Ingersoll-Rand 7AD1, 7 Series, 7AH1, 7AJ1, 7AJJ1 Operation And Maintenance Manual

...

03530896

OPERATION AND MAINTENANCE MANUAL

for

SERIES 7 AIR DRILLS

TPD1388

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING TOOL.

Form P6532

Edition 10

February, 1994

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

• Always operate, inspect and maintain this tool in

accordance with American National Standards

Institute Safety Code for Portable Air Tools

(ANSI–B186.1).

• For safety, top performance and maximum

durability of parts, operate this tool at 90 psig

(6.2 bar/620 kPa) maximum air pressure at the

inlet with 3/8” (10 mm) inside diameter air supply

hose.

• Air powered tools can vibrate in use. Vibration,

repetitive motions or uncomfortable positions may

be harmful to your hands and arms. Stop using any

tool if discomfort, tingling feeling or pain occurs.

Seek medical advice before resuming use.

• Always turn off the air supply and disconnect the

air supply hose before installing, removing or

The use of other than genuine Ingersoll–Rand replacement parts may result in safety hazards, decreased tool

performance, and increased maintenance, and may invalidate all warranties.

Ingersoll–Rand is not responsible for customer modification of tools for applications on which Ingersoll–Rand was not

consulted.

Repairs should be made only by authorized trained personnel. Consult your nearest Ingersoll–Rand Authorized

Servicenter.

It is the responsibility of the employer to place the information in this manual into the hands of the operator.

adjusting any accessory on this tool, or before

performing any maintenance on this tool.

• Keep hands, loose clothing and long hair away

from rotating end of tool.

• Anticipate and be alert for sudden changes in

motion during start up and operation of any power

tool.

• Tool accessory may continue to rotate briefly after

throttle is released.

• Do not lubricate tools with flammable or volatile

liquids such as kerosene, diesel or jet fuel.

• Do not remove any labels. Replace any damaged

label.

• Use accessories recommended by Ingersoll–Rand.

• Always use a Dead Handle (47) with Models 7AN4

and 7AQ4.

Refer All Communications to the Nearest

Ingersoll–Rand Office or Distributor.

Ingersoll–Rand Company 1994

Printed in U.S.A.

WARNING LABEL IDENTIFICATION

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

2

2

PLACING TOOL IN SERVICE

LUBRICATION

Ingersoll–Rand No. 10. Ingersoll–Rand No. 28.

Always use an air line lubricator with these tools.

We recommend the following Filter–Lubricator–Regulator

Unit:

For USA – No. C22–04–G00

For International – No. C26–04–A29

Motor

Before starting the tool and after each eight hours of

operation, unless the air line lubricator is used, detatch

the air hose and inject 1.5 cc of Ingersoll–Rand No. 10 Oil

into the air inlet.

For models with D, H, J, JJ, K, and L gearing, after

each 50,000 cycles or one month of operation,

whichever comes first, inject approximately 6 cc of

Ingersoll–Rand No. 28 Grease into the Grease Fitting (39).

For models with M, N, or Q gearing, after each 50,000

cycles or one month of operation, whichever comes first,

inject approximately 9 cc of Ingersoll–Rand No. 28

Grease into the Grease Fitting (39).

INSTALLATION

An air line filter can greatly increase the life of an air tool.

The filter removes dust and moisture. Low pressure (under

90 psig; 6.2 bar/620 kPa) reduces the speed of all air tools.

Low air pressure not only wastes time, but also costs

money . High air pressure (over 90 psig; 6.2 bar/620 kPa)

raises performance beyond the rated capacity of the tool

and could cause injury. Be sure all hoses and fittings are

the correct size and are tightly secured.

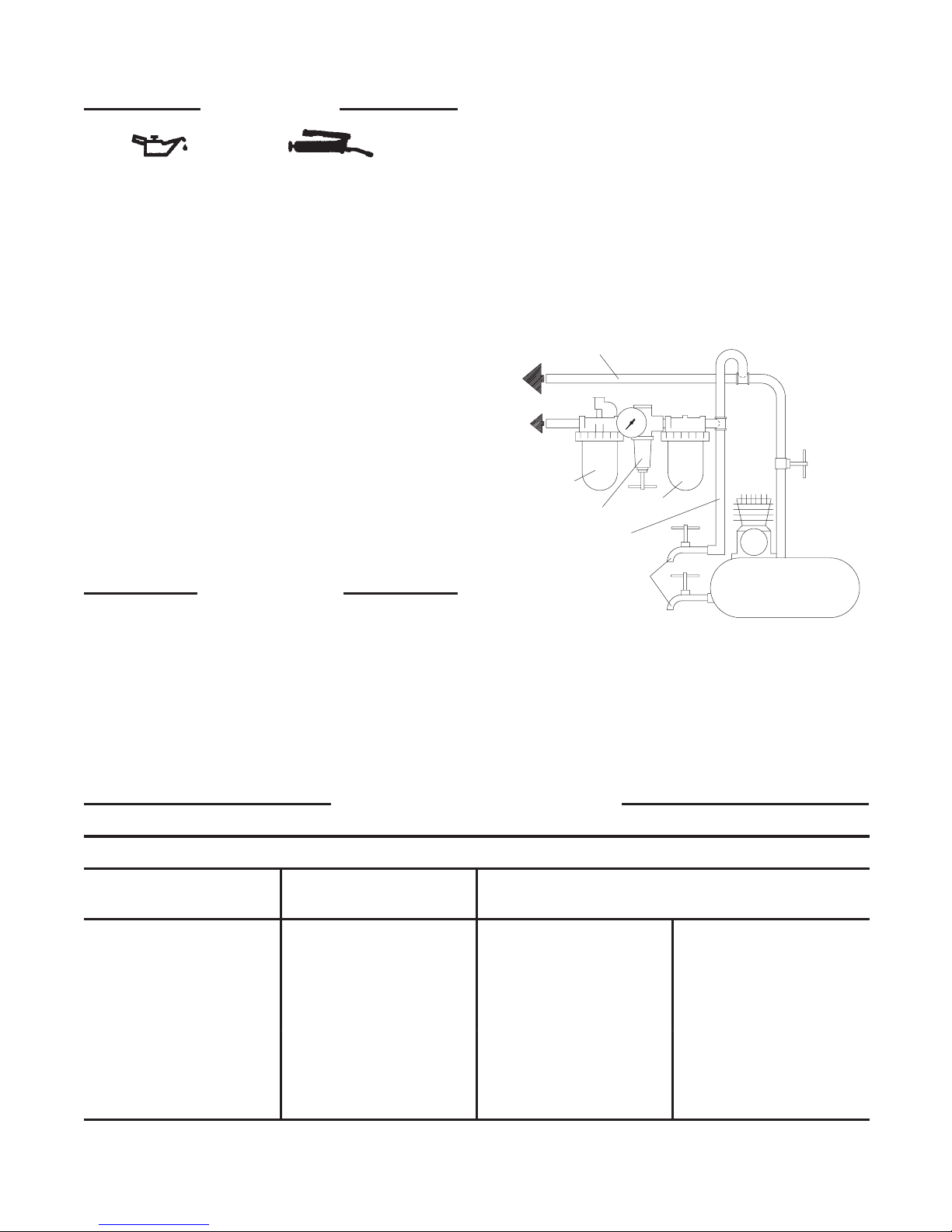

See Dwg. TPD905–1 for a typical piping arrangement.

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

FILTER

COMPRESSOR

Air Supply and Connections

Always use clean dry air . Dust, corrosive fumes and/or

excessive moisture can ruin the motor of an air tool.

(Dwg. TPD905–1)

Series 7 Air Drills are designed for drilling operations in the aerospace, automotive, appliance, electronic,

machining and furniture industries.

HOW TO ORDER AN AIR DRILL

PISTOL GRIP HANDLE

Free Speed Chuck Capacity

Model rpm in mm

7AD1

7AH1 6 000 1/4 6

7AJ1 4 800 1/4 6

7AJJ1 4 000 1/4 6

7AK2 3 200 3/8 10

7AL3 2 400 3/8 10

7AM3 1 400 3/8 10

7AN4 900 1/2 13

7AQ4 600 1/2 13

20 000 1/4 6

3

3

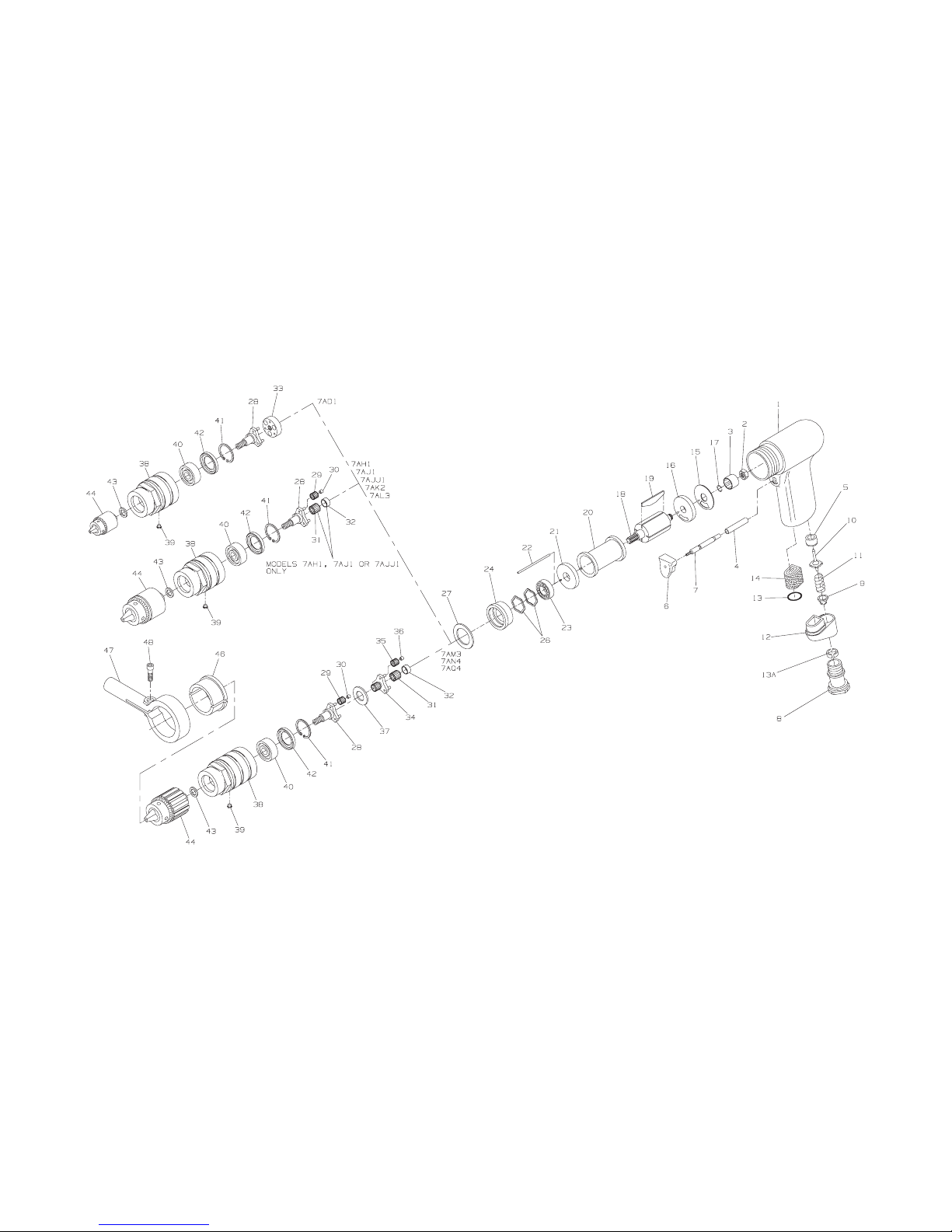

MAINTENANCE SECTION

4

(Dwg. TPA786–5)

Loading...

Loading...