Ingersoll-Rand 7792-A, 7790-A User Manual

HOISTS

Series 7790-A & 7792-A

Operator’s Manual

Form 10590149

Edition 2

September 2005

Save These Instructions

Safety Information

Operating Precautions

To aid the operator’s understanding of proper and safe use of

hoists, the publication “OVERHEAD HOISTS”,

ANSI B30.16-1981, can be purchased from:

American Standards Institute, Inc.

1430 Broadway

New York, New York 10018

• Do not use the hoist described in this manual to lift or

transport humans.

• Never try to lift a load heavier than the rated capacity of

the hoist.

• Operate hoist with caution. Operator should have a good

attitude toward safety.

• Always follow “proper operating” instructions given in this

manual.

• Allow only people who have received training in “proper

hoist operation” to operate hoists.

• Follow all operating and routine inspection procedures

prescribed in this manual.

• Operator of hoist shall operate hoist in a position that will

not be hazardous to his health.

• Do not attempt to operate hoist if it is not operating

properly.

• Before operating hoist, all routine inspection and

lubrication procedures should be completed.

Lubrication

Routine Lubrication Requirements

Lack of or an excessive amount of lubrication will affect the

performance and life of this tool Use only recommended

lubricants at below time intervals:

EVERY 8 HOURS OF TOOL OPERATION -fill lubricator

reservoir with spindle oil (29665). If an in line or air line

lubricator is not used, fill oil reservoir of built-in oiler of hoist

head.

EVERY 80 HOURS OF HOIST OPERATION - Grease fittings

in lower BLOCK HOOK ASSEMBLY and TROLLEY

WHEELS with NLGI #1 grease 33153).

EVERY 160 HOURS OF HOIST OPERATION - Fill oil

reservoir in GEAR CHAMBER with “EP” gear oil (40164).

Coat load chain of hoist with EP” gear oil (40164).

Air Supply Requirements

For maximum operating efficiency, the following air supply

specifications should be maintained to this hoist.:

• AIR PRESSURE - 90 PSIG (6 bar)

• AIR FILTRATION - 50 micron

• LUBRICATED AIR SUPPLY

• HOSE SIZE - l/2” (13 mm) I.D.

An AR0 model 128241-800 airline FILTER/REGULATOR/

LUBRICATOR (F-R-L) is recommended to maintain the

above air supply specifications.

Recommended Lubricants

After disassembly is complete all parts, except sealed or

shielded bearings, should be washed with solvent. To

relubricate parts, or for routine lubrication, use the following

recommended lubricants:

Where Used ARO Part# Description

Air Motor 29665 1 qt. Spindle Oil

Gears and Bearings 33153 5 lb. “EP” - NLGI #l1Grease

“O” Rings & Lip Seals 36460 4 oz. Stringy Lubricant

Gearing Oil Chamber 40164 1 qt. “EP” Gear Oil

Operation

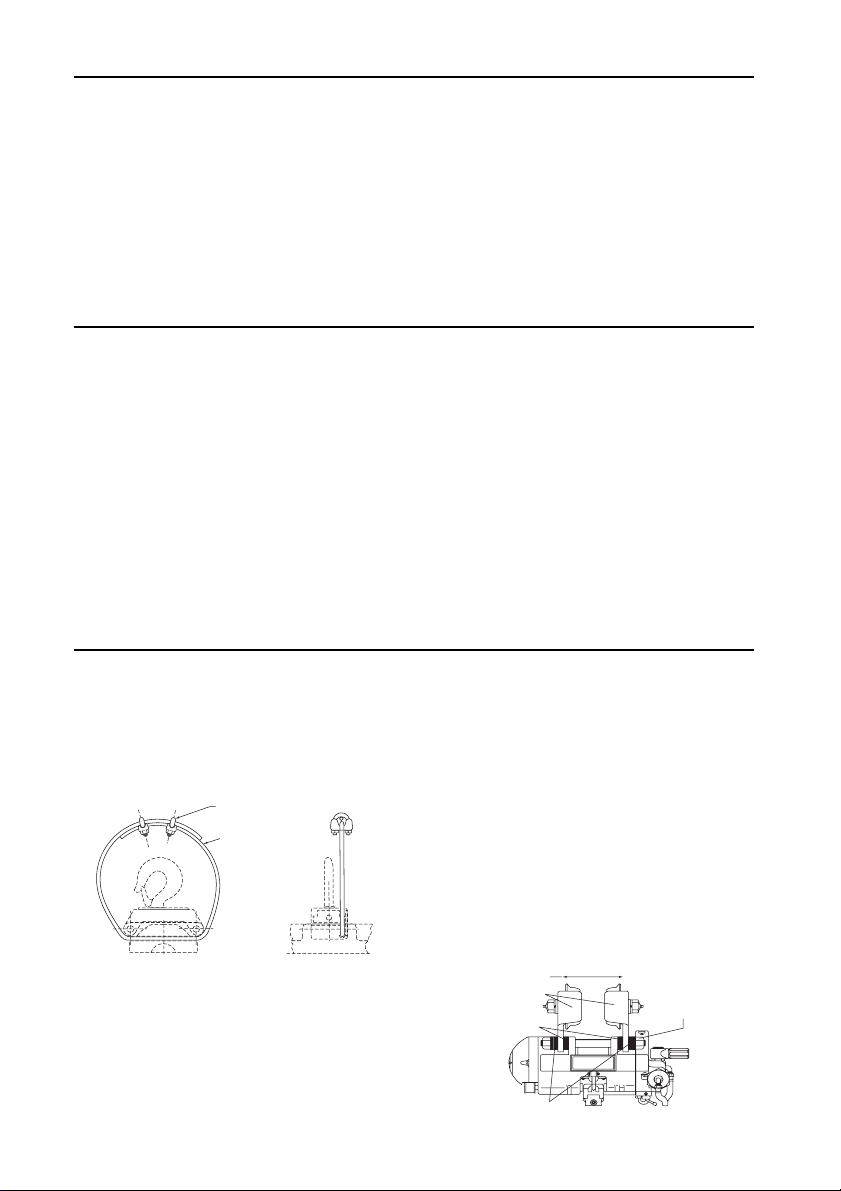

Suspending Hoist Adjusting Brake

Always select an overhead support capable of supporting

combined weight of hoist, trolley, and hoist’s load capacity.

Hook Suspended Models

• Upper hook should be firmly seated in center of hook

saddle and that safety latch is closed.

• 43059 secondary support cable is recommended.

42631 CLAMP (2)

43066 RESTRAINING CABLE (5/16”

DIA. X 3½ FT. LONG

AIRCRAFT CABLE)

(Dwg. )

Trolley Suspended Models

• Be sure TROLLEY WHEELS are compatible with beam

being used.

• Width between outside of TROLLEY WHEELS should be

the width of beam flange + l/2”.

• If 43111 - 90’ ADAPTER is used, mount to hoist before

attempting to install trolley.

• Width is varied by using SPACERS between the hoist

body and the trolley SIDE PLATES.

2 Form 10590149-Edition 2

• Insert an equal number of SPACERS on each inside of

the trolley SIDE PLATES until beam flange + l/2”

measurement is reached. SIDE PLATES must be

vertical.

• Insert SHAFTS (43009) through hoist, or adapter if used,

and trolley SIDE PLATES.

• Position trolley and hoist assembly on beam.

• Put an equal number of SPACERS on each end of

SHAFTS (43009) with lock washer being last.

• Tighten nuts on SHAFTS (43009). SHAFTS should

extend all the way through the NUTS.

• Move trolley over entire length of beam. If it appears the

trolley SIDE PLATES can be moved closer together and

freedom of movement will be maintained, remove an

equal number of SPACERS from inside the SIDE

PLATES and assemble these SPACERS to the outside of

the SIDE PLATES.

• Tighten NUTS to 25-30 ft. Ibs.

• Connect sufficient length of air hose to reach the

maximum travel distance of trolley.

WIDTH OF BEAM

FLANGE PLUS 1/2”

SIDE PLATES MUST

BE VERTICAL

EQUAL NO. OF SPACERS

EQUAL NO. OF SPACERS

TIGHTEN NUTS 46049

25 TO 30 FT. LBS. TORQUE

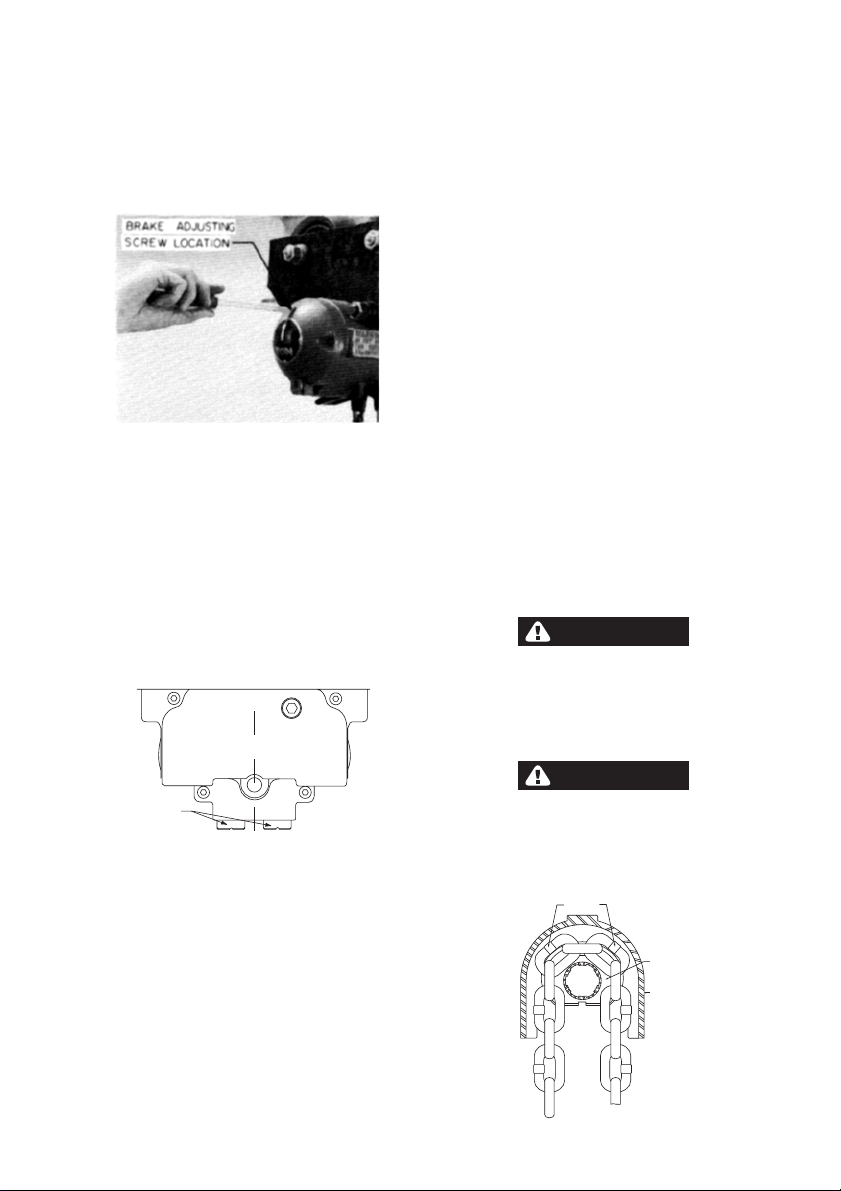

Adjusting Brake

UP

DN

• Properly attach rated load of hoist to load chain hook.

• Slowly raise load to 6” height above floor by slowly pulling

pull chain handle or depressing pendent control.

• Release pull chain handle or pendent control.

• If load starts to lower, tighten brake adjustment by turning

counter-clockwise until load stops lowering.

• Do not over tighten brake. If brake it too tight, the lifting

and lowering of load will be eratic, not smooth.

Setting Maximum Up and Down Speeds

• Never attempt to adjust speed regulator valves on spark

resistant hoists. They are preset by ARO.

• Attach rated load of hoist to load chain hook.

• Turn speed regulator valves clockwise until they stop.

This is lowest setting.

• Lift load by pulling pull chain or depressing pendent

control completely. As load is being lifted, turn up speed

regulator valve counter-clockwise to set the hoist at the

desired maximum “lift” speed.

• Lower load by pulling pull chain or depressing pendent

control completely. As load is lowered, turn “DN” speed

regulator valve counter-clockwise to set the hoist at the

desired maximum “lowering” speed.

• The pull chain or pendent control is used as the variable

control of lift and lowering speeds up to the maximum

speed set by the speed regulator valves.

REGULATOR

VALVE S

UP

DN

Chain Stop

• Do not operate hoist unless chain stop is properly

attached to hoist load chain.

• Do not use chain stop to limit the distance the load is to

be lifted. The function of the chain stop is to keep the

lower hook components from striking the control arm

should an over-run condition ever occur.

Installation instructions should be completed before

attempting to operate the hoist.

Before Securing Load to Lift Chain

• Perform routine inspection and lubrication procedures.

Securing Load to Lift Chain

• DO NOT WRAP LOAD CHAIN AROUND LOAD.

Approved slings or other approved devices should be

used to provide adequate single point securing of load to

hoist load chain hook. Be sure safety latch on hook is

closed.

• Be sure load chain is not twisted or kinked.

• Hoist should be centered over the load. Always secure

load chain hook to center of load. Never lift a load from

the side or end.

• Allow only a sufficient amount of slack in load chain to

permit attaching hook to load.

Lifting and Lowering Load

1. Pull (pull chain models) or depress (pendent control

models) controls slowly to eliminate abrupt, jerky

operation.

2. Take up slack in chain slowly.

3. Speed of load lifting can be controlled by the pull chain or

pendent control. Pulling the chain further or depressing

the pendent further will result in a faster speed.

Load Chain Removal

- Drive out roll pin (106) and remove clevis from chain.

- If a chain basket is being used with hoist, remove

chain stop from end of chain.

- 2-Ton models with double reeved chain; remove

retaining ring (110) and pin (111) from anchor bracket

(112).

- Pull down on one end of control arm (68) to release

brake and pull chain from housing.

Load Chain Installation

-

A new chain should never be used on a worn

pocketwheel. Replace chain and pocketwheel as a pair.

- Place hoist in vise and clamp on upper hook mount.

- Remove housing cap (95), brake spring (94) and brake

shoes (92).

- Turn brake wheel (93) by hand to rotate pocketwheel

while carefully feeding chain thru chain guide and

around pocketwheel (64).

- Pull sufficient chain thru housing to allow end link to be

attached to anchor lug on housing.

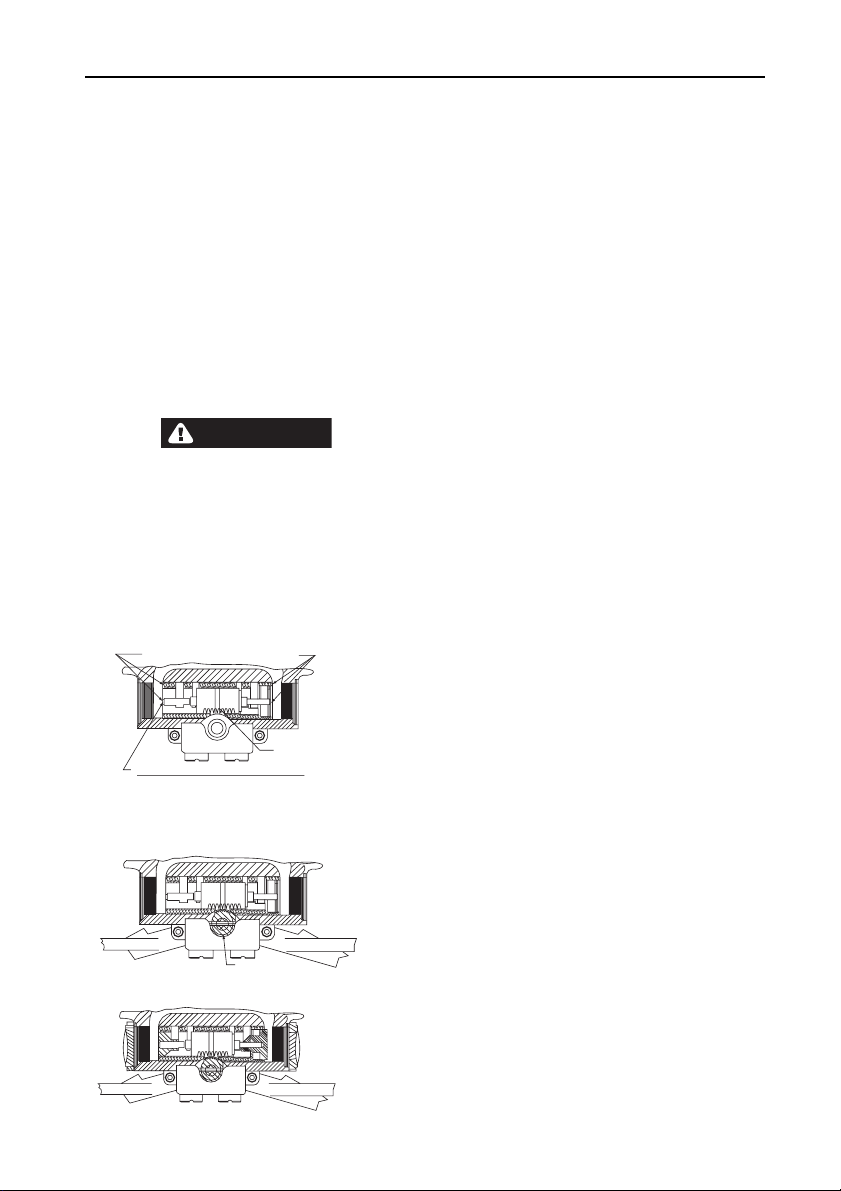

CAUTION

Chain must be positioned around pocketwheel so weld

on the standing links face outward from pocketwheel see illustration.

- End link of chain must also be positioned properly to

permit attaching to anchor lug on housing without

twisting of chain.

WARNING

Do not attempt to feed chain over pocketwheel by air

power as chain will be pulled thru housing at a very fast

rate.

- Attach other end of chain to lo wer hook (or anchor

bracket on 2-Ton models).

CHAIN WELD

POCKET WHEEL

CHAIN GUIDE

Form 10590149-Edition 2 3

Routine Inspection

The type of application for a hoist varies so greatly it is

impractical to recommend an exact time-table for inspection

of the hoist. Where hoist is subjected to continuous operation

with capacity loads, it is recommended the unit be inspected

twice a week. If the application is less demanding, the unit

should be inspected twice a month. In general, the frequency

of inspection should be determined by the severity of the

application. The user of a hoist should be guided by any

existing federal, state or local re gulations governing the use,

testing or inspection of the hoist.

If any damage or malfunction is evident do not operate hoist

until all repairs have been made and hoist tested for proper

operation.

The following points and areas are recommended for

inspection:

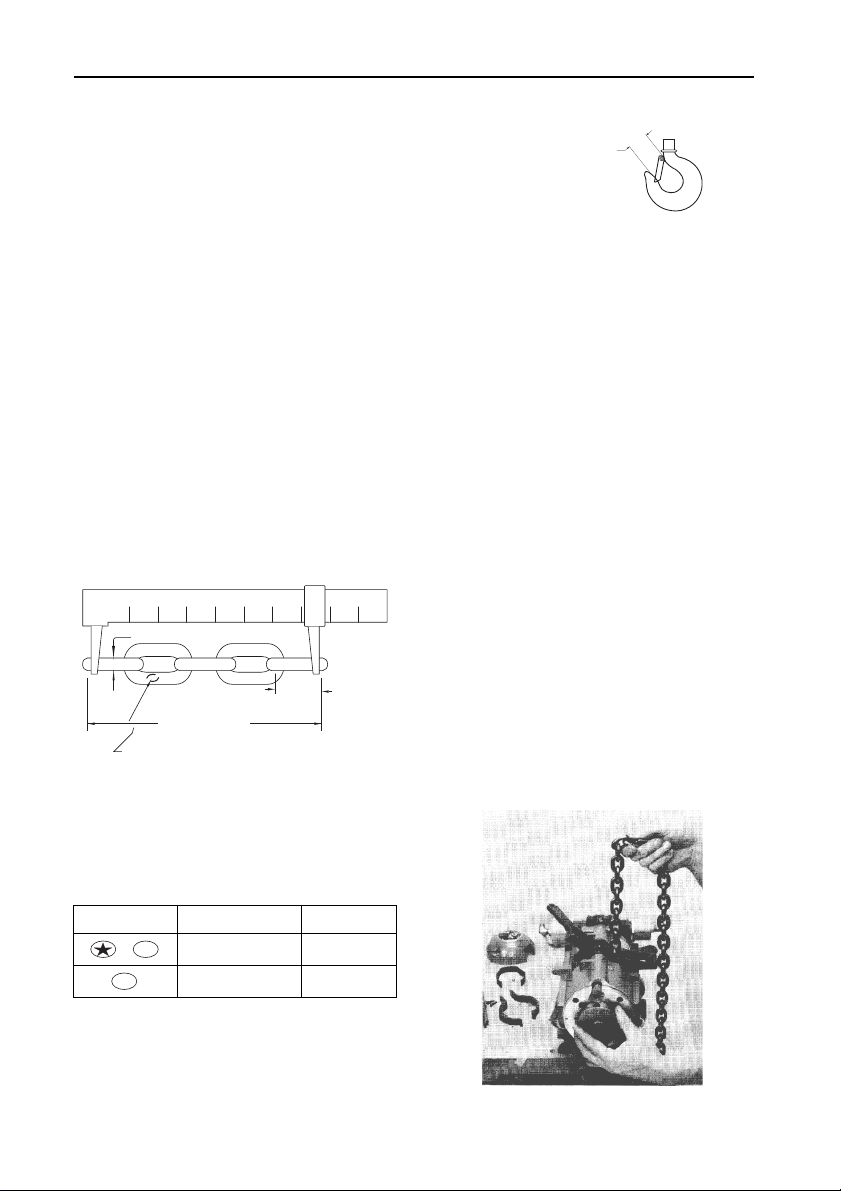

Load Chain and Anchor Points

• Visually check for nicked, gouged, twisted, bent,

corroded, rusted, worn or broken links. Check ends of

chain where chain is anchored to hoist frame and where

chain is fastened to lower hook. Check anchors and pins

• Check chain elongation with a vernier caliper as shown.

IF VISUAL CHECK REVEALS NO DEFECTS,

PROCEED AS FOLLOWS:

LAY USED CHAIN ON FLAT SURFACE AND MEASURE

BETWEEN FIVE (5) LINKS AS SHOWN.

MEASUREMENT SHOULD BE TAKEN ON PORTION

OF CHAIN WHICH HAS MOST PASSED OVER THE

POCKET WHEEL.

IF MEASUREMENT TAKEN IS (SEE TABLE) INCHES

OR MORE, CHAIN SHOULD BE REPLACED.

VERNIER CALIPER

5/16

.8583 PITCH

NEW CHAIN

DETERMINE TYPE OF IDENTIFICATION MARKINGS EMBOSED ON LOAD CHAIN

AND FIND DIMENSIONS IN TABLE

IT IS NOT INFERRED that a chain is safe prior to the

occurence of elongation of the chain. It is inferred ONLY, that

when said elongation is evident, the chain must be replaced.

Other factors, such as those mentioned as a visual check,

may render chain unsafe long before replacement due to

elongation is necessary. NOTE: New chain should never be

used on a worn pocketwheel, repl ace chain and pocketwheel

as a pair. Chain should also be replaced when replacing

brake shoes.

IDENTIFICATIONS

MARKINGS

ARO

or

R

OC

NEW CHAIN

MEASUREMENT

4.291 4.366

4.340 4.415

REPLACE CHAIN

Hooks and Suspension

• Check upper and lower hooks and related parts for bent,

worn, cracked, broken or otherwise damaged parts.

• On trolley suspended models, check conditions of trolley

parts, trolley adapter and related parts.

• Check for loose bolts, nuts, or rivets.

CORRECT

HOOK OPENING

1-1/4" ON 1-TON UPPER & LOWER HOOKS

1-3/8" ON 2-TON UPPER & LOWER HOOKS

Brake

1. Check brake operation - see Adjusting Brake, page 2.

2. Check brake linings and components. NOTE: When

replacement of brake shoes is indicated, they must be

replaced as a pair. Also replace chain at this time.

Gears, Bearings and Pocketwheel

• Check teeth on gears and motor shaft pinion.

• Check pockets of pocketwheel.

• Check bearings for noisy operation indicating wear.

Throttle Valve Head and Gears

• Check valve body, valves, and “O” rings on valves.

• Check gear teeth and bearings.

Air Motor

• Check end faces of rotor for roughness and blade slots

for wear or burrs. A new blade should slide in and out of

slots without binding.

• Check blades for wear, warpage or other damage.

• Check cylinder bore diameter for rough circular grooves

from scoring. A badly scored cylinder cannot be restored

by honing since it will only enlarge bore diameter,

widening seal point between rotor and cylinder, hindering

free exhaust of air and result in loss of speed and power.

• Check end plates for wear or scoring. Check bearings.

• Follow all operating and routine inspection procedures

prescribed in this manual.

• Disconnect air supply from hoist before performing

maintenance or service procedures.

• Never apply excessive pressure by a holding device

which may cause distortion of a port.

• Apply pressure evenly to parts which have a press fit.

• Apply even pressure to the bearing race that will be press

fitted to the mating part.

• Use correct tools and fixtures when servicing this tool.

• Don’t damage “O” rings when servicing tool.

• Use only genuine ARO replacement parts for this tool.

When ordering specify part number, description, tool

model number and serial number.

4 Form 10590149-Edition 2

Maintenance

A

A

Dissassembly

Head Disassembly

To remove head section from housing without disassembling

head components, remove head with control rod (59)

attached to gear (25). To accomplish this -

- Remove two screws (96) and housing cap (95).

- Drive out roll pin (61) and remove brake block (60).

- Drive out roll pin (69) from control arm (68).

- Remove six screws (22) and washers (23).

- Remove head section and control rod from housing as

one unit.

To disassemble head components without removing head

section from hoist:

- Remove two screws (96) and housing cap (95).

- Drive out roll pin (69) from control arm (68).

- Drive out roll pin (26) from gear (25) and drive control

rod (59) back thru gear (25) and remove gear.

- Remove adapters (19), valves (17) and (29) and valve

body (15).

- Remove set screws (24) and regulator valves (28).

CAUTION

do not attempt to adjust or remove regulator valves (28)

from spark-resistant hoist models - these valves are

pre-set at fatctory.

- Remove adapter (1) and screen (2).

- Remove retaining ring (4), swivel (3), swivel body (6)

and screen (8).

- Remove two screws (9), washers (10), exhaust

deflector (11), screen (12) and muffler filler (13).

STEP 1 :- POSITION HOIST SO YOU ARE FACING END WITH AIR INLET, WITH VALVE

PARTS AND GEAR [25] REMOVED, PLACE VALVE BODY IN VALVE OPENING. INSERT

FINGER IN EACH END OF VALVE OPENING AND ALIGN END OF VALVE BODY WITH ENDS

OF BUSHING.

NOTE: VALVE BODY MUST BE INSTALLED WITH IDENTIFICATION MARK AS SHOWN.

ENDS OF VALVE BODY FLUSH WITH BUSHING

NOTE: When reassembling head to housing a new Gasket

(31) must be installed. Tighten Screws (22) to approximately

60 in-lbs. torque. When tightening these screws it is

recommended that an air line be attached to the air inlet and

the hoist operated to insure that no binding of the motor

occurs. Tighten screws alternately and gradually until desired

torque is reached without binding of motor. Lubricate all

O-Rings with O-Ring lube (36460) before assembling. Insure

O-Ring (32) is properly positione d in head.

- Assemble valve body (15) into head - see “Timing of

Head”, this page.

- Assemble o-rings (27) to regulator valves (28).

- Assemble regulator valves (28) to head and secure

with set screws (24). NOTE: groove in regulator valve

must be aligned to accept set screw. See setting hoist

speed, page 2.

- Assemble muffler filler (13), screen (12) and exhaust

deflector (11) to head and secure with washers (10)

and screws (9).

- Clean and assemble screen (8) to head.

- Assemble o-rings (5) and (7) to swivel body (6) and

assemble body to head.

- Assemble swivel (3) to swivel body and secure with

retaining ring (4).

- Clean and assemble screen (2) and inlet adapter (1) to

swivel.

- Fill oil reservoir in head with spindle oil 2966 5.

Pendent Control Disassembly

- Remove pendent hoses from fittings (156) and (165).

- Remove adapter (166) from head releasing strain

cable.

- Remove screws (168), springs (170) and valves (171).

Pendent Control Assembly

- Lubricate o-rings (172) and assemble to valves (171).

- Assemble valves (171) and springs (170) to handle.

- Lubricate o-rings (169) and assemble to screws (168).

- Assemble screws (168) to handle securing valve

components.

Pendent Cylinder Disassembly

- Unthread cylinder (157) from adapter (163).

Pendent Cylinder Assembly

UP DN

IDENTIFICATION MARK "x" ON END OF VALVE BODY

STEP 2 :- WITH BRAKE RELEASE BLOCK ASSEMBLED TO CONTROL ROD, INSERT ROD

THROUGH BRAKE END OF HOUSING, THROUGH CONTROL ARM [68] AND ON THROUGH

HOUSING STOPPING BEFORE ROD PROTRUDES FROM HEAD.

SSEMBLE GEAR [25] TO HEAD ALIGNING CENTER TOOTH OF GEAR BETWEEN TWO

GROOVE MARKINGS ON THE VALVE BODY AS SHOWN.

SSEMBLE CONTROL ROD THROUGH GEAR AND SECURE WITH ROLL PIN [26]. SECURE

CONTROL ARM TO ROD WITH ROLL PIN [69].

TIMING GROOVES

ON VALVE BODY

- Assemble piston rod (160) to piston (159).

- Lubricate and assemble o-ring (158) to piston (159).

- Lubricate and assemble o-rings (162) and (164) to

adapter (163).

Motor Disassembly

- Remove head section - see “Head Disassembly”.

- Remove motor from housing.

- Remove retaining ring (36); motor assembly will come

apart,

Motor Assembly

UP DN

STEP 3 :- ASSEMBLE O-RINGS [16] TO VALVES [17] AND [19] AND ASSEMBLE VALVES

INTO HEAD AS SHOWN. ASSEMBLE O-RINGS [18] TO ADAPTERS [29] AND O-RINGS

[20] TO VALVE CAPS [21] AND ASSEMBLE TO HEAD.

GEAR [25]

UP DN

- Lubricate bearings (37) with NLGI #1 “EP” grease

(33153) and assemble bearings to end plate (38) and

(43) - shielded side of bearing facing out.

- Assemble end plate (43) to spindle (45) and slide up to

shoulder of spindle.

- Assemble key (44) to key slot in spindle (45).

- Assemble rotor (41) over spindle aligning key way and

key (44).

- Assemble cylinder (39) over rotor (41) and insert

blades (42) into blade slots of rotor - straight side of

blade out.

- Assemble end plate (38) to spindle and align hole in

end plate with roll pin (40).

- Secure assembled parts to spindle with retaining ring

(36).

Form 10590149-Edition 2 5

Loading...

Loading...