Ingersoll-Rand 650531-1, 650530-1 User Manual

OPERAT

OR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

ALSO INCLUDEMANUALS: 67075 CART, 6711X-XPUMP, F252XX-X MODULE/AIR F-R-L & FM 3637-2 GEN

INFO SHEET

3” AIR MOTOR

21.7:1

RA

TIO

4” STROKE

650530–1

CARBON STEEL

PUMP

SYSTEM

650531–1

ST

AINLESS STEEL

650530–X

650531–X

RELEASED:

(REV

3–6–95

. A) IPP

READ THIS MANUAL CAREFULL

OPERA

TING OR SER

SERVICE KITS

• Use only genuine ARO replacement parts to assure compatible

pressure rating and longest service life.

• 637066-B for repair of Air Motor Section.

• 63729X-XXX for repair of Lower Pump 6710X-X.

GENERAL

WARNING DO NOT EXCEED MAXIMUM OPERATING

PRESSURE OF 3,262 P.S.I. (224.9 BAR) AT 150 P.S.I. (10.4

BAR) AIR INLET PRESSURE.

WARNING REFER TO GENERAL INFORMATION SHEET

FOR ADDITIONAL SAFETY PRECAUTIONS AND IMPORĆ

TANT INFORMATION.

By delivering a smooth, continuous bead of the proper size, an ARO

system helps the operator maintain both his production rate and proĆ

duce quality standards. Maintained quality standards assures that the

material benefits are realized. To further maximize operator production

time, the ARO System has a built-in lift feature for quick and easy

drum changeover.

ARO Systems are totally enclosed, sealing the material in the system

from air and moisture, preventing premature cure-out of the material.

This allows for either continuous or intermittent use of the system and

reduces the need for daily system clean-up.

Built-in lift capability allows for quick drum changeover and easy lifting

of pump assembly from container.

The 21.7:1 ratio is an expression of the relationship between the effecĆ

tive air motor area and the effective lower pump area. When 150 PSI

(10 bar) of air pressure is supplied to the air motor, the lower pump area

will develop a maximum of 3,262 PSI (224.9 bar) of fluid pressure (at

no flow) as the fluid control is opened, the flow rate will increase as the

air motor cycle rate increases to keep up with the demand

DESCRIPTION

Y BEFORE INST

VICING THIS EQUIPMENT

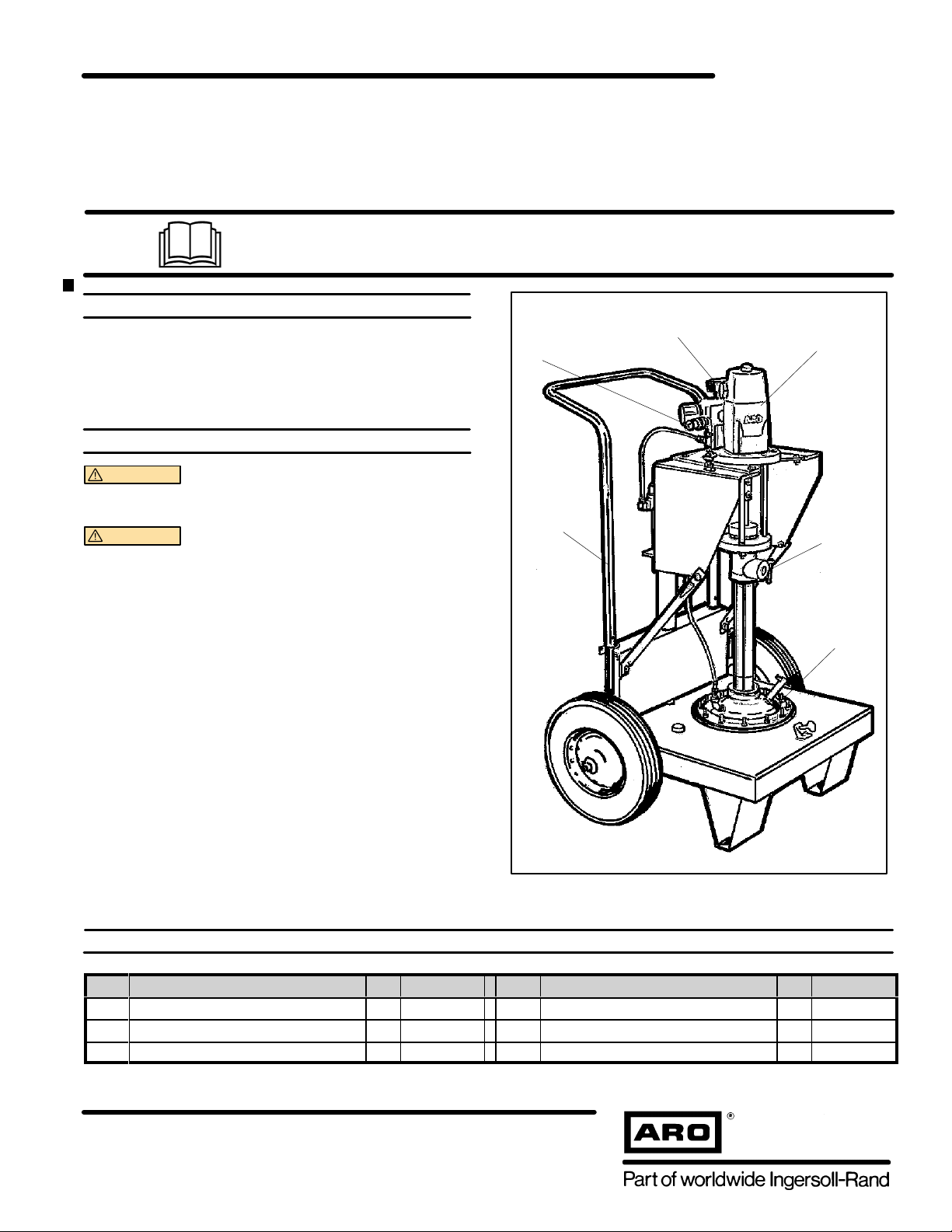

Pump Air

Cart/Lift

Air Inlet

1

Manifold

ALLING,

.

3

Material

Outlet

2

FIGURE 1

MAJOR COMPONENTS LIST

Item Description Qty Part No. Item Description Qty Part No.

1 Cart/Lift 1 67075 3 Basic Pump Assembly (650530-1) 1 67110-P43

2 Follower Plate (650530-1) 1 651840-1 Basic Pump Assembly (650531-1) 1 67111-P43

Follower Plate (650531-1) 1 651841-1

THE ARO CORPORA

%

(419) 636–4242 D F

E1995

THE ARO CORPORA

TION

AX (419) 636–21

D ONE ARO CENTER D BRYAN, OHIO 43506–0151

TION

D PRINTED IN U.S.A.

15

INSTALLATION

The 65053X-X Chop-Check Dispensing System comes completely

assembled. Remove unit from crate and place on a level surface.

Install material hose and dispensing device as required.

When the following instructions are observed, heavy paste materials

can be pumped directly from their original 5 gallon drum without air inĆ

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS / INITIAL SETUP PROCEDURE

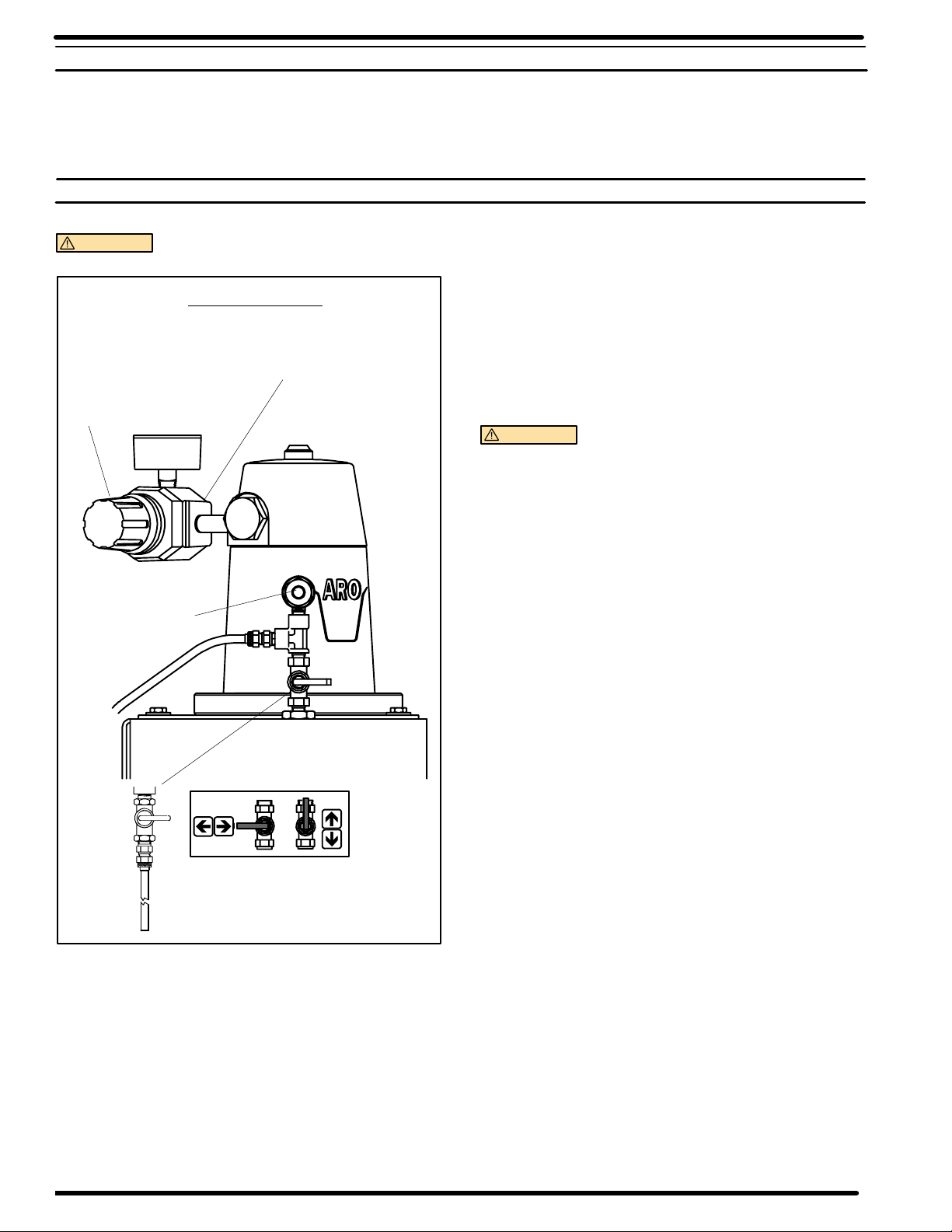

WARNING STAND CLEAR. When raising or lowering the

lift.

2

AIR CONTROLS

PUMP AIR

PUMP AIR

INLET

CART/LIFT

AIR INLET

OFF

FOLLOWER PLATE

AIR SUPPLY VALVE

FIGURE 2

TO RAISE LIFT, (THE FIRST TIME):

1. Take note of the pump/drum clearance above. Be certain the lift is

clear of any objects above the unit.

2. Adjust (Turn Needle Valve Knob Counter-Clockwise) air pressure to lift.

Connect the air supply (160 PSI MAX) to the air inlet.

3. Raise the lift high enough to clear the height of the drum. Stop the lift

upward travel by adjusting (Turn Needle Valve Clockwise until tight.)

Needle Valve.

REFER TO PAGE 3:

1. Once lift assembly and pump are in the ``UP" position, place and

center an opened 5 gallon drum of material on the lift base. Use the

REGULATOR

ON

clusion, or excessive waste. The follower plate creates an air tight seal

as well as clean-wiping action in its progressive downward movement

into the drum.

stops on the base to center 5 gallon drum. Tighten thumb screw to

secure drum.

2. Lubricate lower follower wiper plate seal with any type grease. (siliĆ

cone, vaseline, gear, etc.) This ensures a smooth fit into the pail as

well as prevents curing type compounds from bonding to seal.

3. Check vent plug on follower plate to be sure it easily threads in and

out. It is recommended to lubricate the threads of the plug to help

prevent possible set up of compound at this point. See 65184X-X

Operator's Manual.

TO LOWER LIFT:

WARNING

causing injury. Keep hands clear when aligning with containĆ

er.

NOTE: Be certain the Follower Plate vent plug has been removed

so that the air trapped between the follower and the material is allowed

to escape from this vent. Captured air between the follower plate and

drum will escape.

NOTE: The lift may hesitate momentarily before starting downward,

the air pressure inside the post air chamber must decrease before it

will begin to descend.

1. Disconnect air line from the lift air inlet. Adjust (Turn Needle Valve Knob

Counter-Clockwise) Needle Valve to Lower the pump end into drum.

2. Replace the vent plug once the material begins to ooze from the

vent opening.

3. Adjust (Turn pump air regulator knob Counter-Clockwise to prevent

over pressurization of pump.) Knob on pump air regulator.

4. Connect air line to pump air regulator and adjust (Turn pump air reguĆ

lator Clockwise) air until pump begins to cycle.

5. Trigger gun to prime pump with material.

PINCH HAZARD. Follower can descend quickly

TO RAISE LIFT, (NORMAL OPERATION):

1. Disconnect air line from pump air regulator and connect to lift air

inlet. Adjust the Follower Plate Air Valve pressure up to approxiĆ

mately 8 psig. DO NO OVERPRESSURIZE THE DRUM to avoid

damage.

NOTE: Air from this valve will only pass when the unit is being

raised.

2. Adjust (Turn Needle Valve Knob Counter-Clockwise) air pressure on lift.

3. Raise the lift high enough to clear the height of the drum. Stop the

lift upward travel adjusting needle valve knob Counter-Clockwise.

TO CHANGE DRUM:

NOTE: The Needle Valve Knob should be turned Clockwise to hold lift

in the ``UP" Position.

1. Unsrew thumb screw and remove old 5 gallon drum.

2. Place and center. a new drum into position. Remove cover. TightĆ

en thumb screw.

PAGE2OF4

Loading...

Loading...