Page 1

OPERATOR’S MANUAL

)

INCLUDING:ĂOPERATION,ĂINSTALLATIONĂ&ĂMAINTENANCE Released: 08-28-72

SECTION M10

MANUAL 25

Revised: 01-14-00

MODELS: 7980–( )–( )

85,000 R.P.M. TURBINE GRINDER

ARO is not responsible for customer modification of tools for applications on which ARO

was not consulted.

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING TOOL.

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PLACE THE INFORMATION

IN THIS MANUAL INTO THE HANDS OF THE OPERATOR.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

PLACING TOOL IN SERVICE

• Always operate, inspect and maintain this tool

in accordance with American National

Standards Institute Safety Code for Portable

Air Tools (ANSI B186.1).

• For safety, top performance, and maximum

durability of parts, operate this tool at 90 psig

(6.2 bar/620 kPa) maximum air pressure at the

inlet with 3/16” (5 mm) inside diameter air

supply hose.

• Always turn off the air supply and disconnect

the air supply hose before installing, removing

or adjusting any accessory on this tool, or

before performing any maintenance on this

tool.

• Do not use damaged, frayed or deteriorated

air hoses and fittings.

• Be sure all hoses and fittings are the correct

size and are tightly secured. See Dwg.

TPD905–1 for a typical piping arrangement.

• Always use clean, dry air at 90 (6.2 bar/

620 kPa) psig maximum air pressure. Dust,

corrosive fumes and/or excessive moisture

can ruin the motor of an air tool.

• Do not lubricate tools with flammable or

volatile liquids such as kerosene, diesel or jet

fuel.

• Do not remove any labels. Replace any

damaged label.

USING THE TOOL

• Always wear eye protection when operating or

performing maintenance on this tool.

• Always wear hearing protection when

operating this tool.

• Keep hands, loose clothing and long hair

away from rotating end of tool.

• Anticipate and be alert for sudden changes in

motion during start up and operation of any

power tool.

• Keep body stance balanced and firm. Do not

overreach when operating this tool. High

reaction torques can occur at or below the

recommended air pressure.

• Tool accessories may continue to rotate

briefly after throttle is released.

• Air powered tools can vibrate in use.

Vibration, repetitive motions or uncomfortable

positions may be harmful to your hands and

arms. Stop using any tool if discomfort,

tingling feeling or pain occurs. Seek medical

advice before resuming use.

• Use accessories recommended by ARO.

• This tool is not designed for working in

explosive atmospheres.

• This tool is not insulated against electric

shock.

The use of other than genuine ARO replacement parts may result in safety hazards, decreased tool

performance, and increased maintenance, and may invalidate all warranties.

Repairs should be made only by authorized trained personnel. Consult your nearest ARO Authorized

Servicenter.

For parts and service information, contact your local ARO distributor, or the Customer Service Dept. of the Ingersoll–Rand

Distribution Center, White House, TN at PH: (615) 672–0321, FAX: (615) 672–0801.

ARO Tool Products

Ingersoll–Rand Company

1725 U.S. No. 1 North D P.O. Box 8000 D Southern Pines, NC 28388–8000

E2000 INGERSOLL–RAND COMPANY D PRINTED IN U.S.A.

Page 2

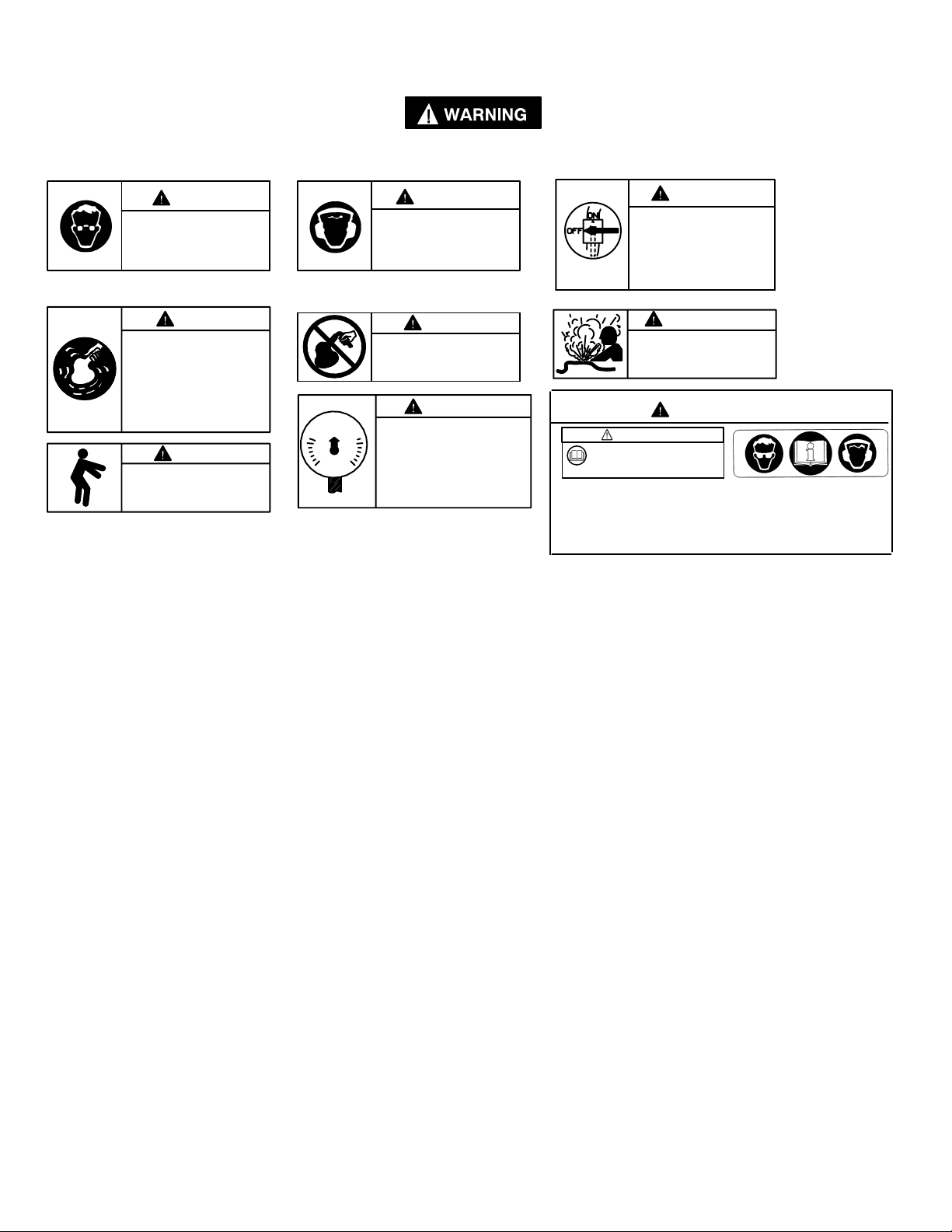

WARNING LABEL IDENTIFICATION

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

M10

25

WARNING

Always wear eye protection

when operating or performing maintenance on this

tool.

WARNING

Air powered tools can vibrate

in use. Vibration, repetitive

motions or uncomfortable positions may be harmful to your

hands and arms. Stop using

any tool if discomfort, tingling

feeling or pain occurs. Seek

medical advice before resuming use.

90 psig

(6.2bar/620kPa)

WARNING

Always wear hearing

protection when operating

this tool.

WARNING

Do not carry the tool by

the hose.

WARNING

Operate at 90 psig (6.2 bar/

620 kPa) Maximum air pressure.

WARNING

Keep body stance balanced

and firm. Do not overreach

when operating this tool.

GRINDER SPECIFIC WARNINGS

• Do not use this tool if actual free speed

exceeds the nameplate rpm.

• Before mounting a wheel, after any tool repair

or whenever a Grinder is issued for use, check

free speed of Grinder with a tachometer to

make certain its actual speed at 90 psig (6.2

bar/620 kPa) does not exceed rpm stamped or

printed on the nameplate. Grinders in use on

the job must be similarly checked at least

once each shift.

• Always use the recommended ARO Wheel

Guard furnished with the Grinder.

• Do not use any grinding wheel, bur or other

accessory having a maximum operating speed

less than the free speed of the Grinder in

which it is being used. Always conform to

maximum rpm on grinding wheel blotters.

• Inspect all grinding wheels for chips or cracks

prior to mounting. Do not use a wheel that is

chipped or cracked or otherwise damaged. Do

not use a wheel that has been soaked in water

or any other liquid.

• Make certain grinding wheel properly fits the

arbor. Do not use reducing bushings to adapt

a wheel to any arbor unless such bushings

are supplied by and recommended by the

wheel manufacturer.

• After mounting a new wheel, hold the Grinder

under a steel workbench or inside a casting

and run it for at least 60 seconds. Make

certain no one is within the operating plane of

WARNING

Always turn off the air supply and disconnect the air

supply hose before installing, removing or adjusting

any accessory on this tool,

or before performing any

maintenance on this tool.

WARNING

Do not use damaged, frayed

or deteriorated air hoses

and fittings.

WARNING

WARNING

Read the manual before

operating this tool.

Operate at 90 psig/6.2 bar max.

PN 48176–1 LABEL

(NON–EU MODELS)

This label must appear on the tool at all times. If it is lost or

damaged, a replacement label is available at no cost.

the grinding wheel. If a wheel is defective,

improperly mounted or the wrong size and

speed, this is the time it will usually fail.

• When starting with a cold wheel, apply it to

the work slowly until the wheel gradually

warms up. Make smooth contact with the work

and avoid any bumping action or excessive

pressure.

• Always replace a damaged, bent or severely

worn wheel guard. Do not use a wheel guard

that has been subjected to a wheel failure.

• Make certain wheel flanges are at least 1/3 the

diameter of grinding wheel, free of nicks,

burrs and sharp edges. Always use wheel

flanges furnished by the manufacturer; never

use a makeshift flange or a plain washer.

Tighten Flange Nut securely.

• Guard opening must face away from operator.

Bottom of wheel must not project beyond

guard.

• Always use a wheel blotter between each

wheel flange and the wheel. The blotters must

be at least as large in diameter as the wheel

flanges.

• Do not attempt to disassemble the Controller.

The Controller is available only as a unit and

is guaranteed for the life of the tool if it is not

abused.

• Before installing a new Cylinder Case

Assembly, always select the correct Assembly

for the motor package you are using.

PN 49883 LABEL

(–EU MODELS)

2

Page 3

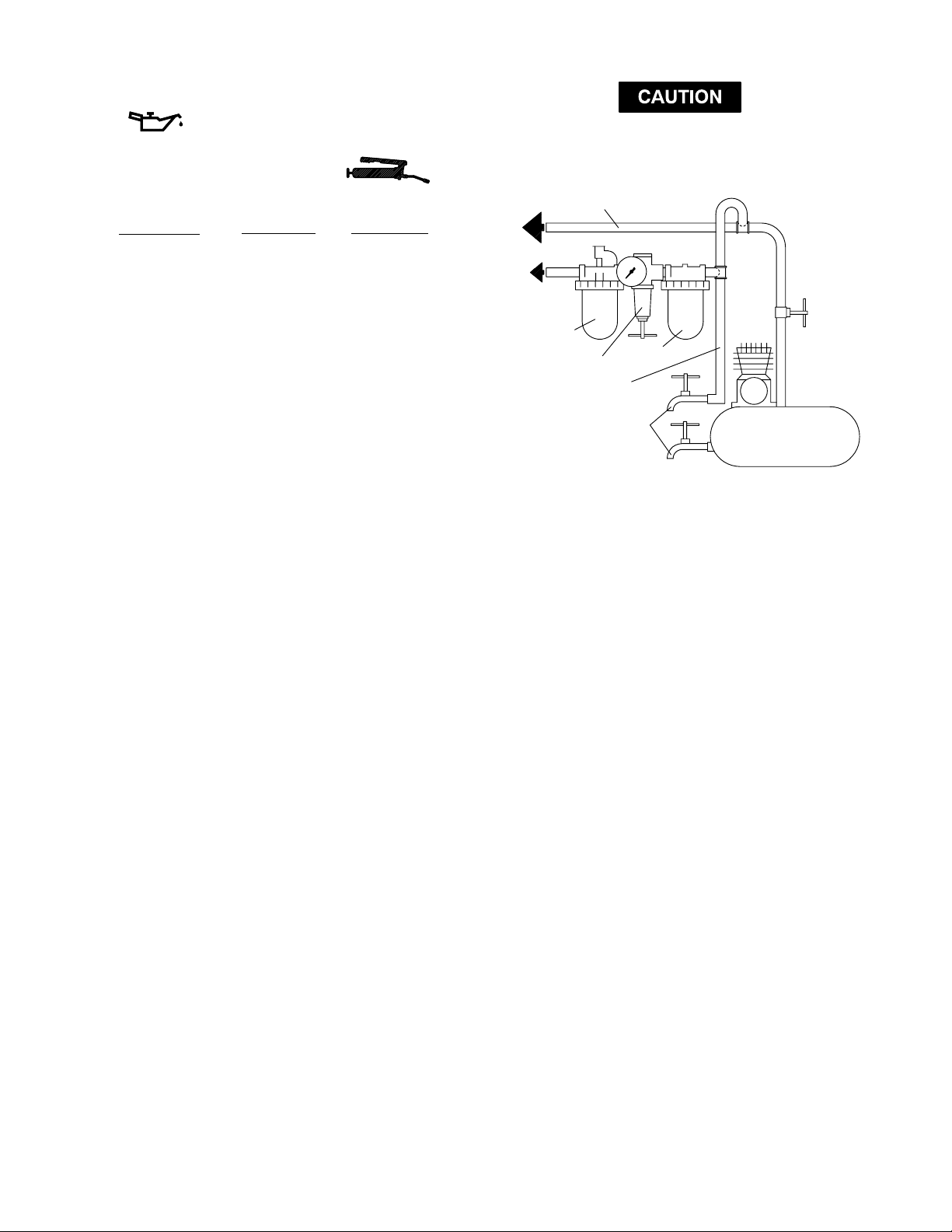

LUBRICATION

Where Used

“O” Rings 36460 4 oz. Stringy

Bearings 33153 5 lb. ‘‘EP” – NLGI

ARO Part # Description

Lubricant

#1 Grease

M10

25

Do not mark any nonmetallic surface on this tool

with customer identification codes. Such actions

could affect tool performance.

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

Always use an air line lubricator with these tools.

We recommend the following Filter–Lubricator–

Regulator Unit:

ARO Model P29231–110

Lack of or an excessive amount of lubrication will

affect the performance and life of this tool. Use only

recommended lubricants.

LUBRICATOR

REGULATOR

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

FILTER

COMPRESSOR

(Dwg. TPD905–1)

3

Page 4

181925 24 23 22 21 20

34 33 32 29 28 27 26

NOT SHOWN

30131 WRENCH

04662532 WARNING LABEL (NON–EU MODELS)

39853 HOSE ASSEMBLY

48176–1 WARNING LABEL (NON–EU MODELS)

49883 WARNING LABEL (–EU MODELS)

PART NUMBER FOR ORDERING PART NUMBER FOR ORDERING

1 Nut 36906. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2a Throttle and Bushing Assembly . . . . . . . .

2b Head Assembly . . . . . . . . . . . . . . . . . . . . . .

2 Head and Throttle Assembly (includes

items 2a and 2b)

for non ‘‘–EU” models 36920–1. . . . . . . . . . . . . . . .

for ‘‘–EU” models 49939–1. . . . . . . . . . . . . . . . . . .

3 ‘‘O” Ring (2 req’d) Y325–15. . . . . . . . . . . . . . . . . . . .

4 Roll Pin 36918. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Head and Throttle Assembly (includes

items 1 thru 4)

for non‘‘–EU” models 36920. . . . . . . . . . . . . . . .

for ‘‘–EU” models 49939. . . . . . . . . . . . . . . . . . .

5 Lever 43885. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Roll Pin Y178–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Throttle Valve Head 38947. . . . . . . . . . . . . . . . . .

8 ‘‘O” Ring Y325–211. . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 ‘‘O” Ring Y325–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Stem V alve 33032. . . . . . . . . . . . . . . . . . . . . . . . . .

11 Spring 31125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Seal 32886. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 Throttle V alve Screw 33023. . . . . . . . . . . . . . . . . .

Head Assembly (includes items 7 thru 13) 38949–1

14 Lever 45952. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 Roll Pin Y178–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 Spring 45778. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17 Arm 45777. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lever Assembly (includes items 14 thru 17) 45953. . . . .

18 Nozzle Plate 36907. . . . . . . . . . . . . . . . . . . . . . . .

19 Nut 32798. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 Sleeve 36908. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21 Impeller 36909. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22 Impeller 36910. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23 Ball Bearing 36913. . . . . . . . . . . . . . . . . . . . . . . . .

24 Impeller 36911. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25 Spacer 36919. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26 Housing

for non ‘‘–EU” models 36901. . . . . . . . . . . . . . . .

for ‘‘–EU” models 49901. . . . . . . . . . . . . . . . . . . .

27 Ball Bearing 36913. . . . . . . . . . . . . . . . . . . . . . . . .

28 Spindle 36902. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29 Lock Sleeve 43881. . . . . . . . . . . . . . . . . . . . . . . . .

32 Housing Cap 36912. . . . . . . . . . . . . . . . . . . . . . . .

33 Collet 31812–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34 Nosepiece 36914. . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

12a342b

MODEL 7980–A–( )

5

78

6

MODEL 7980–2

14151617

9

10

MODEL 7980–2–EU

11

12

13

DISASSEMBLY/ASSEMBLY INSTRUCTIONS

NOTICE

• Never apply excessive pressure by a holding device which

may cause distortion of a part.

• Apply pressure evenly to parts which have a press fit.

• Apply even pressure to the bearing race that will be press

fitted to the mating part.

• Use correct tools and fixtures when servicing this tool.

• Don’t damage ‘‘O” rings when servicing this tool.

• Use only genuine ARO replacement parts for this tool. When

ordering, specify part number, description, tool model number

and serial number.

DISASSEMBLY

_ Remove hose assembly (not shown) from the inlet of the tool.

_ Insert A 1/8” diameter pin thru the hole in the housing (26), lock

sleeve (29) and spindle (28).

_ Using a wrench on flats of housing cap (32), unthread and re-

move housing cap (32) and lock sleeve (29).

_ Using a wrench on flats of nosepiece (34), unthread and re-

move from spindle, releasing collet (33).

• Models 7980–2–( ) – Place head (7) in a vise and, using a

strap type wrench, unthread and remove housing (26).

• Models 7980–A–( ) – Clamp wrench (30131) flatwise in a vise

and place slot in air inlet of tool on wrench. Using a strap type

wrench, unthread and remove housing (26).

_ Remove nozzle plate (18).

_ Insert a 1/8” diameter pin thru the hole in housing (26) and

spindle (28), and remove nut (19).

_ Press spindle (28) out nose end of housing.

_ Remove impellers (21, 22 and 24), sleeve (20), bearing (23)

and spacer (25) from housing.

_ Do not remove bearing (27) from spindle unless damage is ev-

ident. To remove, press off of spindle.

• Models 7980–2–( ) – Remove valve screw ( 13) and sea l (1 2),

releasing spring (11), stem valve (10) and ‘‘O” ring (9).

• Models 7980–A–( ) – To remove ‘‘O” rings (3), remove nut (1),

releasing throttle and bushing assembly (2a).

ASSEMBLY

_ Assemble bearing (27) to spindle (28), pressing on inner race

of bearing.

_ Assemble spindle into housing theu nose end, pressing on

outer race of bearing.

_ Assemble spacer (25), impeller (24), impeller (22) with bear-

ing (23) and impeller (21) with sleeve (20) to spindle, securing

with nut (19). NOTE: Assemble impellers with grooves in the

direction shown on page 4.

_ Assemble nozzle plate (18) and head to tool.

_ Assemble lock sleeve (29) to housing, aligning hole in lock

sleeve (29) with hole in housing.

_ Insert a 1/8” diameter pin thru hole in housing and lock sleeve

(29).

_ Assemble housing cap (32) to housing, tightening securely.

_ Assemble collet (33) and nosepiece (34) to spindle.

• Models 7980–2–( ) – Grease and assemble ‘‘O” ring (9) to

stem valve (10). Assemble stem valve (10) and spring (1 1 ) to

head, securing with seal (12) and valve screw (13).

6

Page 6

TYPICAL CROSS SECTION OF TOOL

M10

25

MODEL 7980–2 MODEL 7980–A–( )

7

Page 7

TYPICAL CROSS SECTION OF TOOL

MODEL 7980–2–EU

8

Page 8

PN 4999–482

Loading...

Loading...