Ingersoll-Rand HRD20-C, HRD25-C, HRD30-C, HRD35-C, HRD40-C Operator's Instruction Manual

...

HEATLESS COMPRESSED

AIR DRYERS WITH

COMPU-PURGE CONTROL

HRD SERIES

Before installation or starting the dryer for the

first time, study this manual carefully to obtain

a clear knowledge of the unit and of the duties

to be performed while operating and

maintaining the unit.

RETAIN THIS MANUAL WITH UNIT.

HRD2-C

HRD5-C

HRD10-C

HRD15-C

HRD20-C

HRD25-C

HRD30-C

HRD35-C

HRD40-C

HRD45-C

HRD50-C

HRD55-C

HRD60-C

HRD65-C

OPERATOR’S

INSTRUCTION MANUAL

HRD70-C

HRD75-C

HRD80-C

HRD85-C

HRD90-C

HRD95-C

This technical manual contains IMPORTANT

SAFETY DATA and should be kept with the

dryer at all times.

Bulletin 342 Revision E (7/97)

Ingersoll-Rand Company 1997

Table Of Contents

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Receiving and Inspection. . . . . . . . . . . . . . . . . . . . . . . . 1

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Ambient Air Temperature . . . . . . . . . . . . . . . . . . . . . . . 2

Location and Clearance. . . . . . . . . . . . . . . . . . . . . . . . . 2

System Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Piping and Connections . . . . . . . . . . . . . . . . . . . . . . . . 2

Desiccant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Mufflers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . 4

INDICATORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Additional Indicators and Alarms . . . . . . . . . . . . . . . . . . . 5

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

How It Works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Compu-Purge Control . . . . . . . . . . . . . . . . . . . . . . . . . 6

Start-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Dew Point Verification . . . . . . . . . . . . . . . . . . . . . . . . . 7

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Desiccant Dusting . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . 8

Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Weekly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Yearly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Returns to Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . 9

Desiccant Replacement. . . . . . . . . . . . . . . . . . . . . . . . . 9

High-Humidity Alarm Field Adjustment . . . . . . . . . . . . . . . 10

Care of Compu-Purge Sensors . . . . . . . . . . . . . . . . . . . . 11

LCD Display Information. . . . . . . . . . . . . . . . . . . . . . . 12

Indicators and Alarms. . . . . . . . . . . . . . . . . . . . . . . . . 12

FIELD SERVICE GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . 13

COMPU-PURGE CONTROL BOARD SERVICE LAYOUT. . . . . . . 14

COMPU-PURGE POWER BOARD SERVICE LAYOUT . . . . . . . . 15

ELECTRICAL SCHEMATIC . . . . . . . . . . . . . . . . . . . . . . . . 16

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . 17

MATERIAL SAFETY DATA SHEET (Molecular Sieve) . . . . . . . . . 20

MATERIAL SAFETY DATA SHEET (Activated Alumina). . . . . . . . 22

INTRODUCTION

HRD Series heatless desiccant compressed air dryers

equipped with Compu-Purge

from compressed air to achieve a standard pressure dew

point of –40°F or an optional dew point of –100°F. The

heatless dryer supplies a continuous flow of dry compressed air by alternately cycling the airflow through

two desiccant beds; one adsorbs moisture from the inlet

air while the other is regenerated by a portion of the dry

air from the active bed.

To ensure continuing good dryer performance and safe

operation, everyone who installs, uses or maintains the

dryer must read and carefully follow the instructions in

this manual. Throughout the manual, the word dryer is

used to refer to HRD Series heatless air dryers.

®

control remove moisture

5. Never perform electrical service on the dryer unless

the main power supply has been disconnected. Parts

of the control circuit may remain energized when

the power switch is turned off.

6. Use only genuine replacement parts from the manufacturer. The manufacturer bears no responsibility

for hazards caused by the use of unauthorized parts.

Safety instructions in this manual are boldfaced for emphasis. The signal words DANGER, WARNING and

CAUTION are used to indicate hazard seriousness levels as follows:

DANGER—Immediate hazard which will result in

severe injury or death.

WARNING—Hazard or unsafe practice which could

result in severe injury or death.

SAFETY

HRD Series dryers are designed and built with safety as

a prime consideration; industry-accepted safety factors

have been used in the design. Each dryer is checked at

the factory for safety and operation. The desiccant vessels are hydrostatically tested to 1½ times the maximum

pressure in accordance with ASME code requirements.

A factory-installed safety relief valve is standard on

each dryer.

WARNING

The following safety rules must be observed

to ensure safe dryer operation. Failure to

follow these rules may void the warranty or

result in dryer damage or personal injury.

1. Never install or try to repair any dryer that has been

damaged in shipment. See the Receiving and Inspection instructions in this manual for appropriate

action.

2. Never operate the dryer at pressures or temperatures

above the maximum conditions shown on the data

plate.

3. Always supply electrical power that complies with

the voltage shown on the data plate.

4. Never dismantle or work on any component of the

dryer or compressed air system under pressure.

Vent internal air pressure to the atmosphere before

servicing.

CAUTION—Hazard or unsafe practice which could

result in minor injury or in product or property damage.

The dryer data plate, attached to the left side of the electrical control box, contains critical safety and identification information. If the data plate is missing or defaced,

immediately contact your local distributor for a replacement.

INSTALLATION

Receiving and Inspection

Immediately upon receipt of the dryer, thoroughly inspect for damage that may have occurred during shipping. Since the dryer is shipped F.O.B. New Castle,

Delaware, the carrier is legally responsible for damage

incurred during shipping. Shipping damage is not covered by the dryer warranty.

If goods are received short or damaged, notify the carrier and insist on a notation of the loss on the face of the

bill of lading. Otherwise no claim can be enforced

against the carrier.

If concealed loss or damage is discovered, notify the

carrier at once and request an inspection. The carrier

will make an inspection and grant a concealed damage

notation. The carrier will not consider any claim for loss

or damage unless an inspection has been made. If you

give the carrier a clear receipt for goods that have been

damaged or lost in transit, you do so at your own risk

and expense.

HRD Series Heatless Dryer with Compu-Purge Control (Bulletin 342) 1

If there is any damage, file a claim with the carrier, then

call your local distributor for further instructions.

Handling

The dryer is designed to be moved by means of the

shipping skid or the base channels. Handle the dryer

with care and only with equipment capable of lifting the

load.

Ambient Air Temperature

Locate the dryer under cover in an area where the ambient air temperature is between 35°F and 120°F. Ambient temperatures over 100°F can be tolerated but will

adversely affect dryer performance. If ambient temperatures below 35°F cannot be avoided, contact your local

distributor.

Location and Clearance

Install the dryer on a level pad. The dryer is provided

5

with a minimum

⁄8-inch diameter anchor bolt holes. For

dryers HRD2-C thru HRD35-C, anchor the dryer to the

floor with four ½-inch diameter bolts with a minimum

4-inch thread engagement. For dryers HRD40-C thru

HRD100-C, anchor the dryer to the floor with four

¾-inch diameter bolts with a minimum 6-inch thread

engagement. Allow 24 inches clearance on all sides of

the dryer for servicing. Provide adequate clearance for

prefilter and afterfilter element replacement. Provide

protection for the dryer if it is installed where heavy vehicles or similar portable equipment is likely to cause

damage.

System Arrangement

Install the dryer downstream of an aftercooler and separator so that the dryer inlet air is between 60°F and

120°F and contains no liquid water. Liquid water and/or

inlet air temperatures above 100°F can reduce drying

capacity. Contact your local distributor for information

on proper dryer sizing at elevated inlet air temperatures.

Oil contaminates the desiccant, reducing drying efficiency and desiccant life. If the inlet air to the dryer

contains oil, an oil-removing filter must be installed at

the dryer inlet. If the inlet air is oil-free, a particulate

prefilter should be installed to remove dirt and other

solid particles. A particulate filter should be installed at

the dryer outlet to capture desiccant particles.

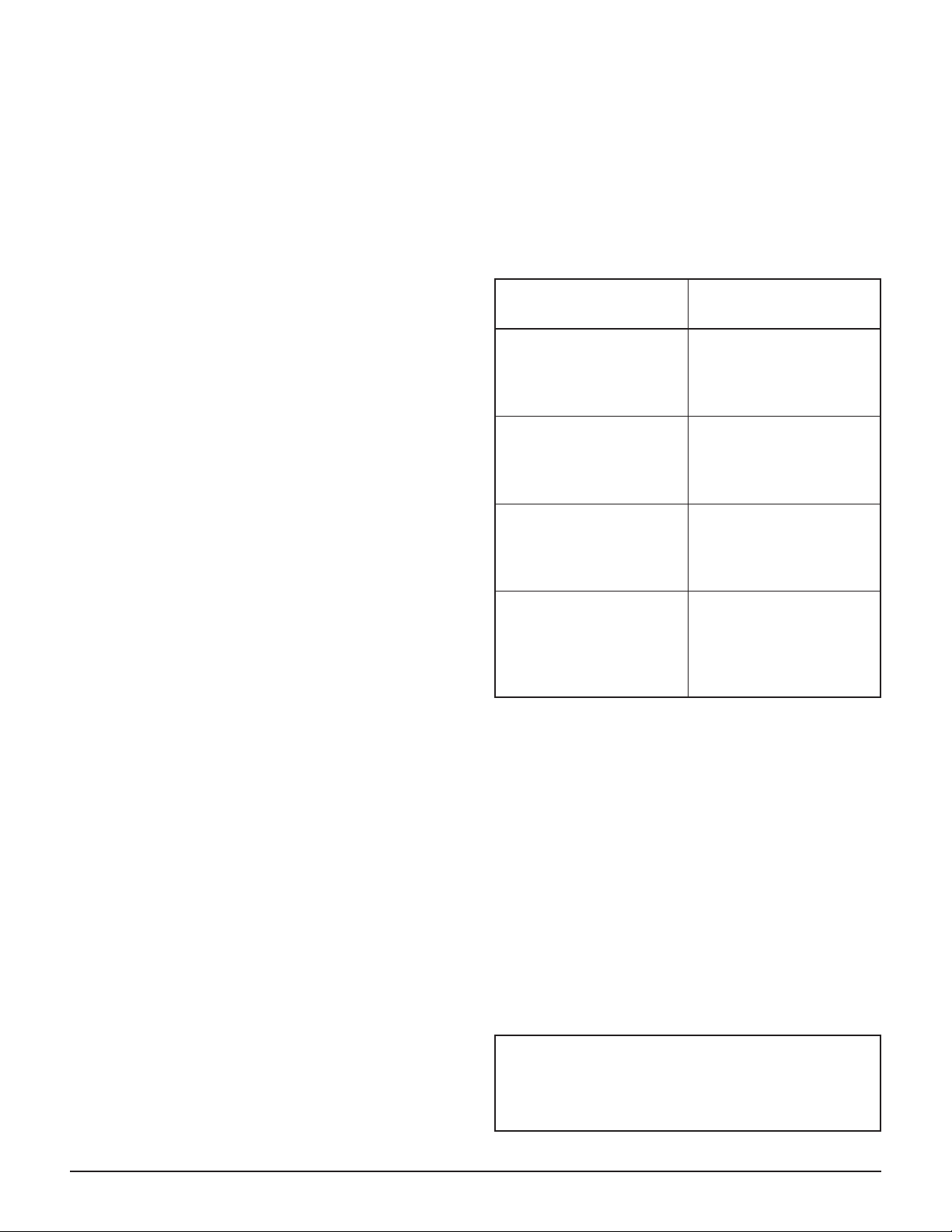

Piping and Connections

All external piping must be supplied by the user unless

otherwise specified. Refer to Table 1 for connection

sizes. Inlet and outlet manual shutoff valves and a vent

valve are recommended so the dryer can be isolated and

depressurized for servicing. Refer to Figure 1 for recommended piping layout. The connections and pipe fittings must be rated for or exceed the maximum

operating pressure given on the dryer data plate and

must be in accordance with industry-wide codes.

Table 1

CONNECTIONS

Model

HRD2-C 1

HRD5-C 1

HRD10-C 1

HRD15-C 1½

HRD20-C 1½

HRD25-C 2

HRD30-C 2

HRD35-C 2

HRD40-C 3

HRD45-C 3

HRD50-C 3

HRD55-C 3

HRD60-C 3

HRD65-C 4" FLG

HRD70-C 4" FLG

HRD75-C 4" FLG

HRD80-C 4" FLG

HRD85-C 6" FLG

HRD90-C 6" FLG

HRD95-C 8" FLG

HRD100-C 8" FLG

In/Out

Connections

(inches NPT)

Be sure all piping is supported. Do not allow the weight

of any piping to bear on the dryer or filters. Piping must

be the same size as or larger than the dryer connections.

Piping smaller than the dryer connections will cause

high pressure drop and reduce drying capacity.

If the purge exhaust muffler piping must be extended

outside the dryer area, the piping must be sized so that it

will cause no back pressure. Back pressure reduces

the capacity of the dryer. Consult your local distributor for piping details if required.

Dryer bypass piping may be installed to allow uninterrupted airflow during servicing. If the downstream application cannot tolerate unprocessed air for short

periods, install a second dryer in the bypass line.

CAUTION

Do not hydrostatically test the piping with the

dryer in the system. The desiccant will be

damaged if saturated with water.

2 HRD Series Heatless Dryer with Compu-Purge Control (Bulletin 342)

Desiccant

Standard dryers, which dry to a –40°F pdp, use activated alumina as the desiccant in the dryer vessels.

Models HRD2-C through HRD35-C are shipped with

activated alumina in the dryer vessels. Activated alumina is shipped loose with all other standard models.

Dryers that dry to a –100°F pdp (designated by the suffix J in the model number) use activated alumina and

molecular sieve in the dryer vessels.

Models HRD2-CJ through HRD35-CJ are shipped with

activated alumina in the dryer vessels. Molecular sieve

for these models is shipped loose. Activated alumina

and molecular sieve are shipped loose with all other

–100°F pdp models.

All desiccant and molecular sieve shipped loose must

be added to the dryer vessels before the dryer is put

into service.

Refer to Table 2 for desiccant type and quantity per vessel.

sel)

Table 2

(lbs per ves-

Activated

Alumina

sel)

Molecular

Sieve

(lbs per ves-

DESICCANT REQUIREMENTS

–40°F PDP –100°F PDP

Dryer Model

HRD2-C 28 19 8

HRD5-C 60 40 16

HRD10-C 95 65 27

HRD15-C 120 80 33

HRD20-C 165 110 46

HRD25-C 210 140 58

HRD30-C 285 190 79

HRD35-C 366 250 101

HRD40-C 475 325 133

HRD45-C 600 400 165

HRD50-C 725 500 200

HRD55-C 875 575 238

HRD60-C 1,025 675 282

HRD65-C 1,200 800 330

HRD70-C 1,366 911 379

HRD75-C 1,567 1,045 435

HRD80-C 1,828 1,219 508

HRD85-C 2,495 1,663 693

HRD90-C 3,205 2,150 890

HRD95-C 4,075 2,717 1,132

HRD100-C 5,126 3,425 1,425

Activated

Alumina

(lbs per ves-

sel)

To add desiccant:

WARNING

The following procedure provides

instructions for adding the initial desiccant to

the vessels. If replacing desiccant, refer to the

instructions on page 9. Pressure gauges on

both vessels must indicate 0 psig.

1. Remove the pipe plug from the desiccant fill port at

the top of each vessel. The fill ports are labeled

“DESICCANT INSPECTION PORT.”

CAUTION

Pouring desiccant creates a fine dust; safety

goggles, gloves and dust mask should be

worn by personnel installing desiccant. Refer

to the Material Safety Data Sheets (MSDS) on

pages 20 - 24 for more complete information.

Do not tamp the desiccant in vessels.

Tamping damages desiccant and causes

dusting.

RECOMMENDED PIPING LAYOUT

Figure 1

HRD Series Heatless Dryer with Compu-Purge Control (Bulletin 342) 3

2. Carefully pour activated alumina into the vessels

through the fill port.

3. If molecular sieve is required, first pour the correct

amount of activated alumina into each vessel; pour

the molecular sieve on top of the activated alumina.

4. Tap the vessels with a rubber mallet to ensure uniform distribution of the desiccant.

5. Replace the plugs in the fill port connections.

Mufflers

Purge exhaust mufflers are supplied with every dryer. If

they are not factory installed, they must be screwed into

the purge exhaust connection on the lower manifold

piping before the dryer is operated. Desiccant dusting

may cause a restriction in the purge exhaust muffler

shortly after start-up. A spare set of muffler cores is

shipped loose with each dryer. Depending on dryer

model, the muffler cores may be in the control enclosure or strapped to a vessel leg. For additional information see Desiccant Dusting in the Maintenance section,

page 7.

WARNING

Operating dryer without mufflers will cause

noise levels exceeding OSHA standards.

Remove mufflers only for servicing and

maintenance and only after internal pressure

of dryer has been completely vented to

atmosphere.

Electrical Connections

The dryer is prewired, ready for use. Connect the dryer

to the power supply specified on the data plate. Connec-

COMPU-PURGE

POWER ON

VARIABLEPURGE MODE

HIGH INLET AIR TEMPERATURE

DRYER OVERLOAD

LOW INLET AIR PRESSURE

SENSOR MALFUNCTION

HIGH HUMIDITY (Optional)

FAILURETOSWITCH TOWERS

INDICATING PANEL

(Optional)

Figure 2

tions, marked L1 and L2, are on a terminal strip inside

the electrical box. Make connections through the

plugged hole (identified by a tag) on the bottom right of

the box.

DANGER

Ground the dryer using the connection

supplied inside the electrical box.Refer to the

electrical schematic on page 16 for

connection details.

Important Note: Do not switch power to the dryer on

and off via a remote disconnect. To avoid dryer malfunction, power to the unit must be switched on and

off using the switch on the dryer control panel.

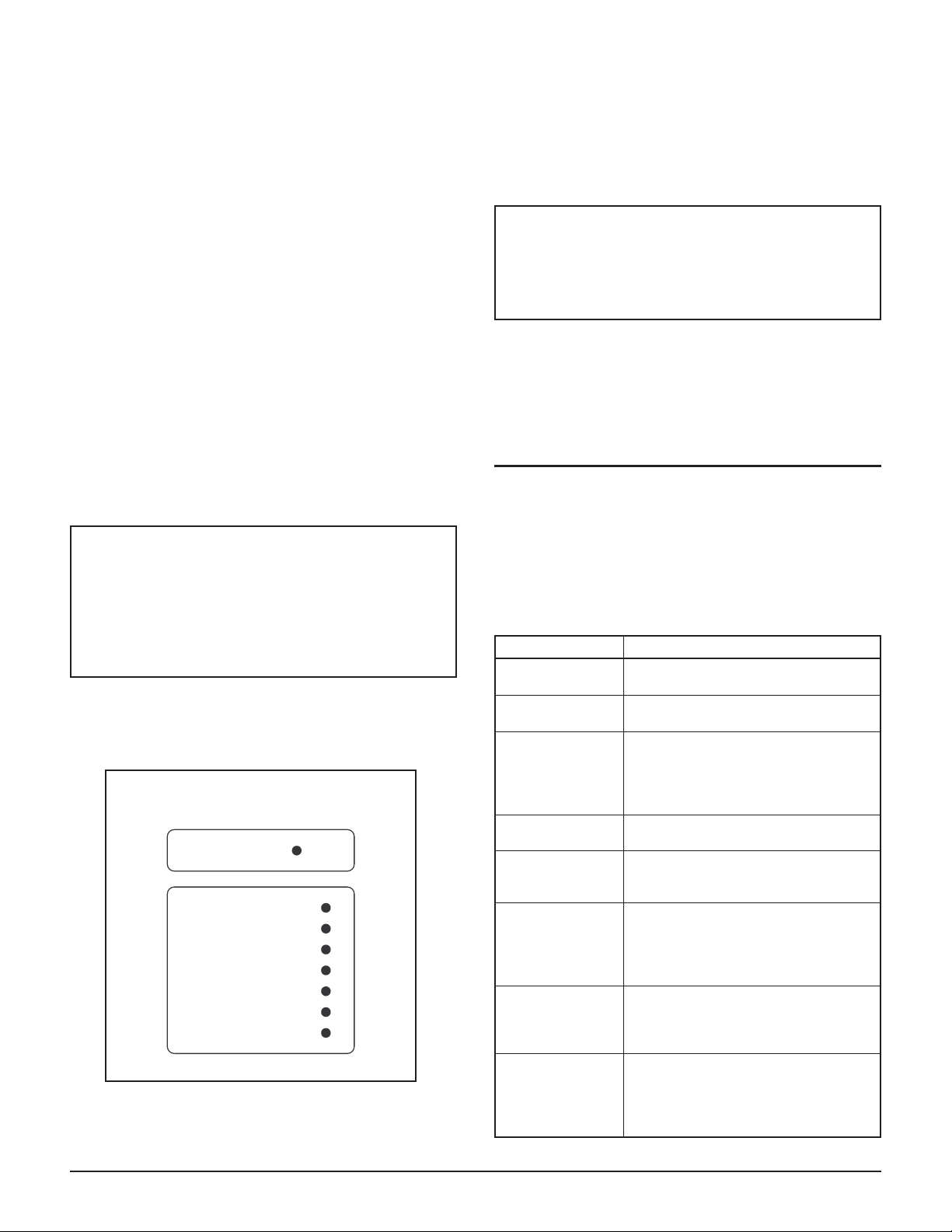

INDICATORS

All HRD Series dryers with Compu-Purge control have

indicating panels (Figure 2) on the door of the main

electrical box. These indicators help in monitoring dryer

operation and performance. If the dryer malfunctions,

first check this panel to determine the cause of the problem.

Light Function

Power ON

Variable Purge

Mode

High Inlet Air

Temperature

Dryer Overload

Low Inlet Air

Pressure

Sensor

Malfunction

High Humidity

(optional)

Failure-to-Switch

(optional)

Lights when switch is in “ON” position

and power is supplied to dryer.

Lights when drying cycle is controlled

by the microcomputer.

Lights when inlet air temperature

exceeds 120°F. Excessive inlet air

temperature significantly decreases

drying capacity and may result in

higher dew point.

Lights when inlet dryer load exceeds

dryer ability to maintain dew point.

Lights when inlet air pressure is less

than 65 psig. See Maintenance section

(page 12) for additional information.

Lights when temperature or pressure

sensor sends the microcomputer a

reading which is outside the normal range

of the sensor. See Maintenance section

(page 12) for additional information.

Lights when the high humidity monitor

senses excessive moisture in the outlet

air. High humidity may result when

dryer is slugged with water.

Lights if airflow fails to alternate

between desiccant vessels at

designated switching time. Failure to

switch causes desiccant saturation,

resulting in higher dew point.

4 HRD Series Heatless Dryer with Compu-Purge Control (Bulletin 342)

Additional Indicators and Alarms

Liquid Crystal Digital (LCD) Display (optional)

The LCD display is above the indicating panel on the

main electrical box. It displays “

TURE

” (°F) and “ENERGY SAVINGS” as a percent of

dryer capacity. See Maintenance section on page 12 for

complete description of additional readouts.

Dew Point Monitor (optional)

The monitor is between the vessels beneath the electrical box. It continuously displays outlet pressure dew

point. (Consult the owner’s manual supplied with the

monitor for more information.)

Vessel Pressure Gauges

A gauge mounted on each desiccant vessel indicates

which vessel is onstream and which is regenerating. The

gauge on the onstream vessel indicates operating pressure; the gauge on the regenerating vessel indicates 0

psig.

Audible Alarm (optional)

For high-humidity and failure-to-switch options, alarms

can be wired to include a horn as well as a light.

INLET AIR TEMPERA-

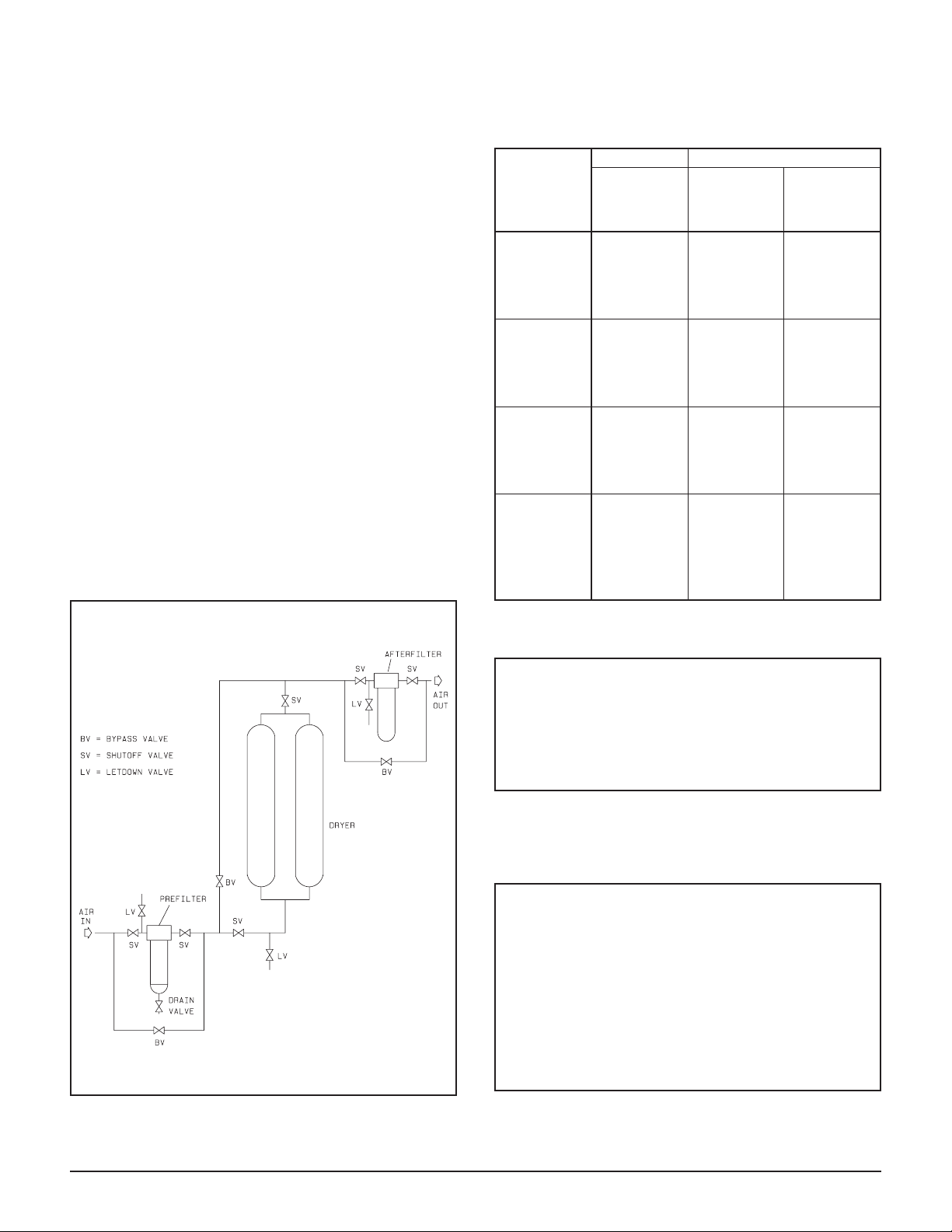

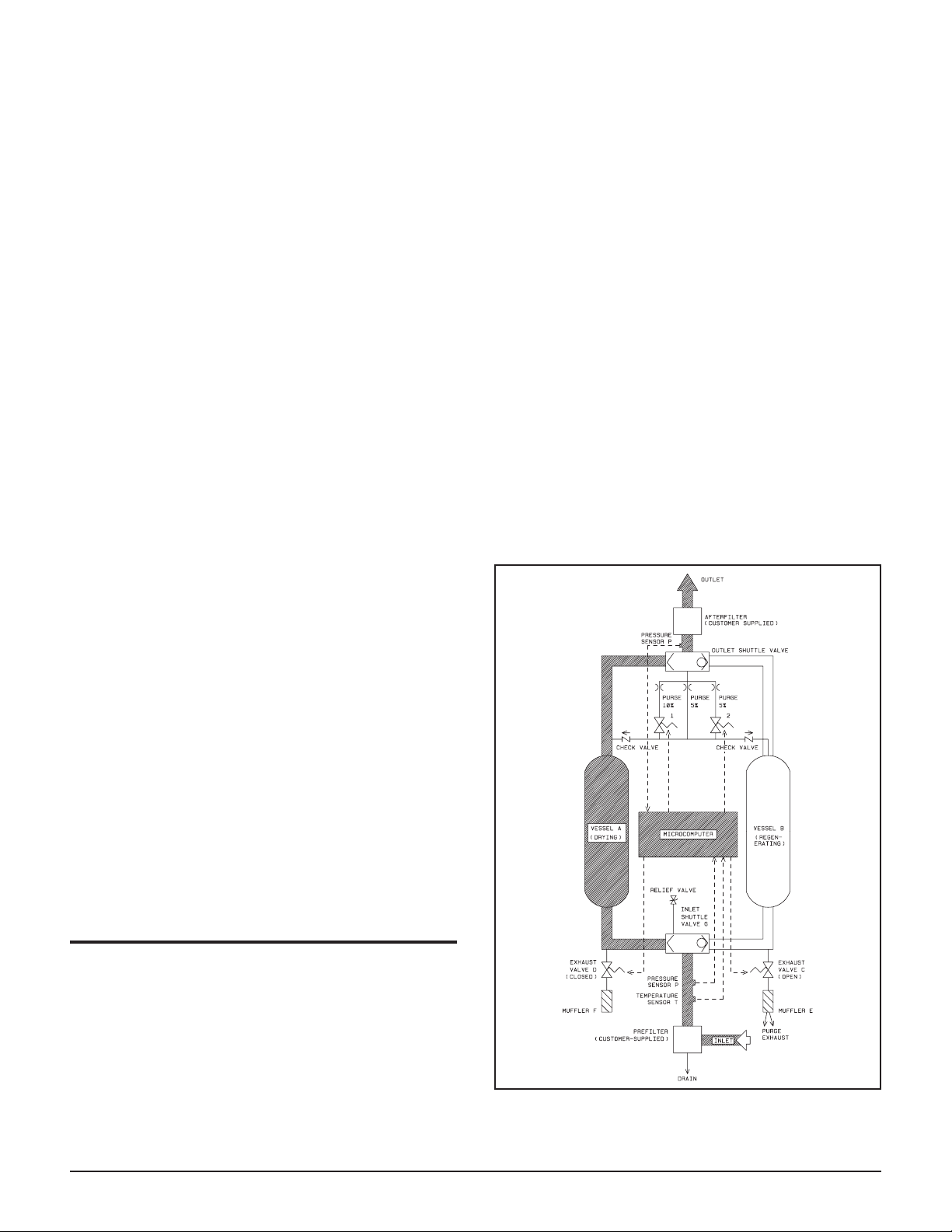

C open and D closed, filtered air enters the inlet shuttle

valve and is directed through vessel A, where moisture

is adsorbed by the desiccant. Dry air exits the vessel,

passes through the outlet shuttle valve and divides into

two streams. The process air passes through the customer-supplied particulate afterfilter and continues to

the process.

A portion of the dried air passes through the purge orifice at approximately atmospheric pressure and passes

downward through vessel B, where it desorbs moisture

from the desiccant. Wet purge air exhausts to the atmosphere through exhaust valve C and muffler E. When

regeneration is complete, exhaust valve C closes and

vessel B is repressurized to dryer operating pressure.

Vessel B is completely regenerated and repressurized,

ready for the next drying cycle.

At the end of the drying period, exhaust valve D opens,

vessel A depressurizes, inlet and outlet shuttle valves

shift, inlet flow switches to vessel B and the drying/regenerating cycle is repeated.

Remote Contacts (optional)

Powered 120 volt, normally open, contacts (1 amp

max.) are furnished to allow hook-up of remote audible

or visible system malfunction alarms. Hook-up contacts

are identified by a tag on the bottom center of the electrical box.

Moisture Indicator (optional)

A color-change moisture indicator is shipped separately

in a moisture-proof bag. The moisture indicator should

be installed at a customer supplied 1¼-inch NPT

threaded port at the dryer outlet. The indicator is green

when dry. The color changes to yellow when the relative humidity of the dryer outlet air is approximately

4%-5%. This indicator is intended only as an inexpensive means of determining possible dryer malfunction.

OPERATION

How It Works

Figure 3 shows the airflow through the dryer with vessel

A drying and vessel B regenerating.

Saturated air enters a customer-supplied prefilter which

separates oil mists, liquid oil, water and particulates

from the airstream. Separated contaminants are discharged through the prefilter drain. With exhaust valve

HRD Series Heatless Dryer with Compu-Purge Control (Bulletin 342) 5

AIRFLOW SCHEMATIC

Figure 3

For standard models designed to provide a –40°F pressure dew point, inlet air continues to flow through one

vessel for half of the standard 10-minute cycle. For

models designed to provide a –100°F pressure dew

point, the standard cycle is 5 minutes.

Compu-Purge Control

Compu-Purge control uses a microcomputer to adjust

the purge airflow rate and drying cycle to automatically

match purge air to the inlet moisture load.

Electronic temperature and pressure sensors continuously track inlet temperature and inlet and outlet pressure and transmit these to the microcomputer. The

microcomputer calculates the dryer load and the most

efficient combination of purge flow rate and duration to

regenerate the moisture adsorbed during the drying period.

able Purge Mode. See Maintenance section (page

12) for additional information.

Start-Up

Once your HRD Series dryer with Compu-Purge control

has been installed according to instructions, it is ready

for start-up.

To start the dryer:

1. Close customer-supplied shutoff valve at dryer inlet.

2. Open customer-supplied bypass valve, if installed.

3. Close customer-supplied letdown and shutoff valves

at dryer outlet.

4. Supply compressed air up to inlet shutoff valve.

Purge flow rate can be varied from 0 to 20% in increments of 5% by purge control valves 1 and 2. Purge duration can also be varied. The optimum combination of

purge control valve openings is automatically selected

by the microcomputer to supply only as much purge air

as needed for complete regeneration.

When the amount of purge air required to regenerate the

desiccant is more than 20% of the inlet flow, the dryer

will operate on a shortened cycle until the overload condition is corrected. For models designed to deliver air at

–40°F pressure dew point, the dryer will operate on a

5-minute cycle when in the Overload Mode. For –100°F

pressure dew point operation, a 3-minute cycle is used.

The microcomputer uses three modes of dryer operation

to match the inlet moisture load:

Compu-Purge Mode – When the microcomputer

adjusts purge air to match dryer load requirements,

the dryer is operating in the Compu-Purge mode.

Standby Mode – When there is low or no demand

for air, the dryer operates in a standby mode: the

dryer purges until the desiccant is regenerated, the

vessels repressurize, then the dryer automatically

shuts down; the dryer purges every 30 minutes to

assure dew point performance.

Fixed-Cycle Mode – If all sensors malfunction, the

“Variable Purge Mode” light will turn off and the

dryer will automatically operate in a fixed cycle

mode, using 15% of the design airflow to regenerate

the offstream vessel. If only one sensor malfunctions, the dryer will default to standard conditions

for that sensor and continue to operate in the Vari-

5. Slowly open inlet shutoff valve and wait for dryer

to reach operating pressure. Pressure gauges on both

dryer vessels will indicate operating pressure.

6. Check all piping connections for air leaks. Remedy

leaks before continuing start-up.

7. Turn on power switch on electrical box.

When power switch is turned on “power on” light

will light. Both vessels will remain at pressure for

up to 60 seconds, then one will depressurize and the

green “Variable Purge” light will light.

Models with LCD display will show in sequence:

DELTECH ENGINEERING, L.P., COPYRIGHT 1988...1991

INLET TEMP. 99° ENERGY SAVINGS = 80%

NO MALFUNCTIONS EXIST

FIRST CYCLE OF OPERATION

USING DEFAULT VALUES

During the next five minutes, the microcomputer

will check itself for any malfunctions. The dryer

will operate in a fixed-cycle mode, using 15%

purge, during start-up.

At the end of this period, dryer operation will be

computer-controlled, the “Variable Purge Mode”

light will be on and the microcomputer will automatically control purge rate to match the dryer load.

Models with LCD display will show:

INLET TEMP XX ENERGY SAVINGS = XX%

NO MALFUNCTION EXISTS

6 HRD Series Heatless Dryer with Compu-Purge Control (Bulletin 342)

Loading...

Loading...