Ingersoll-Rand 650556-1 User Manual

OPERATOR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

INCLUDE MANUALS: 66302-X LOWER PUMP END (PN 97999-648), 650685-X PUMP (97999-657), 65142X-X

FILTER (97999-6) & GENERAL INFORMATION S-636 (97999-636)

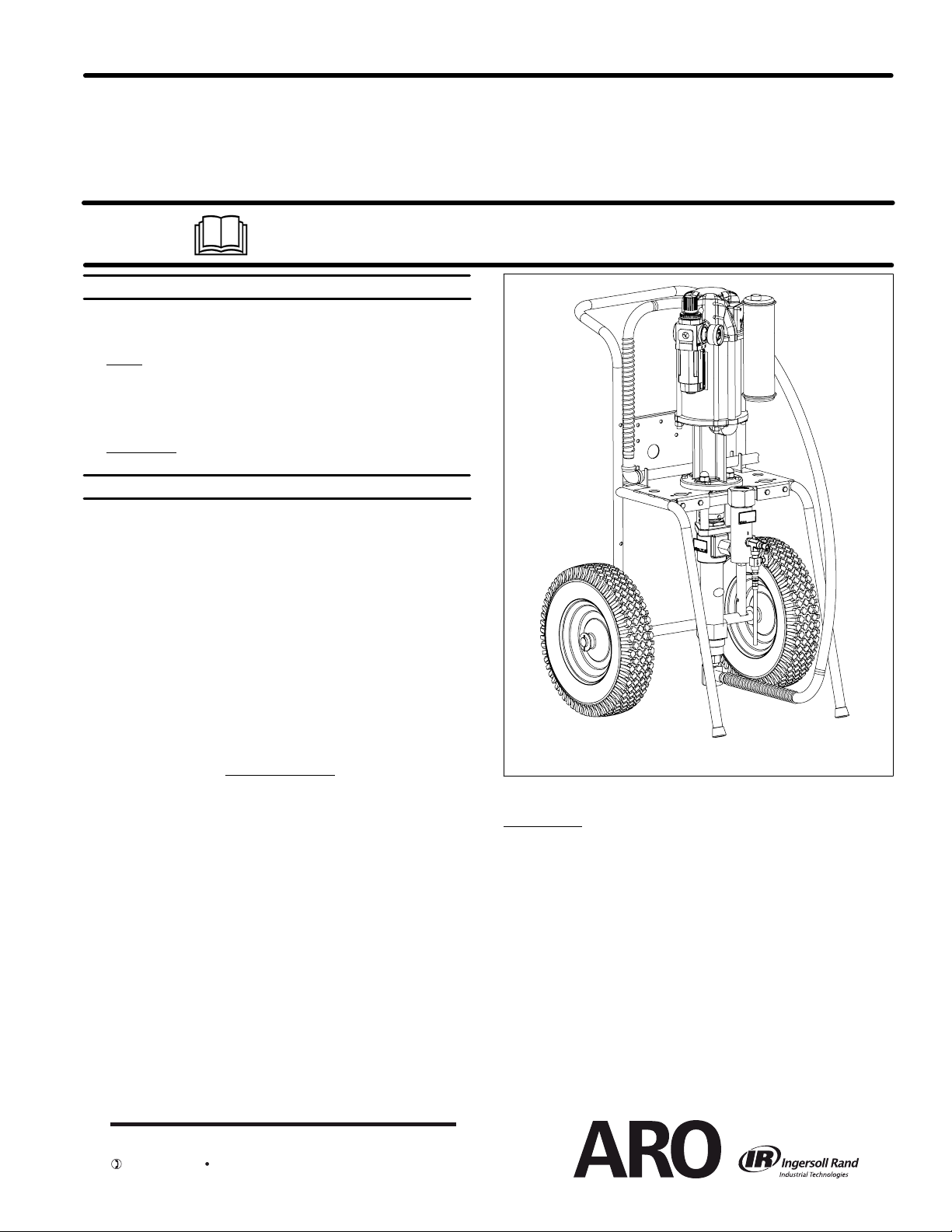

650556-1

AIRLESS SPRAY PUMP SYSTEM - CART MOUNTED

6” STAINLESS STEEL, TWO BALL PUMP, 60:1 RATIO

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

SERVICE KITS

x Use only genuine AROR replacement parts to assure compatible

pressure rating and longest service life.

x 61355

x 637307-P43

Model 650556-1...................

Pump System Type Cart Mounted Portable,.........

Pump Model 650685-P43..............

Ratio 60:1....................

Air Inlet 1/2”-14 N.P.T.F.-1 (female).................

Air Exhaust Muffler included..............

Material Inlet Suction Tube.............

Dimensional Data See page 3.........

Air Motor 65665-B.................

Motor Repair Kit 61355..........

Lower Pump End 66302-P43...........

Lower Pump Repair Kit 637307-P43.....

Weight (less carton) 111 Lbs (50 Kgs).......

Air Inlet Pressure Range 30-100 p.s.i. (2-6.9 bar).....

Fluid Pressure Range 1800-6000 p.s.i. (124-414 bar).......

Max. Rec’d Cycles / Minute 60...

Displacement In

Volume / Cycle 3oz.(90ml).............

Cycles Per Gallon 41.9..........

Flow @ 60 Cycles / Minute 1.4 g.p.m. (5.4 lpm)....

Noise Level @ 60 Psi - 40 Cpm 84.8 db(A) *

* The pump sound pressure level has beenupdated to an Equivalent Continuous Sound Level (L

meet the intent of ANSI S1. 13-1971, CAGI-PNEUROP S5.1 using four microphone locations.

for repair of Air Motor section.

Service Note: The Air Motor Service / Parts Manual is not shipped

with the pumpbut it is included with each Service Kit. If this Service /

PartsInformation is needed, requestthe Air MotorOperator’s Manual from ARO. (Manual 6564X-X, PN 97999-174).

for repair of Lower Pump section.

PUMP SYSTEM DATA

Air Operated, Two Ball S’Steel

PERFORMANCE

3

Per Cycle 5.5...

Aeq

IMPORTANT

system. Replacement copies of these forms are available upon

request.

- 66302-X LOWER PUMP END OPERATOR’S MANUAL

(97999-648)

= 650556-1 PUMP SYSTEM MANUAL (97999-840)

- 650685-X PUMP MODEL OPERATOR’S MANUAL (97999-657)

)to

- 65142X-X MATERIAL FILTER (97999-6)

- GENERAL INFORMATION MANUAL S-636 (97999-636)

This is one of the five documents which support the

650556-1

RELEASED: 12-11-98

REVISED: 2-26-11

(REV. C)

FIGURE 1

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276

www.ingersollrandproducts.com

FAX(800) 892-6276

© 2011

CCN 99779159

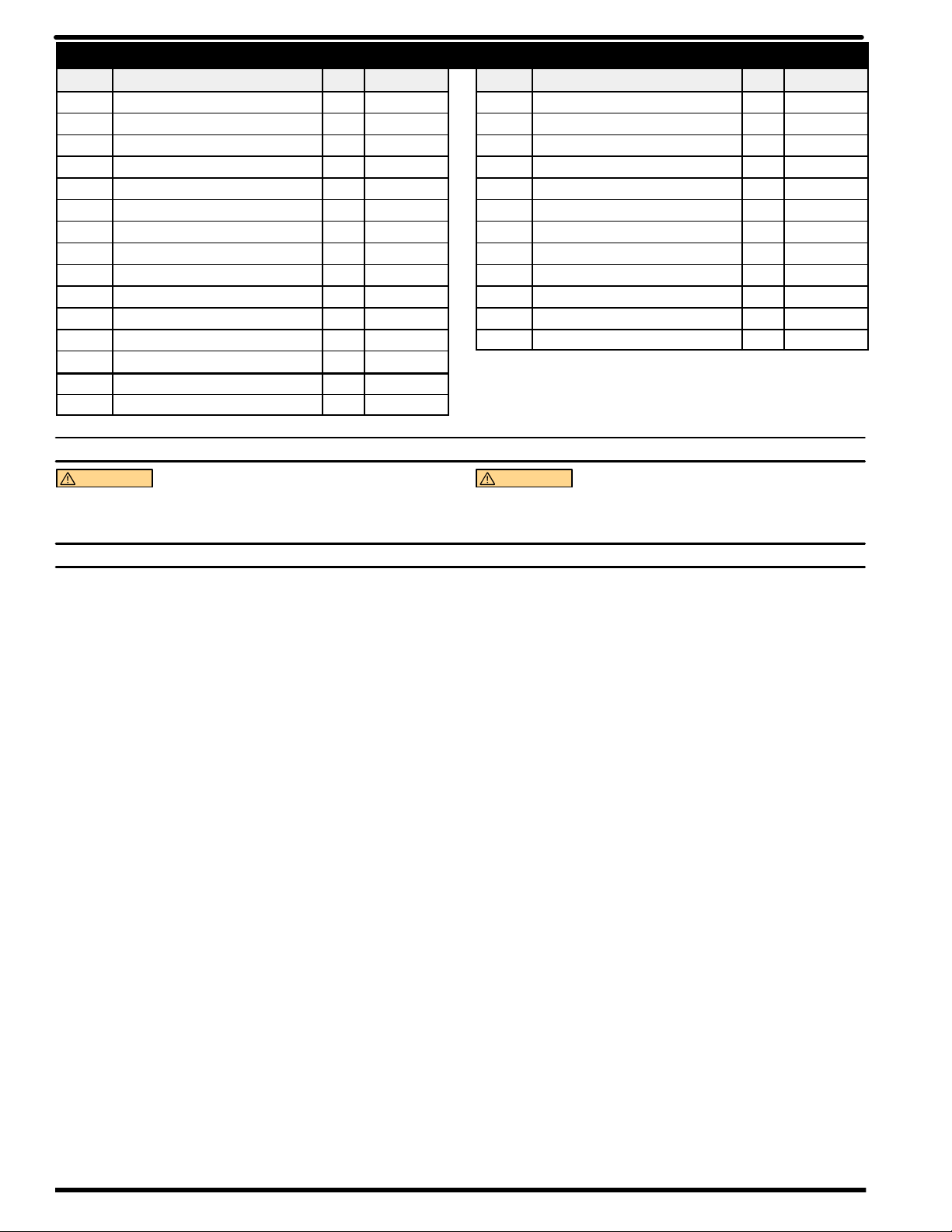

PARTS LIST / 650556-1

ITEM DESCRIPTION (Size in Inches)

1 TwoBallPistonPump (1) 650685-P43

2 Cart Assembly (Includes Items 6 thru 14) (1) 67139

6 Washer (3/8”) (4) Y13-6-C

7 Screw (3/8” - 16 x 1-1/4”) (4) Y6-66-C

8 Nut (3/8” - 16) (4) Y12-6-C

10 Brace (1) 95102

11 Screw (5/16” - 18 x 3/4”) (4) Y6-53-C

12 Nut (5/16” - 18) (4) Y12-5-C

13 Washer (5/16”) (4) Y14-516-C

14 Cart Welding Assembly (1) 67138

15 Material Filter (Includes Item 16) (1) 651422-70

16 Plug (3/8”) (1) Y17-13-S

17 Muffler (1) 91790-ZZ

j 18 3/4” Suction Hose Assembly (1) 622606-5

j 19 90_ Elbow (3/4”) (1) Y43-15-S

QTY

PART NO. ITEM DESCRIPTION (Size In Inches)

OPERATING INSTRUCTIONS

QTY

j 20 Suction Tube (5 Gallon) (1) 94263-1

21 Hose Assembly (1) 628092-F

22 Gauge (1) 104500

23 Piggyback Filter/Regulator (1) P39344-100

24 Nipple (1/2” x 2” (m)) (1) Y44-31-C

25 Bushing (1/2” - 14 (m) x 1/4” - 18 (f)) (1) 94271

26 Nipple (1/4” - 18 (m)) (2) 1950

27 Street Tee (1/4” - 18) (1) 94270

28 Needle Valve (1) 94269

29 Adapter (1” (m) x 1/2” (f)) (1) 94256

30 90_ Adapter (1” (m) x 1/4” (f) x 3/4” (f)) (1) 94254

31 Plug (1) Y17-11-S

j Parts included in 67140-1 Asm (std)

Available: 67140-2 Asm. uses 94263-2 (36” Inlet Tube)

PART NO.

WARNING

DO NOT EXCEED MAXIMUM OPERATING PRES-

SURE OF 6000 P.S.I. (414 BAR) AT 100 P.S.I. (6.9 BAR) AIR INLET PRESSURE.

INSTALLATION

OPERATING INSTRUCTIONS / INITIAL SETUP PROCEDURE

This unit comes assembled except for the air supply hose, gun and material hose which must be attached.

x A connector, coupler and air supply hose and must be supplied to

the air regulator.

x Attach a Ground wire to a suitable ground and the Ground Lug

provided on the pump Air Motor.

x Keep containers covered to prevent contamination.

WARNING

REFER TO THE PUMP MANUAL FOR ADDITION-

AL OPERATING AND SAFETY PRECAUTIONS AND OTHER IMPORTANT INFORMATION.

1. Turn the knob on the air regulator counter-clockwise to zero p.s.i.

2. Attach hose and gun. Place pump inlet tube into a full container of

material.

3. Start the pump to cycle by turning the air regulator knob clockwise.

The pump will cycle several strokes until pressure is built up in the

system, at which time it will stall, check for any loose fittings or leakage. Check all connections and re-tighten as necessary.

4. Relief Valve (28) is used to relieve pressure in the hose in order to

change spray tips. Open the relief valve to relieve pressure. Close

the relief valve to continue spray operation.

PAGE2OF4

650556-1

Loading...

Loading...