adjusted accordingly –

reference the IEC decal mounted inside the starter door. Also,

the transformer primary voltage connections will need to be

re–wired for the new supply voltage.

Re–wiring should only be effected by a competent Electrician.

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

http://air.ingersollrand.com

INSTALLATION / HANDLING

DRYER OPTION TECHNICAL INFORMATION 60Hz

General

Refrigerant type R404A

Refrigerant charge

kg (lbs)

Refrigerant oil Emkarate RL32CF or Texaco Capella HFC32

Control settings

Hot gas setting

barg (psig)

High pressure switch setting

barg (psig)

Fan pressure switch setting

on/off

barg (psig)

Performance

(2) (3)

Dew point temperature at rated

conditions and flow

(3)

30 / 40HP 50HP

41_F (5_C)

(4)

1.8 (0.84)

72 – 74 (5.0 – 5.1)

425 (29.3)

225 / 175 (15.5 / 12.1)

17

50_F (10_C)

Maximum ∆P across dryer

barg (psig)

(1)

In accordance with PNEUROP PN8NTC2.3

(2)

In accordance with ISO 7183 at the modified rated conditions.

(3)

60Hz machines: 85_F ambient, 125 psig inlet.

(4)

40hp 200v unit dewpoint is 50_F (10_C)

2.2 (0.15) 3.0 (0.21)

http://air.ingersollrand.com

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

18

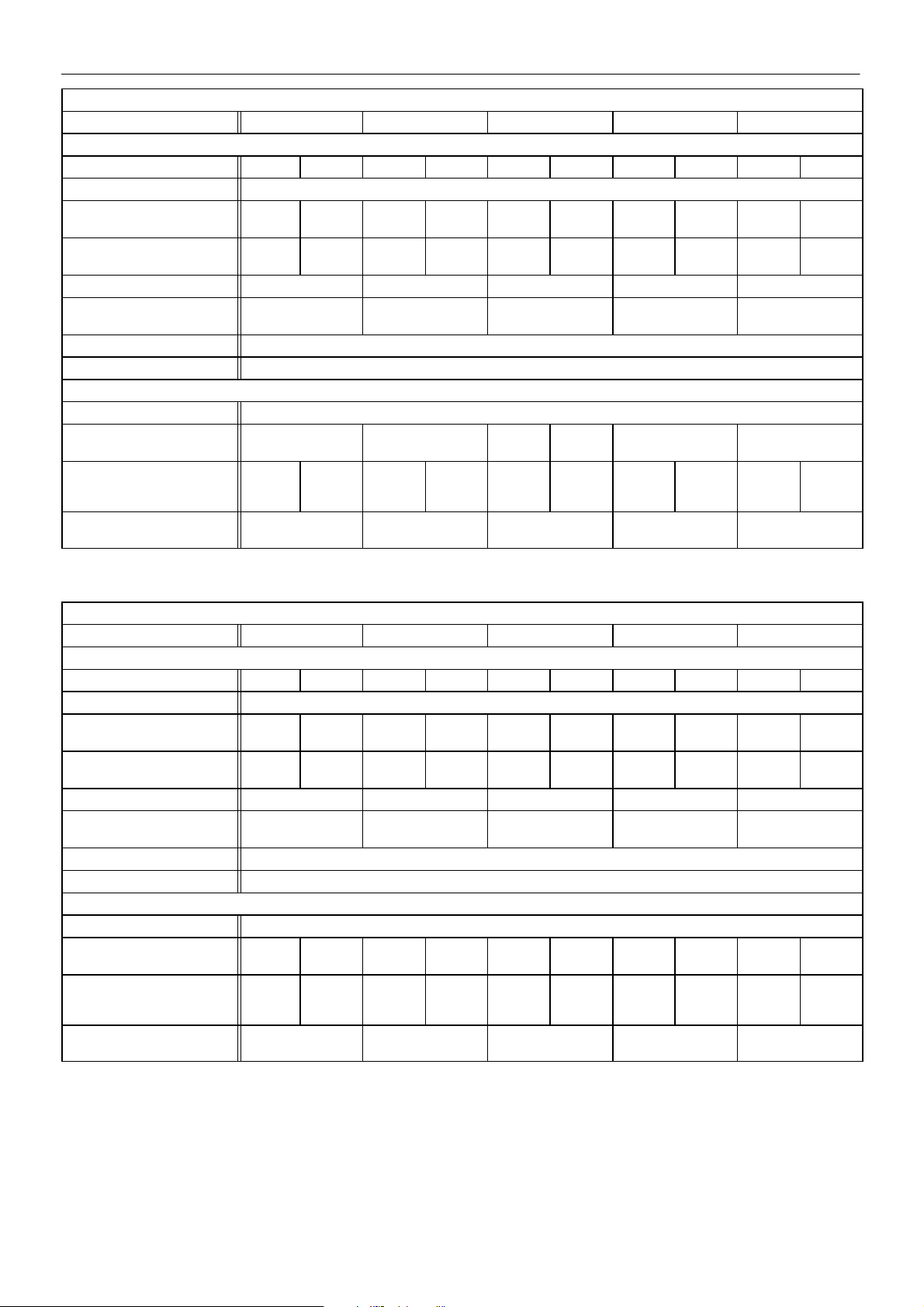

ELECTRICAL DATA – ALL UNITS SSR UP6–40

Standard voltage 200V 230V 380V 460V 575V

PACKAGE

Motor enclosure ODP TEFC ODP TEFC ODP TEFC ODP TEFC ODP TEFC

Power (nominal) 40HP

Full load current at maximum

pressure

Full load current at maximum

pressure with dryer option

Starting current FV (STAR) 706.1 (264.5) 614 (230) 367 (135.2) 307 (115) 245.6 (92)

Starting current FV (STAR)

with dryer option

Starting time FV (STAR) 3–5 Sec (7–10 Sec)

Starts per hour (maximum) 6

ELECTRICAL DATA – FV / Star Delta

Control voltage 120VAC

Minimum fuse rating

See note 1

Minimum fuse rating with dryer

option

See note 1

Minimum wire size AWG

See note 2

INSTALLATION / HANDLING

136.0A 125.6A 118.3A 109.2A 71.6A 66.1A 59.2A 54.6A 47.3A 43.7A

143.7A 133.3A 125.2A 116.1A – – 62.5A 57.9A – –

744.4 (302.5) 652 (268) – 323 (131) –

175A 150A 100A 90A 75A 60A

200A 175A 175A 150A – – 80A 75A – –

4/0 3/0 2 3 4

ELECTRICAL DATA – ALL UNITS SSR UP6 50PE, UP6 50PEI, HF50–PE, EP50–PE, HP50–PE and HXP50–PE

Standard voltage 200V 230V 380V 460V 575V

PACKAGE

Motor enclosure ODP TEFC ODP TEFC ODP TEFC ODP TEFC ODP TEFC

Power (nominal) 50HP

Full load current at maximum

pressure

Full load current at maximum

pressure with dryer option

Starting current FV (STAR) 876.3 (321.2) 762 (279.3) 461 (169.0) 381 (139.7) 304.8 (111.7)

Starting current FV (STAR)

with dryer option

Starting time FV (STAR) 3–5 Sec (7–10 Sec)

Starts per hour (maximum) 6

ELECTRICAL DATA – FV / Star Delta

Control voltage 120VAC

Minimum fuse rating

See note 1

Minimum fuse rating with dryer

option

See note 1

Minimum wire size AWG

See note 2

170.8A 160.0A 148.5A 139.1A 89.8A 82.2A 74.2A 67.9A 59.4A 55.7A

– – 155.4A 146.0A – – 77.5A 71.2A – –

– 800 (317) – 397 (156) –

225A 200A 200A 175A 110A 110A 100A 90A 75A 70A

– – 200A 200A – – 100A 90A – –

250 4/0 1 2 3

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

http://air.ingersollrand.com

INSTALLATION / HANDLING

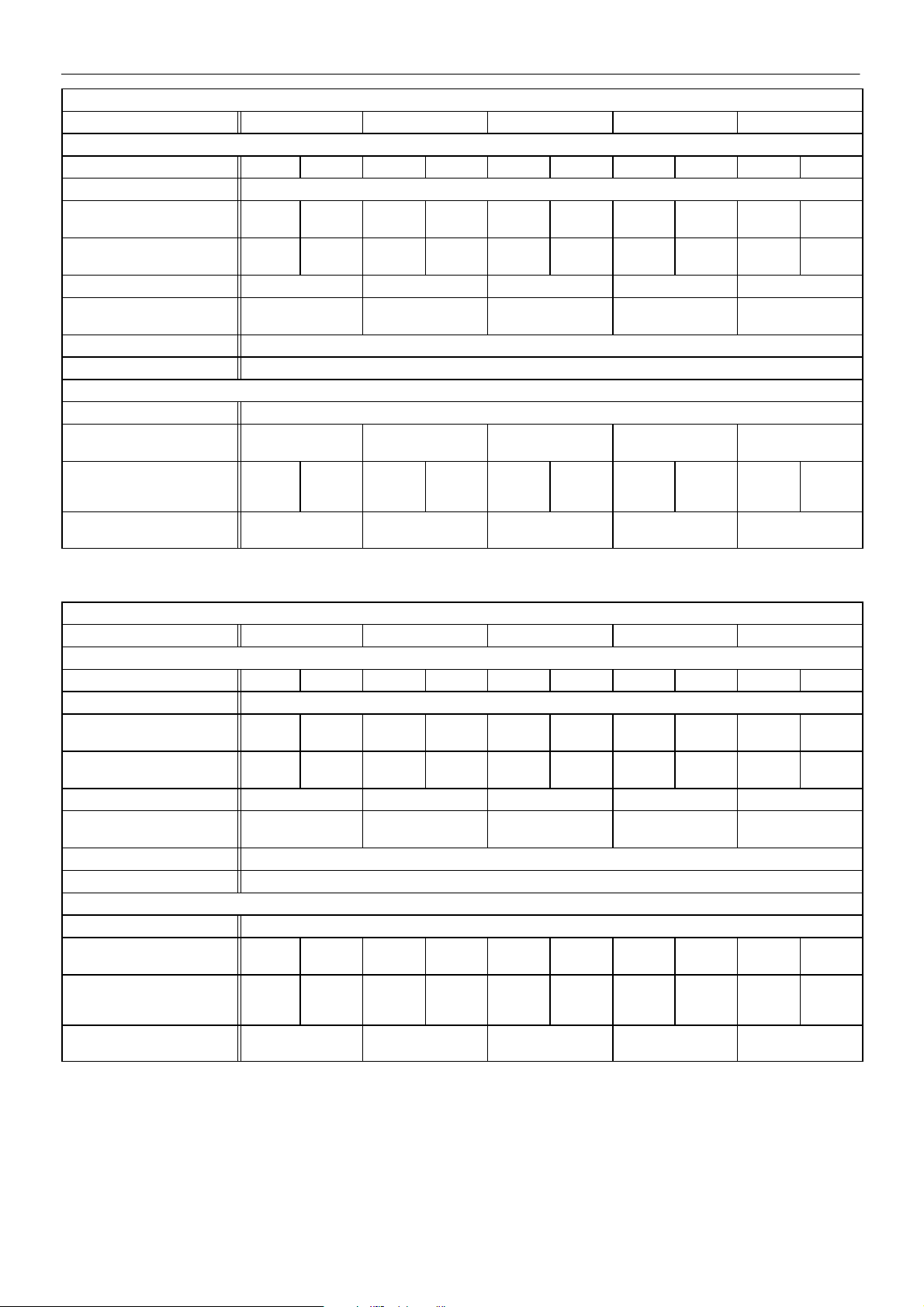

ELECTRICAL DATA – ALL UNITS SSR UP6–40–HA

Standard voltage 200V 230V 380V 460V 575V

PACKAGE

Motor enclosure ODP TEFC ODP TEFC ODP TEFC ODP TEFC ODP TEFC

Power (nominal) 40HP

Full load current at maximum

pressure

Full load current at maximum

pressure with dryer option

Starting current FV (STAR) 706 (265) 617 (231) 374 (140) 309 (115) 247 (93)

Starting current FV (STAR)

with dryer option

Starting time FV (STAR) 3–5 Sec (7–10 Sec)

Starts per hour (maximum) 6

ELECTRICAL DATA – FV / Star Delta

Control voltage 120VAC

Minimum fuse rating

See note 1

Minimum fuse rating with dryer

option

See note 1

Minimum wire size AWG

See note 2

136.0A 128.3A 119.0A 111.5A 71.6A 65.1A 59.5A 56.9A 47.6A 44.7A

– – 123.5A 116.0A – – 61.7A 58.1A – –

– 652 (268) – 323 (131) –

175A 150A 90A 75A 60A

– – 175A 150A – – 80A 75A – –

4/0 3/0 2 3 4

19

ELECTRICAL DATA – ALL UNITS SSR 30E–HA

Standard voltage 200V 230V 380V 460V 575V

PACKAGE

Motor enclosure ODP TEFC ODP TEFC ODP TEFC ODP TEFC ODP TEFC

Power (nominal) 30HP

Full load current at maximum

pressure

Full load current at maximum

pressure with dryer option

Starting current FV (STAR) 567 (212.4) 493.2 (184.8) 298.5 (111.8) 246.6 (92.4) 197.3 (73.9)

Starting current FV (STAR)

with dryer option

Starting time FV (STAR) 3–5 Sec (7–10 Sec)

Starts per hour (maximum) 6

ELECTRICAL DATA – FV / Star Delta

Control voltage 120VAC

Minimum fuse rating

See note 1

Minimum fuse rating with dryer

option

See note 1

Minimum wire size AWG

See note 2

109.2A 100.9A 95.0A 87.8A 57.5A 53.1A 47.5A 43.9A 38.0A 38.3A

– – 99.5A 92.3A – – 49.7A 46.1A – –

– 516.6 (193.5) – 258 (96.7) –

150A 125A 125A 125A 75A 75A 60A 60A 50A 50A

– – 150A 150A – – 75A 75A – –

3/0 1/0 3 4 6

http://air.ingersollrand.com

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

20

INSTALLATION / HANDLING

1. If a circuit breaker is selected it should only be a magnetic trip type,

set above the anticipated starting current of the machine, but below the

maximum prospective fault current for the circuit. The circuit breaker

or fuseable disconnect must be capable of breaking the prospective

fault current at its terminals.

2. PVC/PVC Type Calculated using the following conditions:

i) PVC insulated cable, armoured, copper conductors.

ii) Cable clipped to a wall, in free air.

iii) Ambient temperature of 104_F (40_C) and relative humidity of 40%.

iv) 65ft (20m) cable run.

v) Volt drop limited to –10% during starting, –5% during normal

running.

vi) Protected by the circuit breaker listed above.

If there are any deviations from the above, or special regulations

apply, the installation must be planned by a competent, qualified

engineer.

NOTE

All data applies to standard product only.

ELECTRICAL DATA

An independent electrical isolator or disconnect should be installed

adjacent to the compressor.

Feeder cables/wires should be sized by the customer/electrical

contractor to ensure that the circuit is balanced and not overloaded by

other electrical equipment. The length of wiring from a suitable

electrical feed point is critical as voltage drops may impair the

performance of the compressor.

Feeder cables / wires connections to isolator or disconnect should

be tight and clean.

The applied voltage must be compatible with the motor and

compressor data plate ratings.

The control circuit transformer has different voltage tappings.

Ensure that these are set for the specific applied voltage prior to

starting.

CAUTION

Never test the insulation resistance of any part of the machines

electrical circuits, including the motor without completely

disconnecting the electronic controller (where fitted).

CAUTION

Ensure that the motor, blower and dryer fan rotate in the

correct direction as indicated by direction arrows, and on

drawing.

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

http://air.ingersollrand.com

OPERATING INSTRUCTIONS – GENERAL

21

GENERAL OPERATION

The compressor is an electric motor driven, single stage screw

compressor, complete with accessories piped, wired and baseplate

mounted. It is a totally self contained air compressor package.

The 40hp compressor packages are designed to operate in an

ambient range of 35.6_F – 104_F (2_C to 40_C) with a special

option package available to operate in ambient temperatures ranges

from 35.6_F up to 124_F (2_C up to 50_C). The maximum

temperature is applicable to either version up to a maximum

elevation of 3280ft (1000m) above sea level. Above this altitude

significant reduction in maximum allowable ambient temperature is

required.

The 50 hp package is designed for a 115_F (46_C) maximum

ambient.

Compression in the screw type air compressor is created by the

meshing of two (male & female) helical rotors.

The air/coolant mixture discharges from the compressor into the

separation system. This system removes all but a few PPM of the

coolant from the discharge air. The coolant is returned to the cooling

system and the air passes through the aftercooler and out of the

compressor.

Cooling air is moved through the coolers by the cooling fan and

discharged from the machine.

CAUTION

Cooling air is drawn in at the end of the machine package

passing through the filter and cooler before being discharged

from the top of the machine. Care should be taken to avoid

blocking the airflow, or causing any restriction in excess of the

maximum backpressure allowed for ducting.

Do not direct the airflow at face or eyes.

The power transmission from the drive motor to the airend male

rotor is by pulley and belts. The constant auto tensioning system, using

airend mass torque and gas arm, ensures that the belts are always

under the correct tension, eliminating the need for adjustment and

maximizing the life of the belts.

By cooling the discharge air, much of the water vapour naturally

contained in the air is condensed and may be drained from the

downstream piping and equipment.

The coolant system consists of a sump, cooler, thermostatic valve

and a filter. When the unit is operating, the coolant is pressurized and

forced to the compressor bearings.

The compressor load control system is automatic on–off line. The

compressor will operate to maintain a set discharge line pressure and

is provided with an auto restart system for use in plants where the air

demand varies sufficiently to allow a compressor to shut down and

save power. Significant system volume will assist this and is

recommended.

With the dryer option, the dryer will run continuously when the

compressor is automatically off line.

WARNING

When the unit stops running as the result of low air demand,

normally indicated by auto restart light, it may restart and return

to load at any time.

Safety of operation is provided as the compressor will shut down if

excessive temperatures or electrical overload conditions should occur.

CAUTION

This unit is not designed or intended to operate when

contaminated with silicone. Lubricants, greases or other items

containing silicone should not be used on this unit.

http://air.ingersollrand.com

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE,

EP50–PE, HP50–PE, HXP50–PE

22

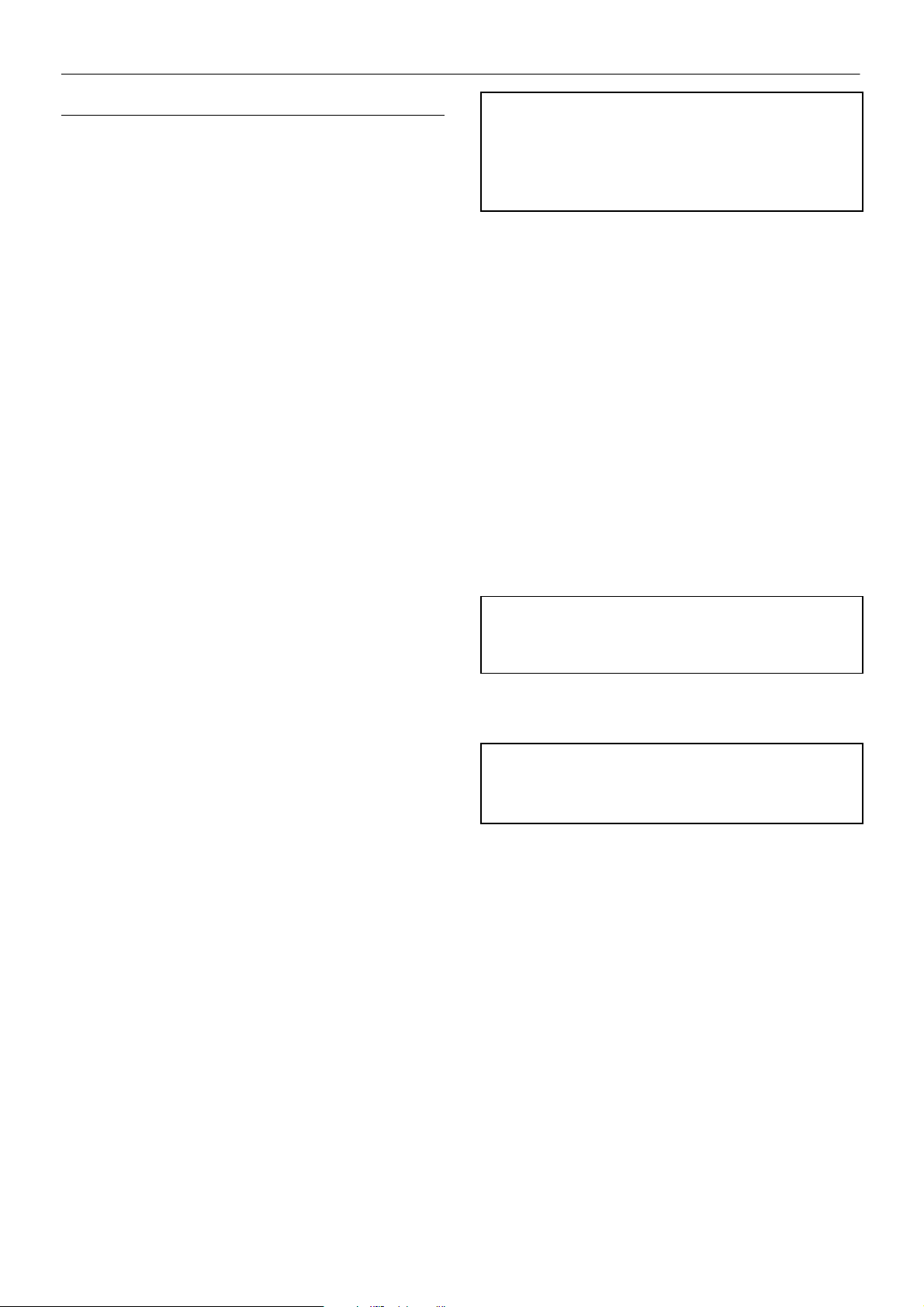

OPERATING INSTRUCTIONS – ELECTRO–PNEUMATIC

1. PRESSURE GAUGE

Indicates the system pressure.

WARNING

DO NOT operate the compressor at discharge pressures

exceeding the maximum operating pressure.

2. HOURMETER

Records the total running time of the compressor.

3. EMERGENCY STOP

When depressed will stop the compressor immediately. The ’Power

on’ indicator will remain illuminated. The emergency stop button must

be released before the compressor can be restarted.

4. START/STOP

When switched to the ON position will cause the unit to start and run

in a loaded condition if there is a demand for air. If there is no demand,

the machine will run unloaded before stopping automatically.

When switched to the OFF position, will unload and stop the unit if

it is running. If the unit is in auto restart it will prevent the unit from

re–starting when there is a demand for air.

5. POWER ON (Green)

Indicates the presence of control voltage at the controller.

6. AUTO RESTART (White)

Will illuminate when the machine has shut-down due to low air

demand. The machine will restart and load automatically as soon as the

demand for air returns.

7. FAULT / HIGH AIR TEMPERATURE ALARM (Red)

Turn off electrical Isolator or disconnect. Investigate cause of fault.

8. RESET BUTTON

Press button to reset the control system following compressor trip.

9. DEW POINT INDICATOR (Dryer Option)

Green indicates good dew point. Red indicates dew point above

65_F (18_C) and blue indicates freezing.

PRIOR TO STARTING

1. Make visual check of the machine, ensure that all guards secure

and that nothing is obstructing the proper ventilation of, or free access

to the machine.

2. Check coolant level. Add if necessary.

3. Make sure main discharge valve is open.

4. Turn on electrical isolator or disconnect. The Power on (5) indicator

will light, indicating that line and control voltages are available.

5. Check direction of rotation at initial start or following interruption in

power supply.

WARNING

Make sure that all protective covers are in place.

Cooling air flow exhaust may contain flying debris. Safety

Protection should be worn at all times to avoid injury.

STARTING

1. Push the RESET button (8). The fault indicator (7) will extinguish.

Switch the ON/OFF switch (4) to the ON position. The compressor will

start and then load automatically.

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE,

EP50–PE, HP50–PE, HXP50–PE

http://air.ingersollrand.com

OPERATING INSTRUCTIONS – ELECTRO–PNEUMATIC

23

NORMAL/EMERGENCY STOPPING

1. Switch the ON/OFF switch (4) to the OFF position. The compressor

will unload and stop.

2. Press EMERGENCY STOP button (3) and the compressor will stop

immediately.

3. Turn off electrical isolator or disconnect.

CAUTION

After shutdown never allow unit to stand idle with pressure in

receiver/separator system.

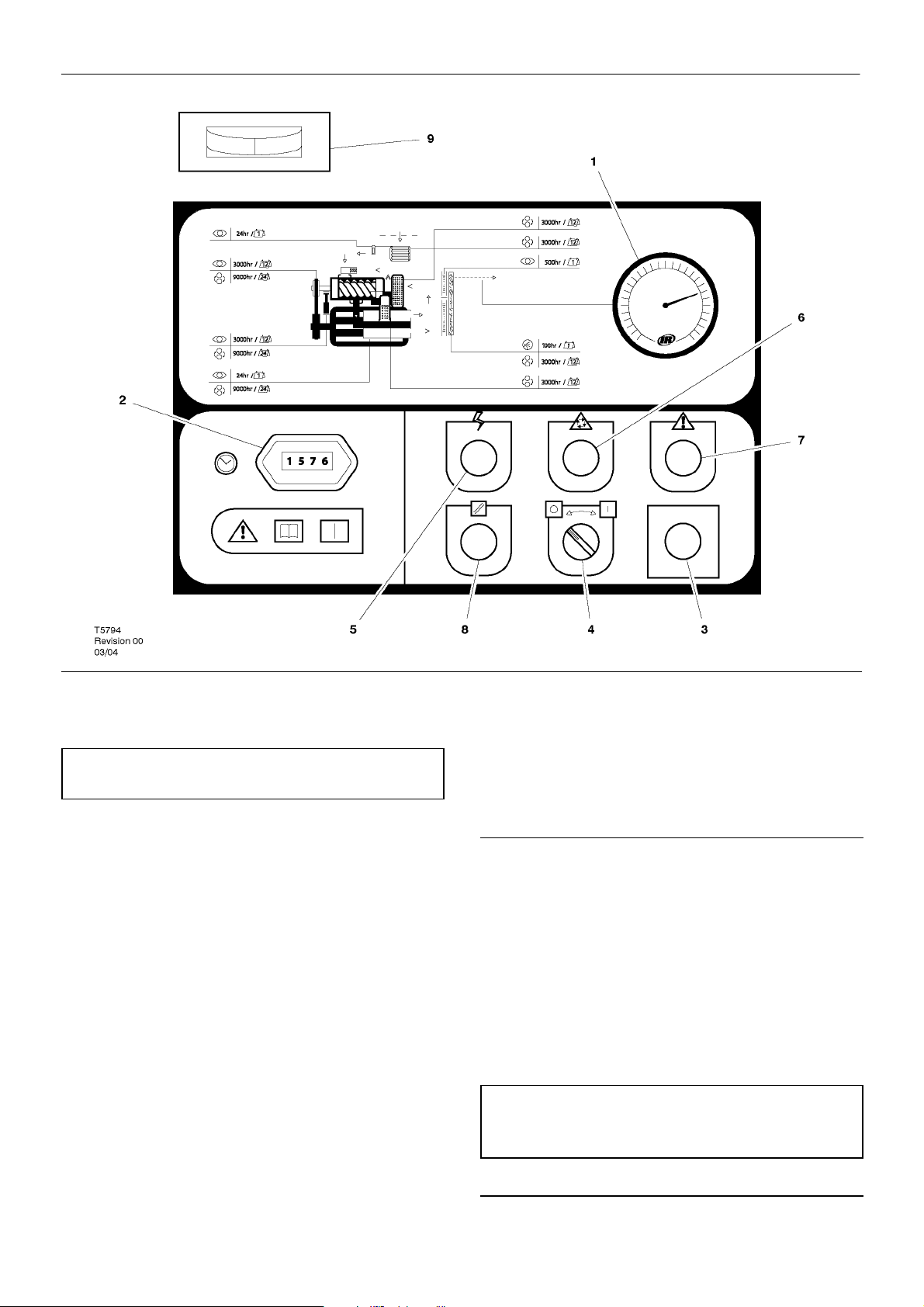

For customers that have interruptions in their incoming power supply

to the compressor and must maintain an uninterrupted supply of

compressed air, the Power Outage Restart Option allows a

compressor to restart automatically 10 seconds (adjustable) after

incoming power is restored.

FUNCTION TEST

To test the operation of the Power Outage Restart Option:

1. Slowly open the main isolation valve.

2. Start the compressor.

3 The compressor will load automatically if there is sufficient demand

for air. Allow the compressor to load.

4. Open the main disconnect to remove power from the compressor.

5. Close the main disconnect to reapply power to the compressor.

The horn will sound for ten seconds; then the compressor will start

automatically.

http://air.ingersollrand.com

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE,

EP50–PE, HP50–PE, HXP50–PE

24

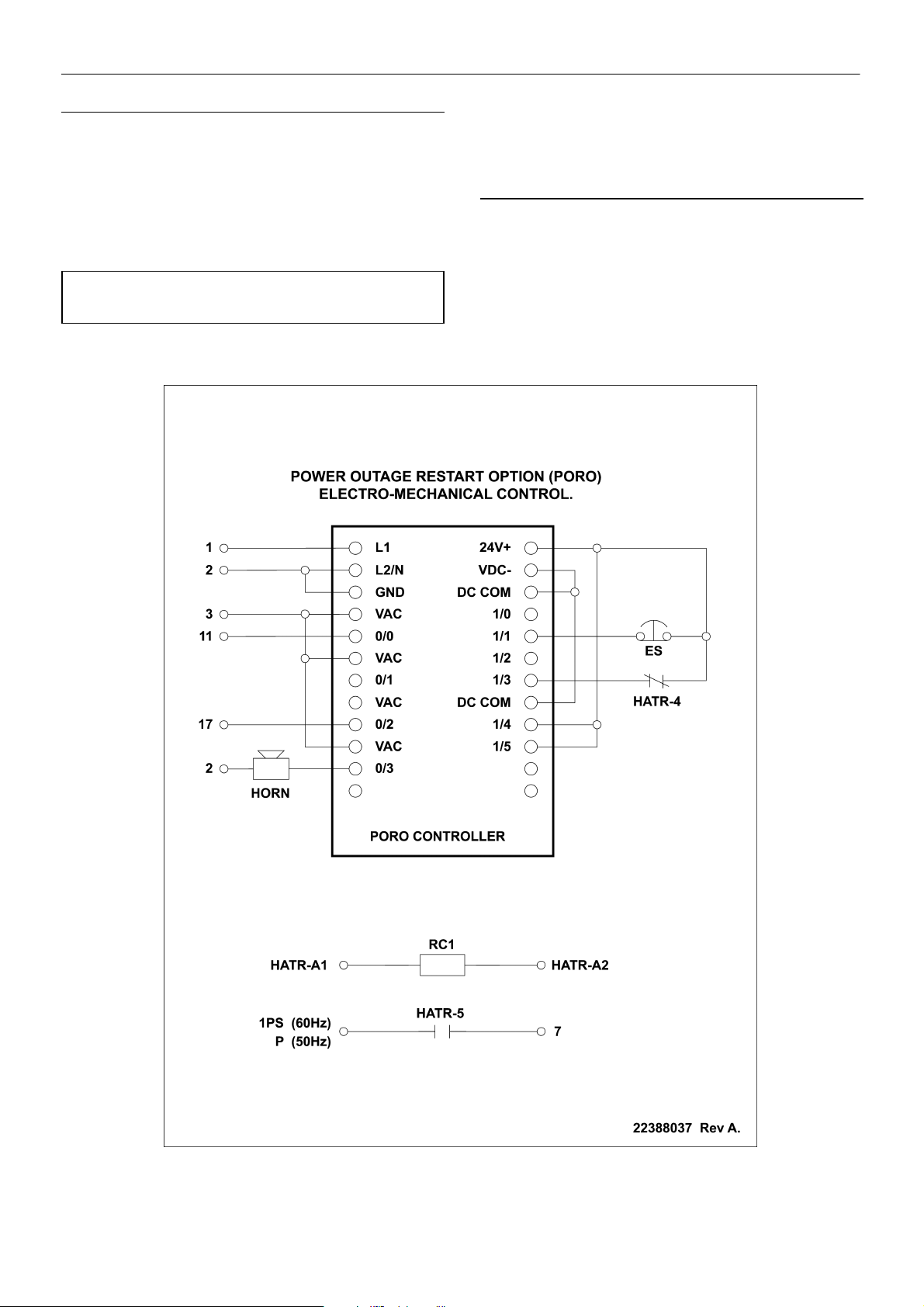

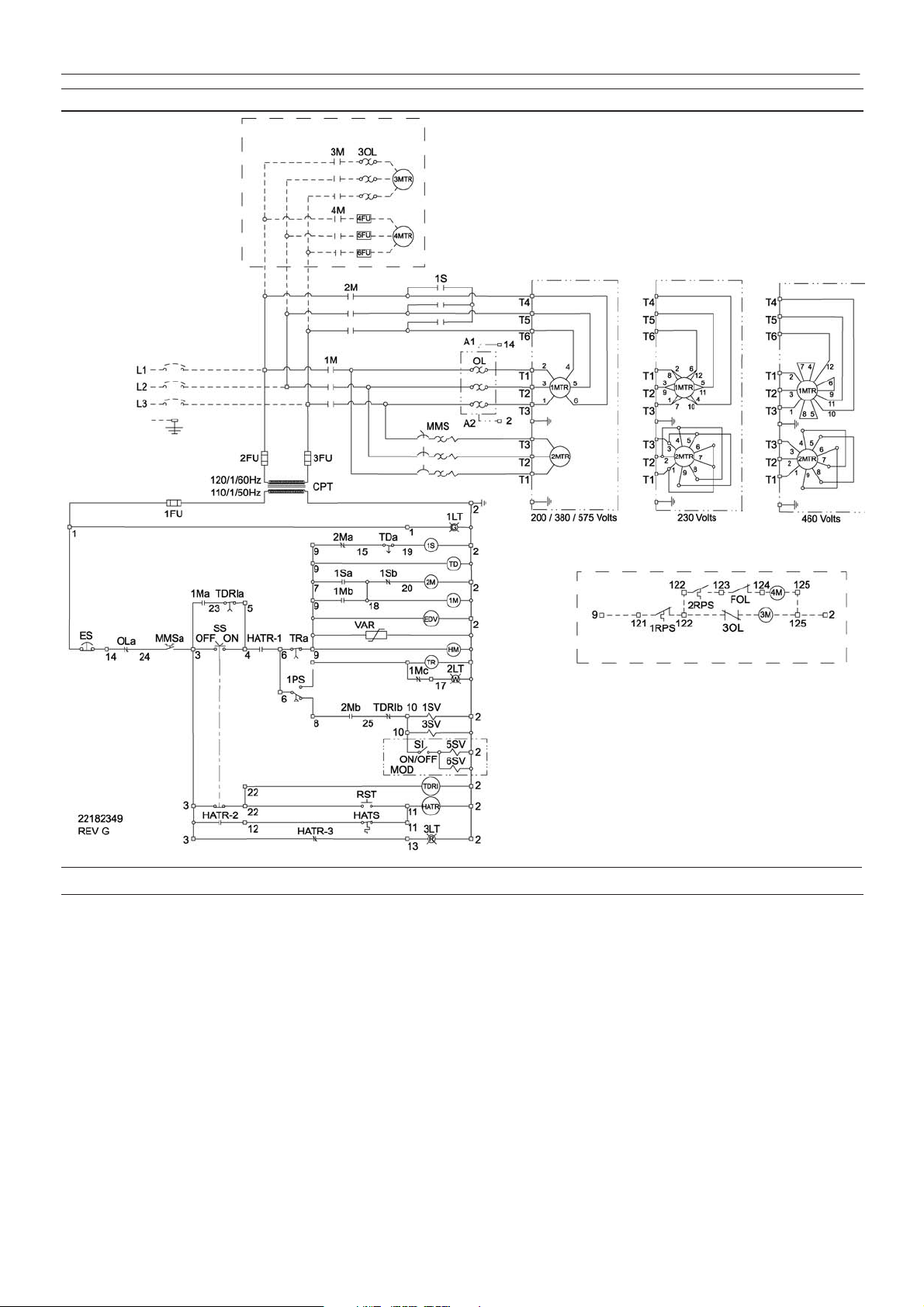

FULL VOLTAGE WIRING SCHEMATIC

SEE NOTES 1 & 2

OPERATING INSTRUCTIONS – ELECTRO–PNEUMATIC

DRYER OPTION

LEGEND

CPT Transformer

EDV Valve, electric drain

ES Switch, emergency stop

FOL Overload, internal fan (option)

1FU Fuse, secondary voltage

2FU, 3FU Fuses, primary voltage

4FU,

5FU, 6FU

HATR Relay, high air temperature

HATR

1,2,3

HATS Switch, high air temperature.

HM Hourmeter

1LT Light, power on indicator (Green)

2LT Light, auto restart indicator (White)

3LT Fault indicator light (Red)

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

Fuses, dryer fan (option)

Contacts, relay – HATR

DRYER OPTION

1M Contactor, main

1Ma, b Contacts, aux. main contactor

3M Contactor, dryer compressor (option)

4M Contactor, dryer fan (option)

MMS Starter & overload, fan motor

MMSa Contact, fan motor overload

MOD Modulation control option

1MTR Motor, compressor

2MTR Motor, fan

3MTR Motor, dryer compressor (option)

4MTR Motor, dryer fan (option)

OL Overload, main motor

OLa Contact, main motor overload

3OL

Overload, dryer compressor (option)

http://air.ingersollrand.com

OPERATING INSTRUCTIONS – ELECTRO–PNEUMATIC

LEGEND

1PS Switch, pressure

1RPS Switch, high refrigerant pressure (option)

2RPS Switch, fan pressure (option)

RST Switch, reset

1SV Valve, solenoid (load) N.C.

3SV Valve, solenoid (blowdown) N.O.

5SV Valve, solenoid (modulation option)

6SV Valve, solenoid (modulation option)

S1 Switch, selector (modulation option)

SS Switch, selector Off/On

TDR1

TDR1a Contact, relay – timed

TDR1b Contact, relay – instant

TR Relay, restart, time delay (6 min)

TRa Contact, relay

Relay timed delay (10 sec.)

25

VAR Varistor

Barrier terminal strip

NOTES

1. Approved fused disconnect or circuit breaker per N.E.C.

requirements must be provided by customer.

2. Dashed lines represent wiring by customer.

3. Sizing of electrical components not supplied by Ingersoll Rand is

the responsibility of the customer and should be done in

accordance with the information on the compressor data plate

N.E.C. and local electrical codes.

4.. When changing the supply voltage, ensure that:

a) The motor and the transformer are rewired for the new voltage

b) The motor overload is adjusted to the proper setting.

5. Verify actual motor conditions with motor schematic.

http://air.ingersollrand.com

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE,

EP50–PE, HP50–PE, HXP50–PE

26

DRYER OPTION

DRYER OPTION

SEE NOTES 1 & 2

STAR – DELTA WIRING SCHEMATIC

OPERATING INSTRUCTIONS – ELECTRO–PNEUMATIC

LEGEND

CPT Transformer

EDV Valve, electric drain

ES Switch, emergency stop

FOL Overload, internal fan (option)

1FU Fuse, secondary voltage

2FU, 3FU Fuses, primary voltage

4FU,

5FU, 6FU

HATR Relay, high air temperature

HATR

1,2,3

HATS Switch, high air temperature.

HM Hourmeter

1LT Light, power on indicator (Green)

2LT Light, auto restart indicator (White)

3LT Fault indicator light (Red)

1M Contactor, main

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

Fuses, dryer fan (option)

Contacts, relay – HATR

1Ma, b, c Contacts, aux. main contactor

2M Contactor, delta

2Ma, b Contacts, aux. delta contactor

3M Contactor, dryer compressor (option)

4M Contactor, dryer fan (option)

MMS Starter & overload, fan motor

MMSa Contact, fan motor overload

MOD Modulation control option

1MTR Motor, compressor

2MTR Motor, fan

3MTR Motor, dryer compressor (option)

4MTR Motor, dryer fan (option)

3OL

OL Overload, main motor

OLa Contact, main motor overload

Overload, dryer compressor (option)

http://air.ingersollrand.com

OPERATING INSTRUCTIONS – ELECTRO–PNEUMATIC

LEGEND

1PS Switch, pressure

1RPS Switch, high refrigerant pressure (option)

2RPS Switch, fan pressure (option)

RST Switch, reset

S1 Switch, selector (modulation option)

1S Contactor, star

1Sa, b Contacts, aux. star contactor

SS Switch, selector Off/On

1SV Valve, solenoid (load) N.C.

3SV Valve, solenoid (blowdown) N.O.

5SV Valve, solenoid (modulation option)

6SV Valve, solenoid (modulation option)

TD Relay, delta starting (10 sec.)

TDa Relay, delay off contact

TDR1

TDR1a Contact, relay – timed

Relay timed delay (10 sec.)

27

TDR1b Contact, relay – instant

TR Relay, restart, time delay (6 min)

TRa Contact, relay

VAR Varistor

Barrier terminal strip

NOTES

1. Approved fused disconnect or circuit breaker per N.E.C.

requirements must be provided by customer.

2. Dashed lines represent wiring by customer.

3. Sizing of electrical components not supplied by Ingersoll Rand is

the responsibility of the customer and should be done in

accordance with the information on the compressor data plate

N.E.C. and local electrical codes.

4.. When changing the supply voltage, ensure that:

a) The motor and the transformer are rewired for the new voltage

b) The motor overload is adjusted to the proper setting.

5. Verify actual motor conditions with motor schematic.

http://air.ingersollrand.com

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE,

EP50–PE, HP50–PE, HXP50–PE

28

OPERATING INSTRUCTIONS – ELECTRO–PNEUMATIC

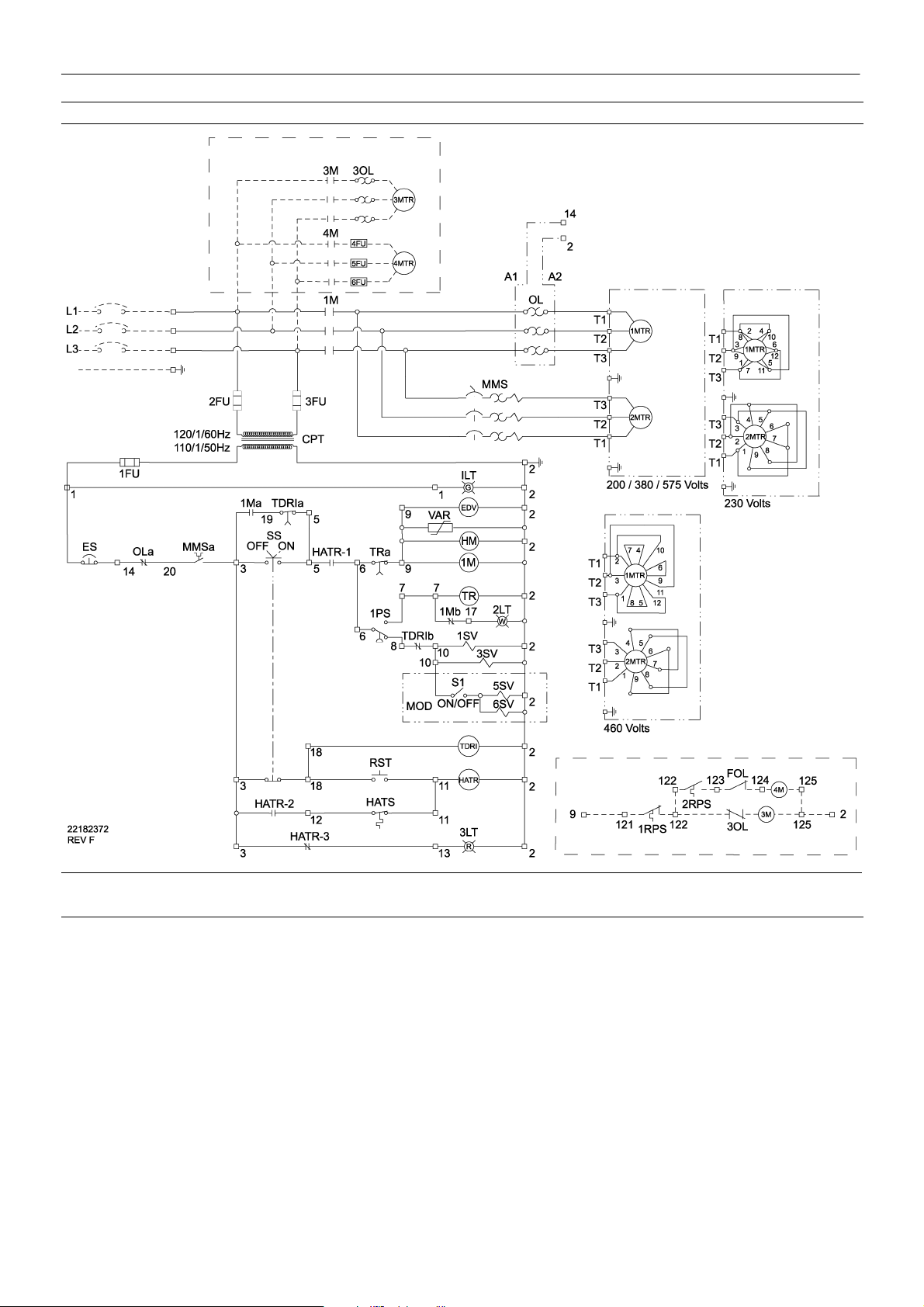

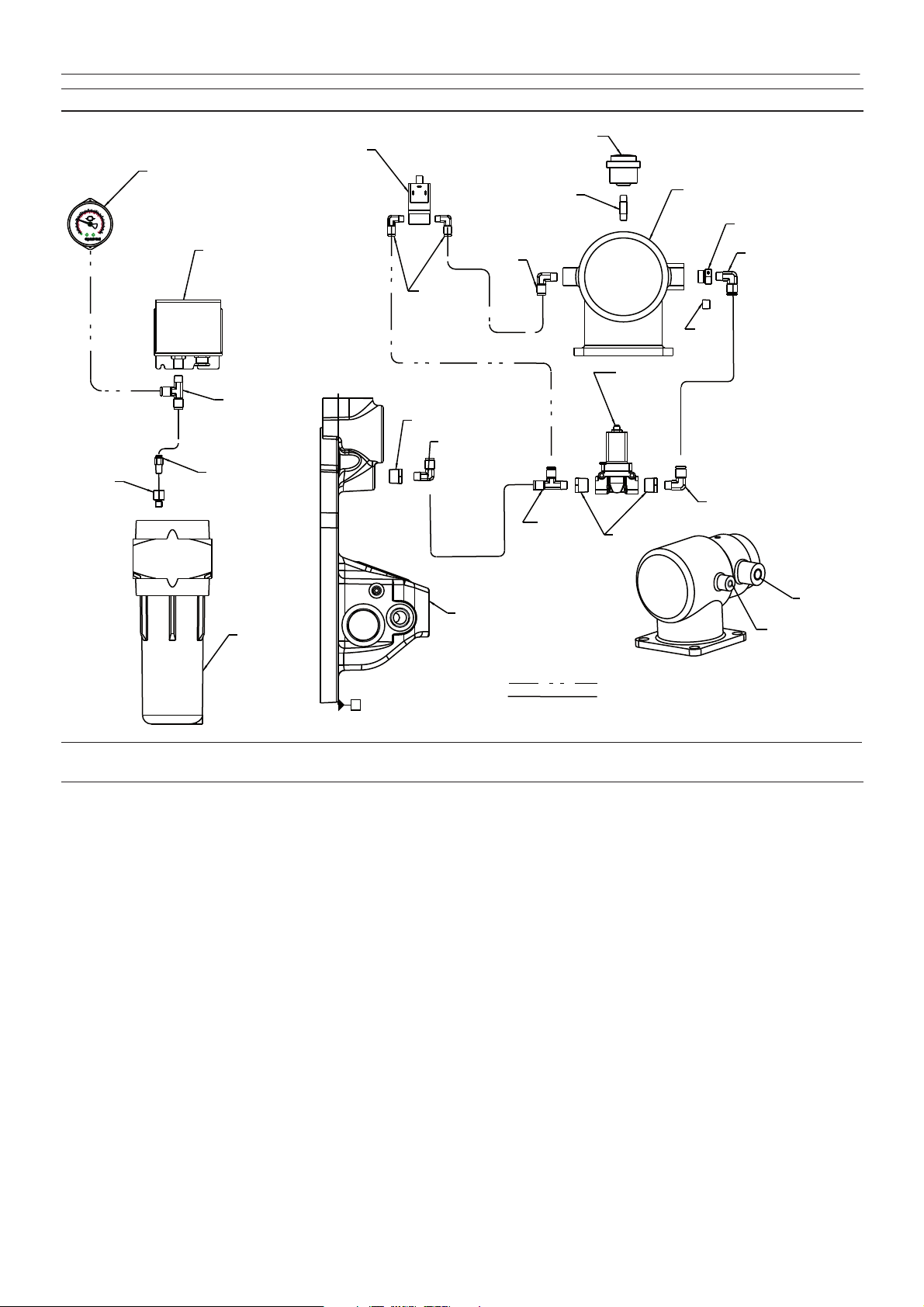

CONTROL PIPING DIAGRAM

10

1

R

P

A

2

6

3

8

6

13

4

6

11

12

9

7

8

14

13

6

18

6

22250039

Revision F

09/06

KEY

1. Pressure gauge

2. Pressure switch

3. Tee

4. Connector

5. Moisture separator

6. Elbow

7. Tee, male run

8. Reducer bushing

9. Blow down solenoid valve

10.Load solenoid valve

11.Indicator air filter

ADAPTER INTO

15

5

A

A

B

THIS PORT

PLUG INTO

THIS PORT

12.Nipple

13.Adaptor

14.Intake valve assembly

15.Separator tank

16.Tee

17.Valve

18.Plug

17.Valve

NOTES:

A. Tubing 3/8 inch

B. Tubing 1/4 inch

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50–PE, EP50–PE,

HP50–PE, HXP50–PE

http://air.ingersollrand.com

Loading...

Loading...