Ingersoll-Rand 650503 User Manual

OPERATOR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

ALSO INCLUDE MANUALS: 66605X-X DIAPHRAGM PUMP (PN 97999-099), 650757-X DIAPHRAGM PUMP (PN 97999-569),

2752X-X MATERIAL REGULATOR (PN 97999-674), AIRLINE SAFETY INFORMATION (PN 100400 --76).

650503

LOW PRESSURE DELIVERY SYSTEM

1/2” DIAPHRAGM PUMP, 1:1 RATIO, WITH WALL / CART MOUNT

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS

Use only genuine ARO replacement parts to assure compatible pressure rating and longest service life.

x Fluid Section Repair Kit 637140-A4.

x Air Section Repair Kit 637141.

Refer to the 66605X-X Operator’s Manual for parts / repair and service

information.

PUMP SYSTEM DATA

Model 650503 Low Pressure Delivery System..................

Pump Model 650758-2A4............

Pump Type Non-Metallic Air Operated Double.............

Material Groundable Acetal..................

Weight 24.5 (11.1 Kg)...................

Air Inlet 1/4” - 18 N.P.T.F...................

Air Consumption 1 c.f.m. per gallon (approximately)...........

Maximum Air Inlet Pressure 100 p.s.i.g. (6.9 bar)...

Maximum Fluid Inlet Pressure 10 p.s.i.g. (0.69 bar).

Maximum Outlet Pressure 100 p.s.i.g. (6.9 bar)....

Maximum Flow Rate 13 g.p.m. (49 l/m)........

Maximum Particle Size 3/32”......

Max. Output Per Cycle .039 gallons (148 cc’s).......

Maximum Temp. Limits 10_ to 180_F(-12_ to 82_C)......

Dimensional Data See page 3..........

Noise Level @70psi,60C.P.M.h 71.1 db(A)

The pump sound pressure levels published here have been updated to an Equivalent Continuous Sound Level (L

h

FOR USE WITH CONVENTIONAL HVLP / AIR SPRAY SYSTEMS

(SPRAY GUN NOT INCLUDED)

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

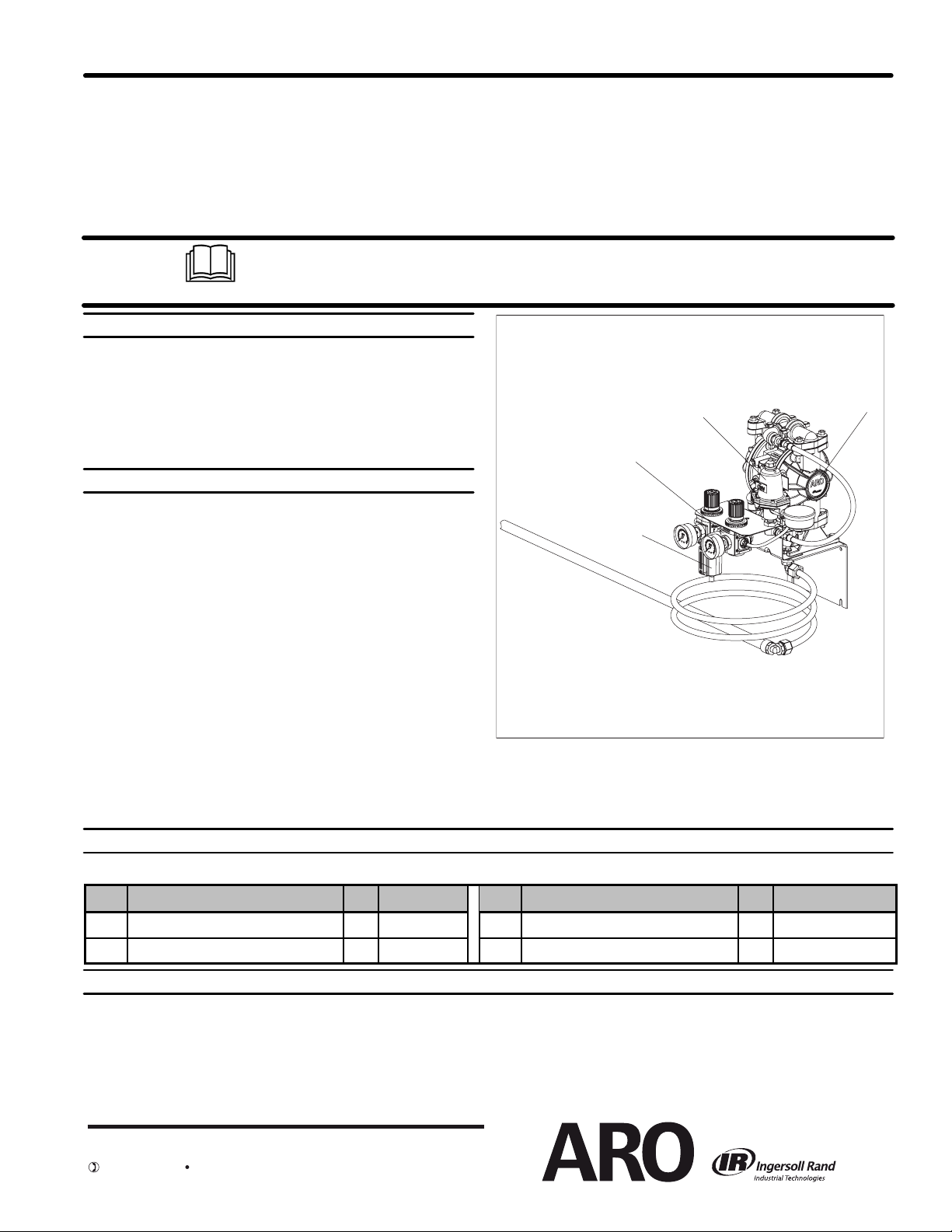

B

A

Diaphragm with stainless steel seats

) to meet the intent of ANSI S1.13-1971, CAGI-PNEUROP S5.1 using four microphone locations.

Aeq

650503

RELEASED: 12-6-96

REVISED: 12-2-09

(REV. E)

C

Figure 1

D

MAJOR COMPONENTS LIST

* Operator’s Manuals are provided, which cover parts and service information.

Item Description Qty Part No. Item Description Qty Part No.

A Filter / Regulator * (1) P39224-210 C 1/4 Sst / Carbide Regulator* (1) 27520-400

B Regulator* (1) R37221-100 D 1/2” Diaphragm Pump* (1) 650758-2A4

GENERAL DESCRIPTION

The 650503 Portable Pumping System includes fittings, wall / cart

bracket, regulators, siphon tube, gauges and hardware. It is intended to

be used in conventional HVLP (High Volume Low Pressure) spray systems. These systems generally operate using low material pressure

(less than 30 p.s.i.), and when complimented with the proper gun, it produces a “soft spray”.

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX(800) 892-6276

www.ingersollrandproducts.com

© 2010

Read the information included with the spray gun for system settings

and operation information.

The diaphragm pump uses stainless steel balls and seats, and PTFE diaphragms and is designed to be used with waterborne paints. The gun

and low pressure air and material hoses are not included. (Continued)

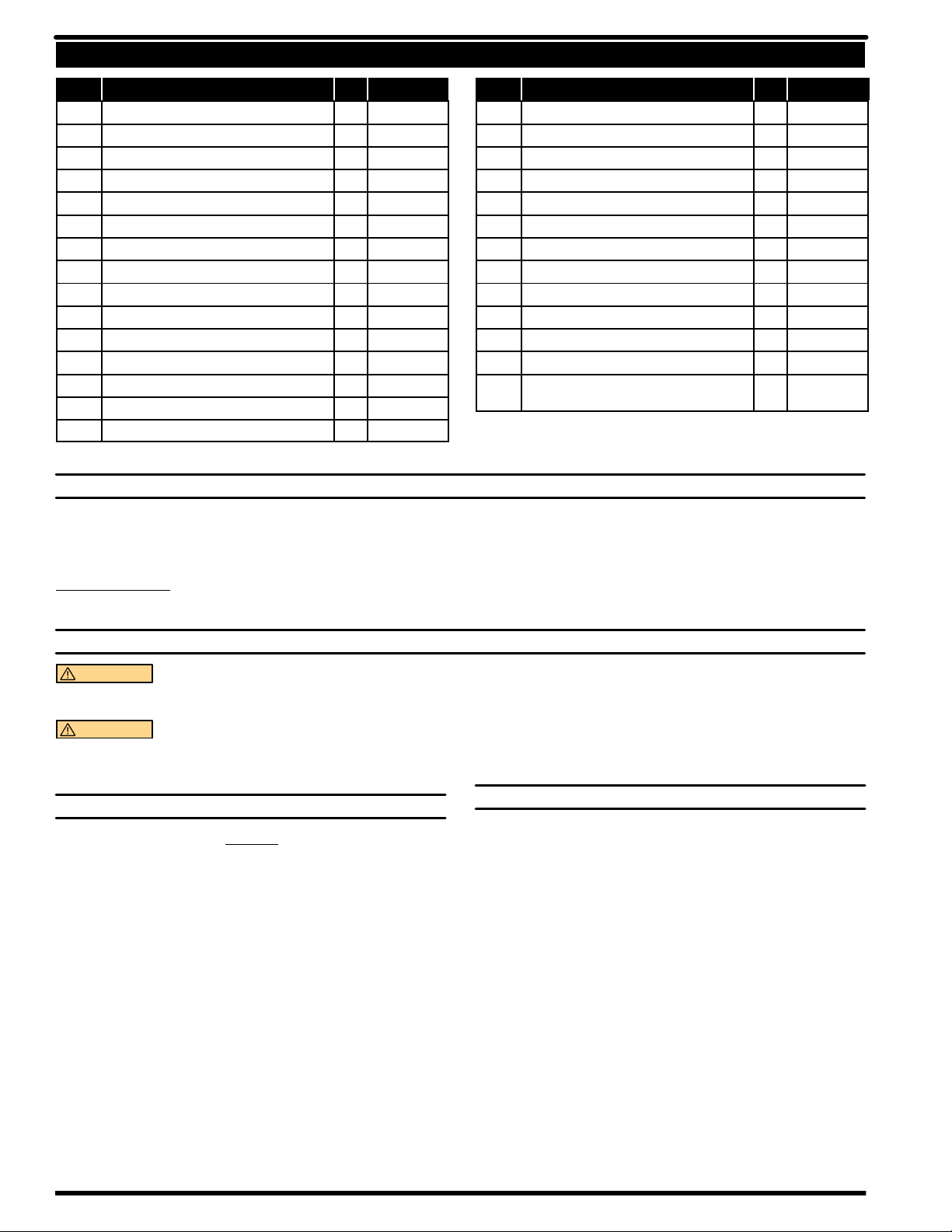

PARTS LIST / 650503

Item Description (Size in inches)

1 90_ Street Elbow (1/2” - 14 n.p.t.f. - 1) (1) Y43-4-S

2 Bracket (1) 94040-1

3 Fitting (3/8” - 18 n.p.t.f. - 1 x 1/4” - 18 n.p.t.f. - 1) (1) 90538

4 Adapter (1/4” - 18 n.p.t.f. - 1) (2) 1950

5 Long Nipple (1/2” - 14 n.p.t.f. - 1 x 3” long) (1) Y44-33-S

7 Gauge (0 - 75 p.s.i.) (1) 104495

8 Gauge (0 - 160 p.s.i.) (1) 104496

9 Coupling (1/4” - 18 n.p.t.f. - 1) (1) Y43-42-C

10 Tee (1/4” - 18 n.p.t.f. - 1) (1) 94039

11 Gauge (0 - 30 p.s.i.) (1) 93769

12 Elbow (2) 94043

13 Tube (20” long) (1) 628091-1-H

16 Male Elbow (1/4” o.d. tube - 1/4” - 18 n.p.t.f. thd) (1) 59756- 156

f 17 Tube (6’ long) (1) 94978- XXX-X

18 Fitting (1/2” - 14 n.p.t.f. - 1 x 1/4” - 18 n.p.t.f. - 1) (1) 94041

fTube is available in bulk quantities only.

Qty

Part No. Item Description (Size in inches)

GENERAL DESCRIPTION (CONTINUED)

Consult your sales representative for the proper low pressure gun and

other accessories which will best match the application.

This system includes a wall mount bracket which can alsobeattachedto

cart pn 67074.

Theory of operation:

HVLP (High Volume, Low Pressure) is a spray process which uses a

high volume of air (15 - 22 c.f.m.) at a low pressure (10 p.s.i. or less) to

OPERATING INSTRUCTIONS

Qty

Part No.

f 19 Tube (1/4” o.d. x 12” long) (1) 59675- XXX-X

20 Tube (36” long) (1) 93320

21 Bracket (1) 93839

22 Bolt (1/4” - 20 x 1”) (4) Y6-45-T

23 Washer (.281” i.d. x .625” o.d.) (4) 93096

24 Nut (1/4” - 20) (4) Y12-4-S

25 Screw (5/16” -18 x 5/8”)(not shown) (1) Y8-58-S

26 Nut (5/16” - 18)(not shown) (1) Y12-5-S

27 Nut (1) 94036

28 Roll Pin (.094” o.d. x .250” long) (1) Y178-18-S

29 Elbow (1/4” - 18 n.p.t.f.) (1) 94044

30 Ground Kit Assembly (not shown) (1) 66885-1

31 Male Straight Fitting

(1/4” o.d. tube - 1/4” - 18 n.p.t.f. thd)

(1) 59474-156

atomize the material, producing both high transfer efficiency (the total

percent of material that actually stays on the intended surface) and a

quality finish. The air cap of the HVLP gun injects air into the fluid after it

passes through the orifice restriction.Thelowvelocityofthematerialbeing sprayed minimizes the over-spray and bounce-back that is associated with conventional air spray.

WARNING

DO NOT EXCEED MAXIMUM OPERATING PRES-

SURE OF 100 P.S.I. (6.9 BAR) AT 100 P.S.I. (6.9 BAR) AIR INLET

PRESSURE.

WARNING

READ THE PUMP MANUAL FOR ADDITIONAL

OPERATING AND SAFETY PRECAUTIONS AND OTHER IMPORTANT INFORMATION.

INITIAL SETUP PROCEDURE

NOTICE

REFER TO THE INFORMATION INCLUDED WITH THE LOW PRESSURE HVLP GUN FOR SYSTEM SETUP INFORMATION. THE SYSTEM IS INTENDED FOR LOW PRESSURE APPLICATION ONLY.

x Attach air supply hose, gun and low pressure material hose.

x Install the connector to the air supply hose.

x Attach (30) ground kit to ground tab, securing with (25) screw and

(26) nut.

x Attach the ground wire to a suitable ground.

x The gun air supply hose must be 5/16” i.d. minimum.

x Keep containers covered to prevent contamination.

x When using an agitator, install a “T” at the air inlet or use a sepa-

rate air supply source.

Nominal system settings:

x Pump Outlet Material Pressure - 15 p.s.i. maximum.

x Spray Gun Air Pressure - 60 p.s.i. maximum. Note: At 30 p.s.i.

nominal setting it will deliver approximately 8 p.s.i. at the air cap

when using 5/16” i.d. x 15’ long air hose.

x Set air pressure to the pump at approximately 2x (two times) the

operating material pressure.

For example: If 15 p.s.i. material pressure is required, adjust the

pump air regulator / gauge pressure to approximately 30 p.s.i.

Use the material pressure regulator to adjust. Control the spray

gun air volume using the air regulator.

START-UP

1. Turn the knob on the air regulator counterclockwise to zero p.s.i.

2. Place pump and cover (with gun and hose attached) onto the container of material.

3. The operating pressure should be set at the lowest needed to atomize and deliver the paint. Start with the gun material pressure about

the same as the air supply and adjust up or down to set the pattern.

4. Start the pump to cycle by turning the air regulator knob clockwise.

The pump will cycle several strokes until pressure is built up in the

system, at which time it will stop. Check for any loose fittings or leakage.

PAGE2OF4 650503

Loading...

Loading...