Ingersoll-Rand 99828618 User Manual

OPERATOR’S MANUAL SB30X-XXX-X

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

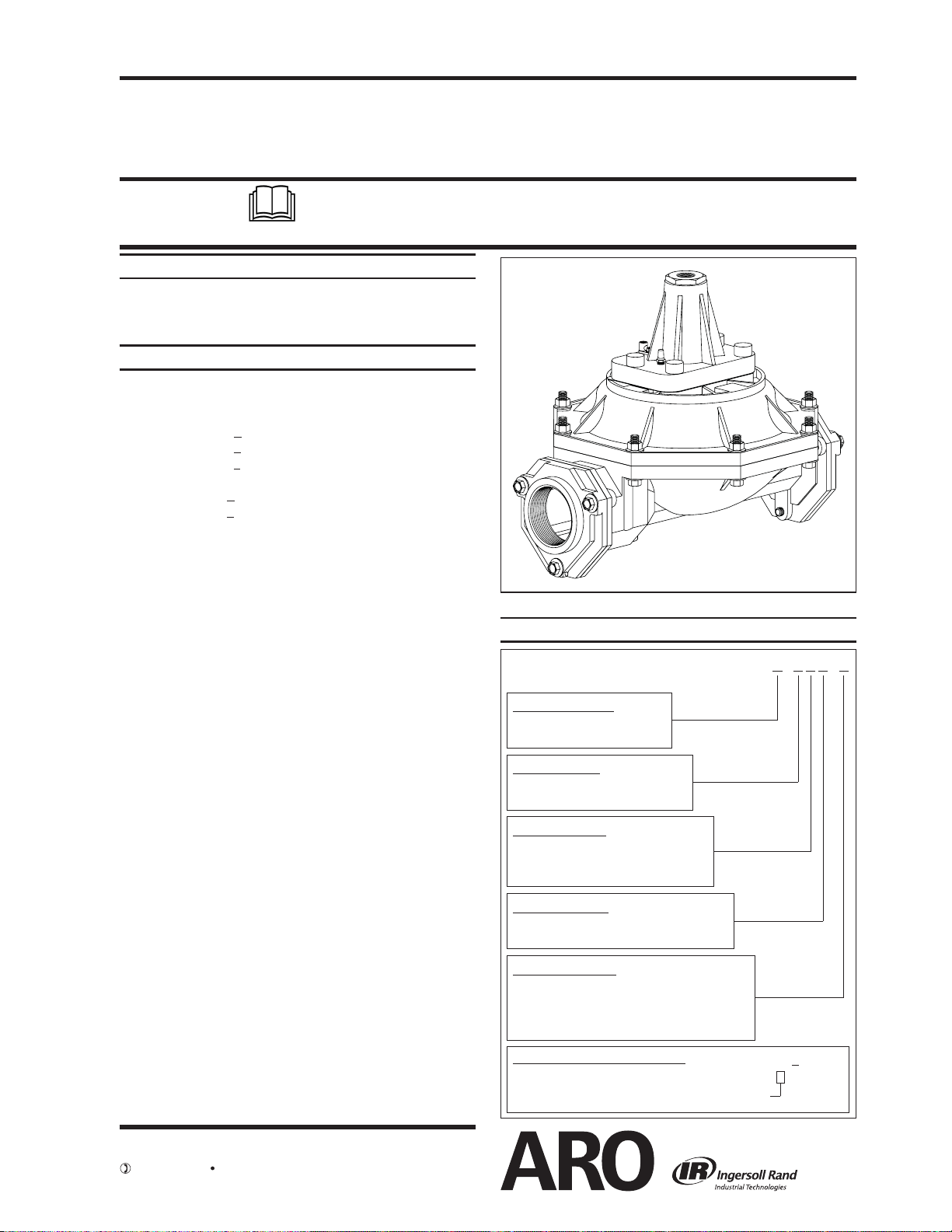

3" SHOCK BLOCKER®

METALLIC PULSATION DAMPENER

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS

Refer to the Model Description Chart to match the pump material

options.

637330-3X for repair of the diaphragms and “O” rings (see page 4).

PUMP DATA

Models . . . . . . . . . . . . . . . . . see Model Description Chart for “-XXX-X”

Pulsation Dampener Type . . . . . . . . . . . . . Metallic

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . see Model Description Chart

Weight . . . . SB30X-XAX-X . . . . . . . . . . . . . . 41 lbs (18.6 kgs)

SB30X-XCX-X . . . . . . . . . . . . . . 94 lbs (42.6 kgs)

SB30X-XSX-X . . . . . . . . . . . . . . . 96 lbs (43.5 kgs)

Material Inlet / Outlet

SB30X-AXX-X . . . . . . . . . . . . . . 3 - 8 N.P.T.F. - 1

SB30X-BXX-X . . . . . . . . . . . . . . Rp 3 (3 - 11 BSP parallel)

Air Inlet (female) . . . . . . . . . . . . . . . . . . . . . . . 3/4 - 14 N.P.T.

Maximum Air Inlet Pressure . . . . . . . . . . . 120 p.s.i.g. (8.3 bar)

Maximum Material Inlet Pressure . . . . . . 120 p.s.i.g. (8.3 bar)

Maximum Temperature Limits (diaphragm / seal material)

E.P.R. / EPDM . . . . . . . . . . . . . . . . . . . . -60° to 280° F (-51° to 138° C)

Nitrile . . . . . . . . . . . . . . . . . . . . . . . . . . . 10° to 180° F (-12° to 82° C)

Santoprene® . . . . . . . . . . . . . . . . . . . . -40° to 225° F (-40° to 107° C)

PTFE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40° to 225° F (4° to 107° C)

Viton® . . . . . . . . . . . . . . . . . . . . . . . . . . . -40° to 350° F (-40° to 177° C)

Maximum Fluid Volume . . . . . . . . . . . . . . . 367 in. (6.01 lit.)

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . see page 7

NOTICE: All possible options are shown in the chart, however, certain

combinations may not be recommended, consult a representative or

the factory if you have questions concerning availability.

MODEL DESCRIPTION CHART

Air Section Material

A - Aluminum

S - Stainless Steel

Fluid Connection

A - 3 - 8 N.P.T.F. - 1

B - Rp 3 (3 - 11 BSP, parallel)

RELEASED: 2-18-00

REVISED: 5-27-10

(REV. G)

Figure 1

SB30 X - X X X - X

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX(800) 892-6276

www.ingersollrandproducts.com

© 2010

CCN 99828618

Fluid Cap Material

A - Aluminum

C - Cast Iron

S - Stainless Steel

Hardware Material

P - Carbon Steel

S - Stainless Steel

Diaphragm Material

A - Santoprene

G - Nitrile

T - PTFE / Santoprene

V - Viton

Fluid Section Service Kit Selection

EXAMPLE: Model #SB30A-BAP-G

Fluid Section Service Kit # 637330-3G

SB30X - XXX - X

637330 - 3 X

Diaphragm

OPERATING AND SAFETY PRECAUTIONS

READ, UNDERSTAND AND FOLLOW THIS INFORMATION TO AVOID INJURY AND PROPERTY DAMAGE.

WARNING

uid inlet pressure of 120 p.s.i. (8.3 bar). Operating at higher

pressure can cause explosion, resulting in property damage or

severe injury.

WARNING

bottled gas products to run the pulsation dampener. Un-

regulated high pressure bottled gas has the potential for overpressurization. Certain gasses, such as Nitrogen, can cause unpredictable results. The pressure source MUST BE REGULATED.

WARNING

use with certain fluids. Incompatible fluids may attack and

weaken the housing, causing rupture or explosion, which can

result in property damage or severe injury. See manufacturer’s

information on uid compatibility.

WARNING

unit when it is under pressure. Relieve all material pressure in

the pumping system before attempting service or disassembly.

Disconnect air lines and carefully bleed any pressure off the

system. Be certain the system is not maintaining pressure due

to a material restriction in the hose, line, dispensing device

or the spray or extrusion tip. Failure to relieve pressure, both

upstream and downstream, may result in an injury upon disassembly.

EXPLOSION HAZARD. Do not exceed maximum

USE ONLY WITH COMPRESSED AIR. Do not use

CHEMICAL COMPATIBILITY HAZARD. Do not

DISASSEMBLY HAZARD. Do not disassemble this

CAUTION

AIR MUST BE SUPPLIED TO THE SHOCK BLOCKER

BEFORE APPLYING FLUID PRESSURE. Failure to pressurize

with air rst can damage the diaphragm.

CAUTION

ALWAYS RELIEVE THE FLUID PRESSURE BEFORE

REMOVING THE AIR PRESSURE. Failure to relieve uid pressure can damage the diaphragm.

CAUTION

NOT FOR STRUCTURAL SUPPORT. Do not use

this product to support other system components or use

as a step. Improper support can result in fracture of the hous-

ing, causing damage. Plumbing must be supported to prevent

stresses upon it.

NOTICE

Replacement warning labels are available upon

request: “Static Spark & Diaphragm Rupture” pn \ 94080.

WARNING

= Hazards or unsafe practices which

could result in severe personal injury,

death or substantial property damage.

CAUTION

= Hazards or unsafe practices which

could result in minor personal injury,

product or property damage.

NOTICE

= Important installation, operation or

maintenance information.

OPERATING INSTRUCTIONS

WARNING

AND SAFETY PRECAUTIONS” ABOVE.

AIR REQUIREMENTS

Supply the unit with clean, dry air.

y

A lter capable of ltering out particles larger than 50 microns

y

should be used on the air supply.

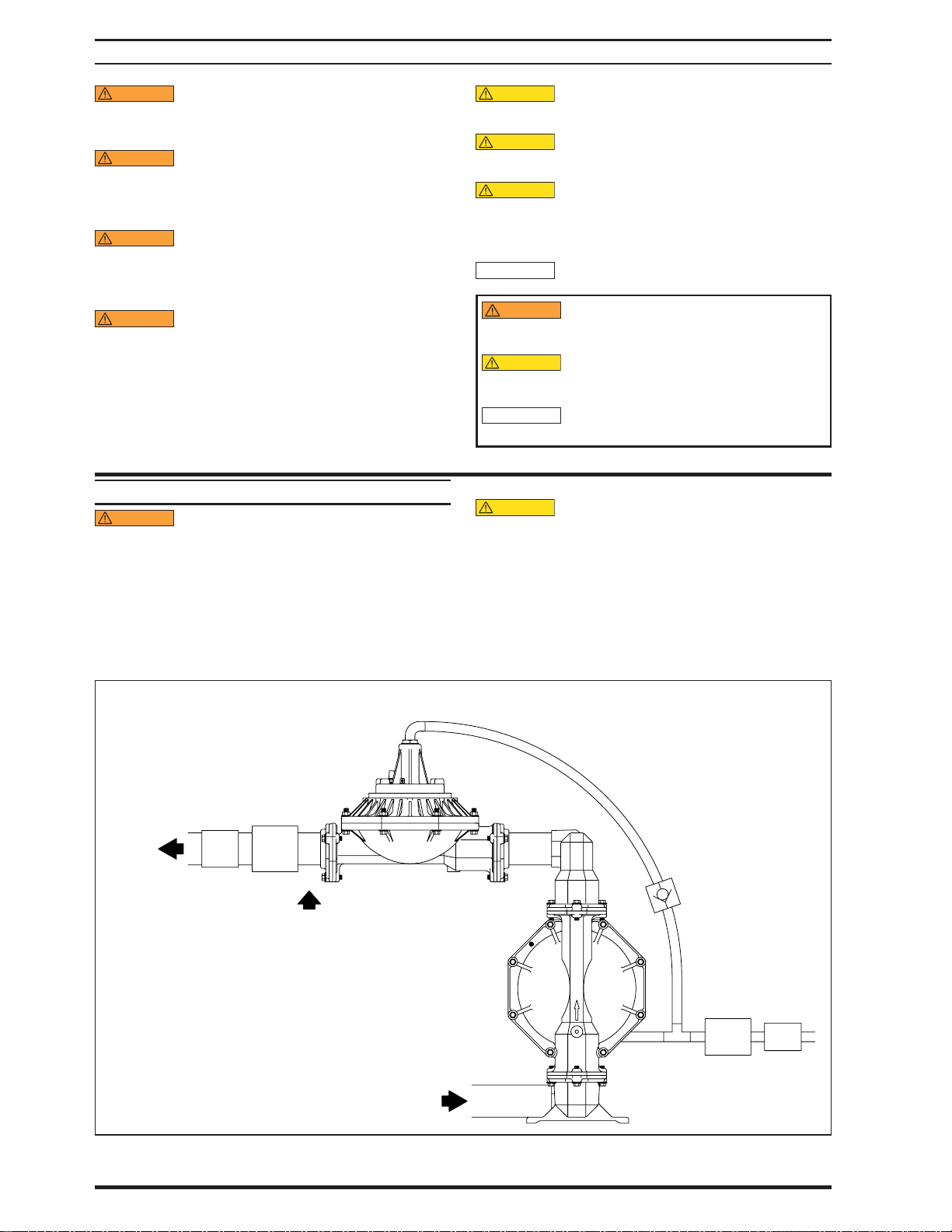

INSTALLATION INSTRUCTIONS

Position the shock blocker pulsation dampener as close to the

y

Discharge

HEED WARNINGS AS SHOWN IN “OPERATING

TYPICAL SYSTEM INSTALLATION

Shut-o

Valve

Back

Pressure

Gauge

(optional)

Support required.

(see “Installation Instruc tions”)

pump discharge as possible (as shown in gure 2).

CAUTION

SUPPORT THE PIPE IMMEDIATELY DOWNSTREAM

FROM THE SHOCK BLOCKER. Support is required to eliminate

forces and moments from the shock blocker anges and pump

manifold. Cantilever support is suggested immediately downstream from the shock blocker.

Use a tee connector after the F-R-L on the pump air supply line

y

and connect the line to the shock blocker’s valve body (1/4”

i.d. hose is su cient). When the air supply to the pump is shut

down, the air to the shock blocker will be shut down as well.

Check

Valve

Suction

Filter

Regulator

Lubricator

Shut-o

Valve

Figure 2

Page 2 of 8 SB30X-XXX-X (en)

GENERAL DESCRIPTION

The ARO® shock blocker pulsation dampener is designed to work

with 1:1 ratio pumps having an outlet pressure not exceeding 120

p.s.i. (8.3 bar). The shock blocker will effectively reduce material

pressure variations, surges and shock to piping and delivery in uid

systems during pump reversal. It can significantly contribute to

pulse reduction in low pressure spray applications.

Accurate selection of wetted material will assure longest service life

and minimize down time. Several material options are available for

the body and diaphragm materials. Fluid section materials available include: aluminum, cast iron and stainless steel. For specific

uid compatibility, consult the chemical manufacturer.

The shock blocker uses a single air pressurized, exible diaphragm

working against the uid line pressure. Several diaphragm material

options are available to allow custom matching to the uid material for best compatibility (refer to the model description chart).

Shock blocker units can also be added in series to provide additional dampening on the material.

Pressure relief through the exhaust port is a normal compensating

function of the control valve in the shock blocker. It will automatically adjust itself to the required operating pressure once the material pressure has been applied. The pressure supplied to the shock

blocker needs to be equal to the material pressure to provide the

proper dampening e ect.

AIR AND LUBE REQUIREMENTS

WARNING

dampener damage, personal injury or property damage.

A lter capable of ltering out particles larger than 50 microns

y

should be used on the air supply. There is no lubrication required other than the “O” ring lubricant which is applied during

assembly or repair.

If lubricated air is present, make sure that it is compatible with

y

the “O” rings and seals in the air motor section of the pump.

EXCESSIVE AIR PRESSURE. Can cause pulsation

OPERATION

CAUTION

at higher pressure can cause explosion, resulting in property

damage or severe injury.

Pressure relief through the exhaust port is a normal compen-

y

sating function of the control valve in the shock blocker. It will

automatically adjust itself to the required operating pressure

once the material pressure has been applied.

Operate the system for a few minutes to equalize air and uid

y

chambers of the pulsation dampener.

DO NOT EXCEED 120 P.S.I. (8.3 BAR). Operating

PARTS AND SERVICE KITS

Refer to the part views and descriptions as provided on pages 4

and 5 for parts identi cation and Service Kit information.

Certain ARO “Smart Parts” are indicated which should be avail-

y

able for fast repair and reduction of down time.

MAINTENANCE

Provide a clean work surface to protect sensitive internal mov-

y

ing parts from contamination from dirt and foreign matter during service disassembly and reassembly.

Keep good records of service activity and include pump in pre-

y

ventive maintenance program.

Before disassembling, empty captured material in the uid cap

y

by tipping the pulsation dampener on end.

FLUID SECTION DISASSEMBLY

Remove (107) reducing bushing.

1.

Remove six (26) screws, releasing two (4) anges and (11) “O”

2.

rings.

Remove eight (27) screws and (29) nuts, releasing (15) uid cap.

3.

Secure (14) screw in a vise, with (101) air valve body upward.

4.

Using a 15/16” socket on (186) screw, unthread and remove

5.

(186) screw and (10) washer.

Remove (68) air cap from (7) diaphragm and components.

6.

Remove (14) screw from the vise. Unthread and remove (1) rod,

7.

releasing (2) stopper, (5) back-up washer, (196) cushion, (7) or (7

and 8) diaphragms, (6) washer, (3) “O” ring and (9) washer from

(14) screw.

Remove four (131) screws, releasing (101) air valve body from

8.

the (68) air cap.

Remove (144) “U” cup from (68) air cap.

9.

Remove (103) sleeve from (101) air valve body.

10.

FLUID SECTION REASSEMBLY

Clean and inspect all parts. Replace worn or damaged parts

y

with new parts as required. Lubricate all replacement parts and

metallic moving parts with Lubriplate® FML-2 grease upon reassembly.

Grease and assemble two (172) “O” rings to (103) sleeve.

1.

Assemble (103) sleeve into the (101) air valve body.

2.

Grease and assemble (70 and 173) “O” rings to (101) air valve

3.

body.

Grease and assemble (144) “U” cup into (68) air cap.

4.

Assemble (101) air valve body to (68) air cap.

5.

Assemble four (131) screws, securing (68) air cap. NOTE: Tighten

6.

(131) screws to 20 - 30 ft lbs (27.1 - 40.7 Nm).

Assemble (9) washer, (3) “O” ring, (6) washer, (7) or (7 and 8)

7.

diaphragms, (196) cushion, (5) back-up washer and (2) stopper

to (14) screw. NOTE: For models with PTFE diaphragms: Item

(8) Santoprene diaphragm is installed with the side marked

“AIR SIDE” towards the pump center body. Install the PTFE diaphragm (7) with the side marked “FLUID SIDE” towards the (15)

uid cap.

Assemble (1) rod to (14) screw.

8.

Grease and assemble two (173) “O” rings to (1) rod.

9.

Place this assembly into (68) air cap.

10.

Assemble (10) washer and (186) screw into (101) air valve body

11.

and thread into (1) rod. Clamp (14) screw in a vise, with (186)

screw upward, and tighten (186) screw to 65 - 70 ft lbs (88.1 -

94.9 Nm).

Remove assembly from the vise and assemble to (15) uid cap,

12.

securing with eight (27) screws and (29) nuts. NOTE: Tighten (27)

screws to 60 - 70 ft lbs (81.3 - 94.9 Nm).

Grease and assemble two (11) “O” rings to two (4) anges.

13.

Assemble two (4) anges to (15) uid cap, securing with six (26)

14.

screws. NOTE: Tighten (26) screws to 60 - 70 ft lbs (81.3 - 94.9

Nm).

Apply Lubriplate FML-2 grease to threads of (101) air valve

15.

body. Apply PTFE tape to threads of (107) reducing bushing

and assemble to (101) air valve body.

Viton® is registered trademarks of the DuPont Company y Santoprene® is a registered trademark of Monsanto Company, licensed to Advanced Elastomer Systems, L.P.

y

Lubriplate® is a registered trademark of Lubriplate Division (Fiske Brothers Re ning Company) y ARO® and Shock Blocker® are registered trademarks of Ingersoll-Rand Company

y

SB30X-XXX-X (en) Page 3 of 8

y

y

Loading...

Loading...