Ingersoll-Rand 95087, 95088, 96270-1 User Manual

OPERATOR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

DIAPHRAGM FAILURE DETECTOR

67237

RELEASED: 5-31-01

REVISED: 4-13-10

(REV. D)

(INTRINSICALLY SAFE COMPONENTS)

(for 1-1/2”, 2” and 3” Metallic Diaphragm Pumps with Cast Iron or Stainless Steel center bodies)

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SENSOR DATA

Protection The components meet the re-...................

quirements for Class 1, Division II, Group C environment.

Voltage 30 VDC max......................

Sensor Type Electro-Optic.................

Sensor Material Polysulfone...............

GENERAL DESCRIPTION

An Aro diaphragm pump equiped with the Aro Diaphragm Failure Detector warns of a diaphragm failure by sensing the presenceof liquid in

the airchamber of the pump. This system usesa liquid sensorin each of

the two air chambers.

OPERATING INSTRUCTIONS

1. Supply voltagefor the components can be through the 95087 cable

or through the 95088 adapter (see pinout information on page 2).

2. The cable can be connected to operate an output device as required (valve, buzzer, light, etc.).

3. To clean the sensors, disconnect the 96270-1 sensors from the

95088 adapter. Unthread the sensors from the air caps. Clean the

prism of the sensors with a mild detergent or water. WARNING:

Chlorinated hydrocarbons MUST NOT BE USED

See note in 5 below.

4. To reassemble, apply PTFE tape or #80725 Permatex to the

threads of each sensorand threadto theair cap.NOTE: Torque the

sensors to NO MORE THAN 120 in. lbs (13.56 Nm).

sensors to the 95088 adapter.

5. Note: Clean the sensorsevery 1,000,000 cycles or every 3months

of use.

for cleaning.

Reconnect the

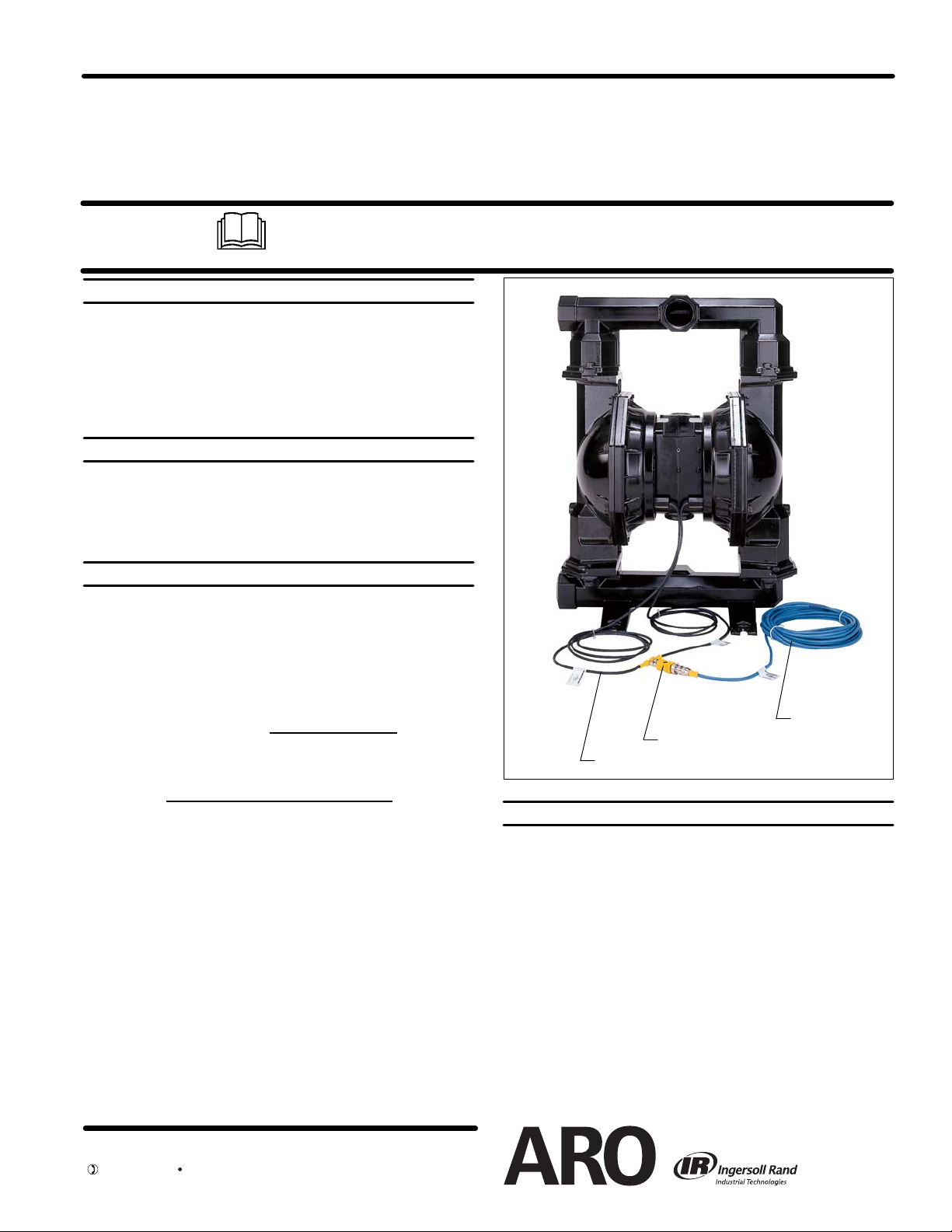

95087 Cable

95088 Adapter

96270-1 Sensor (2)

10 m (32.8 ft)

INSTALLATION AND WARNINGS

NOTE: The power supply cable is not furnished with the unit and must

be supplied by the customer.

ALL WIRING MUST COMPLY WITH ALL LOCAL AND / OR NATIONAL ELECTRICAL CODES.

S Electrical codes that apply must be strictly adhered to; failure to do

so may lead to shock hazard or serious injury.

S Some local electrical codesmay require theinstallation of rigidcon-

duit.

S The diaphragm failure detector components must be installed by a

qualified electrician in compliance with all national, state and local

codes and regulations to reduce the riskof electrical shock or other

serious injury during installation and operation.

S ARO isnot responsiblefor accidents resultingfrom improper instal-

lation of components or hardware.

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 276-4658 FAX (800) 266-7016

www.ingersollrandproducts.com

© 2010 CCN 99856692

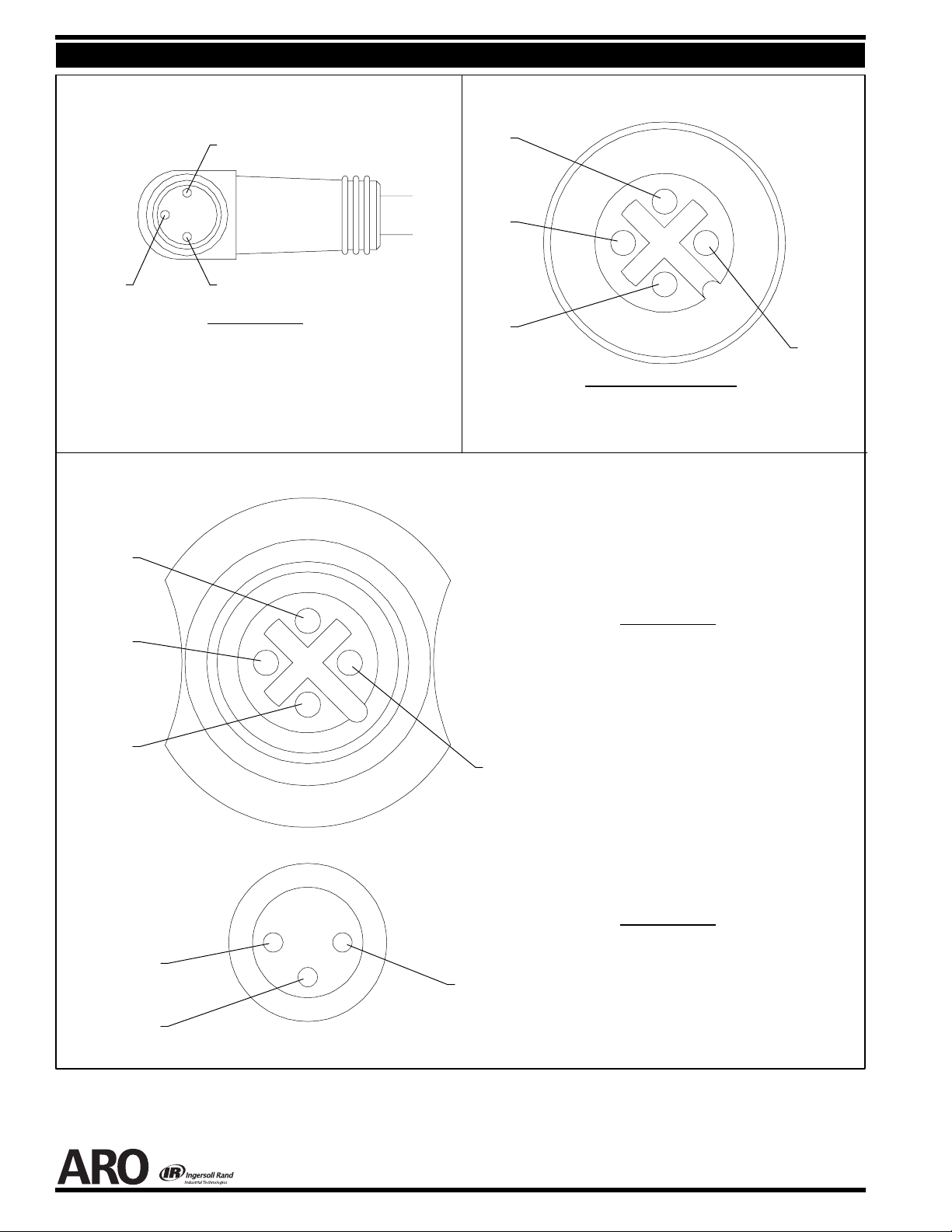

PINOUT DESCRIPTIONS

94712-1 SENSOR PINOUTS

B

C

A

Pinout Function

A+24VDC

B Ground

C Signal

4

3

2

95087 CABLE PINOUTS

1

Pinout Cable Color Function

1 Brown +24 VDC

2 White Signal

3 Blue Ground

4 Black Signal

95088 ADAPTER PINOUTS

4

Pinout Function

3

2

1

A

B

1+24VDC

2 Signal

3 Ground

4 Signal

Pinout Function

A+24VDC

B Ground

C Signal

C

PN 97999-896

67237Page 2 of 2

Loading...

Loading...